Rare non-ferrous metal vertical type automatic casting machine and matching casting method thereof

A technology for non-ferrous metals and casting machines, applied in the field of vertical automatic casting machines for rare and precious non-ferrous metals, to achieve the effects of improving current efficiency, increasing yield and improving automation level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

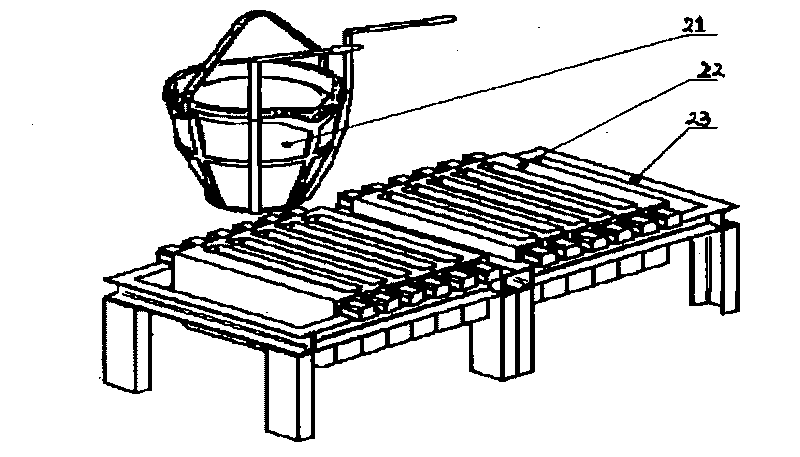

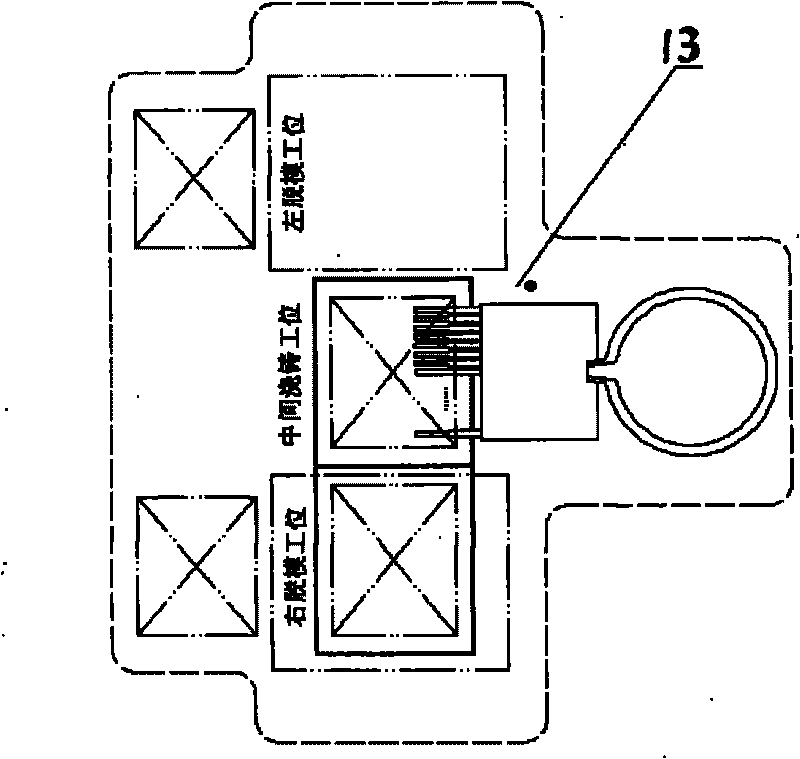

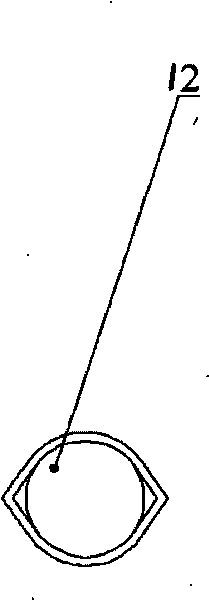

[0041] Embodiment 1: When the number of casting molds of the left and right casting modules is 2, the multi-mode intermediate casting device 2 is provided with 2 parallel casting ports. At this time, the capacity of the multi-mode intermediate casting device 2 must match the quality of the two ingots to achieve quantitative casting control of rare and precious non-ferrous metal ingots, such as image 3 shown. The origin position of the vertical automatic casting machine for rare and precious non-ferrous metals is as follows: ①The induction electric heating furnace 1 and the multi-mode intermediate casting device 2 are in the state of waiting for casting; ②The casting trolley 4 is in the right working position, as shown in Figure 4(a) ; ③ the left casting module 9 is in a clamped state, and the right casting module 5 is in an equidistant separation demoulding state; ④ the left casting module 9 is in the middle casting station, and the right casting module 5 is in the right demo...

Embodiment 2

[0043] Embodiment 2: The optimal number of molds of the vertical automatic casting machine for rare and precious non-ferrous metals of the present invention is 10, when the number of molds of the left and right casting modules is 10, the multi-mode intermediate casting device 2 is provided with 10 parallel castings mouth. At this time, the capacity of the multi-mode intermediate casting device 2 must match the quality of 10 ingots, so as to realize the quantitative casting control of rare and precious non-ferrous metal ingots, such as image 3 shown. 10 The concrete usage steps of the vertical automatic casting machine for rare and precious non-ferrous metals in casting mold are similar to those in 2.

Embodiment 3

[0044] Embodiment 3: The maximum number of casting molds of the rare non-ferrous metal vertical automatic casting machine of the present invention is 100, when the number of casting molds of the left and right casting modules is 100, the multi-mode intermediate casting device 2 is provided with 100 parallel casting ports . At this time, the capacity of the multi-mode intermediate casting device 2 must match the quality of 100 ingots to achieve quantitative casting control of rare and precious non-ferrous metal ingots, such as image 3 shown. The specific use steps of the 100-mold rare and precious non-ferrous metal vertical automatic casting machine are similar to the specific use steps of the 2-mold rare and precious non-ferrous metal vertical automatic casting machine.

[0045] 1. Heat preservation or heating furnace; 2. Multi-mode intermediate casting device; 3. Right demoulding device; (4). Casting trolley; 5. Right casting module; 6. Right receiving ingot stacking device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com