Swinging-type long-pipe inner wall electroplating method and electroplating equipment applying same

A technology for electroplating equipment and long pipes, applied in the field of the method for electroplating the inner wall of a swinging long pipe and the field of electroplating equipment, can solve problems such as influence on electroplating quality, easy formation of arcs, influence on production efficiency, etc., to ensure the quality of electroplating and the uniform thickness of the coating , Improve the effect of electroplating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

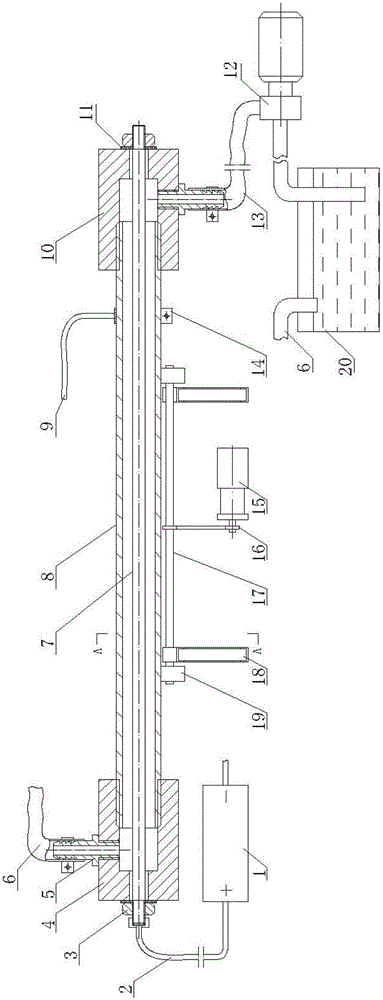

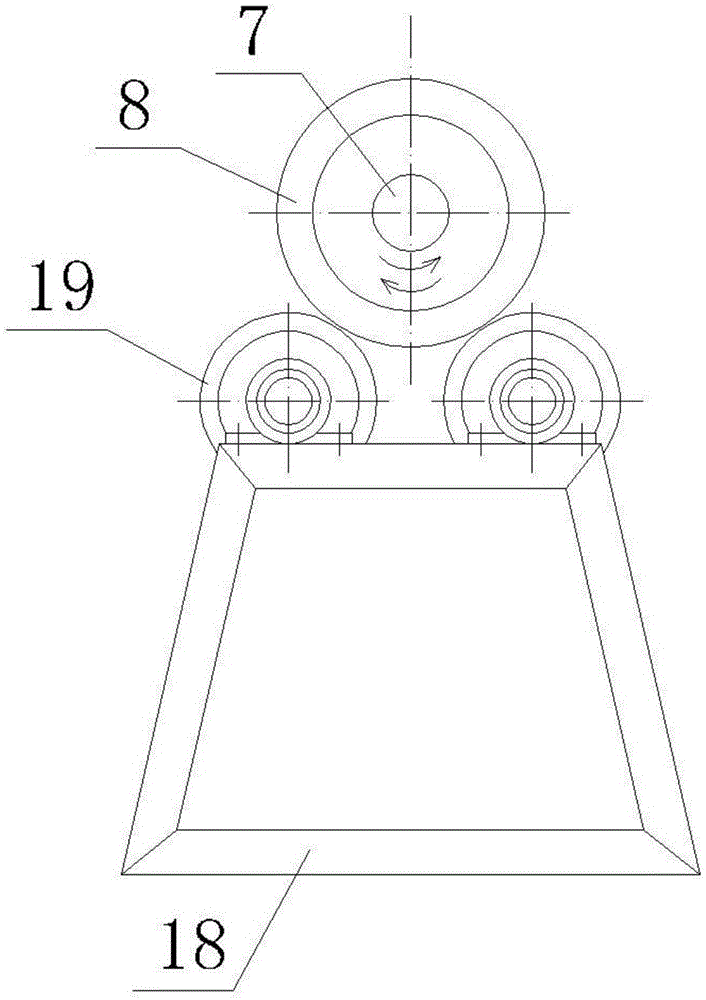

[0030] Such as figure 1 As shown, the electroplating method for the inner wall of the swing type long tube involved in the present invention adopts the following technical scheme:

[0031] 1. Pass the inner anode 7 through the long cathode tube 8 to be electroplated, and seal the two ends of the long cathode tube 8 to the liquid inlet joint 10 and the liquid outlet joint 4 respectively, so that the long cathode tube 8 passes through the liquid inlet joint 10 Form a closed solution cavity with the liquid outlet joint 4; the liquid inlet joint 10 and the liquid outlet joint 4 are respectively communicated with the liquid storage tank 20 through the liquid inlet hose 13 and the liquid outlet hose 6; and installed on the liquid inlet hose 13 Pump body or filter 12.

[0032] 2. Fix the two ends of the inner anode 7 on the liquid inlet joint 10 and the liquid outlet joint 4 respectively, and then connect one outlet end of the inner anode 7 and the outer wall of the long cathode tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com