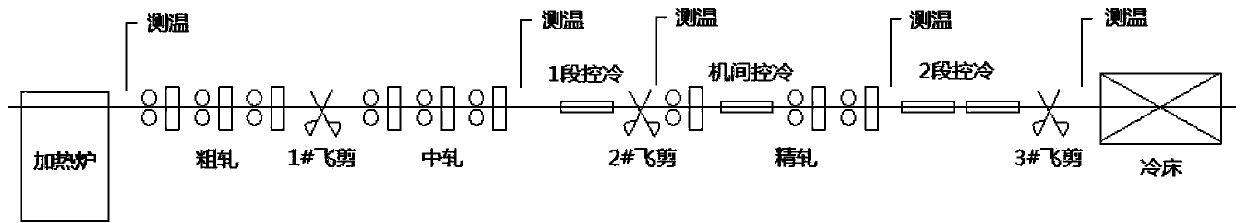

Automatic temperature control method for rod material cold control system

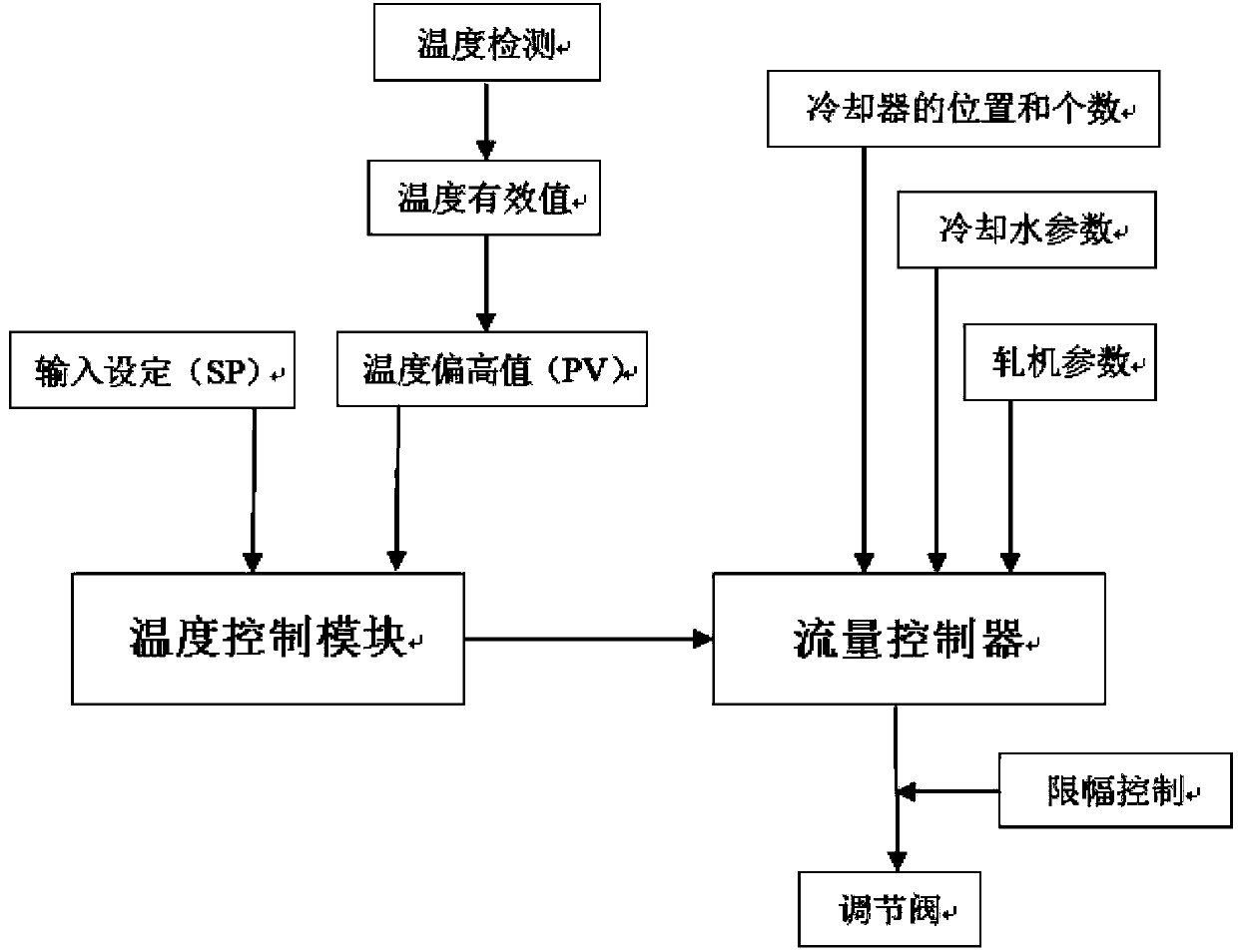

A cooling system and bar technology, which is applied in the field of automatic temperature control of bar control cooling system and bar control cooling automatic control field, can solve the problem that the tensile strength fluctuation of bar mechanical properties exceeds the index, and the cooling water cannot be adjusted in time. Unsatisfactory metallographic structure and other problems can avoid human intervention, reduce the amount of alloy used, and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A set of temperature automatic control method applied to the bar material cooling system proposed by the present invention adopts the control method combining water cooling parameter self-correction, PI parameter self-learning and fuzzy control, and a specific bar material control cooling system is used as the implementation below Examples detail the specific steps of the entire implementation process.

[0025] 1. Install and configure the required control hardware, software and Ethernet. The actual implementation content is as follows:

[0026] (1) Install computer operating system, automation programming software and man-machine interface software: the computer adopts Advantech industrial computer and Microsoft windows XP sp3 operating system, the automation programming software adopts Siemens step75.5 version programming software, and the man-machine interface software adopts Siemens Wincc7 .0 Asian version.

[0027] (2) Install and configure PLC hardware control e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com