Patents

Literature

81results about How to "Improve final quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

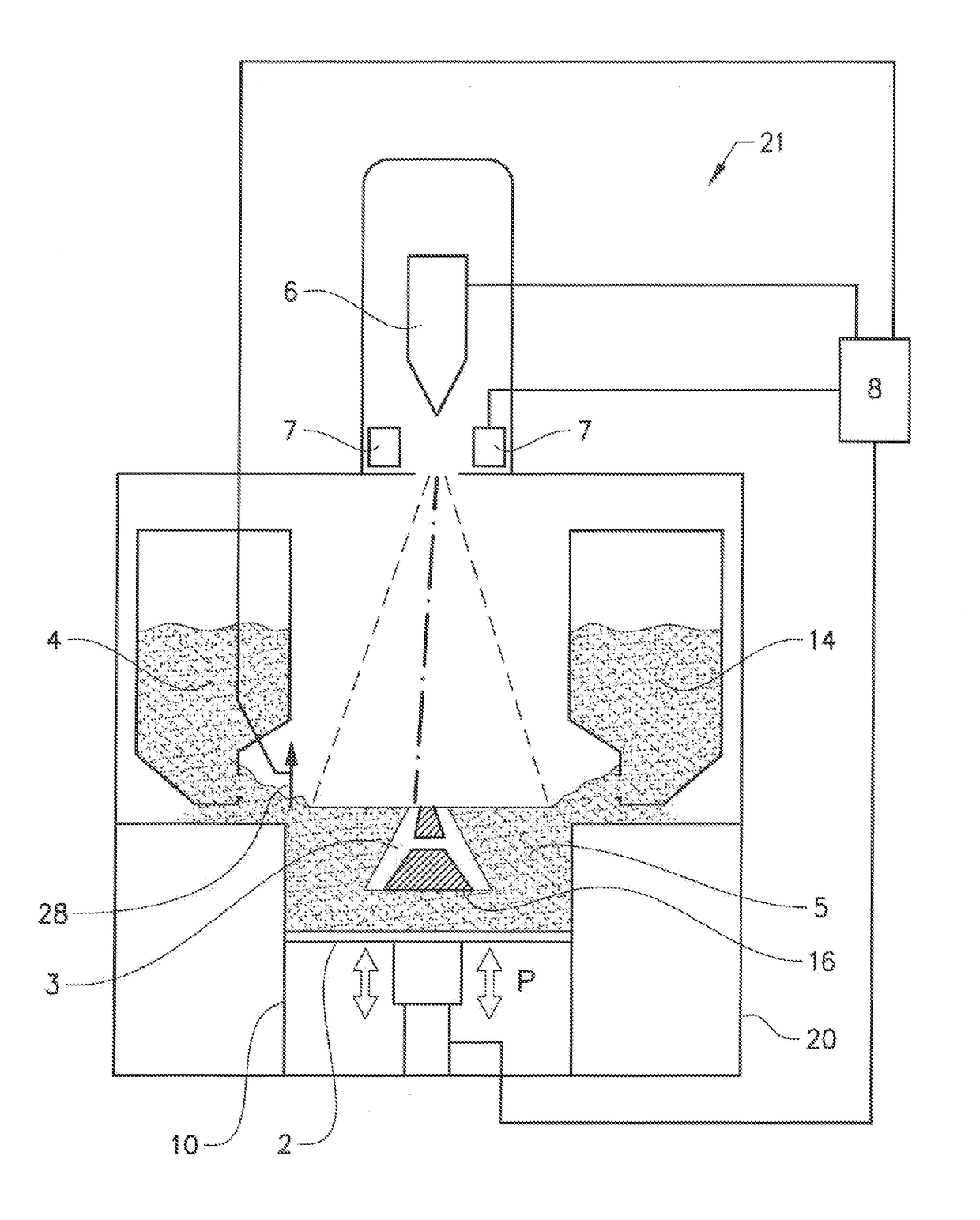

Additive manufacturing of three-dimensional articles

ActiveUS20150165525A1Improve material characteristicImprove material propertiesAdditive manufacturing apparatusArc welding apparatusBeam sourcePower flow

The present invention relates to a method for forming a three-dimensional article through successively depositing individual layers of powder material that are fused together so as to form the article, said method comprising the steps of: providing at least one electron beam source emitting an electron beam for heating and / or fusing said powder material. Controlling the electron beam source in a first mode when said formation of said three dimensional article is in a first process step. Controlling said electron beam in a second mode when said formation of said three dimensional article is in a second process step, wherein in said first mode an electron beam current from said electron beam source is controlled in a feed-forward mode and in said second mode said electron beam current is controlled in a feed-back mode.

Owner:ARCAM AB

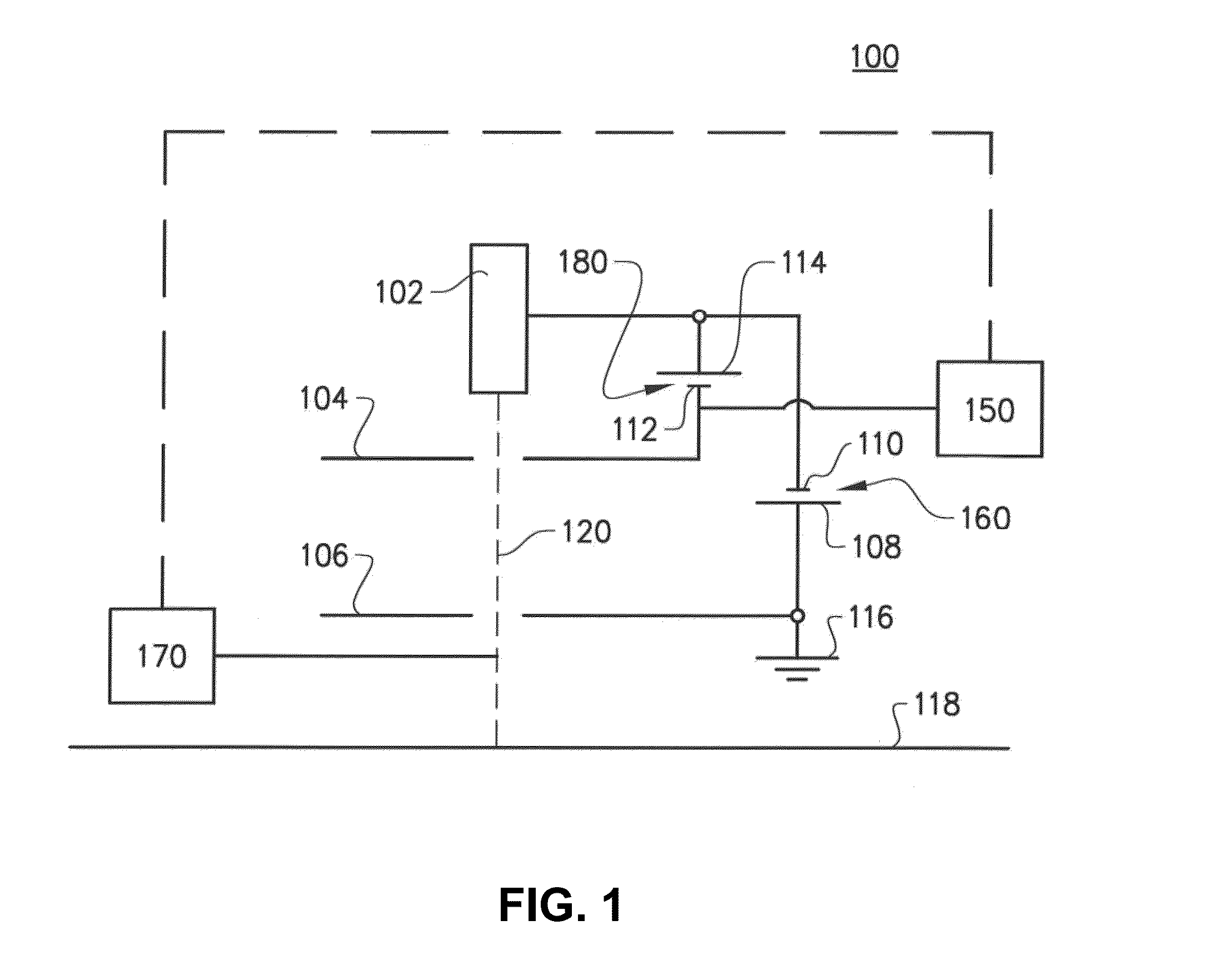

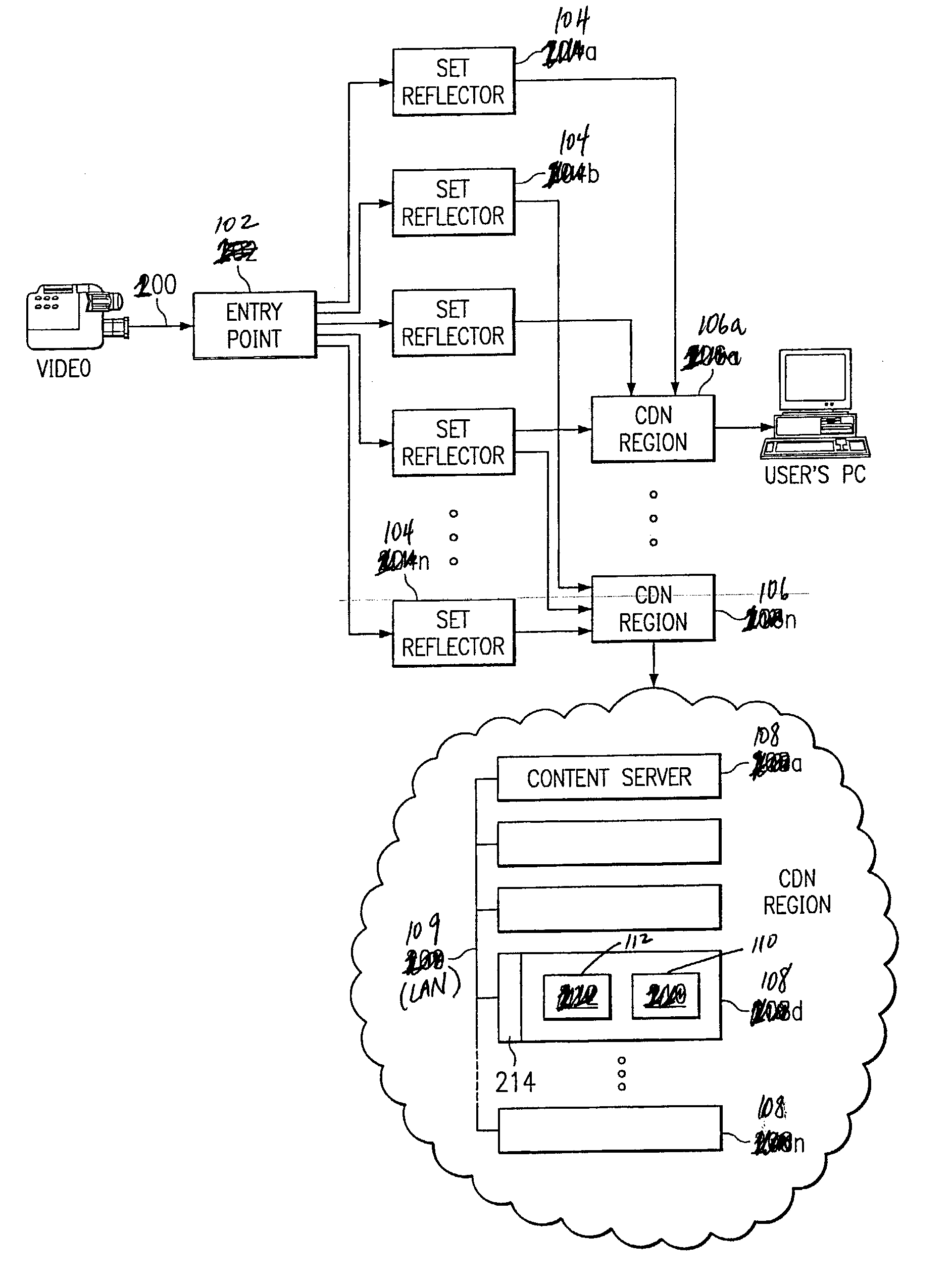

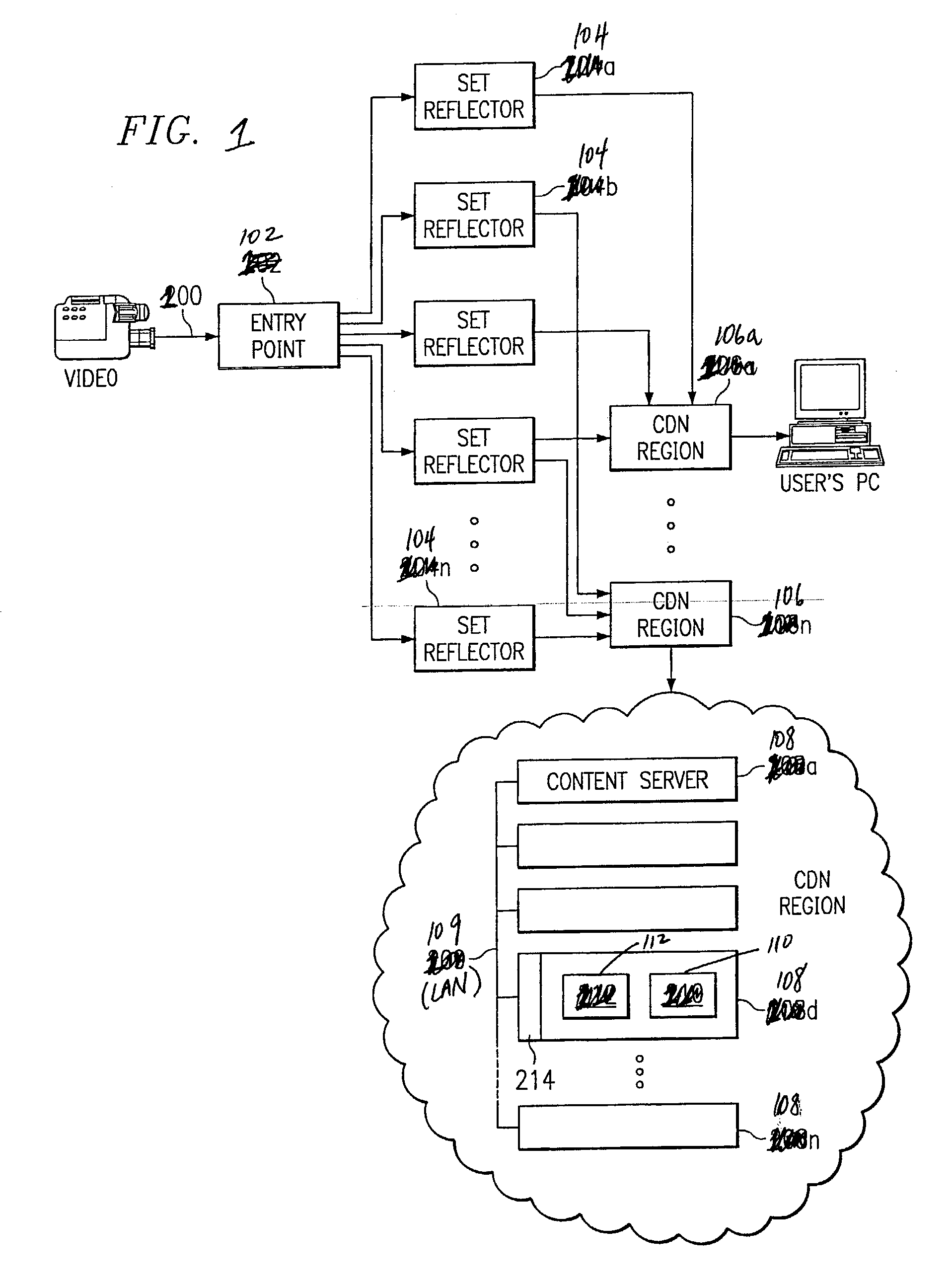

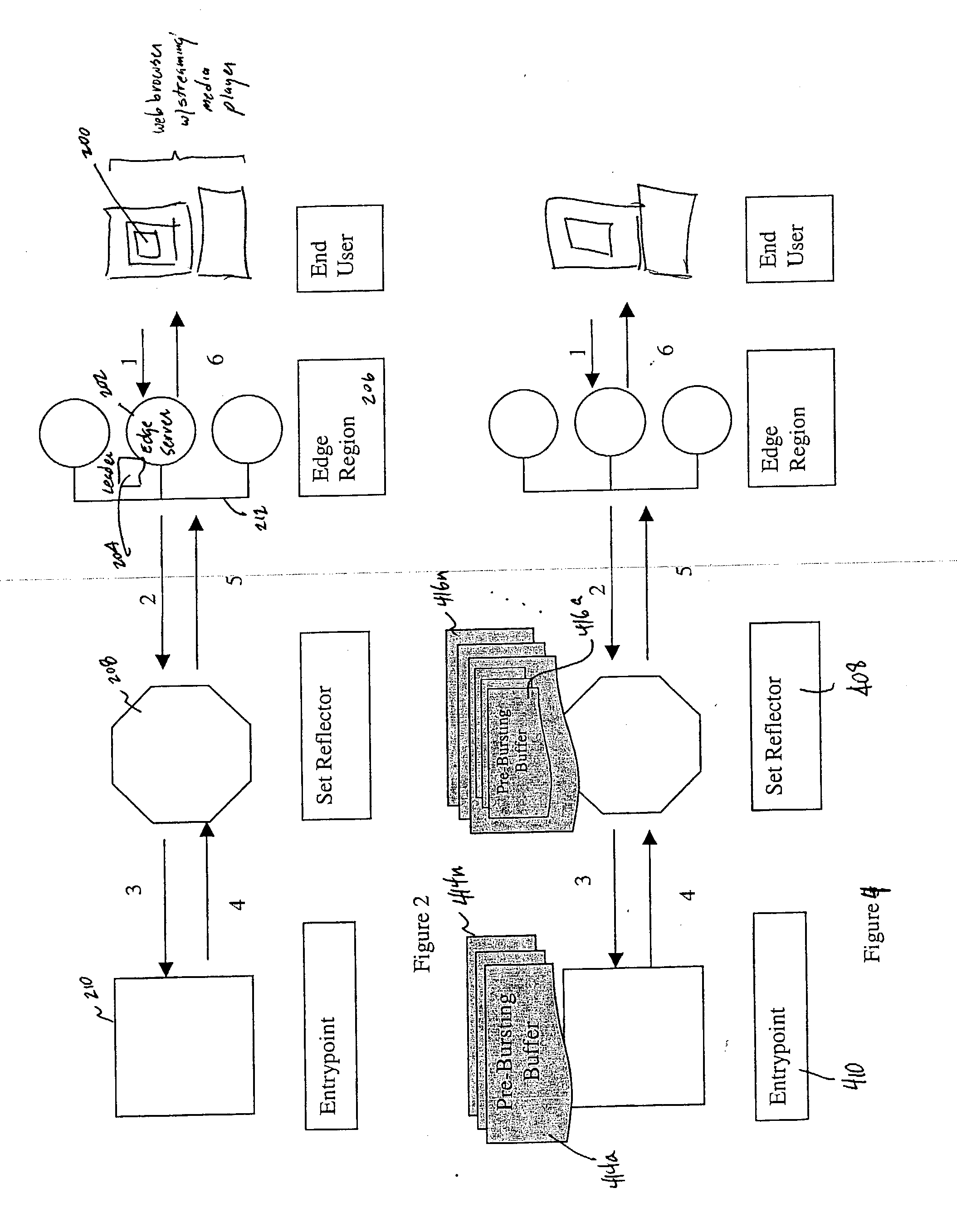

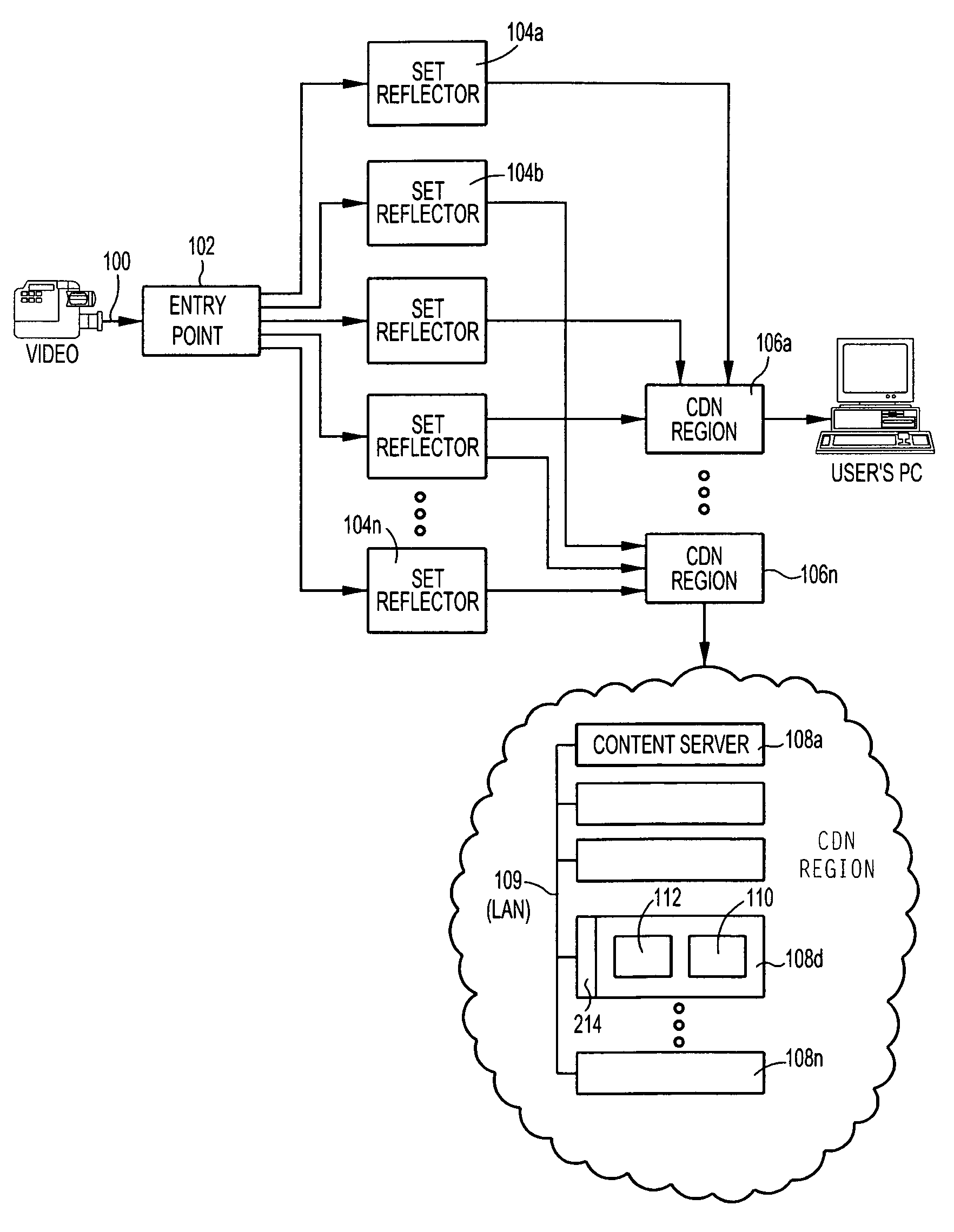

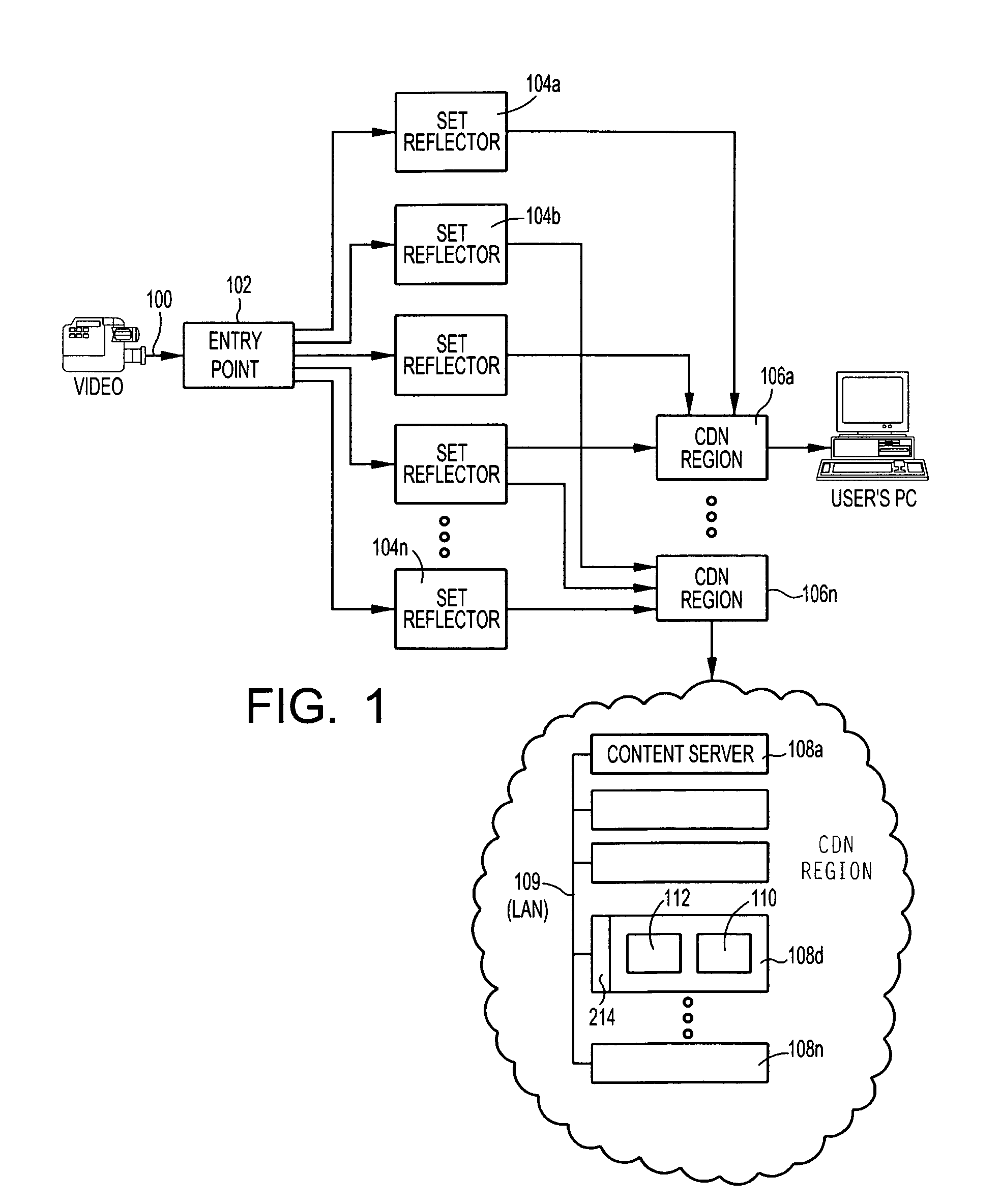

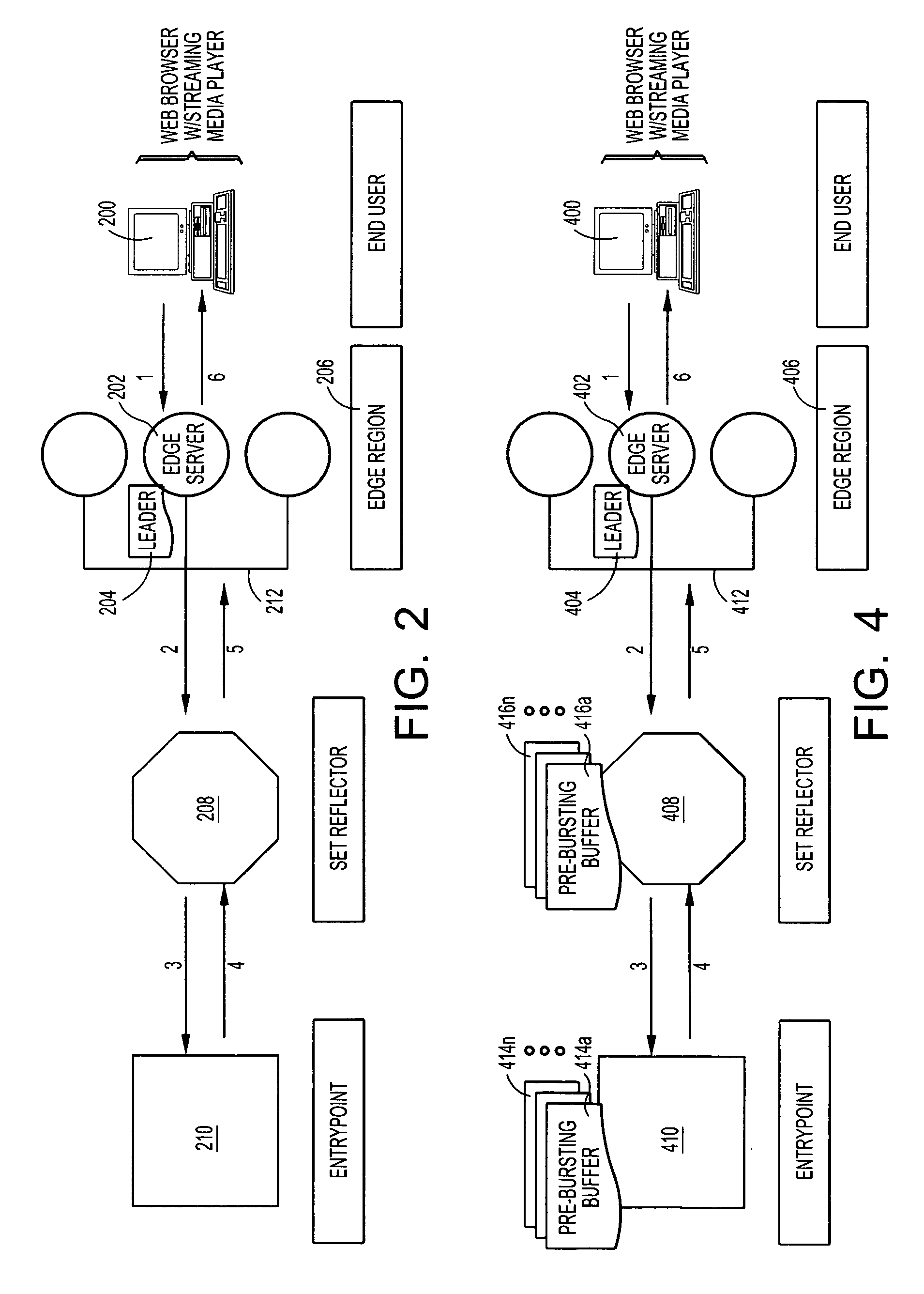

Method and system for enhancing live stream delivery quality using prebursting

InactiveUS20050015509A1Reduce deliveryHow to improveTime-division multiplexMultiple digital computer combinationsData streamPacket loss

A method to “accelerate” the delivery of a portion of a data stream across nodes of a stream transport network. According to the invention, a portion of a live stream is forwarded from a first node to a second node in a transport network at a high bitrate as compared to the stream's encoded bitrate, and thereafter, the stream continues to be forwarded from the first node to the second node at or near the encoded bitrate. The disclosed technique of forwarding a portion of a stream at a high bitrate as compared to the encoded bitrate of the stream is sometimes referred to as “prebursting” the stream. This technique provides significant advantages in that it reduces stream startup time, reduces unrecoverable stream packet loss, and reduces stream rebuffers as the stream is viewed by a requesting end user that has been mapped to a media server in a distributed computer network such as a content delivery network.

Owner:AKAMAI TECH INC

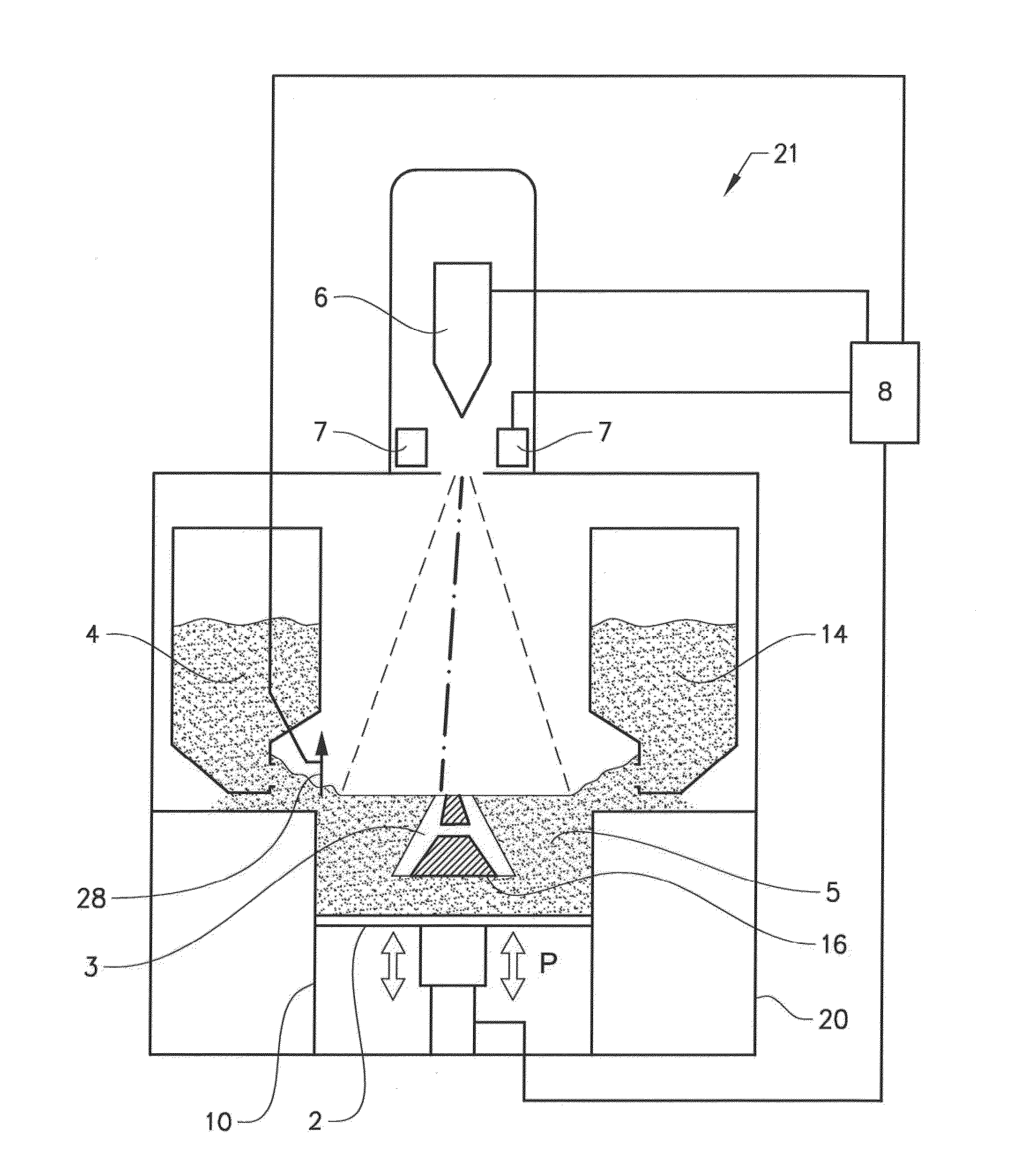

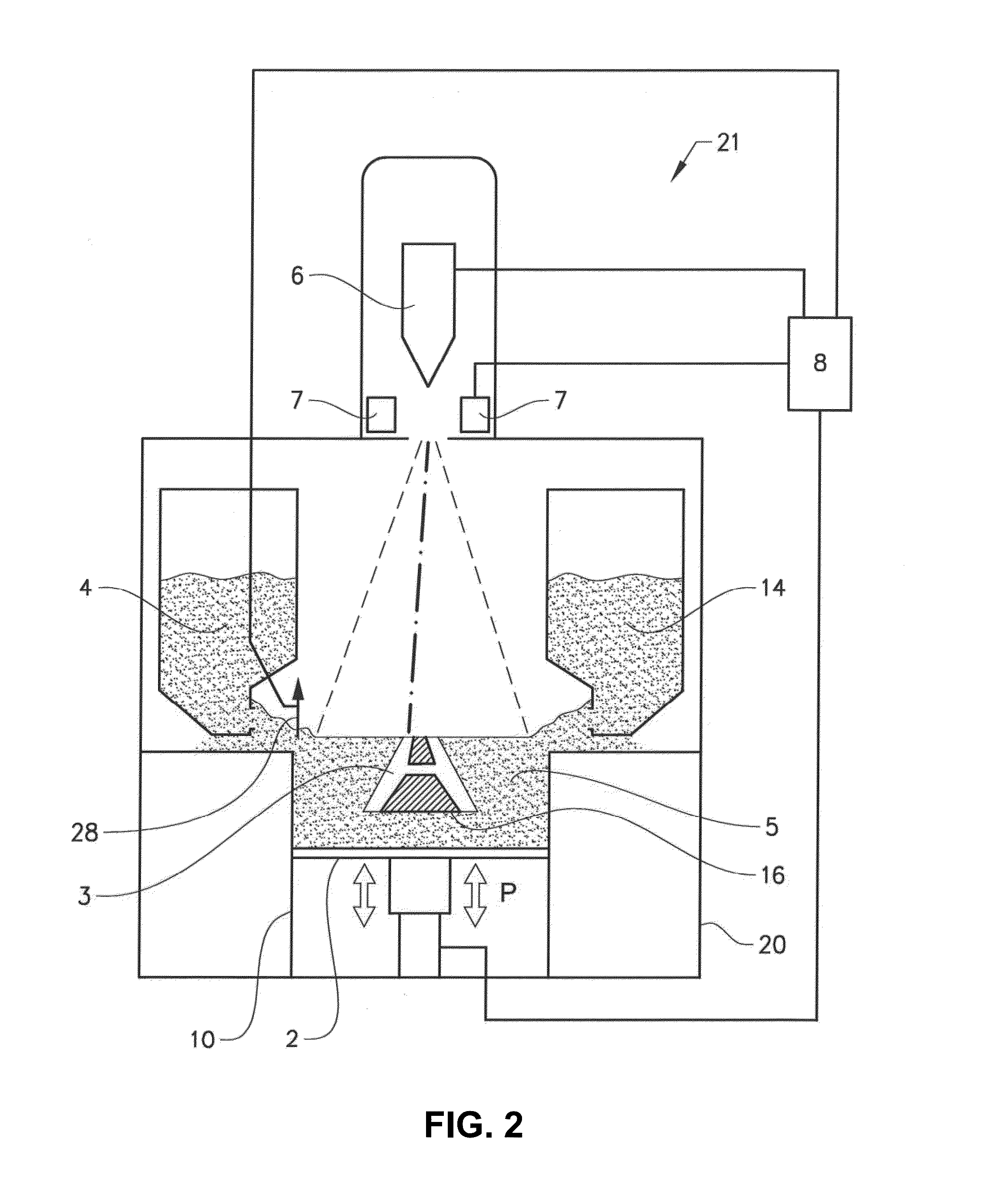

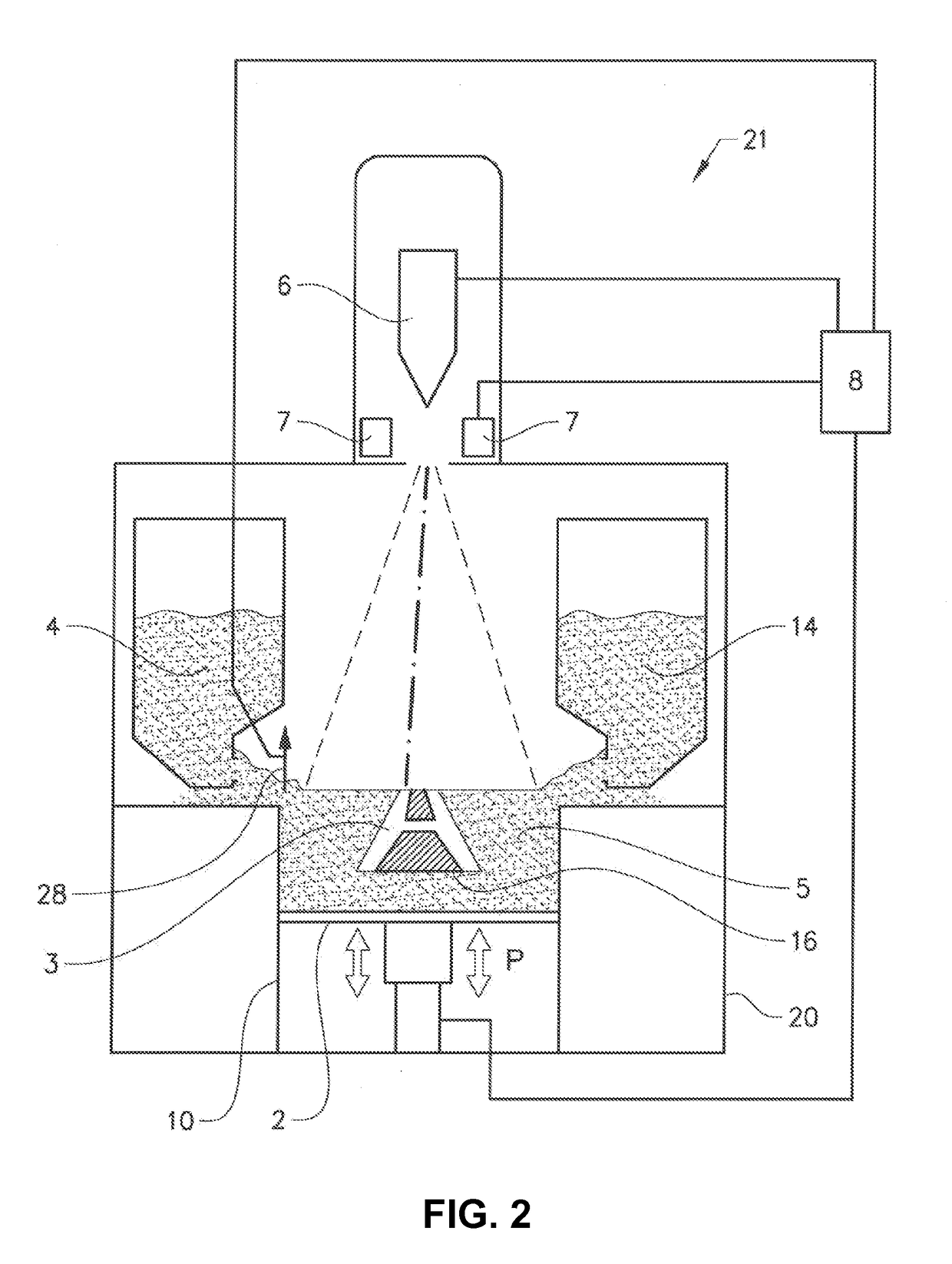

Additive manufacturing of three-dimensional articles

ActiveUS20170173691A1Improve final qualityAdditive manufacturing apparatusCeramic shaping apparatusBeam sourcePower grid

Provided is a method for forming a three dimensional article comprising the steps of: providing at least one electron beam source emitting an electron beam for at least one of heating or fusing said powder material, where said electron beam source comprises a cathode, an anode, and a grid between said cathode and anode; controlling the electron beam source in at least two modes during said formation of said three dimensional article; applying a predetermined accelerator voltage between said cathode and said anode; applying a predetermined number of different grid voltages between said grid and said cathode for producing a corresponding predetermined number of electron beam currents; and at least one of creating or updating a look-up table or mathematical function during one of the at least two modes, wherein said look-up table or mathematical function defines a relationship between a desired electron beam current and an applied grid voltage.

Owner:ARCAM AB

Method and system for enhancing live stream delivery quality using prebursting

InactiveUS7409456B2Reduce deliveryHow to improveTime-division multiplexMultiple digital computer combinationsPacket lossData stream

A method to “accelerate” the delivery of a portion of a data stream across nodes of a stream transport network. According to the invention, a portion of a live stream is forwarded from a first node to a second node in a transport network at a high bitrate as compared to the stream's encoded bitrate, and thereafter, the stream continues to be forwarded from the first node to the second node at or near the encoded bitrate. The disclosed technique of forwarding a portion of a stream at a high bitrate as compared to the encoded bitrate of the stream is sometimes referred to as “prebursting” the stream. This technique provides significant advantages in that it reduces stream startup time, reduces unrecoverable stream packet loss, and reduces stream rebuffers as the stream is viewed by a requesting end user that has been mapped to a media server in a distributed computer network such as a content delivery network.

Owner:AKAMAI TECH INC

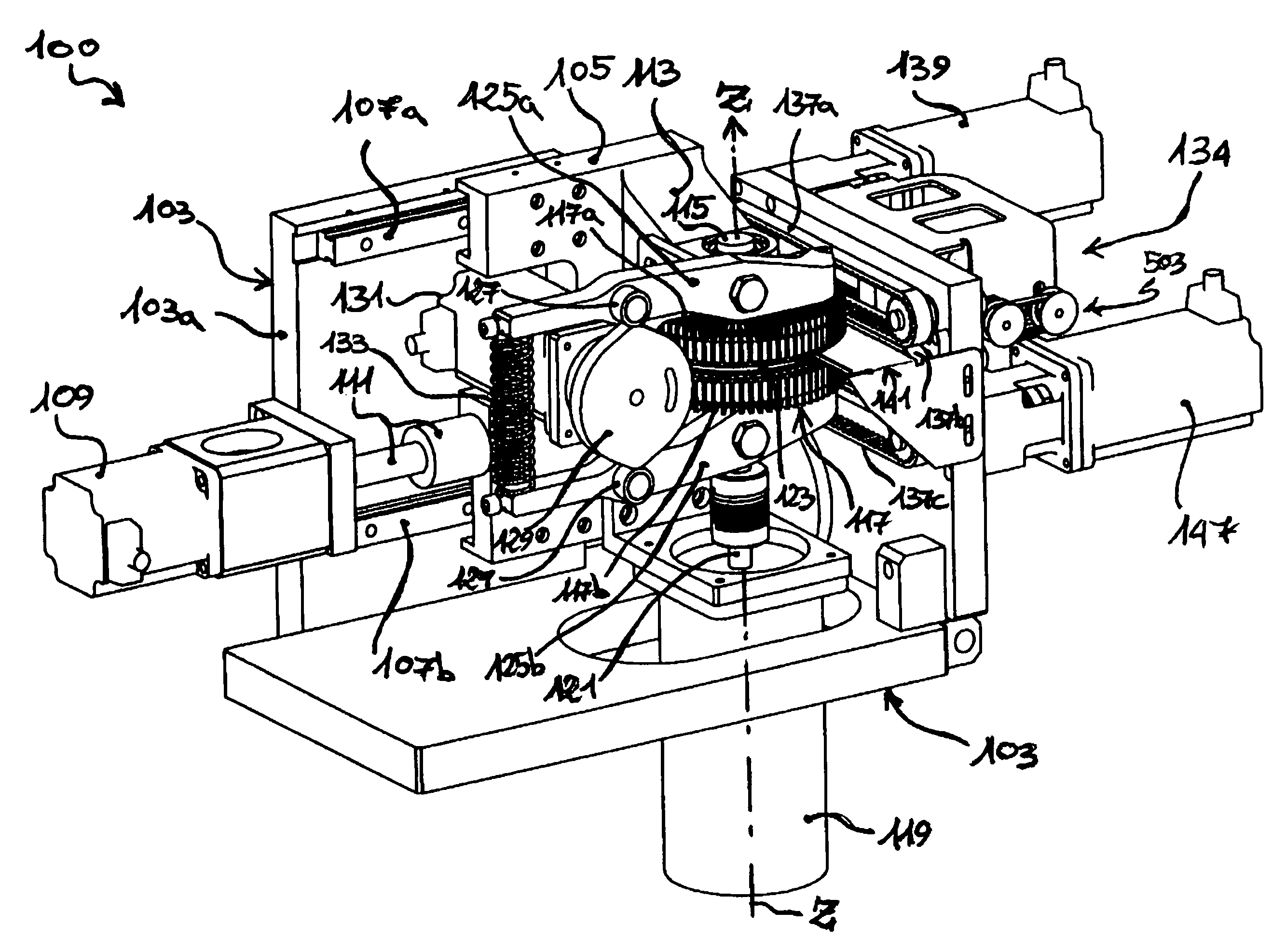

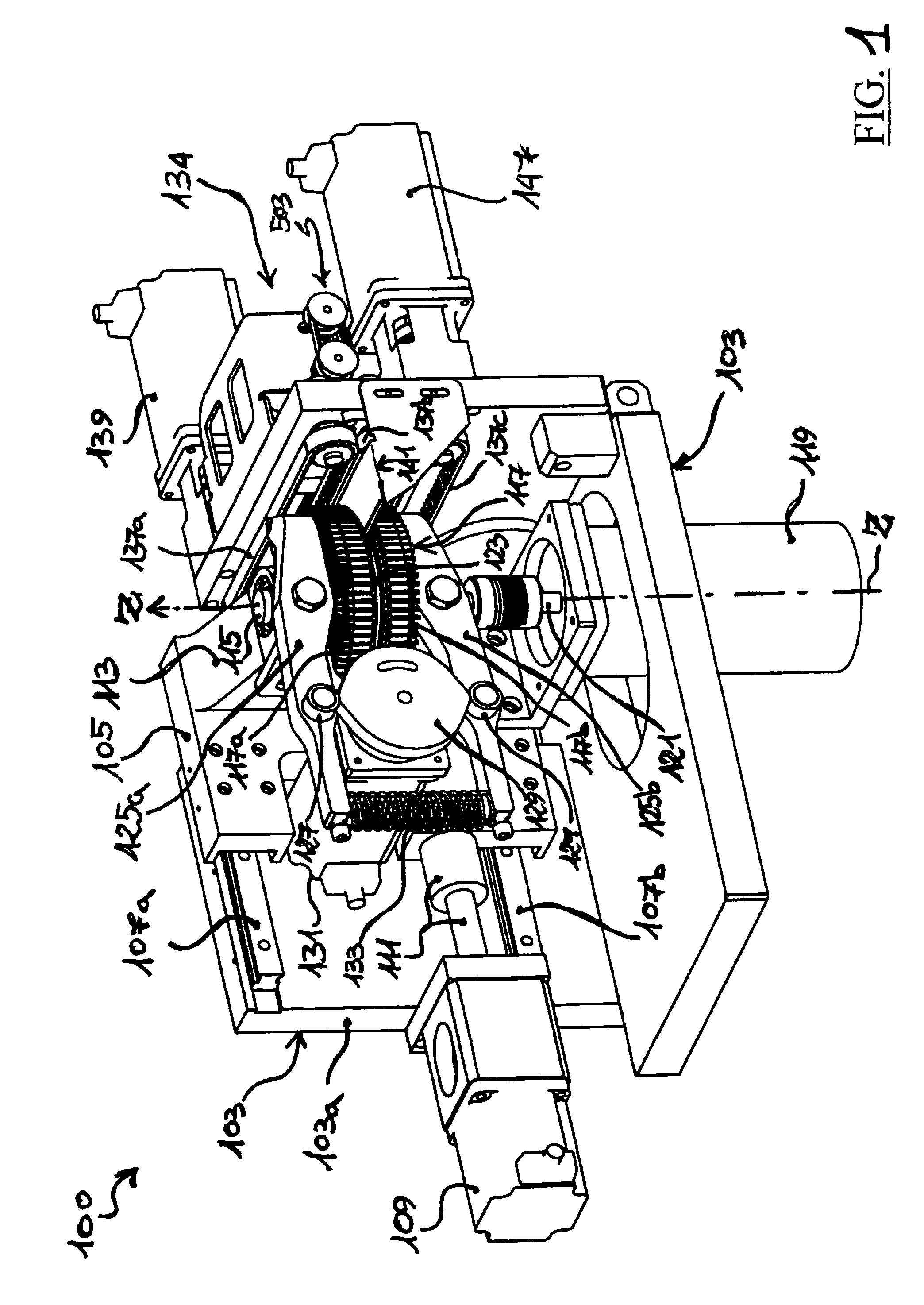

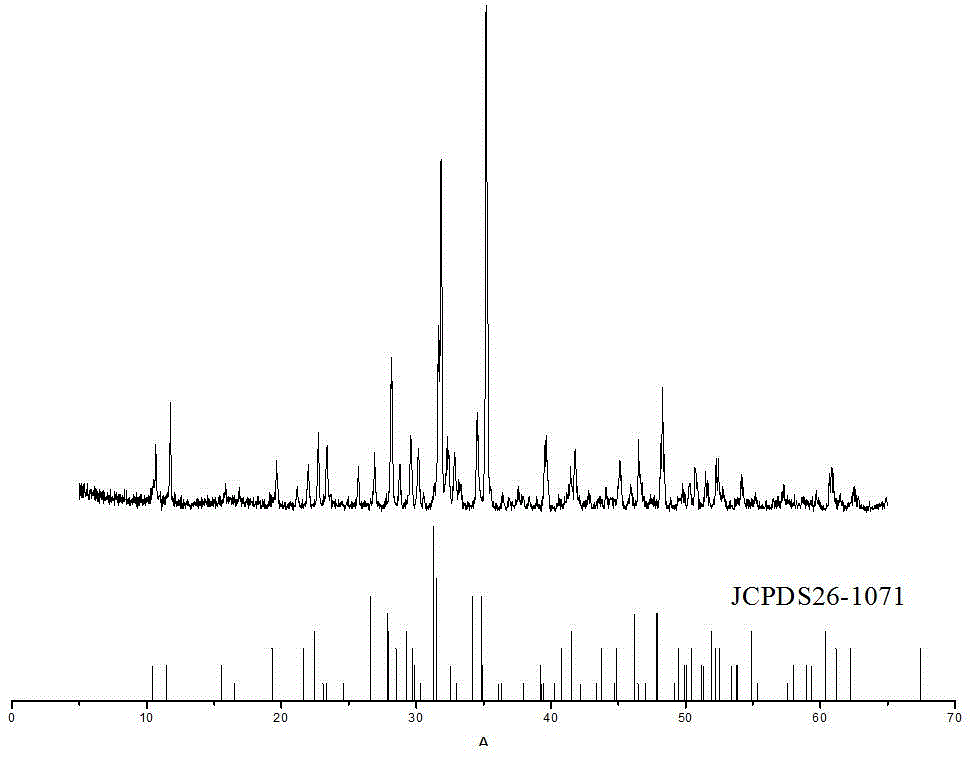

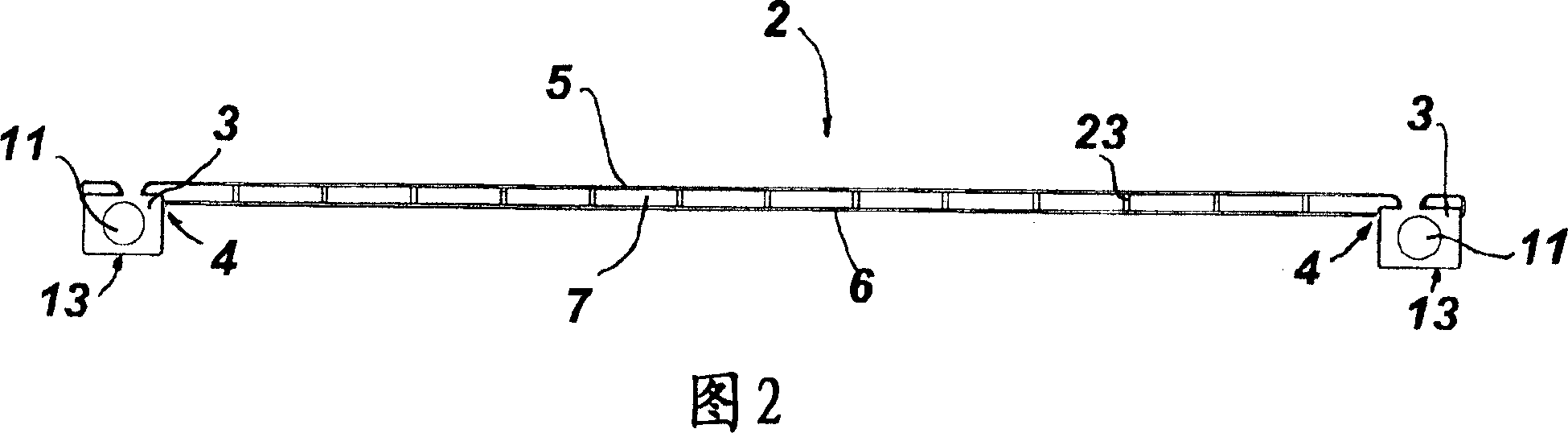

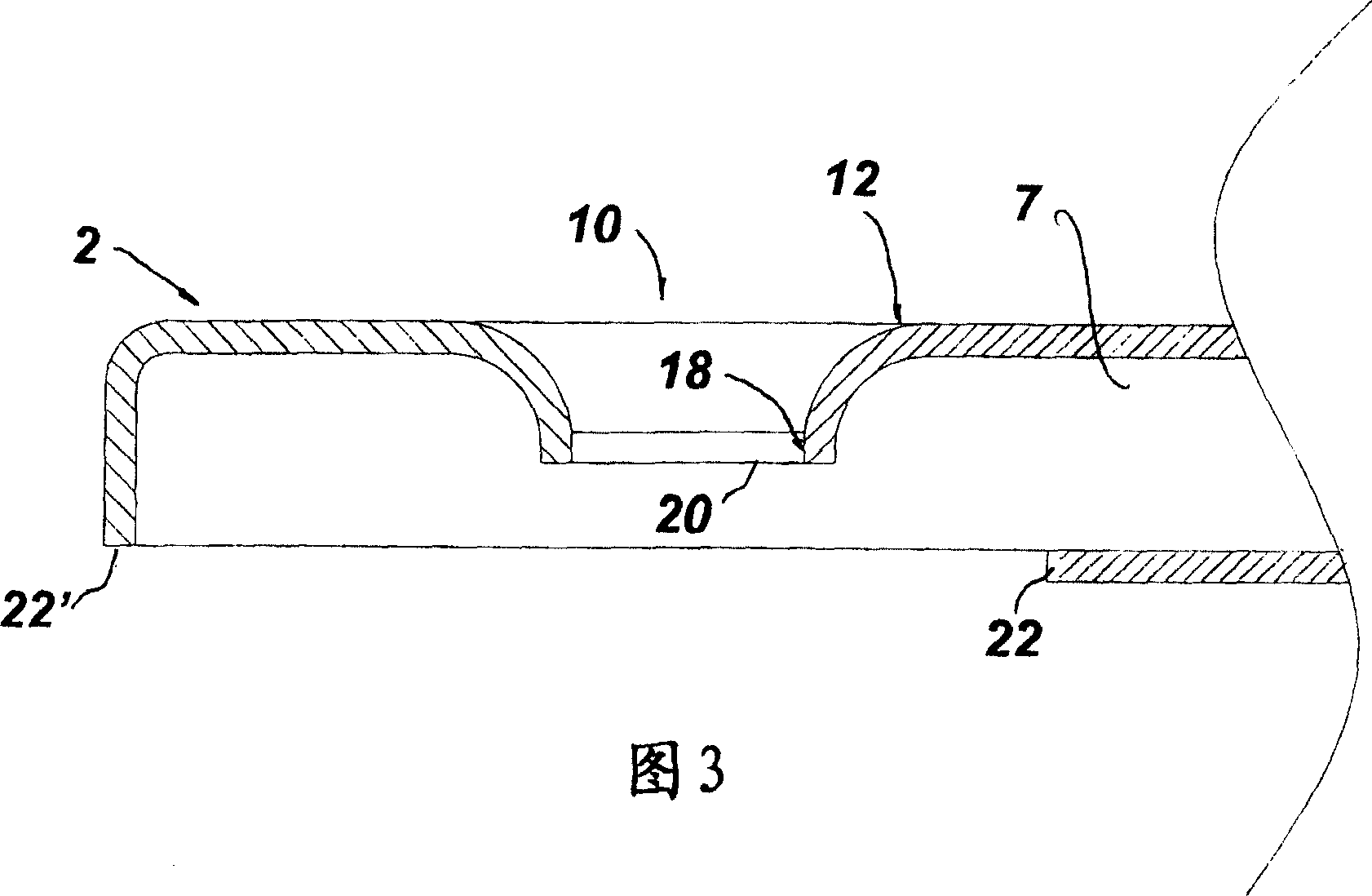

Machine for the mechanical personalization of supports of the identification card type

InactiveUS7143935B2High speedImprove productivityTypewritersOther printing apparatusPersonalizationBand shape

A machine for the mechanical personalization of supports of the type identification card, comprising a mechanical personalization group of the cards adapted to interact with a card to be mechanically personalized so as to form, on a surface of the card, strings of symbols, and a moving and positioning device of the cards to be mechanically personalized with respect to the mechanical personalization group. The moving and positioning device of the cards includes a pair of elements belt-like extending and jointly movable along a first direction of a plane containing the card to be personalized, said belt-like elements being arranged at a mutual distance, in a second direction orthogonal to the plane, such as to allow said pair of belt-like elements to receive, accommodate and hold therebetween by friction the card.

Owner:ARGOS

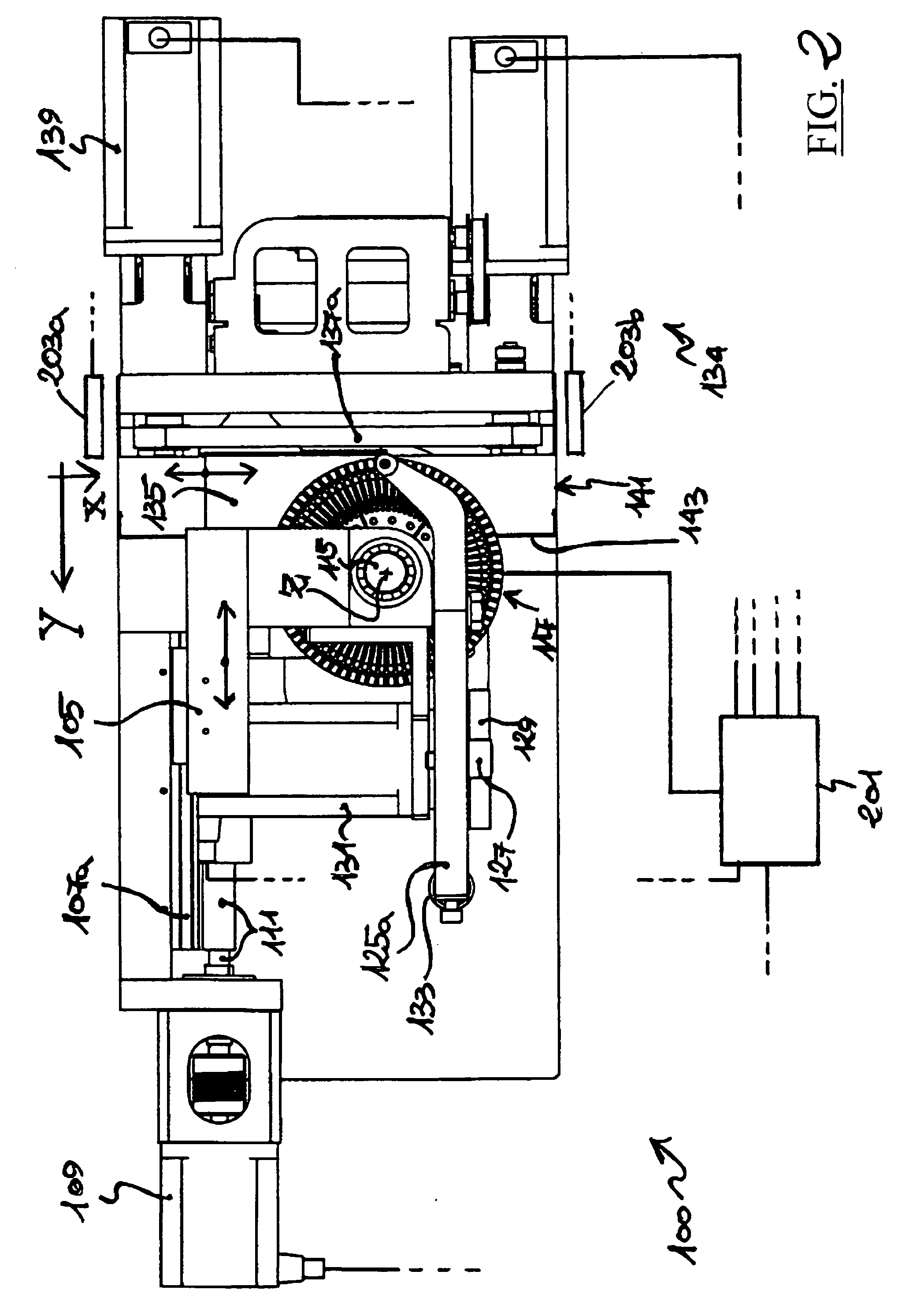

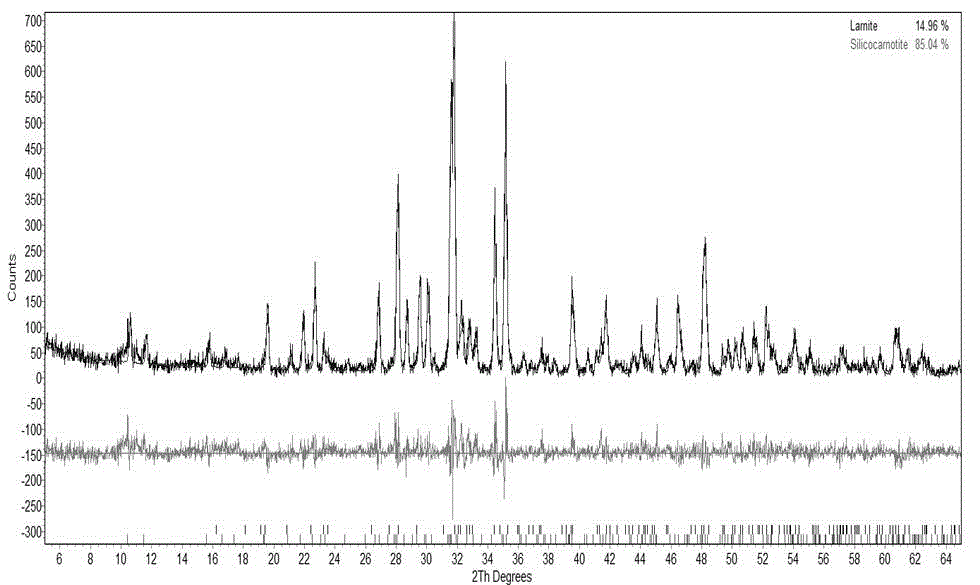

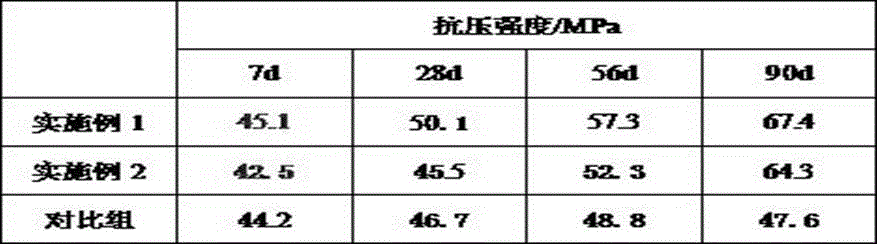

Preparation method and application method of calcium sulphosilicate mineral

InactiveCN104609434AThe synthesis process is simpleSynthetic raw materials are abundant and easy to obtainAlkaline-earth metal silicatesCalcium silicateAluminate

The invention discloses a preparation method of a calcium sulphosilicate mineral. The preparation method is characterized by comprising the steps of respectively finely grinding a calcium oxide raw material, a silicon oxide raw material and gypsum and uniformly mixing; calcining at a high temperature, maintaining the temperature for a period of time to obtain mixed mineral constituents mainly including calcium sulphosilicate; and grinding the mixture to a certain fineness so as to obtain the calcium sulphosilicate mineral. The invention further discloses an application method of the calcium sulphosilicate mineral. The application method is characterized in that the calcium sulphosilicate mineral is applied to a sulphate aluminum cement additive so as to increase the later strength of the sulphate aluminum cement. According to the application method, the later strength of the sulphate aluminum cement can be effectively improved, and the quality of a concrete structure of a final product is improved; meanwhile, the preparation method has the advantages that the preparation is simple, the implementation is convenient and the cost is low.

Owner:CHONGQING UNIV

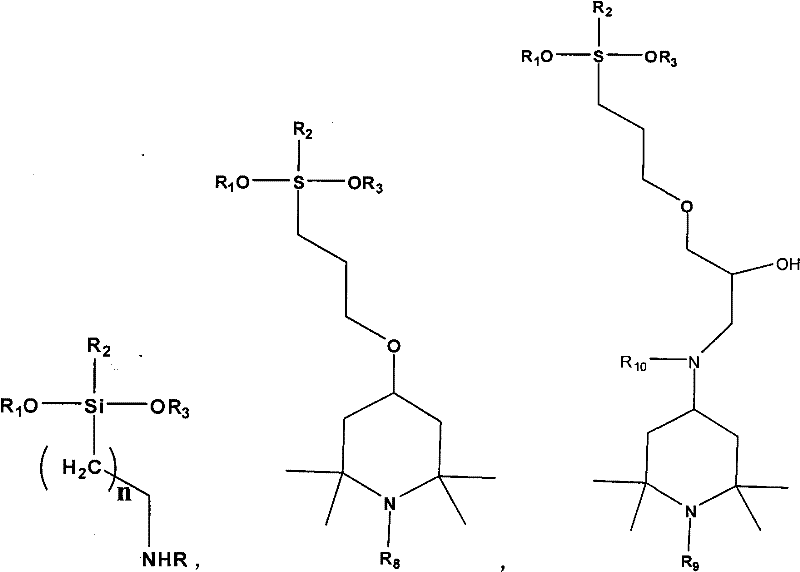

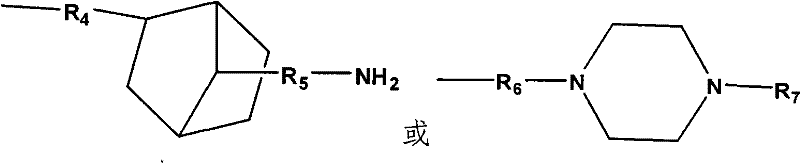

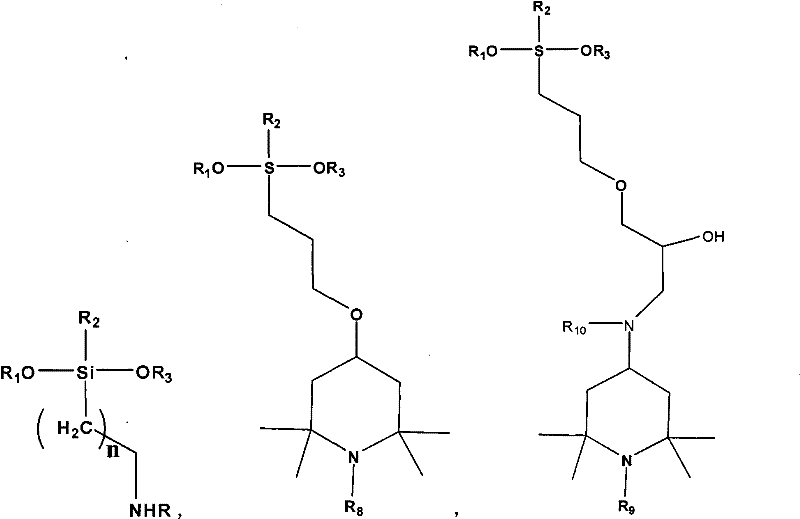

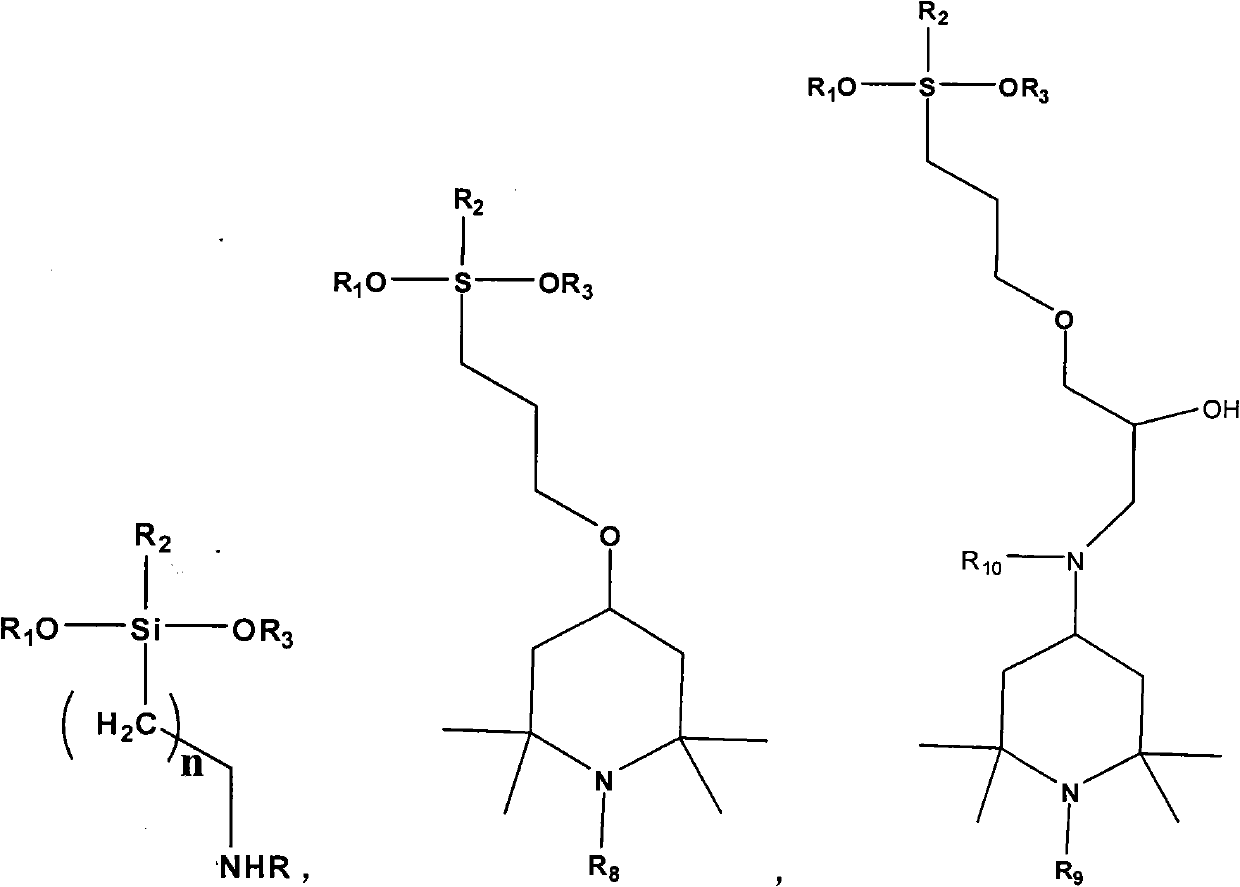

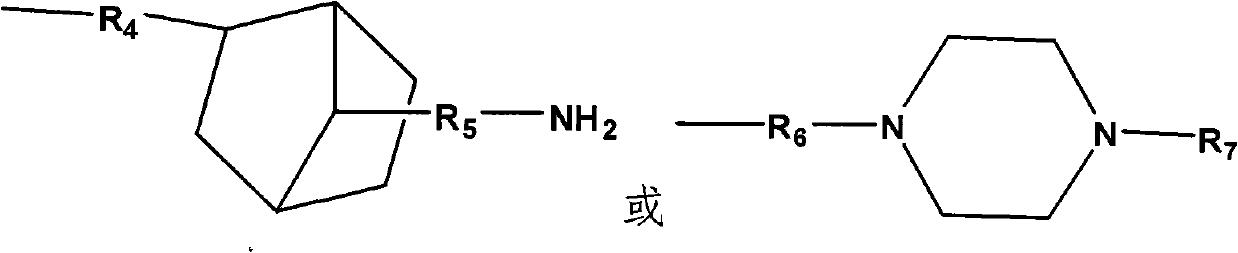

Amino modified silicone oil and preparation method thereof

The invention relates to amino modified silicone oil which has low content of metal ions and stable viscosity and a preparation method thereof. The amino modified silicone oil is prepared by using dihydroxy silicone oil and an amine coupling agent as raw materials and tetramethylammonium hydroxide as a catalyst, subjecting the above-mentioned materials to a bulk condensation reaction and adding micro-molecular compounds with active groups after the reaction lasts for 2 to 5 h. Compared to conventional methods, the invention has the following characteristics: tetramethylammonium hydroxide is used as a catalyst to substitute metallic compounds, and after the reaction is finished, temperature rises again, which enables the catalyst to be destroyed, the micro-molecular compounds to be removed, the content of metallic impurities in an obtained product of the amino modified silicone oil to be controlled and the amino modified silicone oil with low content of metals and stable viscosity to be synthesized; during utilization, the amino modified silicone oil can substantially reduce metallic impurities introduced into fibers, especially into carbon fiber precursors, thereby improving finalquality of carbon fibers, and viscosity of the silicone oil does not change in the process of storage.

Owner:CHINA NAT BLUESTAR GRP CO LTD

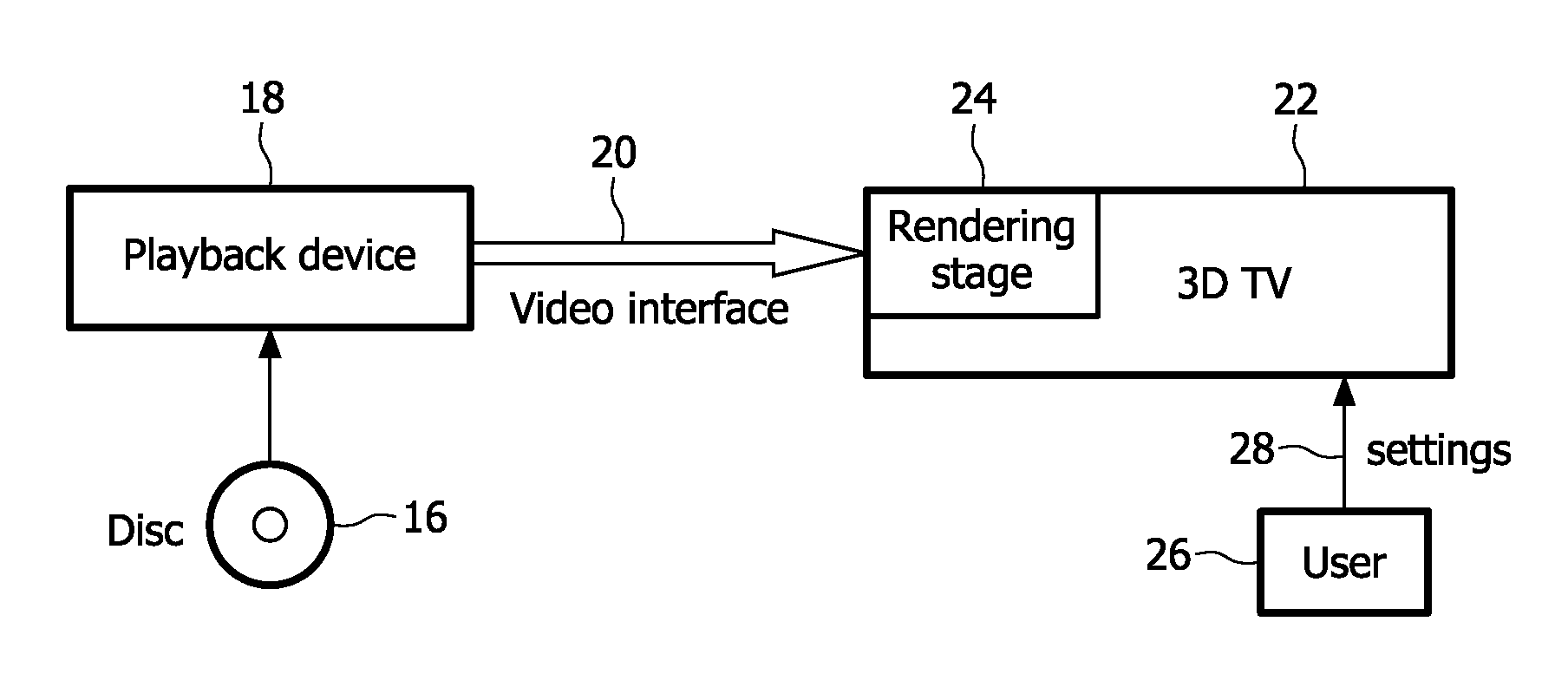

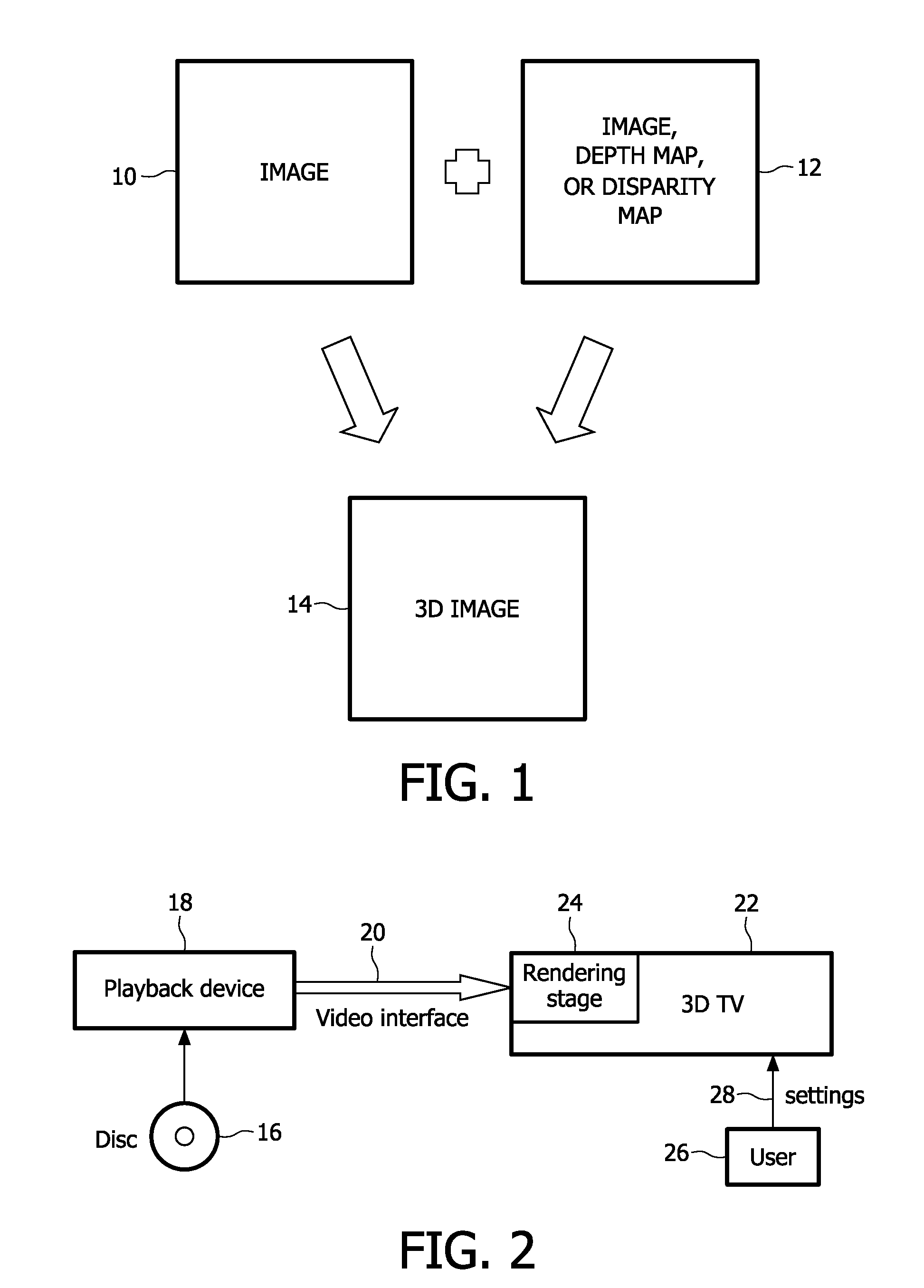

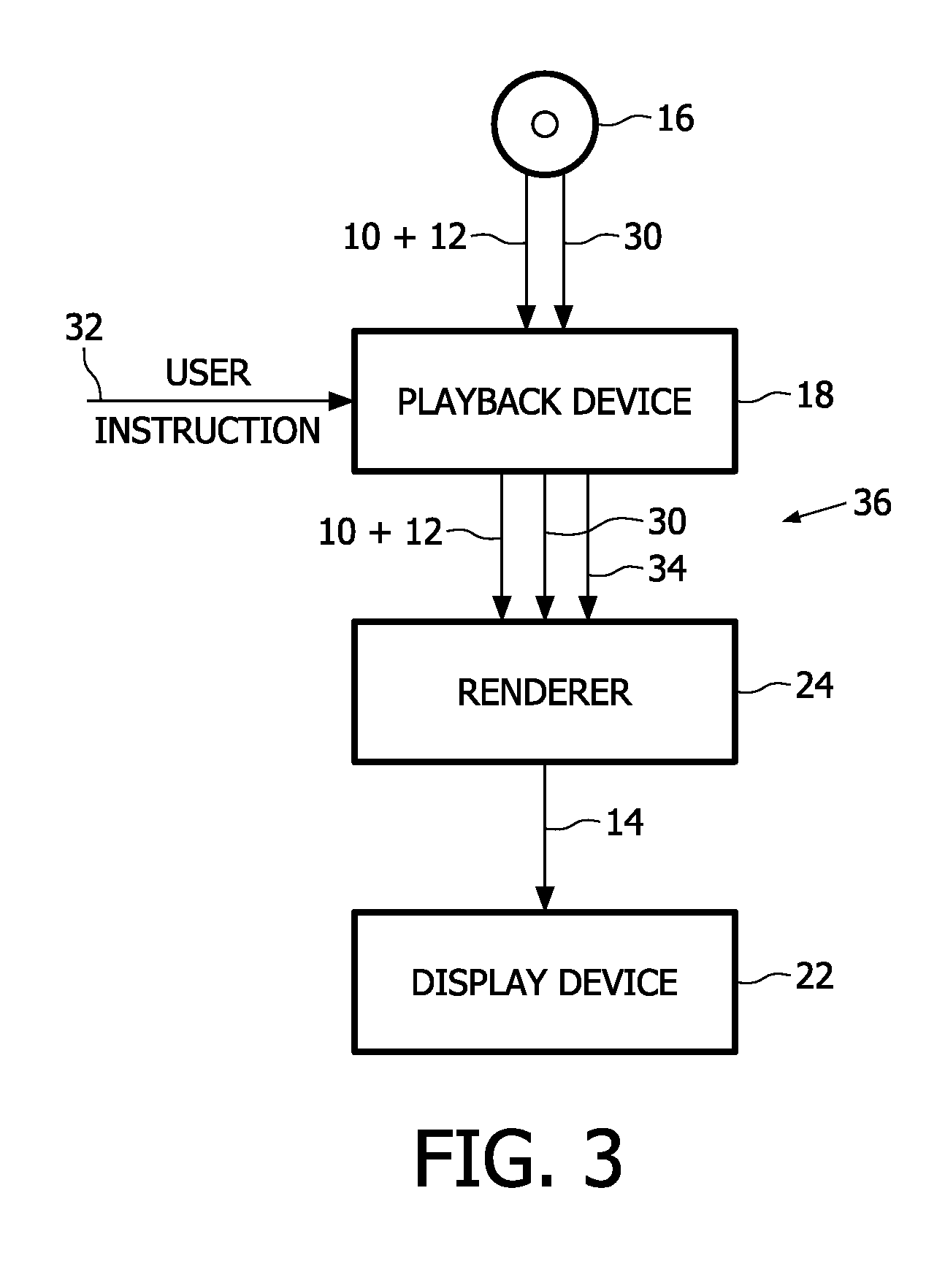

3D display handling of subtitles

ActiveUS20110292189A1Improve readabilityImprove final qualityTelevision system detailsColor television detailsGraphicsImage signal

A non-transitory three-dimensional image signal includes a first image component, a second component for creating a three-dimensional image in combination with the first image component, and a text component that includes text-based subtitles and / or presentation graphics-based bitmap images for including in the three-dimensional image. A shared Z-location component includes Z-location information describing the depth location of the text component within the three-dimensional image. The signal is rendered by rendering the three-dimensional image from the first image component and the second component. The rendering includes rendering the text-based subtitles and / or presentation graphics-based bitmap images in the three-dimensional image. Further, the rendering of the text component includes adjusting the depth location of the text-based subtitles and / or presentation graphics-based bitmap images based on the shared Z-location component. The Z-location for both text-based and presentation-graphics-based subtitles may be the same and only needs to be stored once per stream.

Owner:KONINKLJIJKE PHILIPS NV

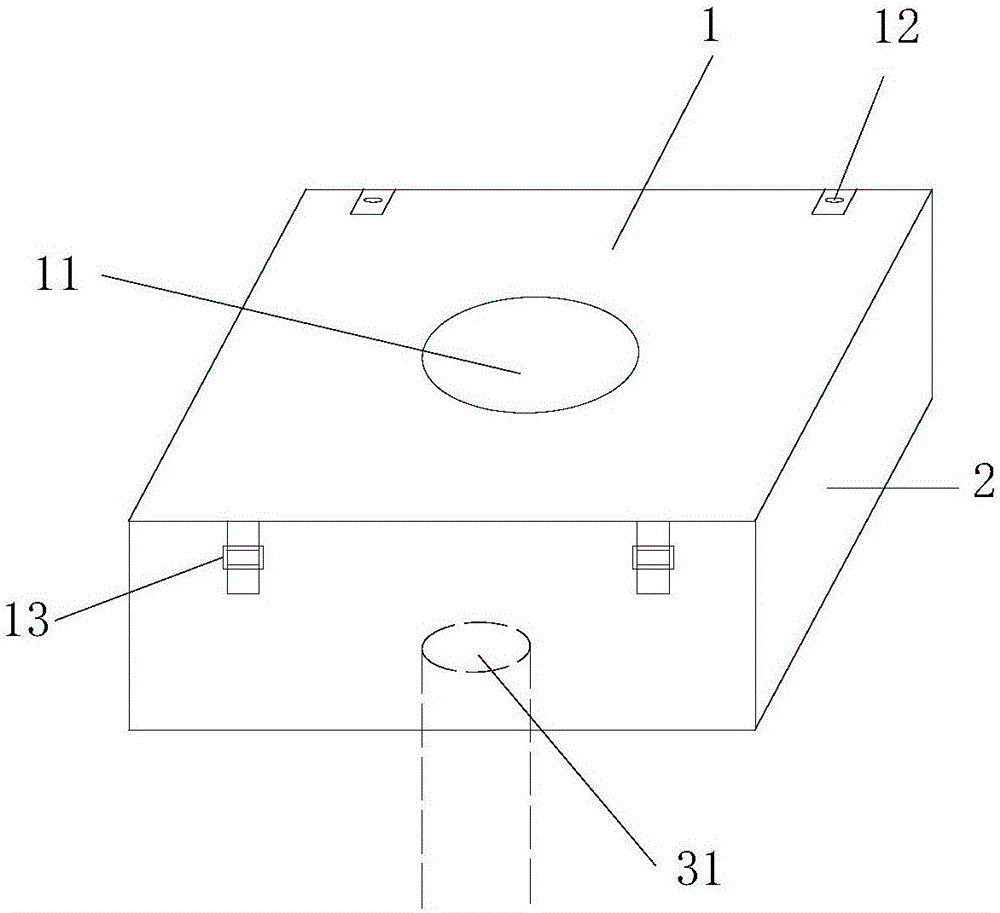

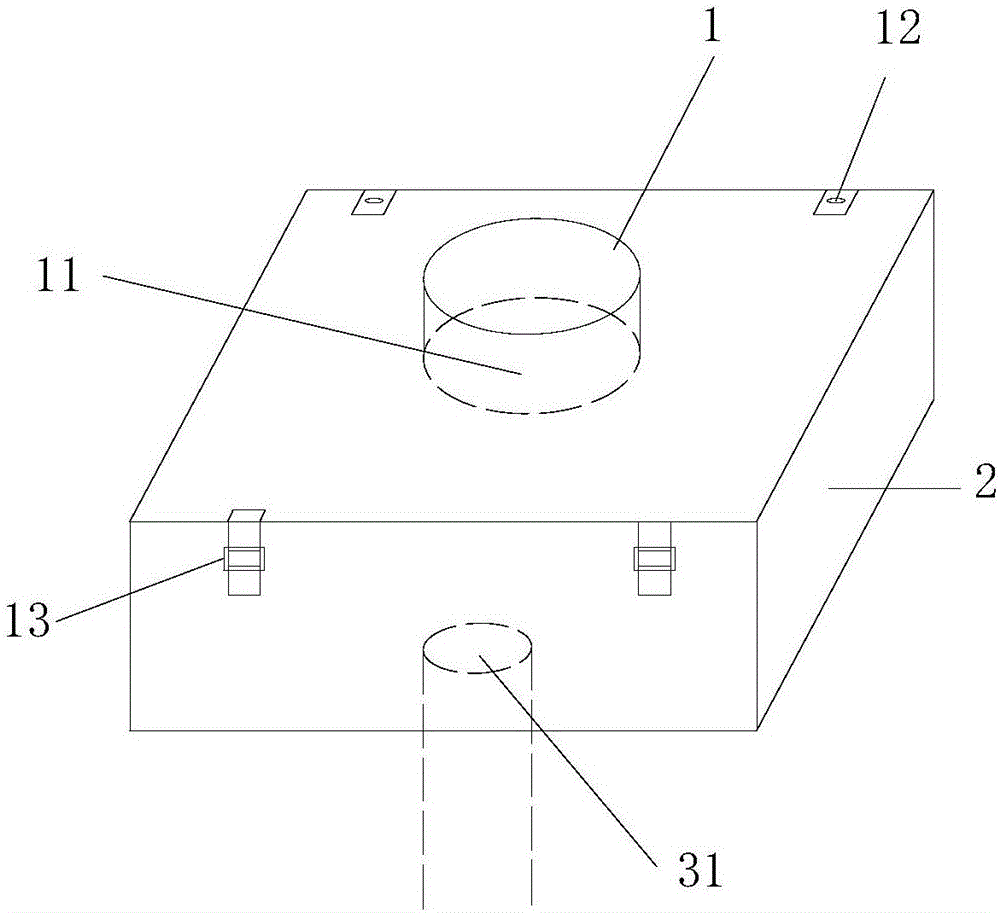

Die and process for producing ceramsite foamed precast concrete

ActiveCN106166788AAvoid floating on the surfaceEvenly distributedMoulding surfacesMould auxillary partsEngineeringPrecast concrete

The invention discloses a die for producing ceramsite foamed precast concrete. The die comprises a top cover, a side template and a base plate which are arranged in the vertical direction in sequence, wherein the side template surrounds the top cover and the base plate and is connected with the top cover and the base plate, the top cover is provided with an overflow hole, and a residual grout pipe is connected to the upper side of the overflow hole; the inner diameter of the overflow hole is 3-5 cm, and the height of the overflow hole is 10-15 cm; a screen net is arranged at the position where the overflow hole is connected with the residual grout pipe, and the aperture of the screen net is smaller than the grain size of ceramsite; a grouting hole is formed in the base plate. The invention further provides a process for producing ceramsite foamed precast concrete. By the adoption of the die and process, a traditional method that mixing is conducted first and then grouting is conducted is replaced, grouting and mixing are conducted at the same time, ceramsite floating is prevented through pre-compacting and the blocking action of the top cover, so that ceramsite is distributed uniformly, ceramsite mixing amount is the largest, the heat insulation property and sound insulation property of the ceramsite foamed precast concrete are improved, and the overall quality of products is improved.

Owner:HUAIHAI INST OF TECH

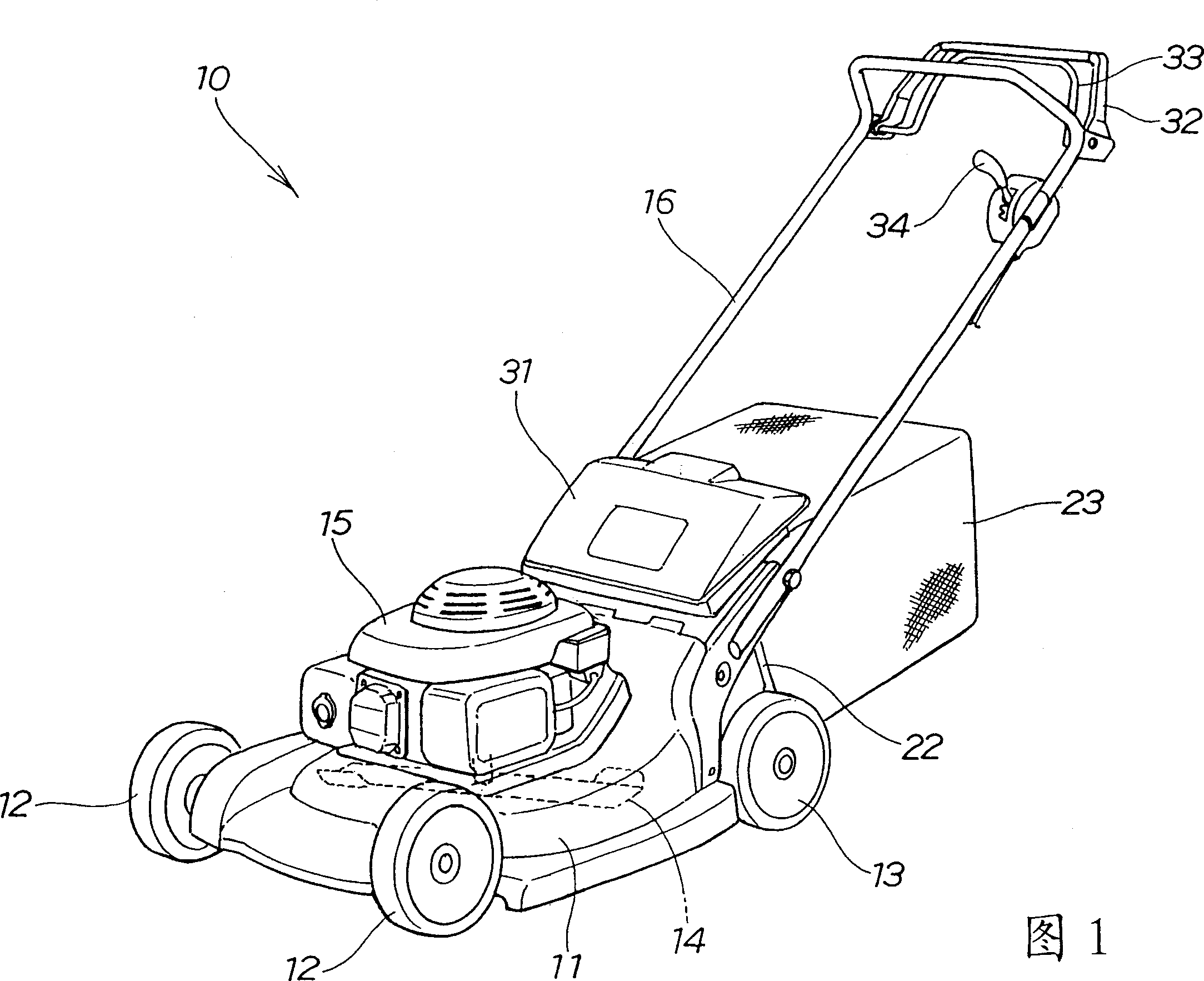

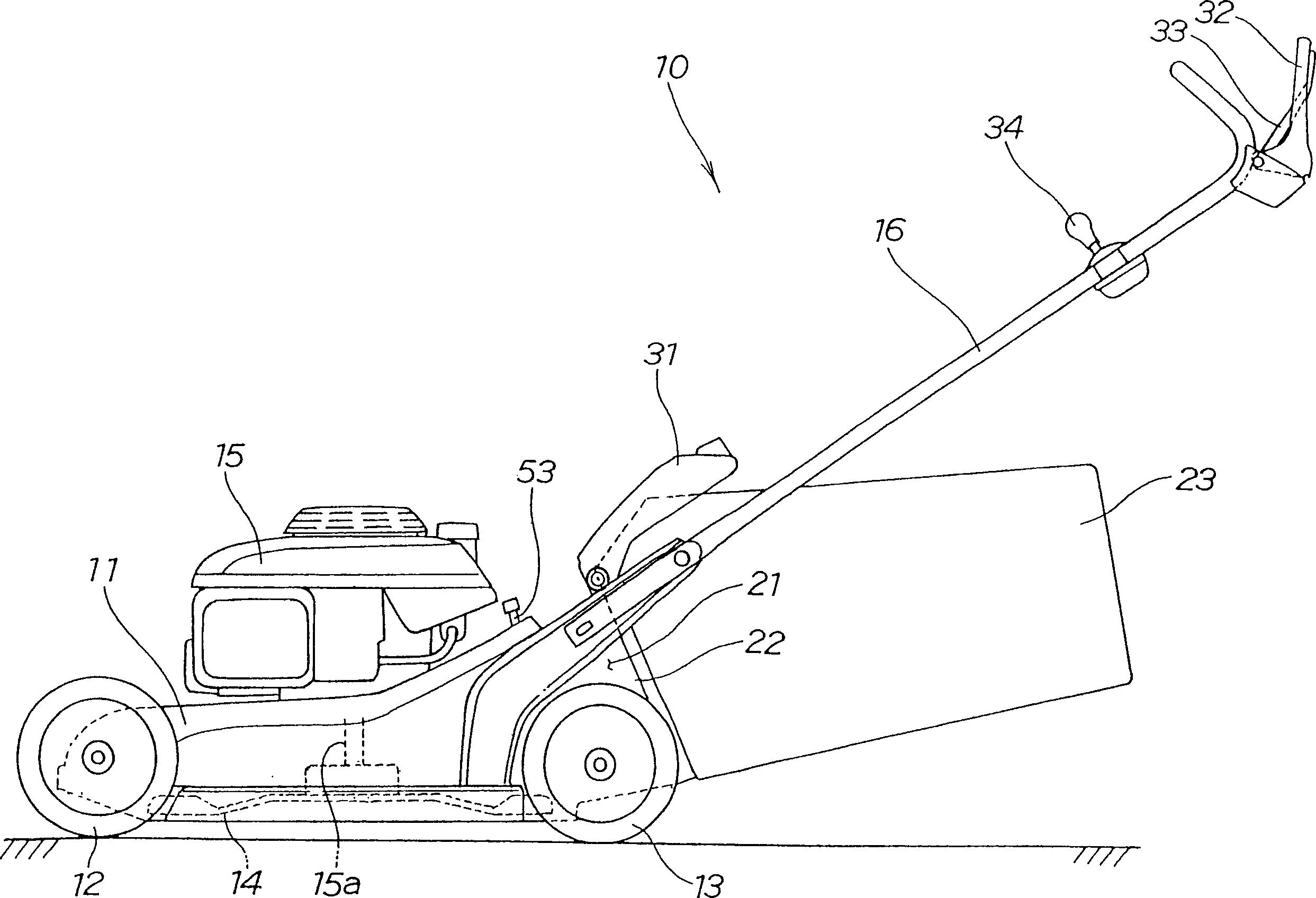

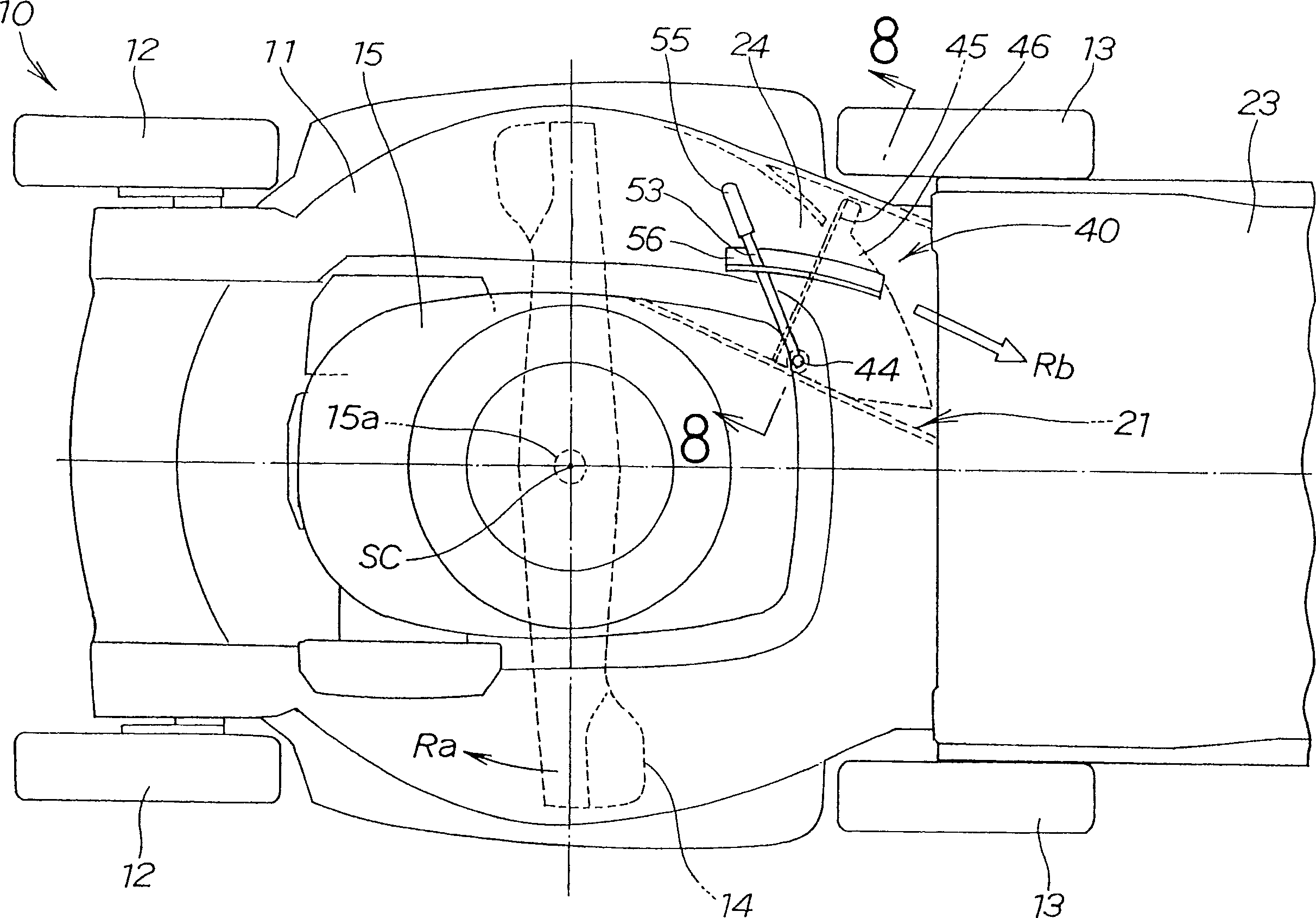

Lawn mower

A lawn mower (10, 100) has a scroll portion (11d) for allowing grass clippings to swirl within a housing (11) while guiding them to a grass discharge passage (21). A guide (70, 170) provided beneath a top plate (11a) of the housing is placed along the scroll portion. A rear guide end (71, 171) of the guide is opposed to a passage opening (24) facing the housing of the grass discharge passage. The direction of a swirling flow is gradually changed and guided toward the passage opening by the guide. A pivotal shutter (40) pivotal about a generally vertical axis is provided for opening and closing the grass discharge passage (21).

Owner:HONDA MOTOR CO LTD

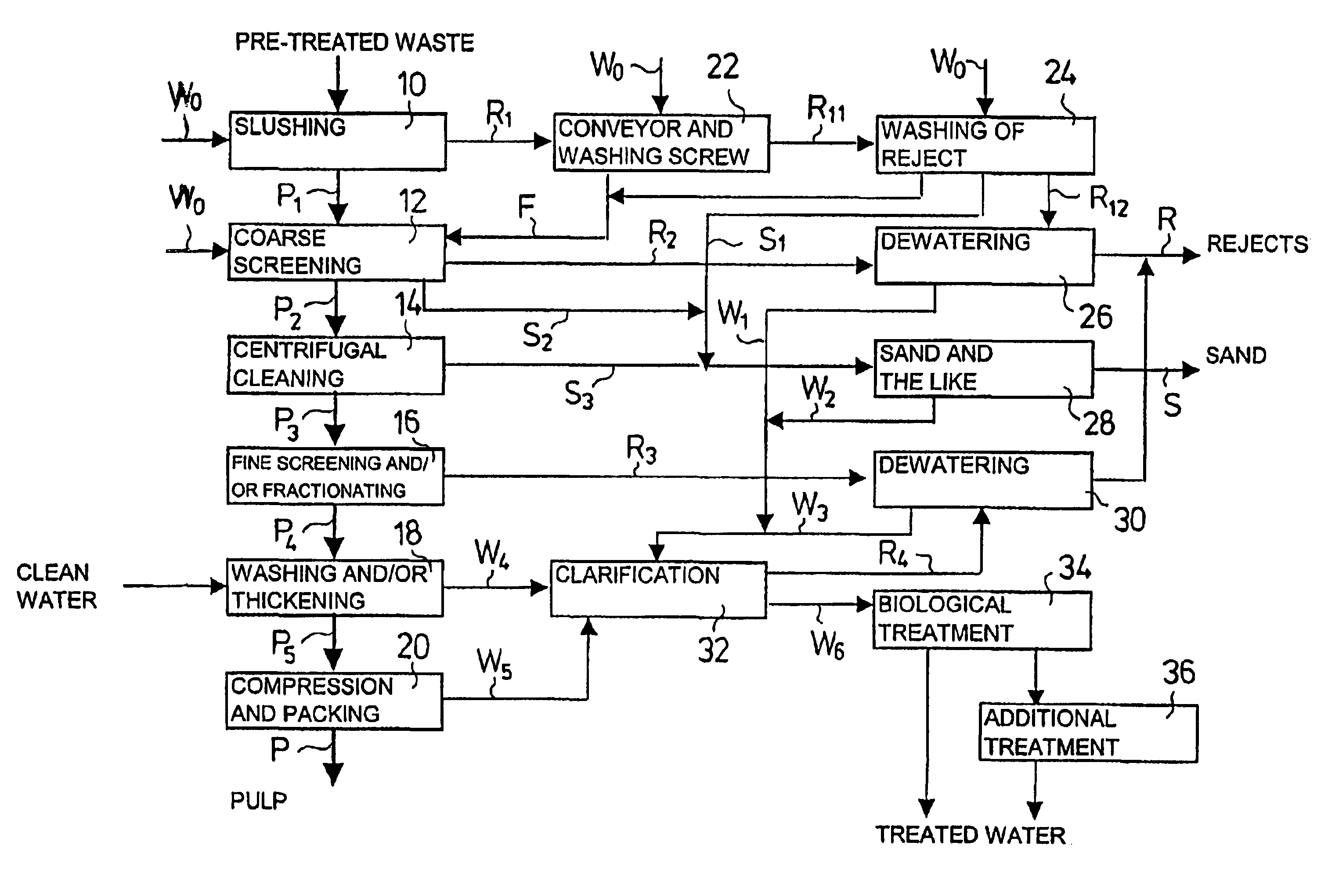

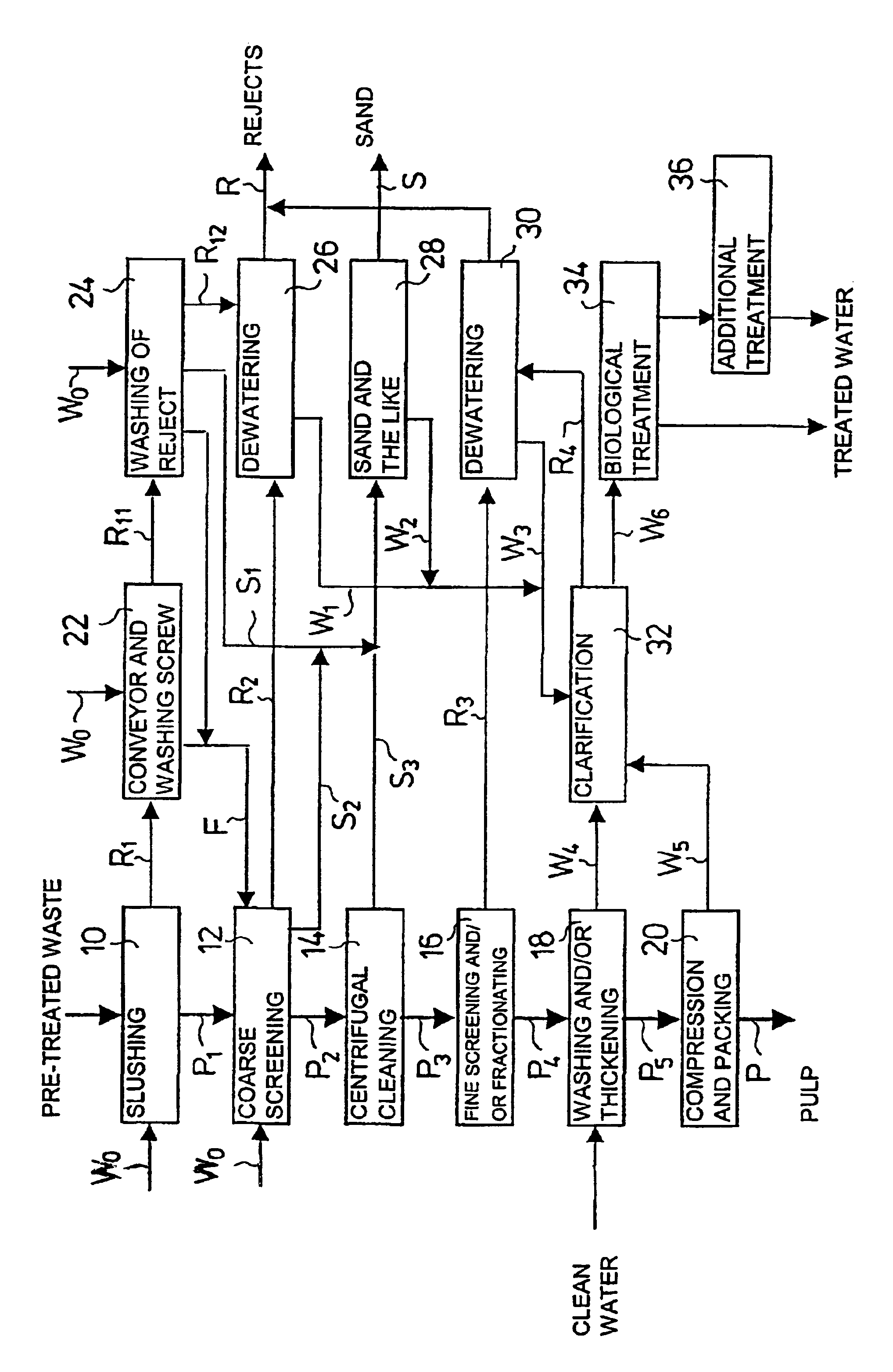

Method and system for utilizing waste

InactiveUS6988682B2Inexpensive materialsYield maximizationGas current separationSolid waste disposalCardboardFiber

Waste that contains fibers and combustible material is slushed in a continuous-operation high-consistency pulper (10) to suspend in water the fibers contained in the waste. From the pulper (10) are discharged substantially continuously a fiber suspension (P1) through a screen plate; and non-defibrable material (R1) by means of a mechanical transfer device (22). The fiber suspension (P1) is sorted and cleaned for use as raw material in paper or board. The non-defibrable material (R1) and the rejects (R2-R4) separated from the fiber suspension (P1) in the sorting and cleaning stages are used as fuel in energy production and / or utilized as raw material.

Owner:VALMET TECH INC

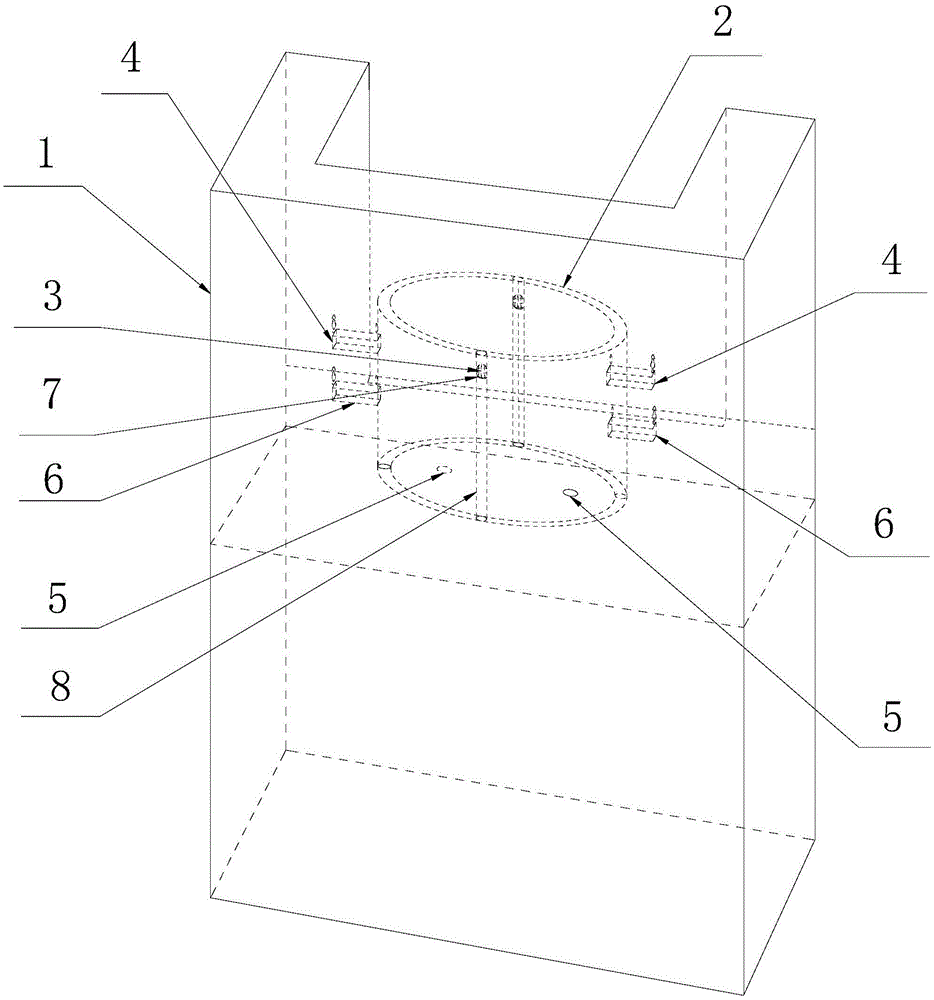

Construction method of bridge bearing platform

ActiveCN110965473AImprove final qualityVibrate compactFoundation engineeringBridge erection/assemblyElectric machineryRebar

The invention relates to a construction method of a bridge bearing platform, and belongs to the field of bearing platform construction. The method comprises the following steps of S1, pre-constructionwork is performed; S2, cushion concrete is poured; S3, bearing platform steel bars are installed; S4, A bearing platform formwork is installed, a plurality of vibrating openings are formed in the lower part of the formwork, a vibrating rod is inserted into the vibrating opening such that the vibrating rod is made to transversely penetrate through the whole bearing platform, attention is paid to that the vibrating rod does not make contact with the reinforcing steel bar and the formwork, temporary sealing is conducted between the vibrating plates and the vibrating opening through foam blocks,then the two vibrating plates are welded to the formwork, the two ends of the vibrating rod are connected with the two vibrating plates correspondingly, and vibrating motors are arranged on the vibrating plates; S5, concrete is poured; S6, the formwork is dismantled, and geotextile covering and watering maintenance are conducted on the bearing platform; and S7, foundation pit backfilling is performed. The construction method has the effect of improving the vibrating quality of concrete at the bottom of the bearing platform.

Owner:四川宝鑫建设有限公司

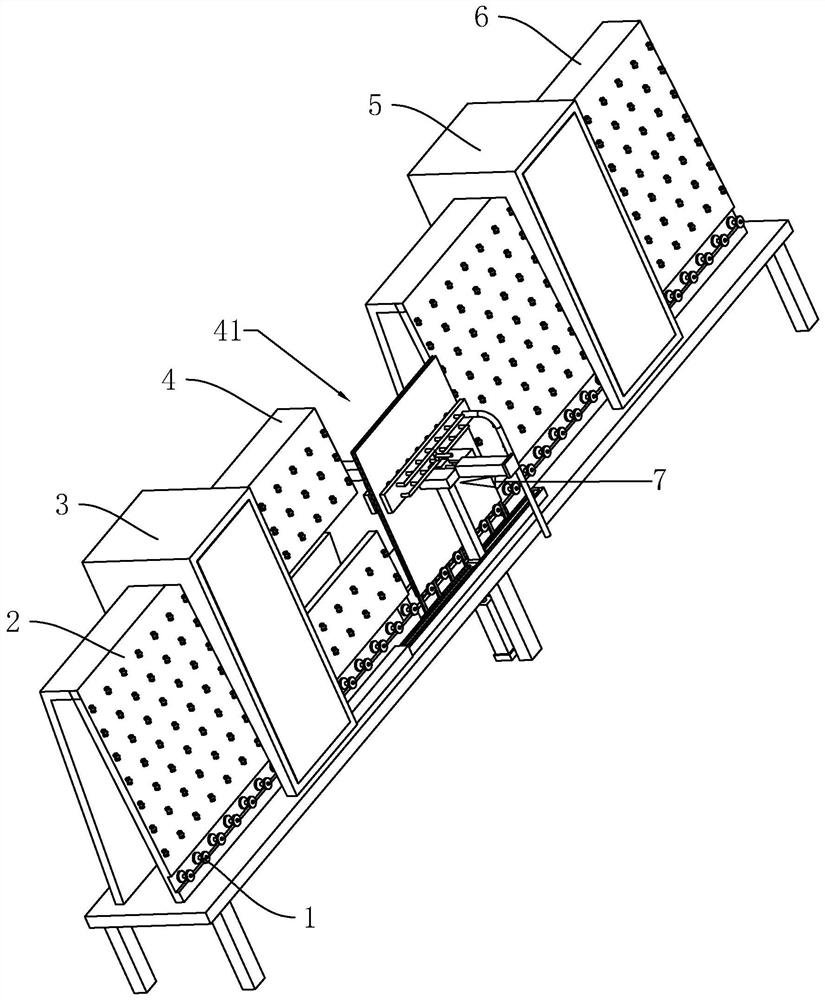

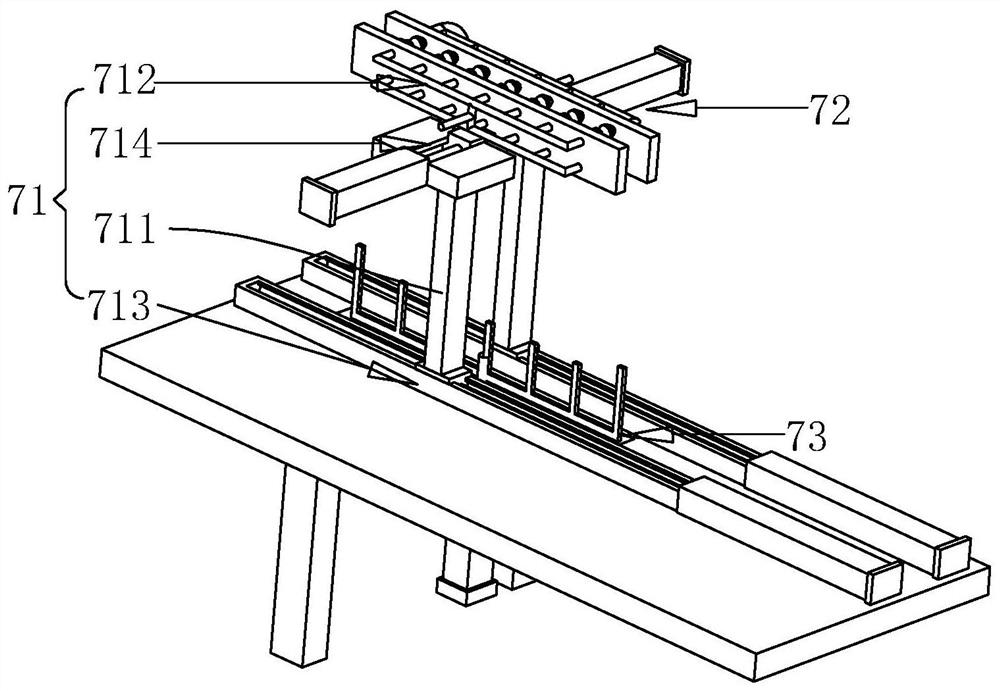

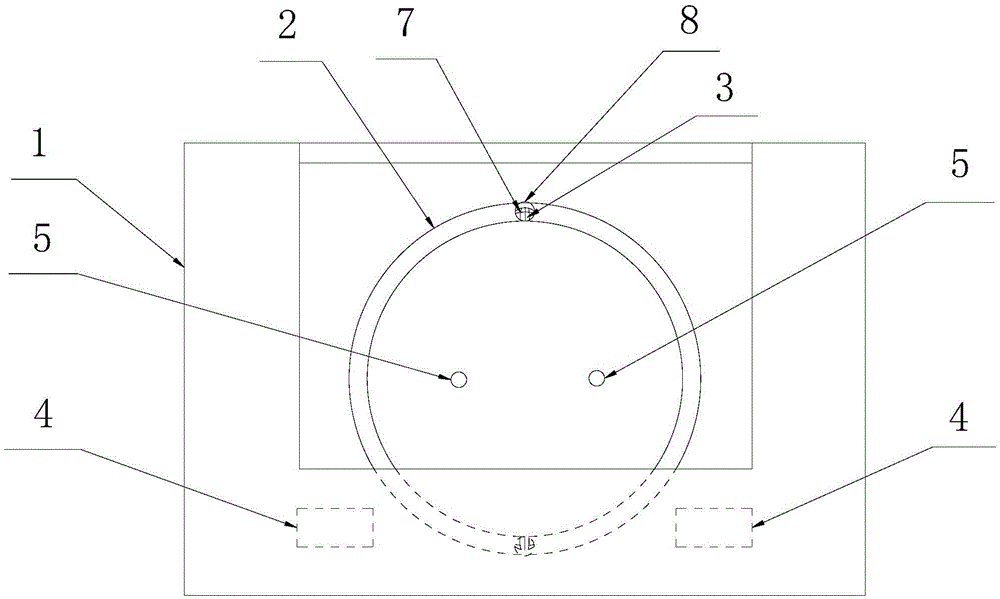

Hollow glass production line

The invention relates to a hollow glass production line which comprises a conveying device, and a feeding section, a cleaning chamber, a pasting section, a pressing chamber and a discharging section which are sequentially arranged on the conveying device in the glass conveying direction, and is characterized in that a notch is formed in the pasting section, and a pasting device is arranged at the notch; the pasting device comprises a first clamping assembly, a supporting assembly and a second clamping assembly, the first clamping assembly and the second clamping assembly are oppositely arranged along the two sides of a glass conveying path, the first clamping assembly comprises a supporting column, a clamping piece, a moving driving piece and a telescopic driving piece, the clamping piece is installed on the supporting column and used for clamping glass, the moving driving piece is used for pushing the supporting column to move in the glass conveying direction, the telescopic driving piece is used for pushing the clamping piece to move in the direction perpendicular to the glass conveying direction in the horizontal direction, and the supporting assembly is located between the second clamping assembly and the first clamping assembly. The hollow glass production line has the effects that the alignment error of the aluminum frame and the glass is reduced, and the quality of the hollow glass is improved.

Owner:陕西中科玻璃有限公司

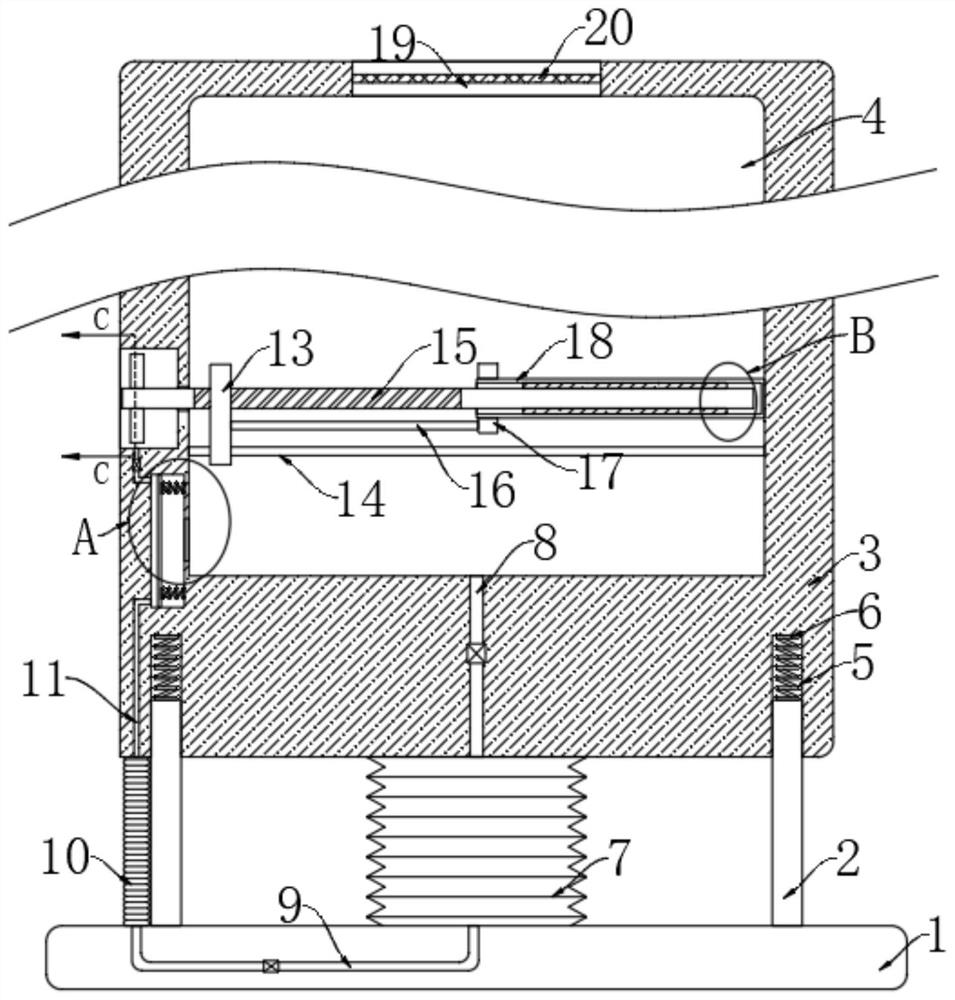

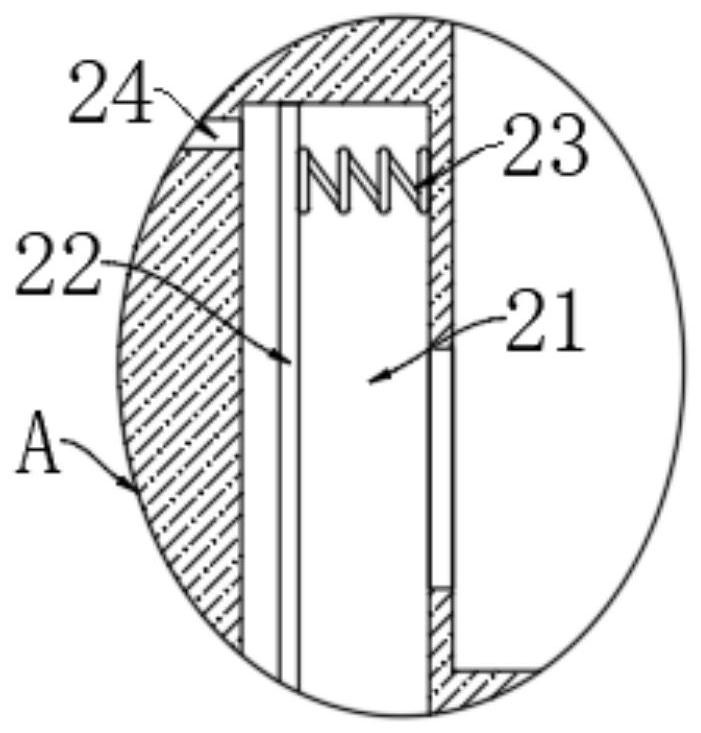

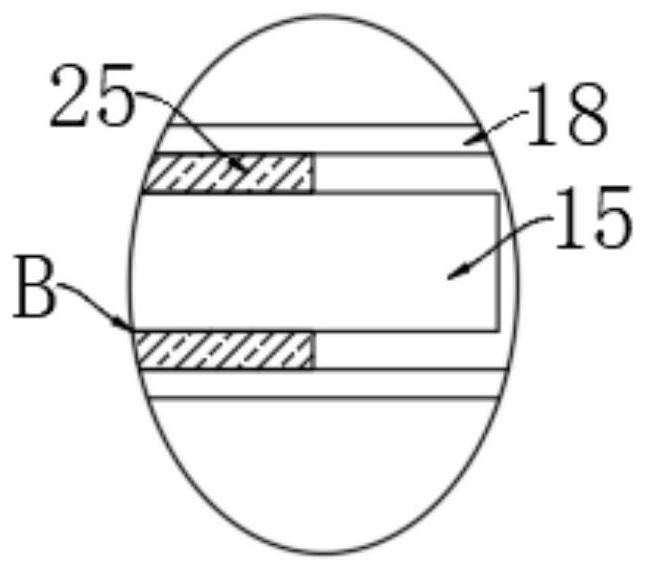

High-precision 3D printing device based on SLA technology

ActiveCN105599306AImprove printing accuracyTraces sleekAdditive manufacturing apparatusChemistryLaser scanning

The invention discloses a high-precision 3D printing device based on an SLA technology. The high-precision 3D printing device comprises a device table, a photocuring working barrel groove formed in the device table, a laser scanning head mechanism and a PLC. At least one photosensitive resin injection opening is formed in the portions, of the same horizontal height, of the inner side wall of the photocuring working barrel groove. The photosensitive resin injection openings are connected with a photosensitive resin storing container through pipelines and a photosensitive resin topping-up pump. At least one bearing medium injection opening is formed in the position, lower than the photosensitive resin injection openings, of the inner side wall of the barrel groove. The bearing medium injection openings are connected with a bearing medium storing container through pipelines and a bearing medium topping-up pump. The photosensitive resin topping-up pump and the bearing medium topping-up pump are electrically connected with the PLC. Photosensitive resin floats on the surface of a bearing medium, while high polymer formed after the photosensitive resin is cured is sunken into the bearing medium. The printing device is high in printing precision, transition of printing cambered surface trails is smooth, the photosensitive resin is cured completely, and curing bonding force among layers is large.

Owner:苏州光宝科技股份有限公司

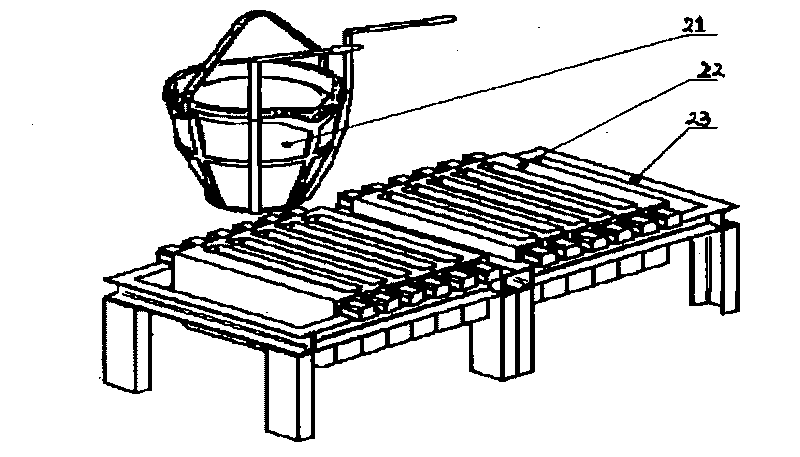

Heating bed structure, vacuum drying system therewith and manufacture thereof

InactiveCN1940444AReduce the temperatureImprove final qualityDrying solid materials with heatDrying chambers/containersEngineeringCooling fluid

An improved heating bed structure, especially a vacuum drying system for fur, leather and the like comprises a table for heating products to be dried with a top dish, a bottom dish and a heating chamber, inlet and outlet pipelines connected with the above chamber for the heater fluid there, a suction inlet of steam released when fur is heated, at least one steam collector, at least a condenser disposed inside the collected capable of making the following freezing liquid flow inside and a unit for connecting with at least one collector and the outside steam suction element.

Owner:OFFICINE DI CARTIGLIANO SPA

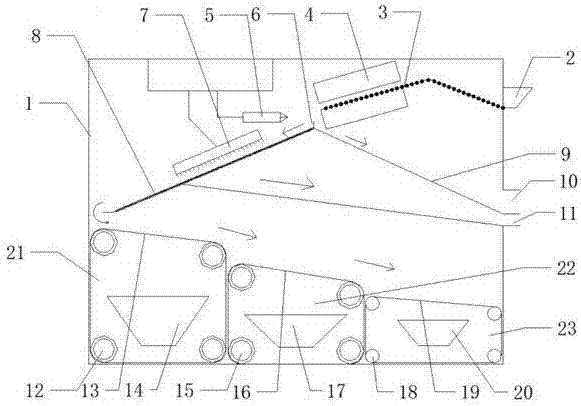

Fresh fruit sorting device and method and application thereof

PendingCN107457196AReduce mistakesImprove qualitySievingGas current separationScreening effectVisual inspection

The invention relates to a fresh fruit sorting device and method and application thereof. The device comprises a color sorting assembly and a screening assembly, wherein the screening assembly is located below the color sorting assembly. Fresh fruits are subjected to color sorting through the color sorting assembly, parts of the fresh fruits are discharged through a first discharge port in the color sorting assembly, and the other parts of the fresh fruits are conveyed to the screening assembly for size sorting after impurities are removed through a rolling shaft conveying belt in the color sorting assembly. According to the fresh fruit sorting device and method and the application thereof, the combination of color sorting and screening can be used for effectively screening the fresh fruits at a time, the error caused by manual visual inspection is greatly reduced, and the quality is improved; the fresh fruit sorting and grading processes of the device are more convenient and reliable, the sorting speed is increased, and the device has lower energy consumption and cost compared with a traditional air pressure sorting mechanism; a single-time multi-index fresh fruit screening is realized through the device, and the redundant design of a traditional sorting machine is avoided; and the impurities in the fresh fruits can be effectively removed while the fresh fruits are screened, and thus the device has a good screening effect.

Owner:KUNMING UNIV OF SCI & TECH

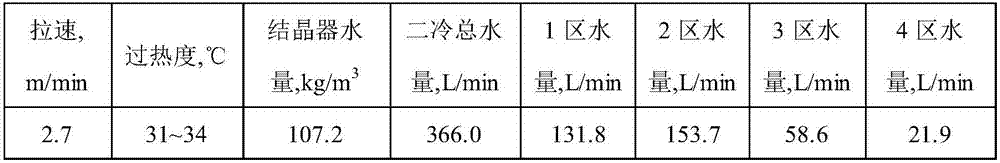

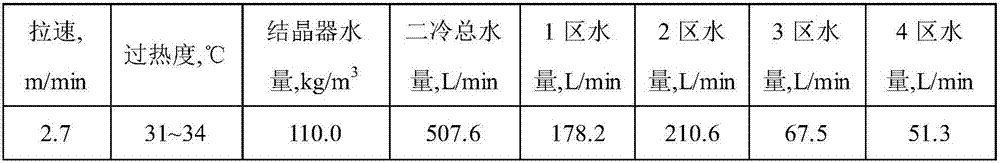

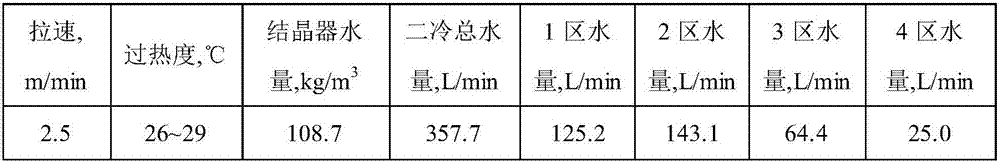

Method for reducing corner cracks of small low-carbon boron-containing steel square billet

The invention discloses a method for reducing corner cracks of a small low-carbon boron-containing steel square billet. The method includes primary cooling and secondary cooling. A reasonable primary cooling water amount and secondary cooling water amount governing equation during continuous casting is given out on the basis that the crystallizer water inlet temperature, season or environmental temperature change influences are fully considered, the proper secondary cooling water distribution ratio of all areas is adjusted on this basis, the first area accounts for 35%-40%, the intermediate area apart from the first area and the tail area accounts for 52%-60%, the tail area accounts for 5%-8%, and therefore the corner temperature of a casting blank at a bent straightened area can be controlled more stably, and a third brittleness temperature interval of low-carbon boron-containing steel is reasonably evaded. By the adoption of the method, through optimized control over a continuous casting cooling technology of the small low-carbon boron-containing steel square billet, the corner crack defect of the casting blank can be greatly reduced, the crack occurrence rate is lowered to be within 0.5% from 6.67% before, surface quality of the casting blank can be stably controlled, and the quality of final products is improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

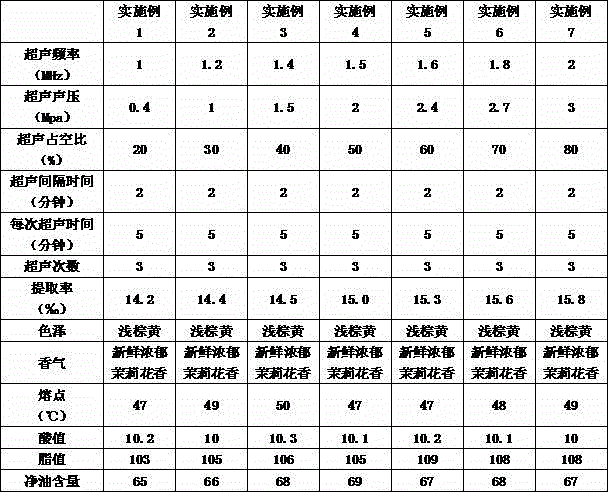

Method for preparing jasmine concrete by using high-frequency ultrasonic cavitation technology

ActiveCN103555425AImprove final qualityBreak cell wallEssential-oils/perfumesEnergy based chemical/physical/physico-chemical processesUltrasonic cavitationSolvent

The invention relates to a preparation method of jasmine concrete and discloses a method for preparing jasmine concrete by using a high-frequency ultrasonic cavitation technology. The method comprises the following steps: A, adding an extracting solvent into an ultrasonic extraction tank, placing arabian jasmine flowers in the extracting solvent which immerses the arabian jasmine flowers, and uniformly stirring; B, in the stirring process, intermittently starting an ultrasonic generator for carrying out direct ultrasonic effect in a megahertz band on the mixed liquid; C, filtering the supernate of the leach liquor, squeezing the residual liquid and mixing the filtrate and the pressed liquor; and D, extracting the mixed filtrate and pressed liquor to obtain the jasmine concrete. The method provided by the invention is applicable to extraction of jasmine concrete, and an effective cavitation effect is generated by using ultrasound in the megahertz band to break the cell walls of the plant, so that the extraction efficiency of effective components is greatly improved and the final quality of the jasmine concrete is further improved.

Owner:ARTSCI BIOLOGY TECH ZHEJIANG

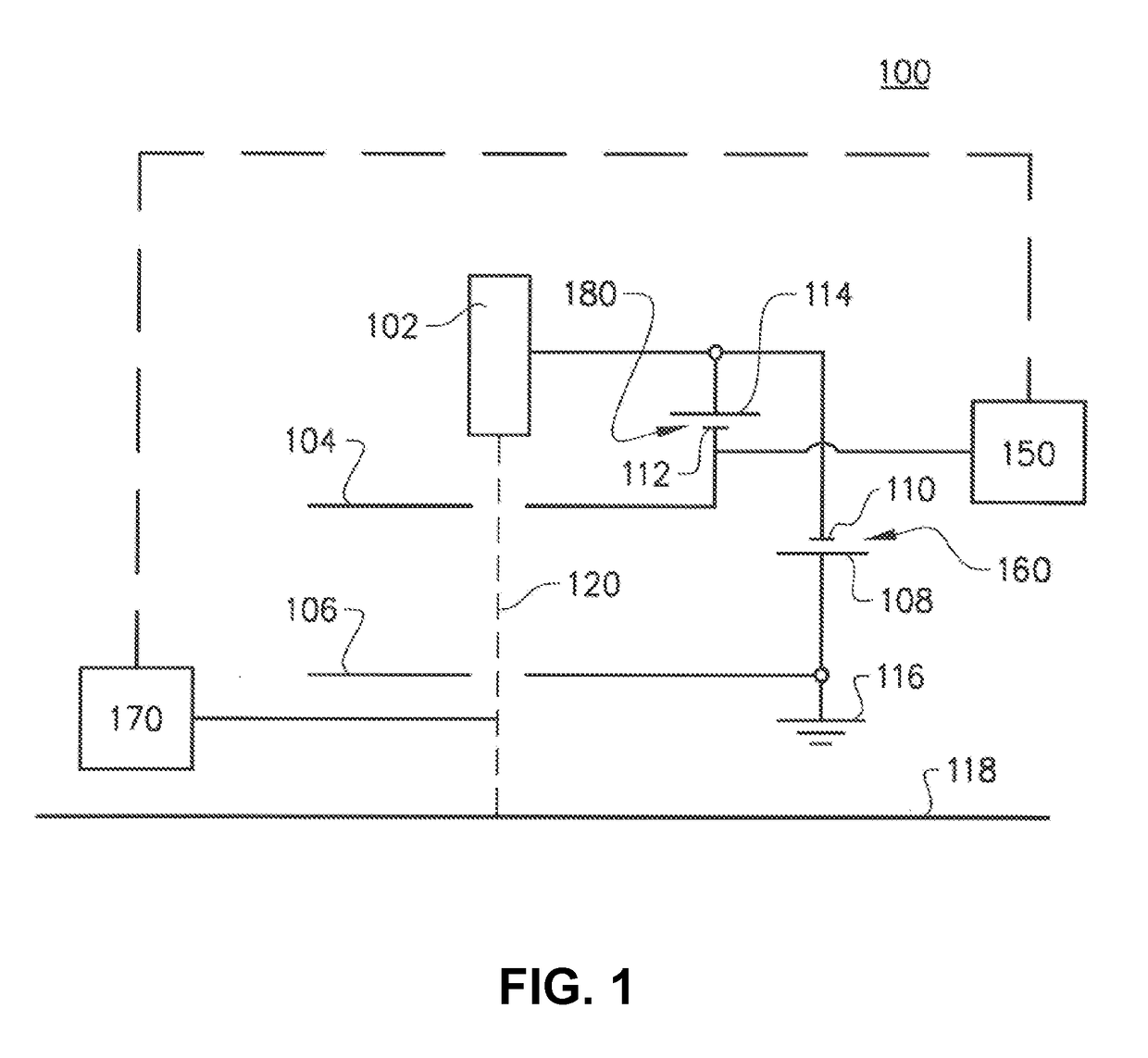

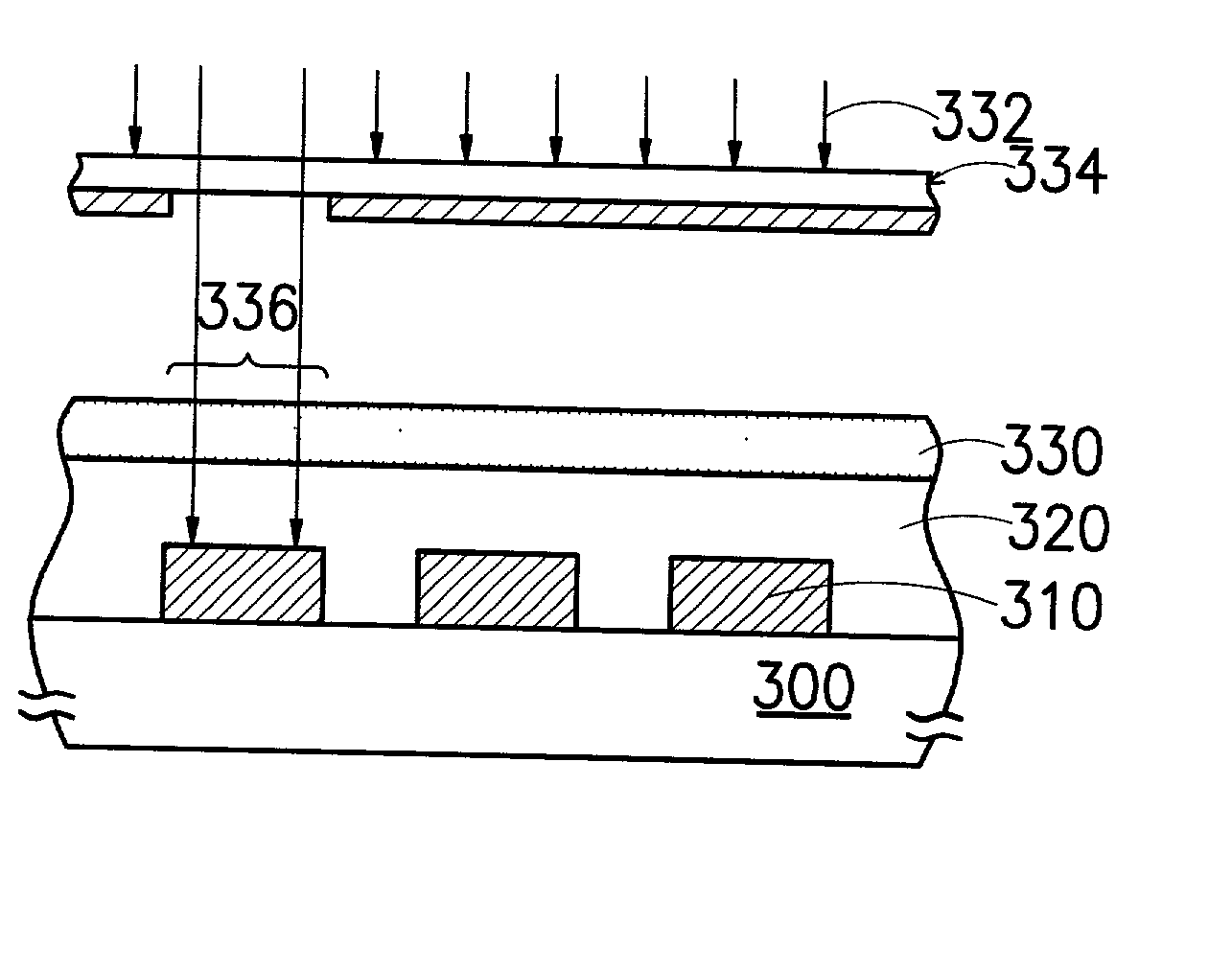

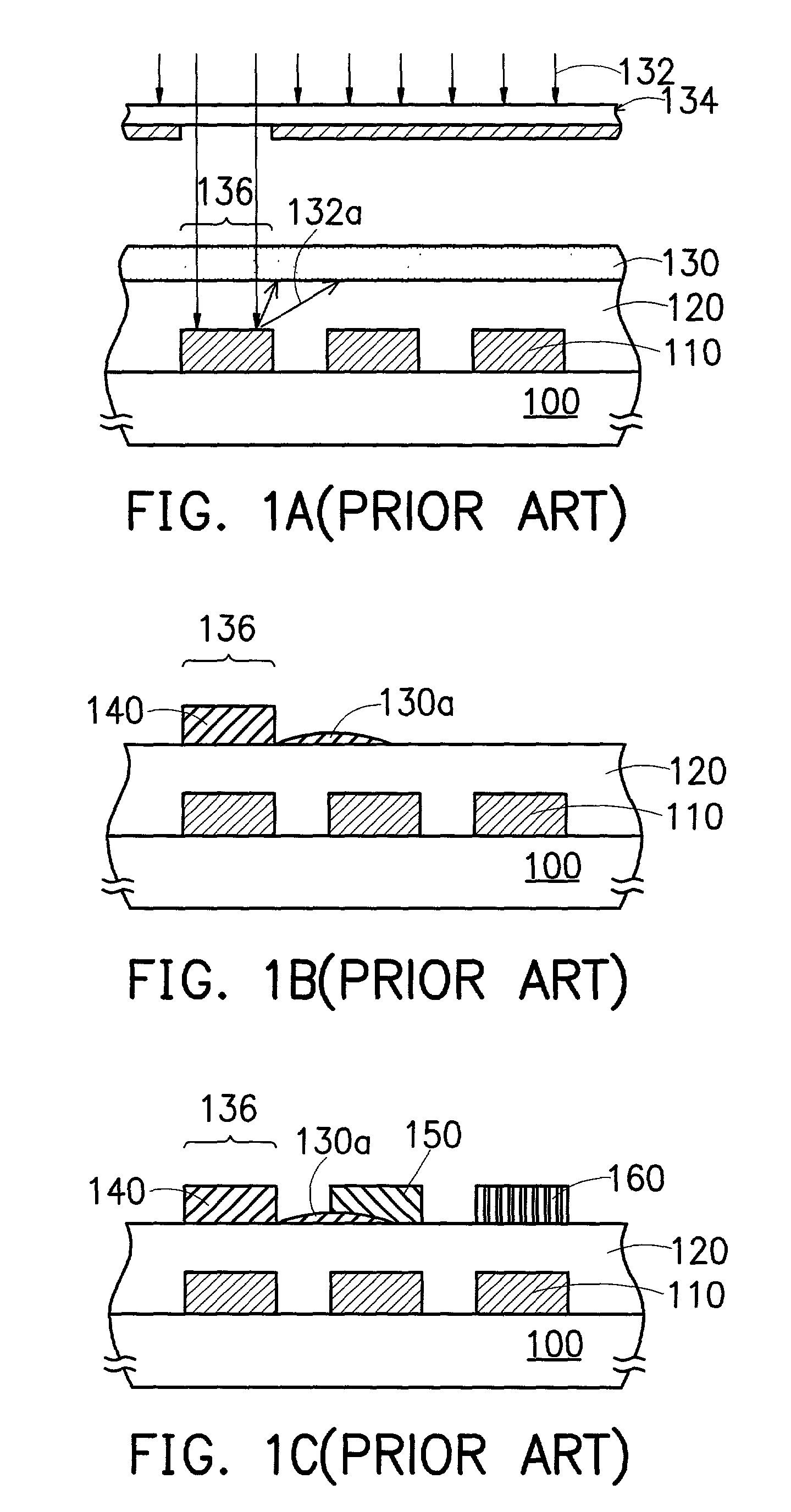

Method of forming color filter array

InactiveUS20020127481A1Enhanced light absorptionImprove final qualityOptical filtersPhotomechanical apparatusLength waveColor filter array

A method of forming a color filter array. A substrate having a passivation layer thereon is provided. A negative color photoresist layer is formed over the passivation layer. A photolithographic exposure process is conducted using a light source with a wavelength less than or equal to 248 nm so that a pattern for forming a color filter array is imprinted on the negative color photoresist layer.

Owner:UNITED MICROELECTRONICS CORP

Semiconductor packaging equipment and packaging process thereof

InactiveCN111883466AAvoid damageIncrease air flowElectrostatic separationSemiconductor/solid-state device manufacturingSemiconductor packageDust control

The invention discloses semiconductor packaging equipment and a packaging process thereof. The equipment comprises a bottom plate and a shell; a damping mechanism is arranged between the bottom plateand the shell, a working chamber is arranged in the shell, an air inlet is formed in the inner top of the working chamber, a dust filtering net is installed in the air inlet, and a folding air bag isarranged between the shell and the bottom plate. The upper end and the lower end of the folding air bag are fixedly connected with the lower end of the shell and the upper end of the bottom plate respectively, a pressure storage cavity is formed in the shell, the upper end of the folding air bag is communicated with the working chamber through an air inlet pipe, the lower end of the folding air bag is communicated with an air outlet pipe, and one-way valves are installed in the air inlet pipe and the air outlet pipe respectively. The semiconductor packaging equipment is provided with the damping mechanism, and the shaking generated when the equipment works can be reduced, so the service life of the equipment is prolonged; meanwhile, the dust removal mechanism is further arranged, the dustcontent in air in a working chamber can be reduced, and the final quality of a packaged semiconductor is improved.

Owner:胡满

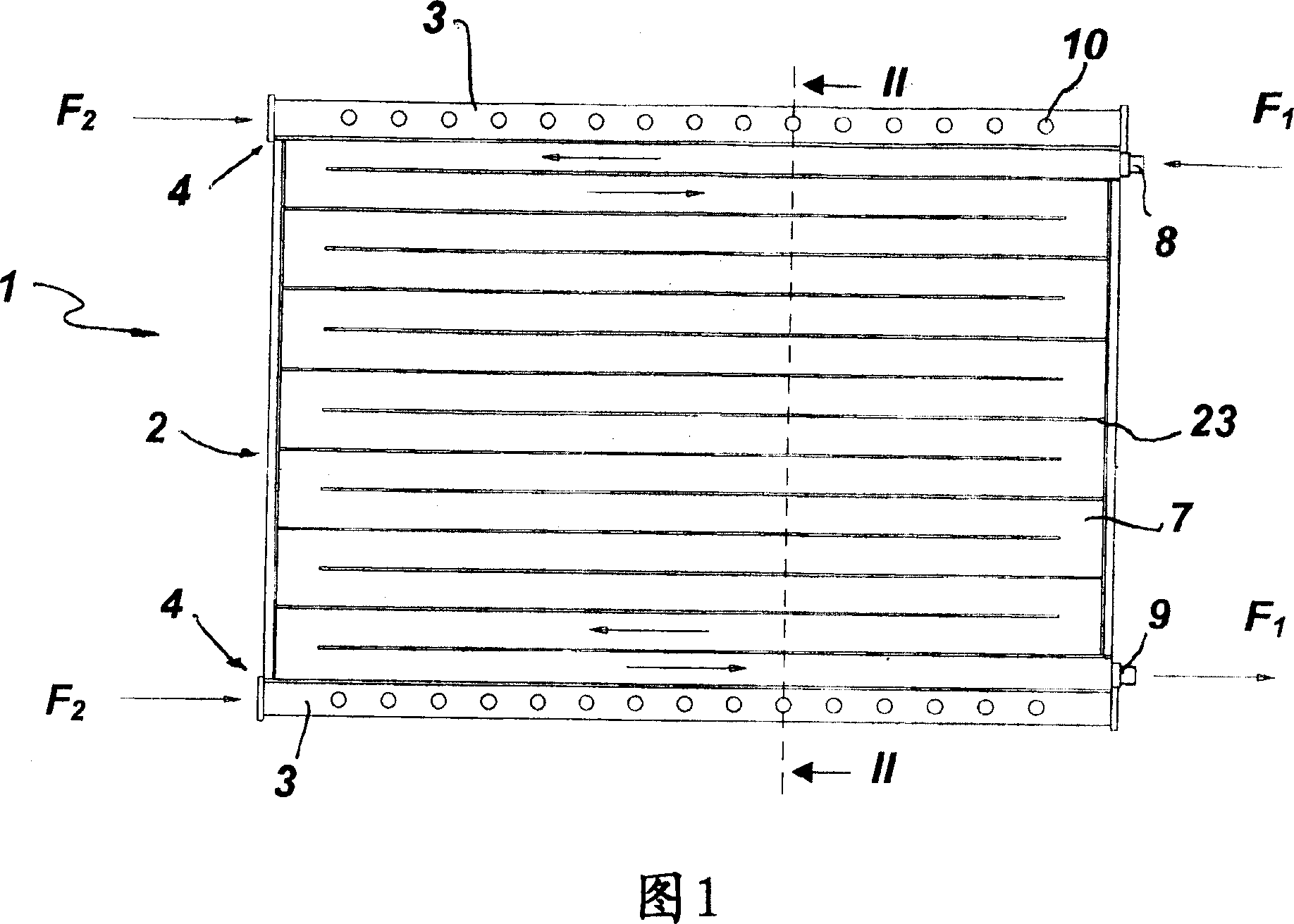

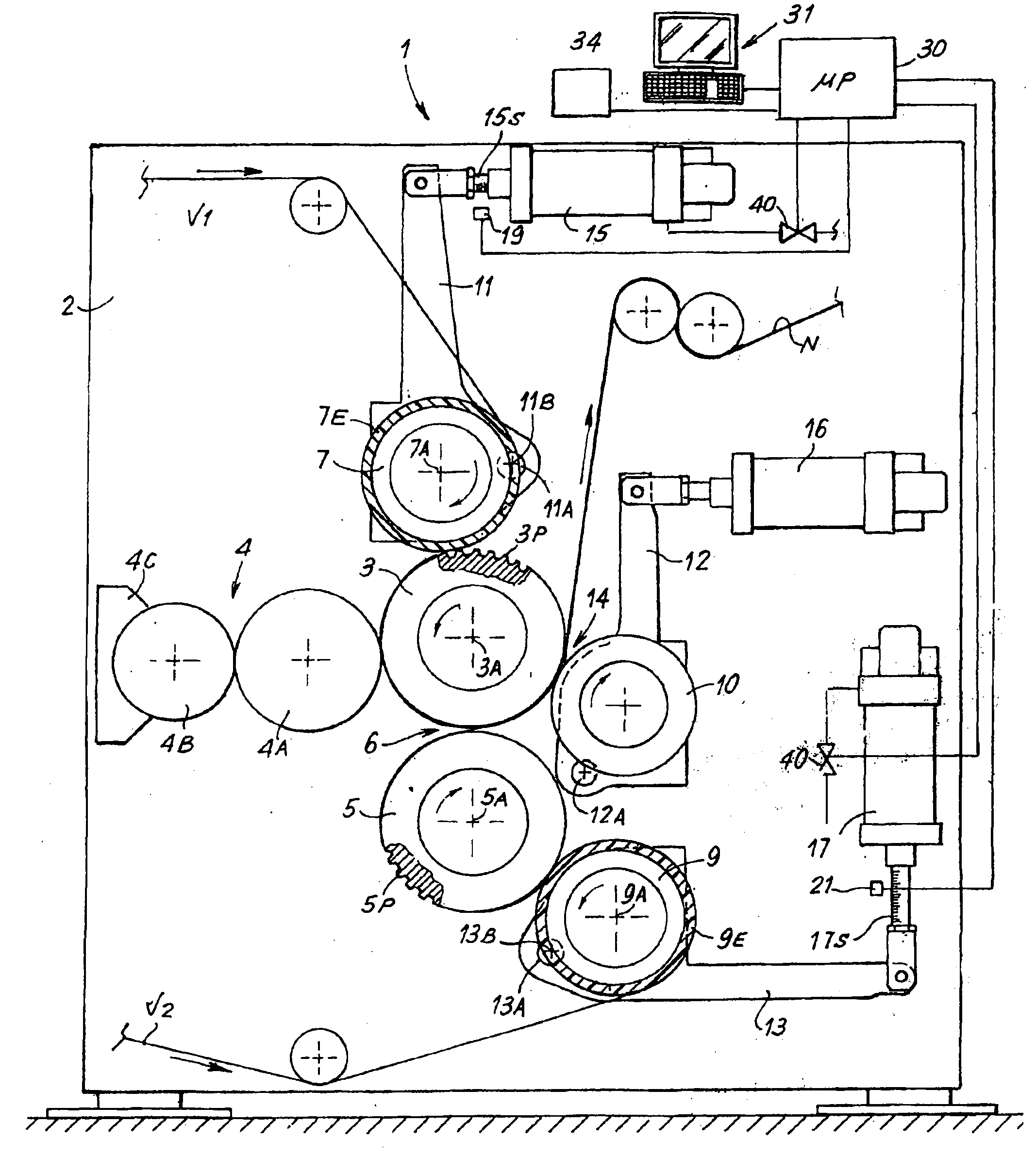

Embossing unit and embossing method

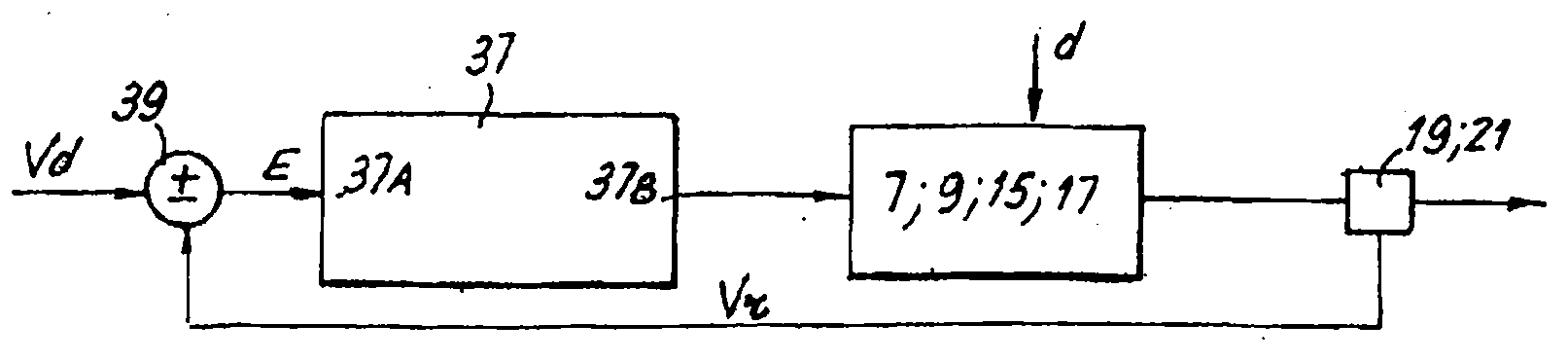

ActiveCN102985251ASimple structureSufficiently constant end resultMechanical working/deformationEngineeringActuator

An embossing unit comprising: at least one embossing roller (3, 5), provided with embossing protrusions or recesses (3P; 5P) on a cylindrical surface; - at least one pressure roller (7; 9) coated with an elastically yielding material (7E; 9E) and cooperating with the embossing roller (3; 5); at least one actuator (15; 17) that presses the pressure roller and the embossing roller against each other; an automatic position adjustment system (37, 39), to adjust the reciprocal position of the pressure roller (7; 9) and the emboss not ing roller (3; 5).

Owner:FABIO PERINI SPA

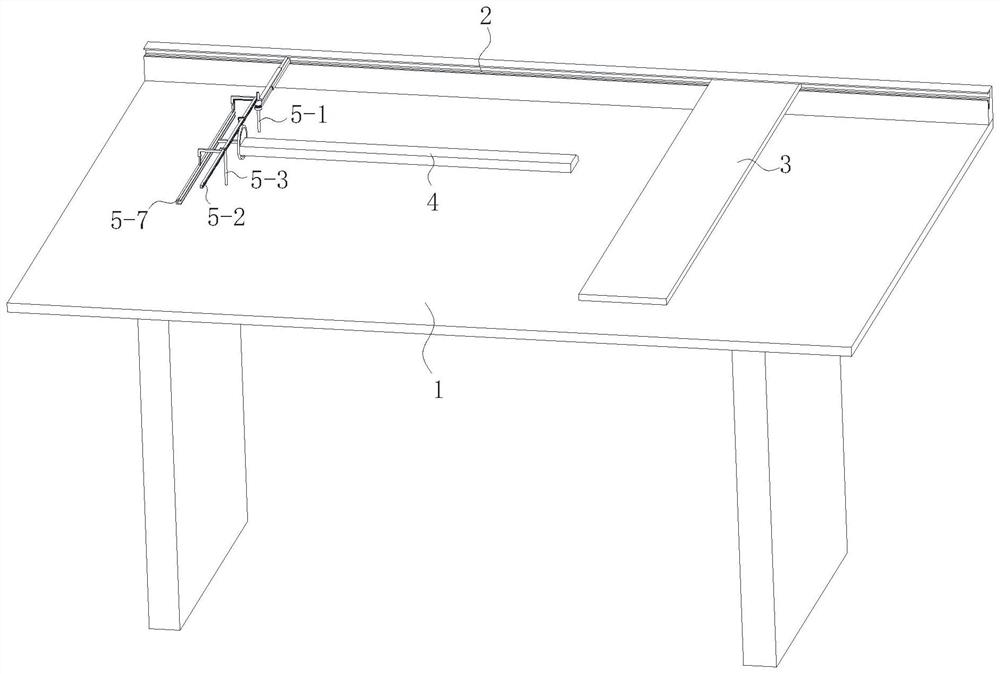

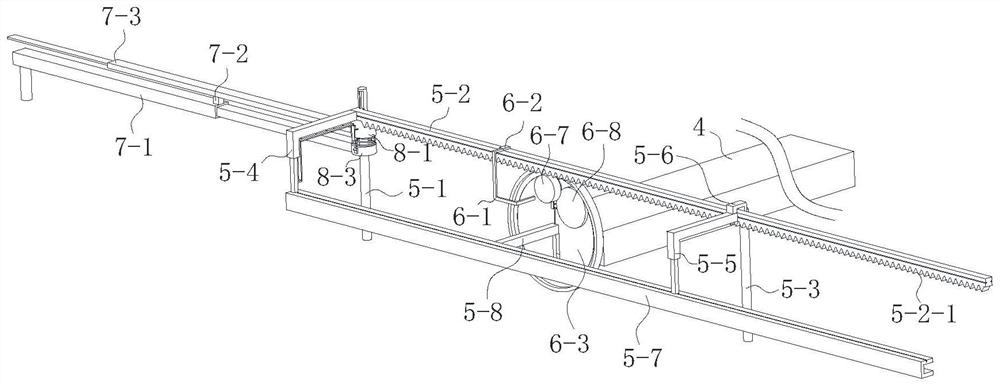

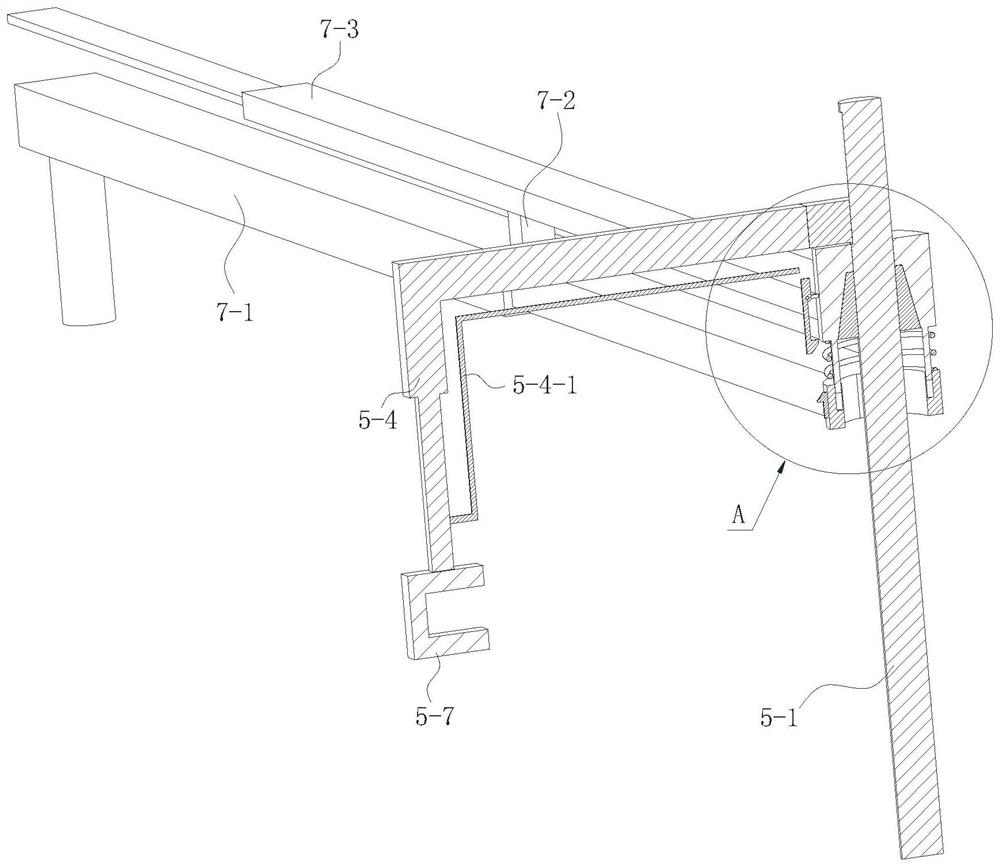

Workbench for drawing house property sketch and use method thereof

PendingCN114537023AImprove qualityEase of workFurniture partsDrawing desksManufacturing engineeringWorkbench

The invention discloses a working table for drawing a house property sketch and a using method thereof in the technical field of drawing tools, the working table comprises a working table body, a sliding rail is fixedly connected to the upper side of the front end of the working table body, the sliding rail is transversely and slidably connected with a hand supporting plate, a caliper is arranged on the left side of the hand supporting plate, and the caliper is connected with a positioning mechanism; the positioning mechanism is rotationally connected with a position changing mechanism, and the position changing mechanism is slidably connected with the sliding rail. The position changing mechanism is used for adjusting the position of the positioning mechanism on the workbench, the hand supporting plate and the caliper which does not reach the preset position are suspended above the workbench, and the caliper can suspend in the air before reaching the preset position; and the phenomena that existing lines are rubbed by the caliper in the process of adjusting the position of the caliper, the lines are fuzzy, and the paper surface is polluted are effectively avoided, so that the quality of a final drawing product is improved, and meanwhile, the working difficulty of a plotter in the drawing process is effectively reduced.

Owner:威海市房地产测绘中心有限公司

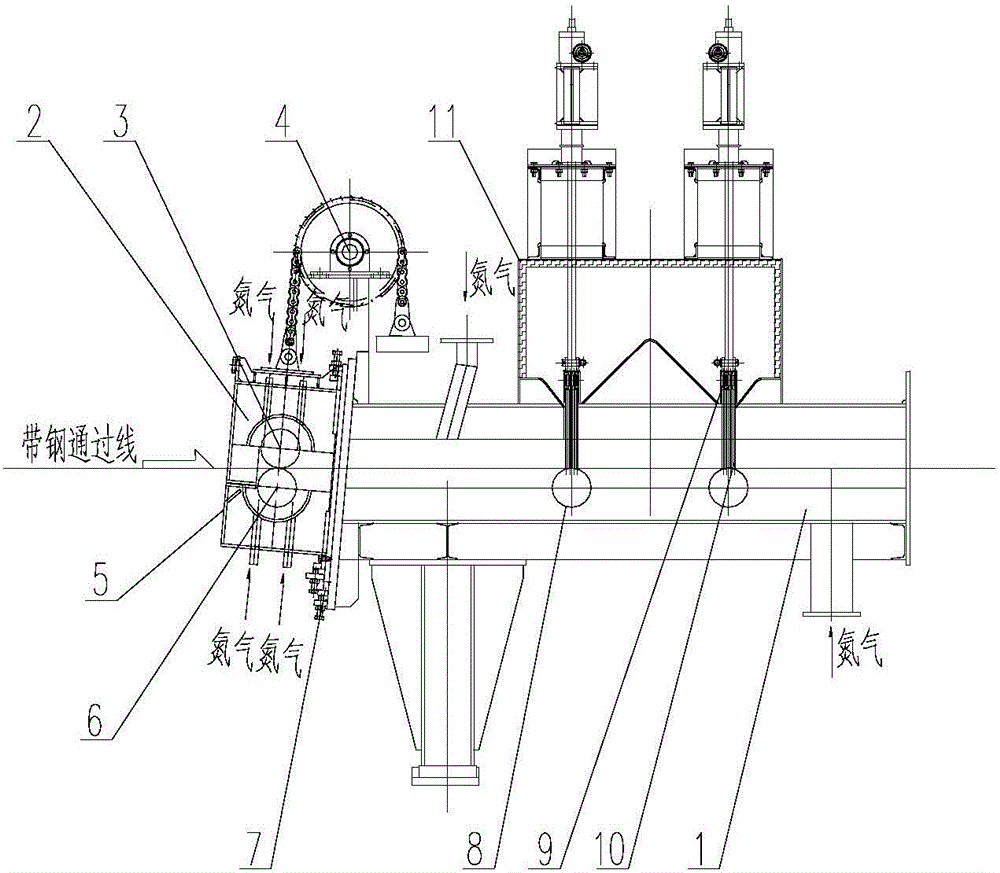

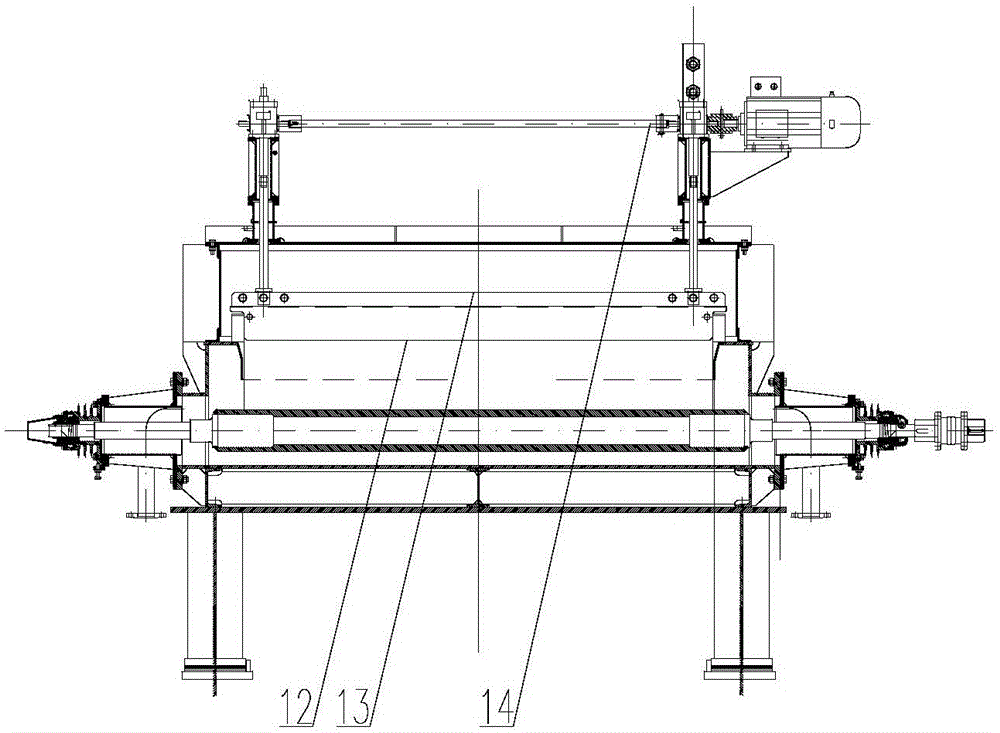

Sealing device for inlet of continuous annealing furnace

InactiveCN106521136AAvoid enteringGuaranteed stabilityFurnace typesHeat treatment furnacesContinuous annealingMaterials science

The invention discloses a sealing device for an inlet of a continuous annealing furnace, and belongs to the technical field of cold rolling. The sealing device comprises a furnace shell, an upper furnace door, an upper sealing roller, a furnace door lifting device, a lower furnace door, a lower sealing roller, a base plate, an in-furnace roller, a flat plate, a sealing curtain, a sealing box, a baffle plate bracket, a connecting rod and a baffle plate lifting device. The end surface flange of the furnace shell and the upper furnace door are separately connected with the base plate through bolts; the angle of inclination of the flange is 5-7 degrees; the lower sealing roller is connected with the lower furnace door through a bearing; the sealing box is mounted on the top of the furnace shell; and the connecting rod is connected with the baffle plate lifting device through a connector. The sealing device has the advantages of being simple in structure, low in cost, good in sealing property, safe and reliable.

Owner:BEIJING SHOUGANG INT ENG TECH

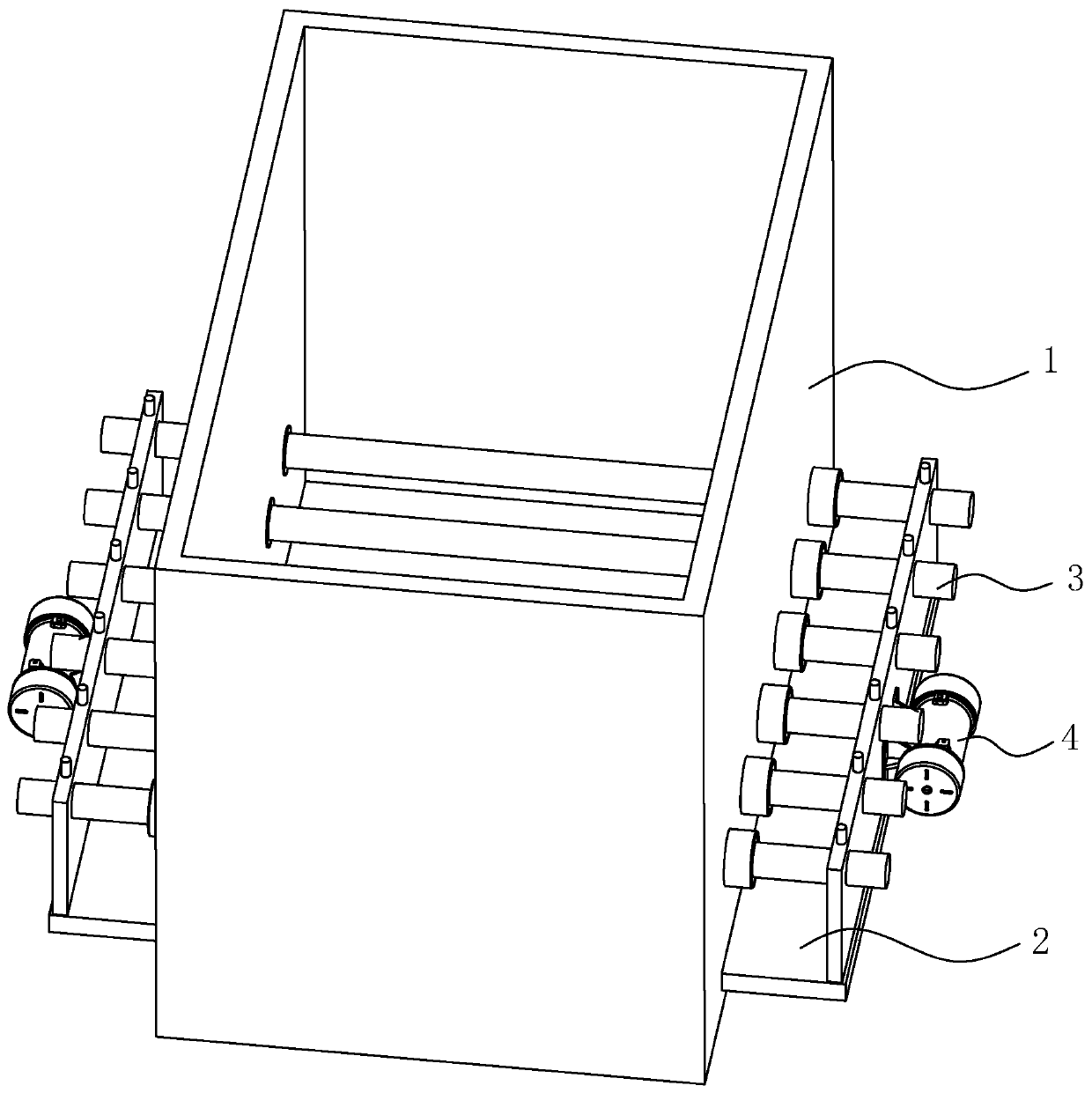

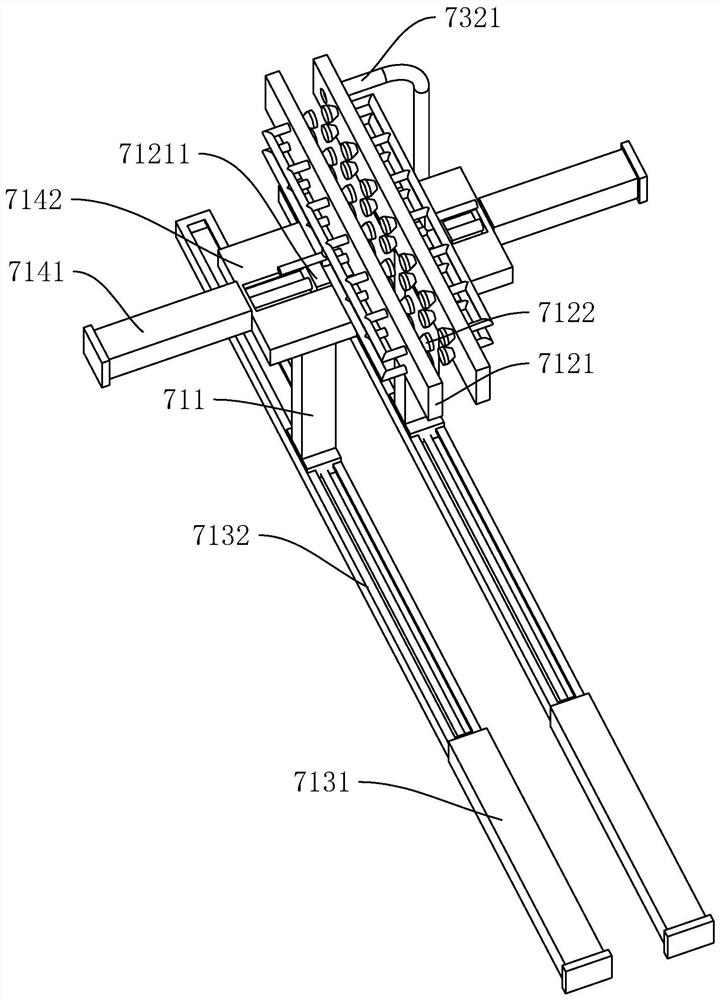

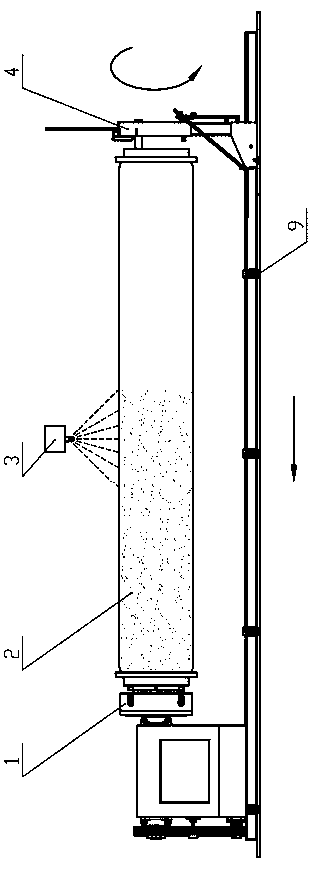

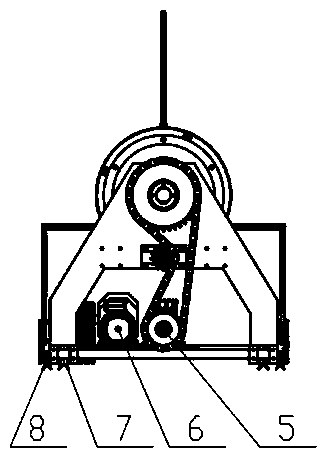

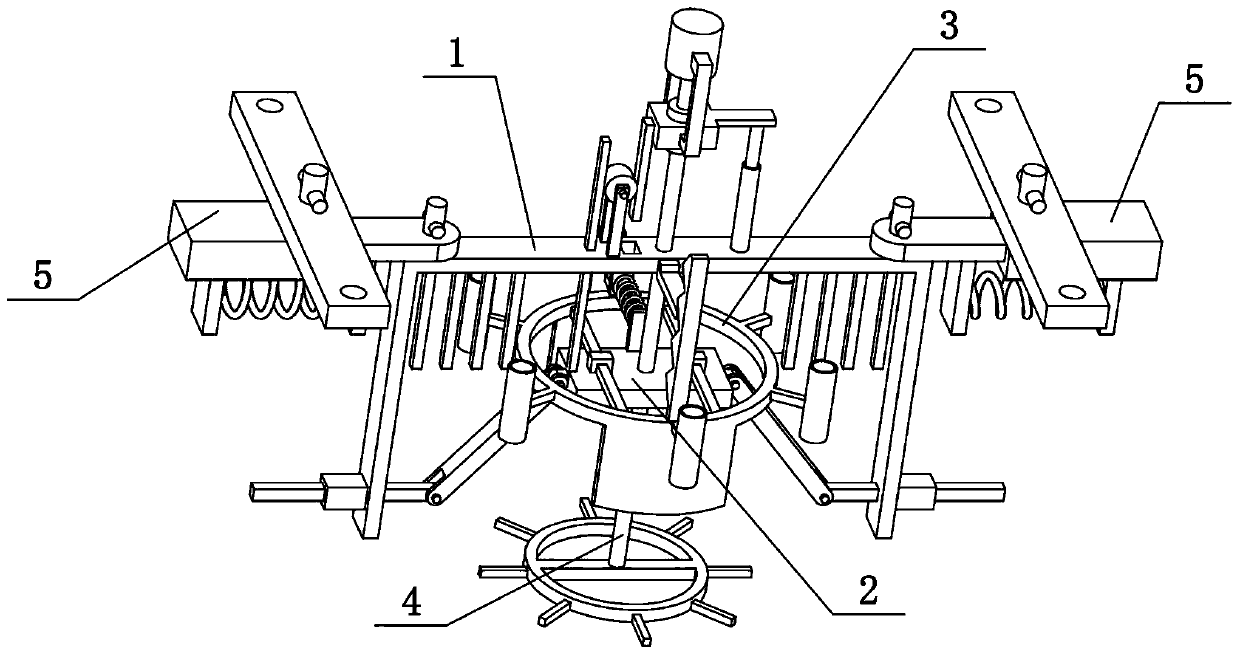

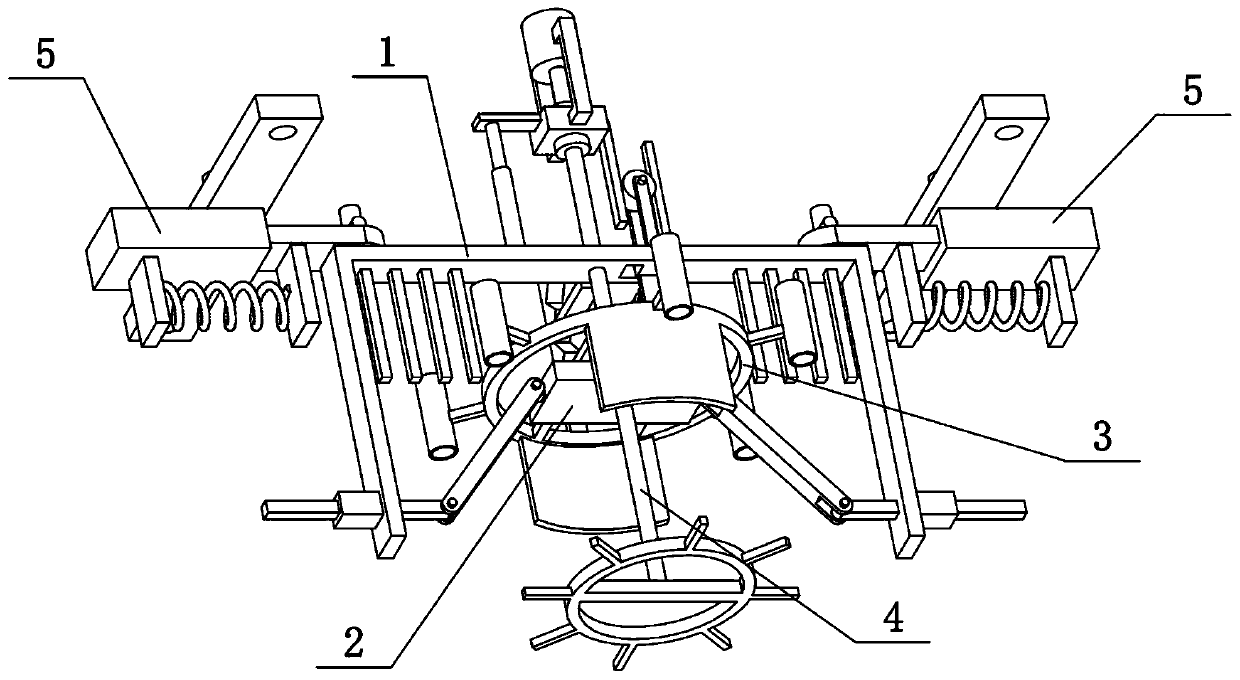

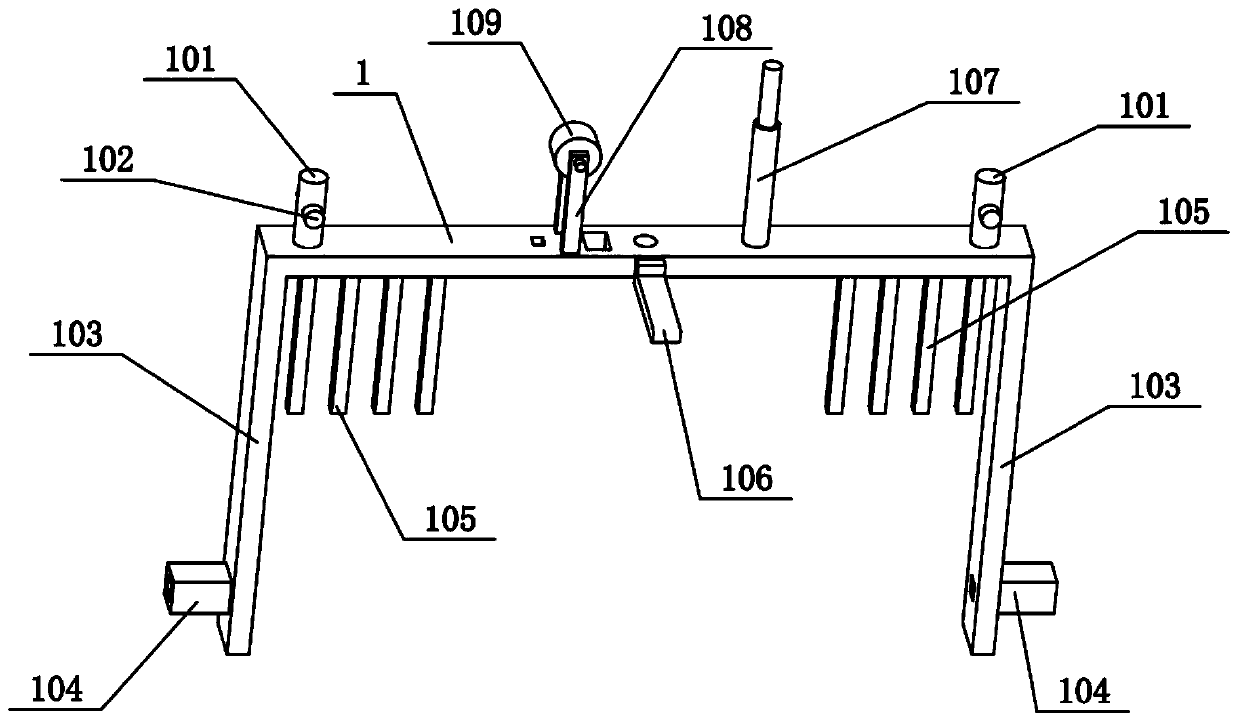

Advancing device and advancing method for polyurethane spraying foaming of prefabricated directly-buried thermal insulation tube

PendingCN109453922AImprove uniformityGuaranteed DensitySpraying apparatusThermal insulationSpray foams

The invention provides an advancing device and an advancing method for polyurethane spraying foaming of a prefabricated directly-buried thermal insulation tube. In the polyurethane spraying foaming process of an existing prefabricated directly-buried thermal insulation tube, the steel tube is installed on a hand-cranking frame, and the advancing and rotating motions are adjusted by manpower, so that the advancing speed and the rotating speed are not uniform, the polyurethane spraying thickness is not uniform, and the polyurethane spraying density and quality are influenced. The advancing device comprises an inner chuck (1) and a polyurethane spray gun (3); the inner chuck (1) is a four-jaw linkage inner chuck; one end of the steel tube (2) is arranged on the inner chuck (2), the other endof the steel tube is connected with a driven end (4), the two ends of the steel tube sleeve with protection plates, a driven end guide rail (8) is arranged at the bottom of the driven end, the inner chuck is connected with a steel pipe autorotation power end (5) through a connecting shaft, the bottom of the polyurethane spray gun is connected with a spraying advancing power end (6), the spraying advancing power end comprises a transmission mechanism, and the transmission mechanism enables an advancing mechanism to horizontally move through chain transmission. The device is used for carrying out spraying foaming on the polyurethane of the prefabricated directly-buried thermal insulation tube.

Owner:HARBIN LOGSTOR ENERGY SAVING TECH

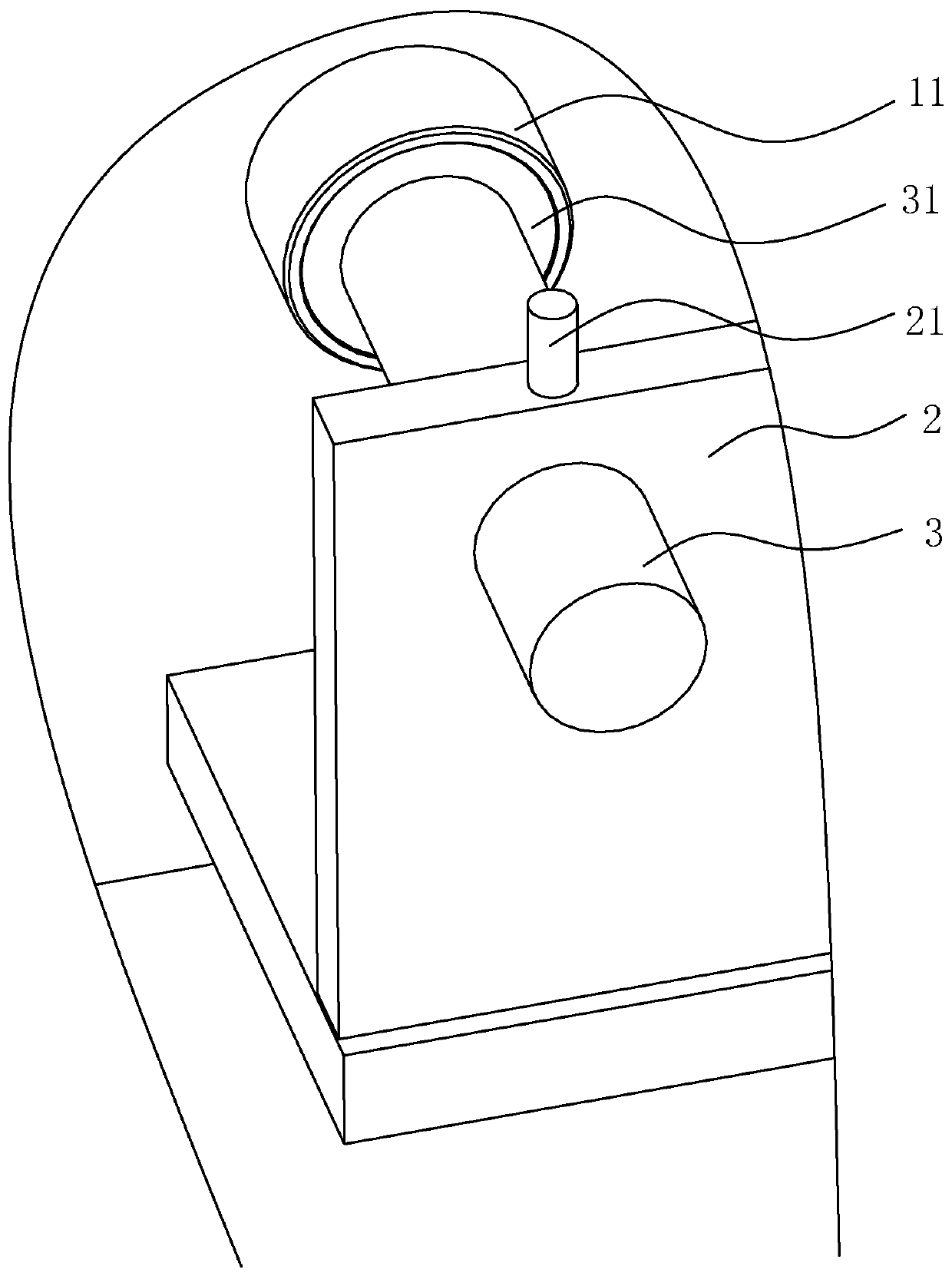

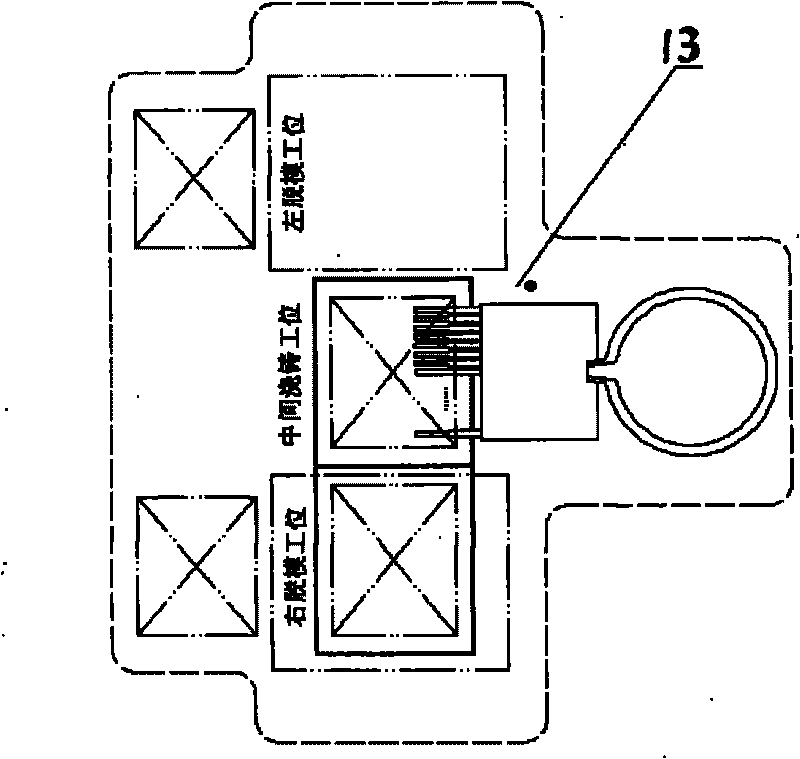

Rare non-ferrous metal vertical type automatic casting machine and matching casting method thereof

The invention discloses a rare non-ferrous metal vertical type automatic casting machine and a casting method thereof. The rare non-ferrous metal vertical type automatic casting machine consists of an insulating or heating furnace, a multimode middle casting device, a right demoulding device, a casting bogie, a right casting mold group, a right ingot-bearing stacking device, a left ingot-bearing stacking device, a left demoulding device, a left casting mold group and a multimode middle casting device casting gate. The rare non-ferrous metal vertical type automatic casting machine and the casting method thereof can obtain a high-quality rare non-ferrous metal ingot blank through only one casting under the condition without manual intervention so as to completely avoid injuries, caused by heat radiation and swashing liquid metals in the casting process, to casting workers, can improve the yield of rare non-ferrous metals, and can conveniently realize the quantitative casting of rare non-ferrous metal ingot blanks to lay a foundation for improving the current efficiency of a subsequent electrolysis process step. The rare non-ferrous metal vertical type automatic casting machine and the casting method thereof have important realistic meanings for promoting the automation level of the whole rare non-ferrous metal casting production, improving the production efficiency, saving energy resources, protecting the environment, improving working conditions and reducing the labor intensity.

Owner:KUNMING UNIV OF SCI & TECH

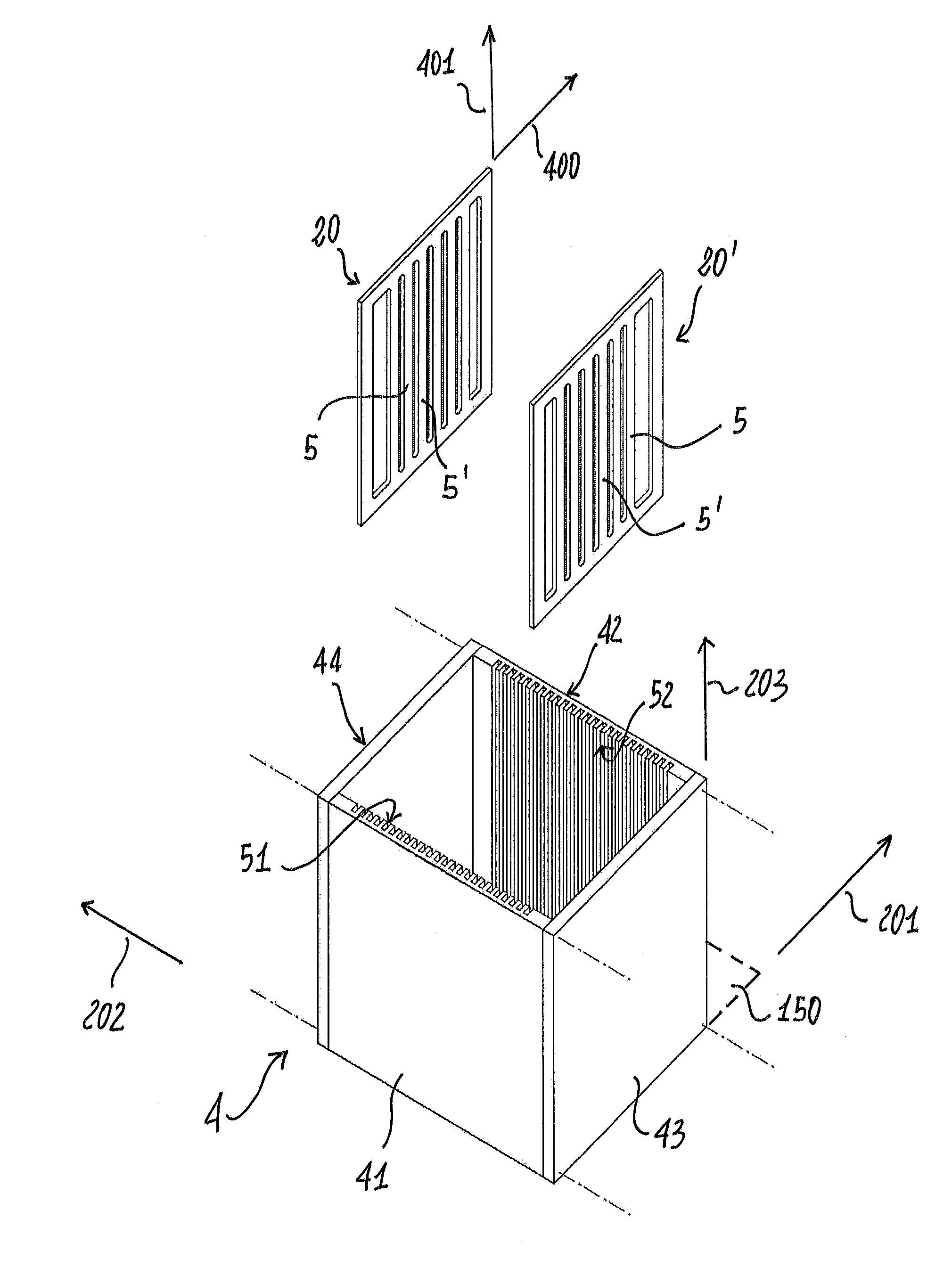

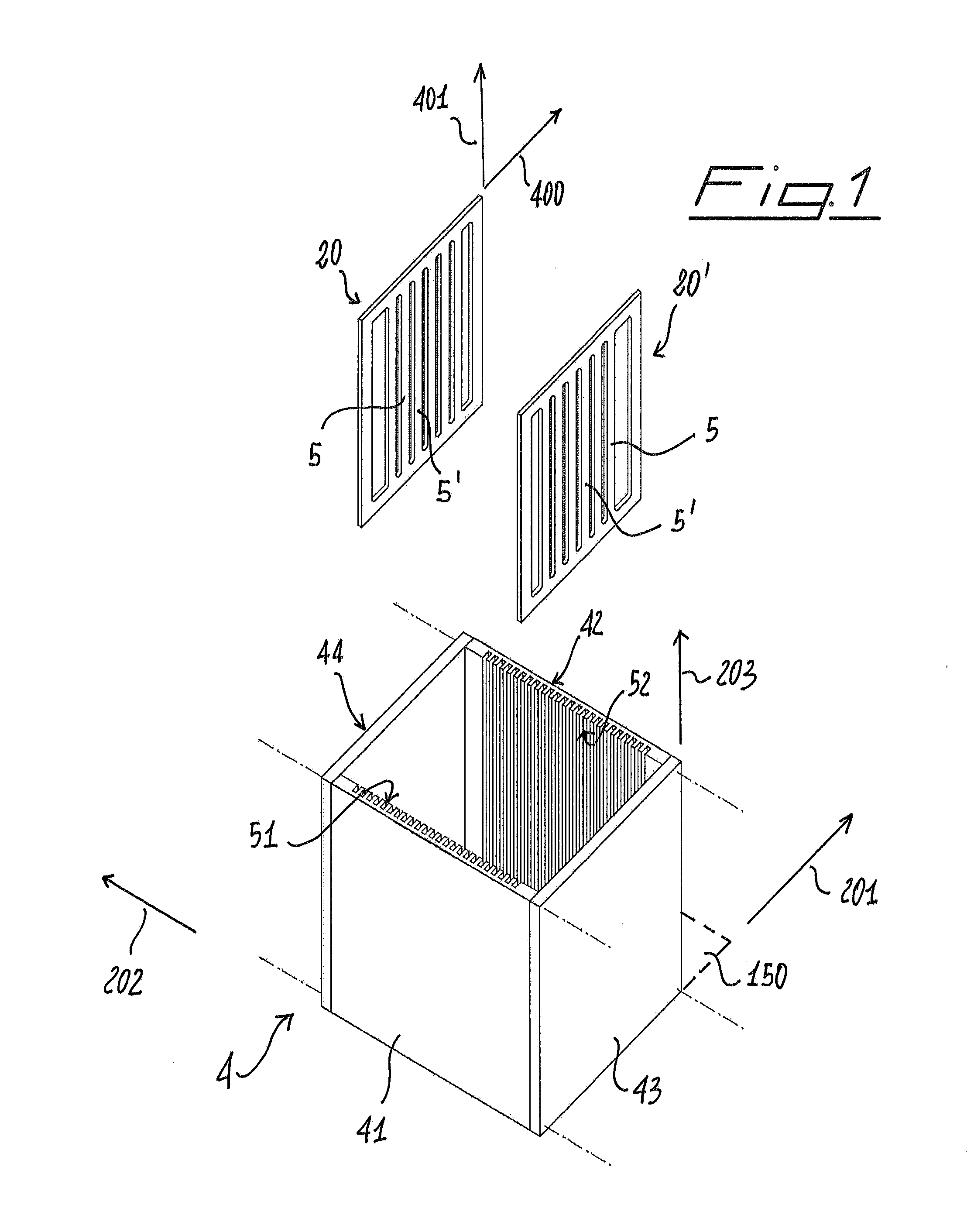

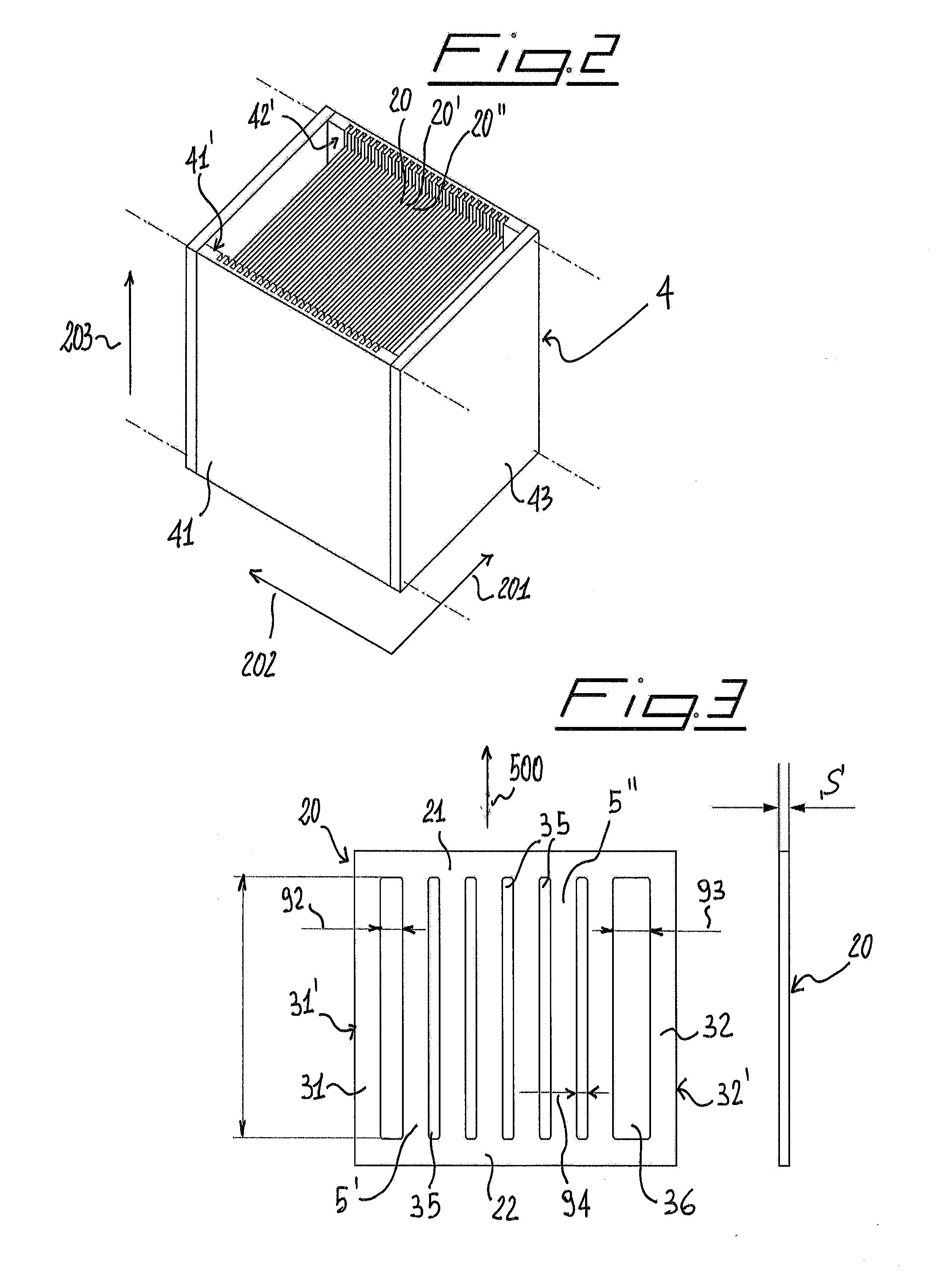

Method for manufacturing panels having translucent elements

InactiveUS20160185016A1Improve accuracyImprove final qualityConstruction materialSpecial ornamental structuresWork in processEngineering

The present invention relates to a method for manufacturing prism-shaped panels (1), each comprising through portions (55) made of translucent material adapted to transmit light between two opposite sides of the panel. The method includes arranging a plurality of elements (5, 5′, 5″) made of translucent material in a formwork so that the main direction of development (500) of such elements is parallel to the vertical direction of development (203) of the formwork. The method includes pouring cementitious mortar into said formwork (4) so that said cementitious mortar is distributed between said elements and so as to generate, after the hardening of said cementitious mortar, a substantially prism-shaped semi-finished cementitious mortar product (2) in which said elements made of translucent material are incorporated. The method further includes extracting the semi-finished product from said formwork after the hardening of the cementitious mortar, and cutting the semi-finished product according to cutting planes orthogonal to the longitudinal direction (500) in which the elements incorporated in said semi-finished product develop, so as to obtain prism-shaped parts, each of which corresponds to one of said panels (1).

Owner:ITALCEMENTI

Amino modified silicone oil and preparation method thereof

The invention relates to amino modified silicone oil which has low content of metal ions and stable viscosity and a preparation method thereof. The amino modified silicone oil is prepared by using dihydroxy silicone oil and an amine coupling agent as raw materials and tetramethylammonium hydroxide as a catalyst, subjecting the above-mentioned materials to a bulk condensation reaction and adding micro-molecular compounds with active groups after the reaction lasts for 2 to 5 h. Compared to conventional methods, the invention has the following characteristics: tetramethylammonium hydroxide is used as a catalyst to substitute metallic compounds, and after the reaction is finished, temperature rises again, which enables the catalyst to be destroyed, the micro-molecular compounds to be removed, the content of metallic impurities in an obtained product of the amino modified silicone oil to be controlled and the amino modified silicone oil with low content of metals and stable viscosity to be synthesized; during utilization, the amino modified silicone oil can substantially reduce metallic impurities introduced into fibers, especially into carbon fiber precursors, thereby improving final quality of carbon fibers, and viscosity of the silicone oil does not change in the process of storage.

Owner:CHINA NAT BLUESTAR (GRP) CO LTD

Hair care liquid processing system, hair care liquid processing method and hair care liquid

PendingCN111297755AImprove qualityProne to squeeze reactionCosmetic preparationsHair cosmeticsEngineeringMechanical engineering

The invention relates to the field of hair care liquid, in particular to a hair care liquid processing system, a hair care liquid processing method and hair care liquid. The method comprises the following steps that 1, two top frame beams are fixed to the upper part of a hair care liquid container; 2, when an electric push rod extends or contracts, an ascending and descending seat is driven to ascend or descend, so that a flat plate and a bottom ring continuously perform reciprocating approaching movement, and when the flat plate and the bottom ring approach to each other, hair care liquid rawmaterials are stirred in an extruded mode; and 3, when vertically moving, a circular ring can also perform forward and backward reciprocating vibration, the two arc-shaped sheet plates perform forward and backward reciprocating vibration, and vibration stirring can be conveniently performed on the upper part of the hair care liquid, so that oxygen gas enters the hair care liquid. The hair care liquid is prepared from the following raw materials in parts by weight: 40 parts of Chinese honeylocust fruits, 15 parts of fleeceflower roots, 15 parts of cacumen platycladi, 3 parts of frost mulberryleaves, 8 parts of flos caryophylli, 10 parts of sesame and 20 parts of aloe.

Owner:刘佳惠

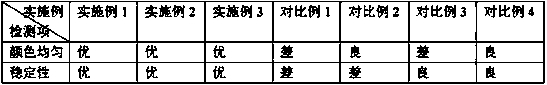

Preparation method of mulberry and red date compound beverage

InactiveCN110637950AUniform colorNo stratificationNatural extract food ingredientsFood ingredient as mouthfeel improving agentBiotechnologyVitamin

The invention discloses a preparation method of a mulberry and red date compound beverage. The mulberry and red date compound beverage is prepared by the following steps: taking mulberries and red dates as raw materials, mixing mulberry juice and red date juice, and performing filtering, blending, homogenizing, canning, sterilizing and packaging. The compound beverage is prepared from the mulberries and the red dates as main raw materials, the content of melatonin in the mulberries is high, and the melatonin can improve sleep and delay senescence; and the red dates contain rich vitamins and have the effects of invigorating spleen-stomach and replenishing qi, and nourishing blood and calming spirit. The invention develops a new utilization way for local rich mulberry resources in Xiajin.

Owner:山东圣源绿色食品科技有限公司 +1

Preparation technology for frozen cooked noodles

ActiveCN110742232ADelay quality deteriorationImprove qualityFood freezingBiotechnologyFood processing

The invention discloses a preparation technology for frozen cooked noodles, and belongs to the technical field of food processing. Curdlan is taken as a modifier of the frozen cooked noodles and is added into flour, the frozen cooked noodles are prepared through technologies, including dough kneading, fermenting, rolling, cutting, maturation and freezing, and an adding ratio is controlled to improve the secondary cooking quality of the frozen cooked noodles. The preparation technology disclosed by the invention creatively utilizes the curdlan to improve the secondary cooking quality of the frozen cooked noodles, a new method is provided for eliminating the quality deterioration of the frozen cooked noodles in a freezing process, and meanwhile, an application range of the curdlan is furtherexpanded.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com