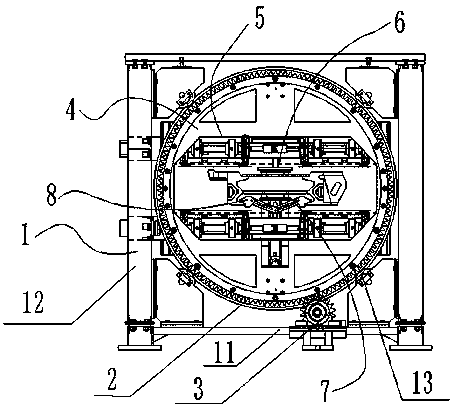

Automatic overturning equipment for middle groove double-sided welding

An automatic flipping and double-sided welding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of long time-consuming turning over equipment, limited specifications of the middle slot, low transmission stability, etc., to achieve applicable The effect of wide range, improved stability and reduced size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

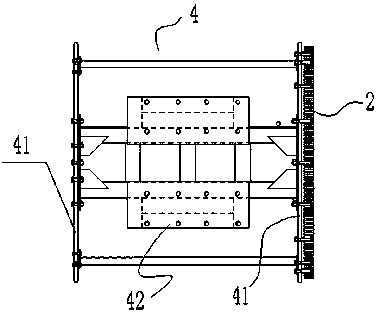

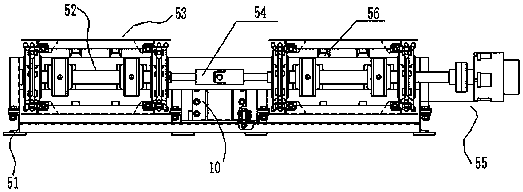

[0039] Embodiment: An automatic turning device for double-sided welding of the middle groove, including: a control system, a turning mechanism, four conveying mechanisms, a clamping mechanism and two lifting mechanisms, and a pair of conveying mechanisms are arranged up and down oppositely on the turning On the connecting frame inside the mechanism, another pair of conveying mechanisms is arranged outside the turning mechanism, respectively connecting with the opposite ends of the bottom conveying mechanism in the turning mechanism; and the middle part of any conveying mechanism is the spare part, and the two sides of the spare part are The conveying part, and a connecting piece is arranged on the spare part, which is used to connect the structure arranged on the spare part; a lifting mechanism is arranged at the spare part of a conveying mechanism outside the turning mechanism, so that the middle groove on the conveying mechanism is separated from the The conveying mechanism; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com