Automatic forming production device for fresh wet noodles

An automatic forming and manufacturing device technology, which is applied to dough forming and cutting equipment, dough forming machinery or equipment, and cutting noodles, etc., can solve the problem that the degree of automatic production is not very high, the maintenance of equipment is cumbersome and inconvenient, and the sanitary conditions cannot be guaranteed. To ensure product quality and consistency, improve production efficiency, and real-time adjustable roller spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

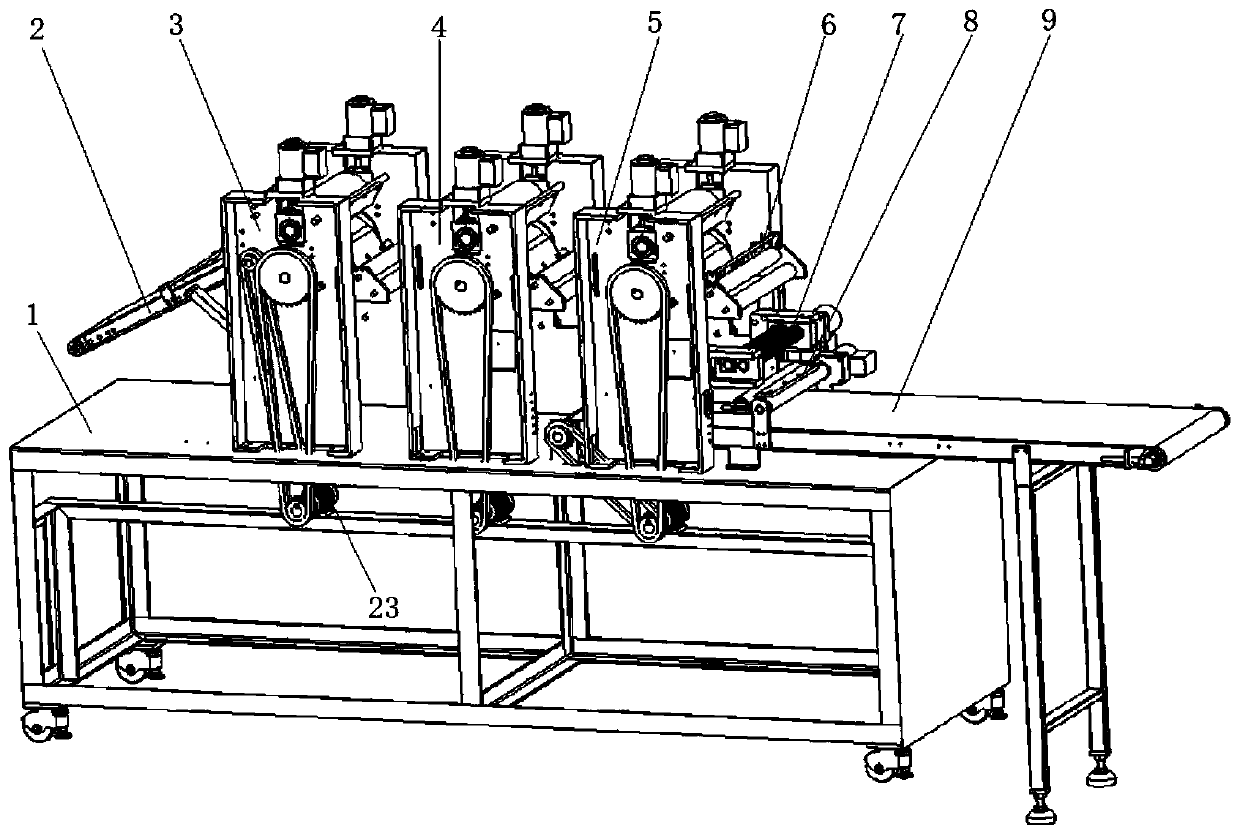

[0049] Such as Figure 1 to Figure 9 Shown, the present invention provides a kind of fresh wet noodle automatic molding making device, and this device comprises:

[0050] Frame 1, the front end of the upper side of the frame 1 is provided with a noodle belt delivery assembly 2, one end of the noodle belt delivery assembly 2 is connected to a first-stage calender 3, and one side of the first-stage calender 3 is provided with a second-stage A calender 4, a third-stage calender 5 is arranged on one side of the second-stage calender 4, a thickness measurement assembly 6 is connected to one side of the third-stage calender 5, and a noodle knife assembly is arranged below the thickness measurement assembly 6 7. A cutting assembly 8 is provided below the noodle knife assembly 7 , and a conveyor belt assembly 9 is provided on the lower side of the cutting assembly 8 .

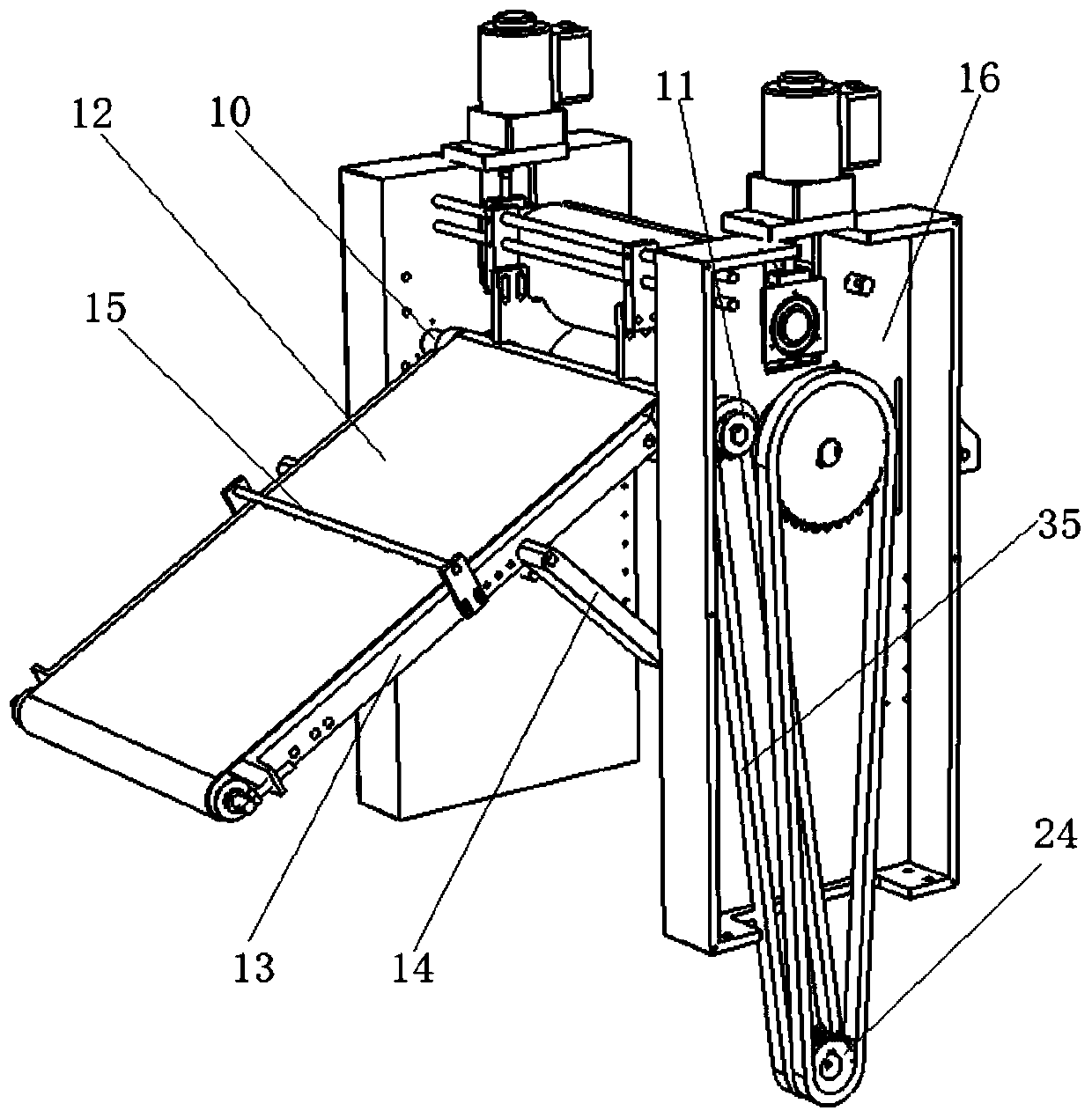

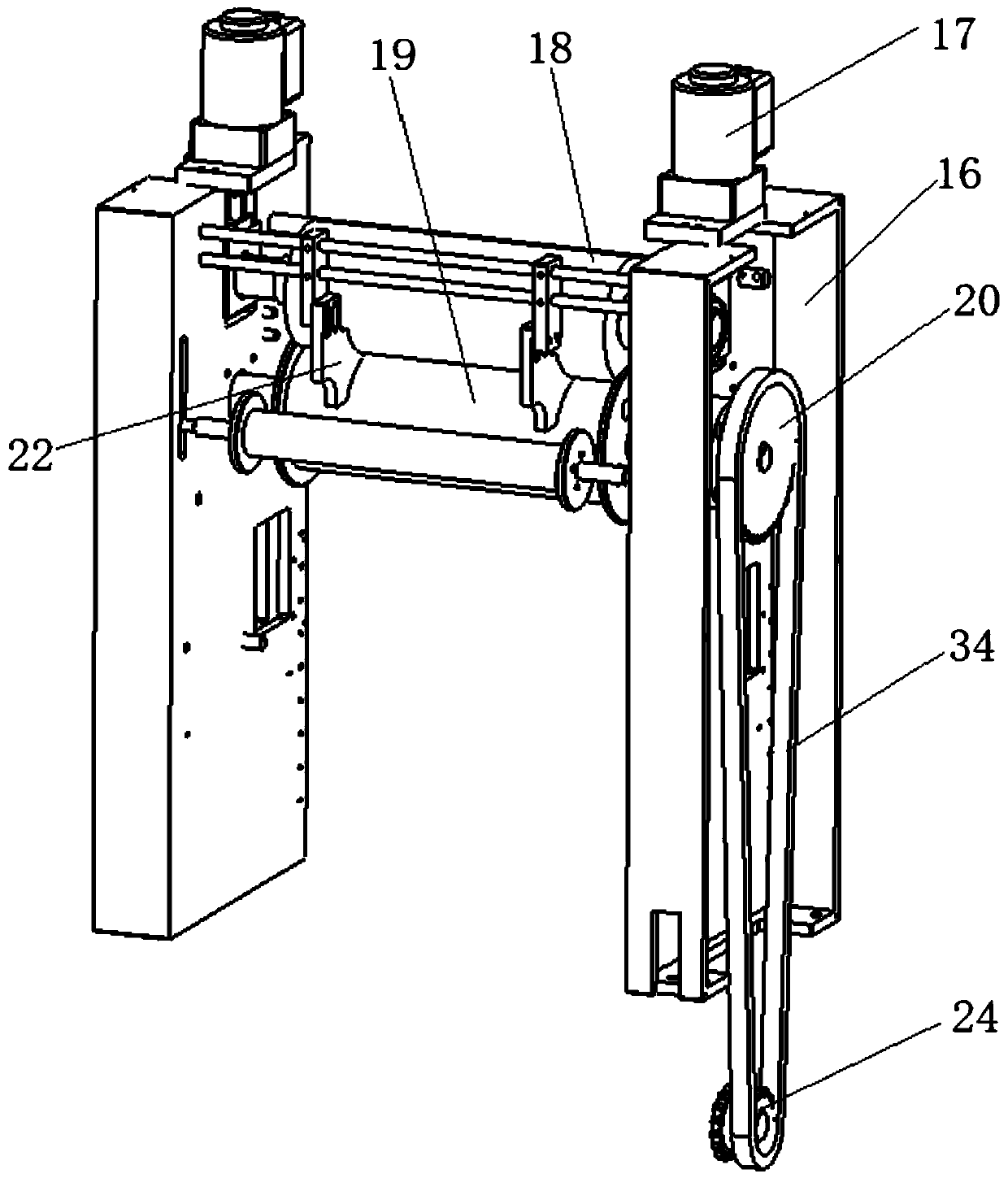

[0051] In this embodiment, the noodle belt conveying assembly 2 includes a transmission shaft 10 penetrating throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com