High-precision 3D printing device based on SLA technology

A 3D printing, high-precision technology, applied in the direction of additive processing, etc., can solve the problems that affect the final quality of the product, the surface of the polymer is rough, and the precision cannot be very high, so as to eliminate the influence of high temperature, improve the bonding force between layers, eliminate The effect of step marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

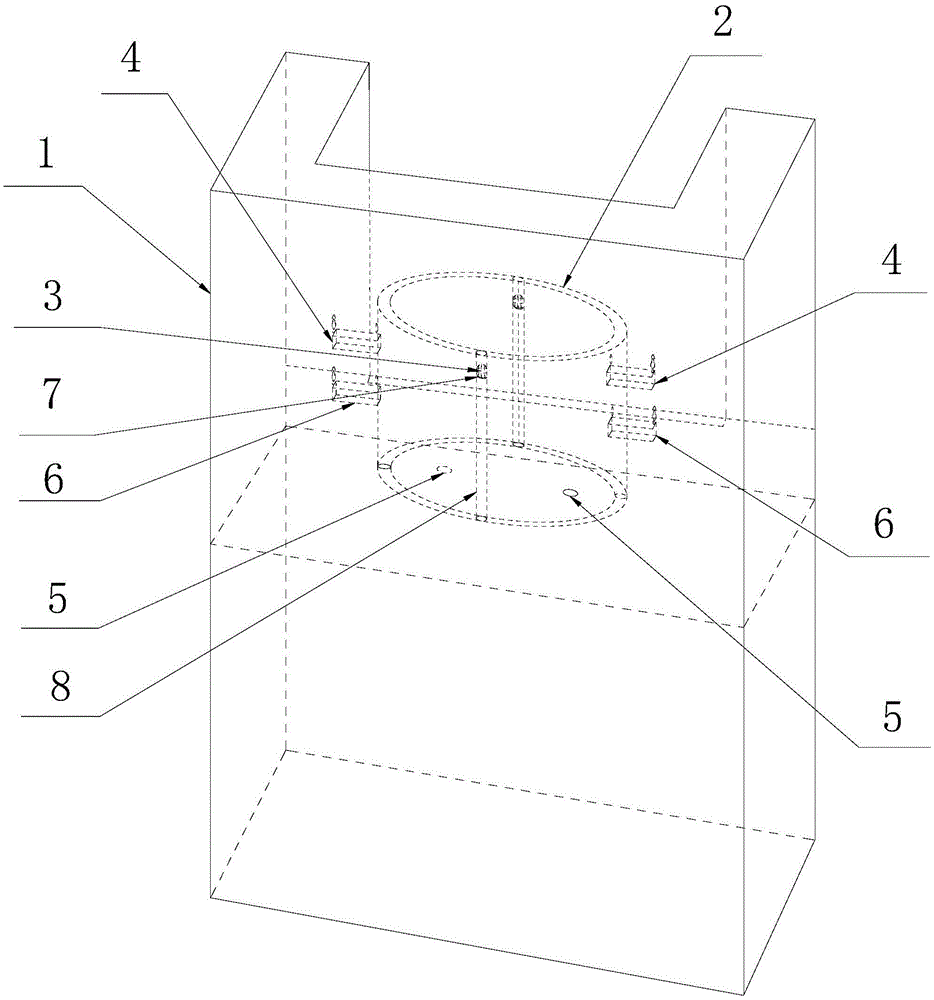

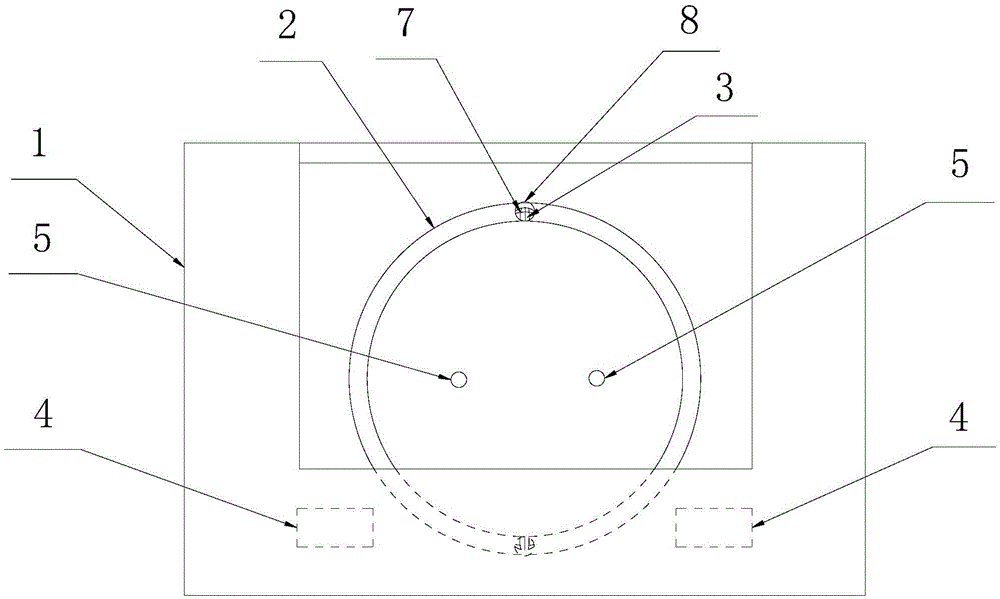

[0029] Example: Combine figure 1 with figure 2 Shown is the specific implementation of the high-precision 3D printing device based on SLA technology provided by the present invention. 2. The upper laser scanning head mechanism (omitted in the figure) also includes a PLC controller (omitted in the figure) electrically connected to the laser scanning head mechanism.

[0030] The improvement in this embodiment is that two longitudinal limiting grooves 8 are provided on the inner side wall of the photocuring working cylinder groove 2, and one side of each longitudinal limiting groove 8 passes through the opening and the light curing working cylinder groove 2. The lumen is connected. Floats 7 are provided in the two longitudinal limiting grooves 8, and each float 7 is provided with a photosensitive resin injection port 3, and the inner cavity of each float 7 is connected to the photosensitive resin injection pump 4 through a pipeline. The photosensitive resin storage cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com