A shell of an angle valve and an angle valve with a shell

A technology of shell and angle valve, applied in the direction of valve shell structure, sliding valve, valve details, etc., can solve the problems of difficult and cumbersome installation of angle valve, achieve the effect of saving cost, avoiding collision and improving the appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

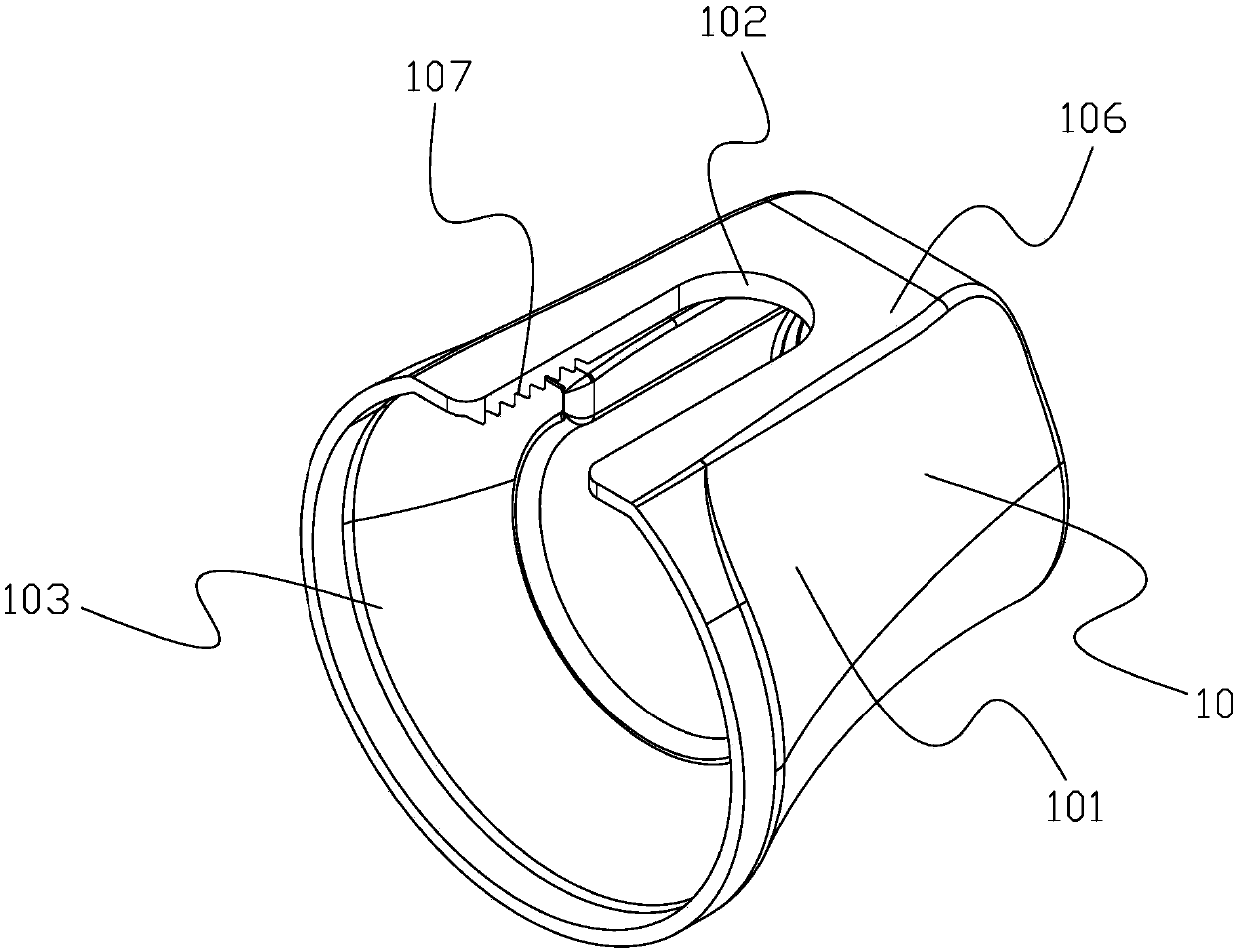

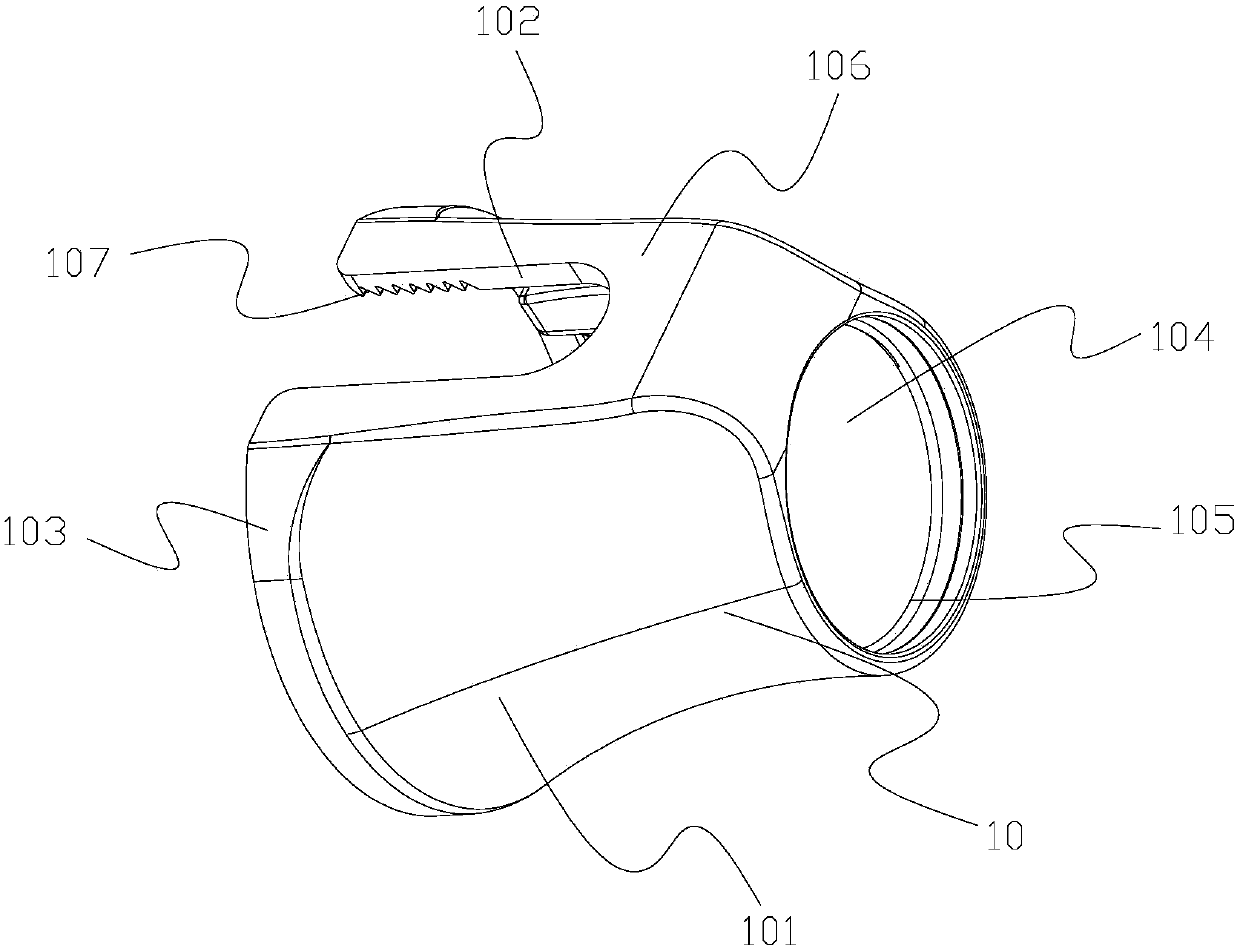

[0044] See figure 1 with figure 2 This embodiment provides an angle valve housing, including a cover body 10, the side surface 101 of the cover body is provided with a pipe-through groove 102, the notch of the pipe-through groove penetrates the bottom surface of the housing, and the bottom of the cover body is provided with a skirt belt 103. The cover is provided with through holes 104 penetrating through the top and bottom surfaces of the cover.

[0045] The housing of the angle valve of the technical solution has a hollow cylindrical cover, and a pipe-through groove is provided on the side of the hollow cylinder. The pipe-through groove is a U-shaped groove for passing through the water outlet channel of the angle valve. . In some embodiments, the diameter of the housing is large, and the skirt belt completely covers the entire valve body, and the pipe-through groove is used to pass through the water pipe connected to the water outlet channel of the angle valve. A skirt belt ...

Embodiment 2

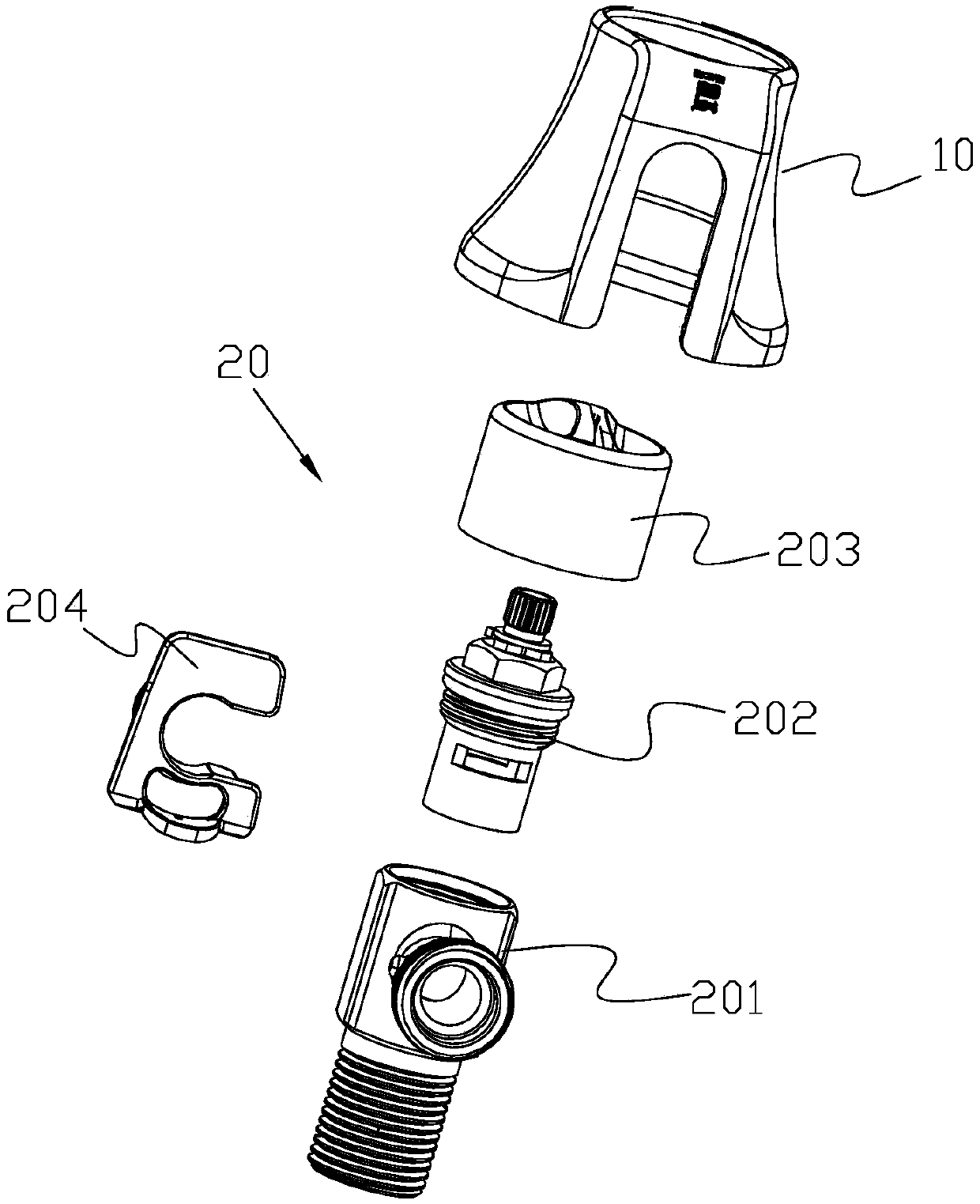

[0050] See Figure 1 to Figure 11 This embodiment provides an angle valve with a shell, including a shell 10 and a valve body 20; the side 101 of the shell is provided with a pipe-through groove 102, and the groove of the pipe-through groove penetrates the bottom surface of the housing, so that the valve body drains The tube can enter the piercing groove through the slot, the bottom of the cover is provided with a skirt 103, and the cover is provided with through holes 104 penetrating the top and bottom surfaces of the cover. Of course, the housing of this embodiment can be The shell of the first embodiment.

[0051] The valve body includes a housing 201, a valve core 202, and a screw cap 203. The valve core is arranged in the water inlet channel 2011 of the housing. The screw cap is sleeved on the top end 2021 of the valve core. There is a groove 2031 for accommodating fingers, the screw cap is arranged in the through hole, and the pipe-through groove is sleeved on the outer si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com