Copper plating production line for producing printing rollers

A production line and printing roller technology, which is applied in the field of roller body electroplating equipment, can solve the problems of roller body surface scratches, roll body volume, and roller body collision, etc., to achieve the effect of improving work efficiency, reducing work burden, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

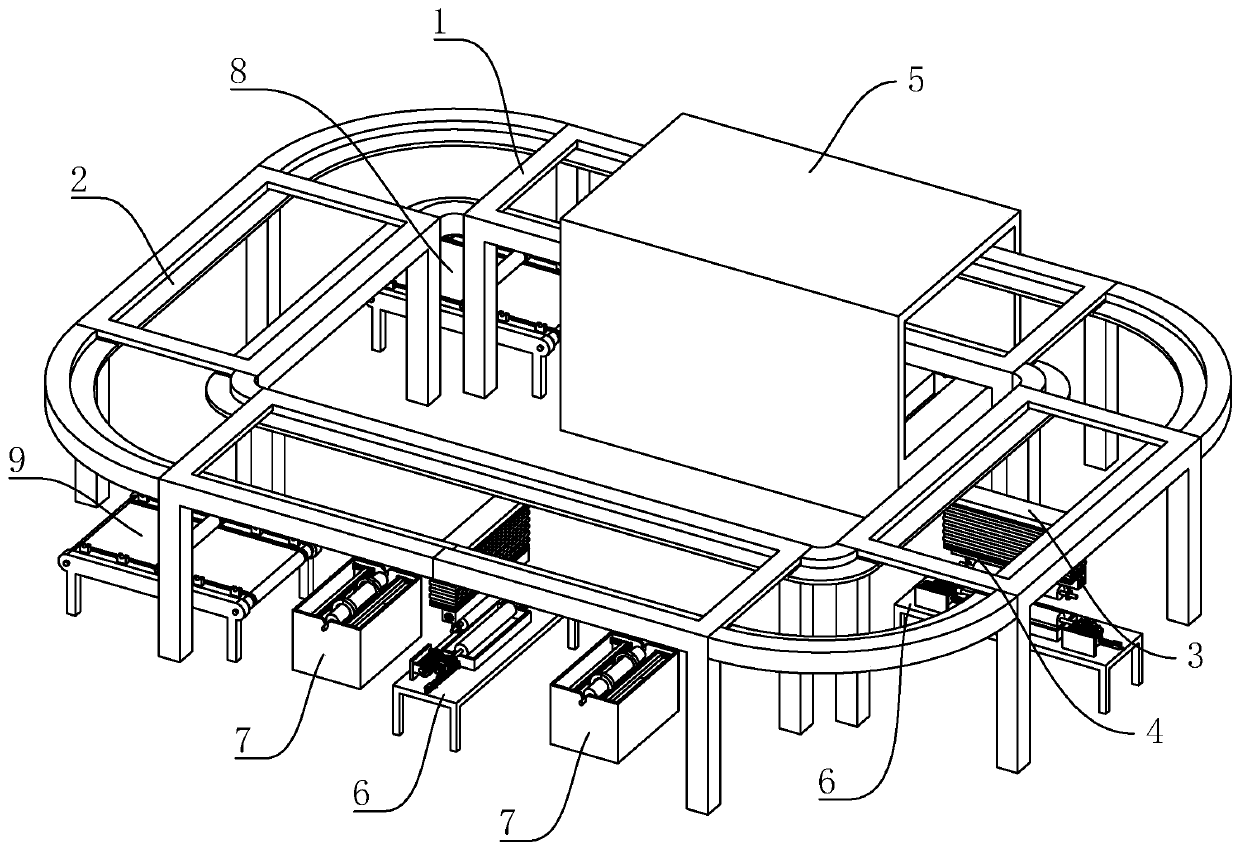

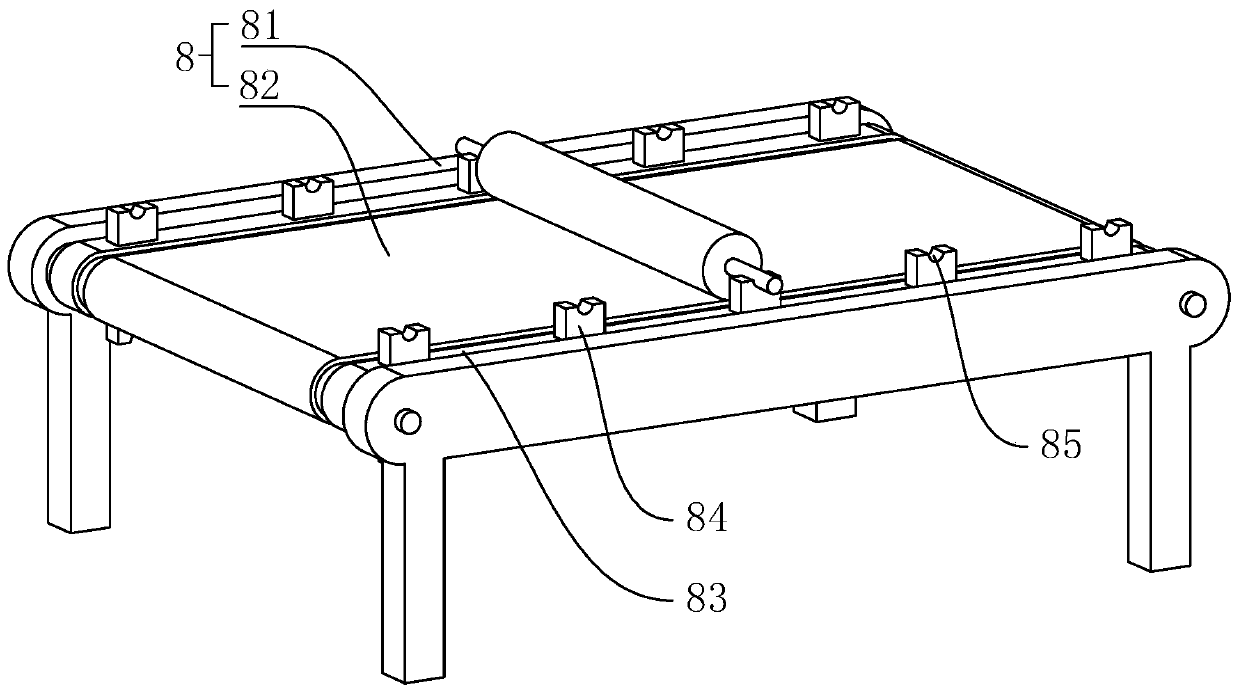

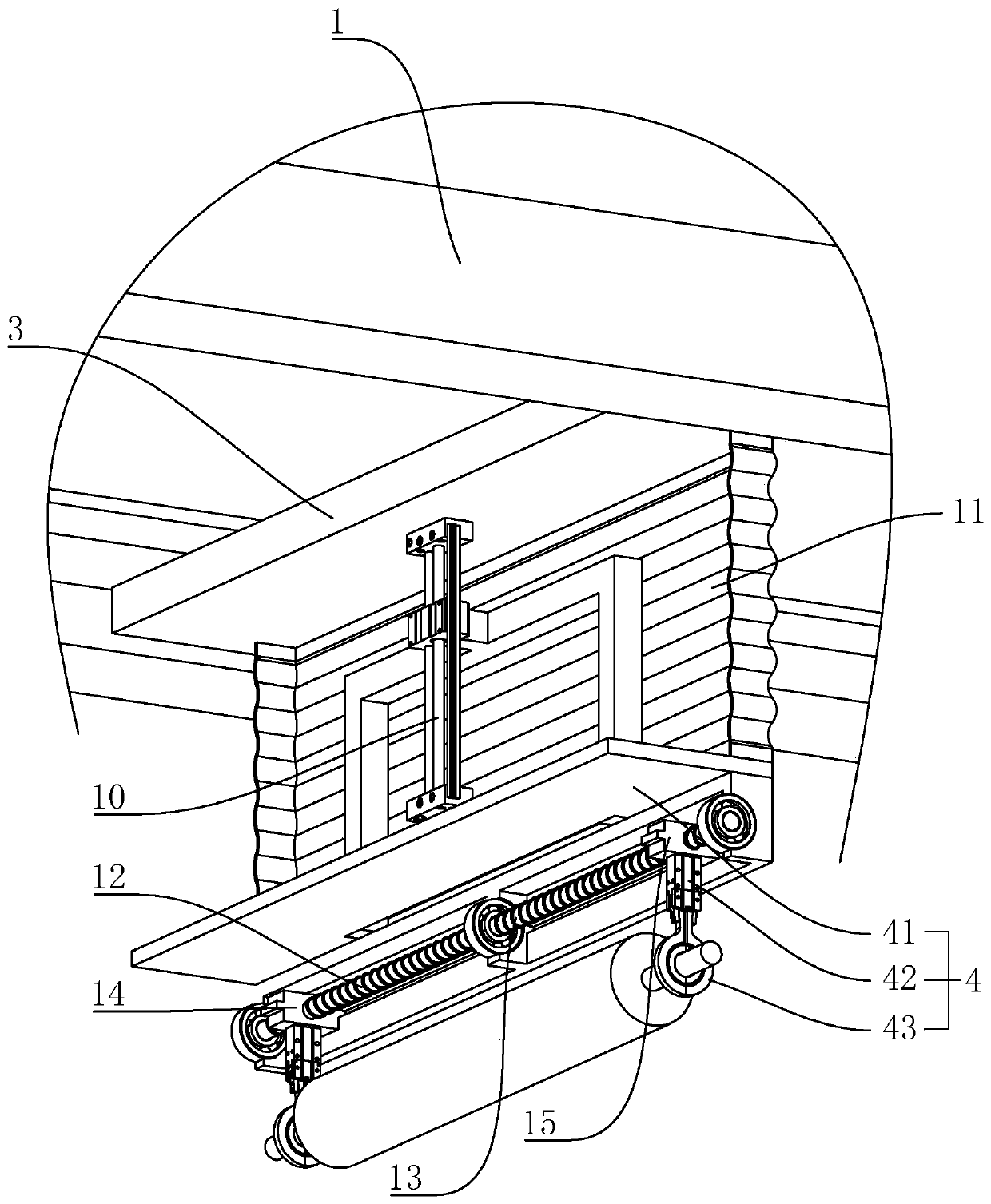

[0043] refer to figure 1 , which is a copper plating production line for producing printing rollers disclosed by the present invention, comprising a support frame 1, on which a circular double-speed chain 2 is arranged, and the circular double-speed chain 2 is arranged in a rectangular shape, connected on the circular double-speed chain 2 There is a horizontal mobile frame 3, and a vertical mobile frame 4 is connected with sliding on the horizontal mobile frame 3. refer to image 3 The vertical moving frame 4 includes a connecting plate 41, a pneumatic finger 42 connected to the lower end of the connecting plate 41, and a roller body limiting ring 43 fixedly connected to the output end of the pneumatic finger 42. The end shaft plays the role of clamping. When the roller body limit ring 43 clamps the roller body, the horizontal moving frame 3 will move under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com