Embossing unit and embossing method

A technology of embossing and embossing rollers, applied in the direction of machining/deformation, can solve the problems of loss, large production, time-consuming, etc., and achieve the effect of simplifying the structure of the machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

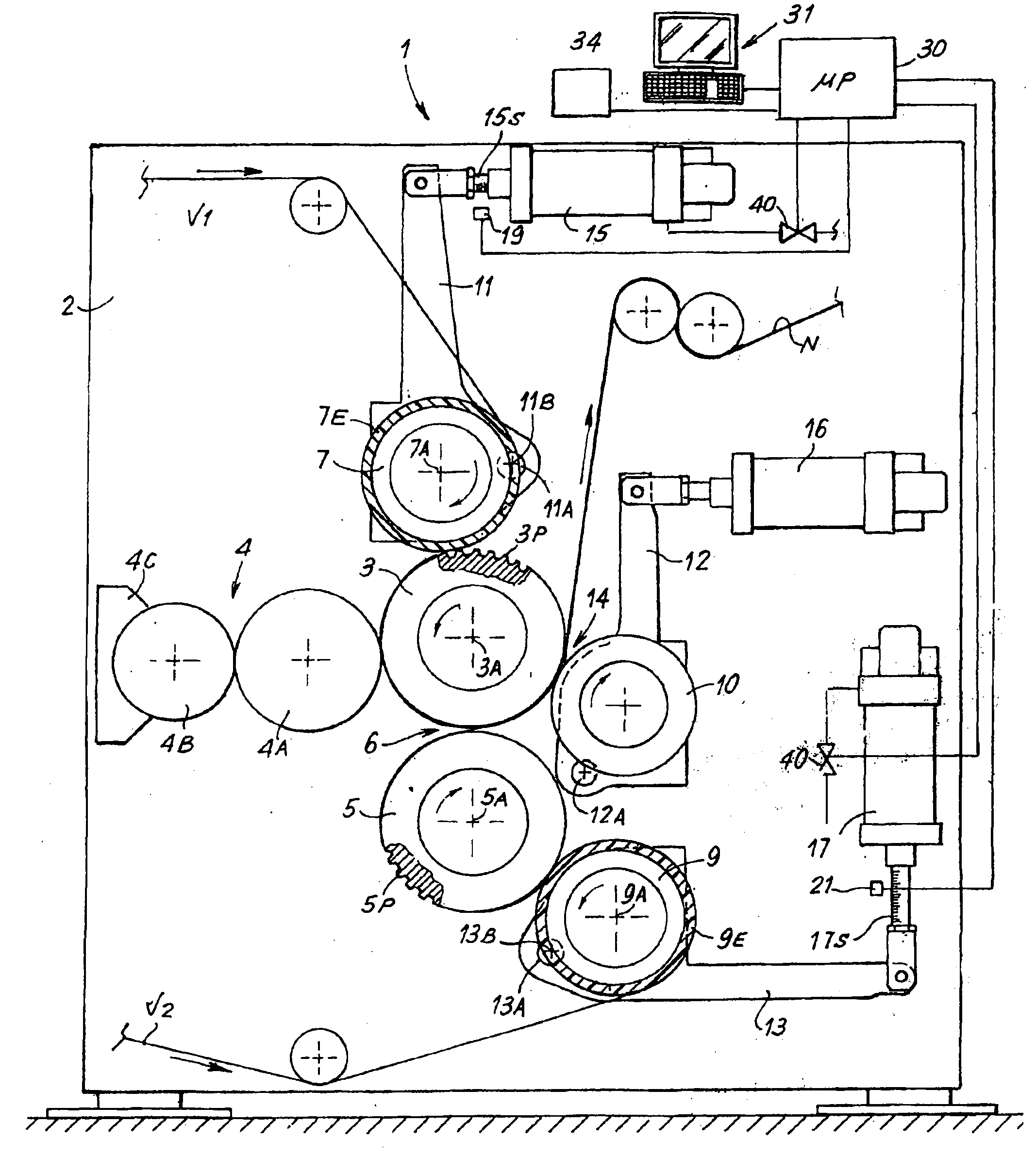

[0033] The application of the invention to a complex embossing lamination unit having two embossing rolls and two pressure rolls, and one laminating roll will be described below. However, it must be understood that the invention may also be advantageously implemented in simpler or other types of embossing units. For example, advantages can also result from applying the invention to simple embossing machines with only one embossing roll and one pressure roll.

[0034] refer to figure 1 , in one possible embodiment, the embossing unit generally indicated by 1 includes a first embossing roller 3 and a second embossing roller 5, the first embossing roller 3 and the second embossing roller 5 are respectively connected with the first embossing roller The pressure roller 7 and the second pressure roller 9 cooperate. Each embossing roll 3, 5 has a plurality of protrusions 3P, 5P on its cylindrical surface, while each pressure roll 7, 9 comprises a cylindrical surface coated with a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com