Hair care liquid processing system, hair care liquid processing method and hair care liquid

A processing system and technology for hair care liquid, which are applied in chemical instruments and methods, hair care, pharmaceutical formulations, etc., can solve the problems of inability to squeeze and stir the raw materials of hair care liquid, and the raw materials are prone to extrusion reaction, so as to improve the final performance. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

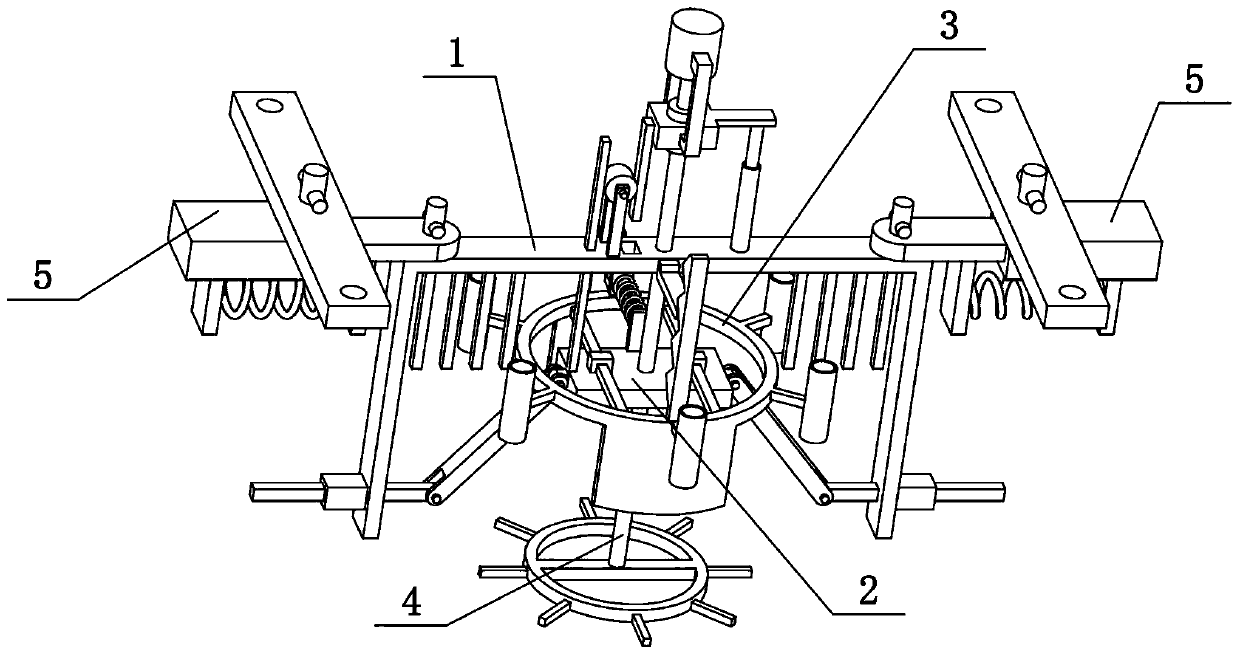

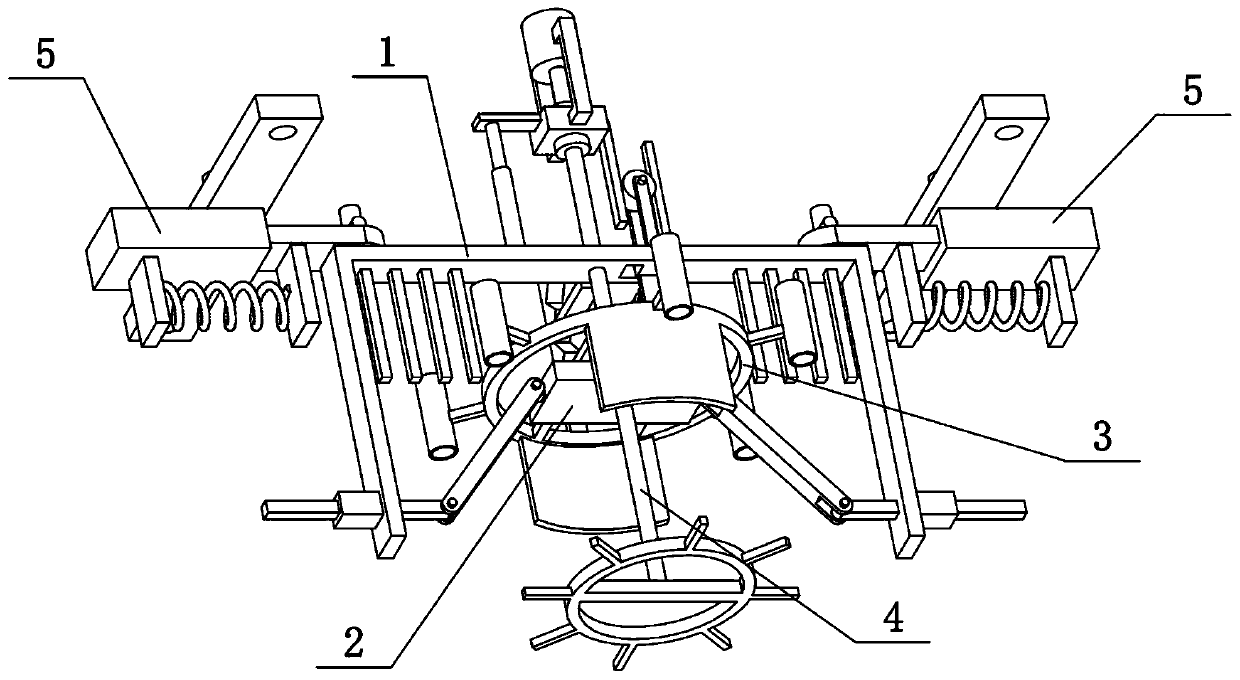

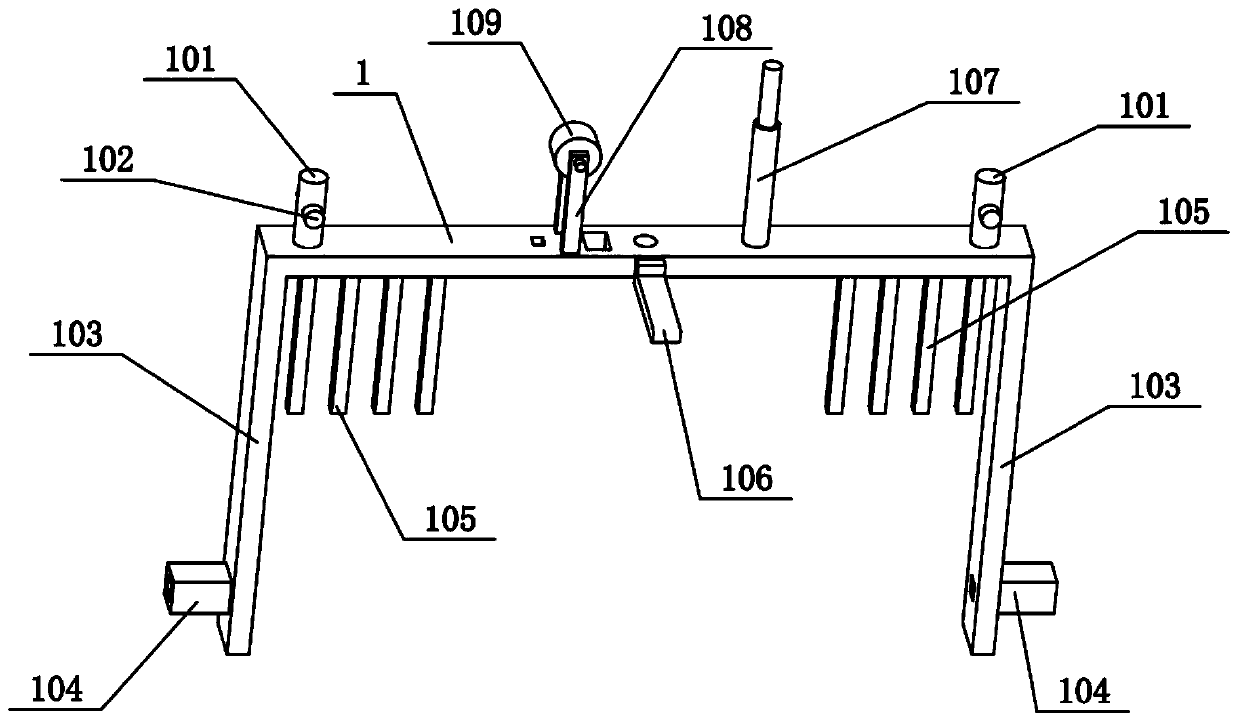

[0034] Combine below Figure 1-9 To illustrate this embodiment, the present invention relates to the field of hair conditioner, more specifically, a hair conditioner processing system, including a beam 1, a vertical beam 103, a fixing sleeve 104, a flat plate 2, an oblique arm 203, and a horizontal sliding column 204 , the vertical shaft 4, the horizontal bar 405 and the bottom ring 407. The present invention can squeeze and stir the raw materials of the hair conditioner, so that the extrusion reaction between the raw materials is easy to occur, and the final quality of the hair conditioner is improved.

[0035]The left and right ends of the lower side of the crossbeam 1 are fixedly connected with vertical beams 103, the lower parts of the two vertical beams 103 are provided with fixed sleeves 104, and the left and right ends of the flat plate 2 are hingedly connected with oblique arm rods 203. The other end of the arm bar 203 is hingedly connected with a horizontal sliding co...

specific Embodiment approach 2

[0037] Combine below Figure 1-9 To illustrate this embodiment, the hair conditioner processing system further includes an electric push rod 107, a gear turret 108, a gear 109, a first rack 202, a lifting seat 401, a motor 402, a limit ring 403 and a second rack 404 The upper side of the plate 2 is fixedly connected with a first rack 202, the first rack 202 is vertically slidably connected to the beam 1, the upper side of the beam 1 is fixedly connected with a gear turret 108, and the gear turret 108 is rotatably connected with Gear 109, the first rack 202 is meshed with the left side of gear 109 for transmission, and the lifting seat 401 is rotatably connected to the top of the vertical shaft 4, and the top of the vertical shaft 4 is fixedly connected with two stop rings 403, and the two stop rings 403 Located on the upper and lower sides of the lifting base 401 respectively, the left side of the lifting base 401 is fixedly connected with a second rack 404, the second rack 40...

specific Embodiment approach 3

[0039] Combine below Figure 1-9 Referring to this embodiment, the hair conditioner processing system further includes a stirring rod 406 , and a plurality of stirring rods 406 are evenly distributed in a ring shape on the bottom ring 407 . A plurality of stirring rods 406 enhance the stirring effect of the bottom ring 407 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com