Micro-vision servo-control micromanipulation robot system

A servo controller, robot system technology, applied in micro manipulators, bioreactors/fermenters for specific purposes, manipulators, etc., can solve the problem of difficult to guarantee accuracy, micro-manipulation tools easily collided and broken, no automatic obstacle avoidance function, etc. problem, to achieve the effect of less cell damage and lower cost of consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

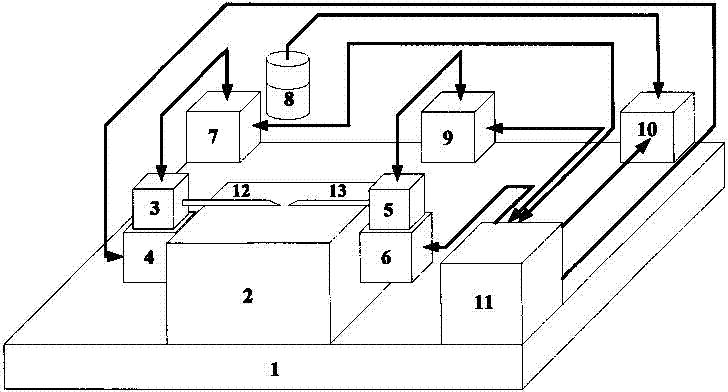

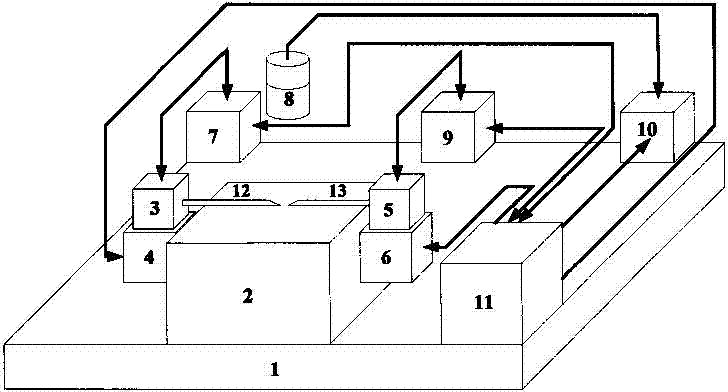

[0018] Please refer to Fig. 1, a biomedical-oriented micro-manipulation robot system of the present invention includes a microscope 2, a left micro-manipulator 3, a right micro-manipulator 5, a left manipulation tool 12 (micro pipette), a right manipulation tool 13 ( microinjection needle), left hand servo controller 7, right hand servo controller 9, camera 8, image processing card 10, computer 11, cell adsorption device 4, gene injection device 6, vibration isolation platform 1, etc. It can complete cell cutting, fusion, injection, chromosome cutting, picking and other micro operations.

[0019] The left and right operating tools 12 and 13 are mounted on the left and right micro-manipulators 3 and 5 respectively, the left micro-manipulators 3 and 5 are three-degree-of-freedom rectangular coordinate motion platforms driven by micro-DC servo linear motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com