Construction method of bridge bearing platform

A construction method and bridge technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems affecting the quality of caps, honeycomb pockmarks, concrete vibration is not dense, etc., to reduce the probability of quality defects, improve final mass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

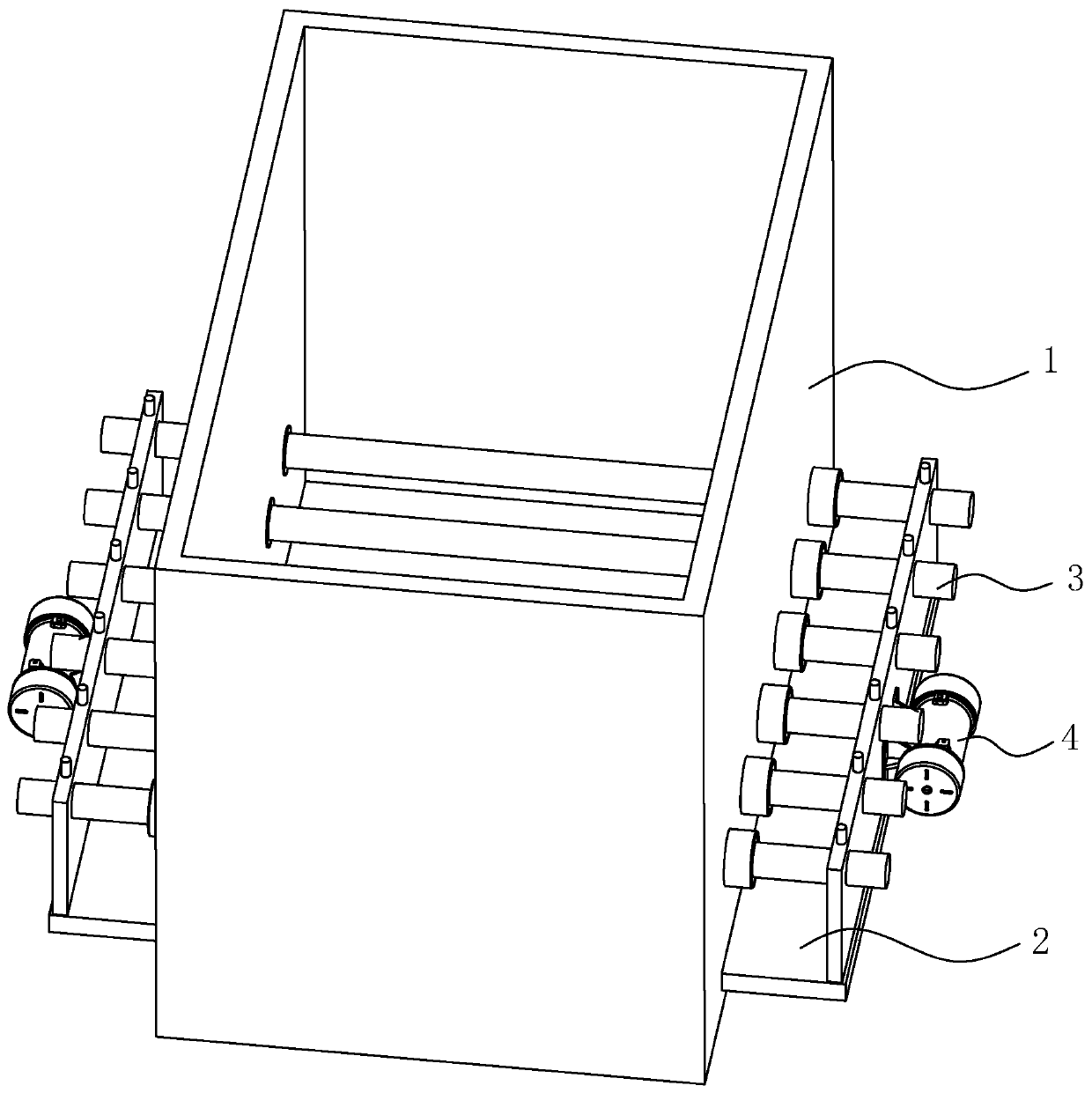

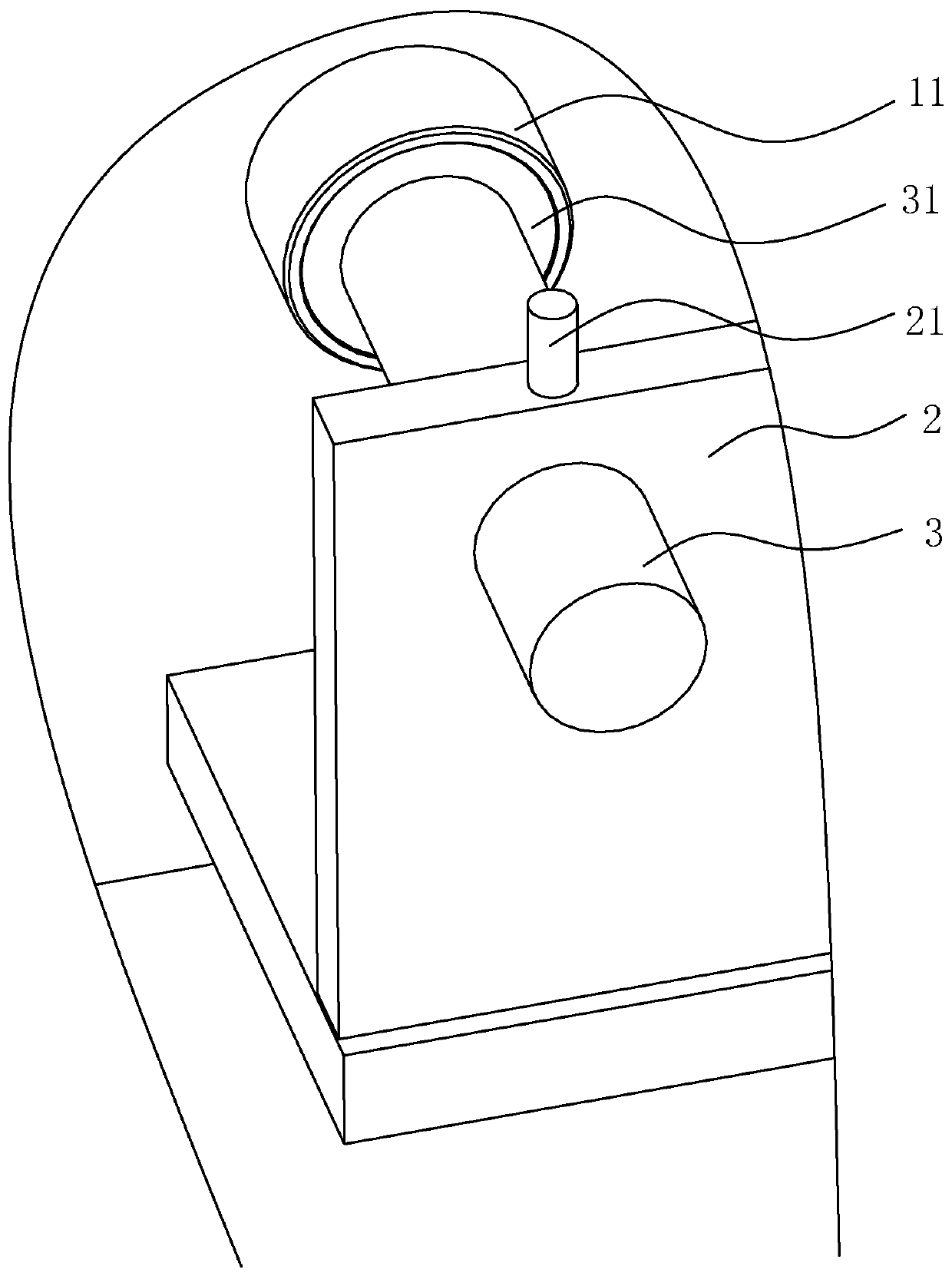

[0035] refer to figure 1 and figure 2 , is the construction method of a kind of bridge bearing platform disclosed by the present invention, comprises the following steps:

[0036] S1: Pre-construction, after surveying and setting out, excavate the foundation pit. When excavating the foundation pit, the foundation pit should be waterproofed. A water diversion ditch can be set at a position 0.5m away from the top edge of the foundation pit to prevent ground water from flowing into the foundation pit. At the same time, in order to ensure that the construction environment in the foundation pit is dry, two sumps can be set at the opposite corners of the foundation pit. The seepage water in the foundation pit flows into the sump and is pumped out of the foundation pit through a water pump. After the excavation of the foundation pit is completed, the edge protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com