Heating bed structure, vacuum drying system therewith and manufacture thereof

A vacuum drying and drying technology, which is applied in the vacuum drying system, the process of manufacturing a bed structure, and the structural field of the heating bed, which can solve the problems of easy failure of welds and damage to fur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Detailed description of preferred embodiments

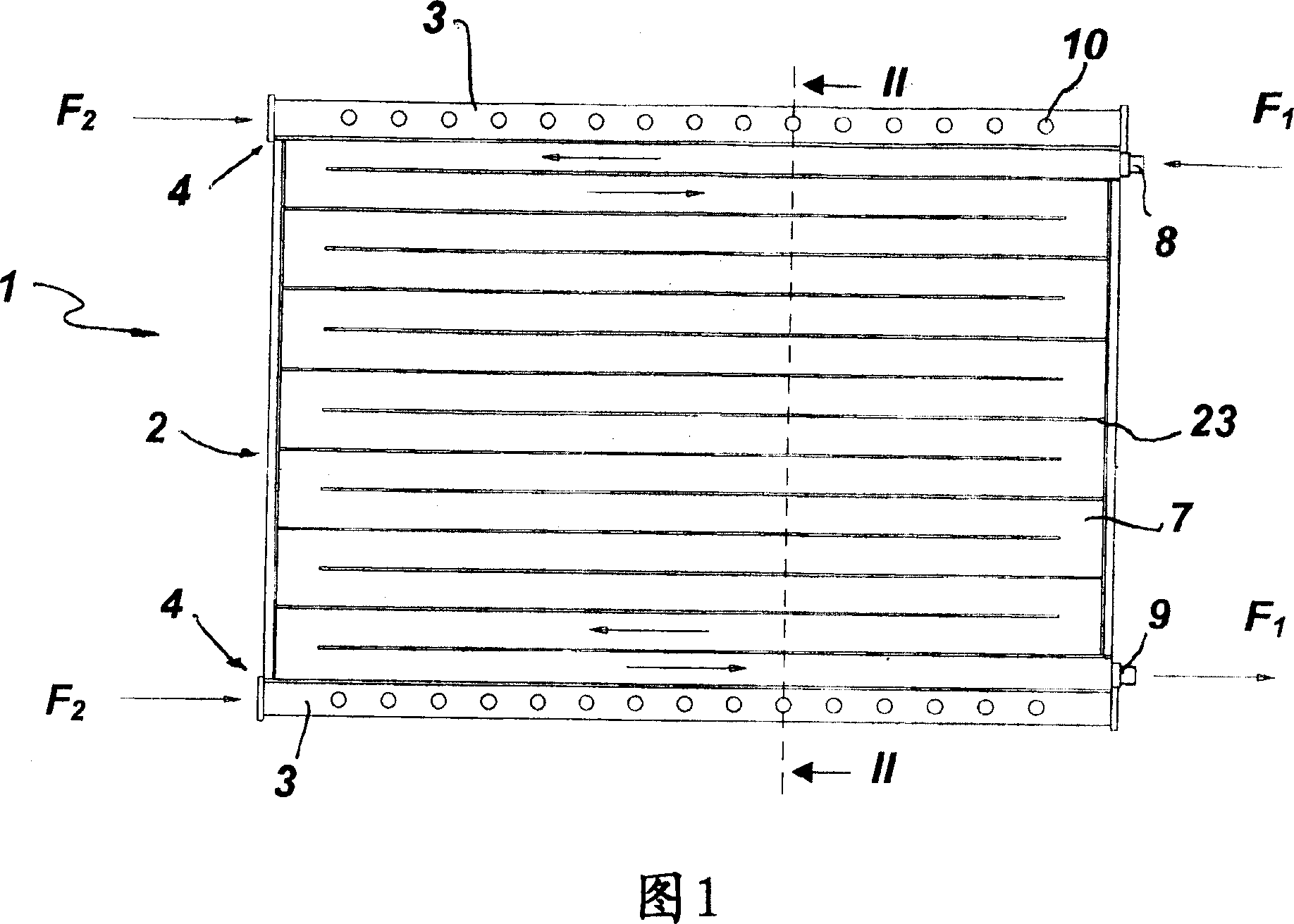

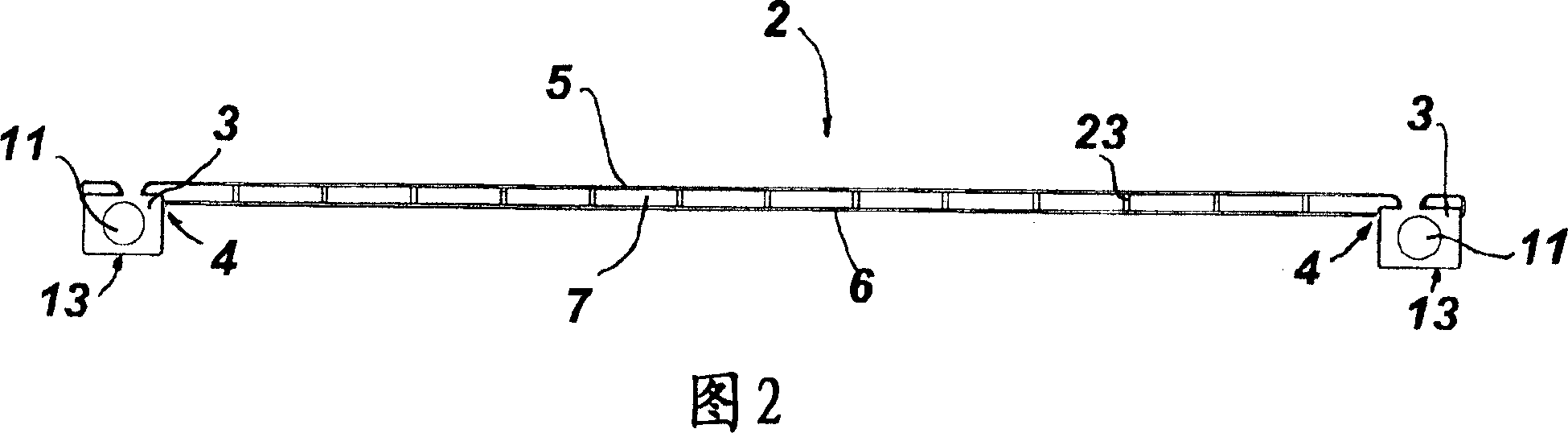

[0032] Referring to the above-mentioned drawings, the structure of the present invention, usually indicated by the number 1, basically includes one, preferably two stations 2 for heating the product to be dried, a collector 3 for steam released therefrom, It is arranged around at least one of its side straps 4.

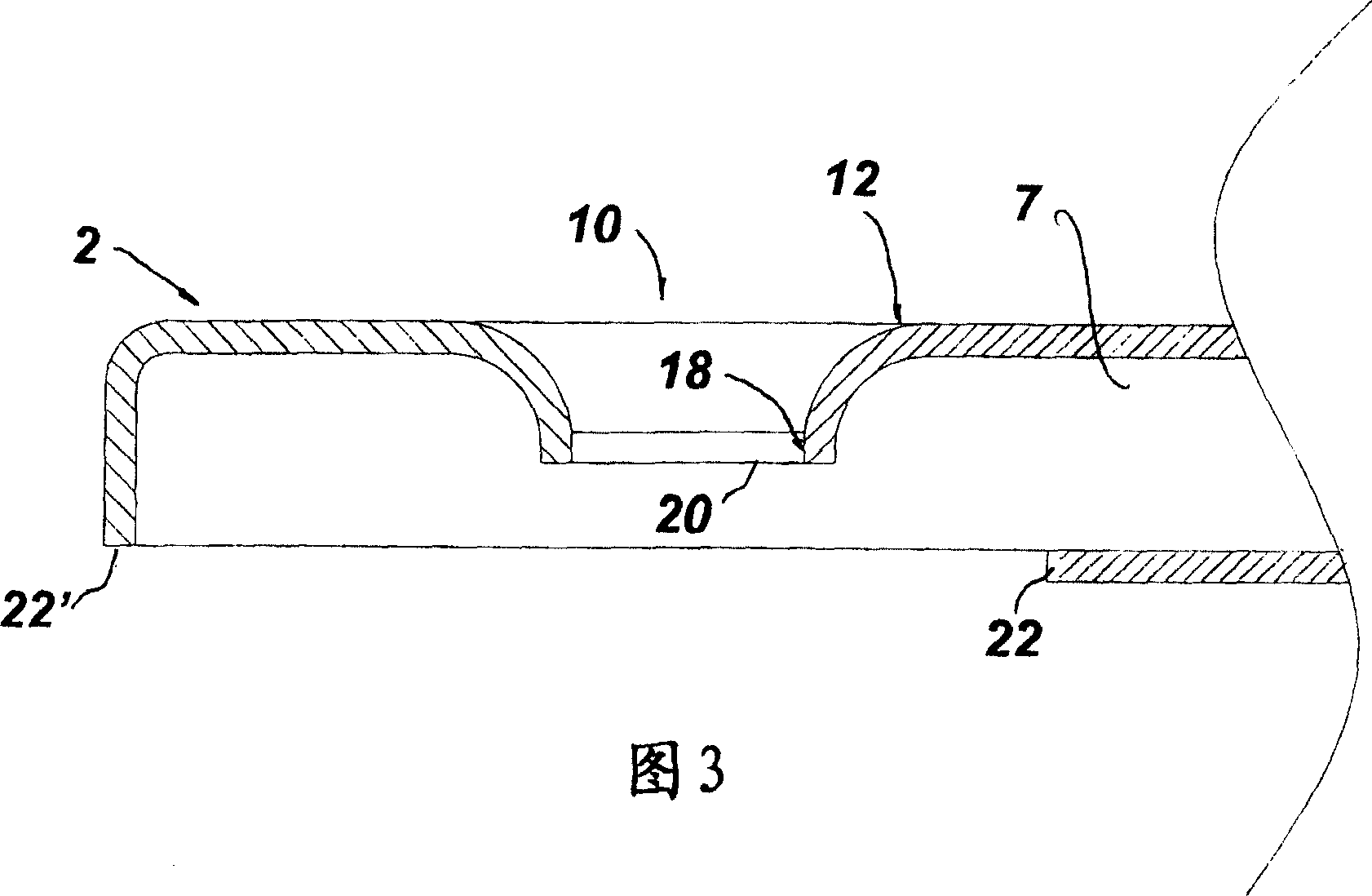

[0033] The table 2 basically includes at least a top disk 5 and a bottom disk 6 which are opposed to and spaced apart from each other to form a heat exchange chamber 7.

[0034] This chamber has an inlet pipe 8 and an outlet pipe 9 for circulating heating fluid F therein. 1 .

[0035] As it circulates in the chamber 7, these fluids will transfer heat through the tray 5 to the product to be dried, and the product will gradually lose moisture.

[0036] The steam released from the fur is absorbed into the collector 3 having a plurality of suction holes 10 through suitable external elements. The collector 3 has suitable e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com