Metal ornament surface electroplating treatment device

A technology of electroplating treatment and jewelry, applied in the direction of electrolysis process, electrolysis components, cells, etc., can solve the problems affecting the quality of the plating layer and the surface quality of the electroplating parts, and achieve continuous and effective electroplating treatment, improve the efficiency of electroplating, and reduce the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

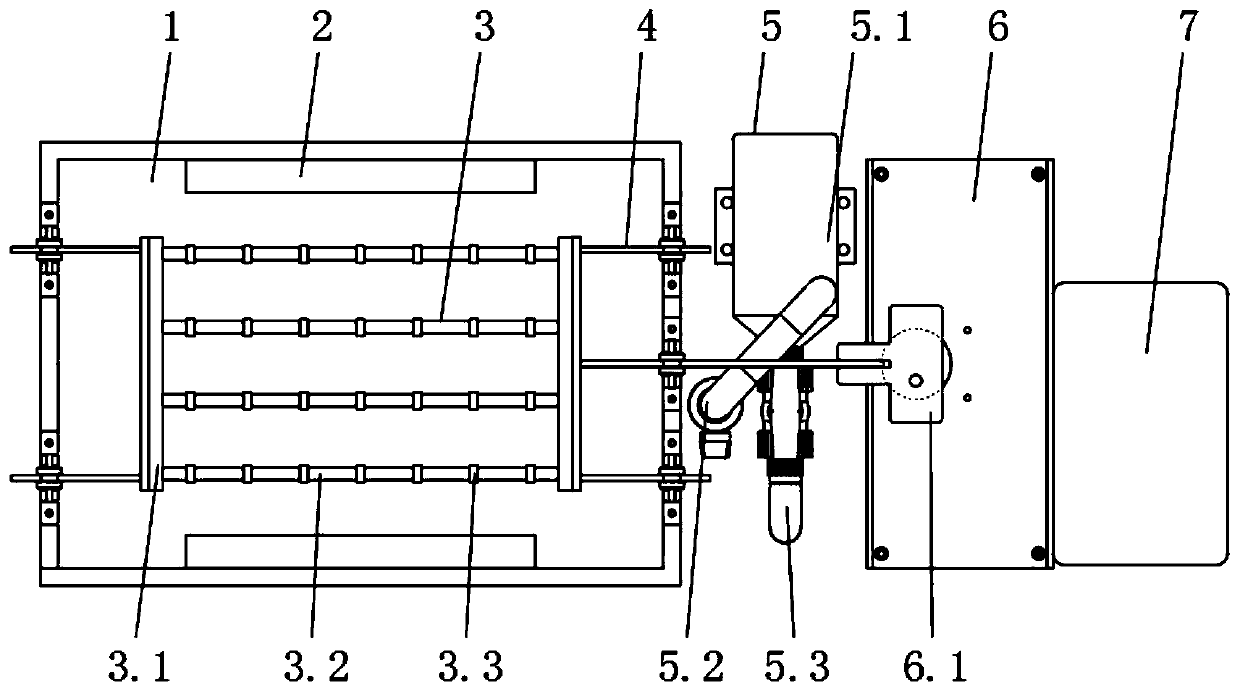

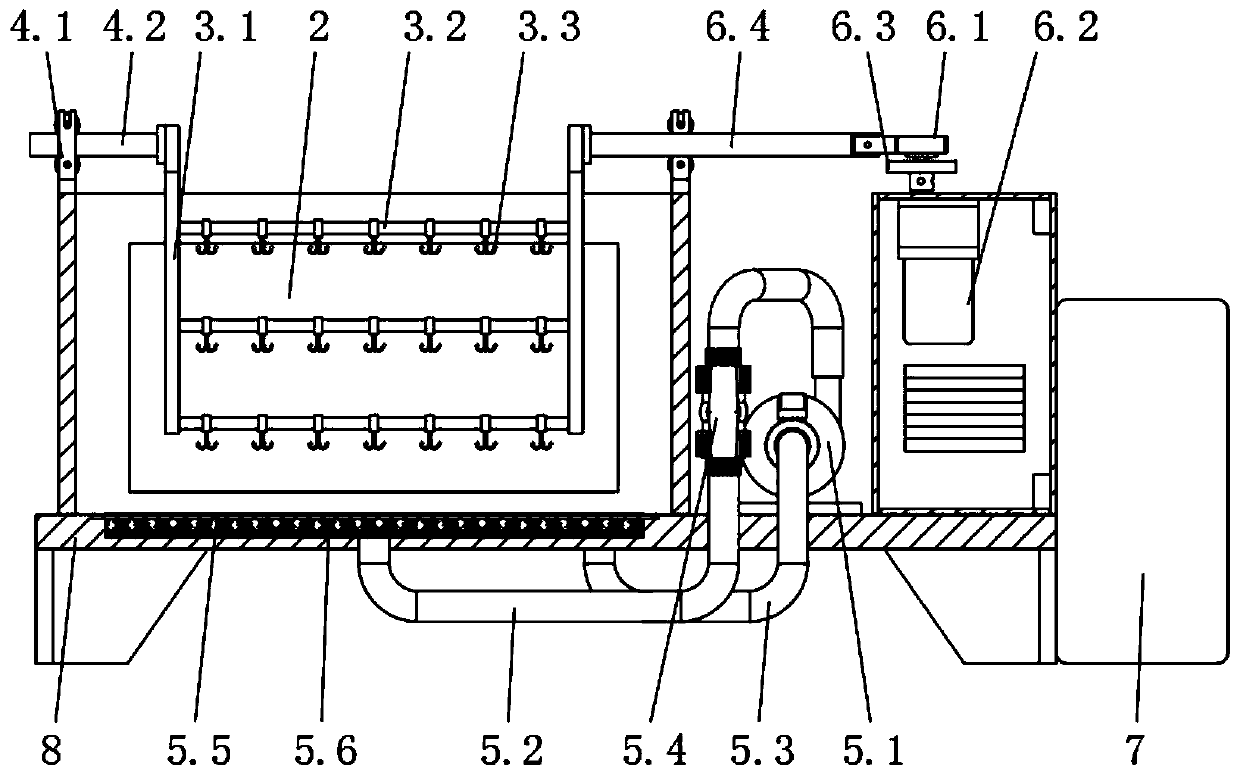

[0030] Embodiment one, with reference to Figure 1-2 , a metal jewelry surface electroplating treatment device, comprising an electroplating pool 1, an anode 2, a cathode 3, a rectifier 7 and a base 8, the electroplating pool 1 is respectively provided with an anode 2, a cathode 3, and the cathode 3 is erected on the electroplating plate through a guide mechanism 4 At the middle position of the pool 1, a base 8 is provided under the bottom of the electroplating pool 1, and a filter unit 5 and a swing mechanism 6 are arranged on one side of the electroplating pool 1 on the base 8 in turn, and a rectifier 7 is provided on one side of the base 8, and a cathode 3 is provided The guiding mechanism 4 is erected in the electroplating pool 1, and used in conjunction with the swing mechanism 6, so that the cathode 3 and the hanging ornaments swing regularly in the electroplating pool 1 at low frequency, thereby accelerating the convection of the solution and consuming near the cathode 3...

Embodiment 2

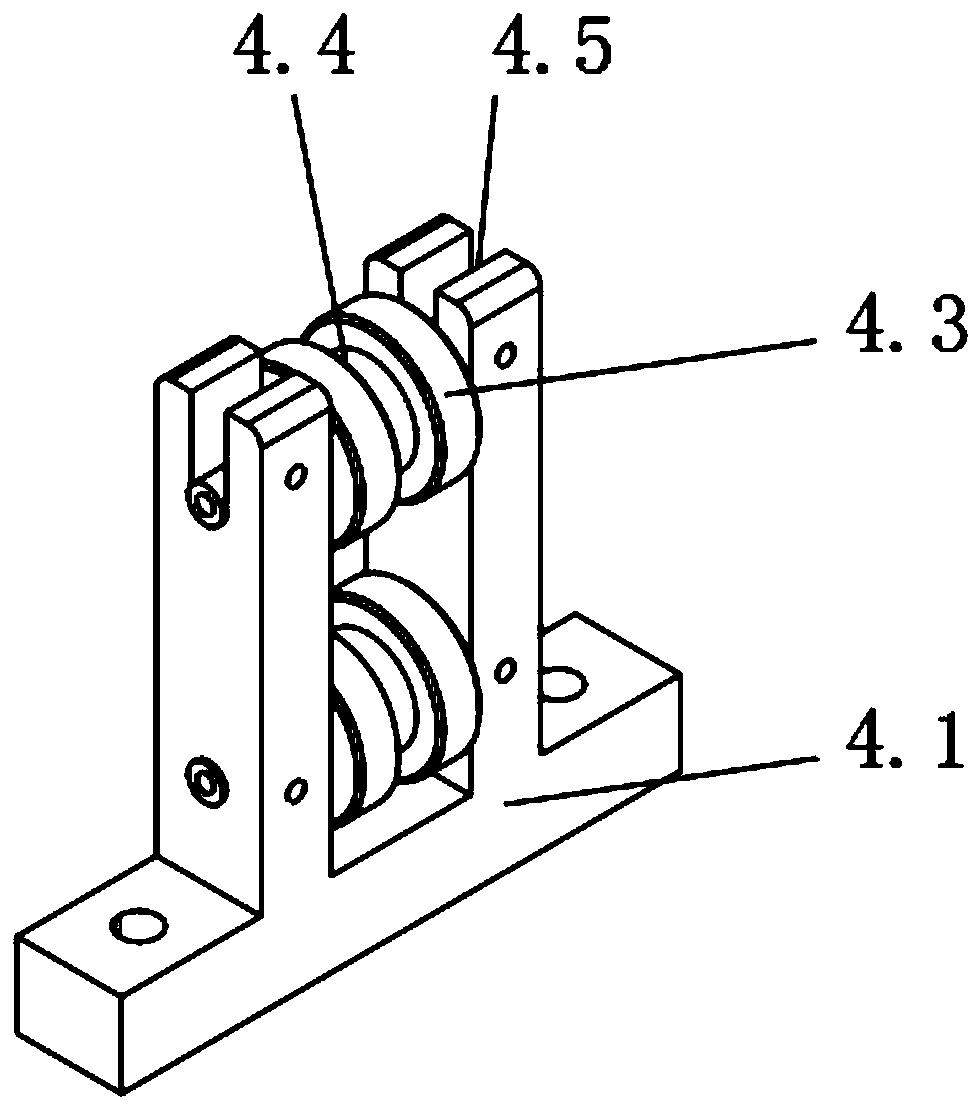

[0031] Embodiment two, refer to Figure 1-3 and Figure 4 , the guide mechanism 4 includes a support seat 4.1, a guide rod 4.2, and a guide wheel 4.3, and the support seat 4.1 is provided with two guide wheels 4.3 from bottom to top, the lower guide wheel 4.3 is fixedly connected with the support seat 4.1 through a pin shaft, and the upper part is fixed through a pin The shaft and the limit groove 4.5 on the top of the support seat 4.1 are clamped, and the middle position of the surface of the guide wheel 4.3 is provided with a groove 4.4 for use with the guide rod 4.2 to ensure the reciprocating movement of the cathode 3 in the electroplating tank 1 and better cooperate with the swing Normal use of mechanism 6.

Embodiment 3

[0032] Embodiment three, refer to Figure 1-2 and Figure 5-6 , the swing mechanism 6 includes a swing member 6.1, a drive motor 6.2, a driving wheel 6.3, a swing rod 6.4, and a driven wheel 6.5, and a guide groove 6.6 is provided on the surface of the swing member 6.1, and the drive motor 6.2 is installed above the inside of the control box, and the drive motor The driving wheel 6.3 is installed above the driving wheel 6.3, and the driven wheel 6.5 is installed eccentrically on the upper surface of the driving wheel 6.3, and the upper part of the driven wheel 6.5 is connected to the swing member 6.1 through the guide groove 6.6, and the side of the swing member 6.1 is connected to the guide mechanism 4 through the swing rod 6.4 The driving motor 6.2 drives the driven wheel 6.5 eccentrically connected to the driving wheel 6.3 to rotate, and the driven wheel 6.5 interacts with the guide groove 6.6 in the swinging member 6.1, so that the swinging member 6.1 and the cathode 3 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com