Bottle stacking machine capable of feeding and discharging bottles from low position

A bottle coding machine and low-level technology, applied in the field of bottle coding machines, can solve the problems of low efficiency and slow working speed, and achieve the effects of realizing mechanical automation, improving quality and appearance, and reasonable layout of internal facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

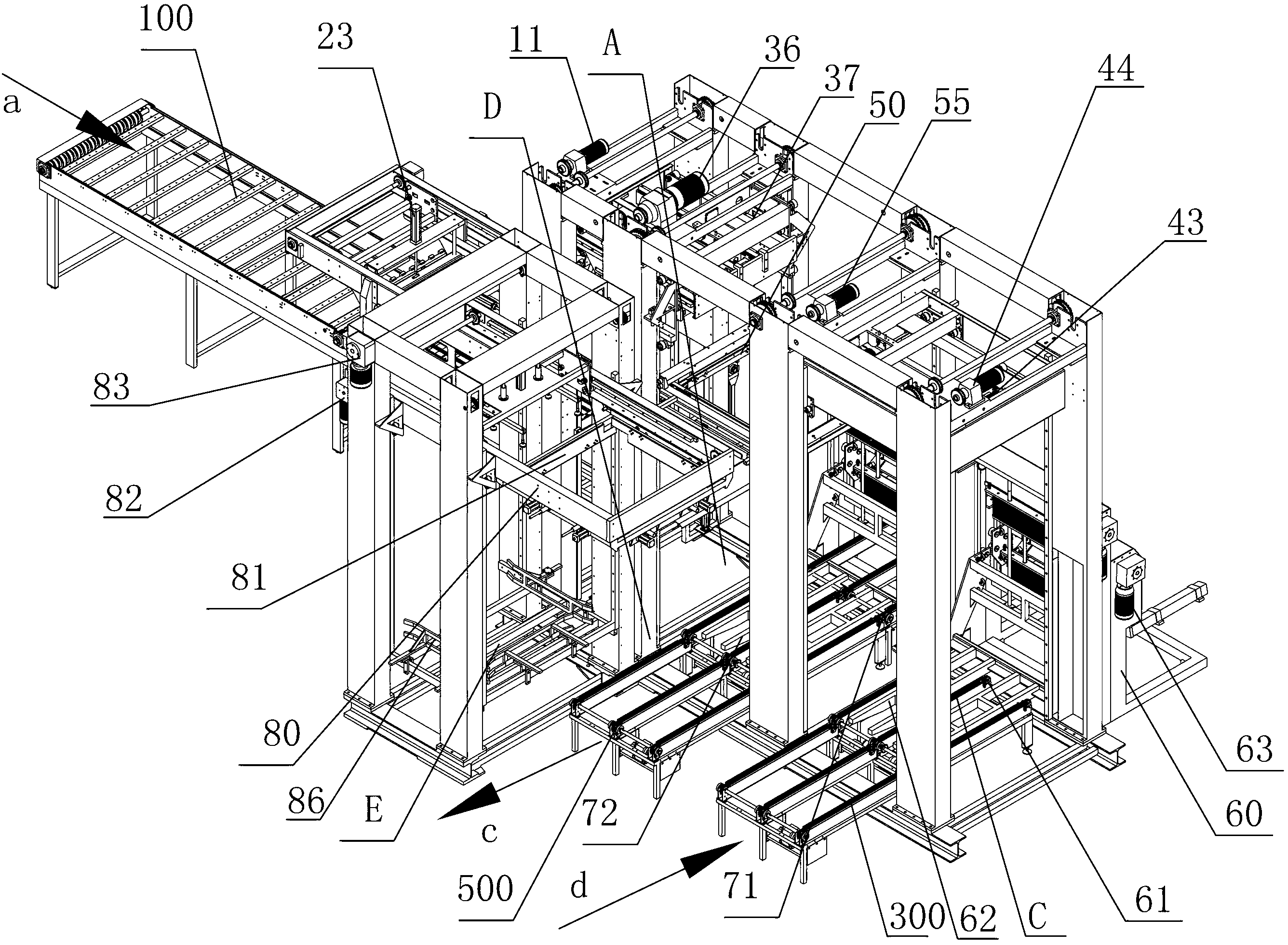

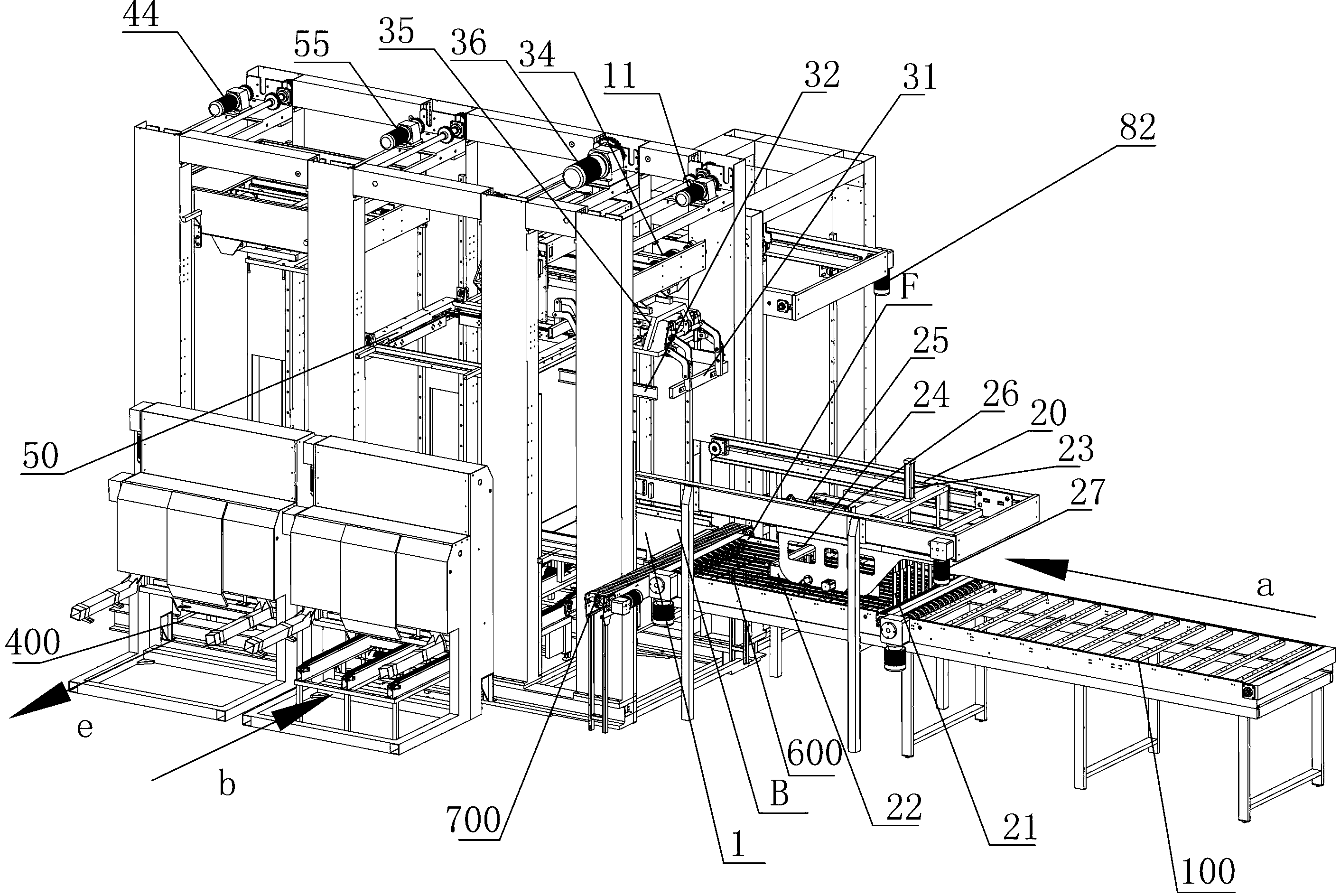

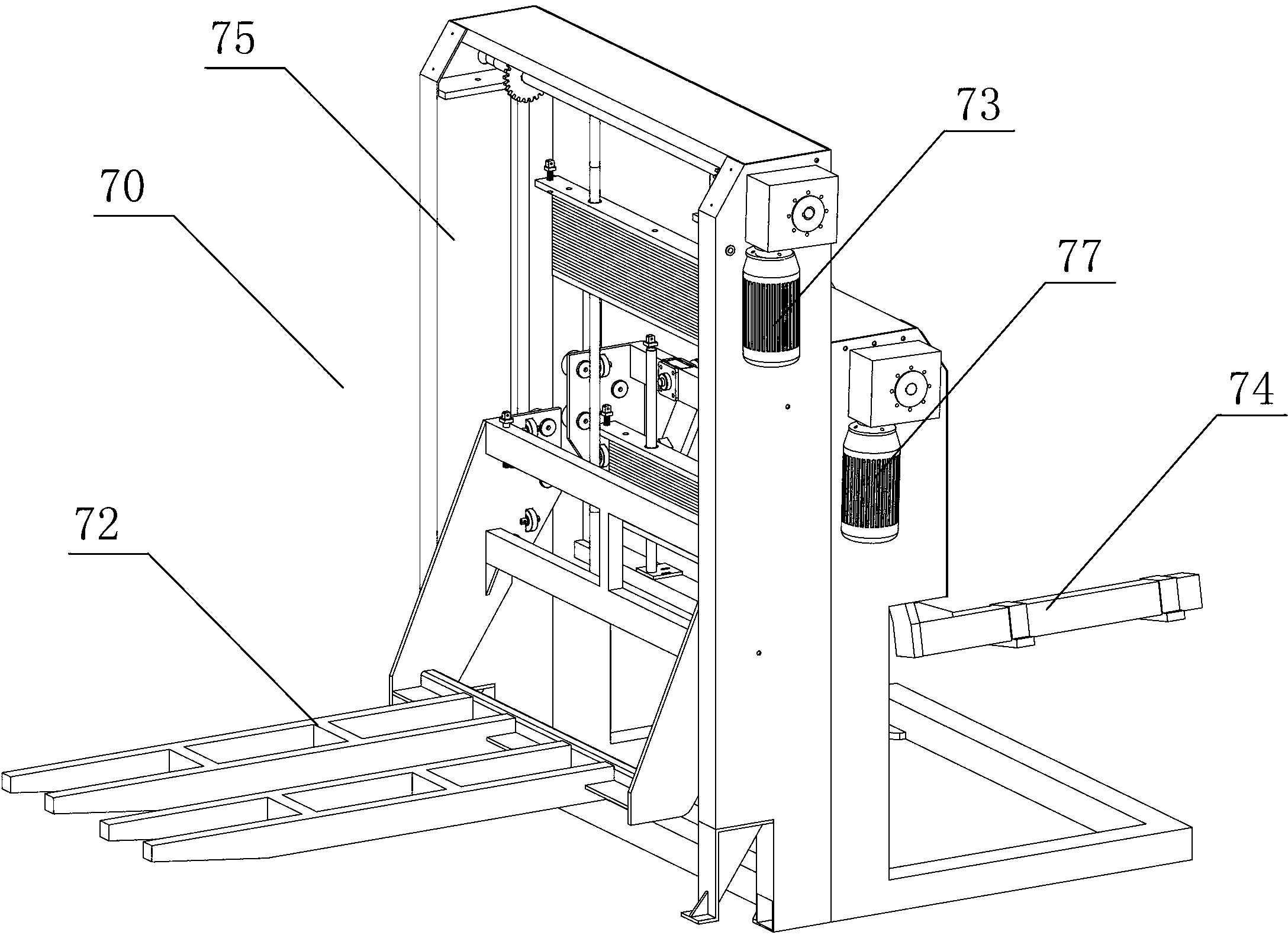

[0036] Refer to attached picture. The present invention includes a bottle conveying line 100 at a low position, a pallet conveying line 200 at a low position, a bottle stack output line 500 at a low position, and a partition conveying line 300 at a low position; the low position is a high point position relative to the bottle stack The concept generally refers to a height position as low as possible without hindering the installation of equipment, or a height position that can directly match or be close to the height of the previous conveying device, so that the conveyed items do not need to be transported first. is conveyed above the height of the stack of bottles.

[0037] The bottle conveying line 100 can adopt a plate chain conveying mechanism or a belt conveying mechanism, the pallet conveying line 200 can adopt a roller table or a chain conveying mechanism, and the bottle stack output line 500 can adopt a roller conveying mechanism or a chain conveying mechanism. The li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com