Preparation method and application method of calcium sulphosilicate mineral

A technology of calcium sulfosilicate and minerals, which is applied in the field of preparation and application of calcium sulfosilicate minerals, can solve problems such as low content, and achieve the effects of simple preparation, improved final quality and good grindability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

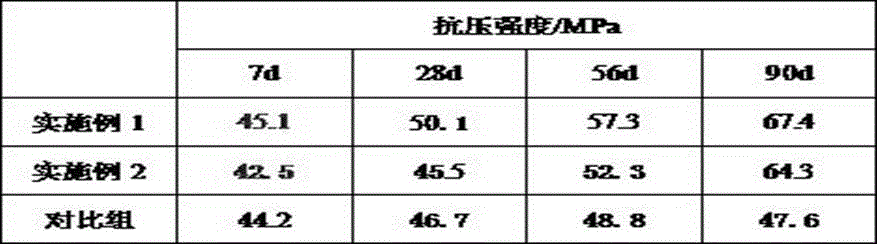

[0039] A preparation method of calcium sulfosilicate mineral, the specific implementation steps and results are as follows: using analytically pure calcium carbonate (replacing limestone), dihydrate gypsum and silica fume (need to measure the SiO of silica fume 2 The content is greater than 80%, and the specific surface area is guaranteed to be greater than 600 m 2 / kg or more) according to the following mass ratio ingredients: 61 parts of analytically pure calcium carbonate, 15 parts of silica fume, 24 parts of dihydrate gypsum (and make it meet CaO:SiO 2 :SO 3 The mass ratio ranges from 7:3:2 to 7:3:2.8), and they are ground together to a fineness of 100 to 200 meshes, and then calcined at a high temperature of 1200 ° C in a high temperature furnace and kept for 4 hours, and then taken out and rapidly cooled in the air; Then it is ground by a ball mill until the specific surface area is 300-450 m 2 / kg to get cement additives.

[0040] The calcium sulfosilicate mixed mine...

Embodiment 2

[0042] A preparation method of calcium sulfosilicate mineral, the specific implementation steps and results are as follows: using analytically pure calcium carbonate (replacing limestone), natural gypsum and quartz powder (the SiO of quartz powder is measured 2 The content is greater than 80%, and the specific surface area is 1000 m2 / kg) according to the following mass proportioning: 61 parts of analytically pure calcium carbonate, 13 parts of quartz powder, 26 parts of natural gypsum (and make it meet CaO:SiO 2 :SO 3 The mass ratio ranges from 7:3:2 to 7:3:2.8), and they are ground together to a standard sieve fineness of 150 mesh, and then calcined at a high temperature of 1200°C in a high-temperature furnace and kept for 8 hours, and then taken out and rapidly cooled in the air; Then it is ground by a ball mill until the specific surface area is 300-450 m 2 / kg to get cement additives.

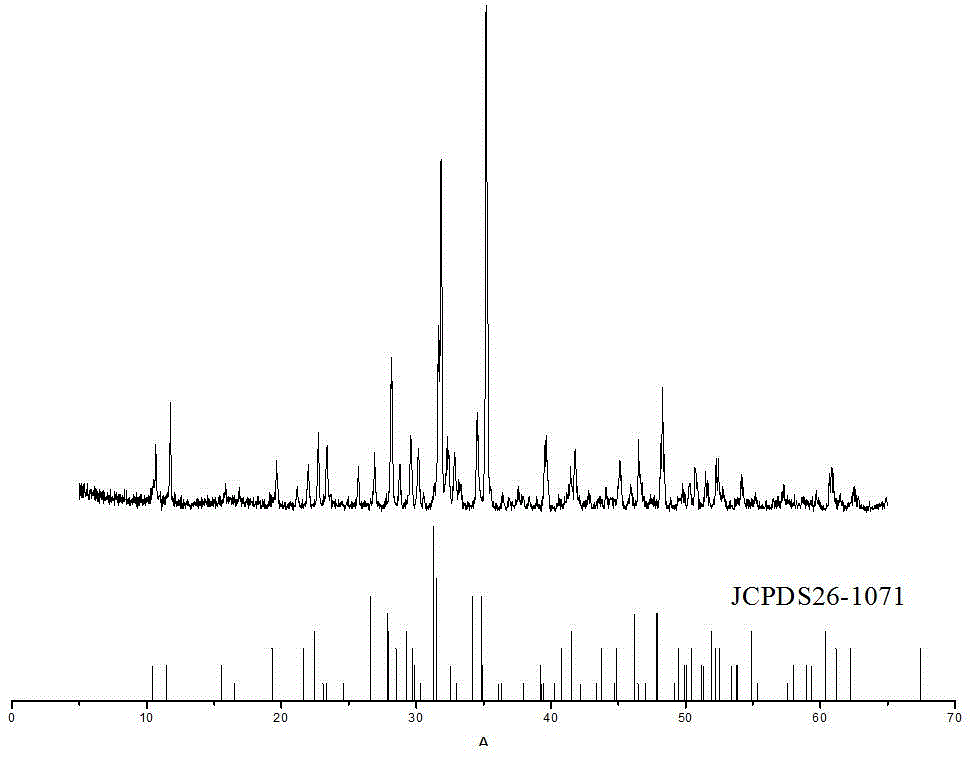

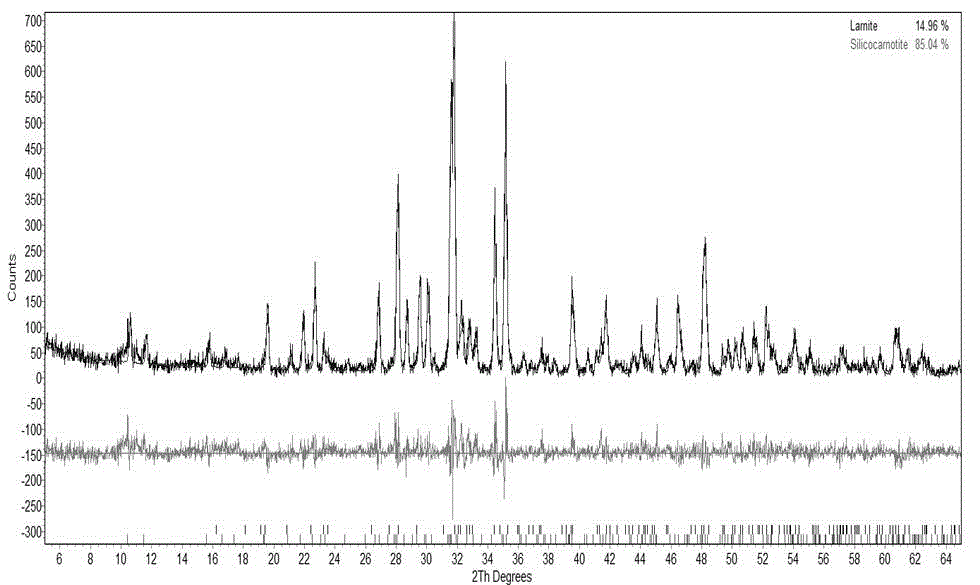

[0043] The cement additive synthesized in the above example 2 was subjected to X-ray ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com