Arc extinguishing device of non-polar high-voltage direct-current contactor

A high-voltage DC, arc extinguishing device technology, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problem of arcing space unable to increase power, avoid occupying arc extinguishing room space, improve magnetic force utilization, improve The effect of the arc extinguishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

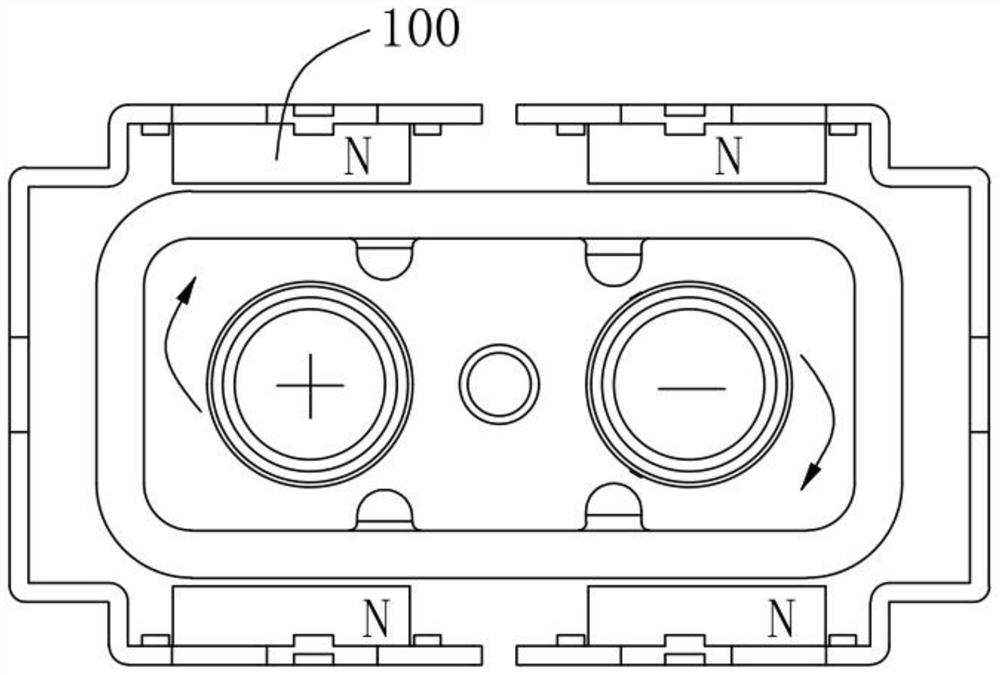

Embodiment 1

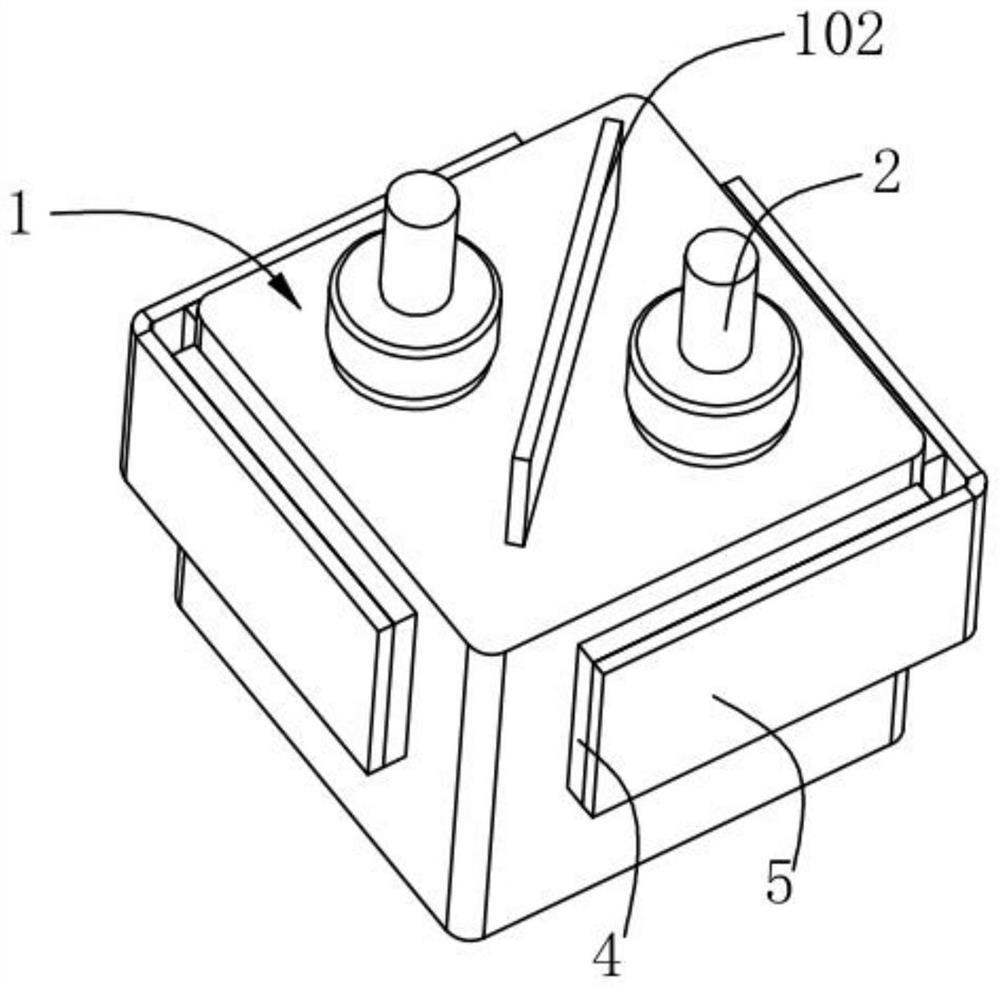

[0048] refer to Figure 3 to Figure 7 , the present invention provides a non-polar high-voltage DC contactor arc extinguishing device, comprising: an arc extinguishing cover 1, two static contacts 2 and a moving contact 3 installed on the arc extinguishing cover 1 at intervals, the extinguishing The arc extinguishing cover 1 is made of ceramic material, and the arc extinguishing cover 1 is sealed and fixedly connected with the magnetic guide plate of the contactor, and the inner cavity of the arc extinguishing cover 1 forms an arc extinguishing chamber 101 . The bottoms of the two static contacts 2 extend into the arc extinguishing chamber 101, the moving contact piece 3 is movably placed in the arc extinguishing chamber 101 and is facing the bottom of the two static contacts 2, the moving contact piece 3 can be opposite to the two static contacts 2 moves upwards to contact two static contacts 2, and then conducts the two static contacts 2.

[0049] refer to Figure 4 , the ...

Embodiment 2

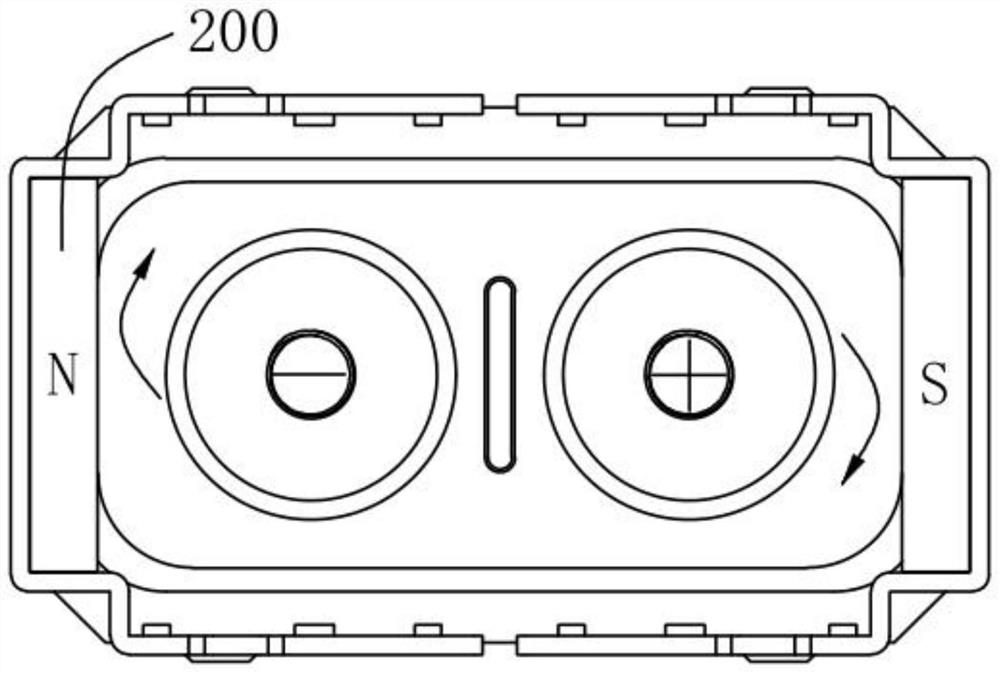

[0058] refer to Figure 8 The difference between this embodiment and Embodiment 1 is that the polarities of the two permanent magnets 4 corresponding to the arcing space 1011 on the same side are different, and the polarities of the two permanent magnets 4 located at the same angle are also different, that is, the four permanent magnets 4 , any two adjacent permanent magnets 4 have different polarities. Specifically: the four permanent magnet poles located at the upper left, lower left, upper right, and lower right are respectively N pole, S pole, S pole, and N pole. The permanent magnet 4 is placed in the same principle as above, regardless of the direction of the current, the arcs generated by the two static contacts 2 can be directed upward or downward into the arcing space 1011 without causing collision of the arcs, realizing No polarity required.

Embodiment 3 Embodiment 4

[0060] refer to Figure 9 and Figure 10 , are respectively the arrangement of the permanent magnets 4 of the third embodiment and the fourth embodiment, the difference from the first embodiment is that permanent magnets 4 with the same polarity are installed on the four side walls of the arc extinguishing cover 1 . Wherein, the polarities of the four permanent magnets 4 in the third embodiment are all N poles, and the polarities of the four permanent magnets 4 in the fourth embodiment are all S poles. Example 3 is used to illustrate: the static contact 2 located on the left is under the joint action of two permanent magnets 4 distributed close to the same angle, and the magnetic force vector it receives is directed to the left, and according to the left-hand rule, the arc will be directed upward Or in the lower arcing space 1011, the specific direction depends on the current flow direction. The arc generated by the static contact 2 on the right will also lead to the same arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com