Patents

Literature

42results about How to "Will not cause a collision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Robot system for micro-operation used for bio-medical engineering

The micro-operation robot system for biomedical engineering includes left and right operation tools which are respectively mounted on the left and right micro-operation hands which are controlled by left and right servo controllers and connected with computer to form micro-operation robot. Its camera head is mounted on the microscope and is connected with computer by means of image processing card, and can imput operation field image information into computer, according to the image information the relative position relationship between operation tools and operated object can be calculated bycomputer to produce operation instruction and implement real time control of left and right micro-operation hands.

Owner:BEIHANG UNIV

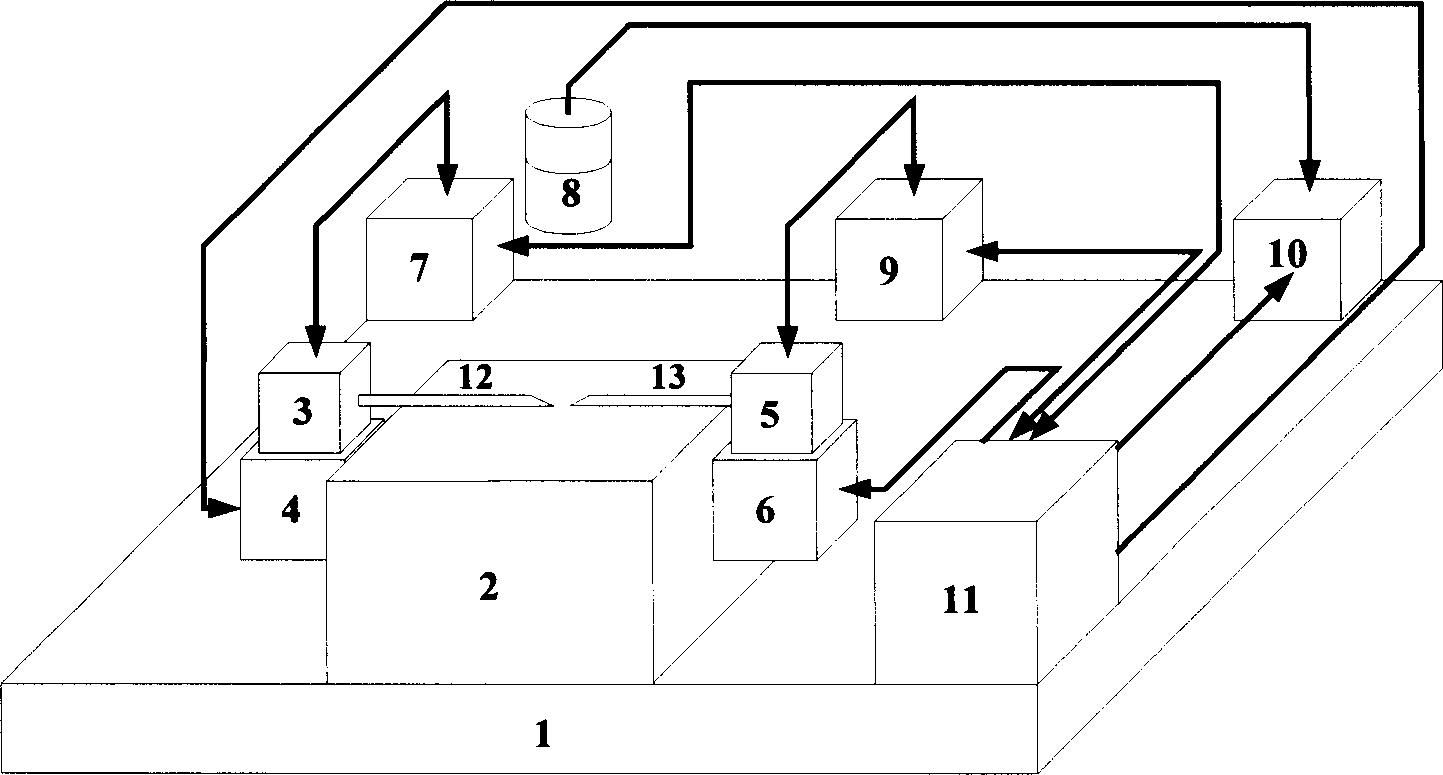

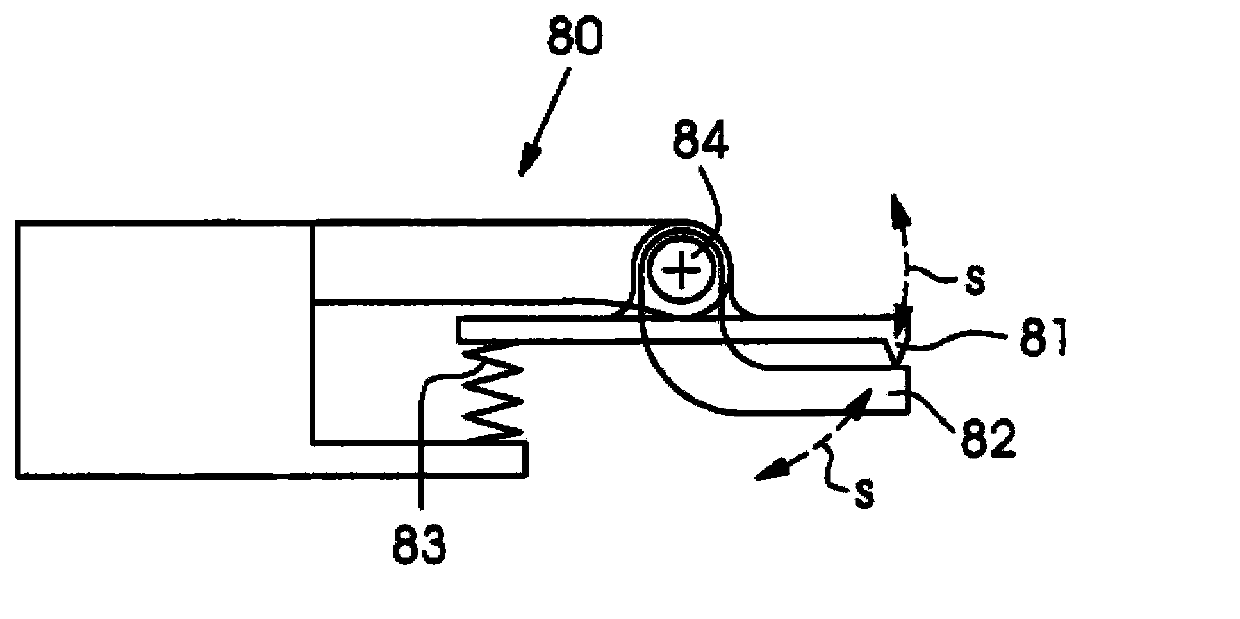

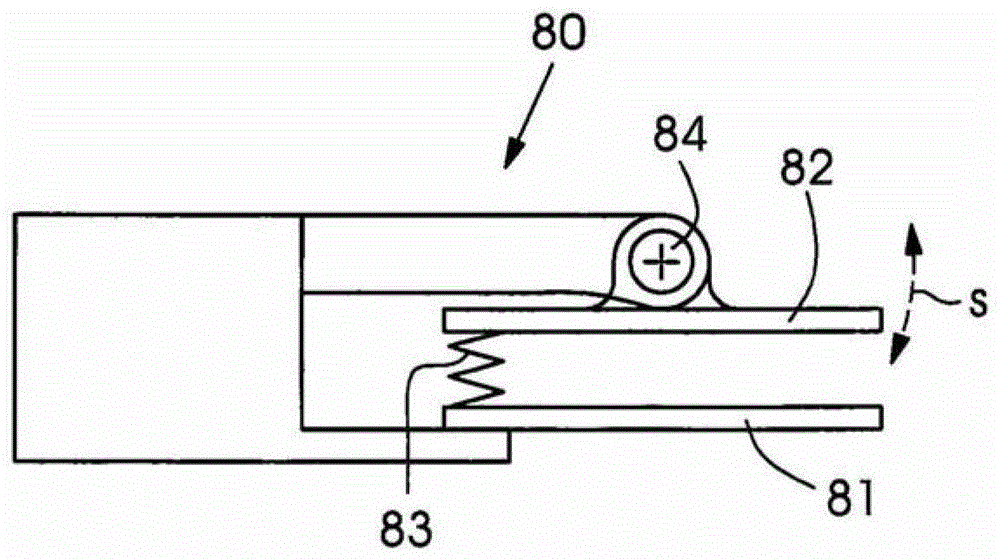

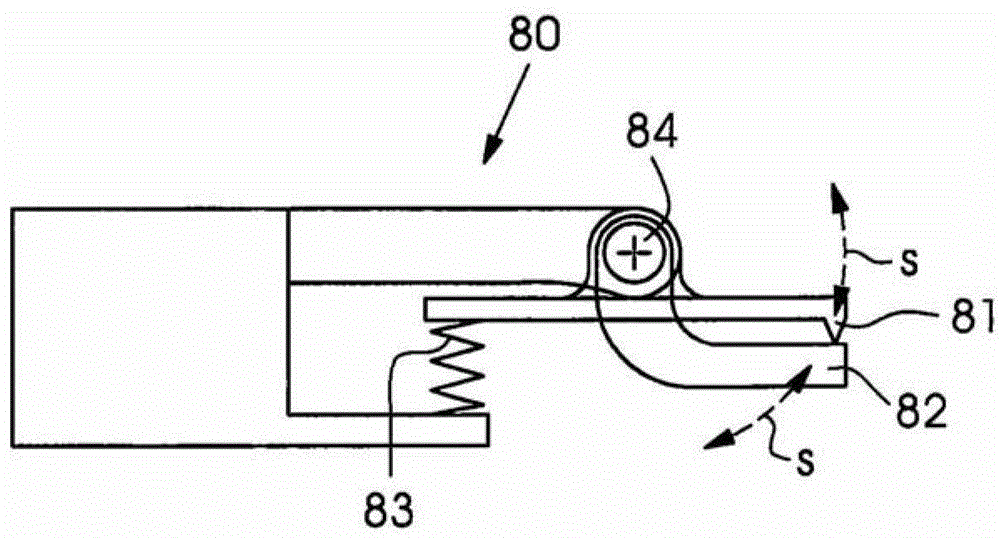

Micro-vision servo-control micromanipulation robot system

InactiveCN102477396AWill not cause a collisionAvoid damageBioreactor/fermenter combinationsMicromanipulatorSimulationMotion planning

The invention relates to a micro-vision servo-control micromanipulation robot system which comprises a left and a right operation tools respectively mounted on a left and a right micromanipulators; the left and the right micromanipulators are controlled by a left and a right servo controller, and are connected with a computer so as to form a micromanipulation robot; a camera is mounted on a microscope, is connected with the computer through an image processing card, and inputs operation site image information to the computer; the computer calculates relative position relation between the left and the right operation tools and an operation object according to the inputted image information, resolves control instructions of the left and the right micromanipulators, and performs motion planning and real-time control of the left and the right micromanipulators through the servo controller respectively. The characteristic of the invention is that the automation and intelligentization of microscopic operation are realized in biomedical engineering. The system has the characteristics of automatic obstacle avoidance, high positioning precision, large work space, high operation efficiency, friendly man-machine interface, and the like.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

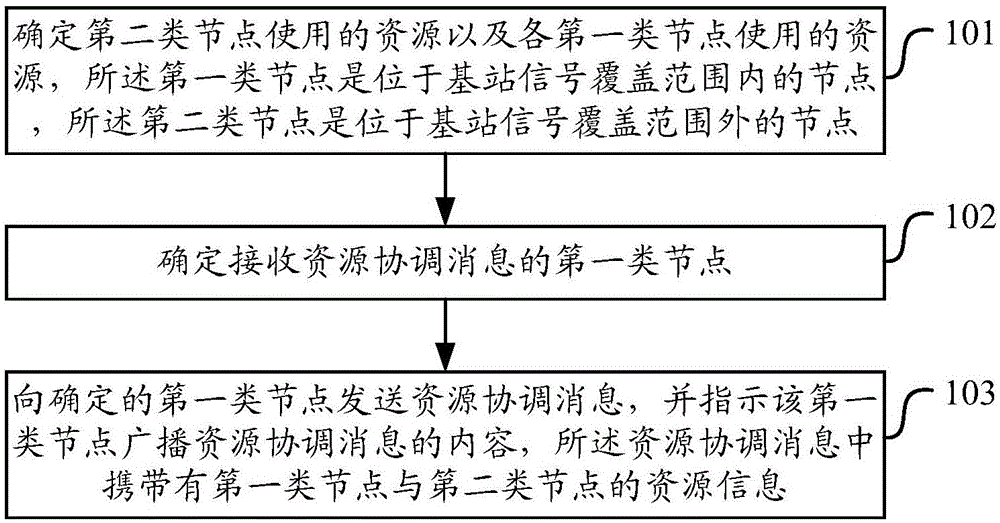

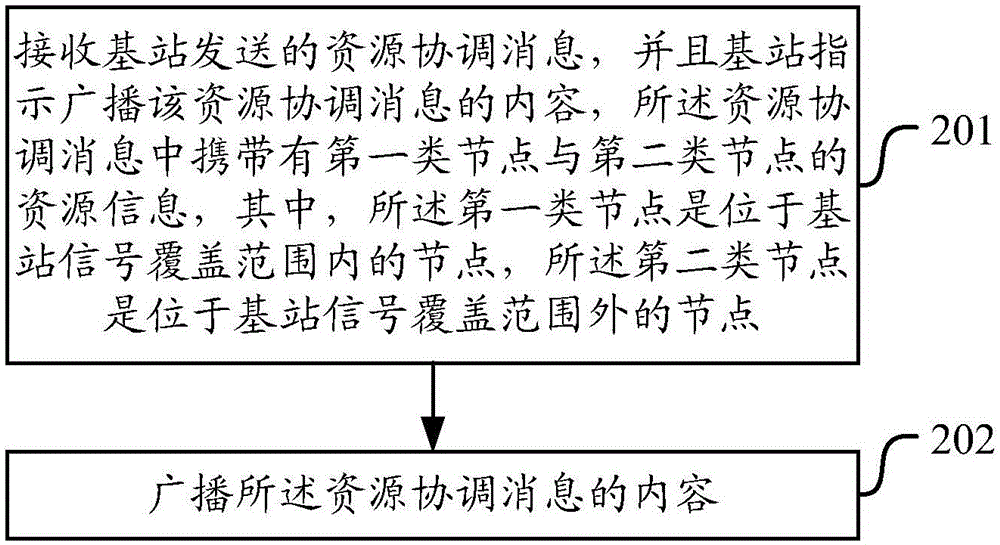

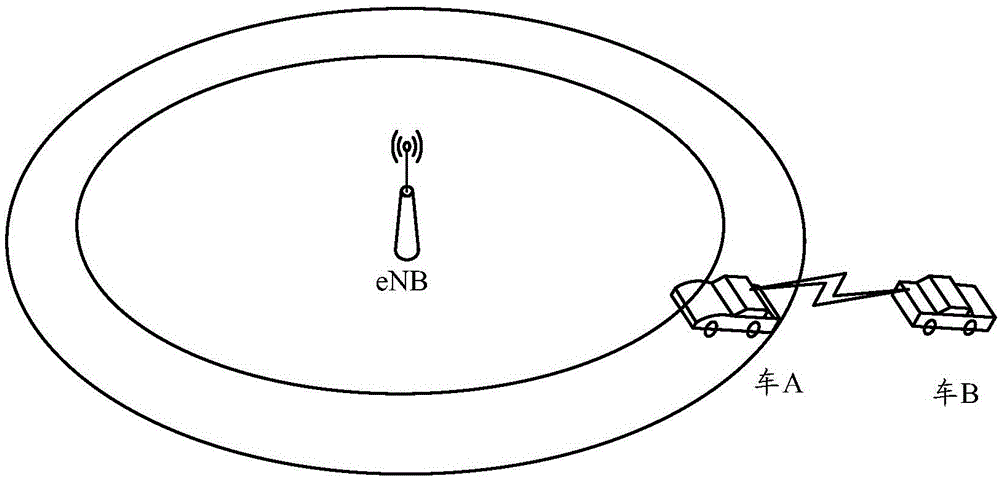

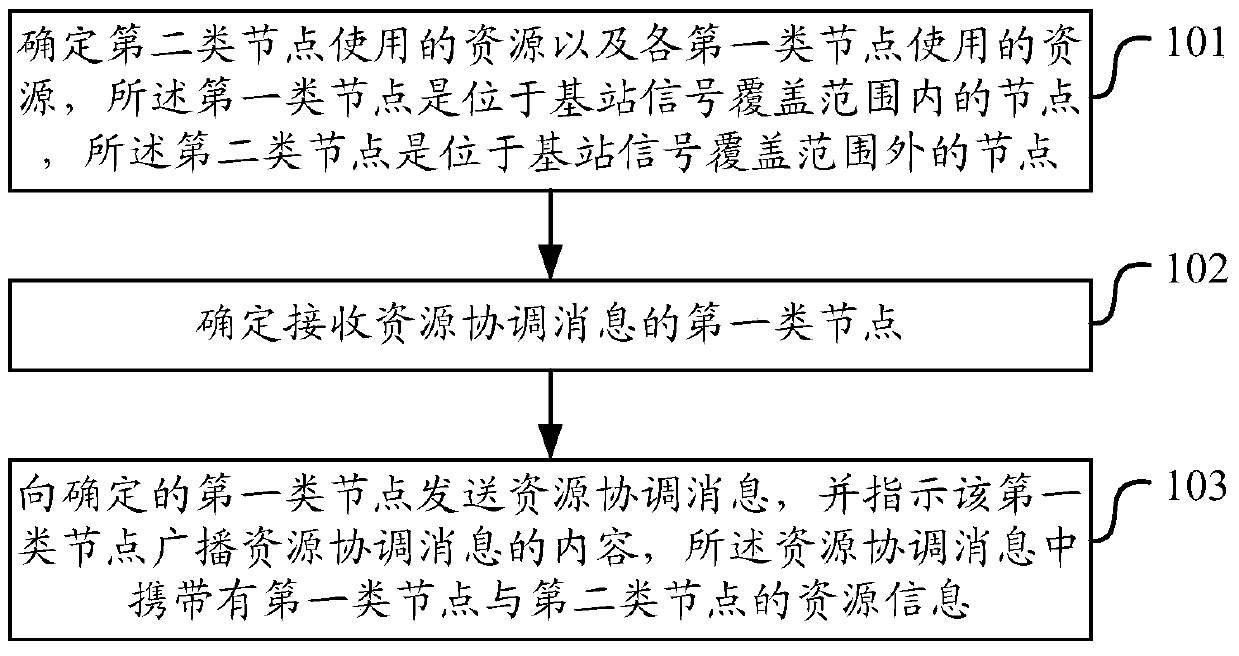

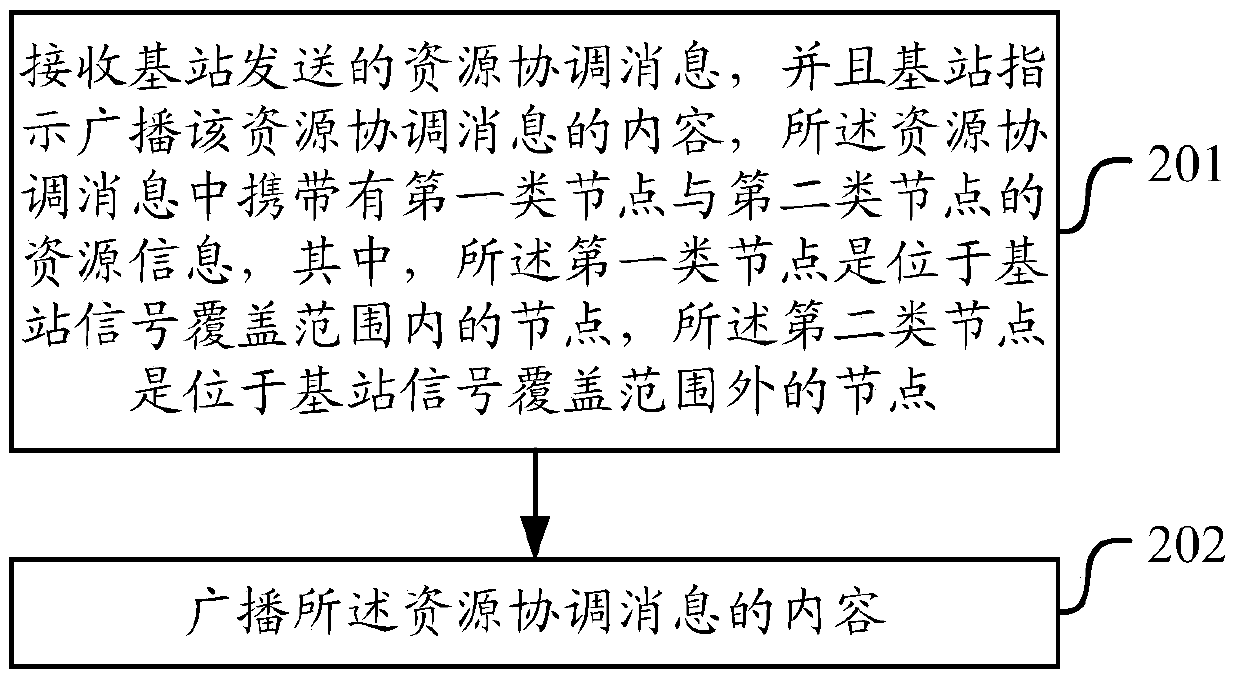

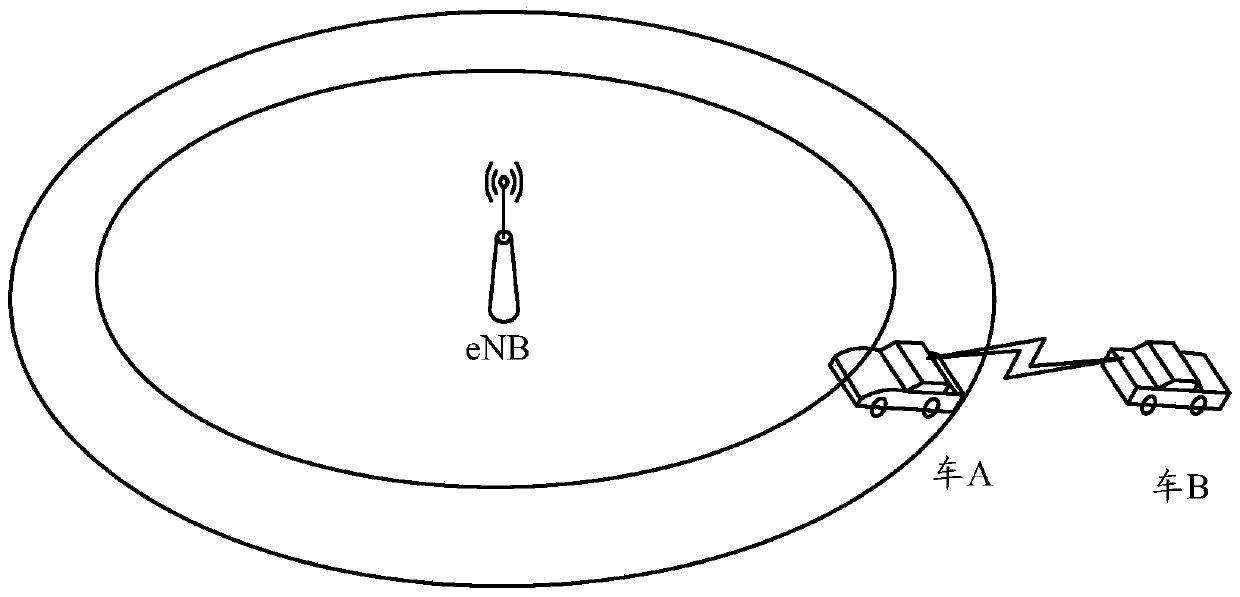

Resource information sending and broadcasting method and device

ActiveCN106454955AWill not cause a collisionAvoid transmission interruptionNetwork traffic/resource managementAssess restrictionResource coordinationResource information

The present invention discloses a resource information sending and broadcasting method and device. The resource information sending method comprises the steps of determining the resources used by the second kind of nodes and the resources used by the first kind of nodes, and determining the first kind of nodes of receiving the resource coordination messages, wherein the first kind of nodes are located within a base station signal coverage range, and the second kind of nodes are located beyond the base station signal coverage range; sending the resource coordination messages to the determined first kind of nodes, and indicating the first kind of nodes to broadcast the content of the resource coordination messages, wherein the resource coordination messages carry the resource information of the first kind of nodes and the second kind of nodes. According to the present invention, the resource continuity during the process that the nodes move at the network coverage edges, is guaranteed, the resource collision is reduced, and the utilization rate of the system resources is improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

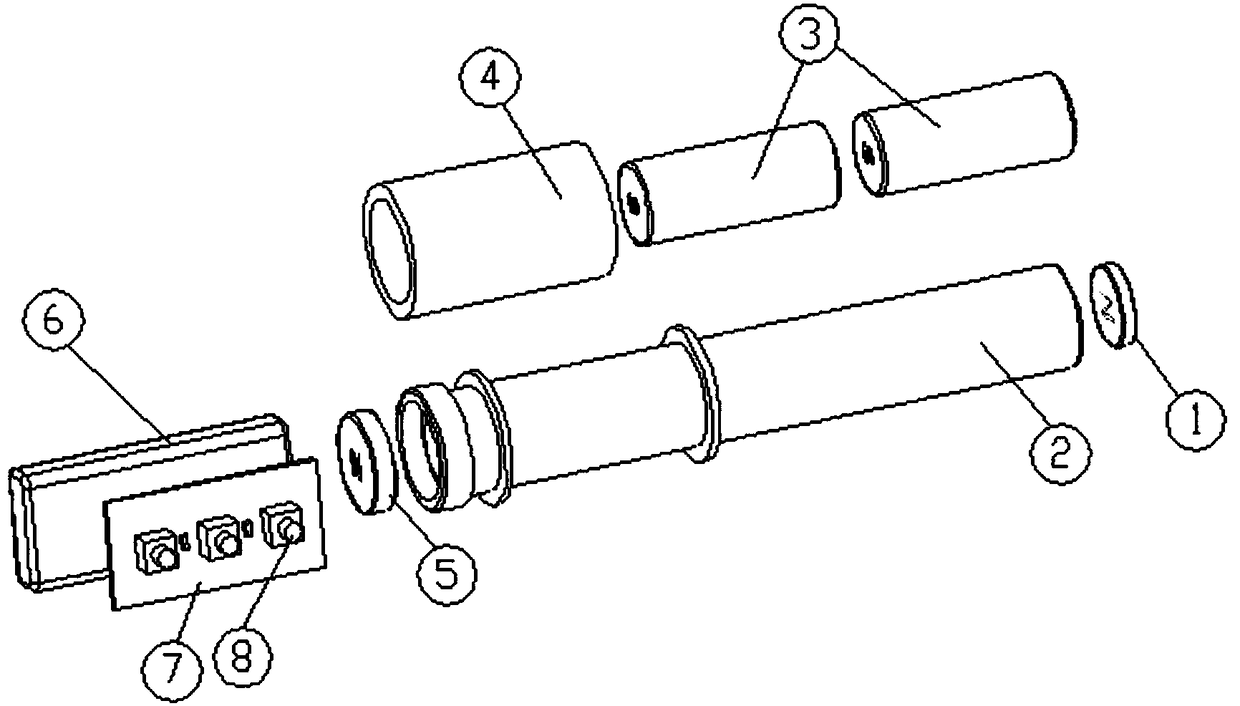

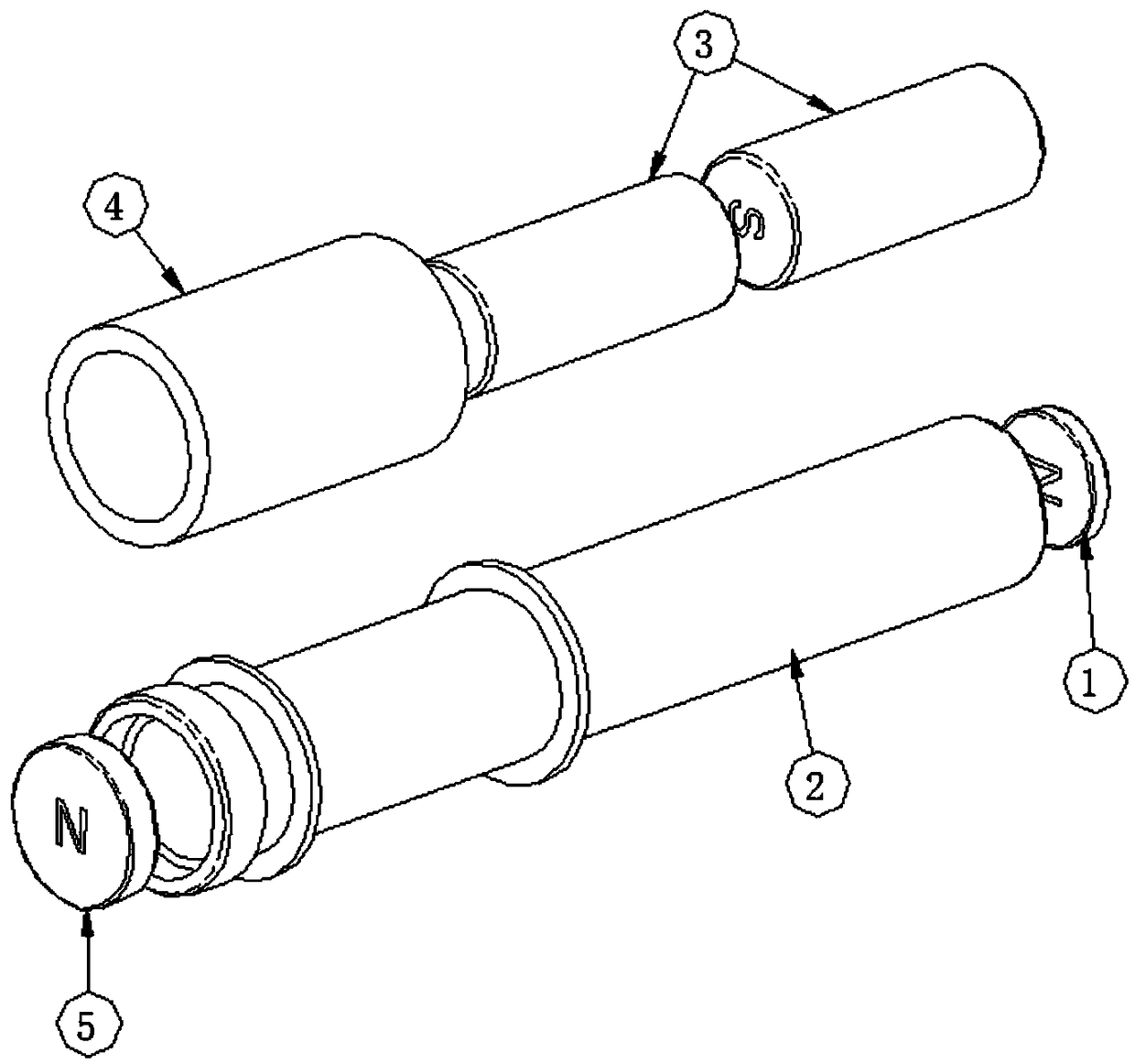

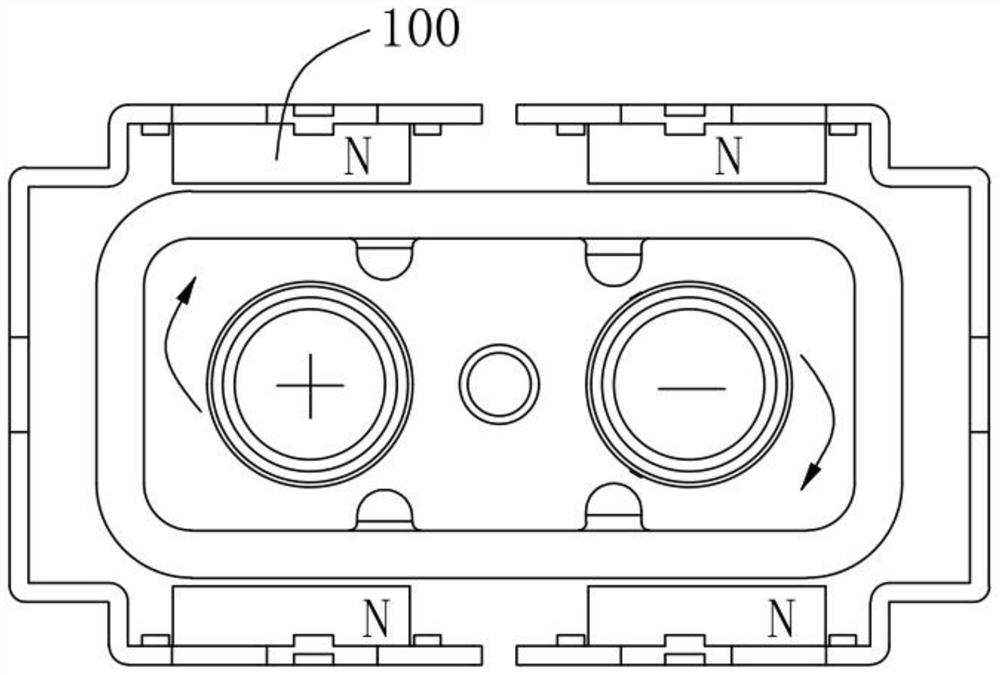

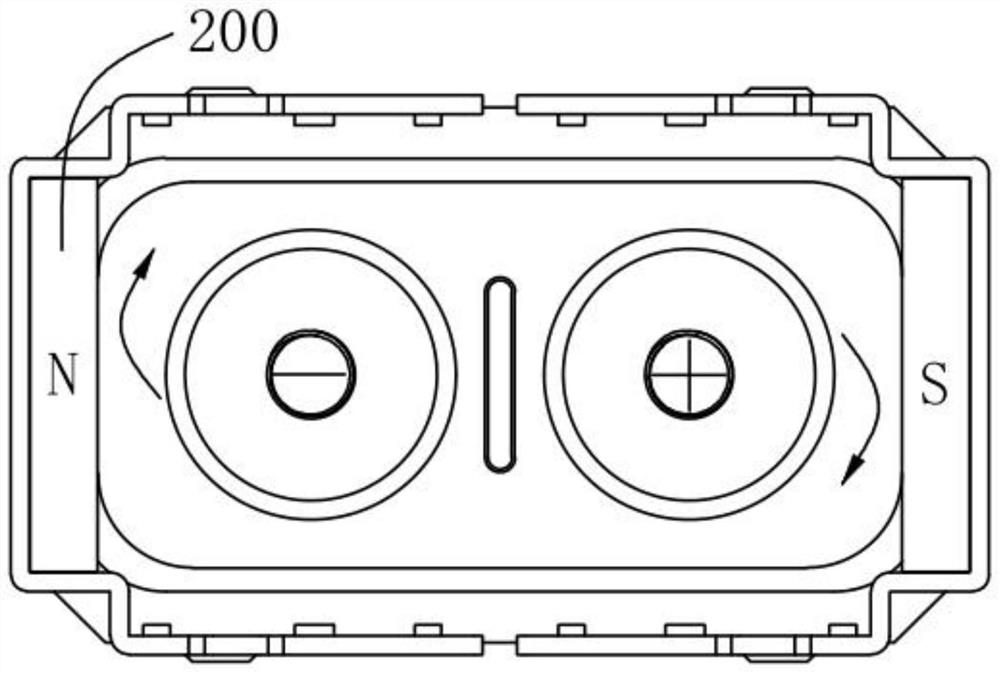

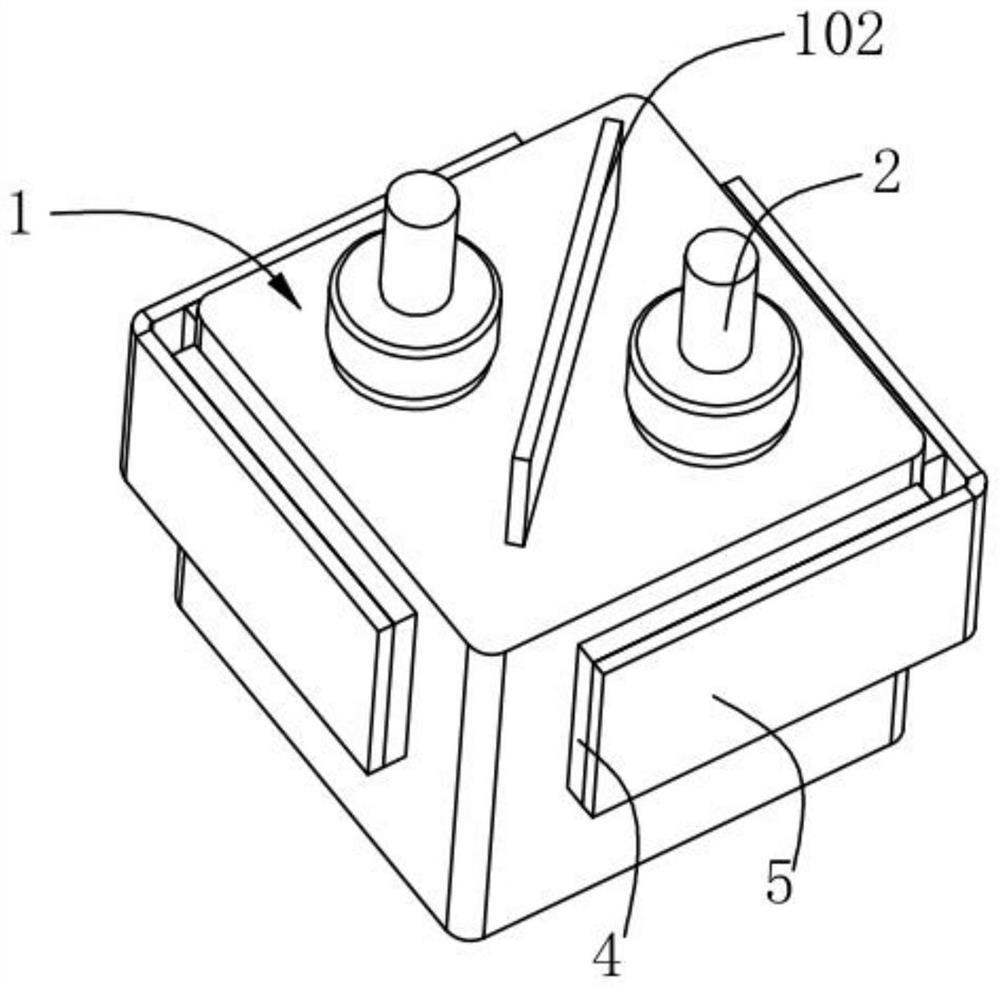

Magnetic impact massage hammer

PendingCN108392389ADifferent massage effectsReduce noiseVibration massageGenitals massagePower flowReciprocating motion

The invention discloses a magnetic impact massage hammer which comprises a shell, a frame, an impact magnet, a small repulsion force magnet, a large repulsion force magnet, a driving coil and an electronic control board. The frame is arranged in the shell, the impact magnet is placed in a cavity of the frame, the small repulsion force magnet and the large repulsion force magnet are mounted at twoends of the frame, the driving coil is wound on the frame and mounted on the periphery of one end of the large repulsion force magnet, the electronic control board controls alternating current of thedriving coil, the large repulsion force magnet and the small repulsion force magnet are mutually repelled with the opposite surface of the impact magnet, and the driving coil generates an intermittentmagnetic field under the action of the electronic control board after being powered on, so that the impact magnet can reciprocate along the axial direction of the frame. The size and the frequency ofthe current in the driving coil periodically change under control of the electronic control board, so that a massage hammer body axially and telescopically reciprocates, various high-frequency massage modes are achieved, and different massage effects are achieved.

Owner:TOPARC TECH SHENZHEN CO LTD

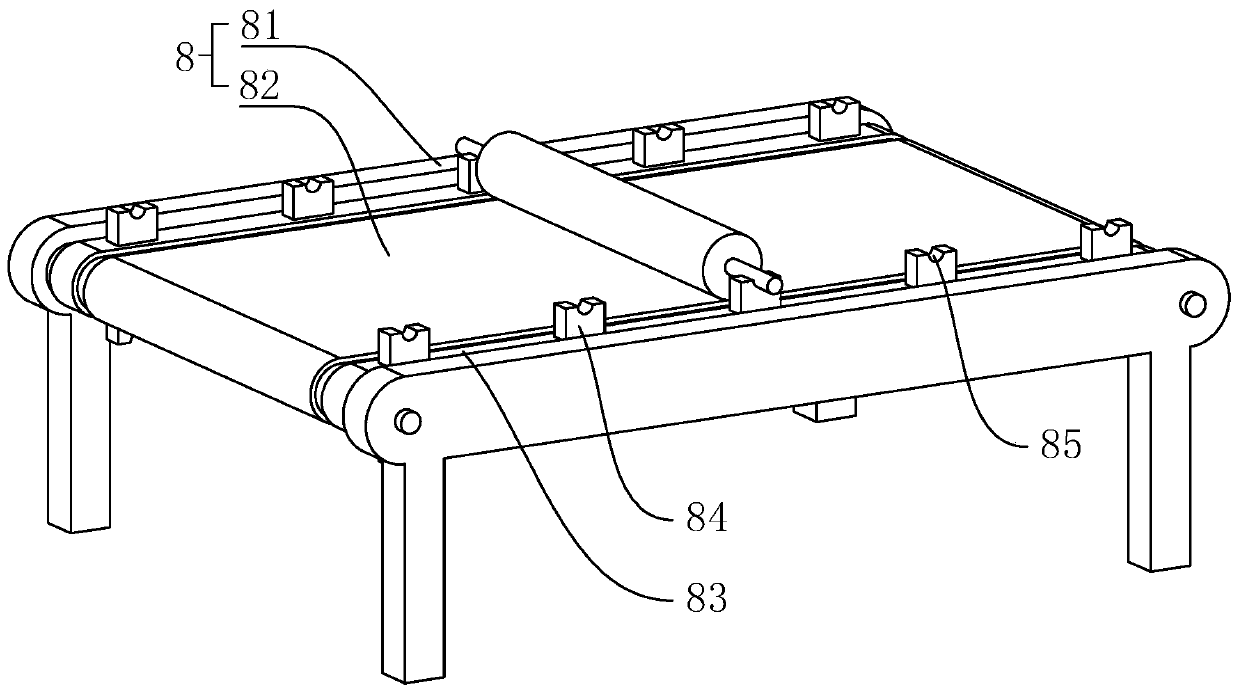

Copper plating production line for producing printing rollers

The invention relates to a copper plating production line for producing printing rollers. The copper plating production line for producing the printing rollers includes a support frame; a circular double speed chain is arranged on the support frame; a horizontal moving frame is connected to the circular double speed chain; a vertical moving frame is slidingly connected to the horizontal moving frame; the vertical moving frame includes a connecting plate, a pneumatic finger connected to the lower end of the connecting plate, and a roller body limit ring fixedly connected to the output end of the pneumatic finger; a pretreatment working section, an electroplating section and a cleaning section are arranged under the support frame in order along the moving direction of the roller body; and aloading device and an unloading device are arranged between the pretreatment working section and the cleaning section. According to the invention, when performing an electroplating operation on the roller body, the circular double speed chain can drive the horizontal moving frame and the vertical moving frame to move, and the roller body can be driven to move automatically during the movement process of the horizontal moving frame and the vertical moving frame, which cannot cause collision between the roller body and the machine body; and therefore, the relatively stable movement of the rollerbody can be ensured, and the quality of the roller body electroplating can be ensured.

Owner:太仓市施美电镀有限公司

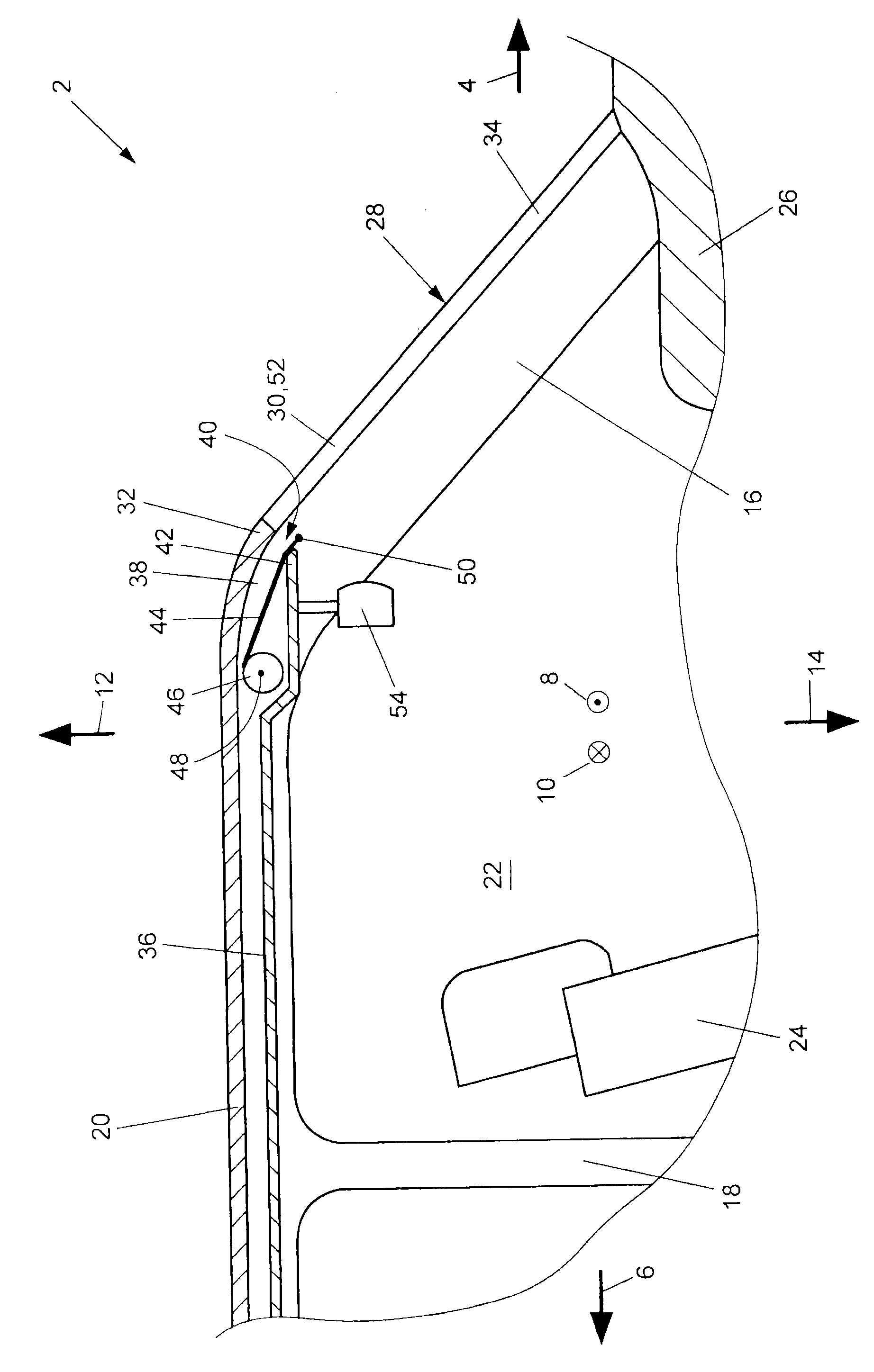

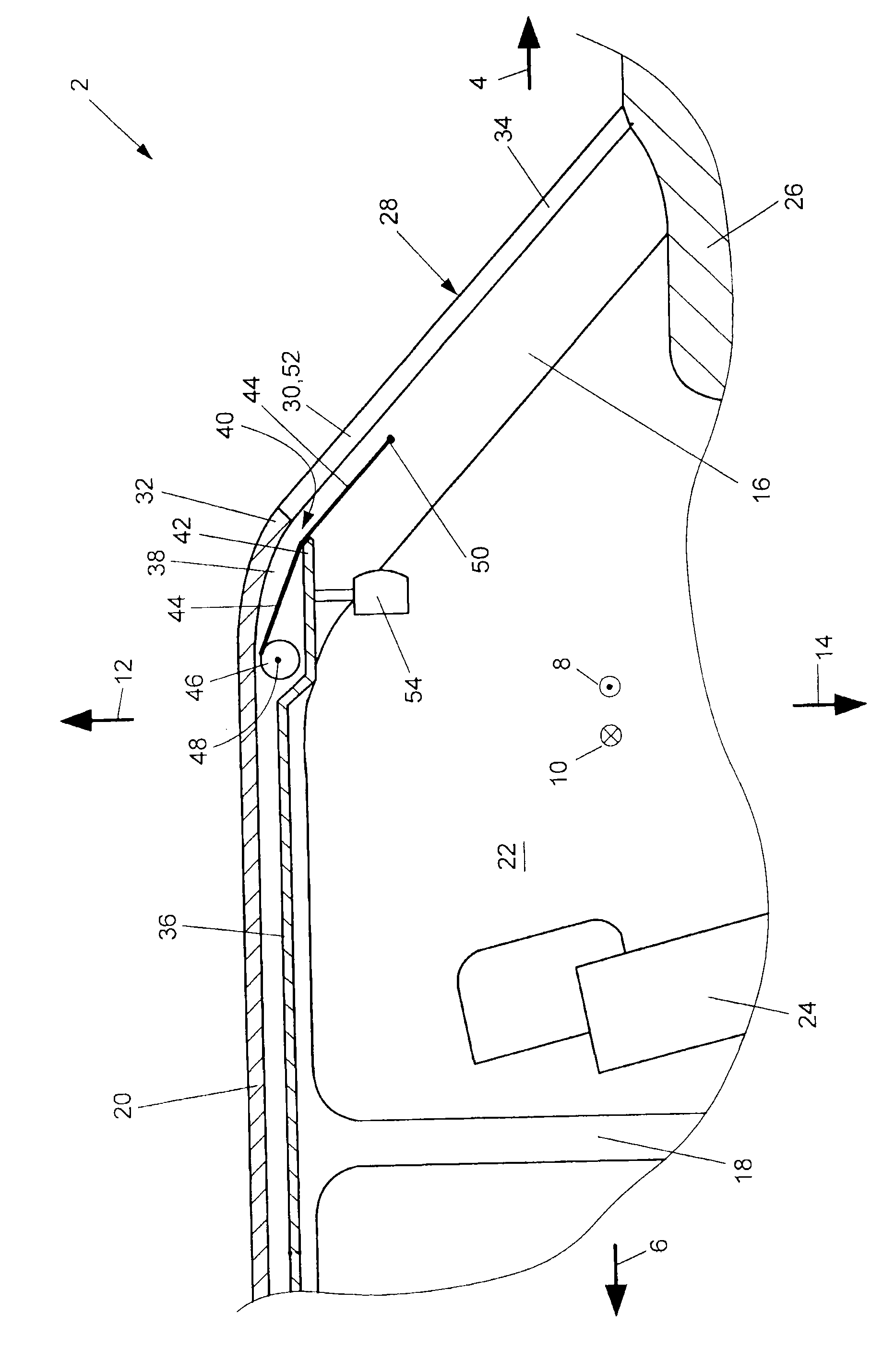

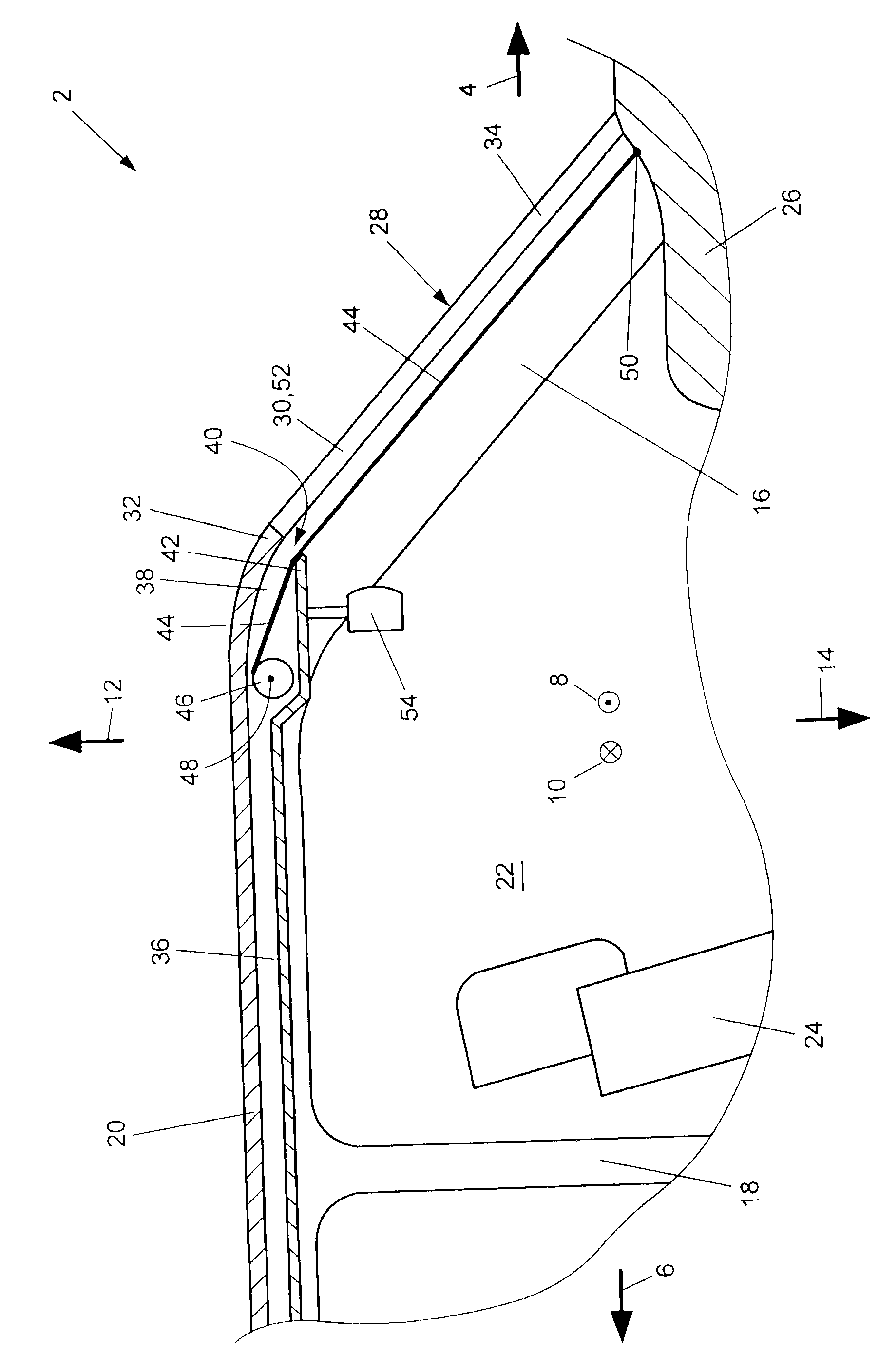

Motor vehicle having a window pane having a sun visor and a cover

A motor vehicle (2) is provided that has a window pane (28), preferably a windshield, which has an upper pane section (30) and a lower pane section (34). Furthermore, a sun visor (52) for the upper pane section (30) and a cover (44) are provided, which may be moved from a starting position via a first position, in which the cover (44) conceals the upper pane section (30), into a second position, in which the cover additionally conceals the lower pane section (34). The sun visor (52) is implemented as light-transparent in a way which attenuates the incident light through the upper pane section (30).

Owner:GM GLOBAL TECH OPERATIONS LLC

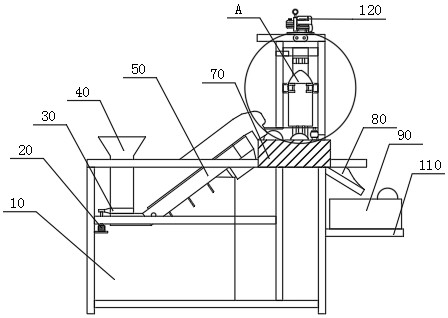

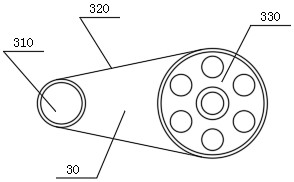

Apple net cover sleeving packaging machine suitable for small planting farmers

InactiveCN113148288AWill not cause a collisionAvoid touchingIndividual articlesPackaging fruits/vegetablesAgricultural scienceAgricultural engineering

The invention discloses an apple net cover sleeving packaging machine suitable for small planting farmers. The machine comprises a separation mechanism, and the separation mechanism comprises a transmission wheel, a belt and a driven mechanism; the driven mechanism is fixedly connected to the bottom end of a feeding hopper and used for placing apples; the transmission wheel is rotationally connected to the upper end of a motor and used for driving the driven mechanism to rotate; and the belt is rotationally connected between the transmission wheel and a driven wheel. On the basis of achieving apple net cover sleeving automatic packaging, the apple net cover sleeving packaging machine is small in size, low in cost and suitable for the fruit farmers planting the apples in a small area, and compared with an existing packaging machine, the packaging machine has the advantages that even if too many apples are poured into a feeding opening of the packaging machine at a time, collision between the apples cannot be caused, and the damage to the apples is reduced.

Owner:张小刚

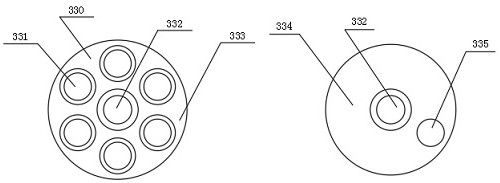

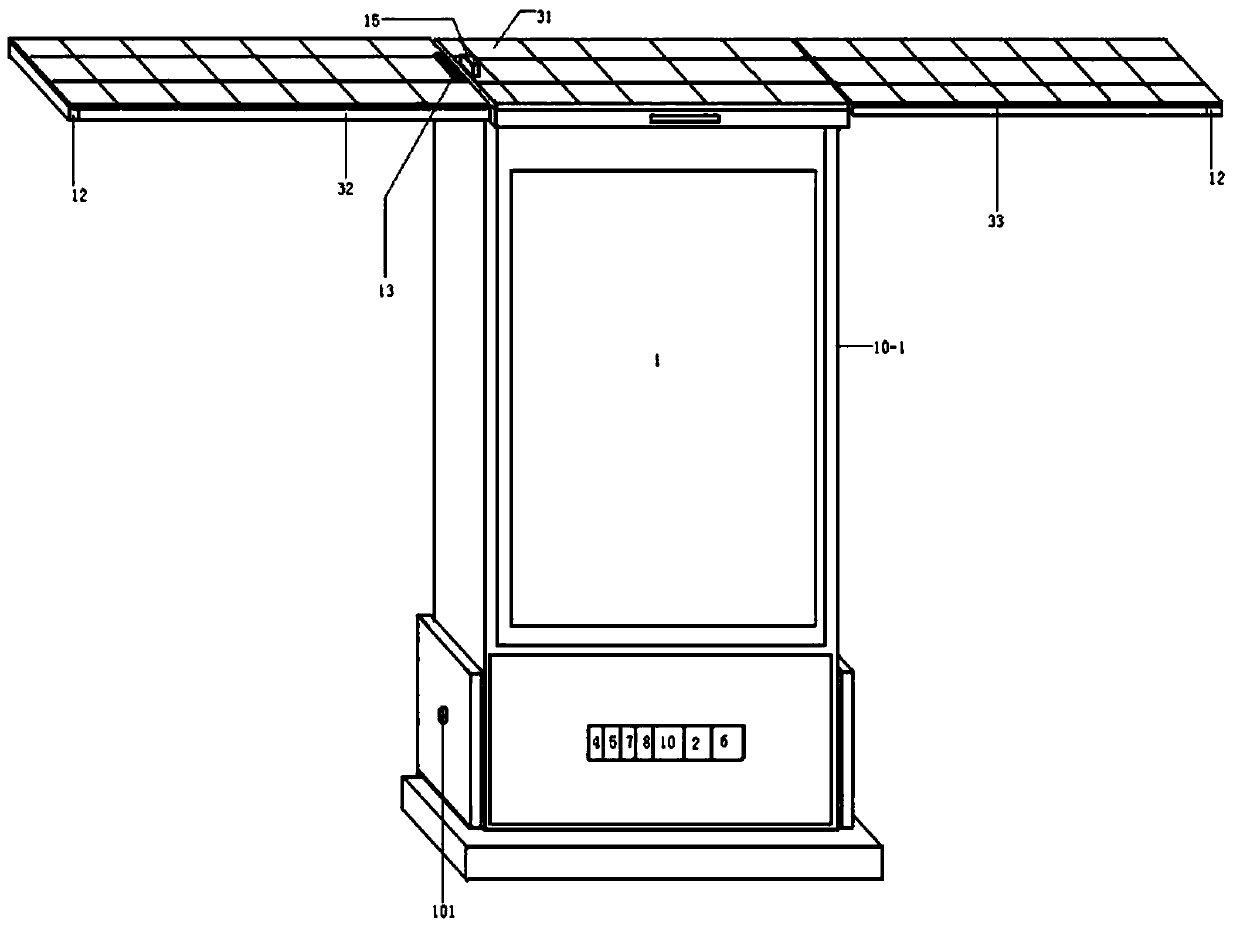

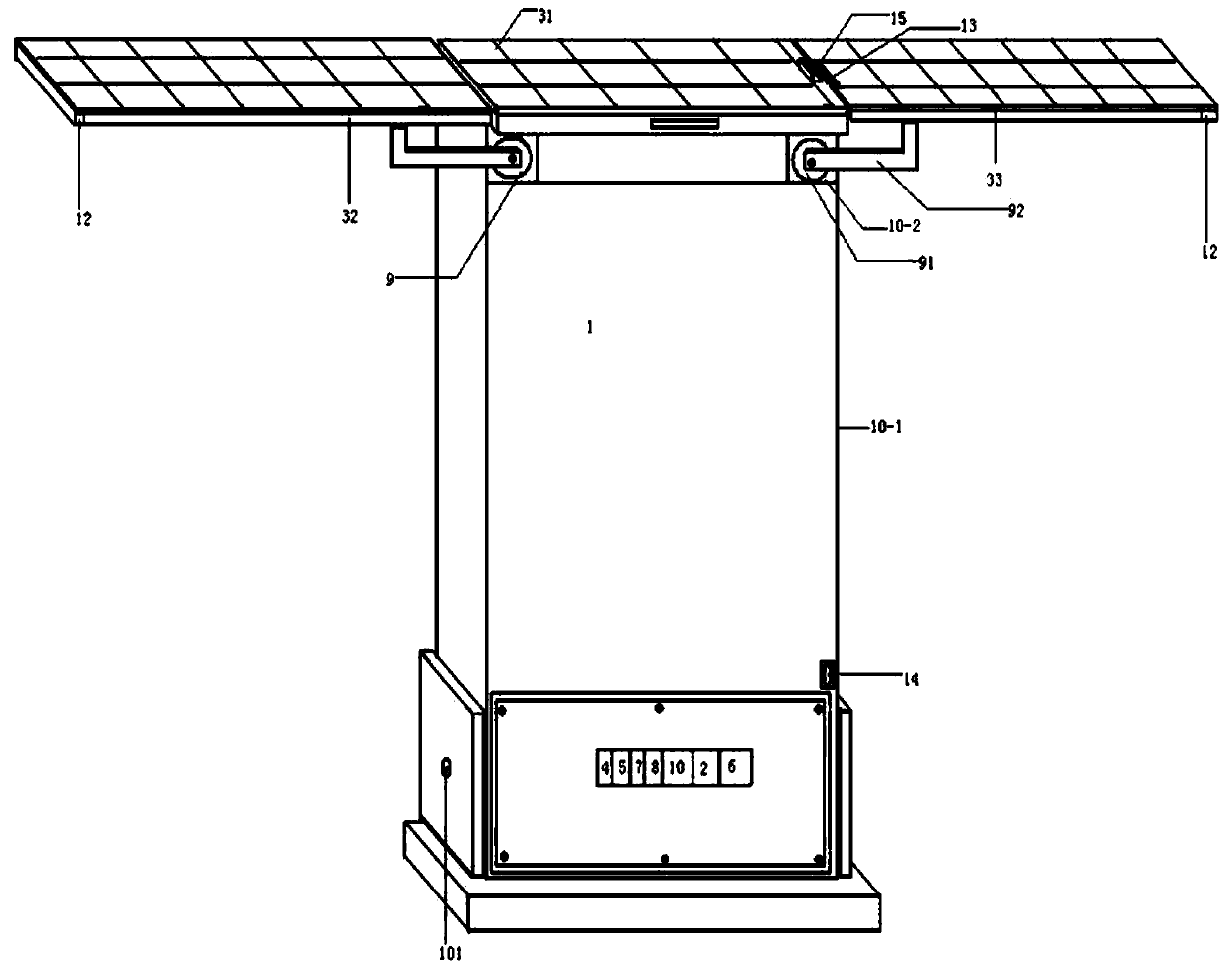

Intelligent internet convergence media broadcast exhibition machine

ActiveCN110364081AGuaranteed electricity needsMeet electricity needsPhotovoltaic supportsBatteries circuit arrangementsPower inverterMotor speed

Disclosed is an intelligent internet convergence media broadcast exhibition machine; the intelligent internet convergence media broadcast exhibition machine comprises an internet convergence media broadcast exhibition machine body, a switching power supply, solar panels, a time control switch, a storage battery, a power inverter, a conversion relay and a micro electro-acoustic conversion device, and also comprises a driving mechanism and light control circuits, wherein one solar panel is arranged at the upper end of the shell of the convergence media broadcast exhibition machine body, and theother two solar panels are hinged to the left side end and the right side end of the shell respectively; the photoelectric switches of the two sets of the light control circuits are arranged at the lower parts of the left side and the right side of the shell respectively, and motor speed reducing mechanisms of the driving mechanism are installed in two grooves of the shell; permanent magnets are arranged on the inner sides of the lower ends of the second solar panel and the third solar panel and the middle of the upper end of the outer side of the second solar panel respectively; reed pipes are arranged on the left end of the back side and the middle of the left end of the upper side of the shell respectively; and the switch power supply, the time control switch, the power inverter, the conversion relay, the micro electro-acoustic conversion device and the rest of the light control circuits, and the storage battery are arranged in the shell of the convergence media broadcast exhibitionmachine body and are connected with the shell through wires.

Owner:黑龙江钉子科技有限公司

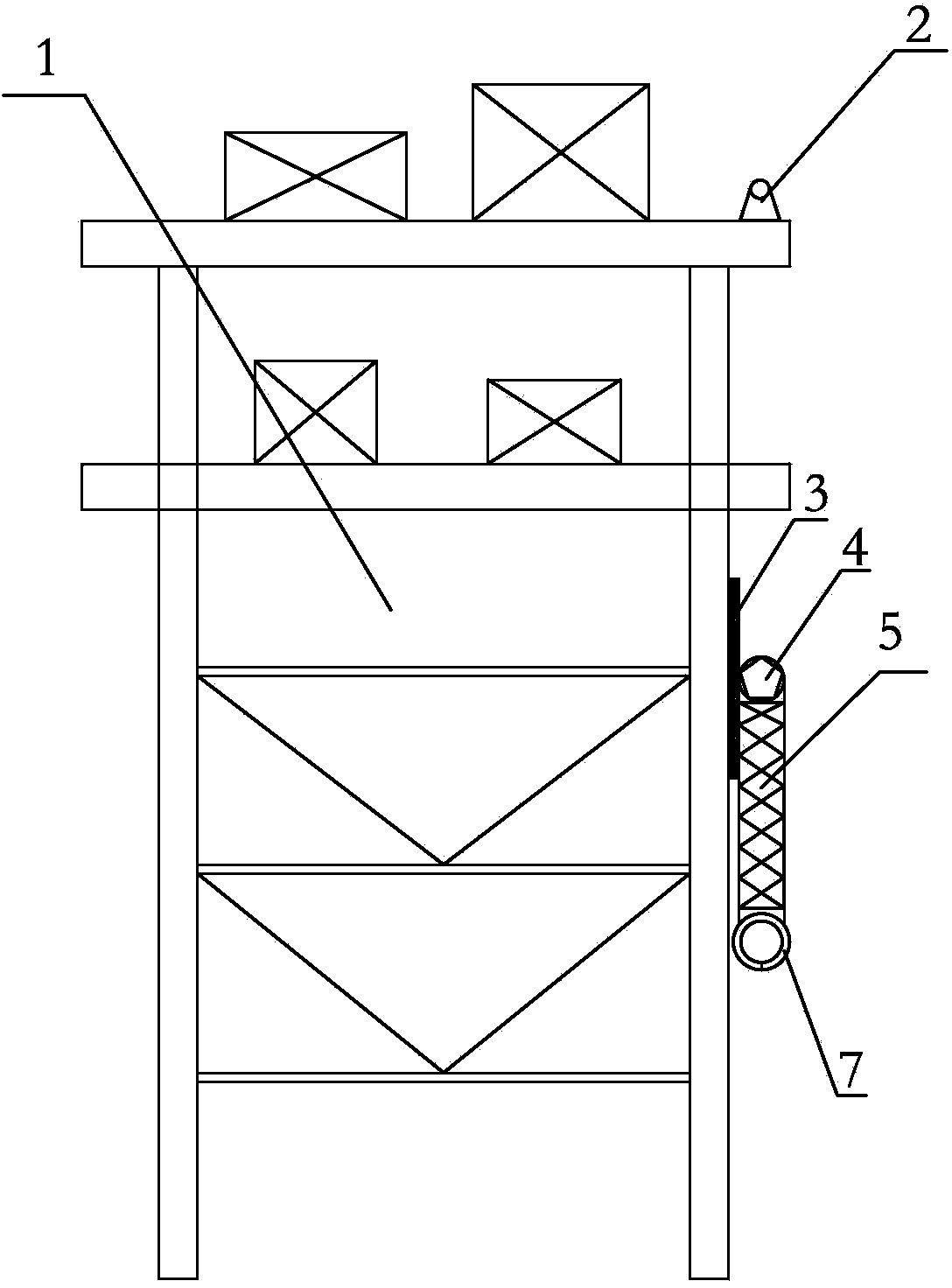

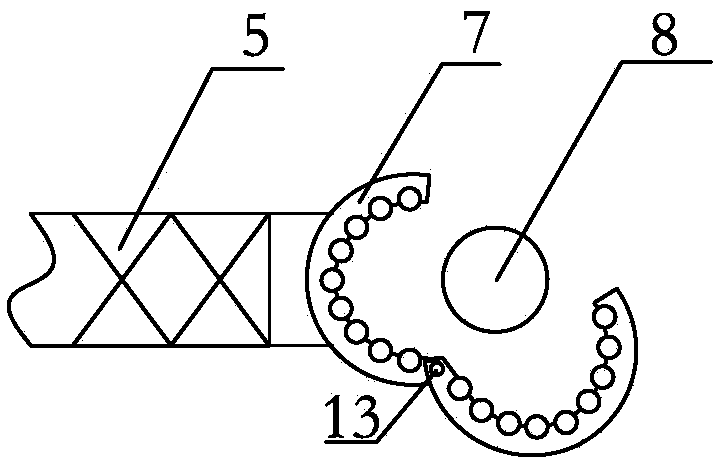

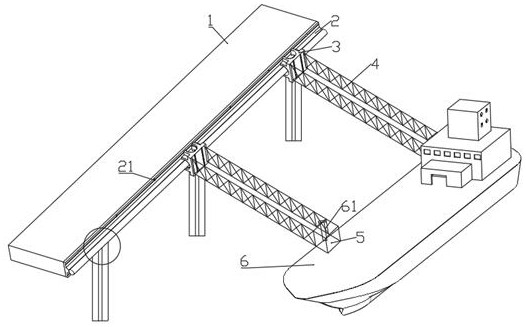

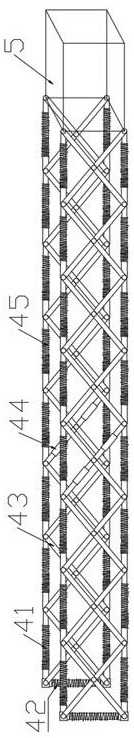

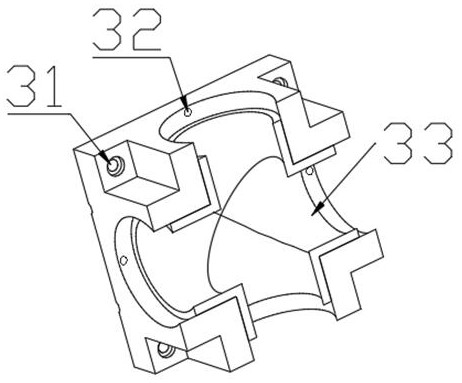

Cantilever-type slidable anti-collision connection device for ship berthing platform

InactiveCN104179153AReduced chance of impact damageGuaranteed service lifeClimate change adaptationShipping equipmentManipulatorCushion

A cantilever-type slidable anti-collision connection device for a ship berthing platform is characterized in that a winch is fixed over the platform, a bidirectional shaft is fixed to the side of the platform, one end of a lattice boom is connected with the bidirectional shaft, and a manipulator is disposed at the other end of the lattice boom, the lattice boom is formed by connecting hydraulic dampers in order, the manipulator is formed by connecting two semicircular rings through a hinge, a steel ball with a retainer is arranged within the manipulator, a rubber cushion layer is arranged between the manipulator and the steel ball, and another rubber cushion layer is fixed between the side of the platform and the bidirectional shaft. The ship connection end of the cantilever-type slidable anti-collision connection device is capable of sliding up and down and rotating, so that damage of connections caused by a ship floating in sea currents and waves during berthing can be prevented. The cantilever-type slidable anti-collision connection device is used a safety distance away from the ship, so that no collision between the ship and the platform occurs. The lattice boom is capable of extending and retracting, an operation range of the ship can be guaranteed to the maximum extent; a hydraulic damping system is mounted in the lattice boom, and the service life of the cantilever-type slidable anti-collision connection device is prolonged. The cantilever-type slidable anti-collision connection device is simple in structure, convenient to use and safe and reliable.

Owner:DALIAN UNIV OF TECH

Cleaning device for electronic technological product accessory

InactiveCN108856082AEasy to useWill not cause a collisionCleaning using liquidsSpray nozzleIndustrial engineering

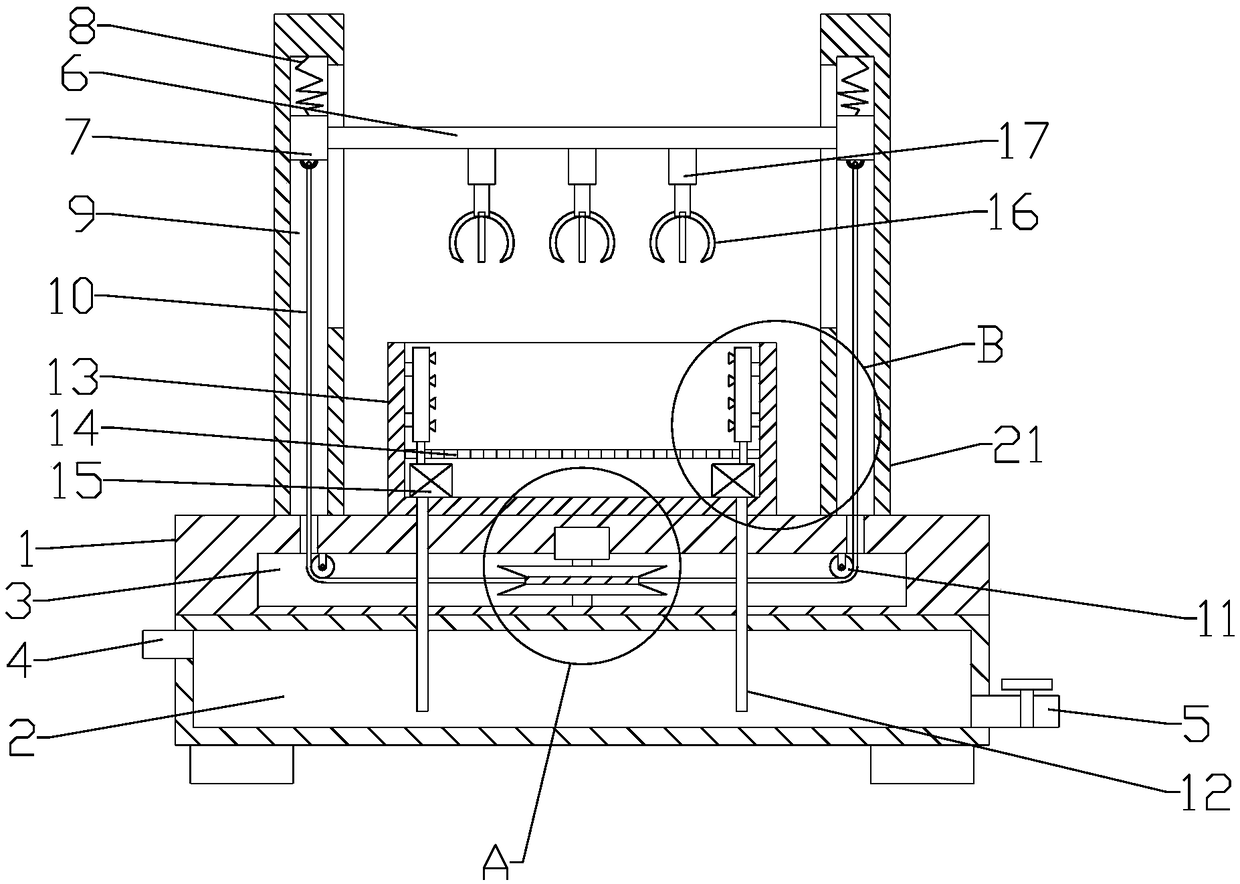

The invention discloses a cleaning device for an electronic technological product accessory. The cleaning device for the electronic technological product accessory comprises a base, a cleaning liquidcavity, a power cavity, a lifting cross beam, rectangular sliding blocks, springs, a rigid stay cord, a cleaning box, mechanical grippers, spray nozzles, support stand columns and a winding wheel. According to the cleaning device for the electronic technological product accessory, through cooperative use of the lifting cross bean, the rectangular sliding blocks, the springs, the rigid stay cords,the cleaning box, the mechanical grippers, the spray nozzles, the support stand columns and the winding wheel, the mechanical grippers can isolate and fix the electronic product accessories and protects the electronic product accessories against collision, it is avoided that the electronic product accessories collide during cleaning and are damaged, and normal use of the electronic products is guaranteed; and due to use of a water pump and the spray nozzles, the electronic product accessories can be comprehensively cleaned, it is guaranteed that the electronic product accessories are thoroughly cleaned, and the problem that the cleaning effect of a cleaning device is poor is solved.

Owner:苏州和必尔斯电子科技有限公司

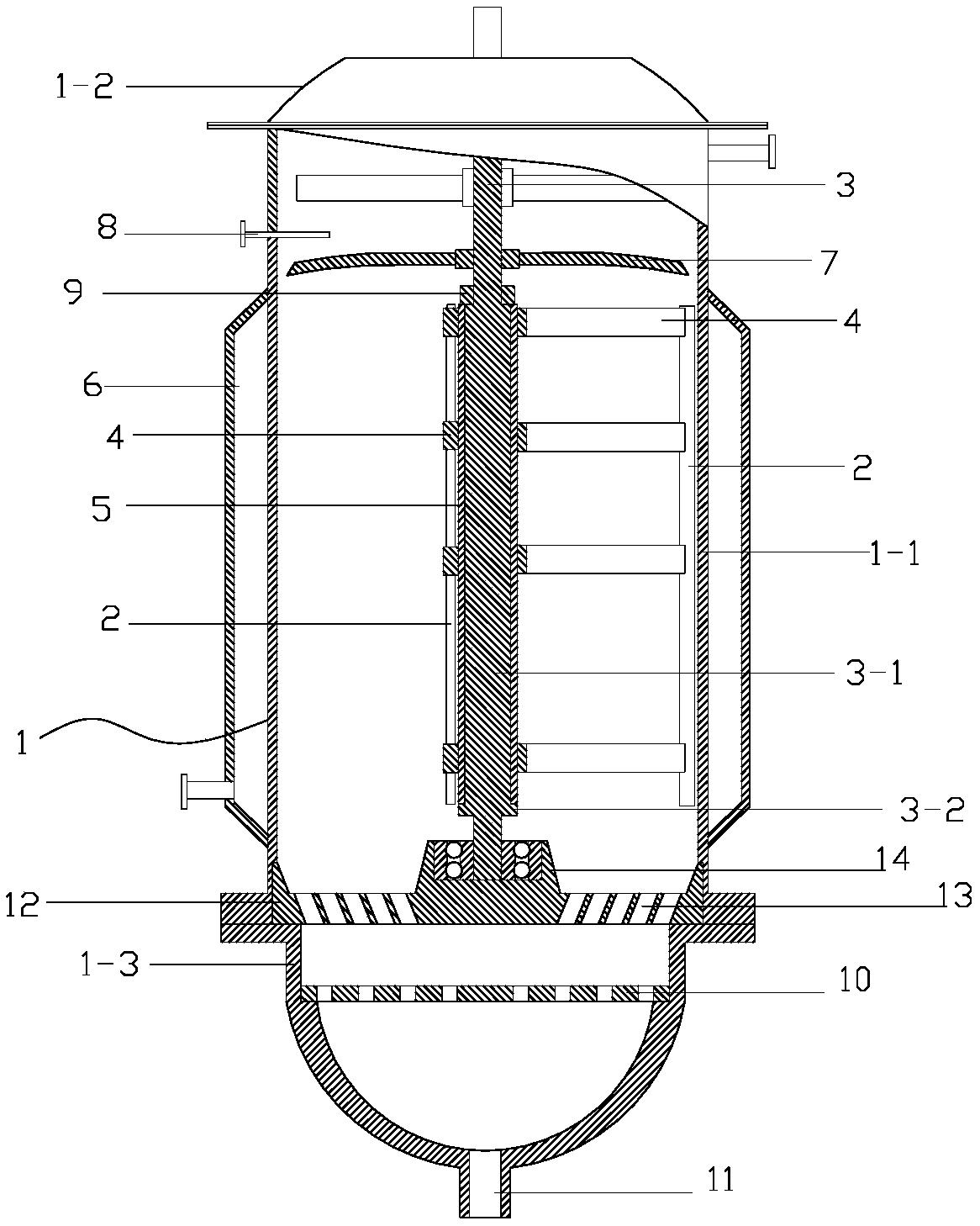

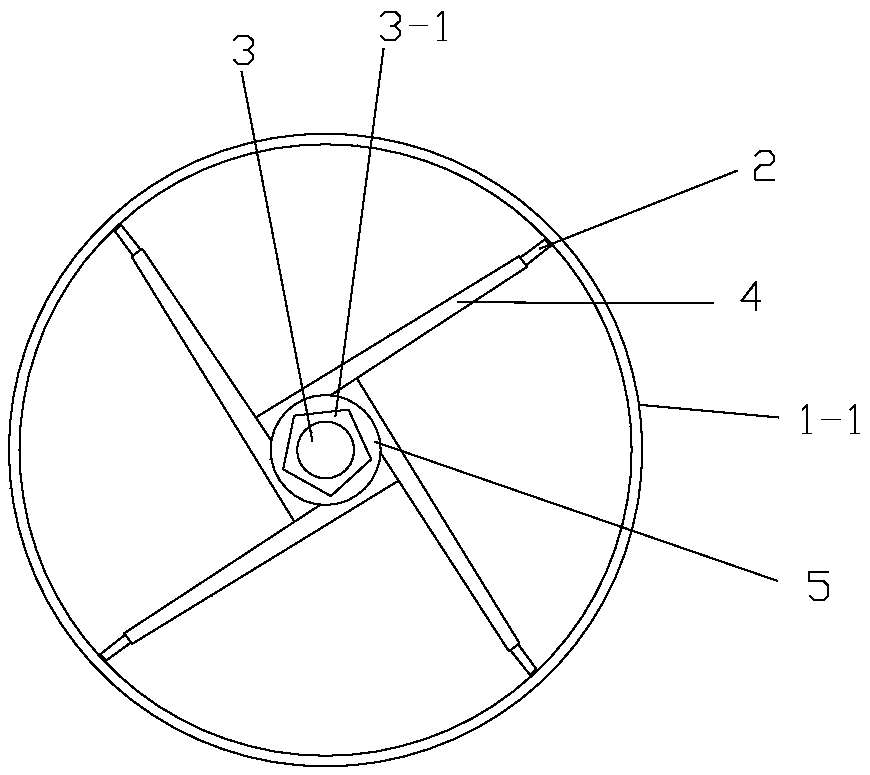

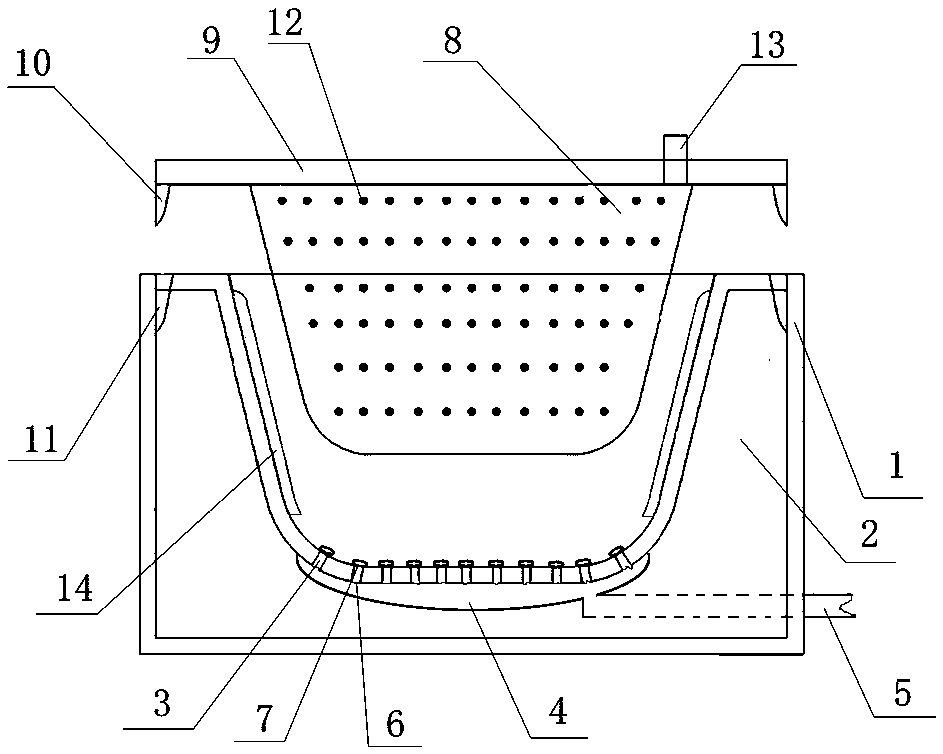

Plant polyphenol concentrating device

InactiveCN108671569ASimple structureEasy to useEvaporator accessoriesBiochemical engineeringPolyphenol

The invention discloses a plant polyphenol concentrating device. The plant polyphenol concentrating device comprises a tank and a scraper mechanism arranged in the tank; the tank comprises a tank body, an upper cover and a lower cover; the tank body is of an inner hollow structure; a jacket used for a steam chamber is formed on the outer side of the tank body; the lower cover is connected with a lower opening of the tank body; a lower support plate supported on the lower cover is arranged at the lower opening of the tank body; liquid guiding holes, for guiding concentrated liquid into the lower cover, are formed in the lower support plate; and a support platform, for running fit with the lower end of a rotating shaft, is arranged on the lower support plate; the device is simple in structure and convenient to use; through the arrangement of the lower support plate and the support platform arranged on the lower support plate, the lower end of the rotating shaft can be matched with the support platform in a running fit manner, so that the lower end of the rotating shaft is less likely to sway during a working process, and a collision between scrapers and the inner wall of the tank isavoided, a concentration effect is ensured, the damage to the scrapers or the inner wall of the tank is reduced, and the service life is greatly prolonged.

Owner:重庆市洲仨科技发展有限公司

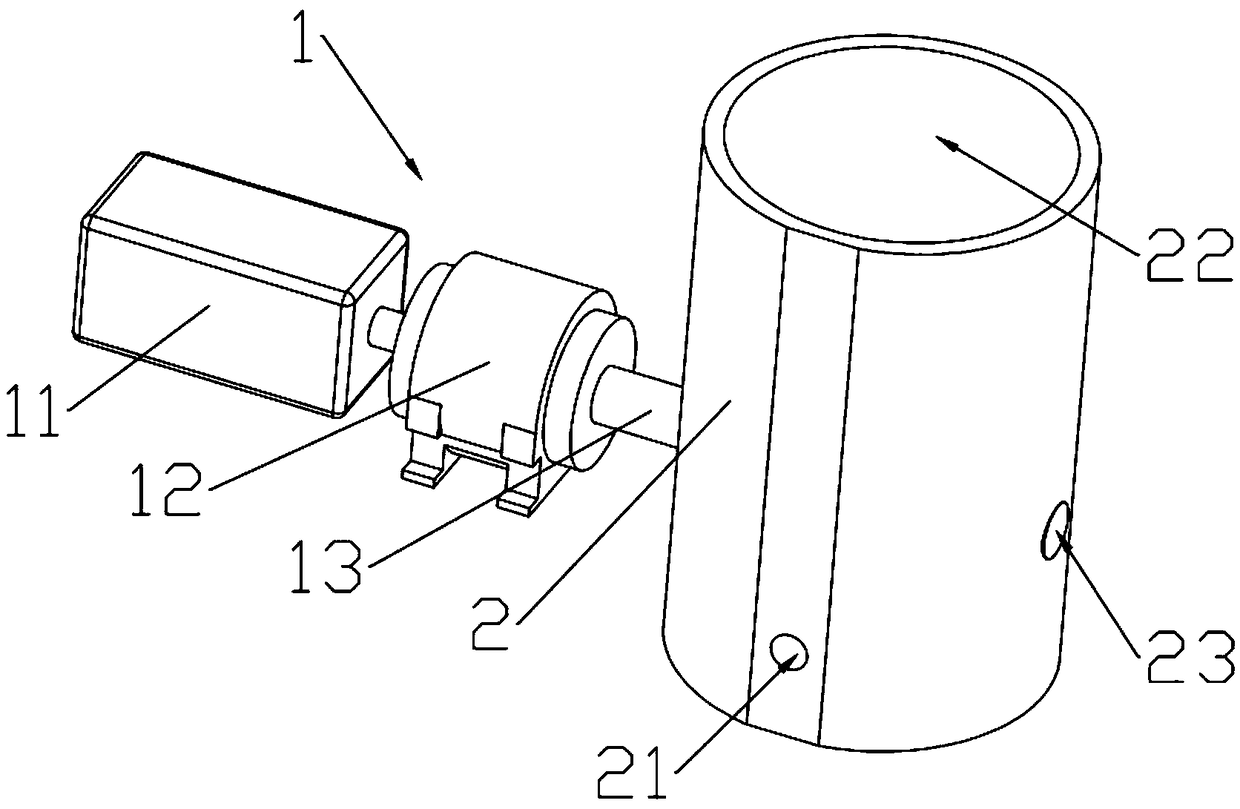

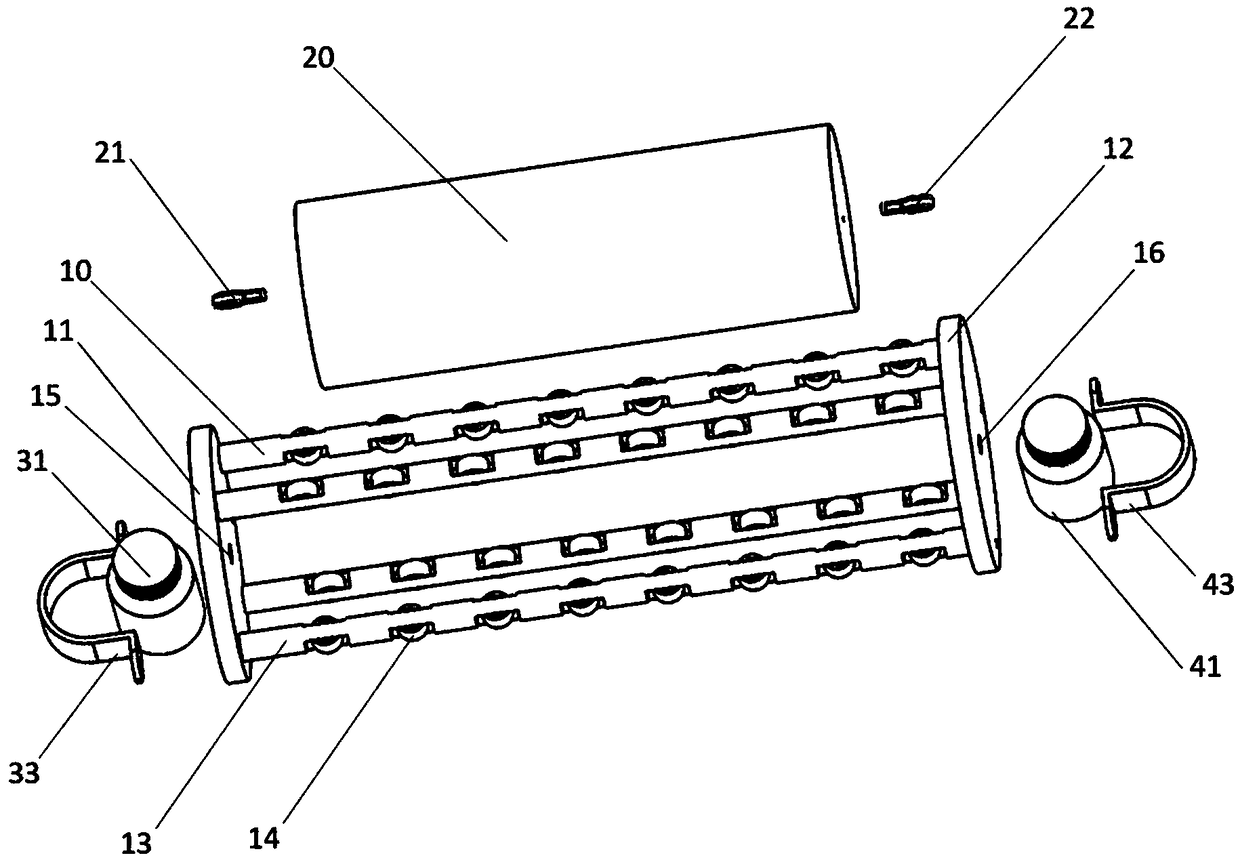

Ball loading device

InactiveCN109335740AEasy linear motionLinear motion does not causeConveyorsLoading/unloadingReduction driveEngineering

The invention relates to an automatic ball loading device. The ball loading device comprises a loading cylinder and a driving mechanism; the loading cylinder comprises a storage cavity and an output channel; the storage cavity and the output channel are positioned in the loading cylinder; the storage cavity communicates with the output channel; the output channel communicates with the external; the driving mechanism comprises a driving motor, a speed reducer and an output shaft; an output end of the driving motor is rotationally connected with the speed reducer; an output end of the speed reducer is rotationally connected with the output shaft; the output shaft penetrates through the loading cylinder; and a stirring wheel is arranged on the output shaft, and is aligned to the output channel. The ball loading device is simple in structure, convenient to assemble, higher in ball conveying speed and easy to enable balls to linearly move, cannot cause collision between the balls to preventinfluence on subsequent steps, meanwhile, saves the labor cost, and cannot block the balls in the output channel.

Owner:东莞市国森科精密工业有限公司

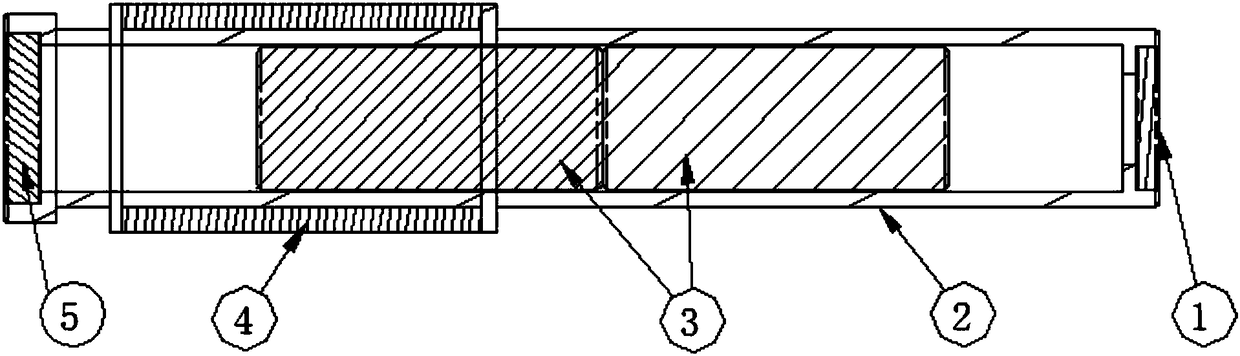

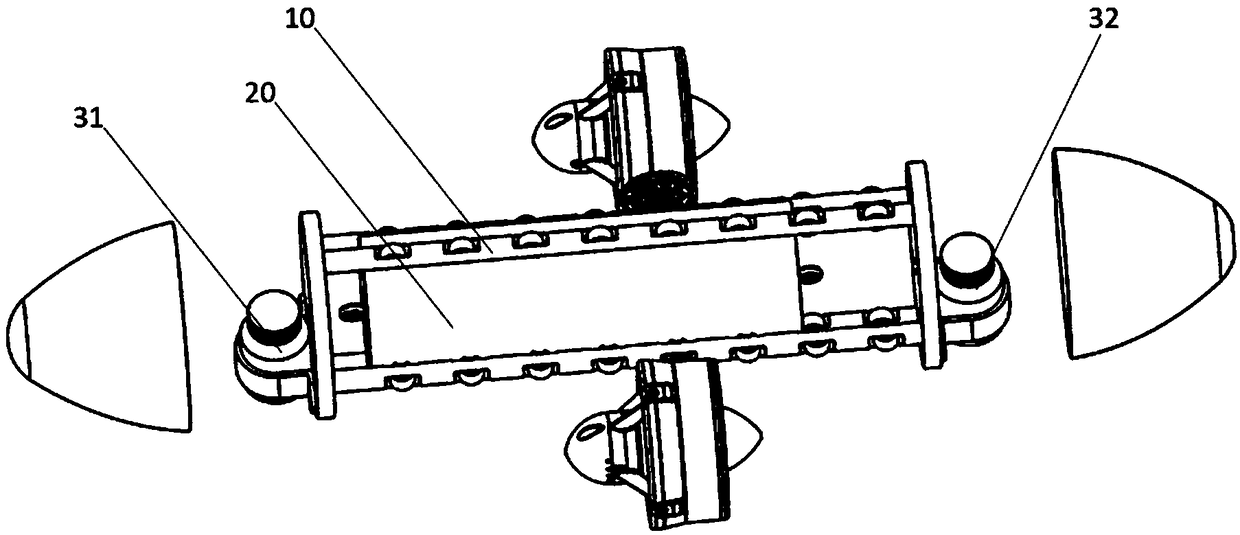

Gravity center adjustment device for underwater submersible vehicle

PendingCN109305313ASolve seal failureWill not cause a collisionUnderwater vesselsUnderwater equipmentInterior spaceGravity center

The invention discloses a gravity center adjustment device for an underwater submersible vehicle. The gravity center adjustment device for the underwater submersible vehicle comprises a sliding frame,a pressure proof cabin and a driving device. The pressure proof cabin is slidably connected to the sliding frame, and the driving device drives the pressure proof cabin to slide on the sliding frameand locks a position of the pressure proof cabin on the sliding frame. By integrally moving the pressure proof cabin, the moving quality of is large, the pressure proof cabin is not limited by internal space of the pressure proof cabin, the gravity center is changed and displacement is larger, the effect is obvious, internal collision of the pressure proof cabin cannot be caused, devices and a pressure proof cabin cover cannot be damaged, more reliability and safety are achieved, the structure is simple, and the problem of disabled invalid sealing of the pressure proof cabin due to the fact that an existing gravity center adjustment device needs to increase pressure proof cabin space during adjusting a battery pack in the pressure proof cabin and is prone to ejecting a sealing cover is solved.

Owner:CETC OCEAN INFORMATION CO LTD

Beating massage device

The invention belongs to the technical field of massage tools, and provides a beating massage device. The beating massage device is used for overcoming the defects that in the prior art, the cost of amassage device is high, and noise is large, and comprises a soft shell, a device shell, a shaft bush, a circuit board and a battery. A first magnet and a second magnet are attracted to the tow ends of a column body respectively, the column body which the first magnet and the second magnet are attracted to integrally moves inside the shaft bush in a reciprocating mode, a third magnet and a fourthmagnet are fixed to the parts, at the two ends of the shaft bush, of the device shell respectively, and external magnetic poles of the magnets at the two ends of the column body are identical with those of the sides, facing the column body, of the corresponding magnets on the device shell. The beating massage device is simple in structure, the usage quantity of the magnets is reduced, meanwhile, by the adoption of homopolar repelling, a shock-absorption effect can be achieved without design of a shock-absorption gasket, collision between the beating massage device and a human body will be avoided during shock absorption, and therefore noise is reduced; due to no collision, the service life of the beating massage device is prolonged.

Owner:蒋仁义

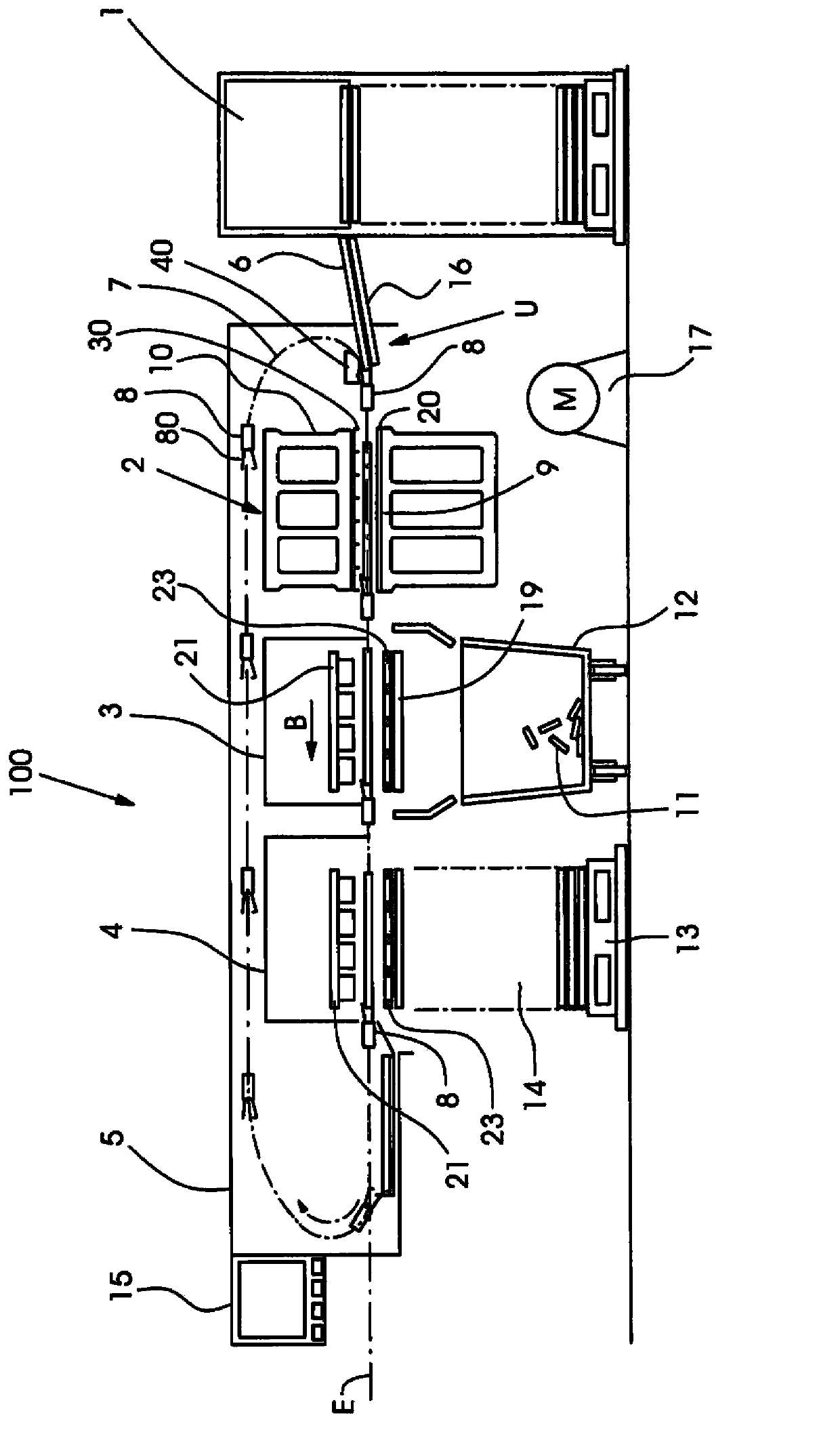

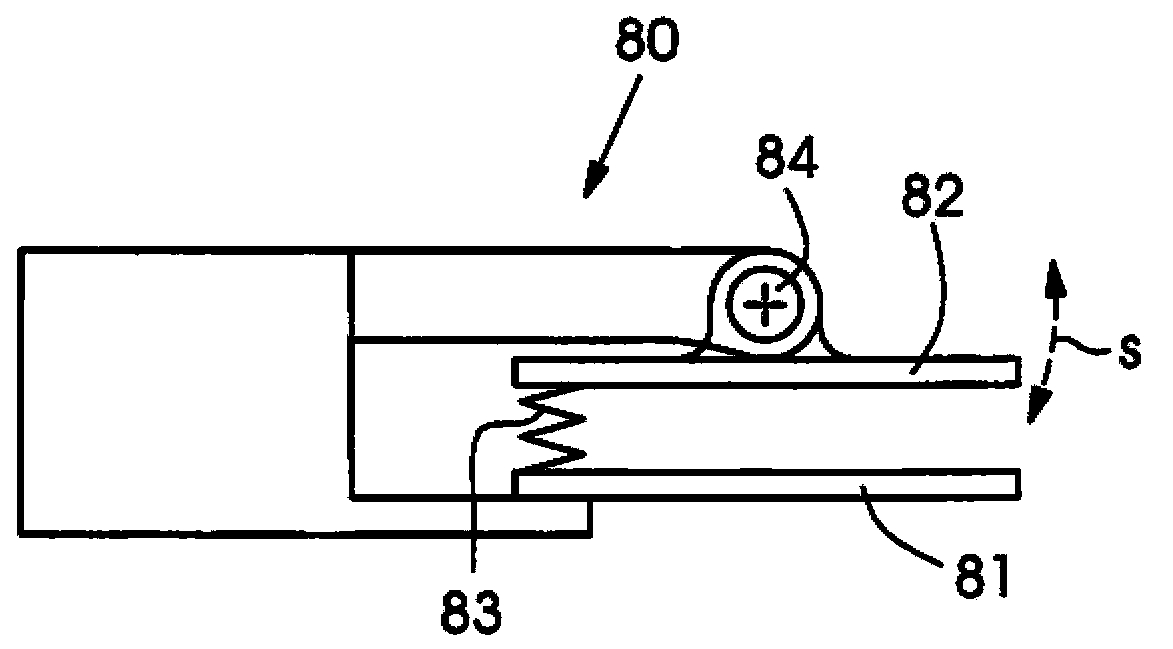

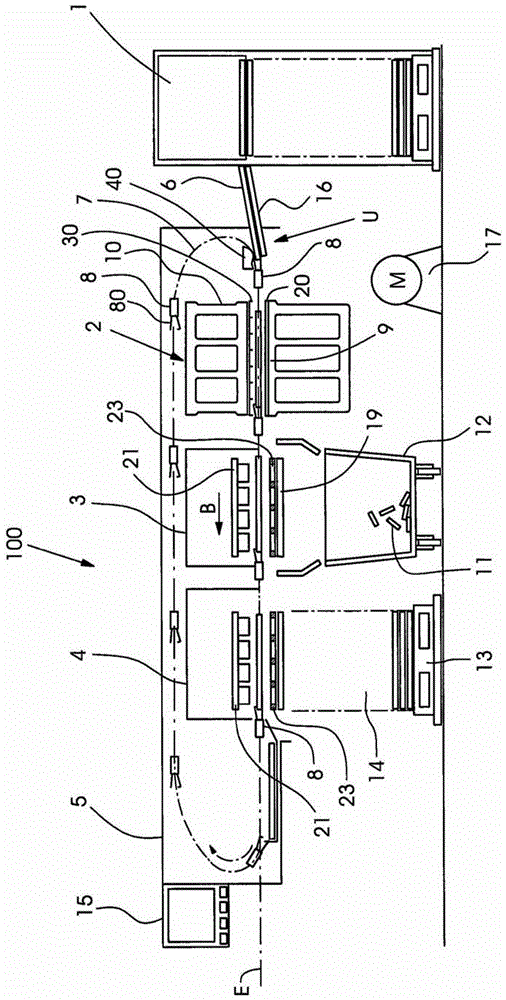

Method for sheet transfer and die cutting with gripper transport system

ActiveCN103373618APrecise Orientation of SheetsHigh registration qualityArticle feedersArticle deliveryEngineeringMechanical engineering

The invention relates to a method for transferring sheets from a sheet feeder to a sheet conveying system. The sheets and a gripper vehicle enter into a sheet transfer part in a non-collision manner. The invention further relates to a sheet die cutting and / or coining machine including a sheet feeder, at least one processing station, and a sheet conveying system. The sheet conveying system is provided with a batch-type revolving gripper vehicle for conveying the sheets to pass through the sheet die cutting and / or coining machine on a sheet operation plane, and the gripper vehicle is provided with a plurality of grippers for gripping the sheets, and the sheets are transferred from the feeder to the sheet conveying system at the sheet transferring part. According to the invention, each gripper is provided with a gripper seat and a gripper rod, and the gripper seat or the gripper rod is capable of pivoting or sliding to the part under the sheet operation plane to enable the corresponding gripper to be opened, so that the grippers can be further opened and pass through the sheet operation plane early.

Owner:MASTERWORK GROUP CO LTD

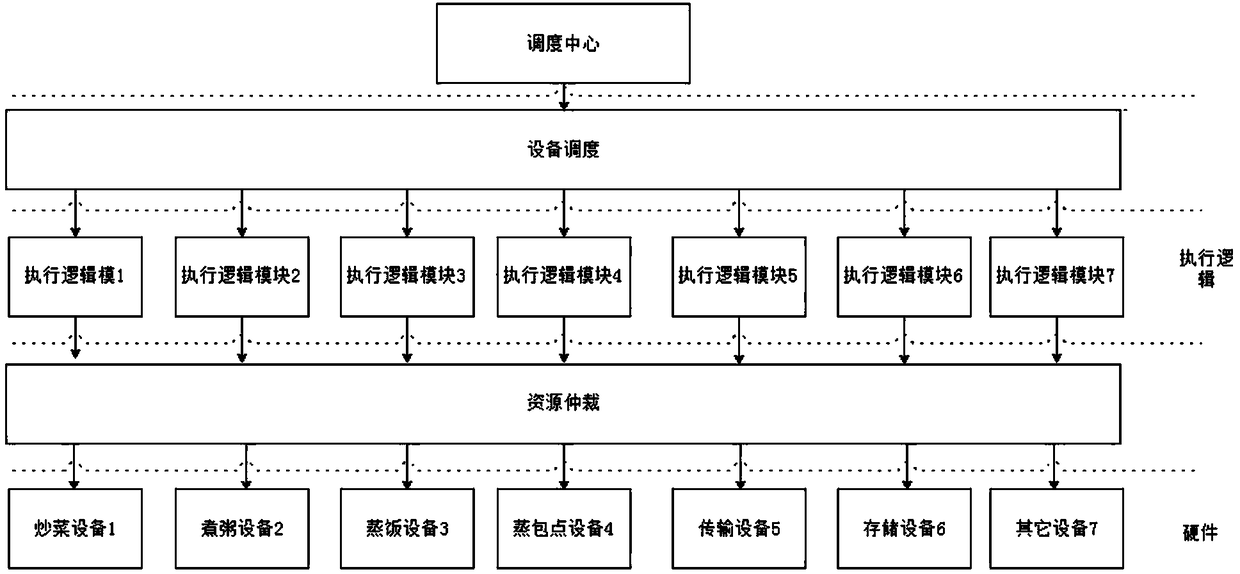

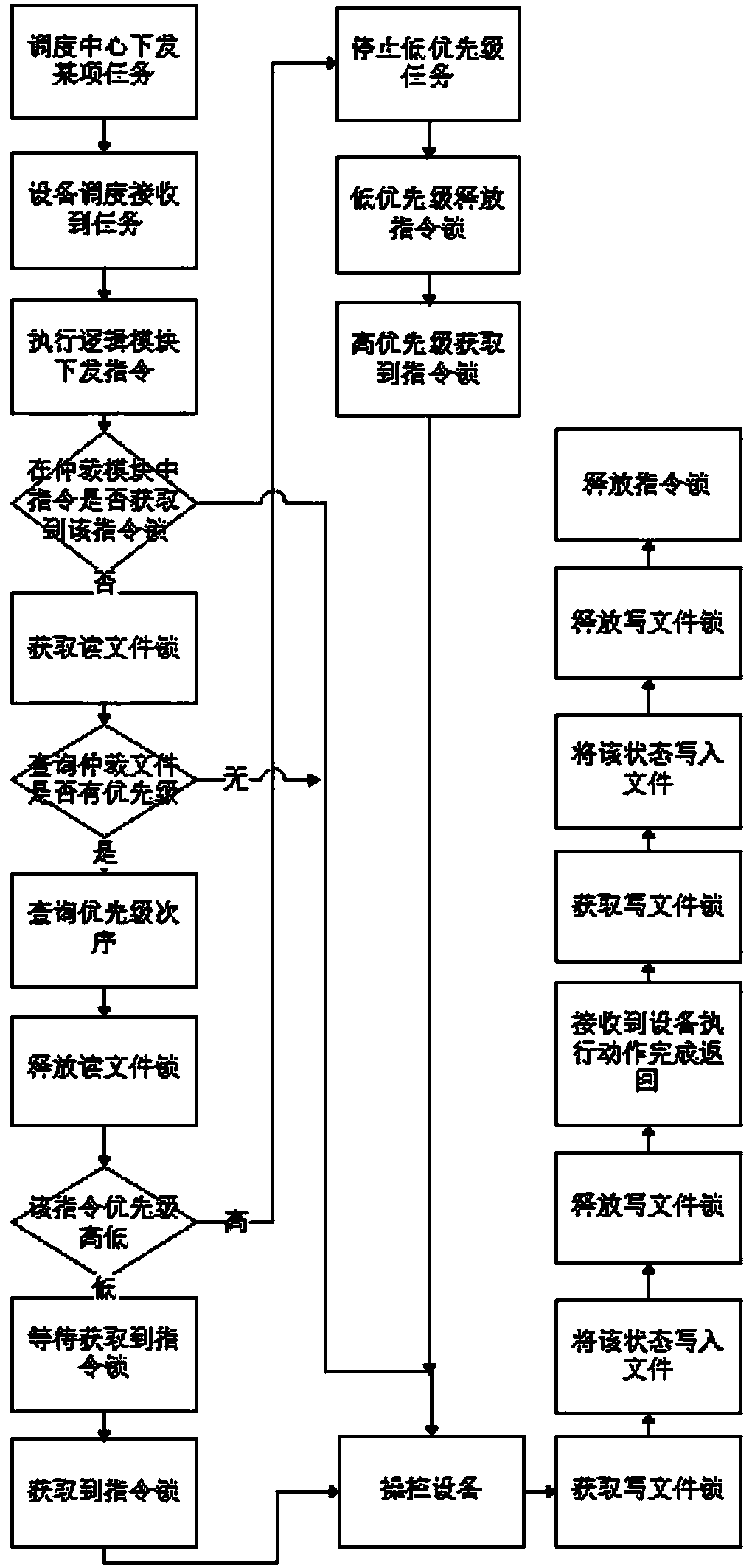

Multi-equipment resource competition method in field of automatic kitchens based on arbitration mechanism

InactiveCN108508810AClear business logicLow module couplingProgramme controlComputer controlEmbedded systemBusiness logic

The invention discloses a multi-equipment resource competition method in the field of automatic kitchens based on an arbitration mechanism. The method comprises the following steps that various piecesof key business execution state information are recorded in a file or a database; resource arbitration is conducted by reading the priorities of various competition resources in the file or database;the priorities of the competition resources are added or deleted or changed in the file or database according to demands; under the condition that equipment is powered off abnormally, after the equipment is started, the state before the equipment is powered off is obtained according to the file or database, and the equipment resets or continues to work at the state position. According to the method, the business logic is clear, the module coupling degree is low, and the arbitration mechanism can be quickly achieved; the competition resources can be easily added, detected and modified; the equipment can also immediately restore on site and continue to work after being started under the condition that the equipment is powered off abnormally, and a collision event does not occur; the controllogic is executed without concerning resource conflicts, and the resource arbitration is implemented by independent modules.

Owner:深圳市智汇牛科技有限公司

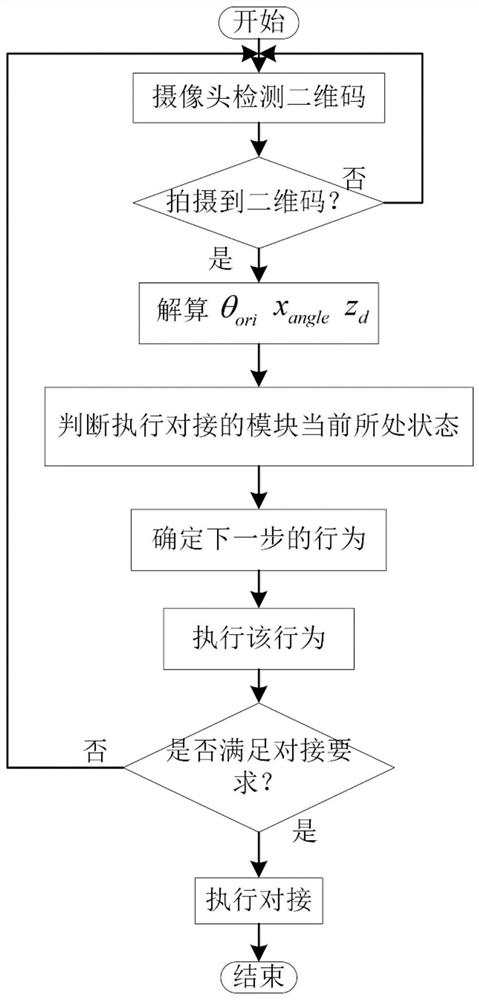

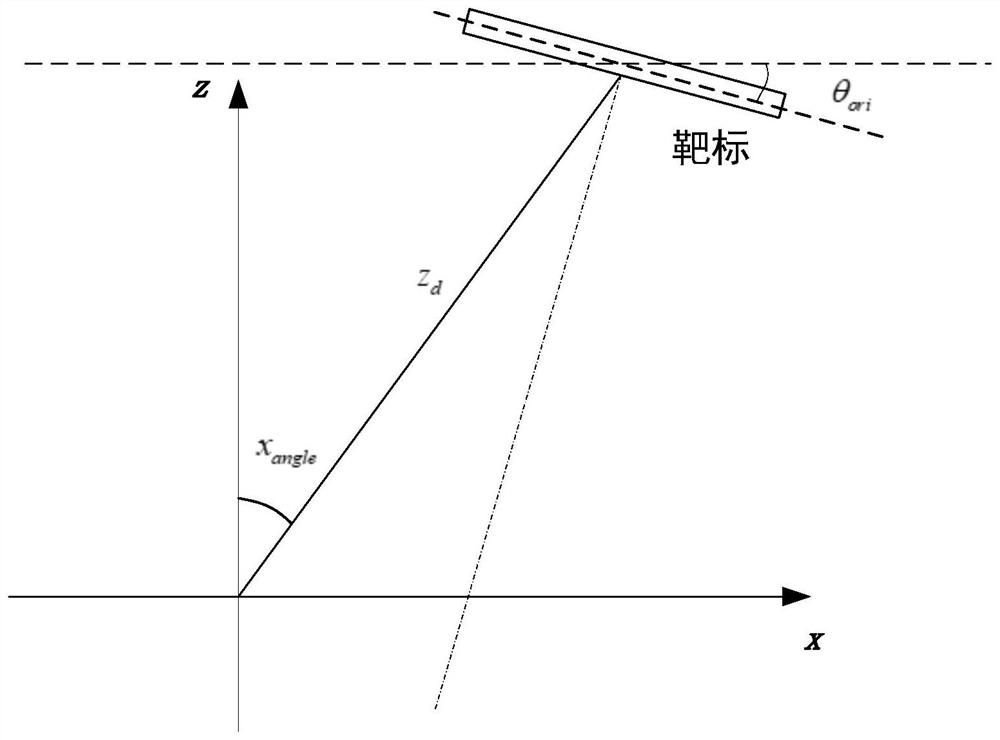

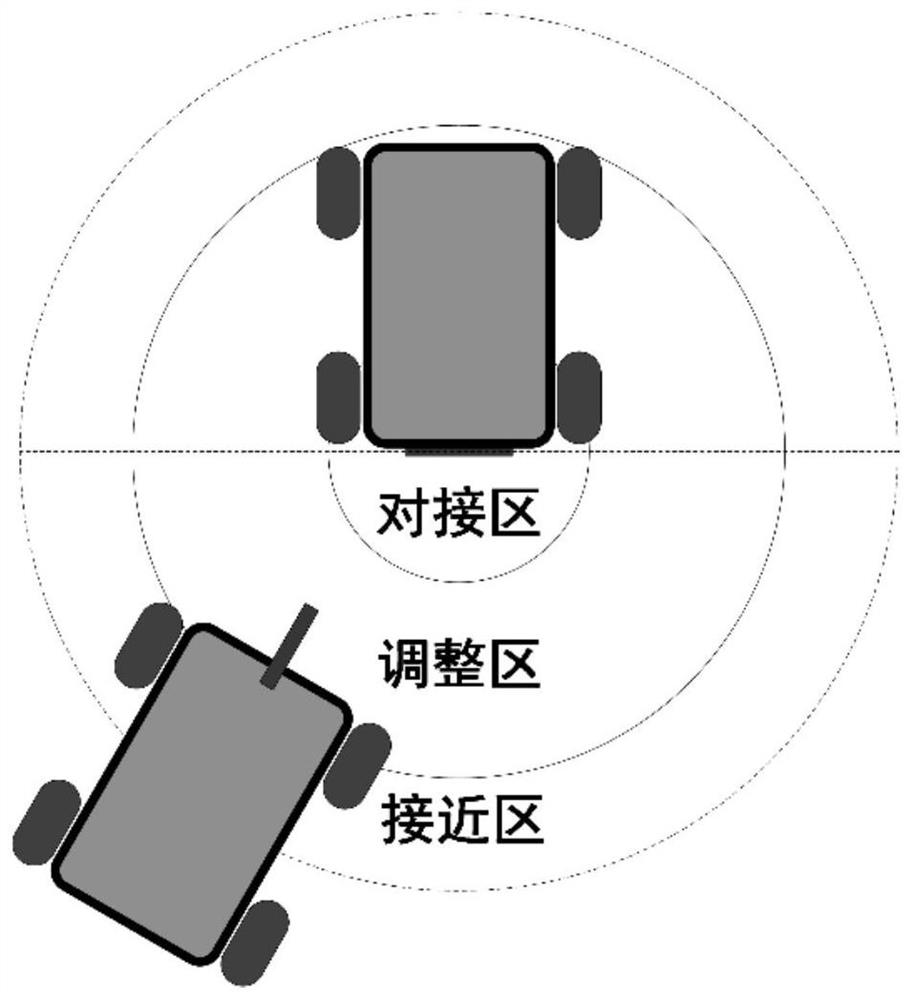

Autonomous docking control method for sliding steering modular robot

PendingCN113641174AEliminate slippageEliminate lateral misalignmentPosition/course control in two dimensionsVehiclesRobotyVideo camera

According to an autonomous docking control method for a sliding steering modular robot, a docked robot is called as a female head module, a robot actively implementing docking action is called as a male head module, the female head module is in a static state, and the male head module is in a moving state; a two-dimensional code is pasted on the female head module to serve as a target, a camera is additionally installed on the male head module, a two-dimensional code image is shot through the camera, the attitude quaternion of the two-dimensional code relative to a camera coordinate system is calculated, and the relative attitude between the modules is obtained; and butt joint of the male head module and the female head module is realized based on stepping control of behaviors. According to the invention, through vision and a cooperative target, the pose of the target is detected by means of the camera, so that the relative pose of the two to-be-docked robots is accurately estimated, and the error of a positioning system is made up; the problems existing in the self-reconfiguration butt joint process of the sliding steering modular robot can be effectively solved, and accurate butt joint control over unit modules is achieved.

Owner:SHANDONG UNIV

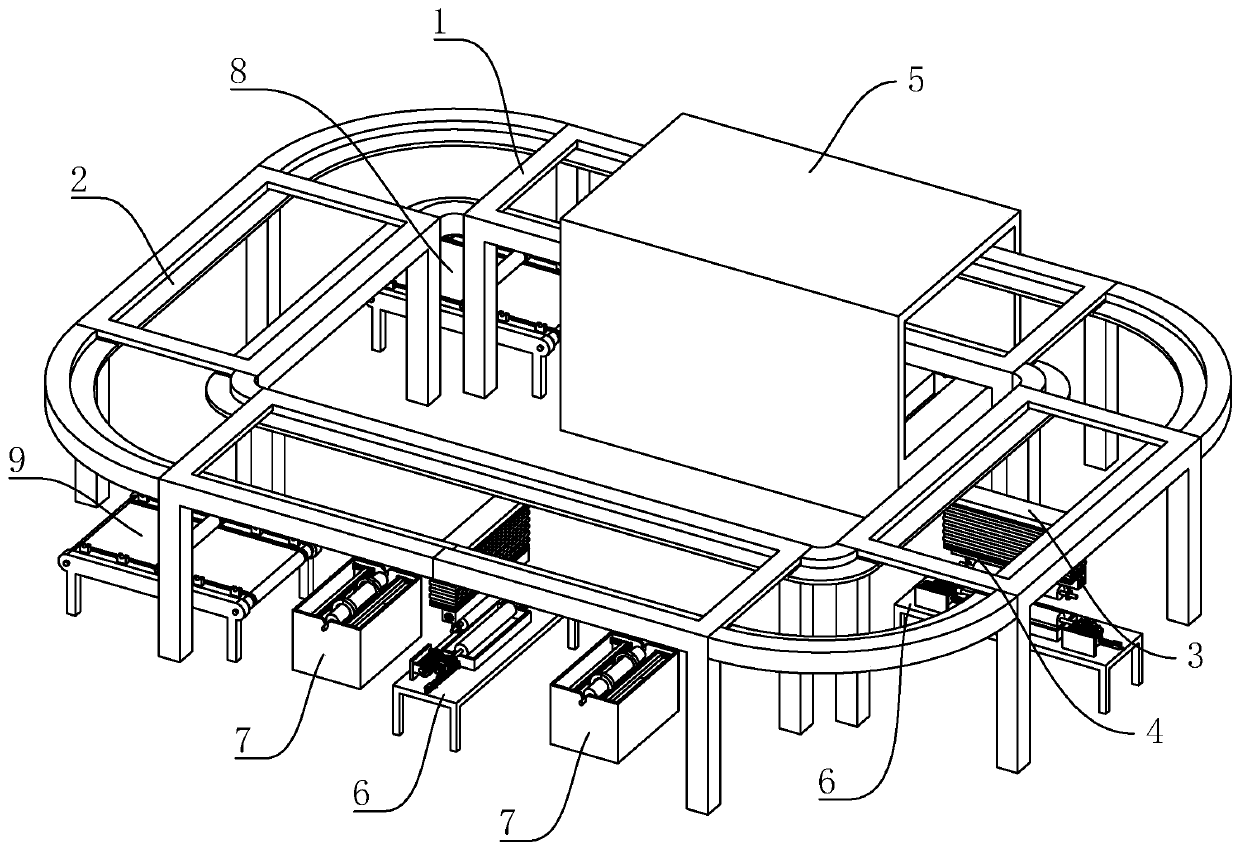

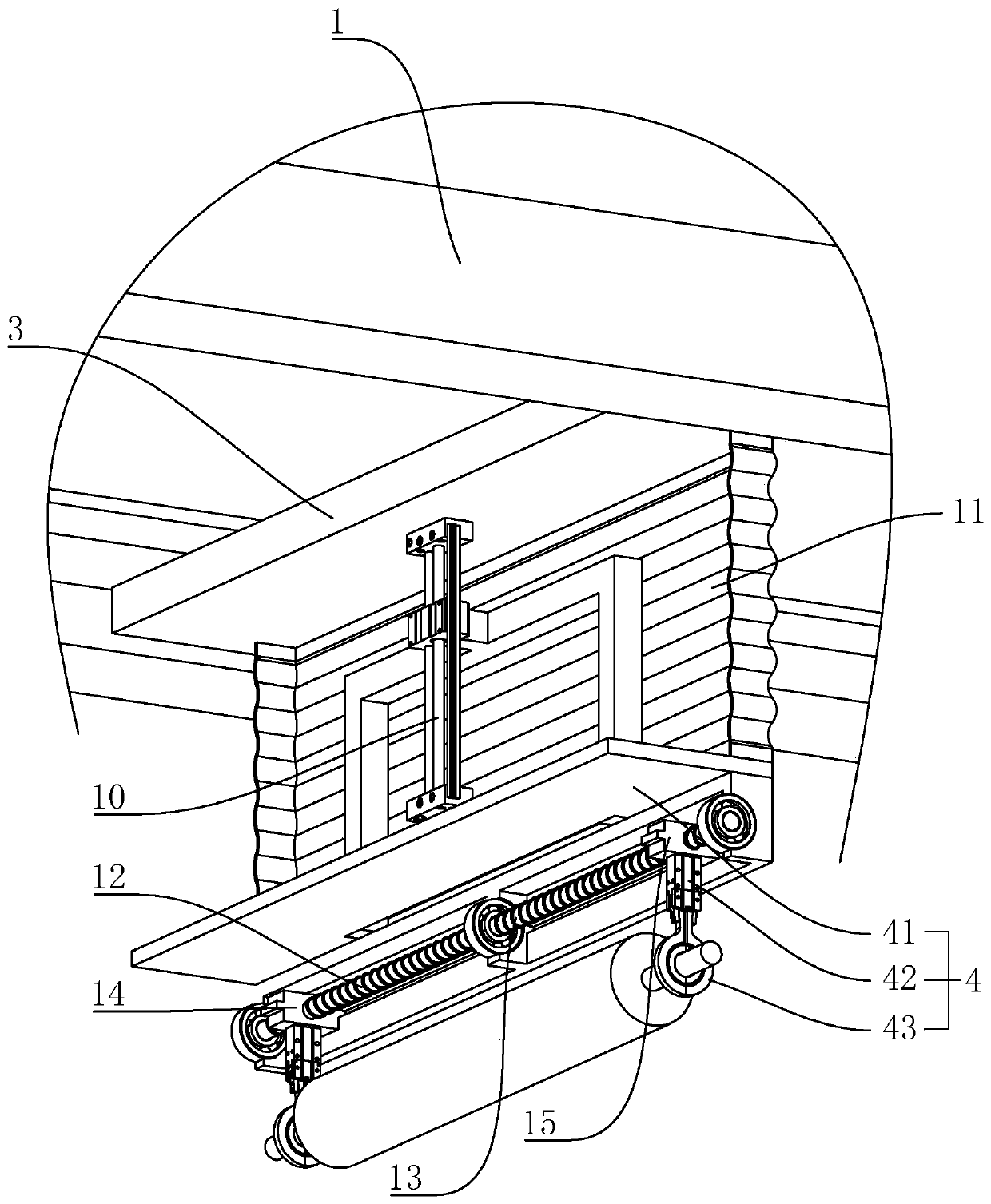

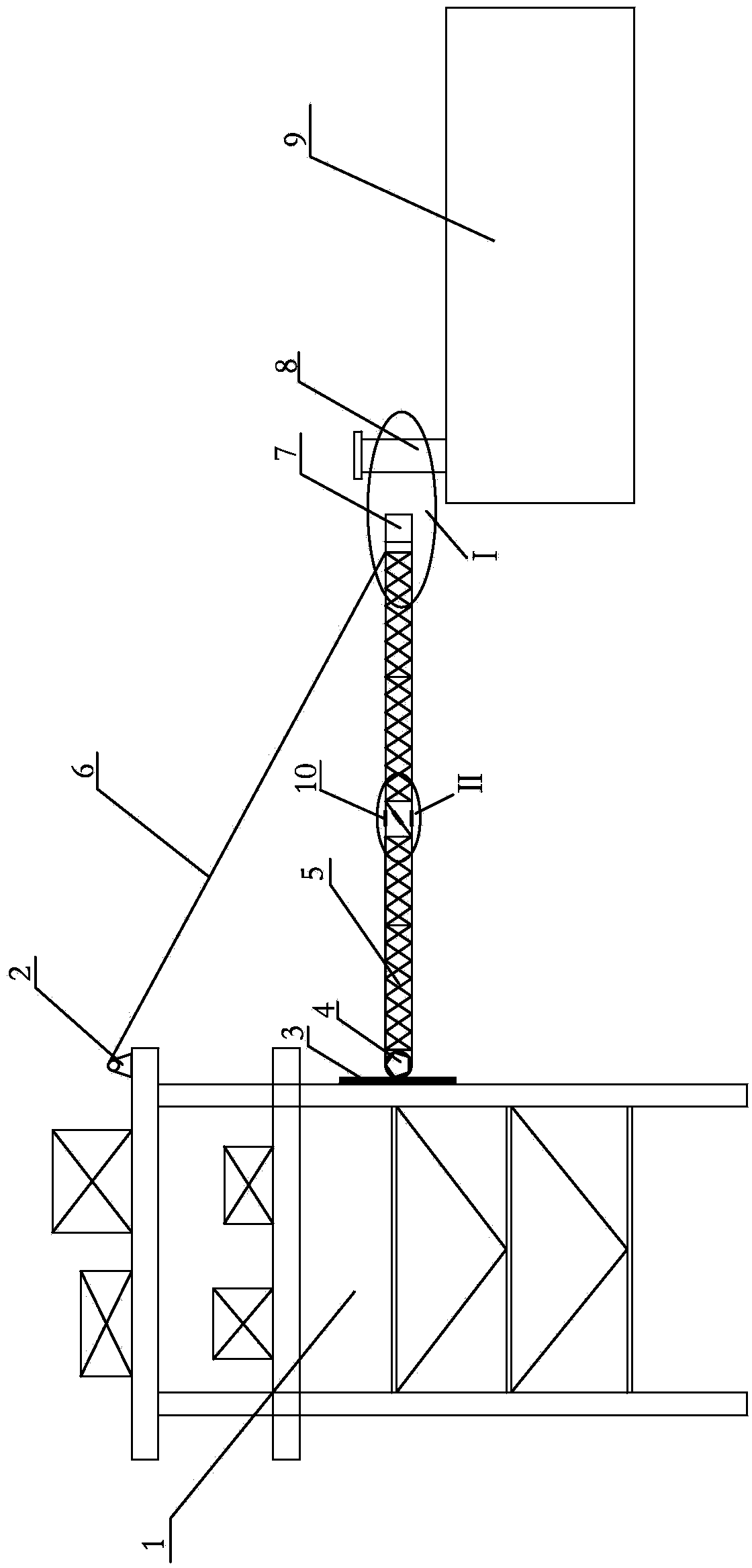

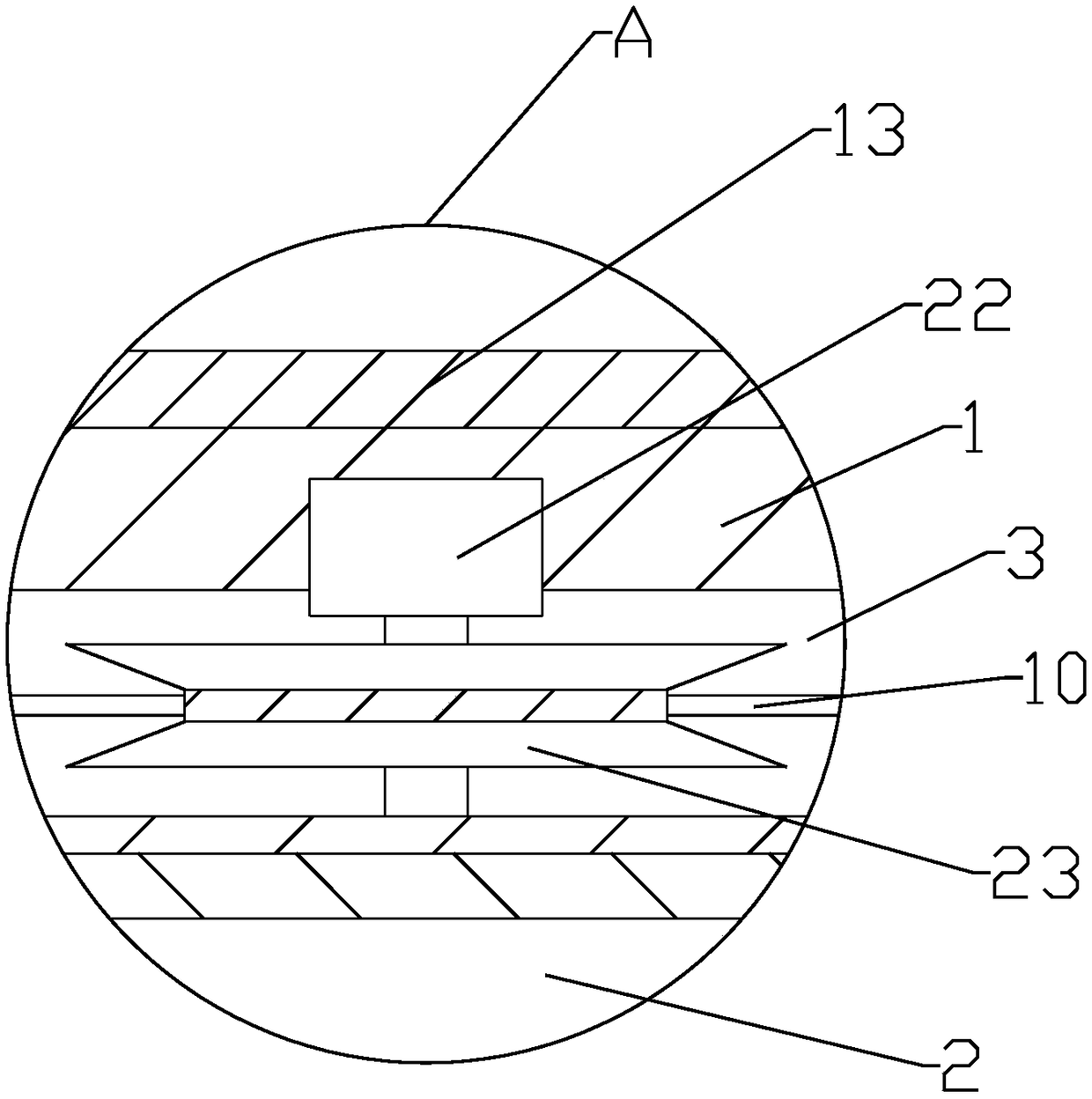

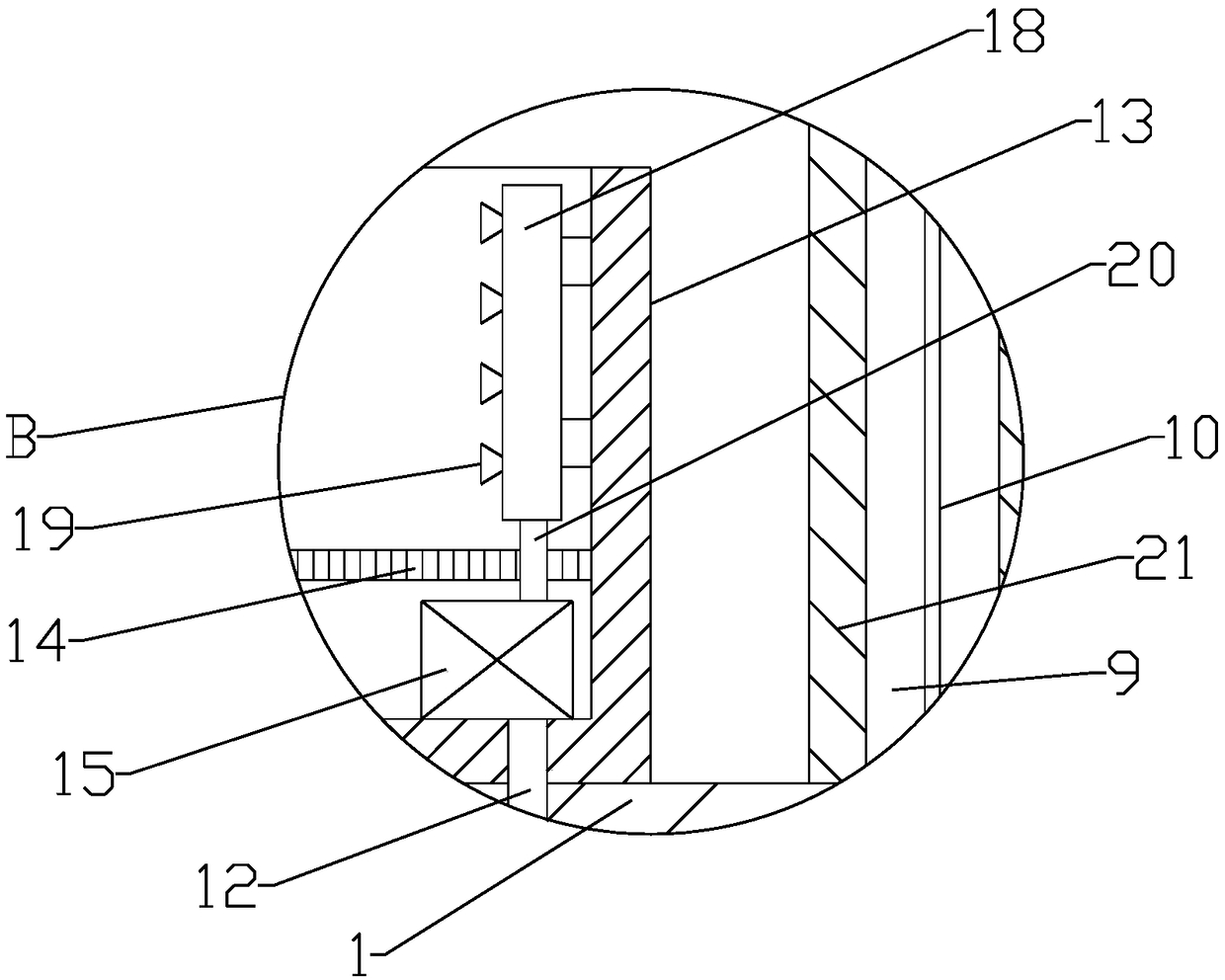

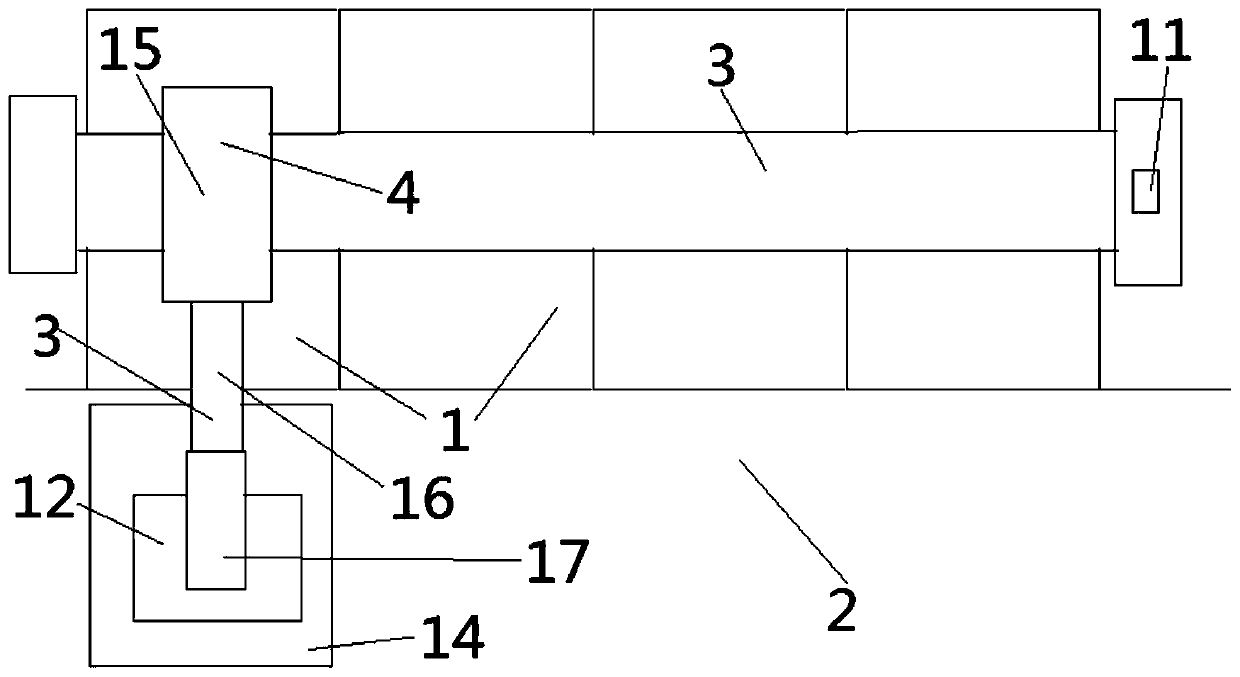

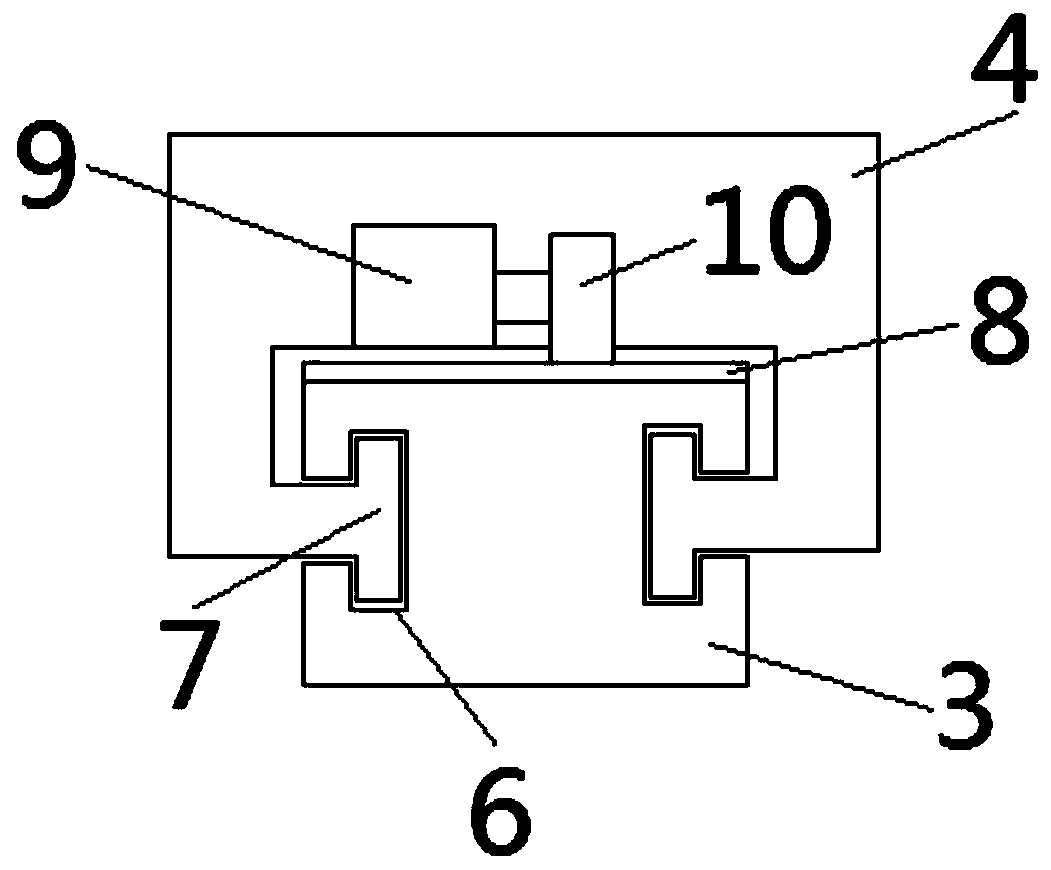

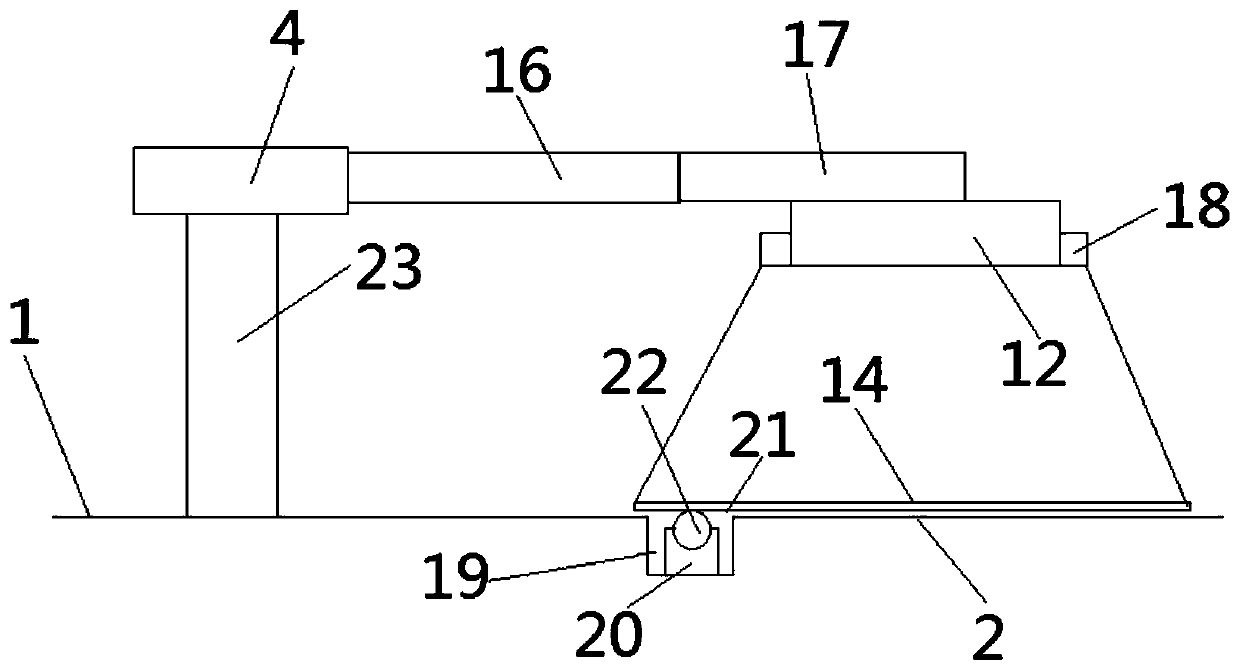

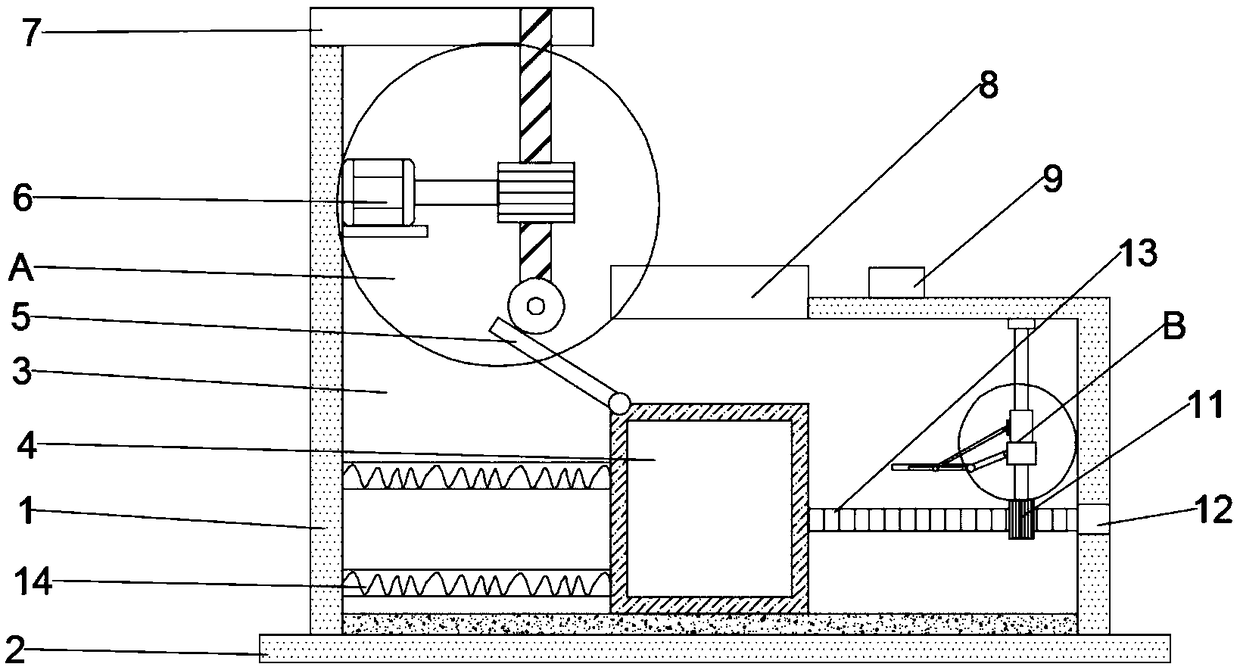

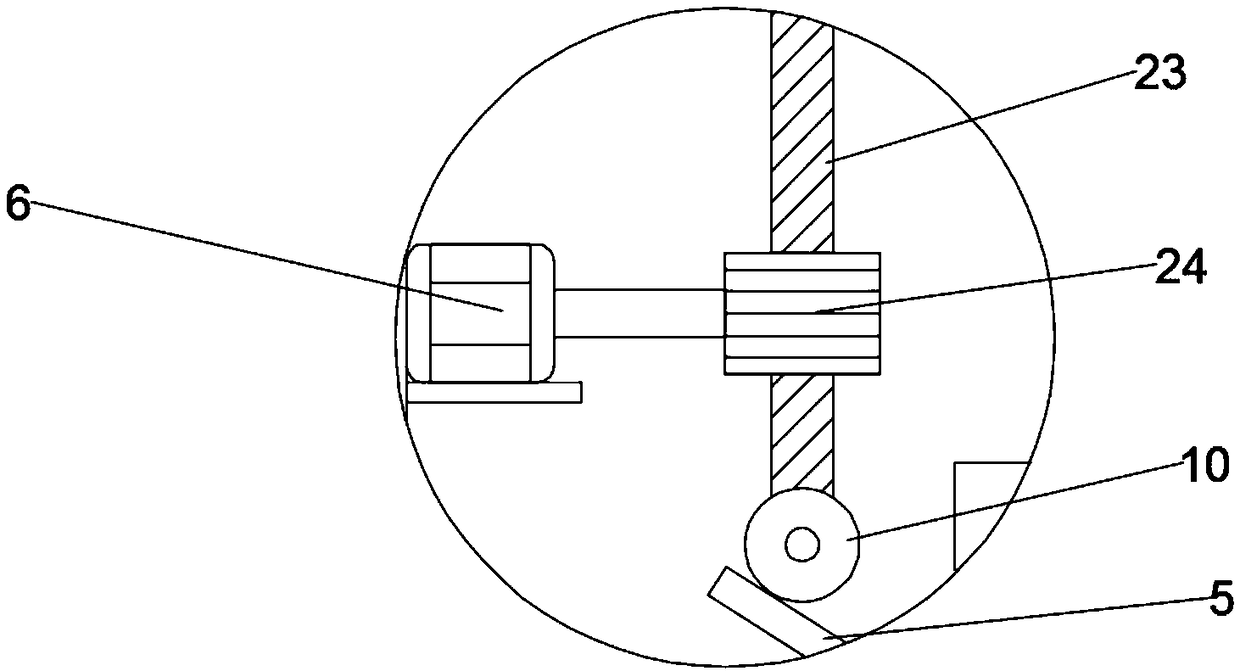

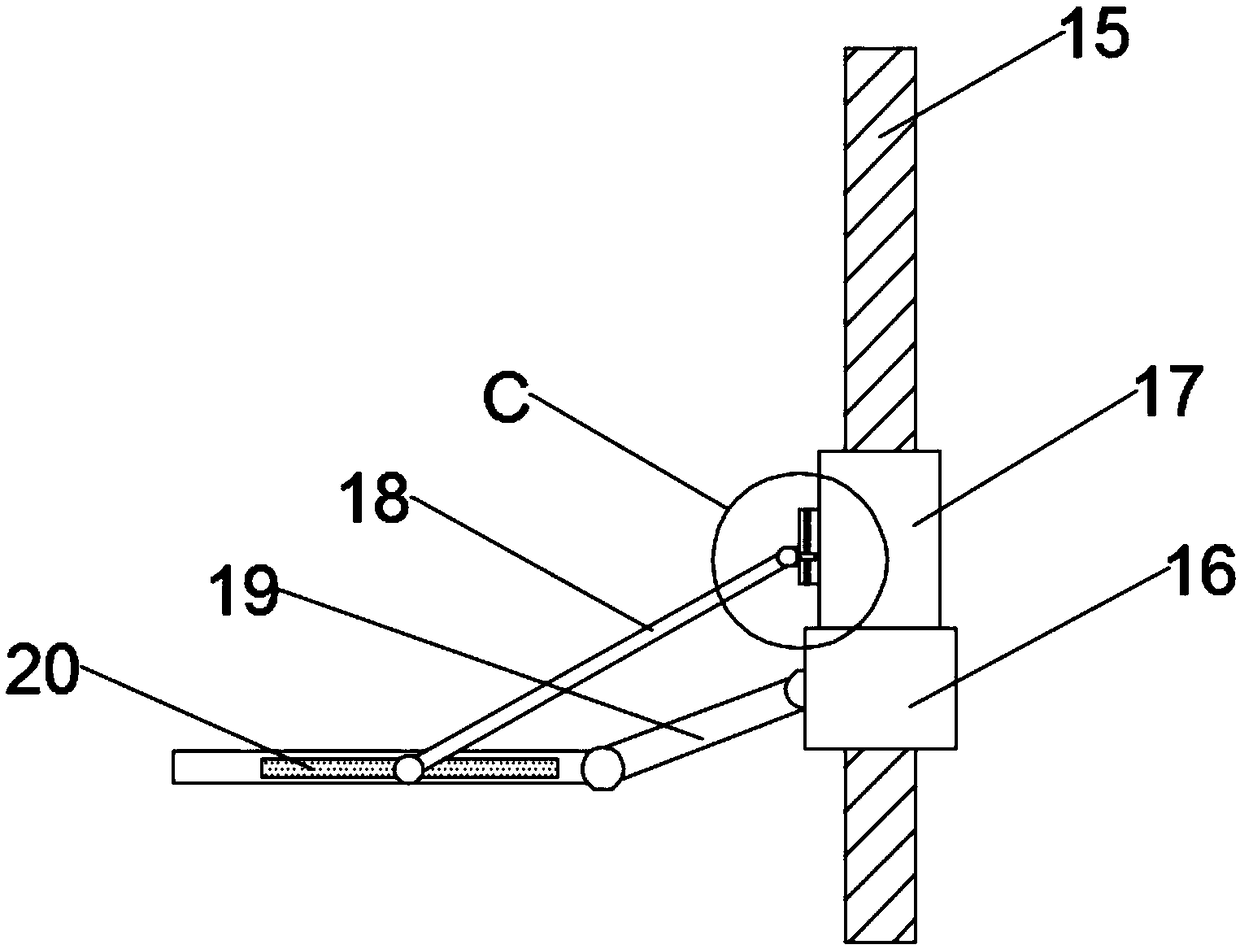

Multi-parking space intelligent robot parking equipment and parking method thereof

InactiveCN111550097AWill not cause a collisionConvenient and reliable automatic entry and exitParkingsParking spaceRoad surface

The invention provides multi-parking space intelligent robot parking equipment applied to the technical field of intelligent equipment. The multi-parking space intelligent robot parking equipment comprises a plurality of parking spaces (1), wherein the plurality of parking spaces (1) are arranged in an adjacent mode, and are arranged on the side surface of a road surface (2), a moving track (3) isarranged above the plurality of parking spaces (1), the moving track (3) is connected with the ground through supporting columns (23), a moving robot (4) is arranged on the moving track (3), T-shapedwheel grooves (6) are arranged on the side surface of the moving track (3), and sliding wheels (7) on the moving robot (4) are clamped in the T-shaped wheel grooves (6). According to the multi-parking space intelligent robot parking equipment, a vehicle can conveniently enter or leave the parking space, a degree of intelligent control over parking space entering and leaving of the vehicle is achieved, so that inconvenience of manual control over parking space entering and leaving of the vehicle is avoided, and the entering and leaving safety during parking space entering and leaving of the vehicle is guaranteed.

Owner:WUHU ZHANGHONG ENG TECH CO LTD

Efficient electronic technology product accessory cleaning device

Owner:合肥伟梦电子科技有限公司

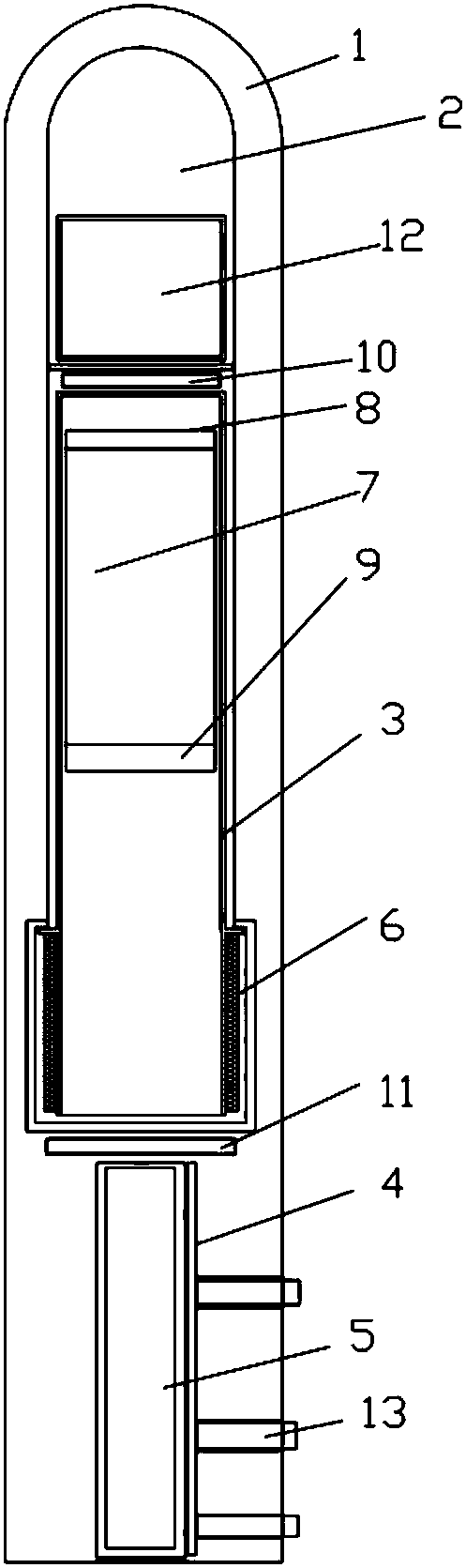

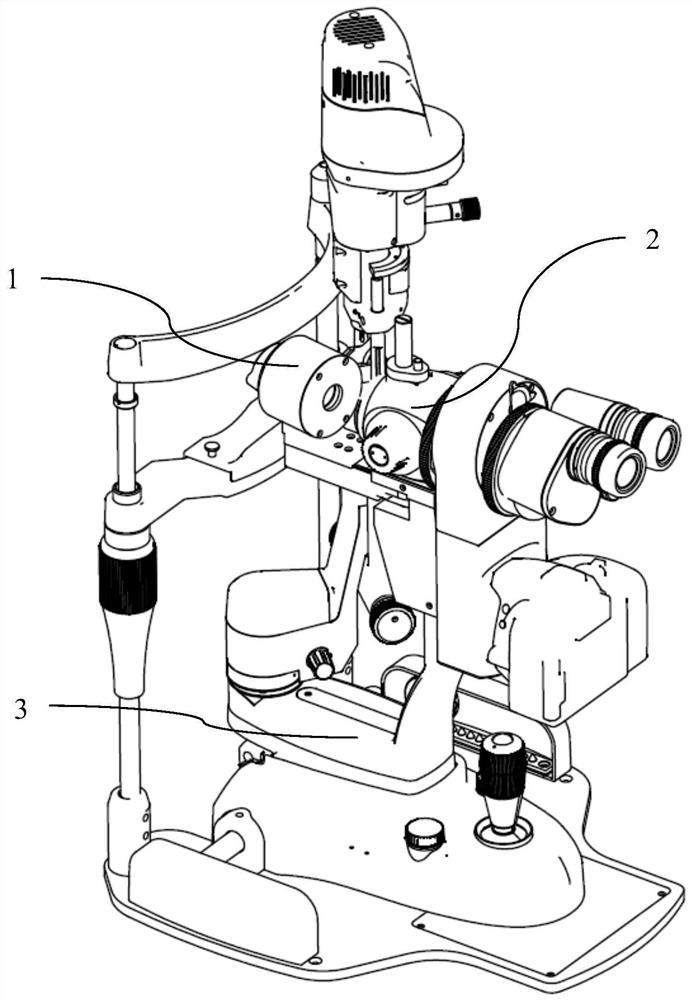

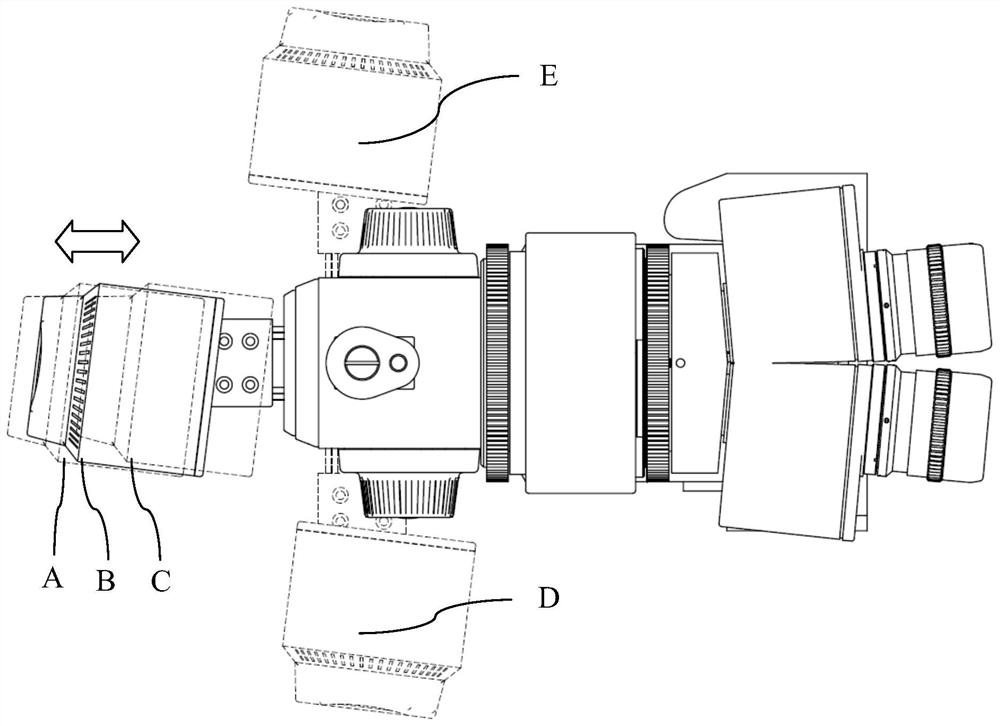

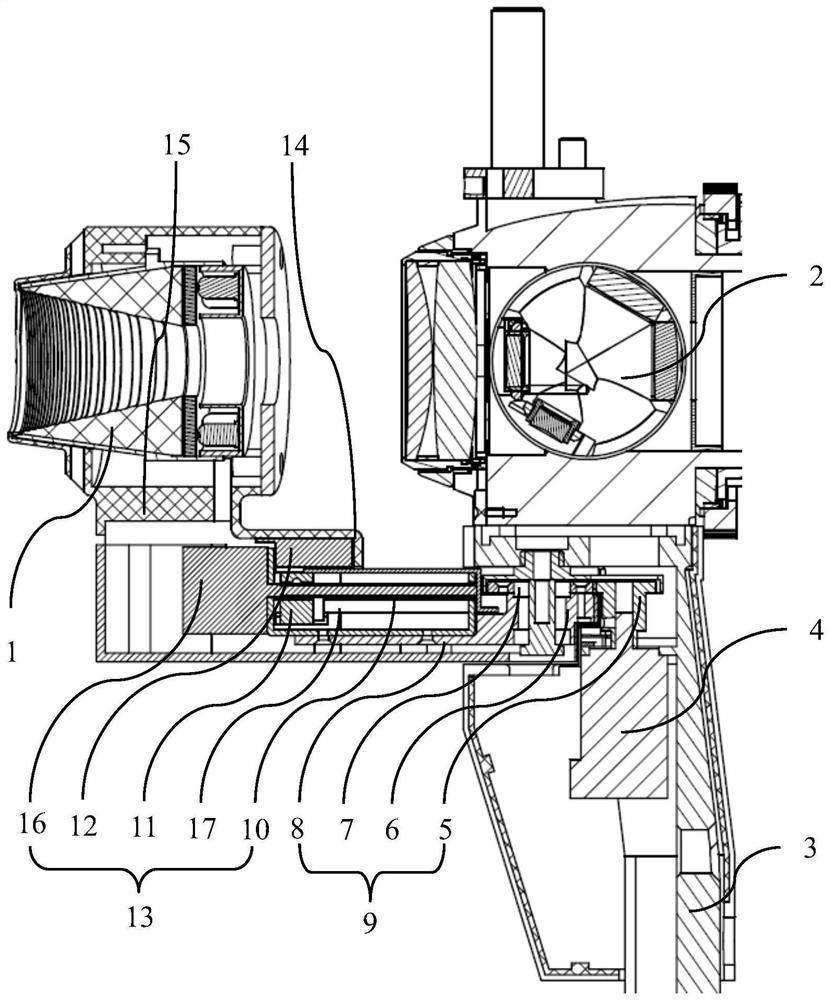

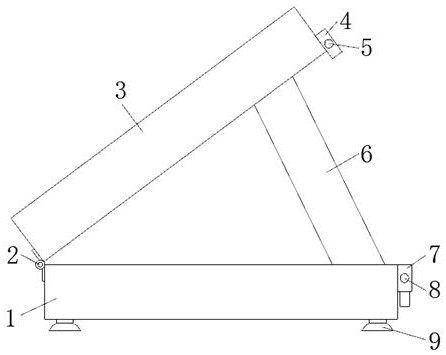

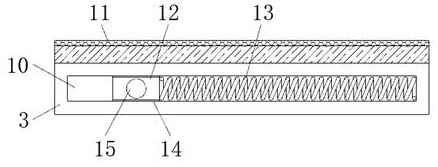

Electric folding and unfolding mechanism and electric adjusting mechanism for dry-eye inspection device

PendingCN112274106AWill not cause a collisionProtection securityOthalmoscopesMeibomian glandEngineering

The invention provides an electric folding and unfolding mechanism and an electric adjusting mechanism for a dry-eye inspection device. According to the invention, a slit lamp optical body, a slit lamp bent arm, the electric folding and unfolding mechanism, the electric adjusting mechanism and the dry-eye inspection device are included. A fixed part of the electric folding and unfolding mechanismis mounted on a slit lamp body; the output part of a first driving device drives a rotating part of the electric folding and unfolding mechanism to rotate; a fixed part of the electric adjusting mechanism is mounted on the rotating part of the electric folding and unfolding mechanism, and the dry-eye inspection device is connected to a sliding part of the electric adjusting mechanism; and the output part of a second driving device drives the sliding part of the electric adjusting mechanism to move in an axis direction. According to the invention, through the arranged second driving device andthe arranged adjusting mechanism and under the control of a computer, the dry-eye inspection device automatically move to respective working positions according to different dry-eye examination items(tear film rupture examination, meibomian gland examination, lipid layer examination, tear river height examination and the like), so the accuracy of inspection results is ensured.

Owner:KANG HUA RUI MING SCI & TECH CO LTD

Method for transferring sheets and die-cutting machine with gripper-conveying system

ActiveCN103373618BHigh registration qualityOrientation is accurateArticle feedersPunchingEngineering

Owner:MASTERWORK GROUP CO LTD

An ais receiver for offshore small ship management

ActiveCN112134579BWill not cause a collisionReal-time graspNetwork topologiesTransmissionMarine engineeringStructural engineering

The invention relates to the technical field of ship management, and discloses an AIS receiver for offshore small ship management. Cover, the box and the box cover are connected by hinges, the bottom of the receiver body is located inside the box, and the bottoms on both sides of the receiver body are respectively connected to the bottom of the box The inner front surface and the inner rear surface are rotationally connected; when the receiver needs to be carried, press the box cover directly down, and the receiver body will rotate to the inside of the box body, and the slider will slide backwards and squeeze Press the first spring to finally close the box cover and the box body. After the box cover and the box body are closed, the two buckles on the box cover are respectively inserted into the two sleeves on the box body, and are locked between the locking block and the box body. Under the snap action between the holes, the box body and the box cover can be fixed, and can be carried by the handle on the box body.

Owner:GUANGDONG OCEAN UNIVERSITY

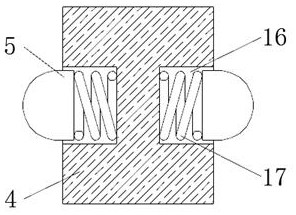

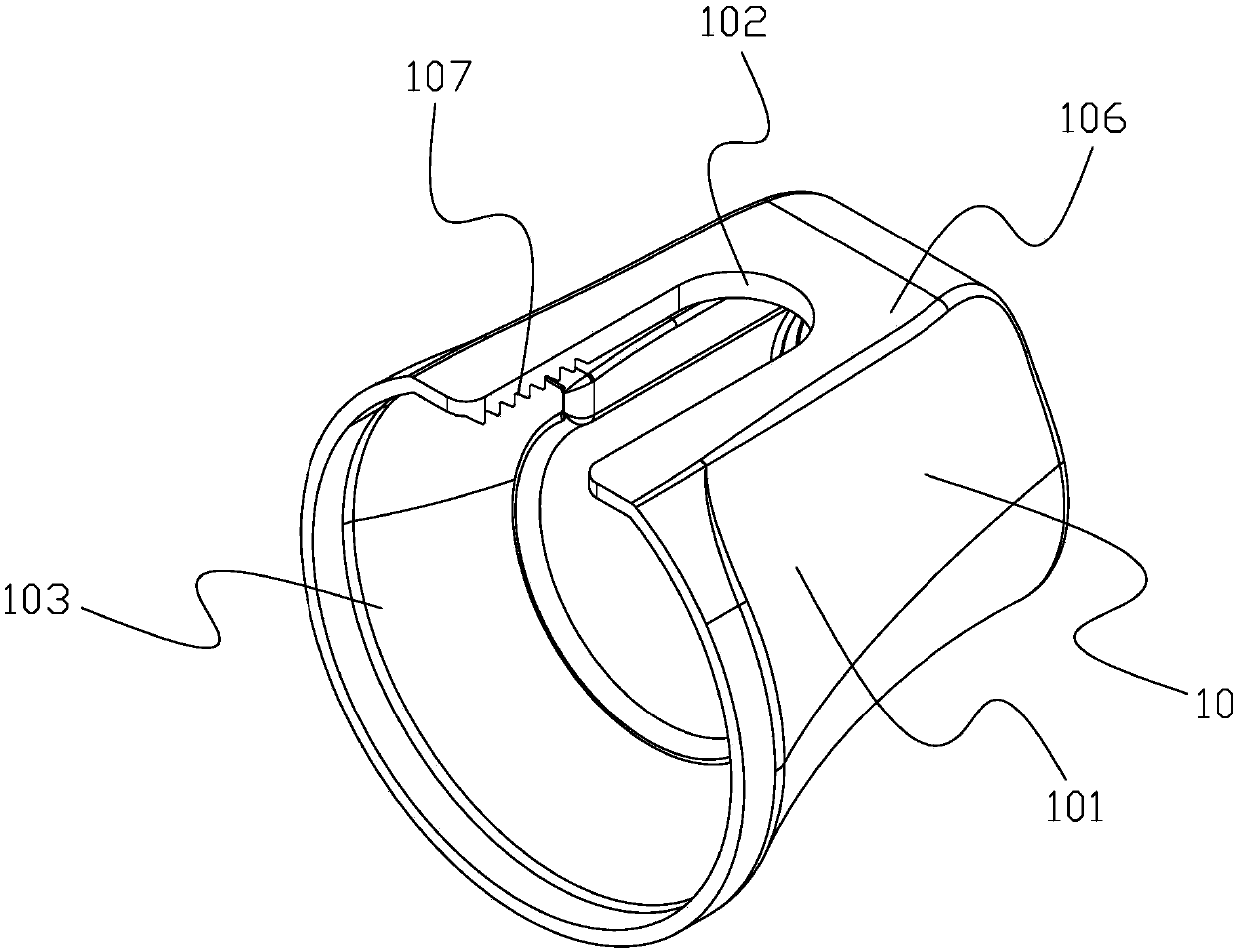

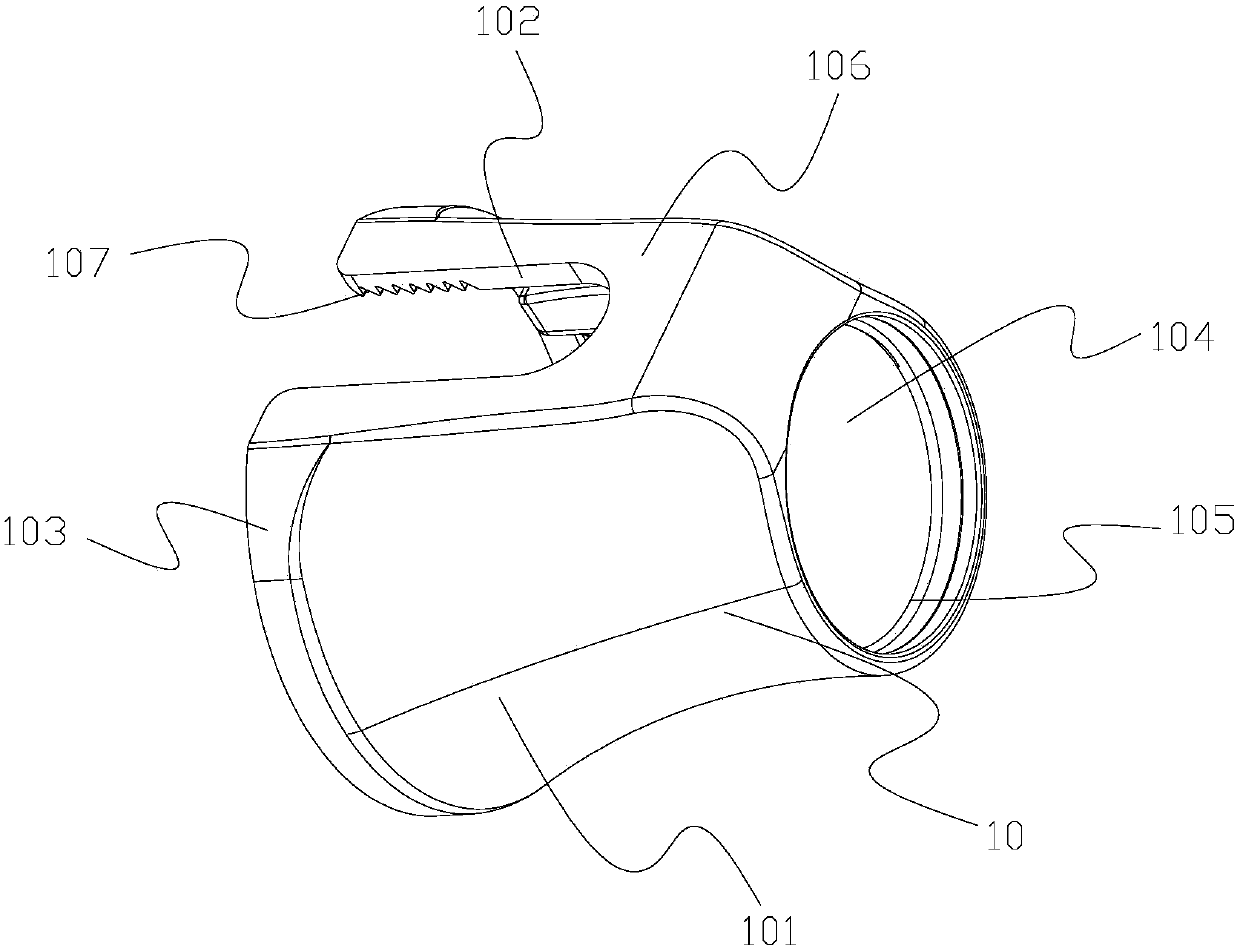

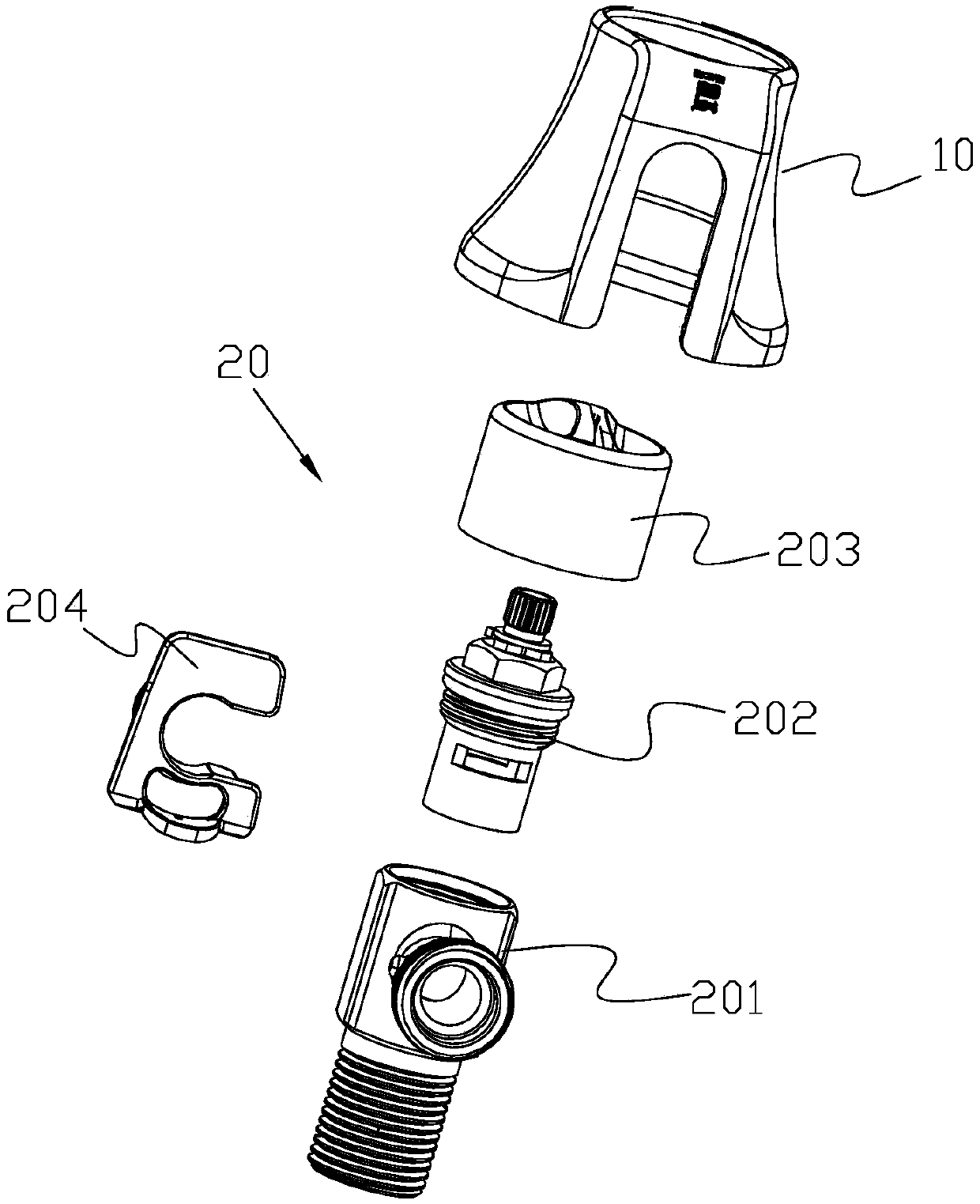

A shell of an angle valve and an angle valve with a shell

ActiveCN106907499BInstallation does not affectEasy to installSlide valveValve housingsEngineeringMechanical engineering

Disclosed are a housing (10) for an angle valve and an angle valve having the housing (10), the angle valve comprising the housing (10) and a valve body (20). A side face of a cover body (10) is provided with a pipe penetrating groove (102), a groove opening of the pipe penetrating groove (102) penetrating through the bottom face of the housing (10). The bottom of the cover body (10) is provided with a skirt (103). The cover body (10) is provided with a through hole (104) penetrating through the top face and the bottom face of the cover body (10). The valve body (20) comprises a housing body (201), a valve core (202) and a rotary cover (203), the rotary cover (203) being sheathed on the top end of the valve core (202), the top end of the rotary cover (203) being provided with a groove (2031) for accommodating a finger, and the pipe penetrating groove (102) being snap-fitted to an outer side wall of a water outlet channel of the housing body (201). The skirt (103) of the housing (10) can cover an angle valve installation hole on a wall. The housing (10) is installed after the installation of the angle valve, which does not influence the installation of the angle valve, and is quick and convenient to install. The housing (10) can be made by means of ABS electroplating, and polishing is not required in the manufacturing process, which is more environmentally friendly.

Owner:福建过江龙卫浴有限公司

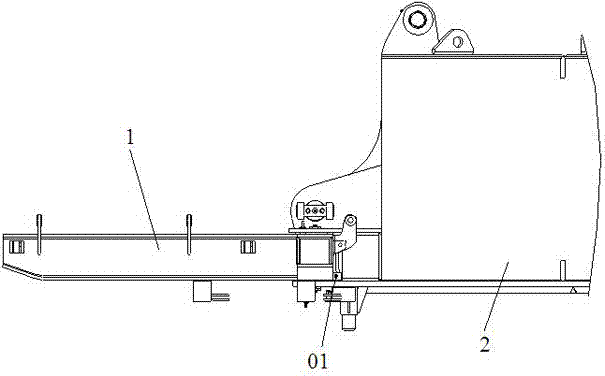

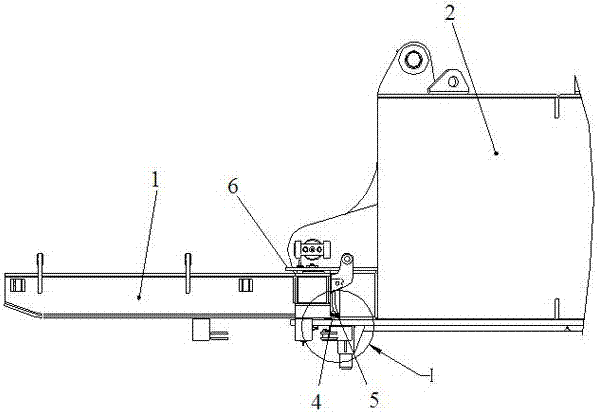

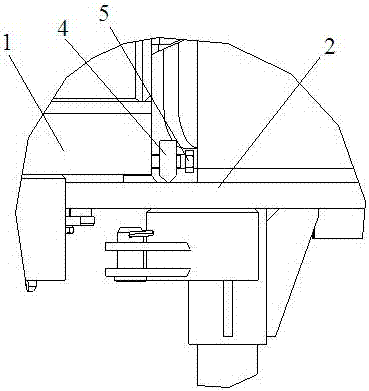

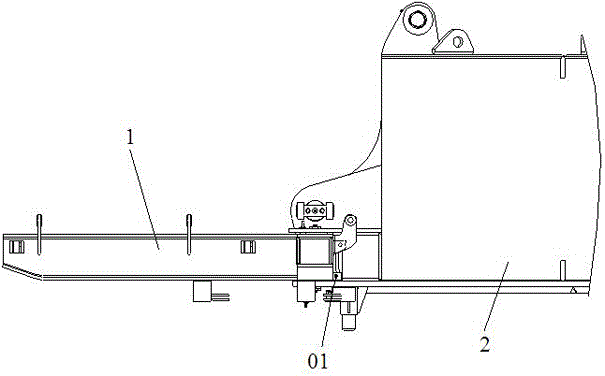

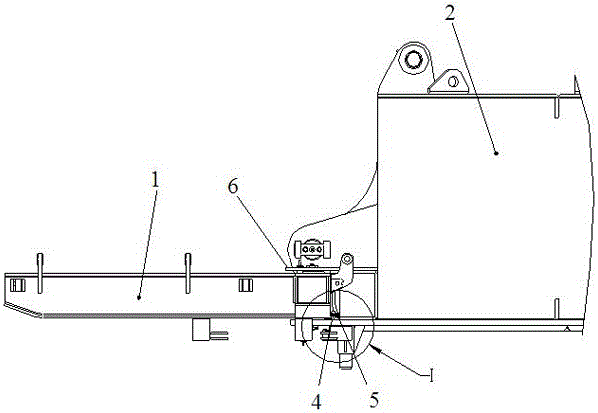

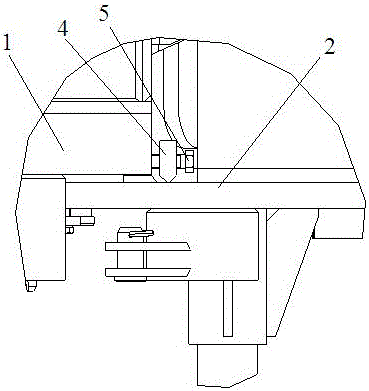

Rotary positioning device for console bracket

ActiveCN105712209BWill not cause a collisionImprove installation efficiencyLoad-engaging elementsEngineeringMechanical engineering

The invention discloses a rotating and positioning device of a control cabin bracket. The rotating and positioning device of the control cabin bracket comprises a bolt positioning assembly and a positioning plate assembly. The control cabin bracket and a rotary table are assembled in a rotary connection mode through a pin shaft so that rotary switching between the transport state and the operation state can be completed conveniently. The bolt positioning assembly comprises a screw rod and a nut plate which are in threaded connection. The nut plate is fixedly connected with the rotary table, one end of the screw rod faces the rotary table, and the other end of the screw rod penetrates through the nut plate and faces the control cabin bracket. The positioning plate assembly comprises a positioning plate and a positioning pin. The positioning plate is fixedly connected with the pin shaft and the rotary table, and provided with more than one positioning hole. The control cabin bracket is provided with more than one positioning hole adapting to the positioning holes in the positioning plate. In this way, when the control cabin bracket is in the transport state or the operation state, one of the positioning holes in the positioning plate communicates with the corresponding positioning hole in the control cabin bracket all the time, and then the positioning pin is plugged into the positioning holes for positioning. The rotating angle of the control cabin bracket is positioned accurately through bolt adjustment, and meanwhile the positioning plate assembly is used in cooperation for positioning, so that the mounting accuracy of the control cabin bracket and the rotary table is improved.

Owner:XCMG CONSTR MACHINERY

Novel bowl washing sink

InactiveCN109183916ASimple structureEasy to use and installKitchenware cleanersDomestic plumbingWater leakWastewater

The invention provides a novel bowl washing sink. The sink comprises a U-shaped sink body preset in a wall body, wherein water leaking holes are formed in the bottom of the U-shaped sink body and areuniformly distributed; a wastewater collection tank for collecting wastewater is formed in the bottom of the water leaking holes; the wastewater collection tank is connected with a water outlet pipe at the bottom of the sink body; a filter screen is arranged at the water outlet under the water leaking holes; a plug lid corresponding to the water leaking holes is arranged at the top of the water leaking holes; and a draining basket is arranged on the sink body. The novel bowl washing sink has the characteristics of simple structure, convenience in use and assembly, pipe blocking prevention andthe like.

Owner:DEQING HUAMENG WOODWORK

Rotating and positioning device of control cabin bracket

ActiveCN105712209ANo need to disassembleNo on-site welding requiredLoad-engaging elementsMechanical engineeringEngineering

The invention discloses a rotating and positioning device of a control cabin bracket. The rotating and positioning device of the control cabin bracket comprises a bolt positioning assembly and a positioning plate assembly. The control cabin bracket and a rotary table are assembled in a rotary connection mode through a pin shaft so that rotary switching between the transport state and the operation state can be completed conveniently. The bolt positioning assembly comprises a screw rod and a nut plate which are in threaded connection. The nut plate is fixedly connected with the rotary table, one end of the screw rod faces the rotary table, and the other end of the screw rod penetrates through the nut plate and faces the control cabin bracket. The positioning plate assembly comprises a positioning plate and a positioning pin. The positioning plate is fixedly connected with the pin shaft and the rotary table, and provided with more than one positioning hole. The control cabin bracket is provided with more than one positioning hole adapting to the positioning holes in the positioning plate. In this way, when the control cabin bracket is in the transport state or the operation state, one of the positioning holes in the positioning plate communicates with the corresponding positioning hole in the control cabin bracket all the time, and then the positioning pin is plugged into the positioning holes for positioning. The rotating angle of the control cabin bracket is positioned accurately through bolt adjustment, and meanwhile the positioning plate assembly is used in cooperation for positioning, so that the mounting accuracy of the control cabin bracket and the rotary table is improved.

Owner:XCMG CONSTR MACHINERY

Arc extinguishing device of non-polar high-voltage direct-current contactor

PendingCN112908754AWill not cause a collisionMaximize utilizationElectric switchesElectromagnetic relay detailsElectrical polarityEngineering

The invention discloses an arc extinguishing device of a non-polar high-voltage direct-current contactor. The device comprises an arc extinguishing cover body, two static contacts and a movable contact piece, the two static contacts and the movable contact piece are arranged on the arc extinguishing cover body in a spaced mode, and an inner cavity of the arc extinguishing cover body forms an arc extinguishing chamber; the movable contact piece is arranged in the arc extinguishing chamber and can move relative to the two static contacts to conduct the two static contacts, arc discharge spaces are formed in the arc extinguishing chamber and located on the two sides of a connecting line of the two static contacts, and at least one pair of permanent magnets is installed at the positions, corresponding to the arc discharge spaces, of the arc extinguishing cover body. And under the action of a magnetic field generated by a permanent magnet, electric arcs generated by the two static contacts move towards the arc discharge spaces. According to the arc extinguishing device of the non-polar high-voltage direct-current contactor, on the premise that the position of the static contacts is not changed, the maximum arc discharge spaces are guaranteed, the arc extinguishing effect is improved, and research and development of high-power non-polar products are completed in a limited space.

Owner:苏州安来强电子科技有限公司

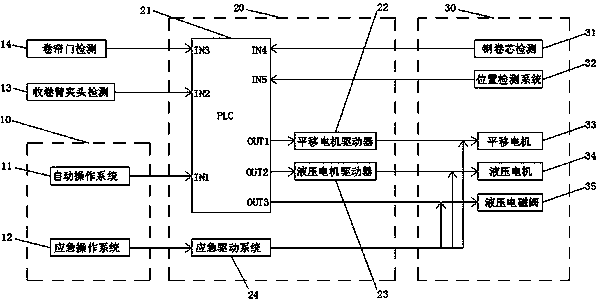

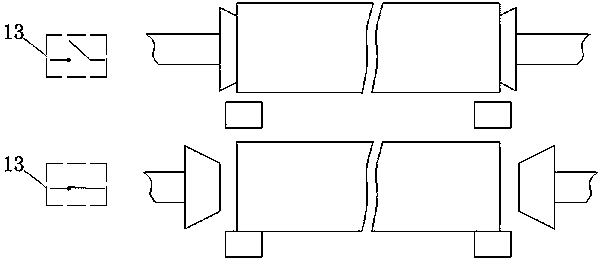

Film production line film transport vehicle control system

ActiveCN108563181AShipped out in timeShipped in timeProgramme control in sequence/logic controllersProduction lineHydraulic motor

The invention provides a film production line film transport vehicle control system. The film production line film transport vehicle control system includes an automatic control system and an emergency control system, wherein the automatic control system comprises: a) an input signal acquisition part, b) a logic control part, and c) a drive part; and the emergency control system comprises: an emergency operating system and an emergency drive system For the film production line film transport vehicle control system, a vehicle body action executing part includes: A) a translation motor for driving the vehicle body to move back and forth along the track, B) a hydraulic motor for driving carriers at two ends of the film transport vehicle to lift, and C) a hydraulic solenoid valve for removingthe hydraulic pressure to lower the carriers at two ends of the film transport vehicle. The film transport vehicle controlled by the film production line film transport vehicle control system has theadvantages of being safe and reliable, being stable in action, being accurate in positioning, and being able to guarantee continuous operation of the production line.

Owner:HEBEI HAIWEI ELECTRON MATERIAL

Method and device for sending and broadcasting resource information

ActiveCN106454955BWill not cause a collisionAvoid transmission interruptionNetwork traffic/resource managementAssess restrictionResource coordinationResource information

The invention discloses a method and device for sending and broadcasting resource information, including: determining resources used by nodes of the second type and resources used by nodes of the first type, and determining nodes of the first type receiving resource coordination messages, the first type A type of node is a node located within the signal coverage of the base station, and the second type of node is a node located outside the base station signal coverage; sending a resource coordination message to the determined first type of node, and instructing the first type of node to broadcast resources The content of the coordination message, the resource coordination message carries the resource information of the first type node and the second type node. By adopting the invention, the continuity of resources is guaranteed during the movement of nodes at the edge of network coverage, resource collisions are reduced, and the utilization rate of system resources is improved.

Owner:DATANG MOBILE COMM EQUIP CO LTD

Ship docking auxiliary device and docking method

PendingCN114604358AWill not cause a collisionReduce impact damageNon-rotating vibration suppressionManipulatorMarine engineeringHeight difference

The invention provides a ship docking auxiliary device and a docking method. The ship berthing auxiliary device comprises a sliding device, a mechanical arm and a mechanical hand which are installed at a berthing point, the sliding device comprises a sliding way and a sliding block, the sliding block is connected with one side of the mechanical arm, the mechanical hand is arranged at the end of the other side of the mechanical arm, and the mechanical hand is connected to a ship body berthing at the berthing point. The ship berthing auxiliary device is used when a ship is a safe distance away from a berthing point, so that collision between the ship and a platform is avoided; the device can adapt to changes of height difference, distance, rotating angle and the like between the ocean platform and a ship connecting point, can be used as a buffer device when the platform is close to a stopping point, reduces the possibility that a shore base and a ship structure are impacted and damaged, improves the safety when a ship stops, also guarantees the service life of the whole device system, and is suitable for popularization and application. And great convenience is brought to offshore operation.

Owner:JIANGSU UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com