Fiber preform rod flexibility measurement method

An optical fiber preform and measurement method technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve problems such as large amount of data and complex data processing, achieve scientific and reasonable data, improve precision and accuracy, and realize automatic measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

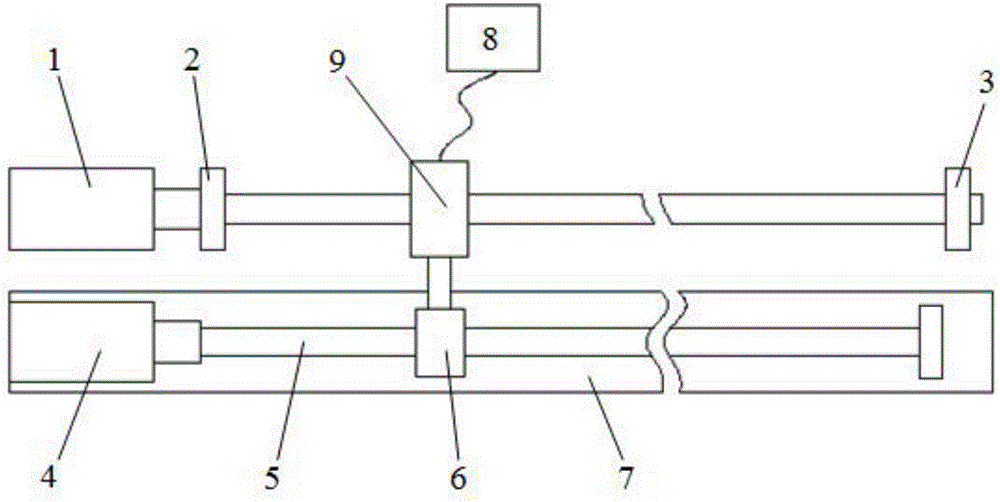

[0032] This embodiment is a method for measuring the curvature of an optical fiber preform, which includes the following steps:

[0033] 1) Set the number of measurement sections and the section selection mode;

[0034] 2) Clamp and position the optical fiber preform;

[0035] 3) Data acquisition: keep the optical fiber preform in a rotating state, position the first selected section with the laser caliper 9, scan the section 360°, and then move the laser caliper 9 to the next section. A section position, repeat this step until all sections are scanned;

[0036] 4) Data processing: each time the laser caliper 9 scans, a group of dynamic distances between the dynamic surface of the section and the reference surface is collected as D, and the maximum value of the dynamic distances obtained by comparison is Dmax and the minimum value is Dmin, the calculated difference between the maximum value Dmax and the minimum value Dmin is ΔD, and ΔD / 2 is the curvature of the section, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com