Automatic conveying and screening device for sheet materials

A technology of automatic conveying and screening device, which is applied to vibrating conveyors, conveyors, conveyor objects, etc., and can solve the problem of inaccurate positioning angle of the small inserts, large changes in the state of the point setting, and small size of the small inserts. problems, to avoid sticking and inaccurate extension lengths, easy to arrange, and simplify the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

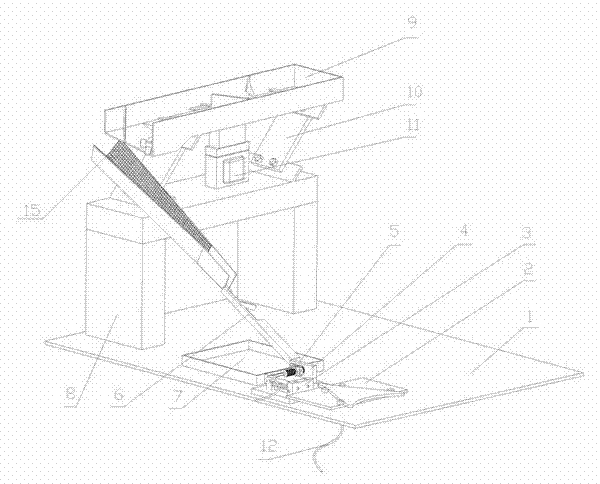

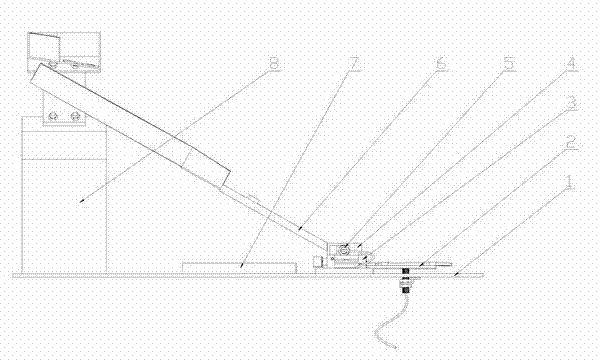

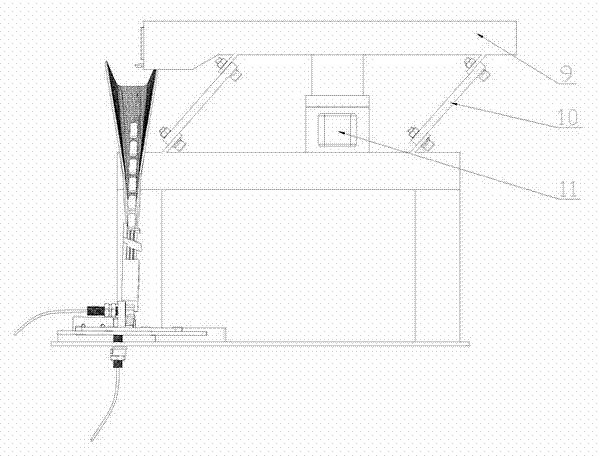

[0064] figure 1 — Figure 4 Shown is a sheet material automatic conveying and screening device, including a workbench 1 and the following parts set on the workbench 1:

[0065] ① Sheet material limited input mechanism

[0066] It includes a material storage box 9, an electromagnet intermittent low-frequency vibration device, a base 8, and a support seat.

[0067] The bottom of the base 8 is disposed on the workbench 1 and extends upward.

[0068] The material storage box 9 arranged horizontally is arranged on the top of the base 8, and the top end of the material storage box 9 is open and one side end is open. There is a support seat connected between the bottom surface of the material storage box 9 and the workbench 1, and two oblique nylon support plates 10 placed parallel to each other are respectively arranged on both sides of the support seat. There are two support plates on the bottom surface of the material storage box 9 The installation positions are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com