High-temperature ceramic drying device

A high-temperature drying and ceramic technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of energy waste, no waste heat utilization, etc., and achieve the goal of improving product quality, fast drying speed and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

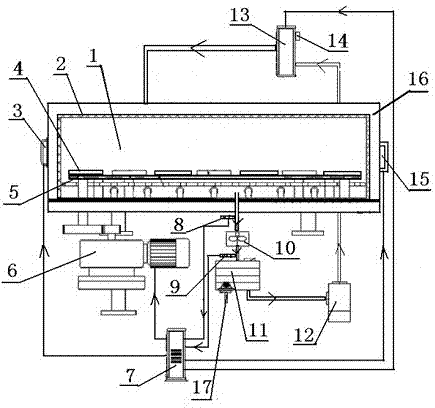

[0021] The specific embodiment of ceramic high-temperature drying device of the present invention is as follows:

[0022] 1. Before use, first set the temperature and humidity values sensed by the temperature sensor 8 and the humidity sensor 9 according to the requirements of ceramic drying.

[0023] 2. Open the feed port 3 of the drying chamber 1 through the control system 7, and the conveyor 6 drives the chain 5 to run. At this time, the ceramic body to be dried is placed on the tray 4 through the feed port 3.

[0024] 3. After placing the ceramic body that needs to be dried, close the feed port 3, close the conveyor 6, start the high-temperature heat pump 13, and the high-temperature hot air generated by the high-temperature heat pump 13 is sprayed into the drying hole 2 on the inner layer of the high-temperature channel 16. On the ceramic body in the drying chamber 1, since the ventilation holes 2 are evenly distributed on the high-temperature passage 16, the high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com