Automatic control system and automatic control method for feeding alloy into converter

An automatic control system, control system technology, applied in the field of control, automatic control of converter alloys, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

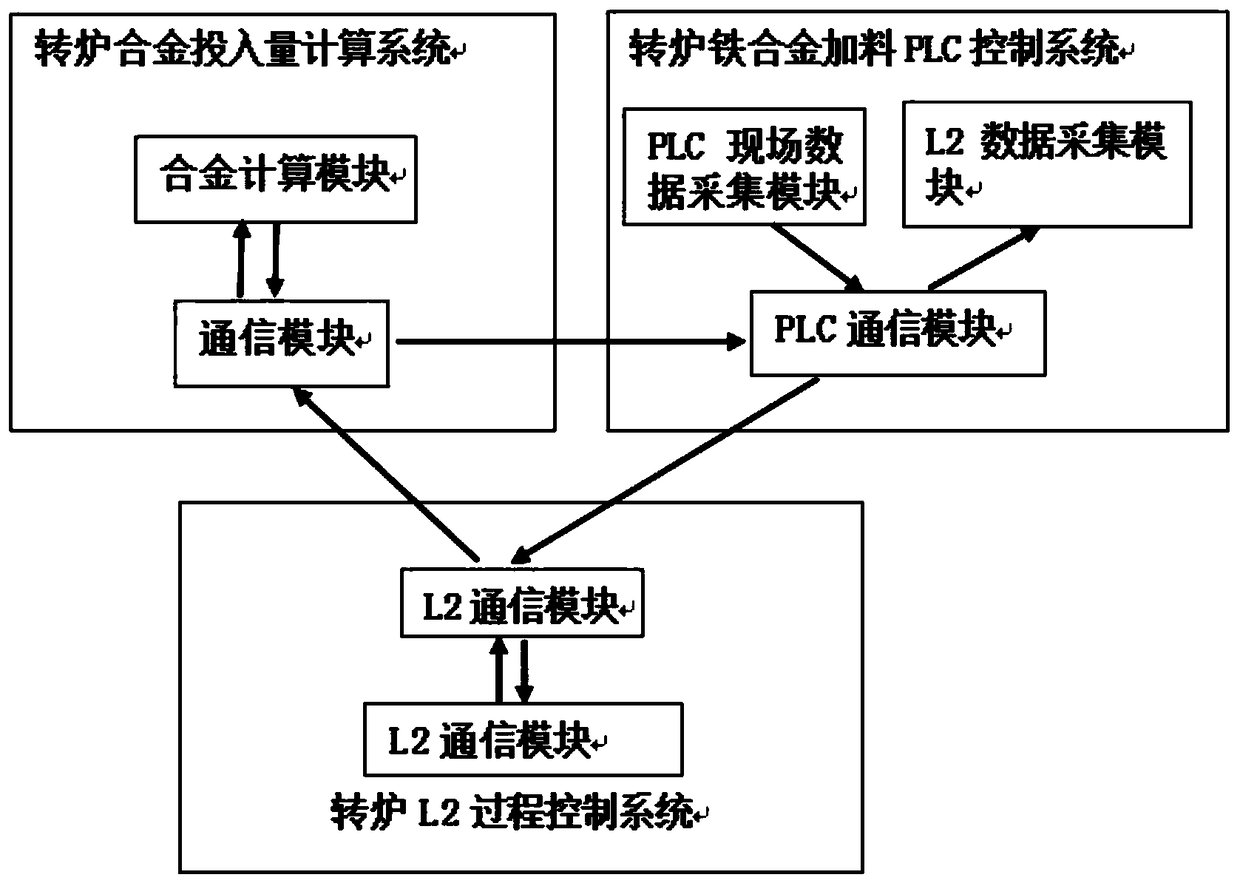

[0073] Embodiment 1: see figure 1 , figure 2 , a converter alloy input automatic control system, the control system includes a converter alloy input amount calculation system, a converter alloy charging PLC control system and a converter L2 process control system; the converter alloy input amount calculation system includes an alloy calculation module and a communication module ; The alloy calculation module is used for calculating and checking the amount of alloy input; the communication module is used for data communication required for calculation with the L2 control system;

[0074] The converter alloy charging PLC control system includes a PLC on-site data acquisition module, a PLC alloy feeding and preparation control module and a PLC communication module; the PLC on-site data acquisition module is used to collect on-site actual production status information and upload it to the L2 process control system; The PLC alloy feeding and preparation control module is used to...

Embodiment 2

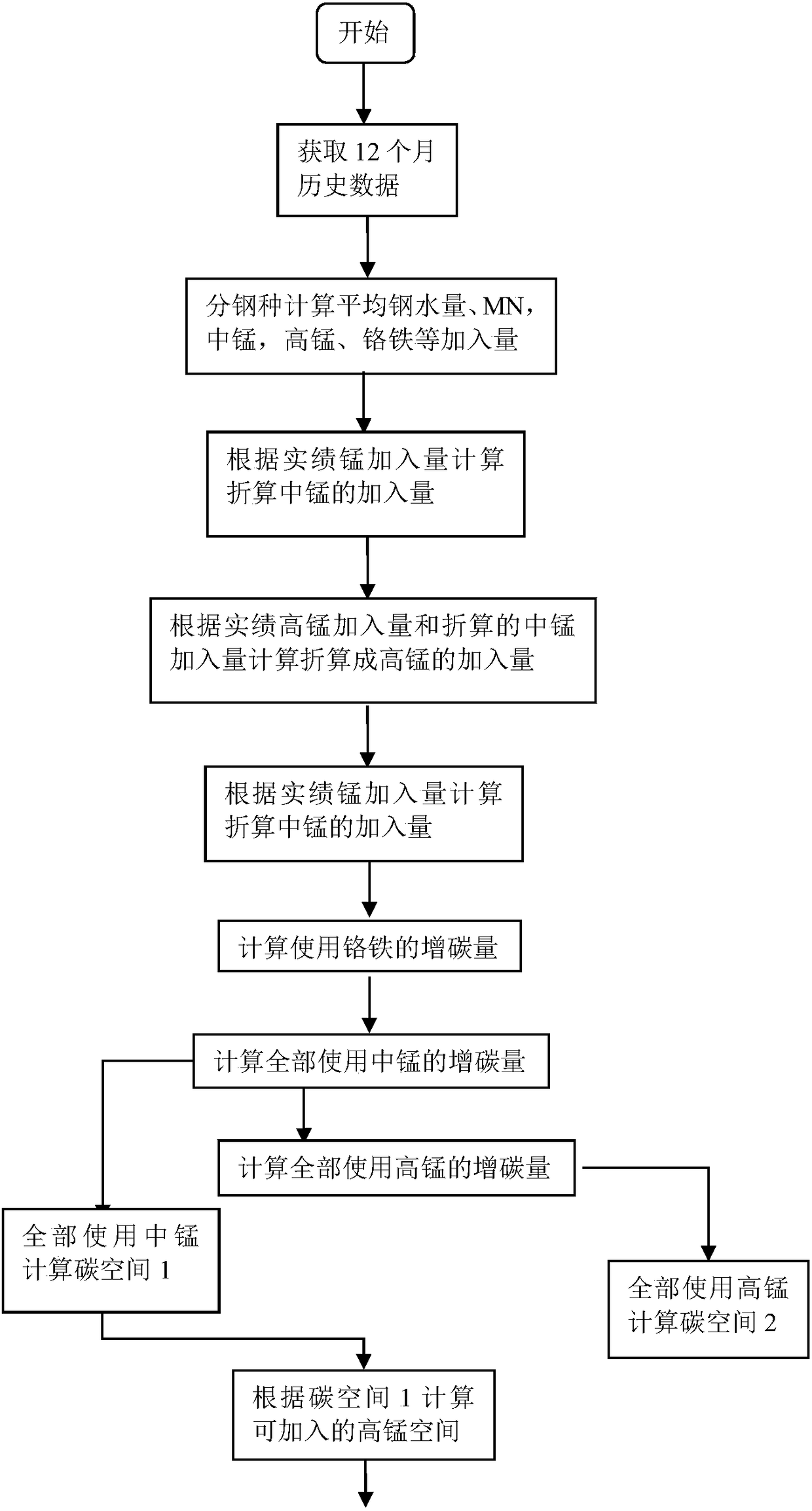

[0075] Example 2: see figure 1 , figure 2 , the converter alloy automatic control method, the control method is as follows:

[0076] (1) The PLC on-site data acquisition module collects the actual production status information of the converter site. The production status information mainly includes: start of furnace, scrap steel collision, molten iron loading, blowing start, sub-lance measurement, blowing end, tapping Start, end of tapping, start of slag splashing, end of slag splashing and end of blowing;

[0077] (2) The PLC communication module uploads the information such as the actual production status of the converter site collected by the PLC site data acquisition module to the L2 control system;

[0078] (3) The L2 control system judges the current furnace state according to the data uploaded by the PLC communication module, and starts the alloy calculation module respectively when the furnace starts and the molten iron is loaded;

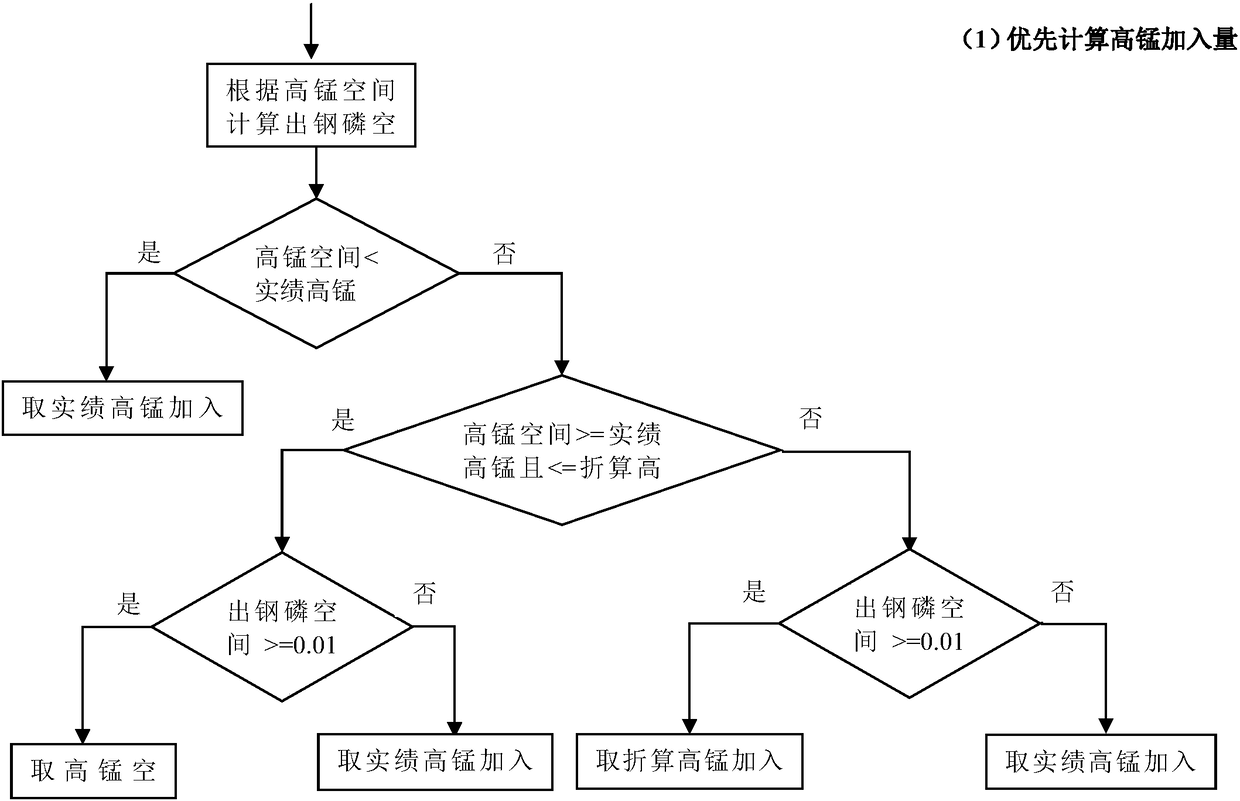

[0079] (4) When the alloy calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com