Patents

Literature

93results about How to "Loading and unloading safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

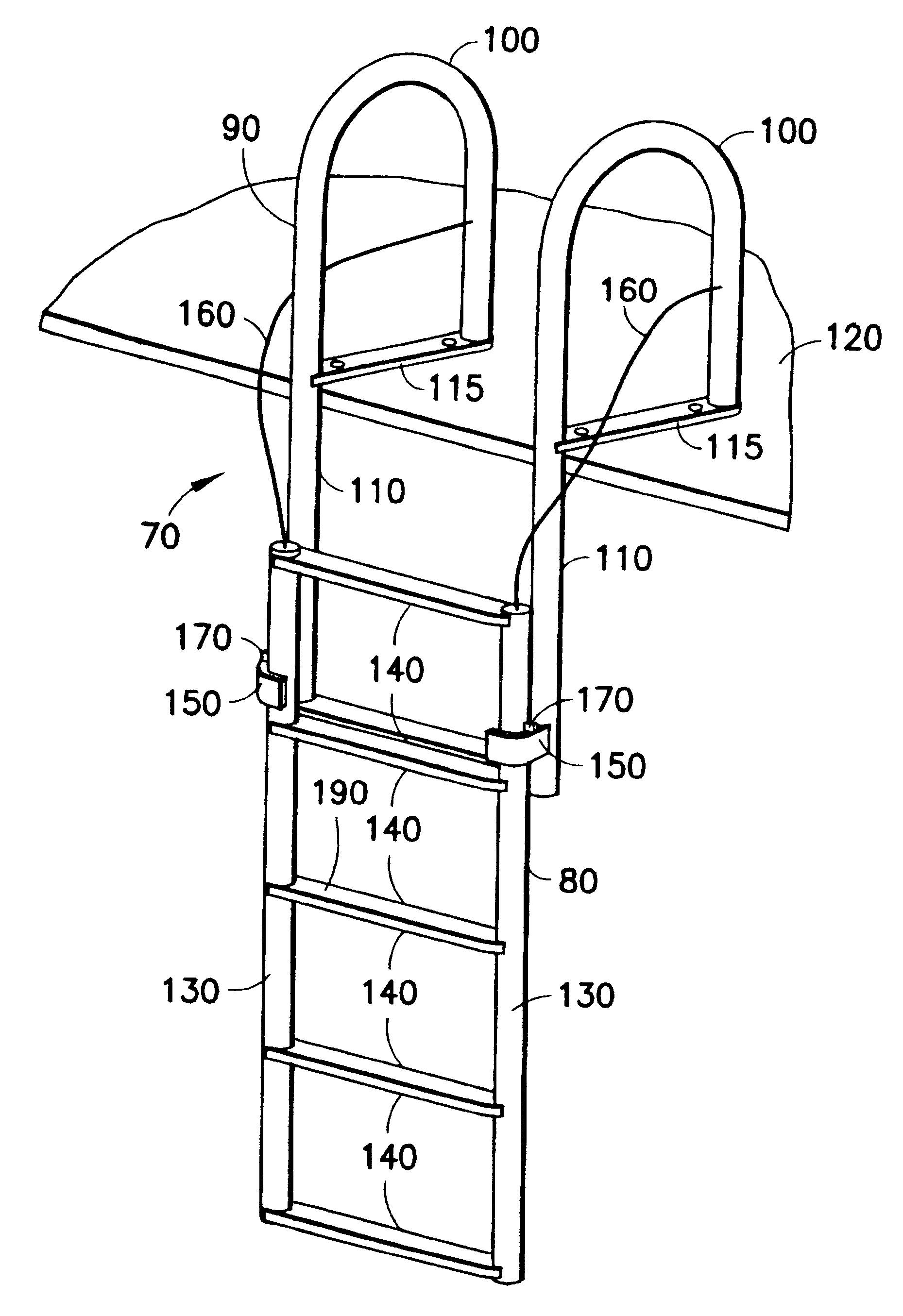

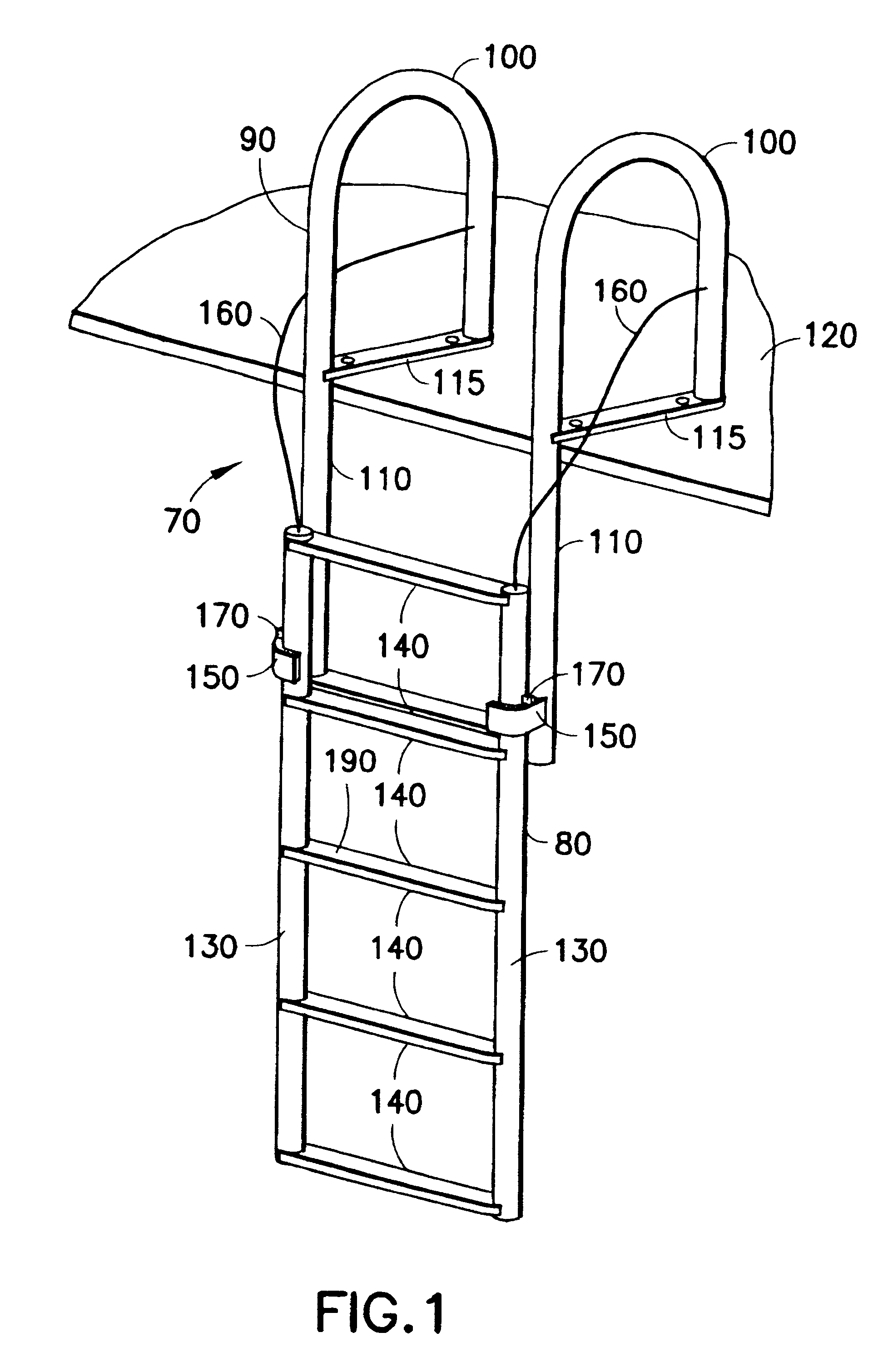

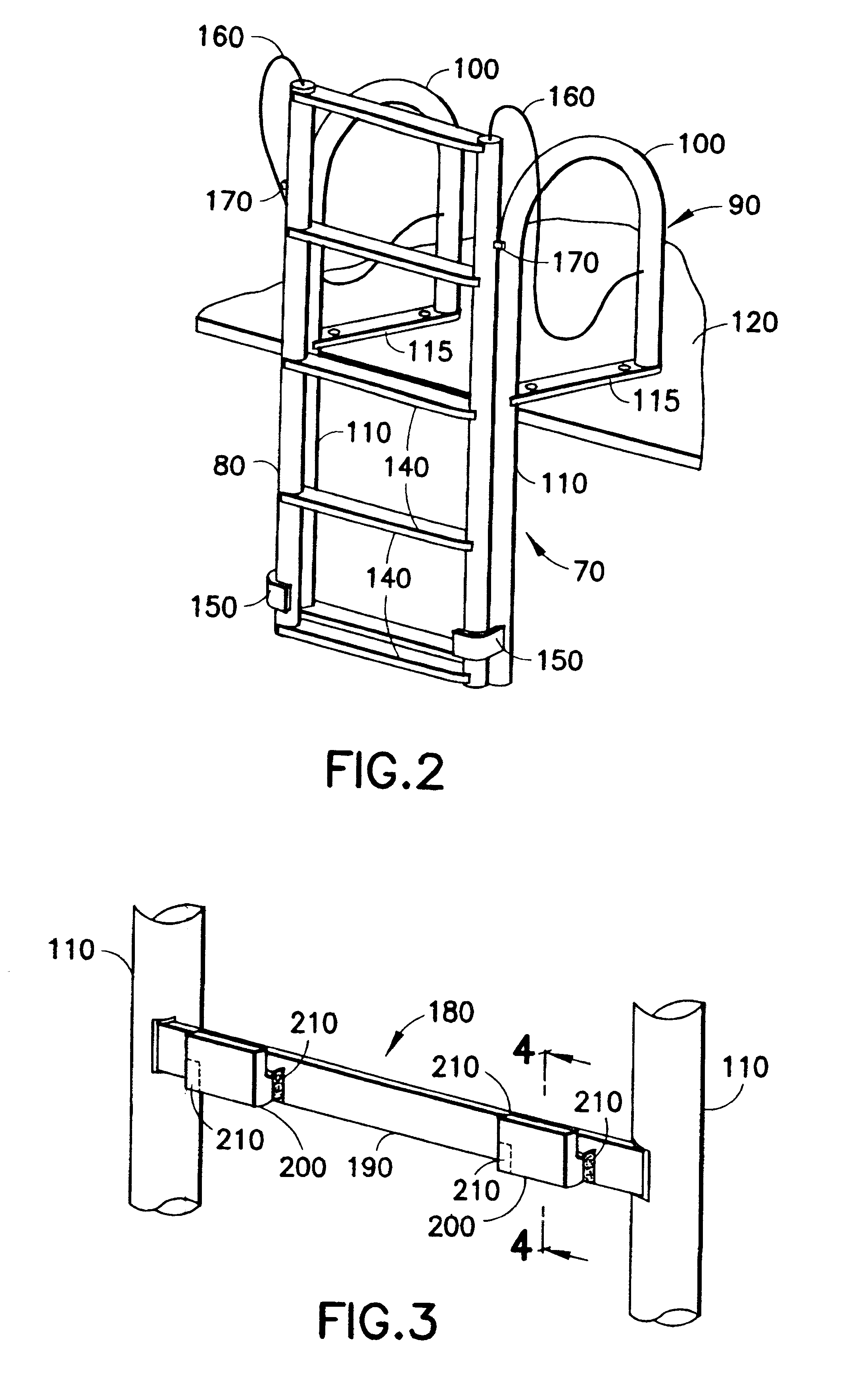

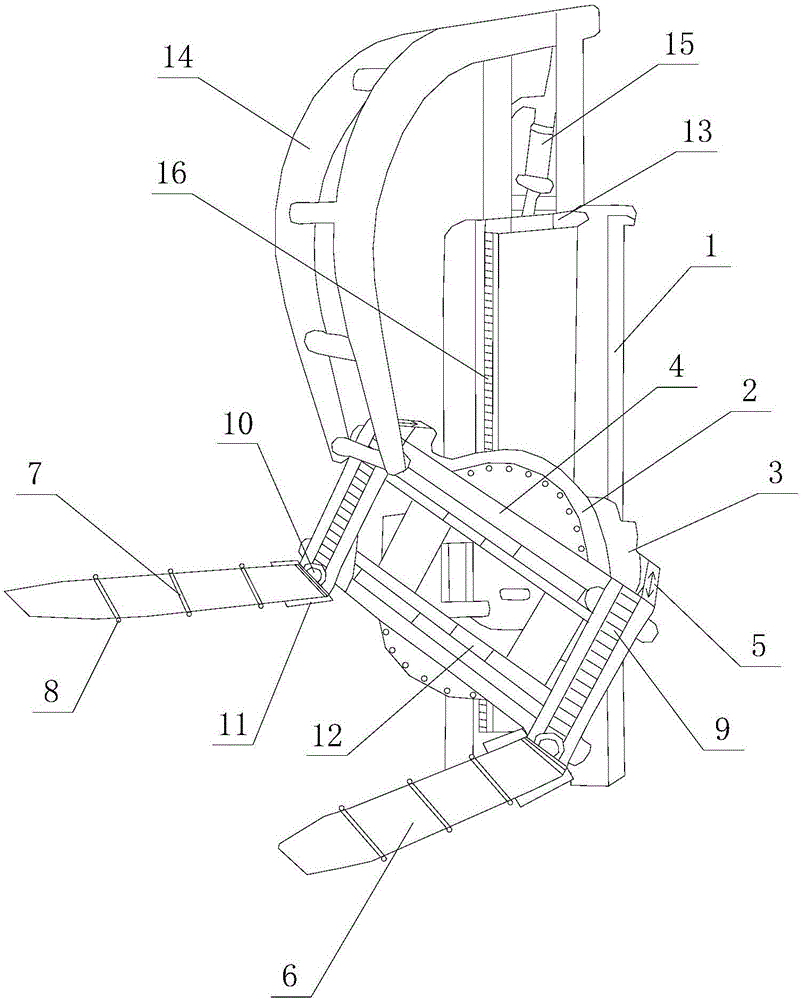

Marine ladder

InactiveUS6422340B1Relieve pressureLoading and unloading safetyCargo handling apparatusPassenger handling apparatusWatercraftMechanical engineering

A marine ladder includes a catch mechanism in which a catch tyne is directly secured to the marine ladder without the need for additional structural members or support. The catch tyne is formed as a substantially L-shaped member that dependingly connects to a transverse bar on the dock-anchored frame of the ladder and defines a channel for receiving a leg of a user-selected one of the un-shaped rungs on an elongated ladder portion. The ladder portion is slidably engageable with and along the anchored frame to thereby selectively adjust the height of the ladder and thereby accommodate ready movement of persons between a dock and a proximate watercraft disposed at relatively different elevations.

Owner:GRUNDLER HELMUT

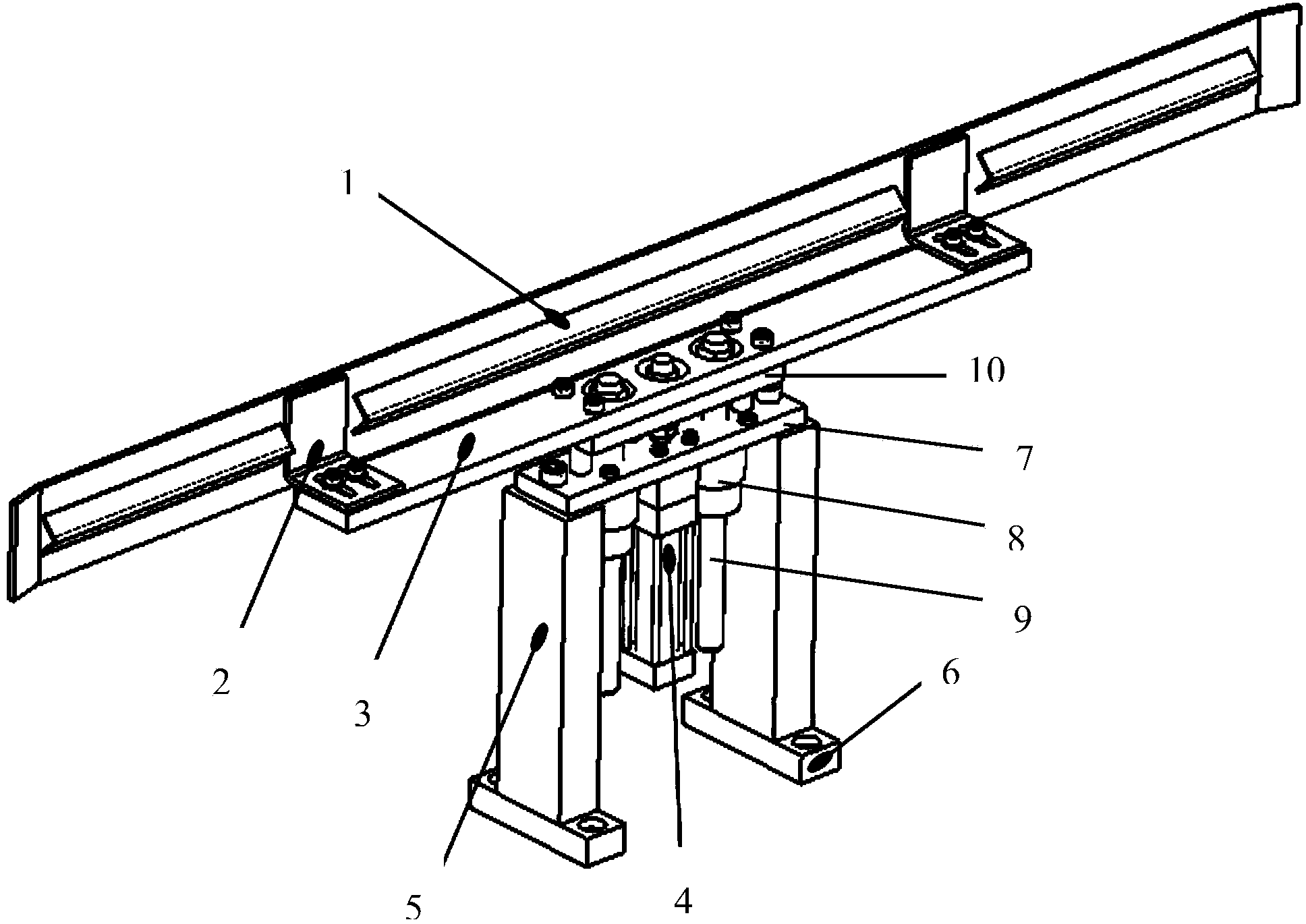

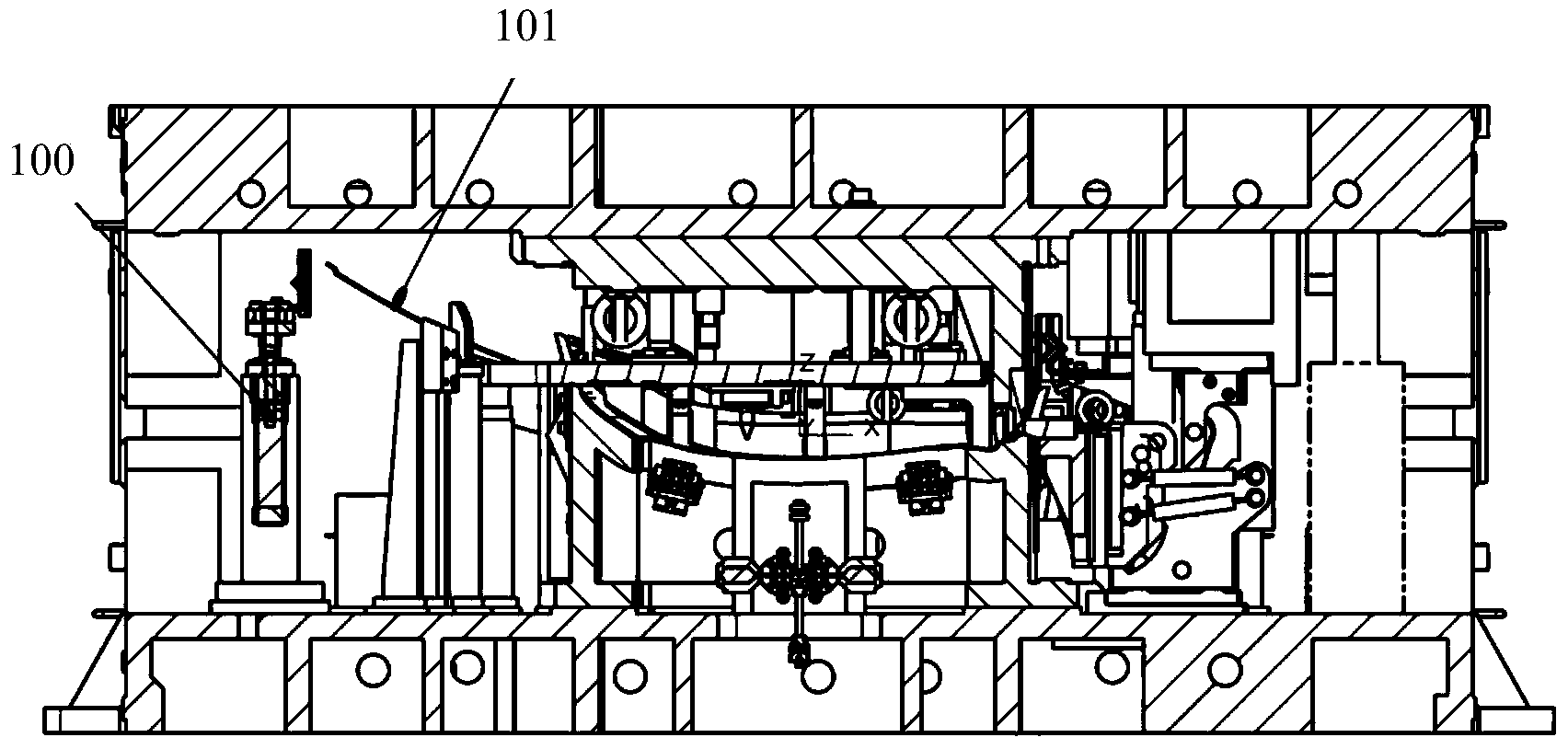

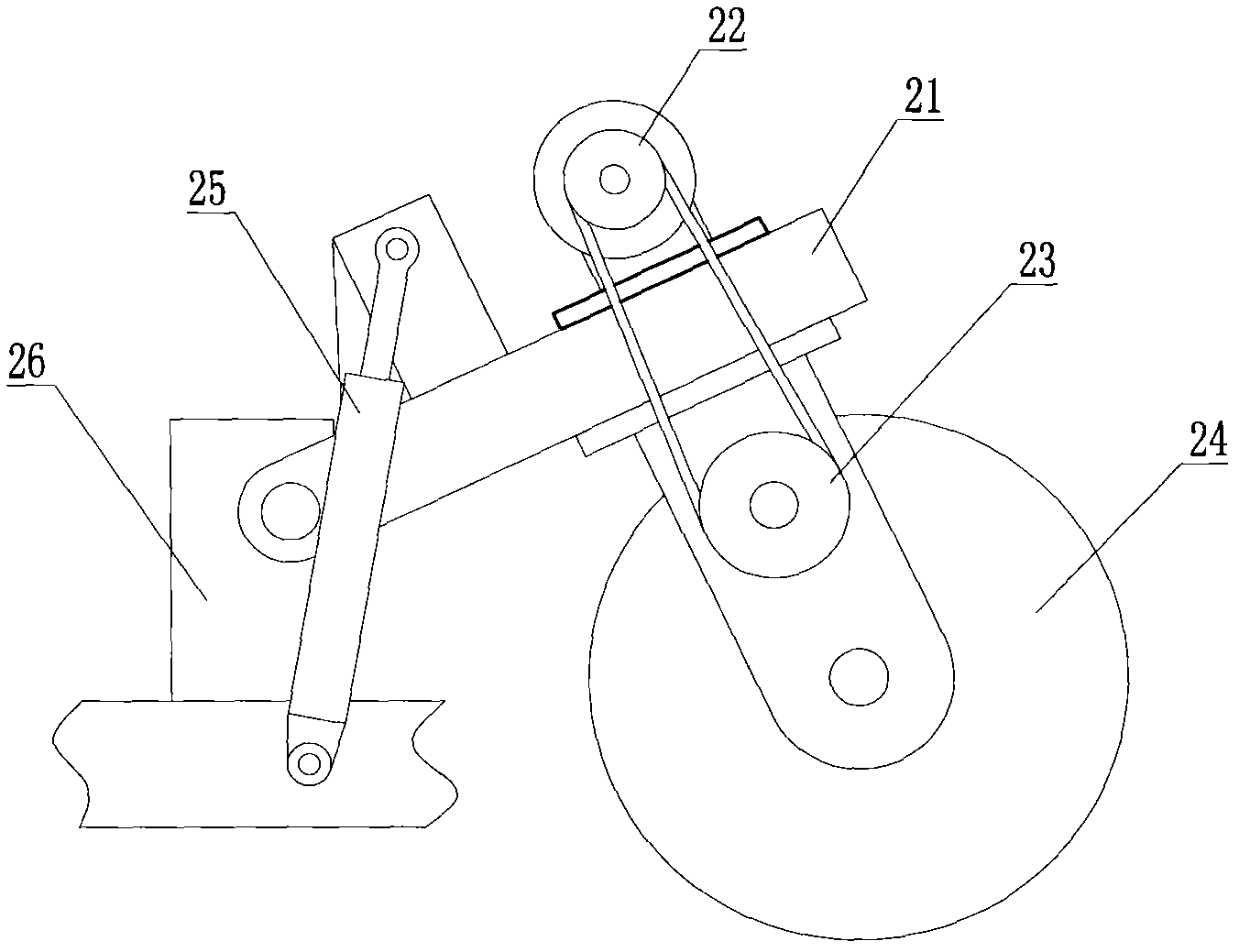

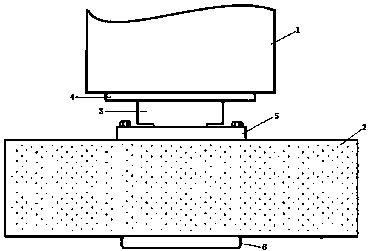

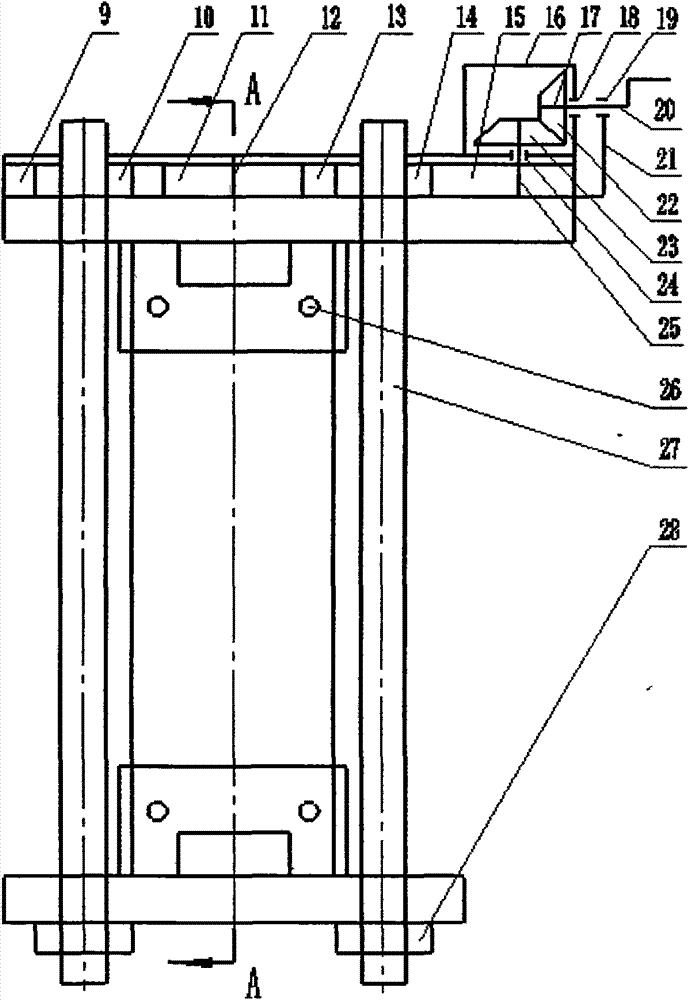

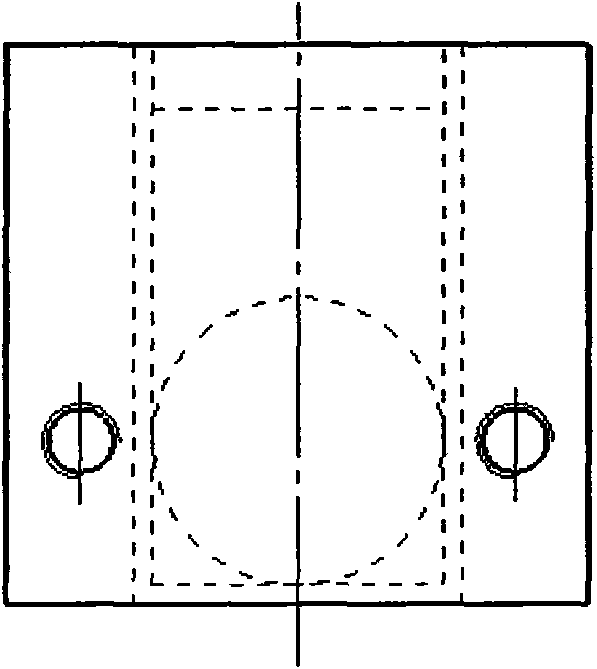

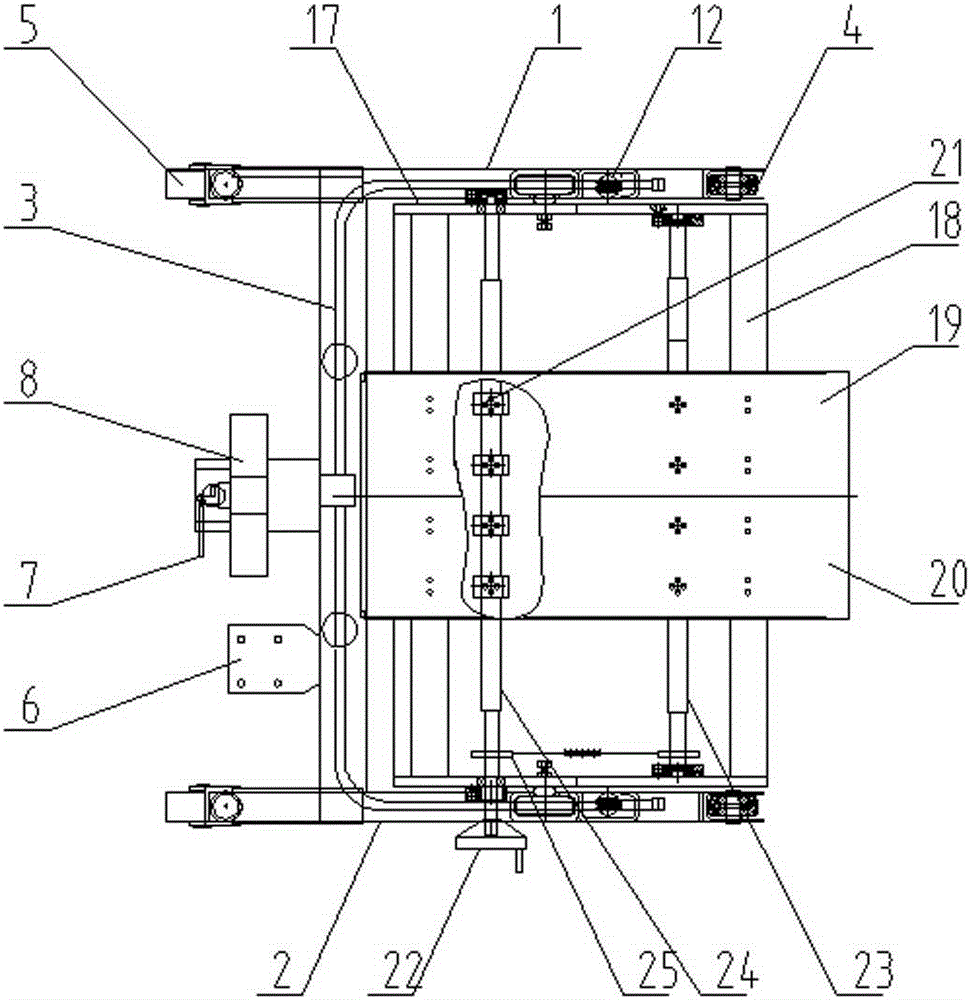

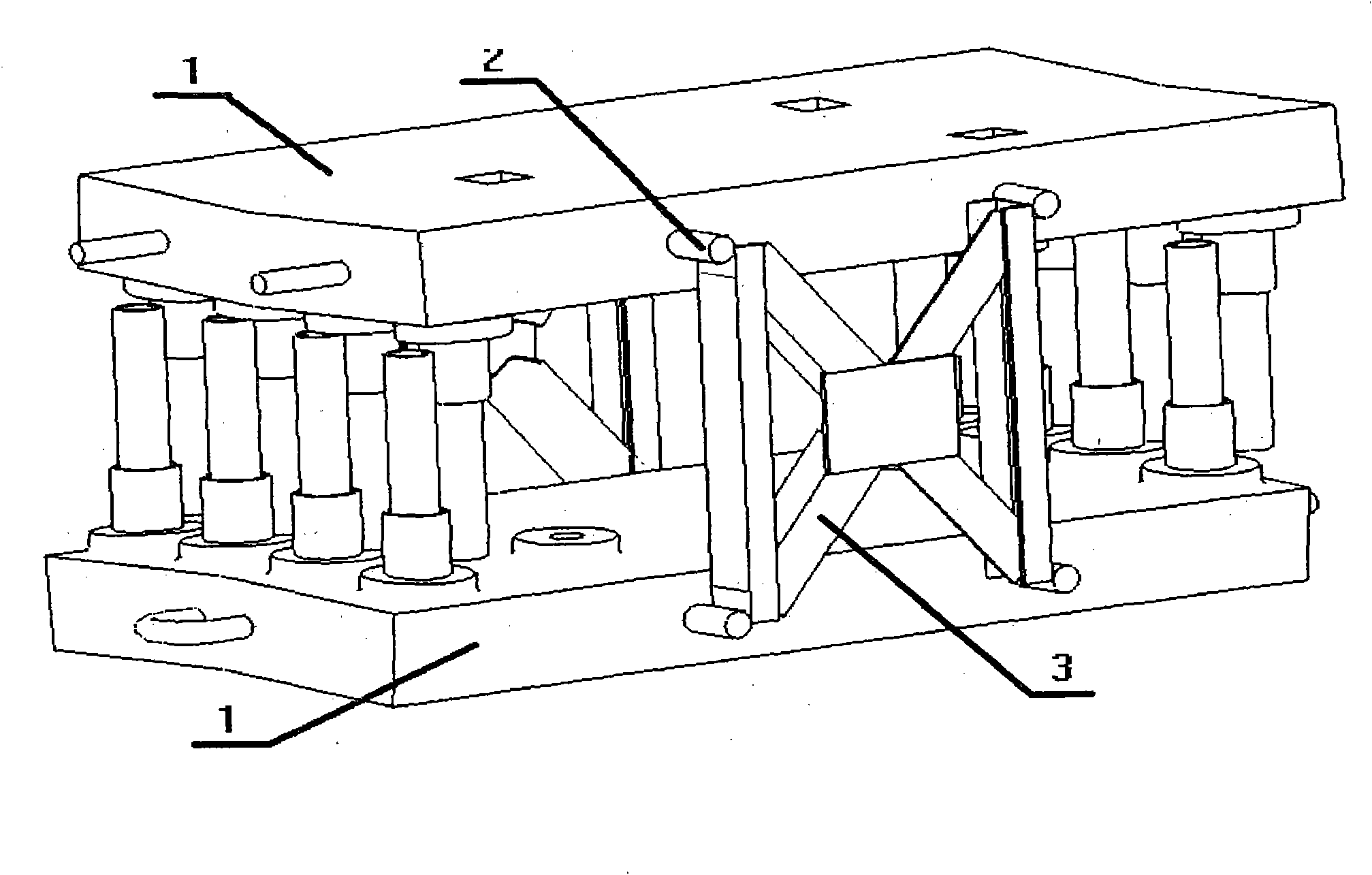

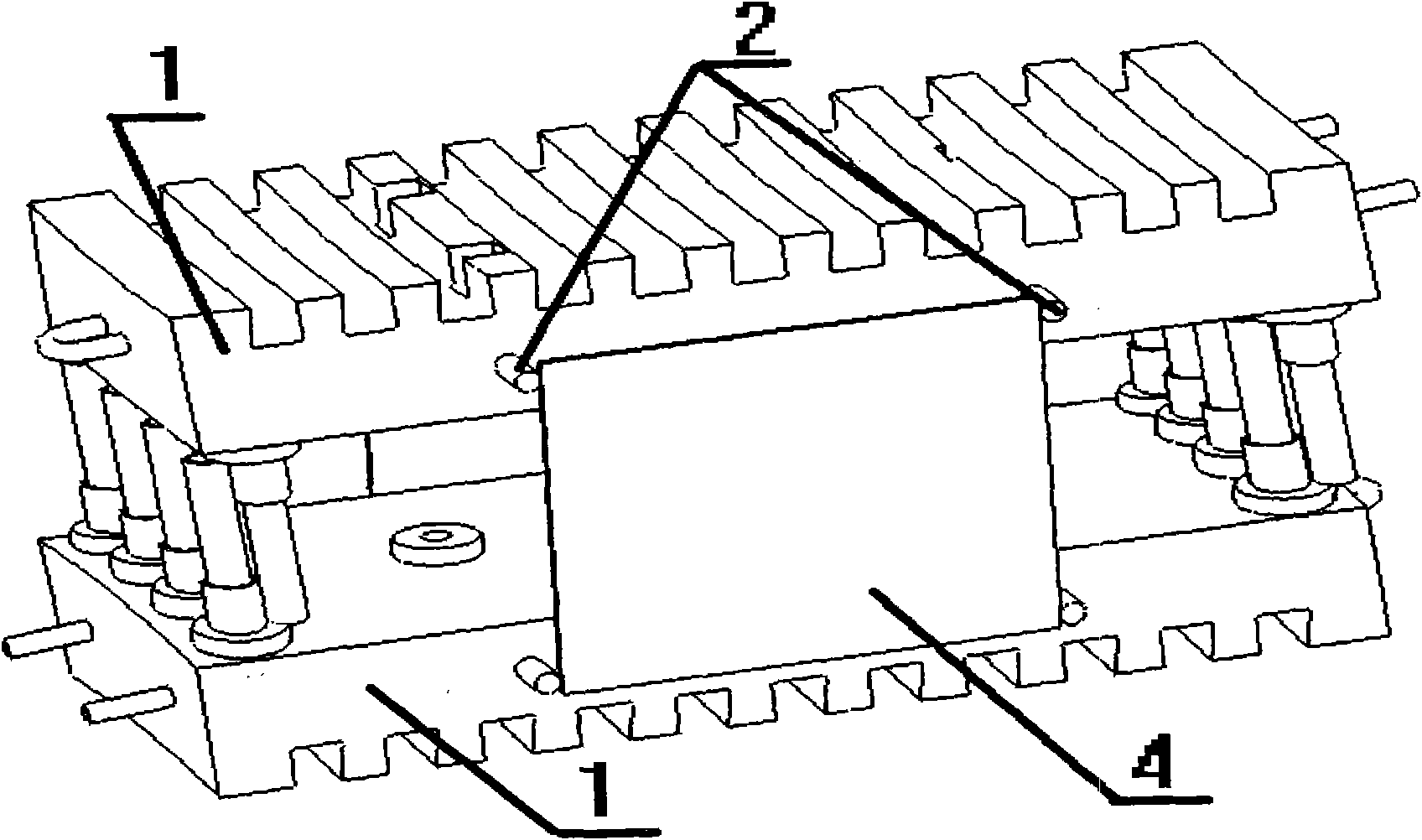

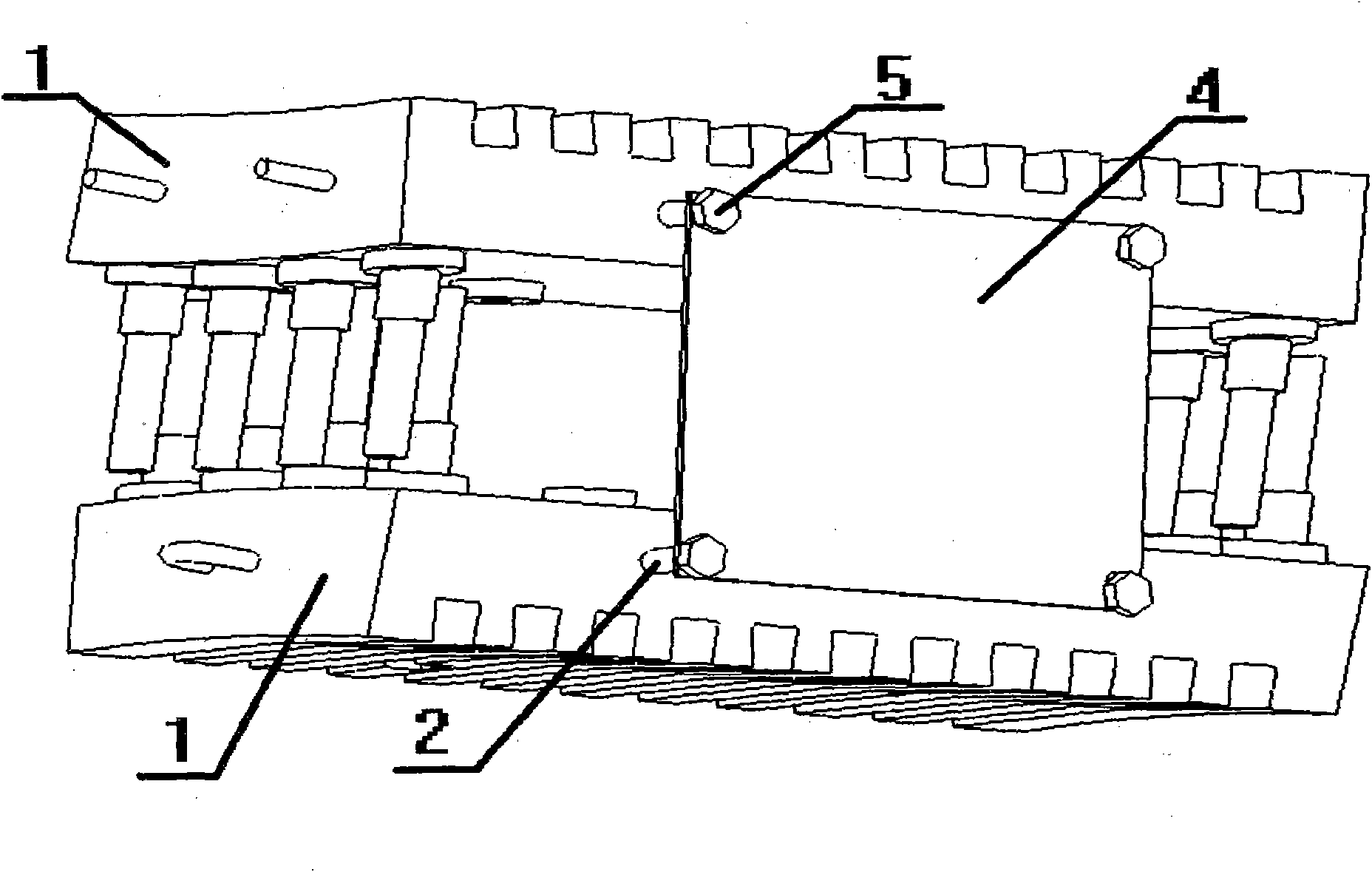

Automobile press fit die transmission and positioning mechanism

ActiveCN103817243ASmooth loading and unloadingLoading and unloading safetyShaping toolsMetal-working feeding devicesMechanical engineeringMental detachment

The invention discloses an automobile press fit die transmission and positioning mechanism, which comprises a positioning plate mounting plate, an assembly transportation positioning plate, a lifting jack and a fixing device, wherein the top surface of the positioning plate mounting plate is vertical to the stamping direction of an automobile press fit die; the assembly transportation positioning plate is mounted on the top surface of the positioning plate mounting plate and faces to a stamping piece in the automobile press fit die; the distance between the assembly transportation positioning plate and the stamping piece is adjustable; the lifting jack is capable of jacking and dropping down the positioning plate mounting plate and the assembly transportation positioning plate; the fixing device is used for fixing the lifting jack. According to the automobile press fit die transmission and positioning mechanism, the height direction and the horizontal direction of the stamping piece transportation positioning mechanism are adjustable, the loading and the discharging of the stamping piece are more stable and safer, and the space is saved; the adjustable positioning mechanism is adopted, the problem that the positioning mechanism intervenes with a press fit cutter block mounting seat and an upper die under the existing die height is solved, and the die height is reduced to 1000 mm, and therefore, the mixed routing manufacturing of different products is realized, the casting cost is reduced, the tool development expense is reduced, and the processing, the detachment, the debugging and the production are facilitated.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

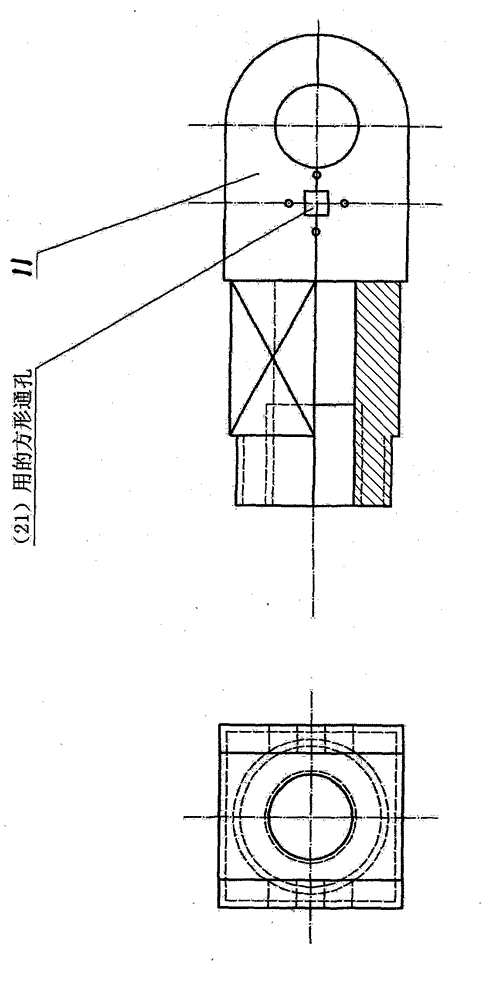

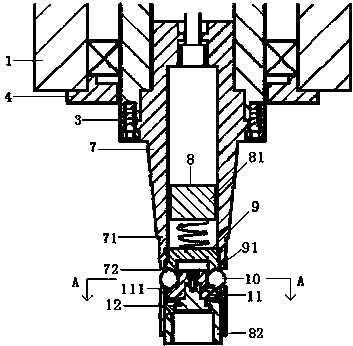

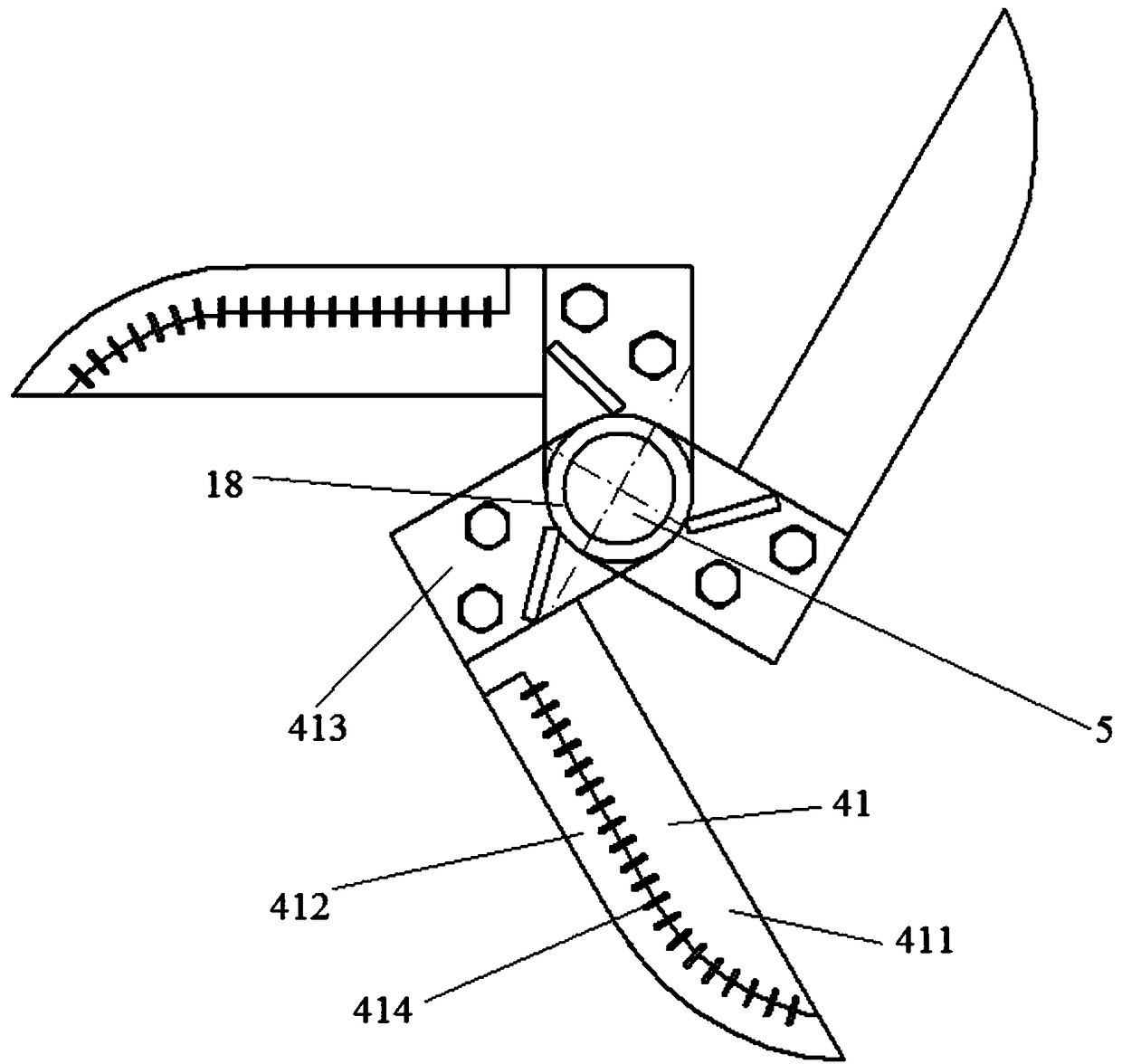

Automatic gravity gripper

ActiveCN104058182AStrong interchangeabilityFast loading and unloadingExternal framesEngineeringMechanical engineering

The invention relates to a gripper for transportation and storage. The gripper consists of a gripper seat assembly, a square shaft assembly, groove-shaped movable gripping head assemblies and a spine lock assembly, wherein the gripper seat assembly looks like a square with a half capable of being separated and combined, and the gripper seat assembly is fastened integrally through screws and adjusting connecting plates; the square shaft assembly is fastened on square holes for square shafts of the gripper seat assembly through fastening nuts; each groove-shaped movable gripping head assembly looks like a bow, the left and right groove-shaped movable gripping head assemblies can be matched to form a sleeved ring which can be opened and closed, and the groove-shaped movable gripping head assemblies are mounted in hinge pin holes in front ends of the square shafts through hinge pins and can be freely opened at 45 degrees-135 degrees; the spine lock assembly penetrates through round spine lock assembly through holes above the front side of the gripper seat assembly and is fastened on the square shafts through screws. The automatic gravity gripper is generally applicable to transportation and storage, and parts are high in interchangeability and can be produced in batches in a standard manner (the automatic gravity gripper can also be assembled on a liftable trolley and is quick, convenient and safe in object transportation, loading and unloading).

Owner:江苏北华微电子科技有限公司

Therma processing method for crankshaft of high-power engine

InactiveCN1540004ASufficient quenching hardnessEnough depthFurnace typesHeat treatment furnacesEngineeringCrankshaft

A technology for thermally treating the crankshaft of high-power engine includes such steps as heating to 830-850 deg.c, holding the temp for 2 hrs, quenching in the liquid at 20-55 deg.C for 6-8 min, tempering at 640-660 deg.C for 3 hrs, and air cooling. Its advantage is high comprehensive mechanical performance of treated crankshaft.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

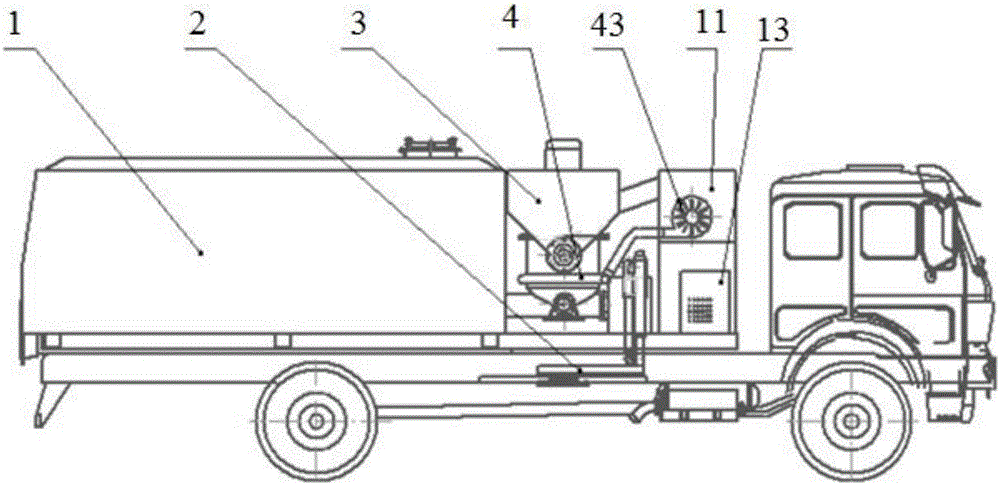

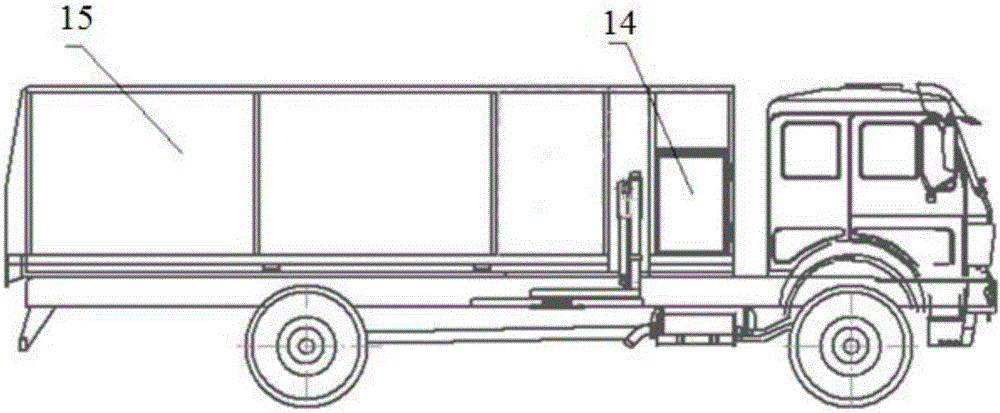

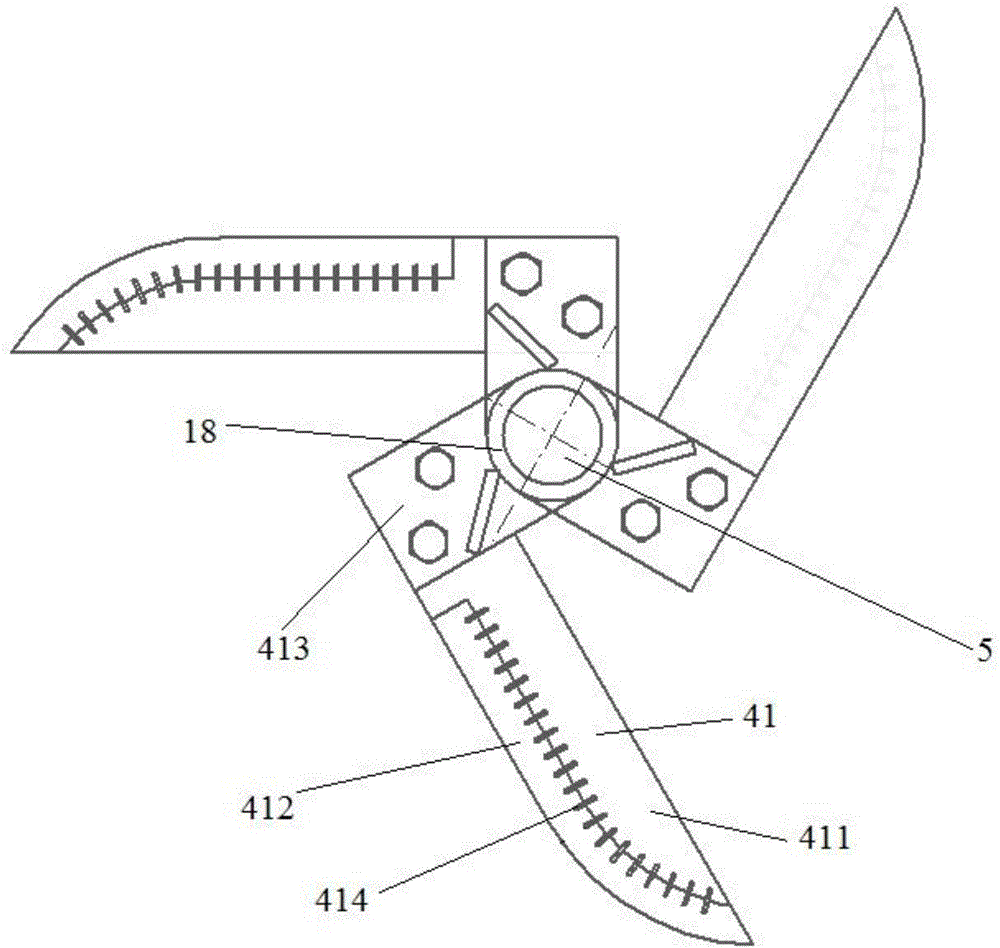

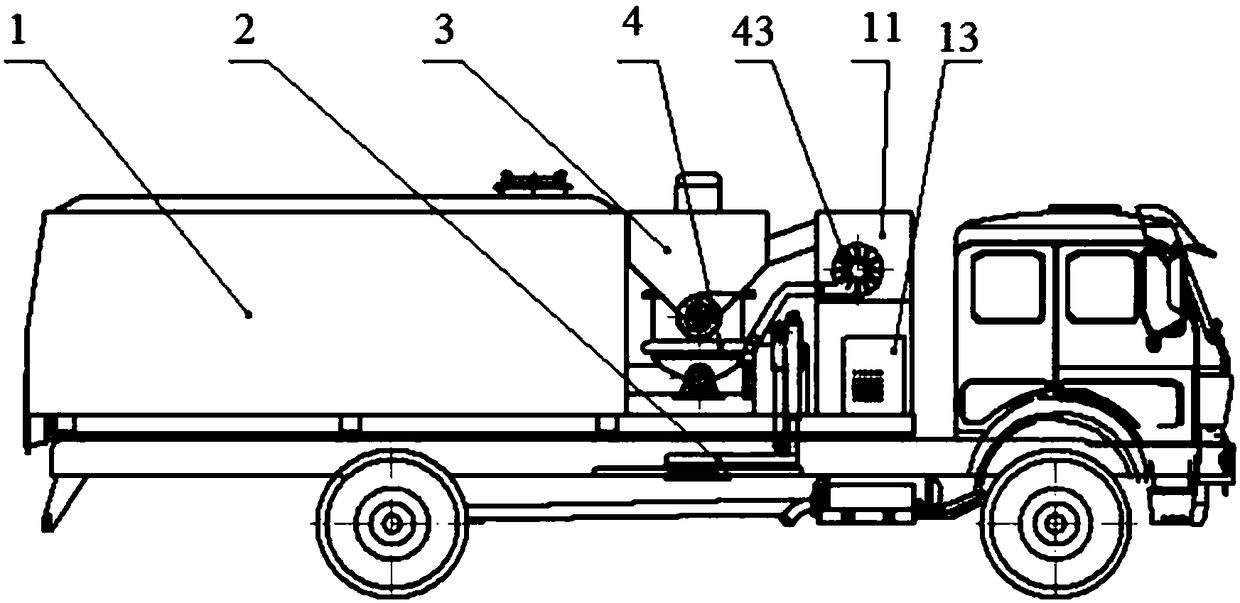

Household garbage smashing, winnowing and compressing transportation car

The invention relates to a household garbage smashing, winnowing and compressing transportation car. The household garbage smashing, winnowing and compressing transportation car comprises a car chassis which is provided with a garbage collecting and compressing tank, an automatic charging device, a garbage can and a smashing and winnowing device; the garbage collecting and compressing tank is arranged on the tail portion of the car; the garbage can and the smashing and winnowing device are arranged between the head portion and the tail portion of the car; the automatic charging device used for grabbing a roadside garbage can is connected with the side edge of the car chassis below the garbage can; and the smashing and winnowing device used for smashing and classifying the garbage is connected with the garbage can and the garbage collecting and compressing tank. The household garbage smashing, winnowing and compressing transportation car has the beneficial effects that the garbage pretreatment function of garbage smashing and plastic thin film winnowing is achieved, the garbage is stored in different bins after being classified, the sealing performance is good, secondary pollution cannot be caused, the garbage smashing and compressing loading capacity is high, the automation level is high, loading and unloading are safe and reliable, and the work efficiency is high.

Owner:新疆思冀金巴环保科技有限公司

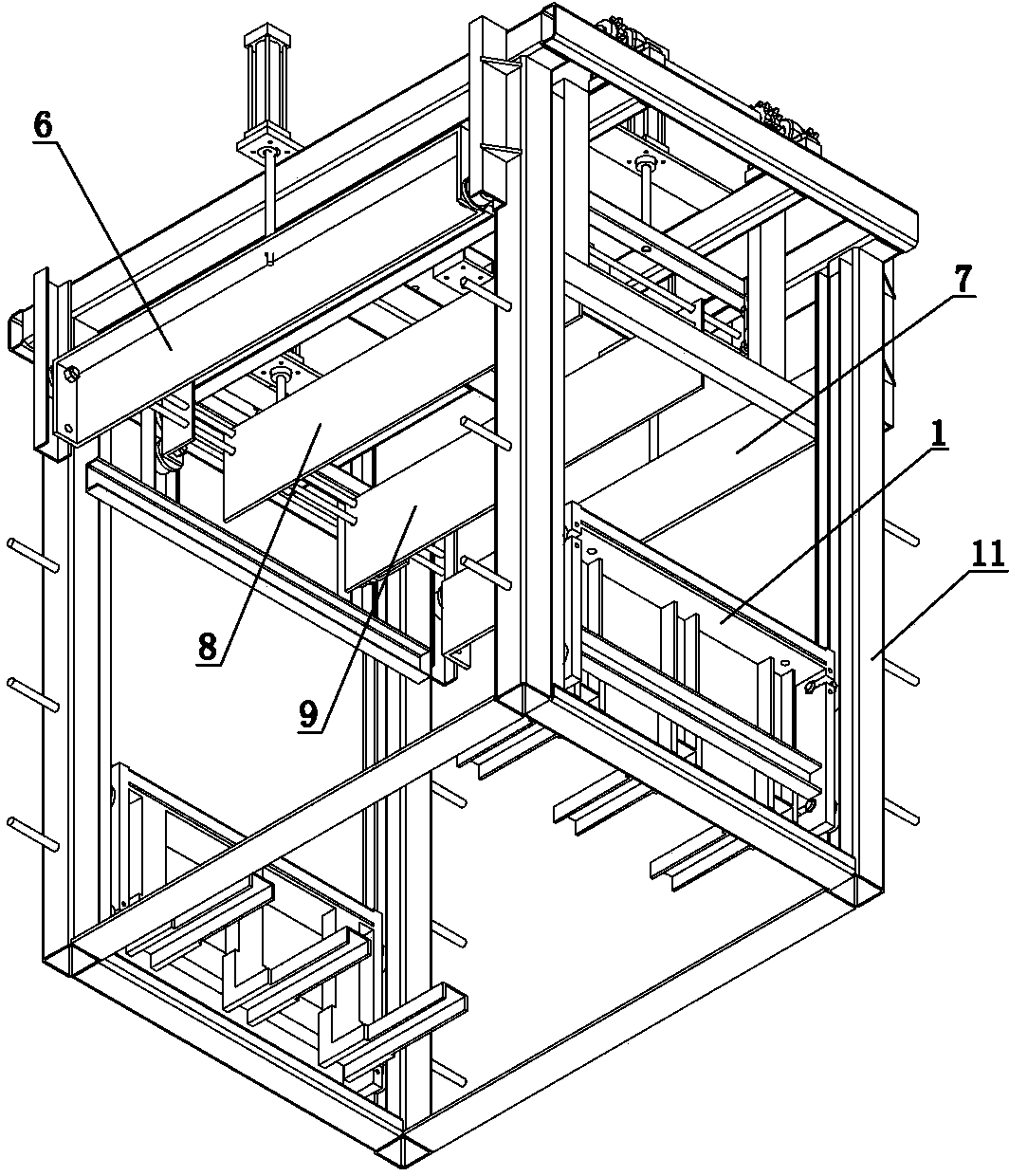

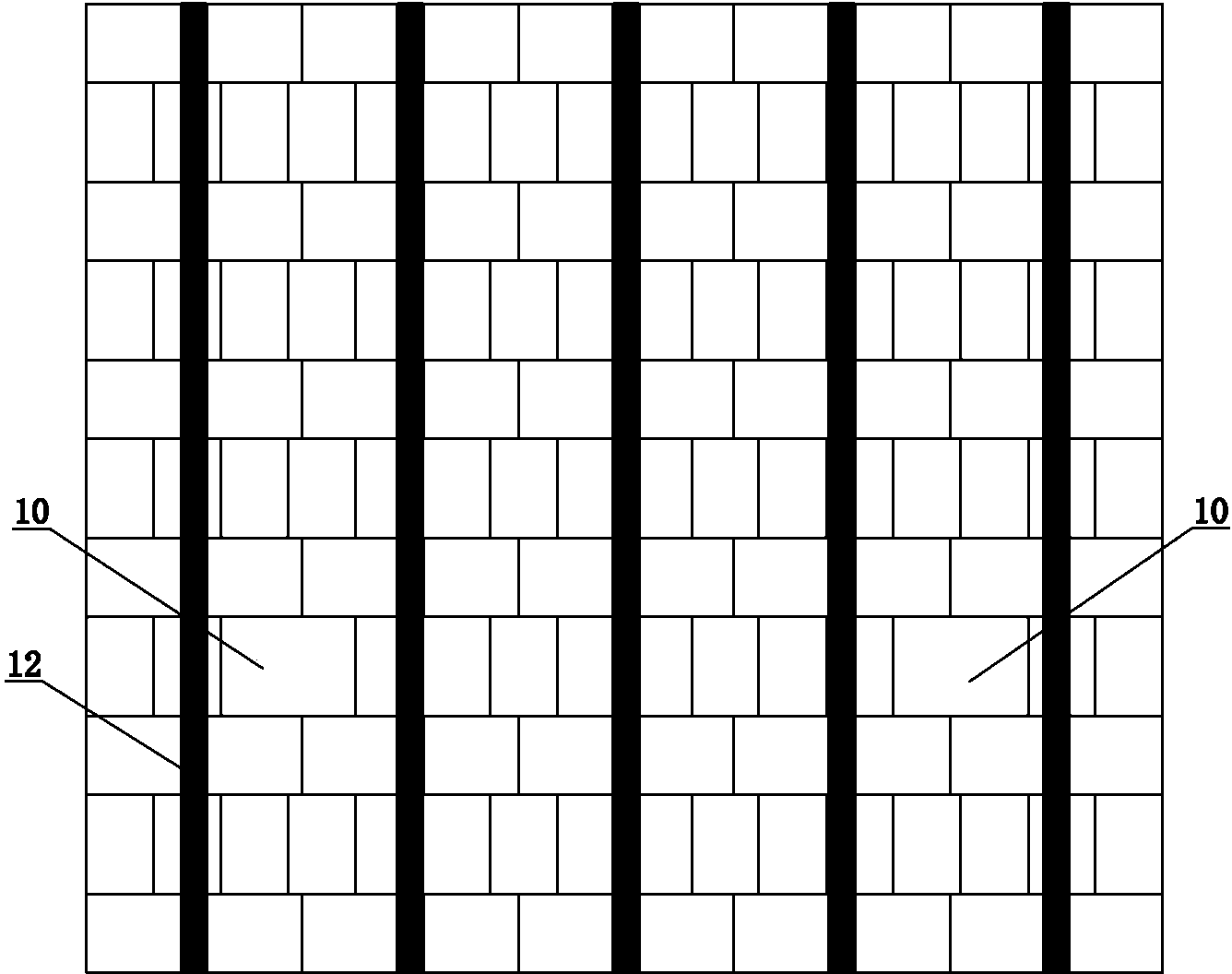

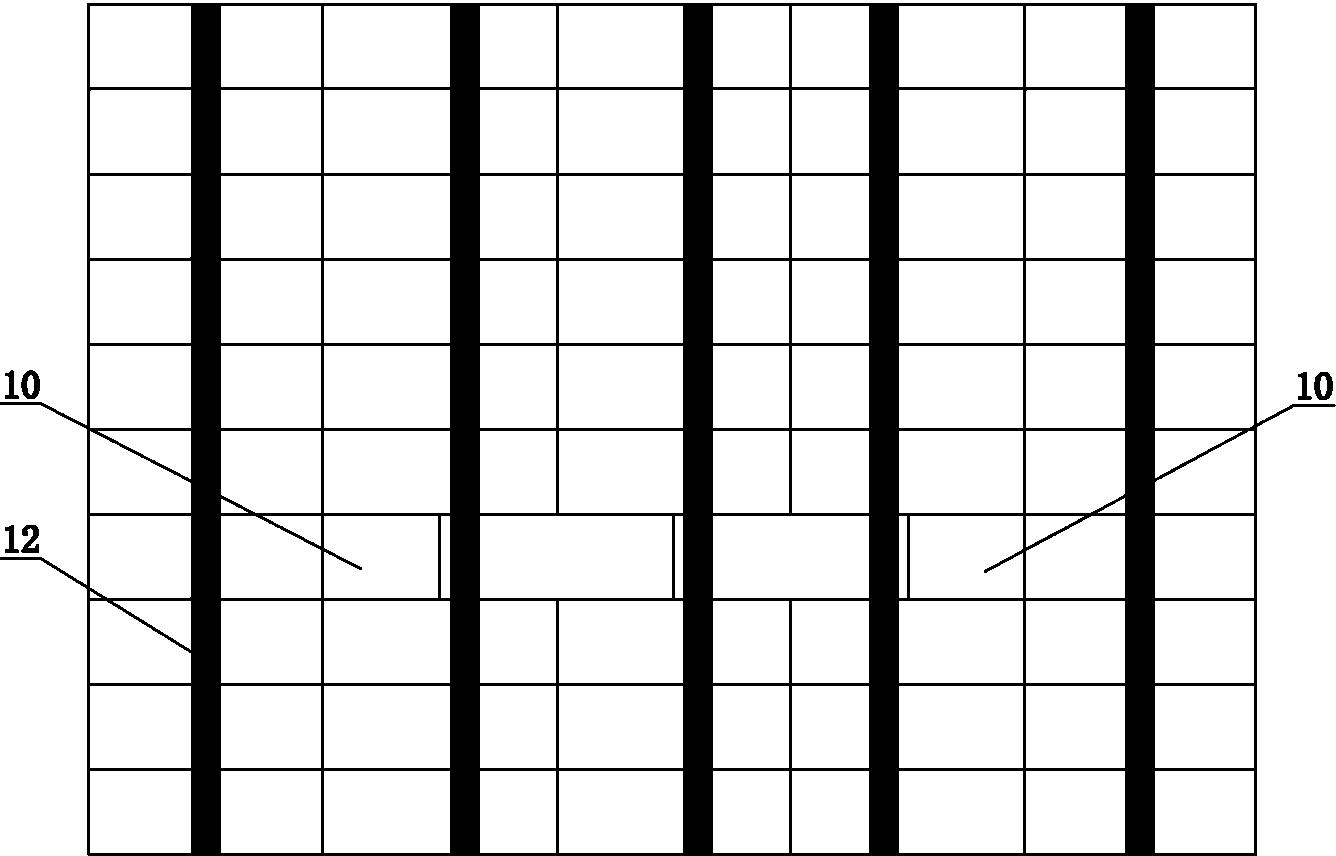

Tray-free stacking machine

ActiveCN103723523ALoading and unloading safetyReasonable designStacking articlesManufacturing FactoriesEngineering

A tray-free stacking machine comprises a carrier plate capable of moving left and right, a brick feeding device for feeding every layer of bricks to the carrier plate line by line and a brick collecting device which is arranged on one side of the carrier plate and capable of going up and down. A baffle capable of going up and down is arranged above one side of the carrier plate. The tray-free stacking machine further comprises two separating plates which are capable of going up and down and are arranged at intervals, the two separating plates are arranged above one side of the carrier plate, the arranging direction of the two separating plates is identical to that of the baffle, when the baffle and the two separating plates go down simultaneously, the multiple lines of bricks on the carrier plate can be divided into three separated parts, and two fork ports allowing two steel forks of a forklift are formed among the three parts of bricks. According to the tray-free stacking machine, after brick stacking is completed, the bricks are bound up and fastened tightly through packing belts, the two steel forks of the forklift are inserted into the two fork ports at the moment, and the forklift can carry the bricks away. Through the adoption of the tray-free stacking machine, stacked bricks can be in order and compact, the breakage rate is reduced, assembling and disassembling are convenient and safe, manufacturing factories do not need to purchase a large amount of trays, production cost and transportation cost are further reduced.

Owner:泉州盛科智能装备制造有限公司

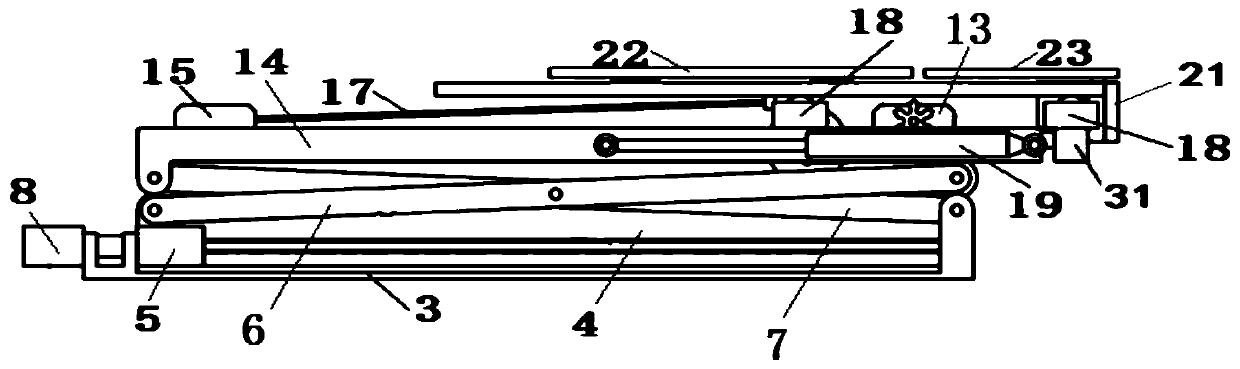

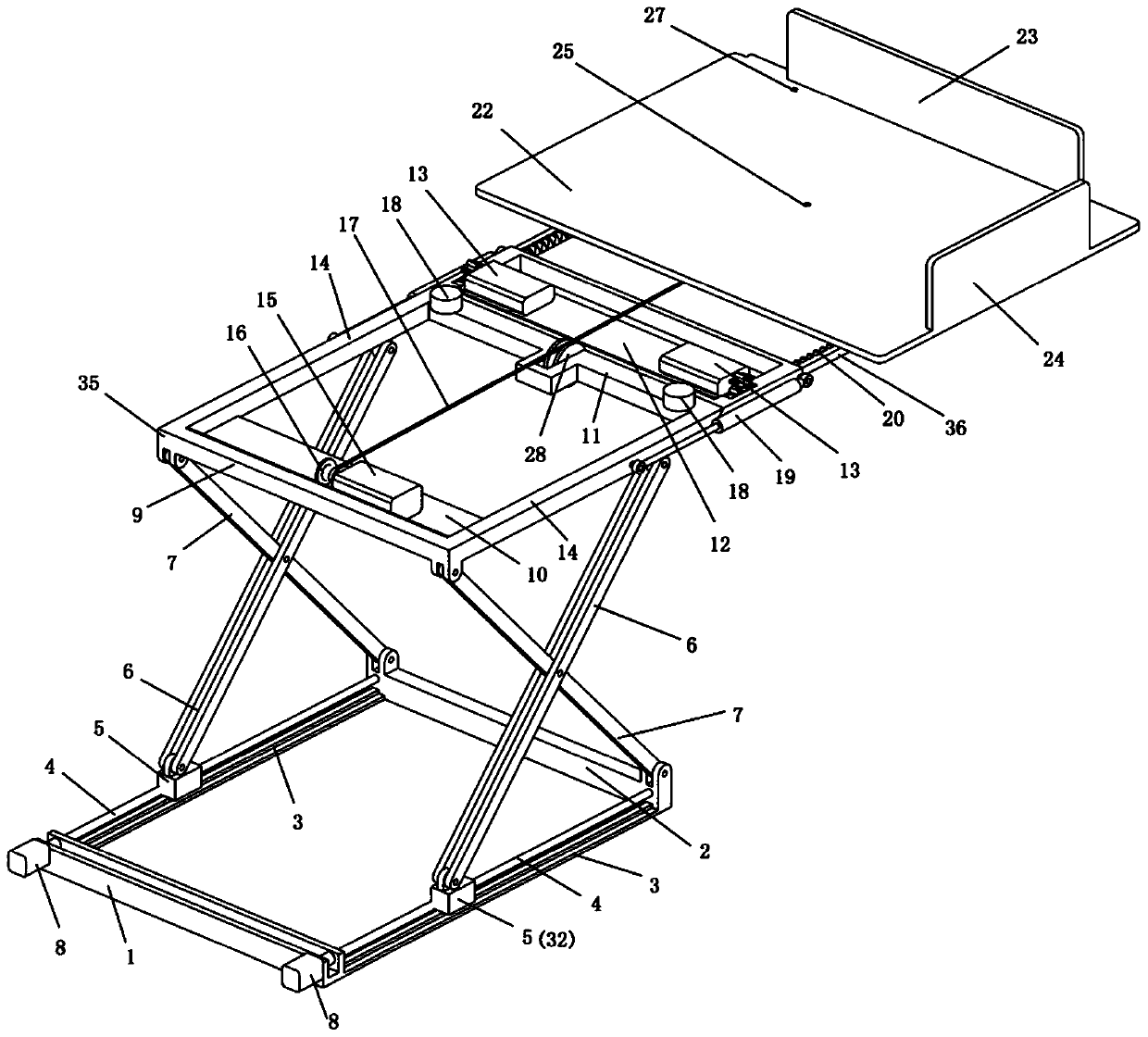

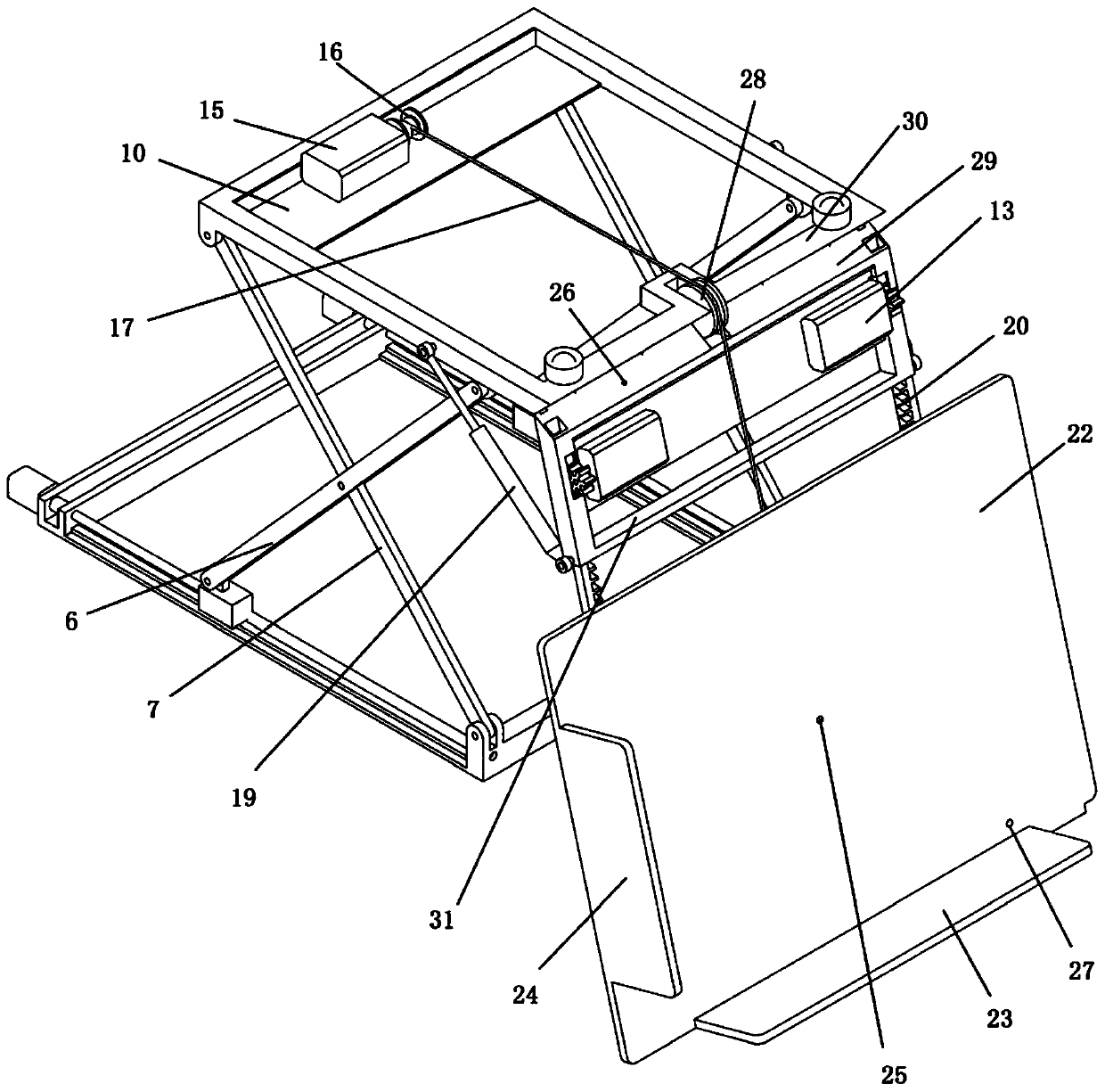

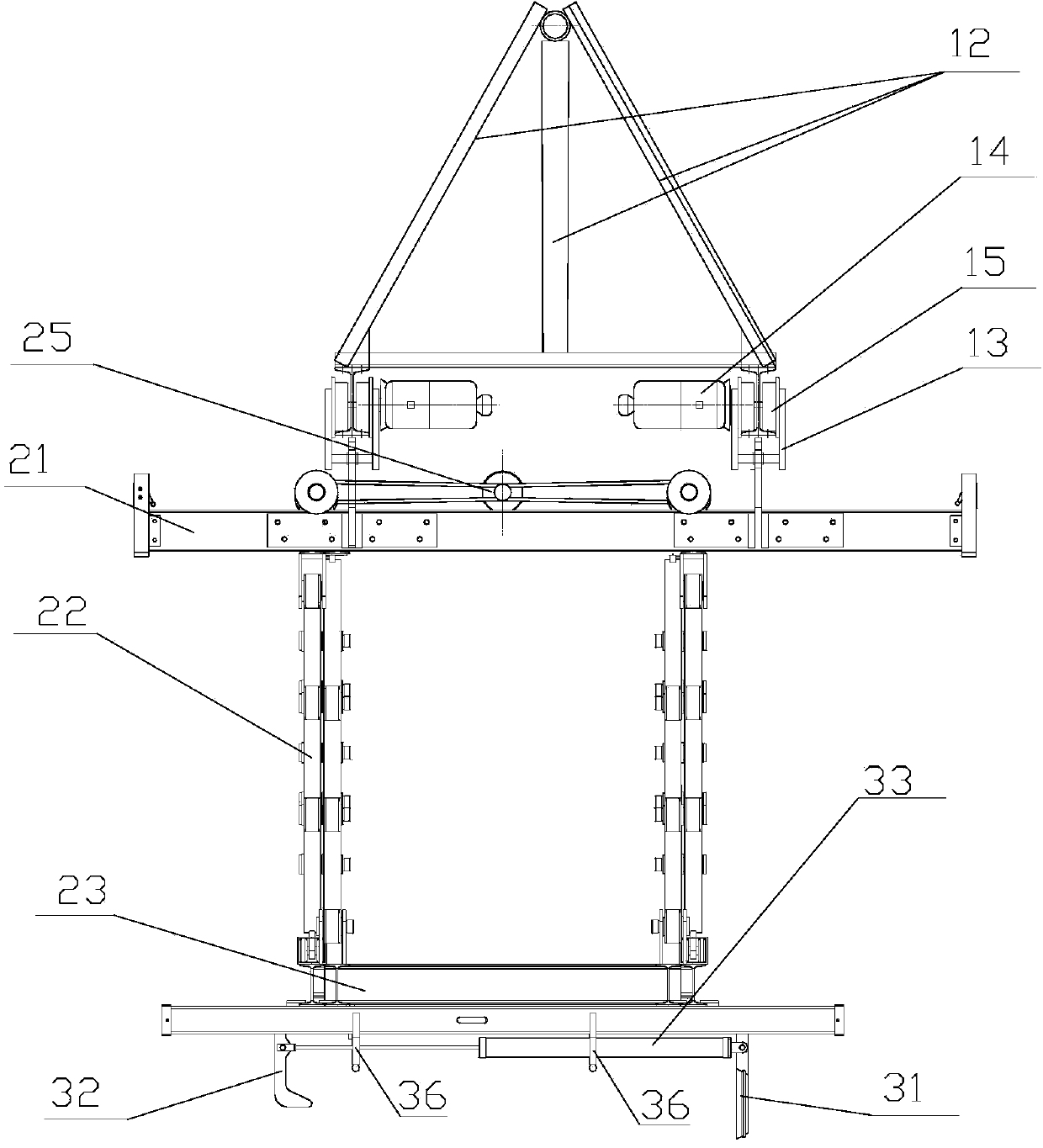

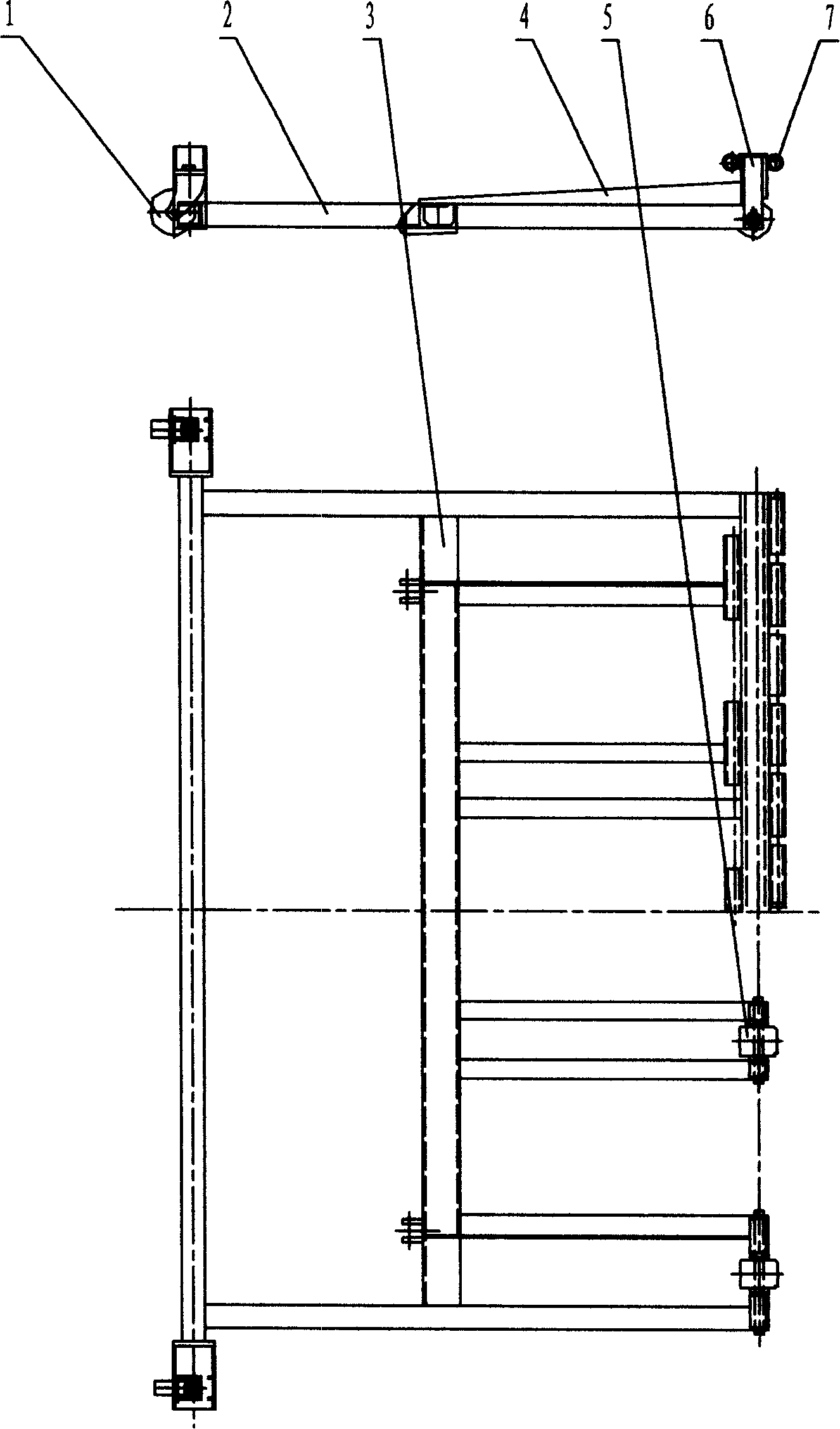

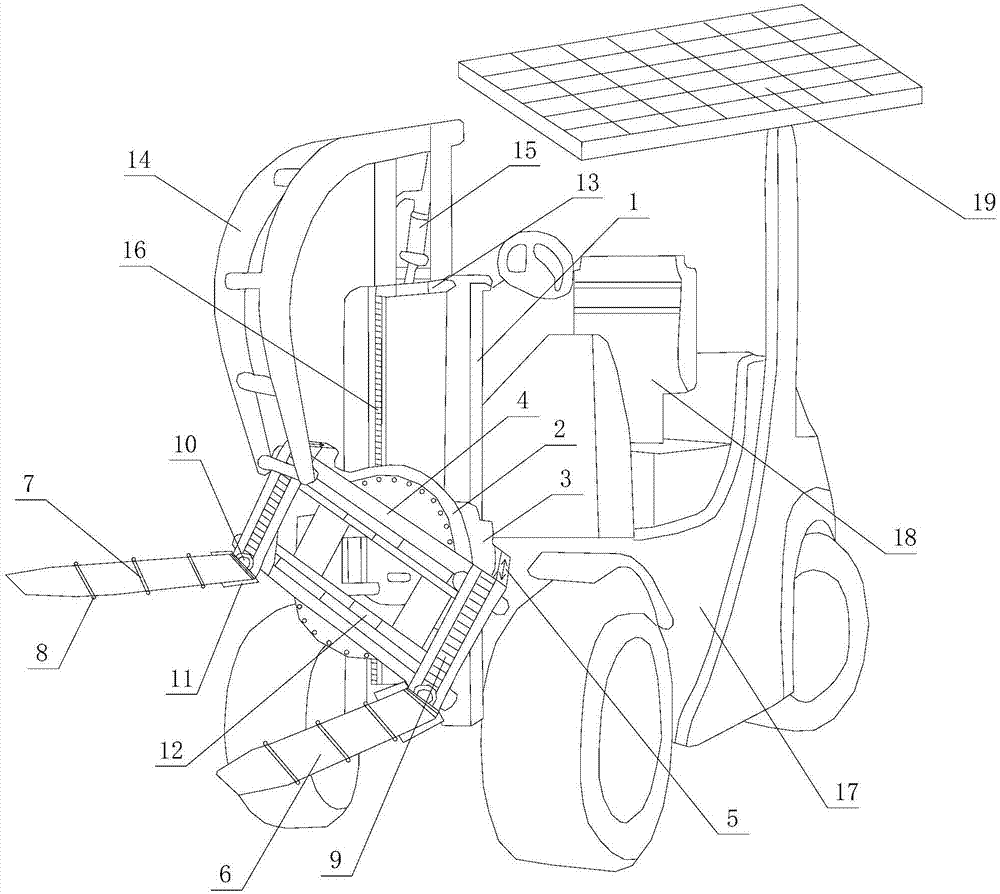

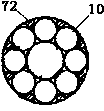

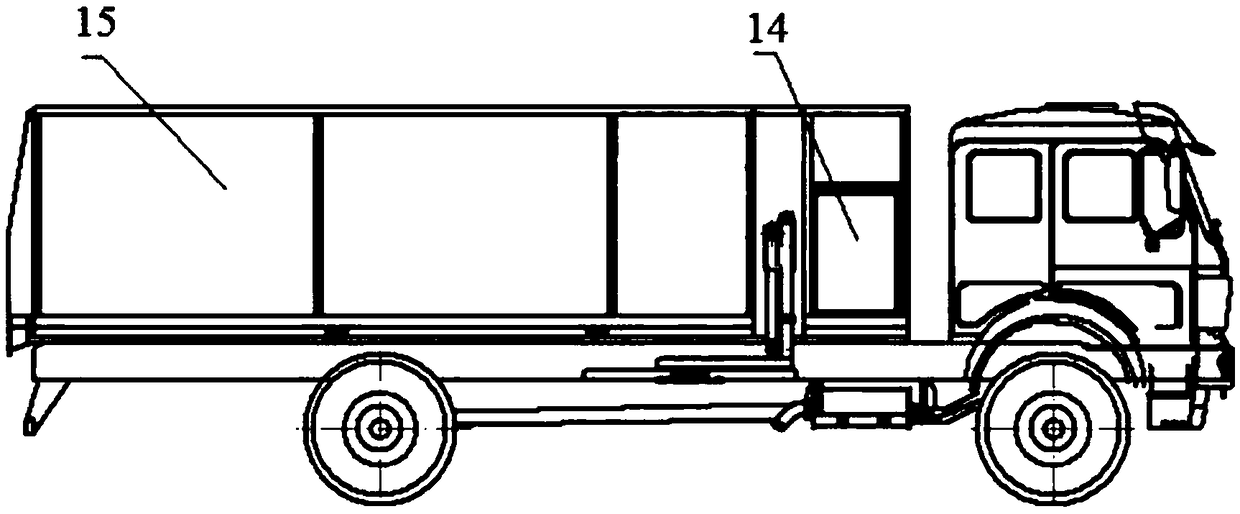

Passenger car trunk luggage automatic loading and unloading system and control method

PendingCN111055775ADoes not affect placementSafe loading and unloadingLifting devicesVehicle componentsGear wheelElectric machinery

The invention relates to the technical field of transportation, in particular to a passenger car trunk luggage automatic loading and unloading system and a control method. The loading and unloading system comprises a base, a main frame, a moving-out frame and a goods shelf arranged on the moving-out frame, and the base is movably connected with the main frame through a fork arm mechanism; the moving-out frame comprises a moving-out rack, a moving-out motor and a moving-out frame cross beam; the main frame comprises a front joint plate and a rear cross beam joint plate which are connected in ahinged mode, the front joint plate is movably connected with the fork arm mechanism, and the rear cross beam joint plate is fixedly connected with the mounting bottom plate of the moving-out motor; the main frame is further provided with a sliding rail in sliding connection with the moving-out rack. One end of the moving-out rack is meshed with the gear of the moving-out motor, and the other end is connected with the moving-out frame beam; the main frame is connected with a goods shelf through a rope wheel mechanism, and the goods shelf is connected with the moving-out rack. The safety, convenience, comfort and intelligent degree of trunk luggage loading and unloading are improved.

Owner:GUANGDONG MECHANICAL & ELECTRICAL COLLEGE

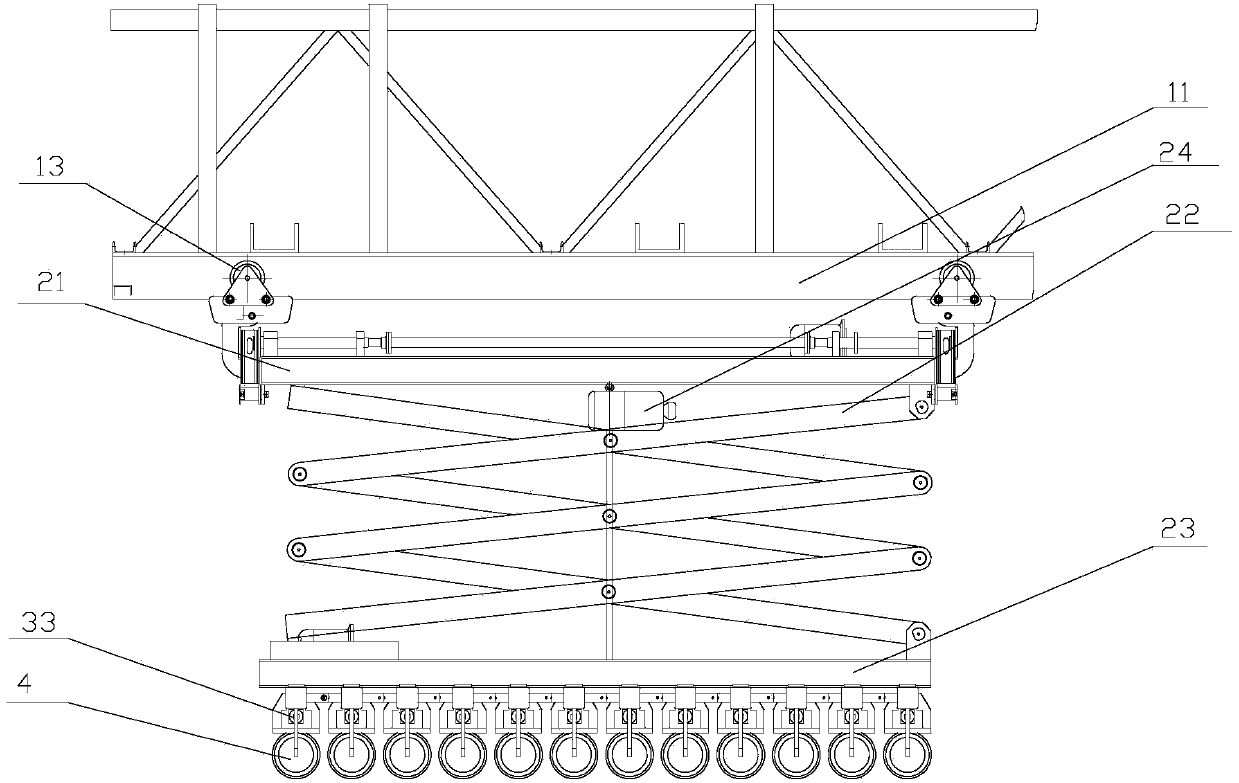

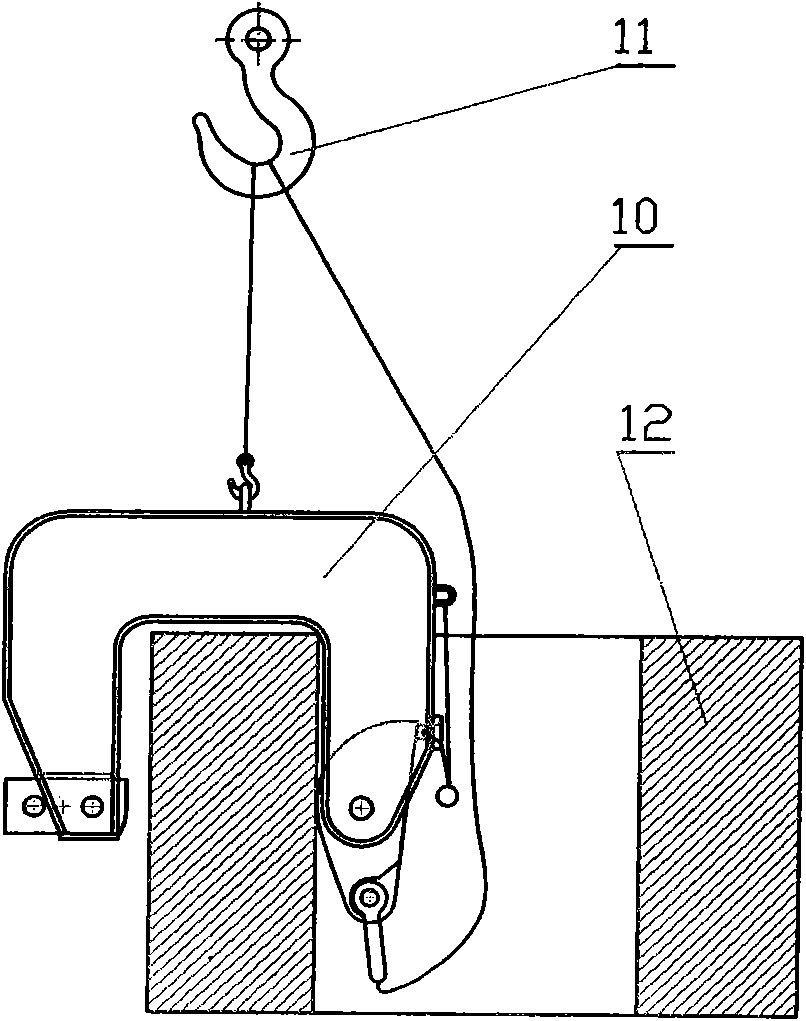

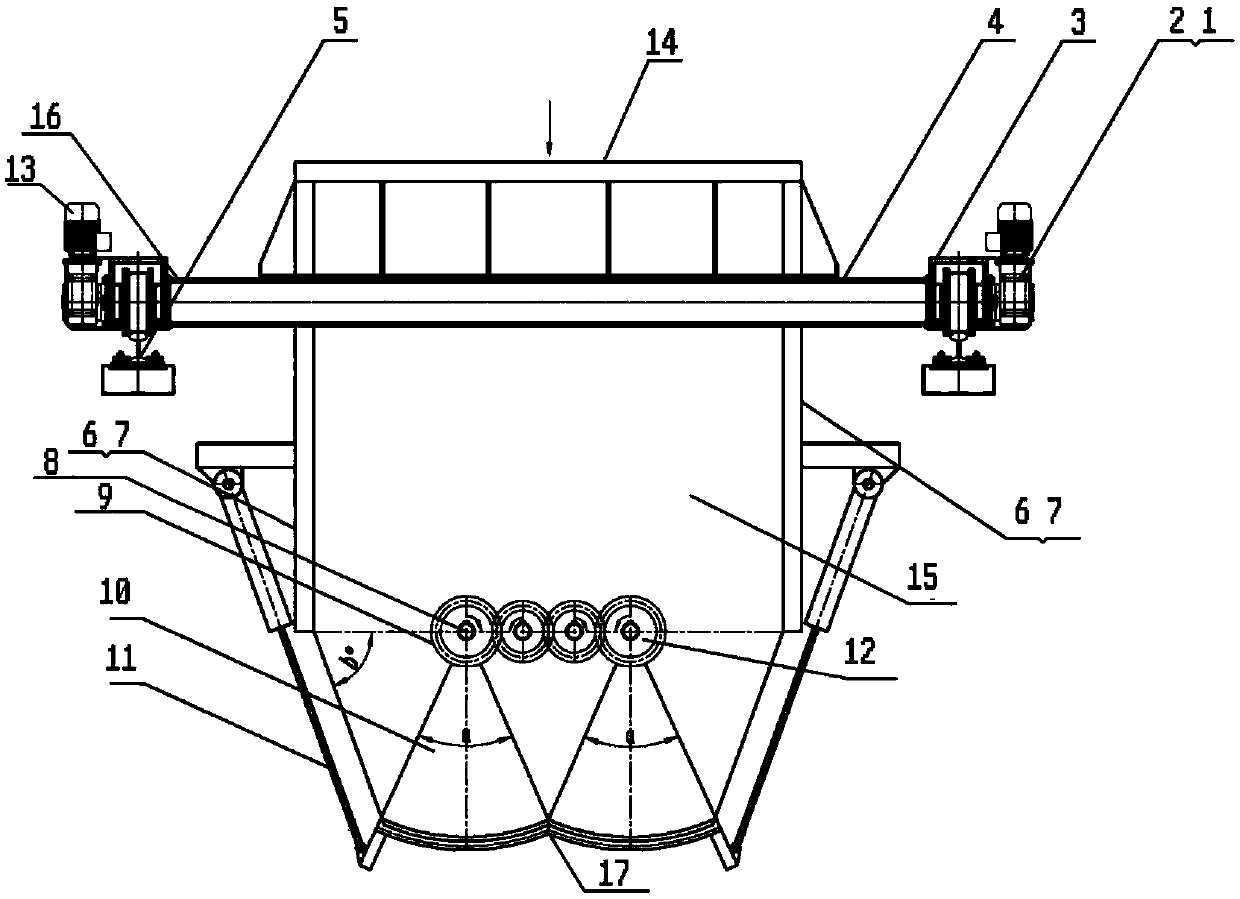

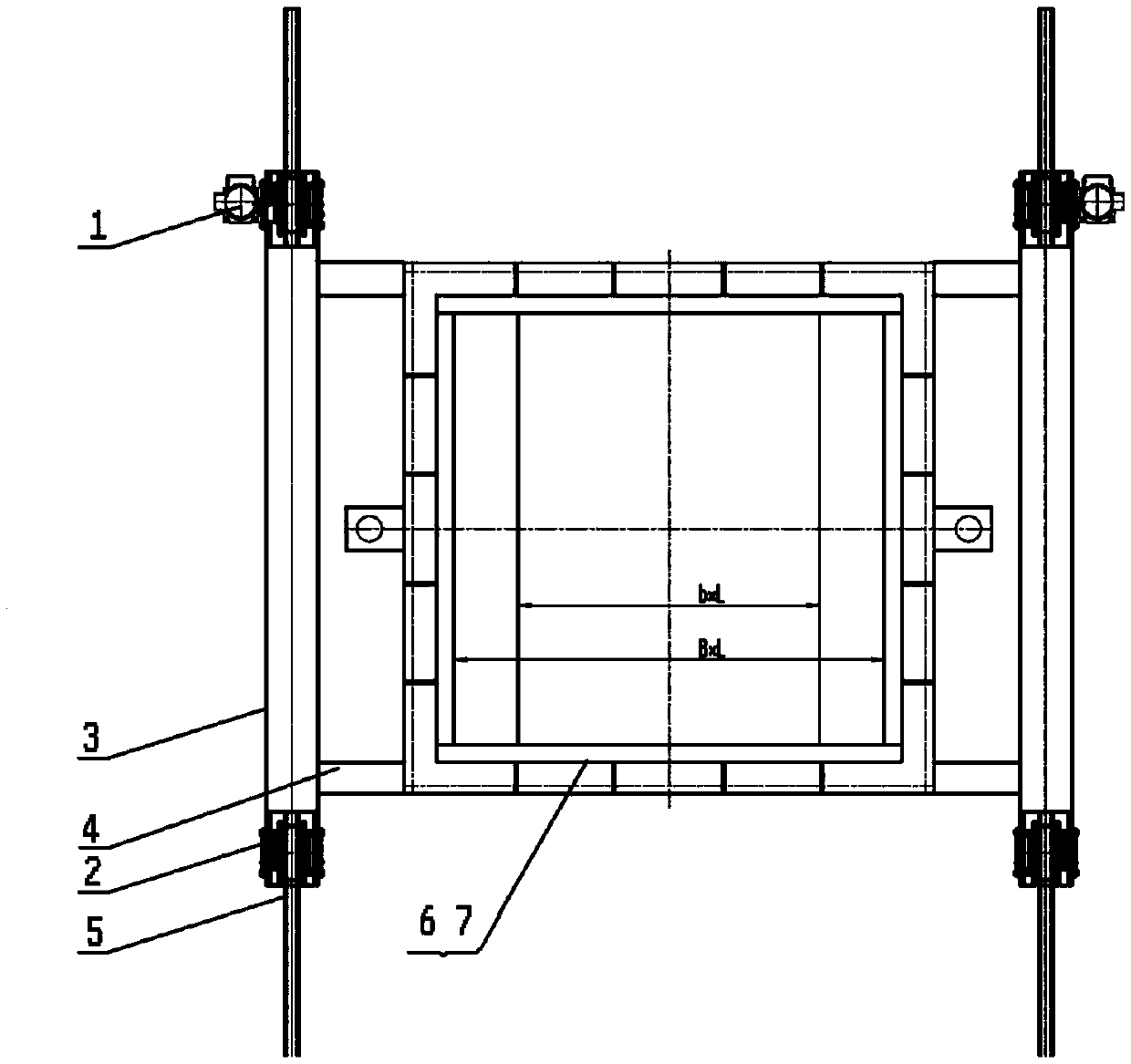

80-ton adjustable large-piece hoister

The 80-ton adjustable large sling includes one rectangular support frame comprising transverse beams and longitudinal beams, two long hangers mounted onto the longitudinal beams, suspending sets in the ends of hangers, pinch wheels and guide wheels in the joints between long hanger and longitudinal beam, one towing shifter on the joining beam for towing long hangers, support legs below the ends of the longitudinal beams, and one hanging plate with holes for hoisting steel cables to pass through. The sling has high adaptability, convenient operation, capacity of raising hoisting efficiency and high large goods hoisting safety and reliability.

Owner:天津港第二港埠有限公司

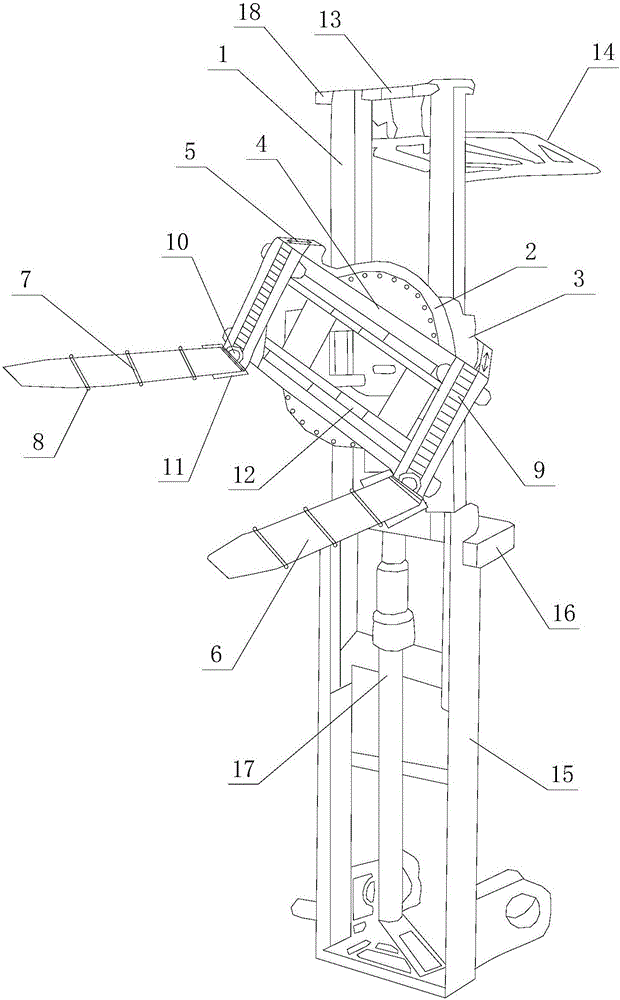

Forklift working device with lifting mechanism

The invention provides a forklift working device with a lifting mechanism. The forklift working device comprises a portal. The portal is arranged in an outer portal in an up-down sliding mode. A lifting air cylinder is arranged in the outer portal and connected with the portal. Limiting stoppers are arranged on the two sides of the top end of the portal. A rotator is arranged on the portal. The rotator is arranged on the portal in an up-down sliding mode through sliding parts on the two sides. An outrigger is arranged on the rotator and rotatably arranged on the portal through the rotator. The lower end of the outrigger is connected with the rotator. A push-pull air cylinder is arranged between the upper end of the outrigger and the rotator. Two sliding guiding devices are arranged on the outrigger. A distance adjusting device is arranged between the two sliding guiding devices. Each sliding guiding device is connected with a pallet fork. Each pallet fork is provided with a plurality of elbows used for adjusting the shape of the pallet fork. The forklift working device with the lifting mechanism is convenient to operate and maintain, high in production efficiency, low in operation cost, safe and reliable in operation and capable of lowering the accident rate, being used for multiple purposes, reducing equipment repeated purchase by users and effectively saving money.

Owner:HEFEI HANDBAROW APPURTENANCES TECH

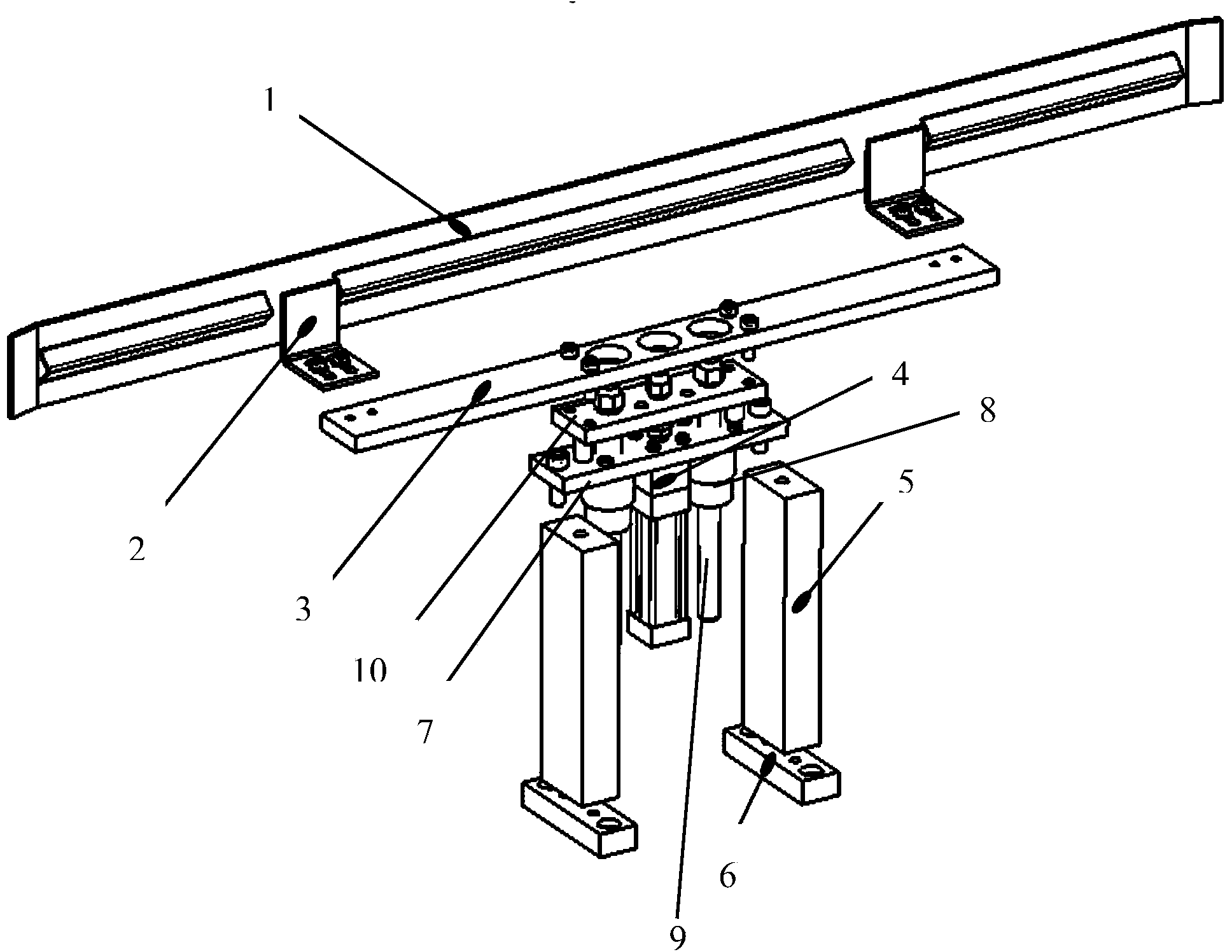

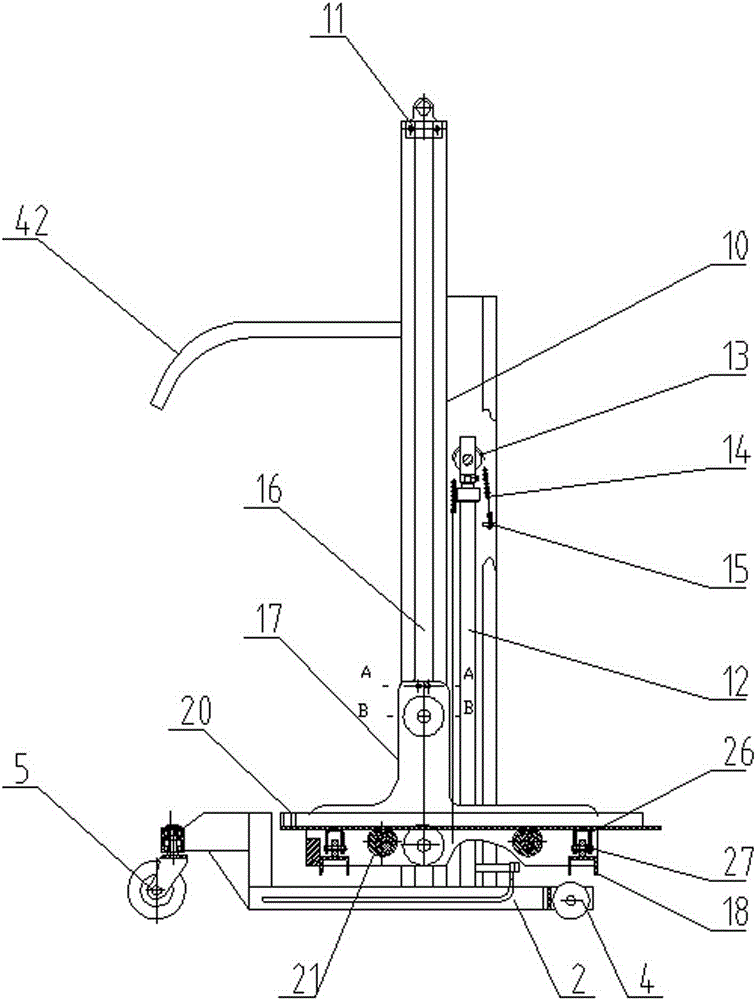

Brand-new intelligent air cylinder mounting and dismounting device

InactiveCN103693564AImprove efficiencyLoading and unloading safetyTrolley cranesRunwaysGas cylinderWork cycle

The invention provides a brand-new intelligent air cylinder mounting and dismounting device which comprises a control system, a running system, a lifting system, a power air cylinder clamping system and an air cylinder positioning system, wherein an electric cabinet in the control system is connected with a PLC (programmable logic controller); the PLC receives signals of an encoder in the running system and a photoelectric sensor in the air cylinder clamping system; the signals are transmitted to the electric cabinet and converted into electric signals; the electric cabinet controls a start or stop command of a driving motor, an electric hoist, a positioning driving motor and an electromagnetic pneumatic valve; and a mounting or dismounting process of an air cylinder can be accomplished automatically by pressing down a mode button of a remote controller according to an actual condition. Multiple actions in a cycle only require once command of field personnel; a working cycle is accomplished within 3min in a slow state; and a working cycle is accomplished within 2min in a fast state. The device is high in efficiency, safe in mounting and dismounting process, low in labor cost and simple in structure, and raw materials are easy to obtain and manufacture.

Owner:CHENGDU JINKEXING GASEOUS

Mobile hydraulic pressure adjusting board

InactiveCN101205021ALoading and unloading safetyEasy to use on the goFluid-pressure actuatorsLoading/unloadingTruckEngineering

The invention relates to a movable regulation plate which can move expediently, form seamless bridge between a platform and a freight car, and carry out forklift handing. The invention comprises a movable under frame, a mesa, a slope, a cylinder and a manual oil pump. The invention mainly adds a trundle on the under frame and a link slope and adopts the manual oil pump as motion. The invention can be used for carrying out loading and unloading work in any position conveniently and needs no transformation on the platform.

Owner:SHENZHEN ELEVATORSKY STORAGE & LOGISTICS EQUIP

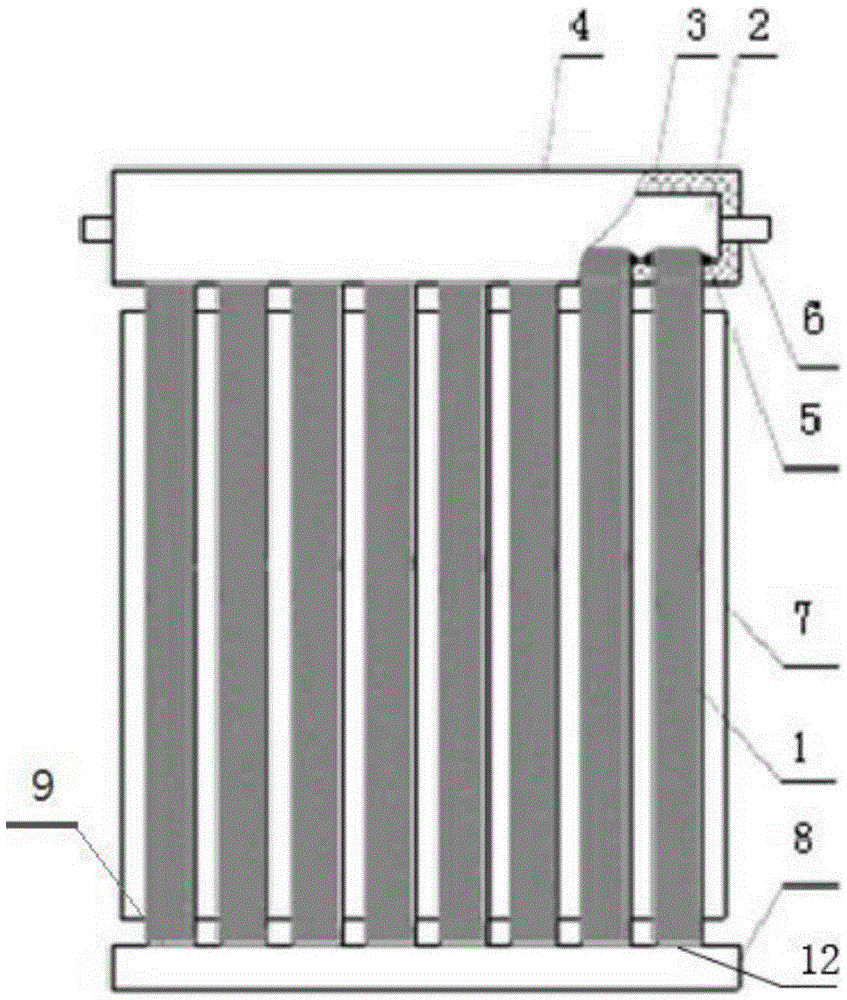

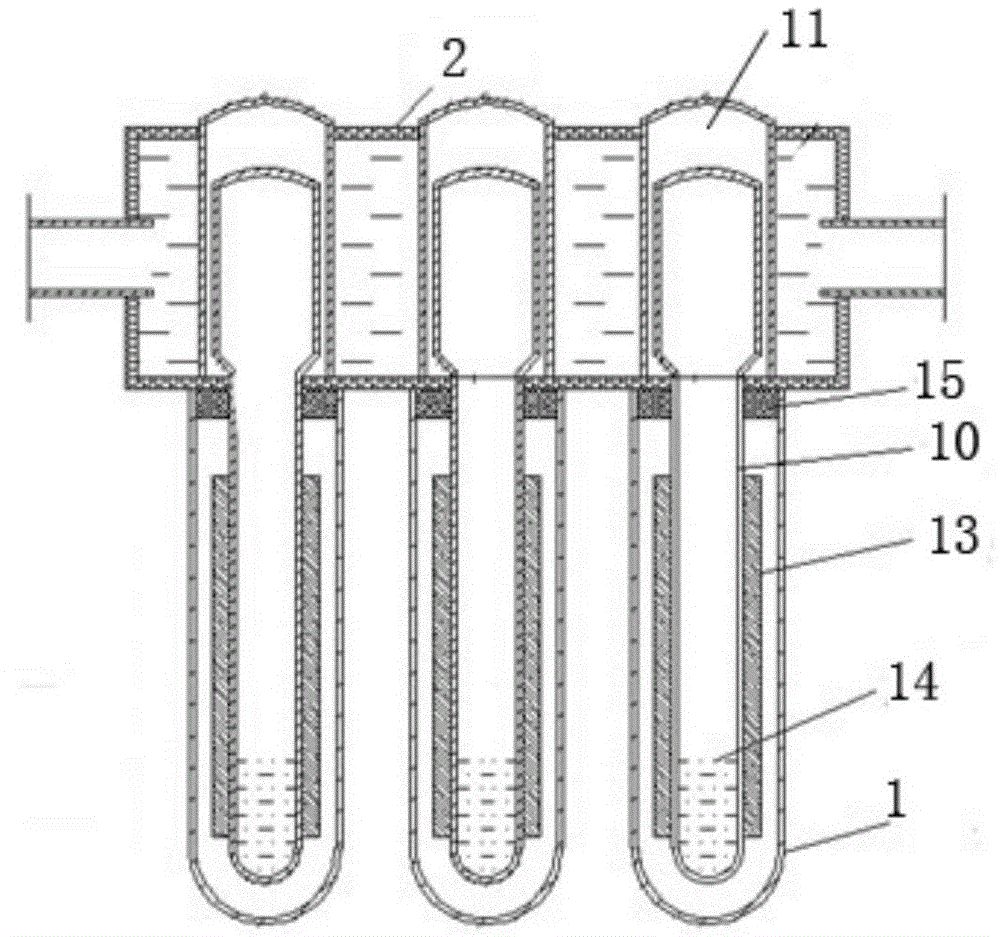

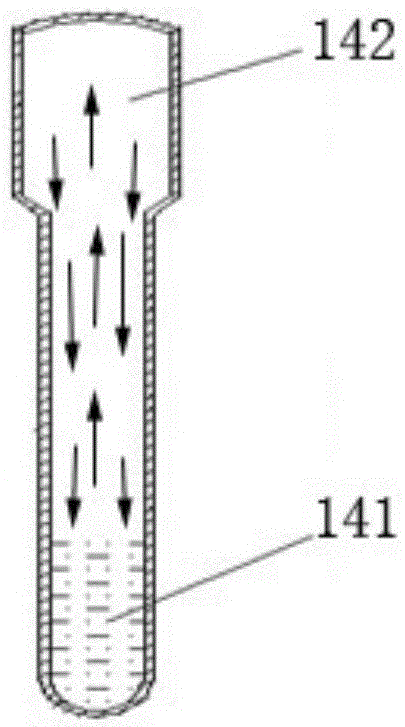

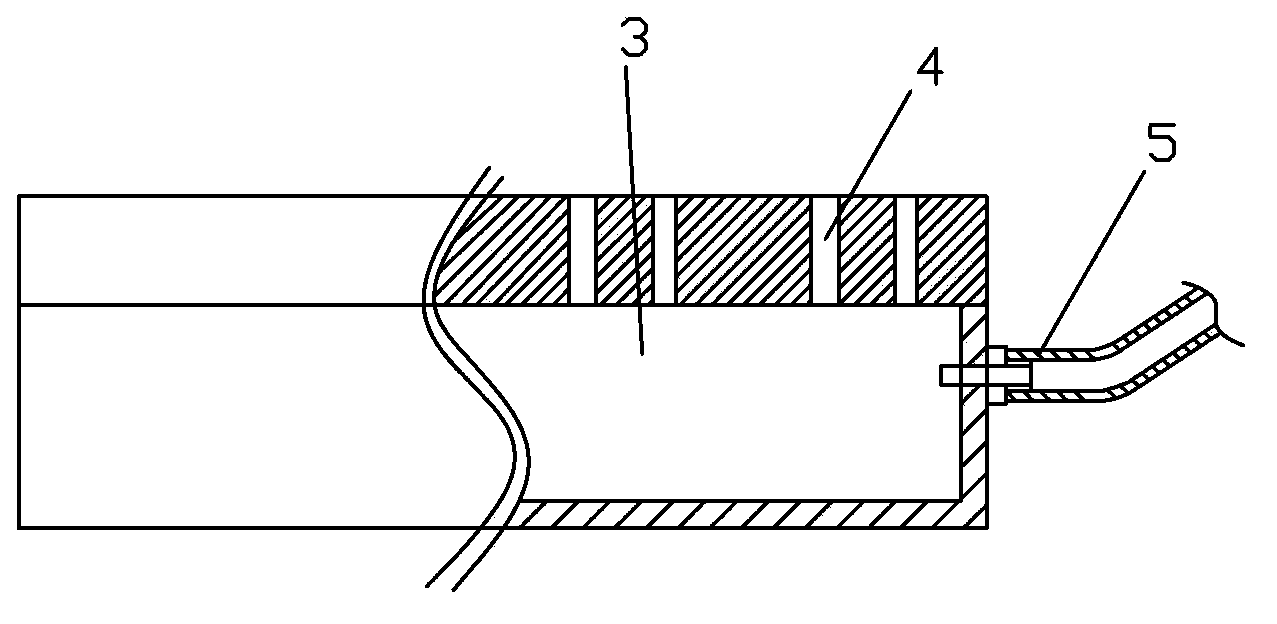

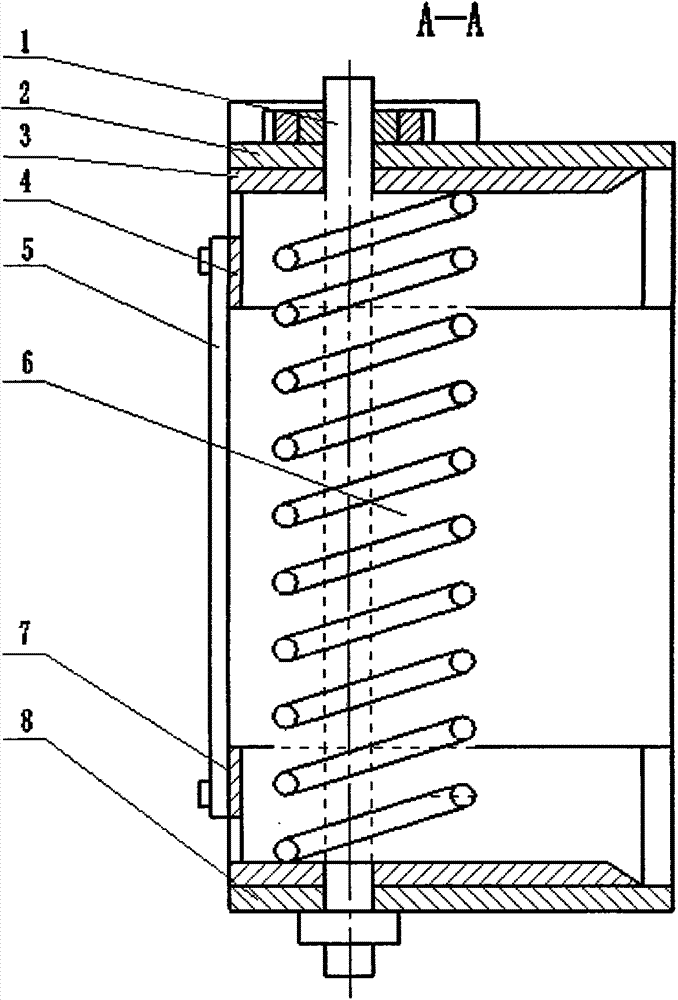

Novel leakage-proof vacuum tube solar heat collector

InactiveCN105571154AFast heat transferSolve freezing and crackingSolar heating energySolar heat devicesFrost crackFrost

The invention relates to a novel leakage-proof vacuum tube solar heat collector. The novel leakage-proof vacuum tube solar heat collector comprises a heat preservation device, a heat collection device and a fixing device. The heat collection device is integrally fixed through the fixing device and transmits heat into the heat preservation device to be stored and to supply the heat to the outside. The heat preservation device sequentially comprises a united collection box, a heat preservation box and a heat preservation box shell from the inside to the outside. The heat collection device comprises all-glass vacuum tubes, superconducting heat tubes and a reflector. One end of each superconducting heat tube is placed in the corresponding all-glass vacuum tube, and the other end of each superconducting heat tube is inserted into the corresponding inserting groove of the united collection box. The all-glass vacuum tubes are placed in installing holes of a frame body of the fixing device. According to the novel leakage-proof vacuum tube solar heat collector, the phenomena of water flowing, water leaking and scale forming inside the all-glass vacuum tubes are avoided, and the heat efficiency of the solar heat collector is stable; moreover, the superconducting heat tubes have the frost resisting performance and the anti-overheating performance, and thus the problems of high temperature under the no-load condition and freezing frost cracks in high-cold areas due to a solar heat collector manufactured through the prior art can be thoroughly solved; in addition, the novel leakage-proof vacuum tube solar heat collector is high in pressure-bearing capacity and stable in operation.

Owner:HANGZHOU SUNRISE ENVIRONMENT TECH

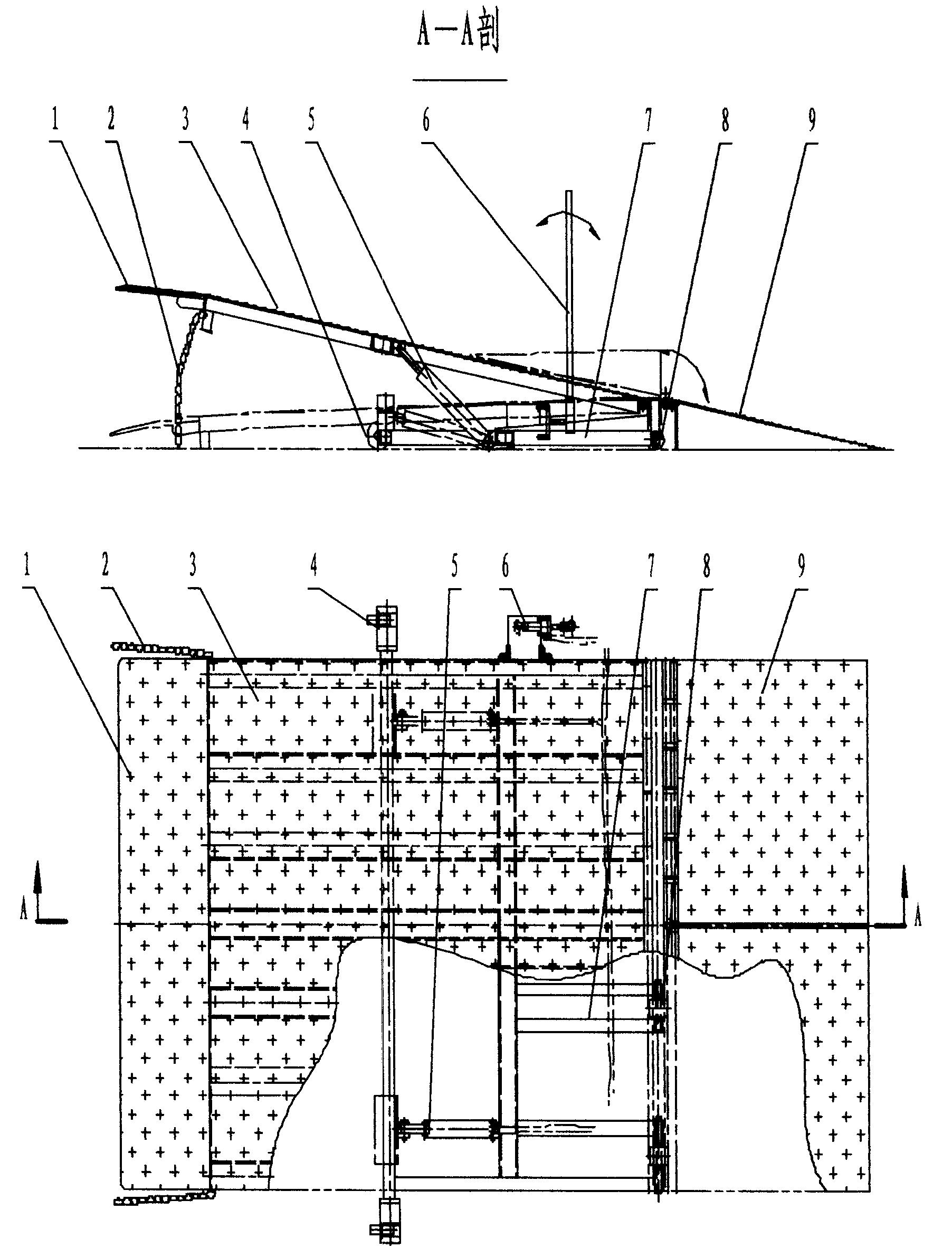

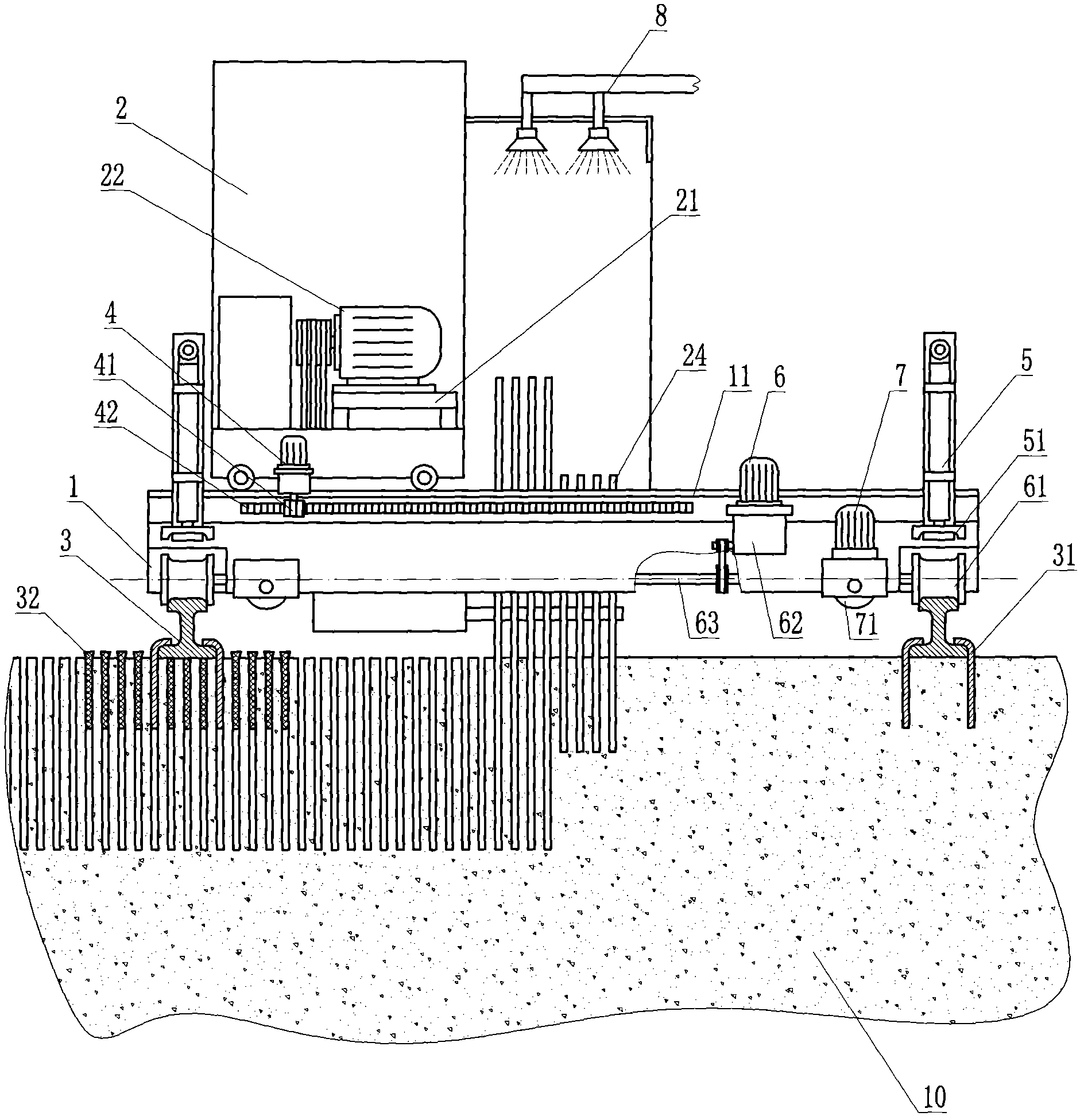

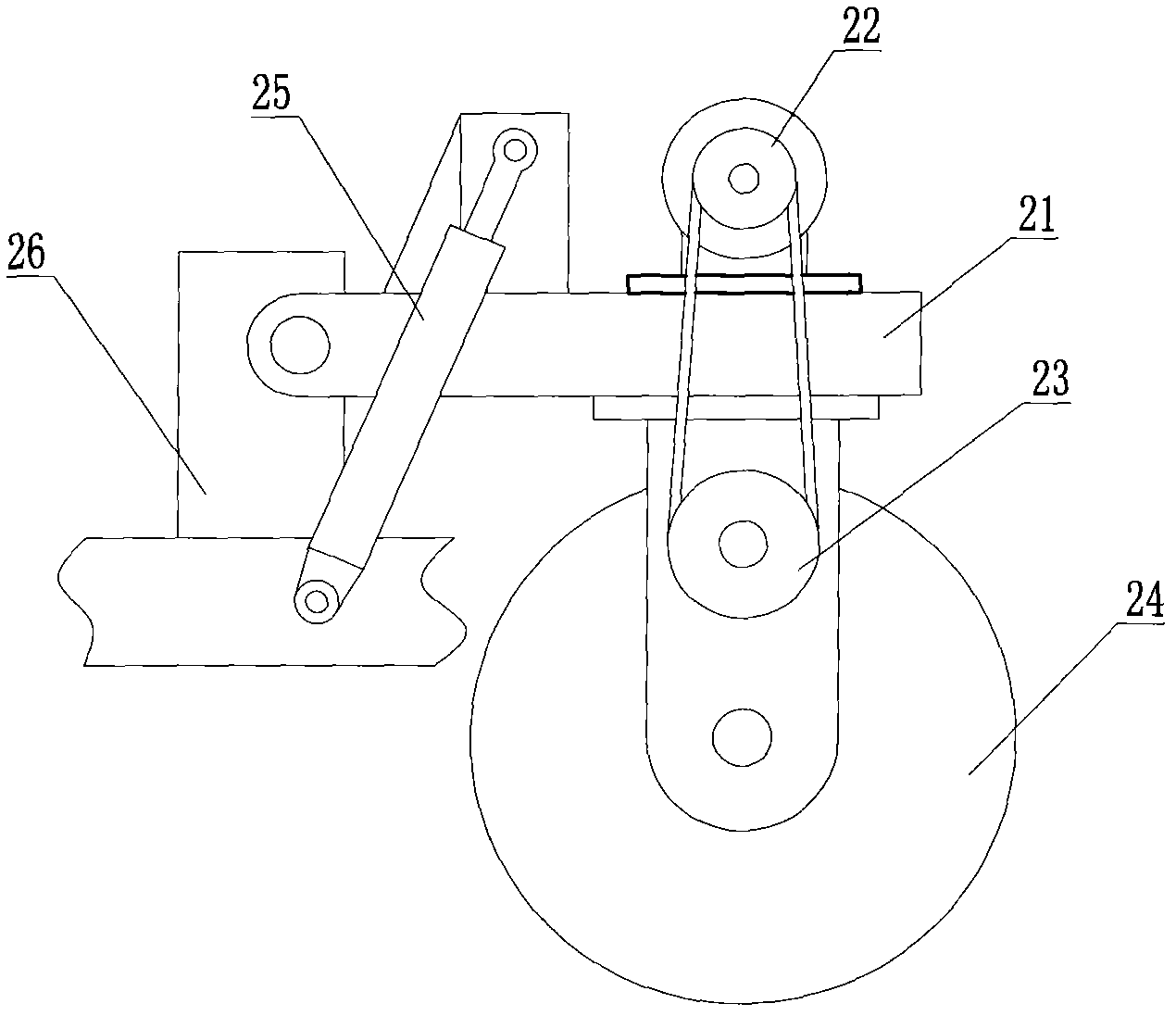

Direct cutting method and direct cutting machine for stone slabs in mines

InactiveCN102294755ALoading and unloading safetyTransportation safetyWorking accessoriesStone-like material working toolsResource utilizationRock cutting

The invention discloses a method for directly cutting stone slabs in a mine pit and a direct cutting machine. The direct cutting machine includes a cutting frame on which a cutting head is installed. The machine head is equipped with a cutting machine head horizontal moving device; the bottom of the cutting frame is equipped with traveling wheels, and the cutting machine track is arranged under the walking wheels, and the cutting machine frame is equipped with a cutting machine for driving the traveling wheels to walk on the cutting machine track. walking gear. When cutting, the cutting is done directly in the bedrock in the pit. The effect is that large-scale lifting equipment is not required, blasting is no longer required during the mining process, the environment is no longer polluted, loading and unloading and transportation are safe, and transportation costs are saved. , so that stone resources will not be exhausted; stone resources will not be wasted, and the utilization rate of stone resources can reach about 95%.

Owner:董衍平

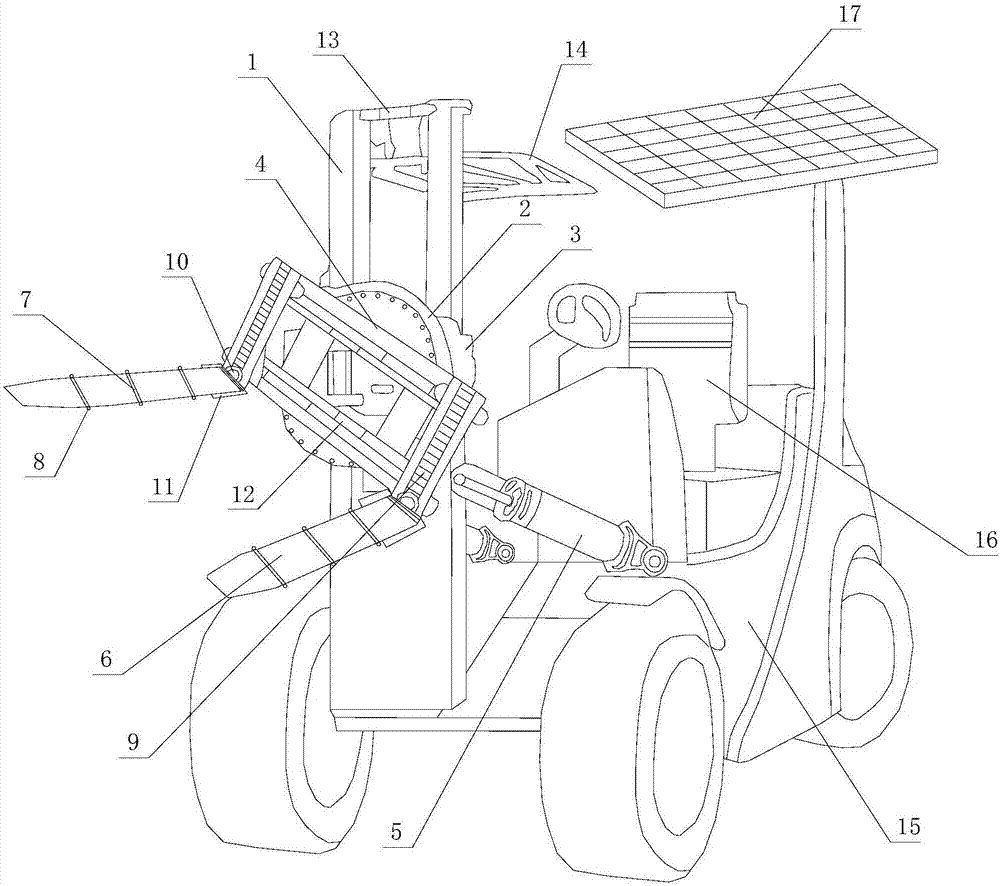

Forklift with steel pipe clamp

The invention proposes a forklift with steel pipe clamps, which includes a car body with a driver's cab, a solar panel installed on the roof of the driver's cab, a door frame at the front end of the car body, and a rotating door frame on the door frame. The rotator slides up and down on the door frame through the sliding parts on both sides, the rotator is provided with a fork frame, the fork frame is rotated and set on the door frame through the rotator, the lower end of the fork frame is connected with the rotator, and the upper end of the fork frame is connected with the door frame. There is a push-pull cylinder between the rotators, two sliding guides are provided on the fork frame, and a distance adjustment device is provided between the two sliding guides. Each sliding guide is connected to a fork, and the fork is provided with A plurality of bent joints for adjusting the shape of the cargo fork, fastening bolts are provided at both ends of the bent joints, slide rails are provided on both inner sides of the mast, a rotating shaft is provided between the two slide rails, and a control cylinder is provided on the steel pipe clamp. The forklift with steel pipe clamp is easy to operate and maintain, has comprehensive functions, safe and reliable operation, reduces the accident rate, and can be used for multiple purposes.

Owner:ANHUI YUFENG WAREHOUSING EQUIP

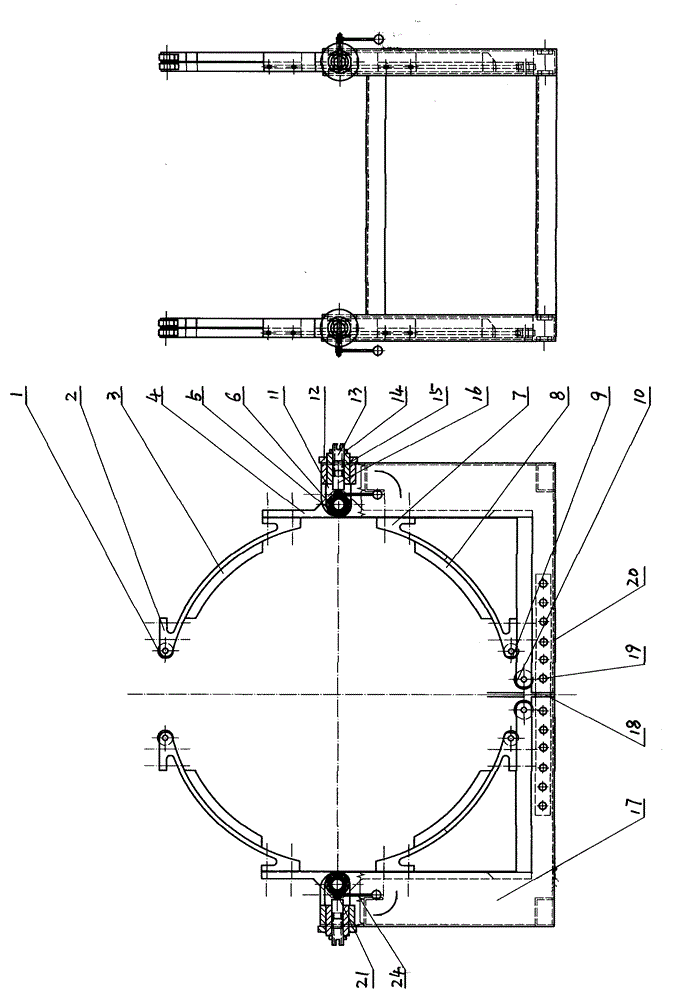

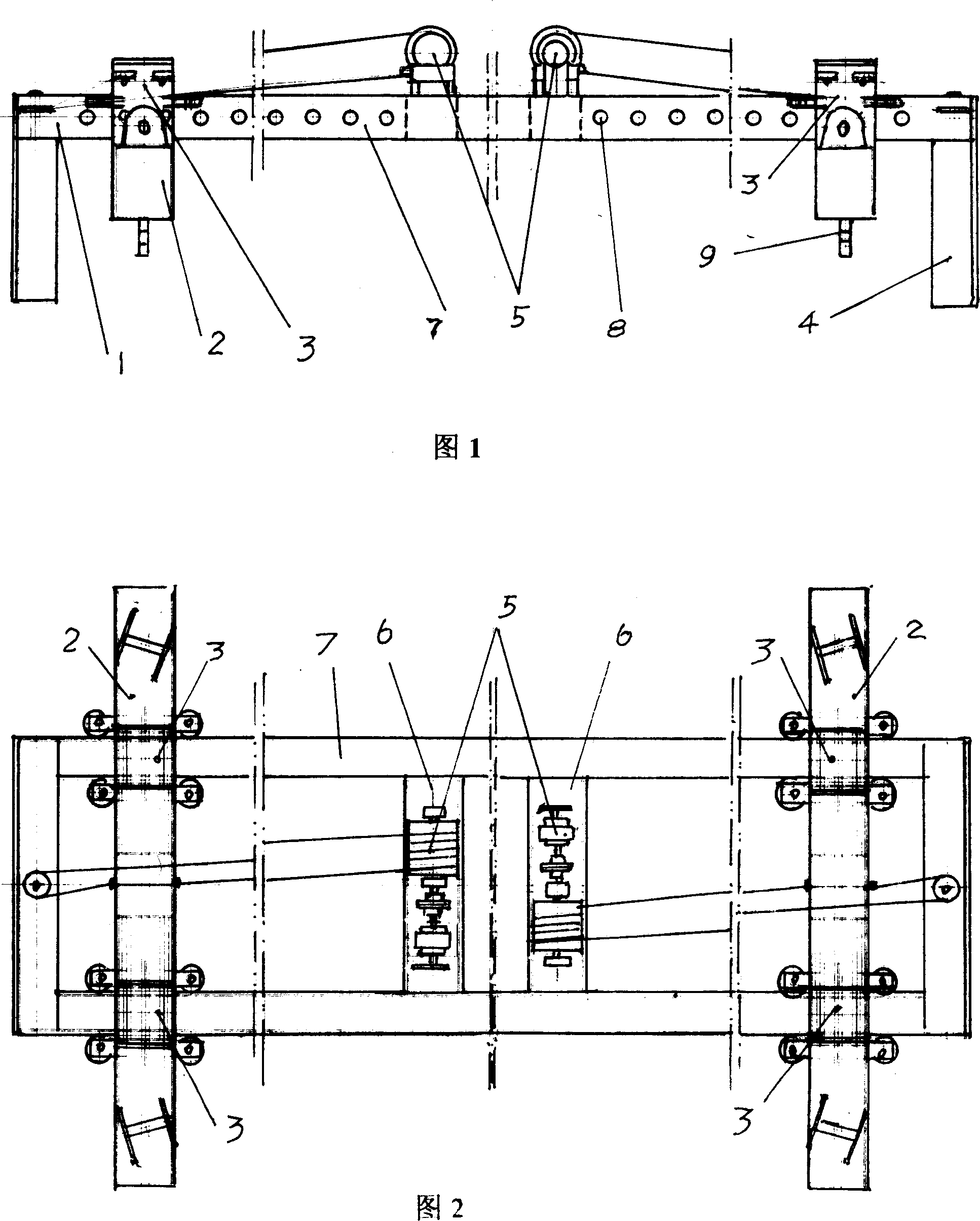

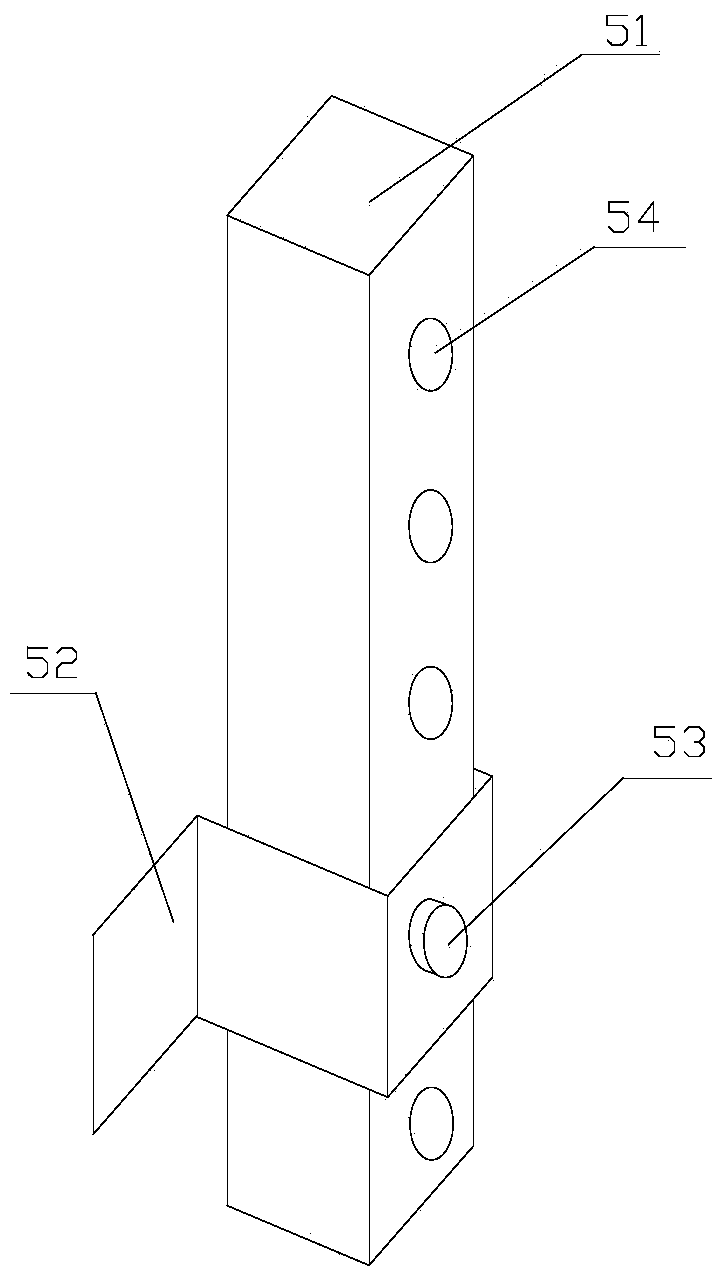

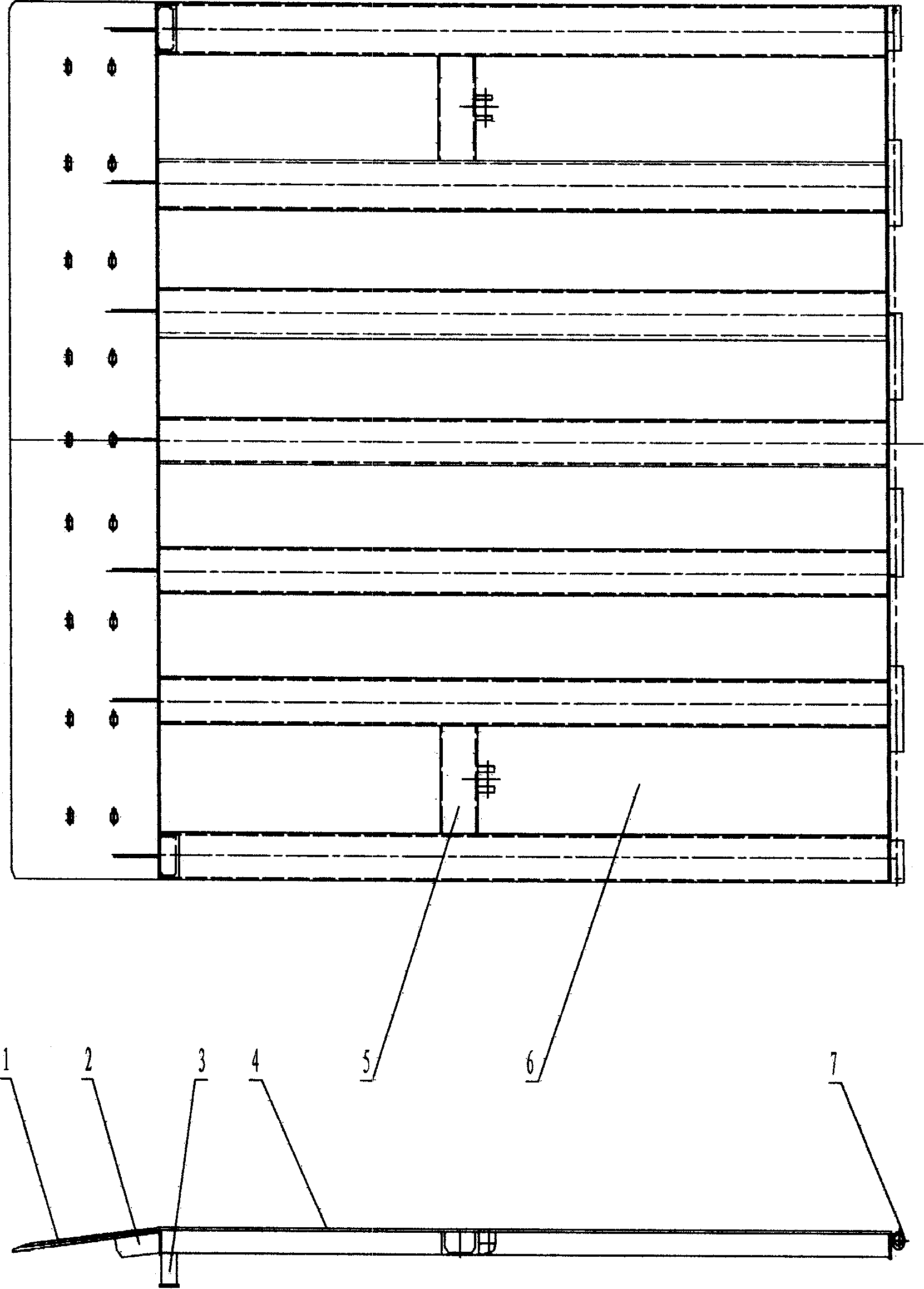

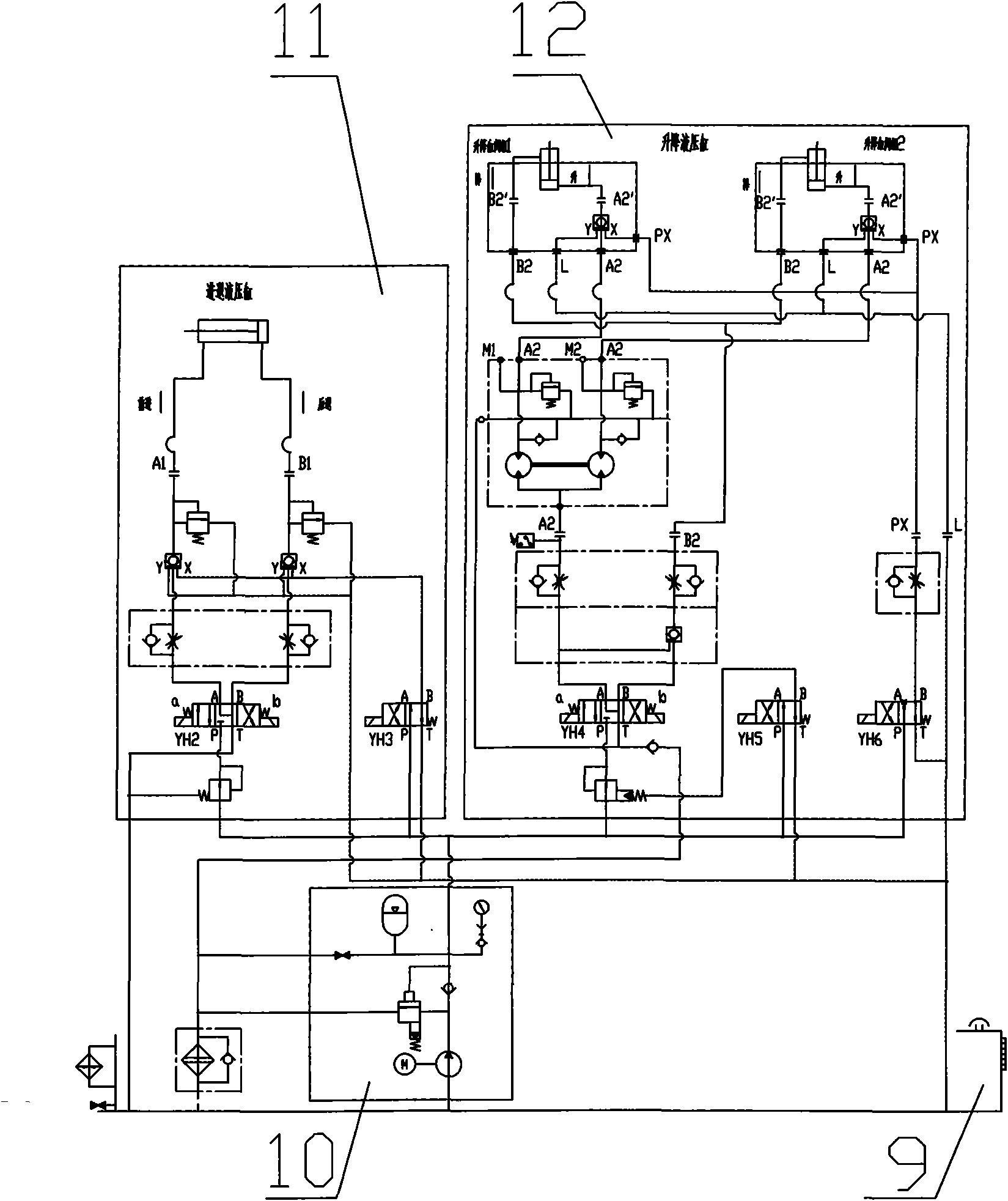

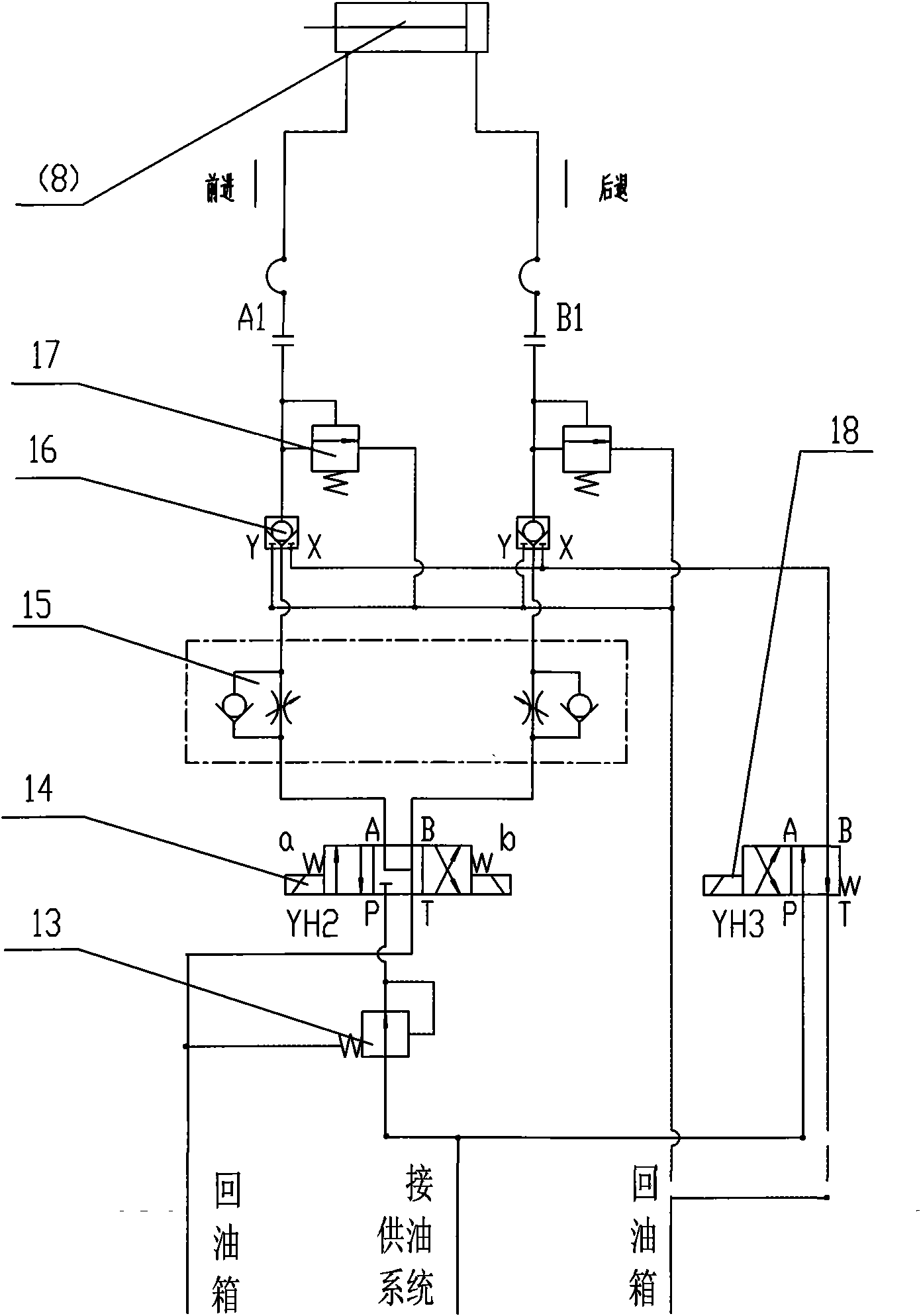

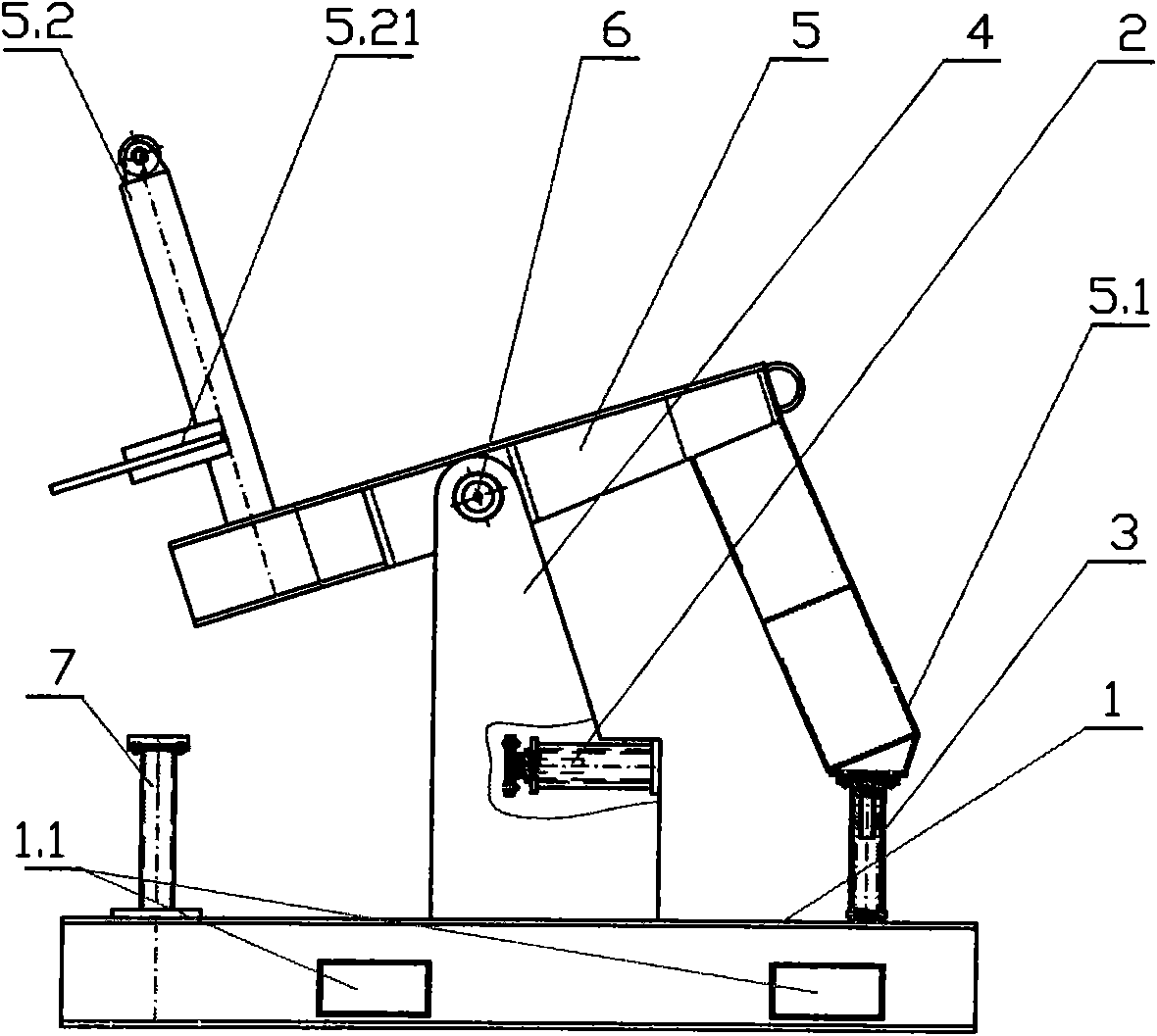

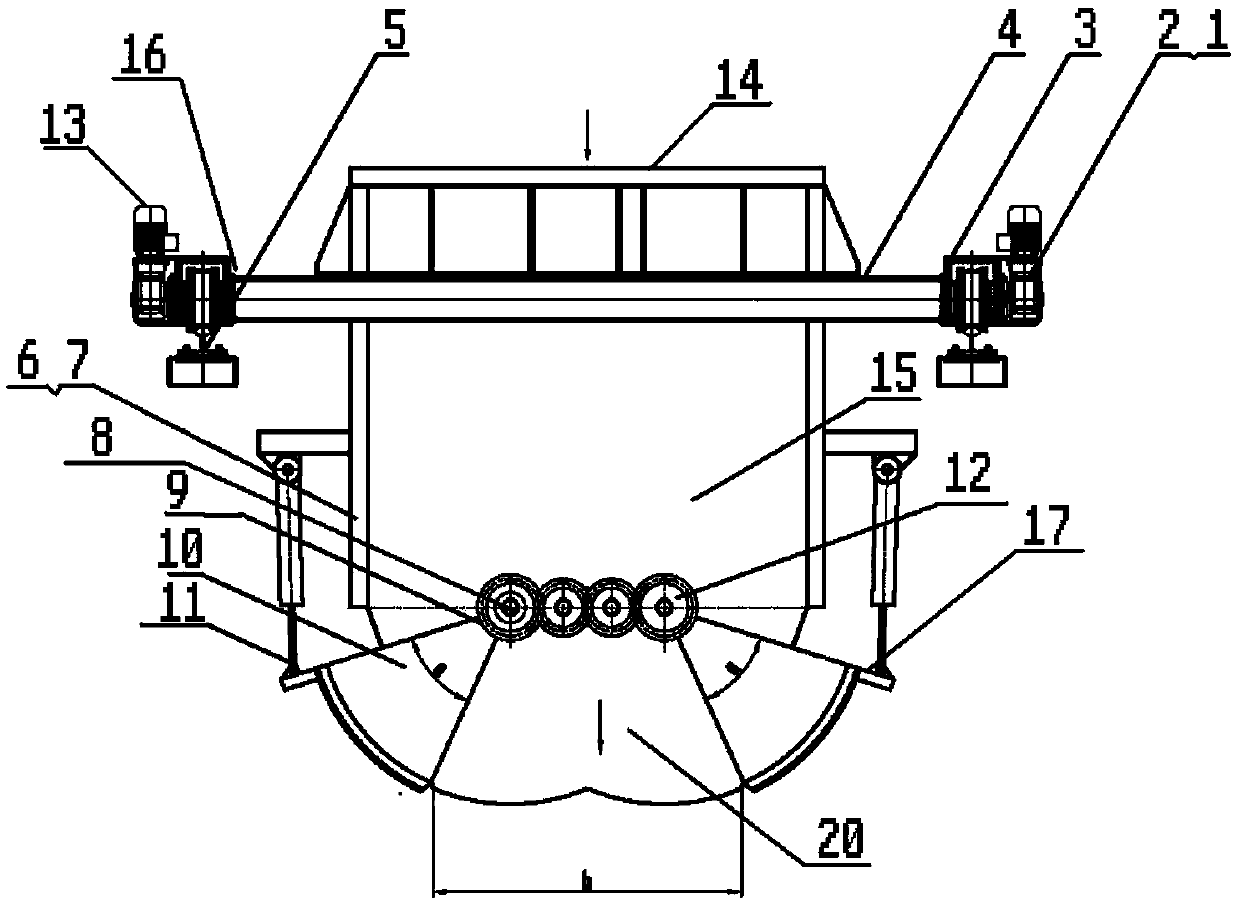

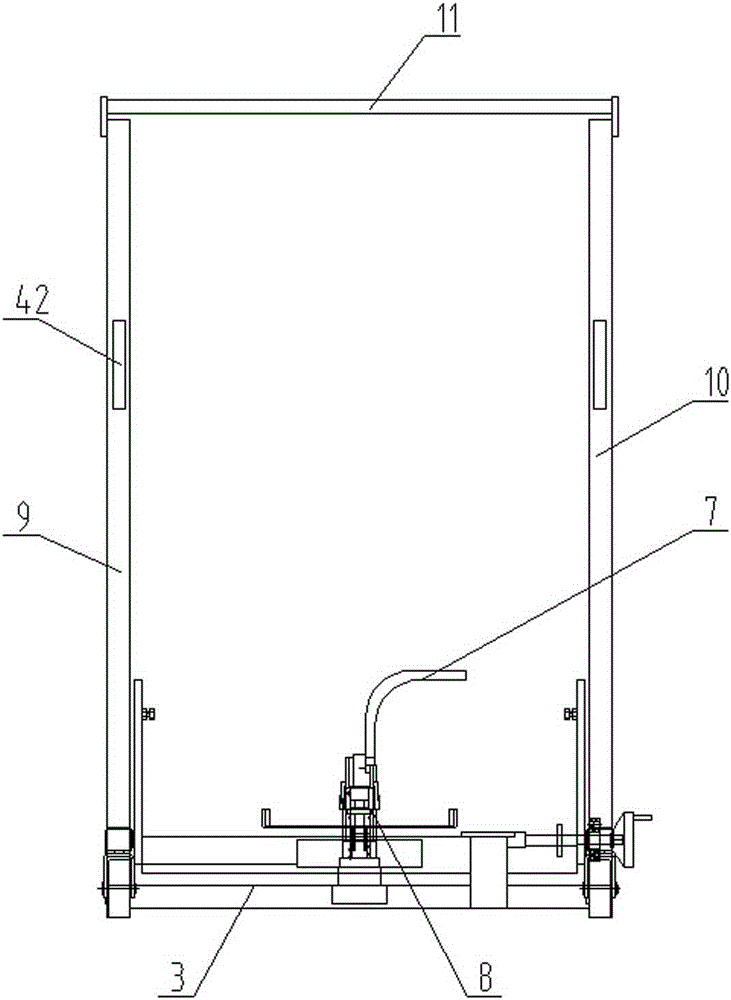

Assembly and disassembly device and method of weight balancing arm for testing wind power pitch bearing

InactiveCN102313647AEfficient loading and unloadingLoading and unloading safetyMachine bearings testingServomotor componentsHydraulic cylinderControl system

The invention discloses an assembly and disassembly device and an assembly and disassembly method of a weight balancing arm for testing a wind power pitch bearing. The device comprises a weight balancing arm assembling and disassembling device and a hydraulic control system, wherein a travelling wheel I and a travelling II are arranged on a fixed rail; a driving arm is arranged on a shaft of the travelling wheel I; a swing arm is arranged on a shaft of the travelling wheel II; a parallelogram mechanism is formed by a pull rod and a base; a lifting hydraulic cylinder is arranged between the base and the driving arm; an advancing and retreating hydraulic cylinder is arranged on a fixed support on a foundation through a lug shaft, and the head part of the advancing and retreating hydraulic cylinder is connected with the base; the hydraulic control system consists of an oil tank component, an oil supply system, an advancing and retreating oil cylinder hydraulic system and a lifting oil cylinder hydraulic system; the advancing and retreating oil cylinder hydraulic system is used for controlling the weight balancing arm to advance and retreat and making the assembly and disassembly device floated; and the lifting oil cylinder hydraulic system is used for controlling the assembly and disassembly device of the weight balancing arm to ascend and descend and keeping pressure, so that the synchronous action of the two hydraulic cylinders is ensured, and low pressure and system pressure in the lifting process can be switched for two times. The device and the method have the advantages of efficient, safe and automatic weight balancing arm assembling and disassembling processes.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Forklift with inclined cylinders

The invention provides a forklift with inclined cylinders. The forklift comprises a gantry; two sides of the lower part of the gantry are respectively connected with the inclined cylinders; the gantry is provided with a rotating machine; the rotating machine is arranged on the gantry in a manner of sliding up and down through slide parts on two sides; a fork frame is arranged on the rotating machine, and is rotationally arranged on the gantry through the rotating machine; two slide guide devices are arranged on the fork frame; a distance adjusting device is arranged between the two slide guide devices; each slide guide device is connected with a goods fork; the goods fork is provided with multiple bent joints for adjusting the shape of the goods fork; and fastening bolts are arranged at two ends of the bent joints. The forklift with the inclined cylinders is convenient in operation and maintenance, high in production efficiency, low in operating cost and safe and reliable in operation, reduces the accident rate, can achieve multiple purposes on one machine, reduces repeated purchase by user equipment, and effectively saves funds.

Owner:ANHUI YUFENG WAREHOUSING EQUIP

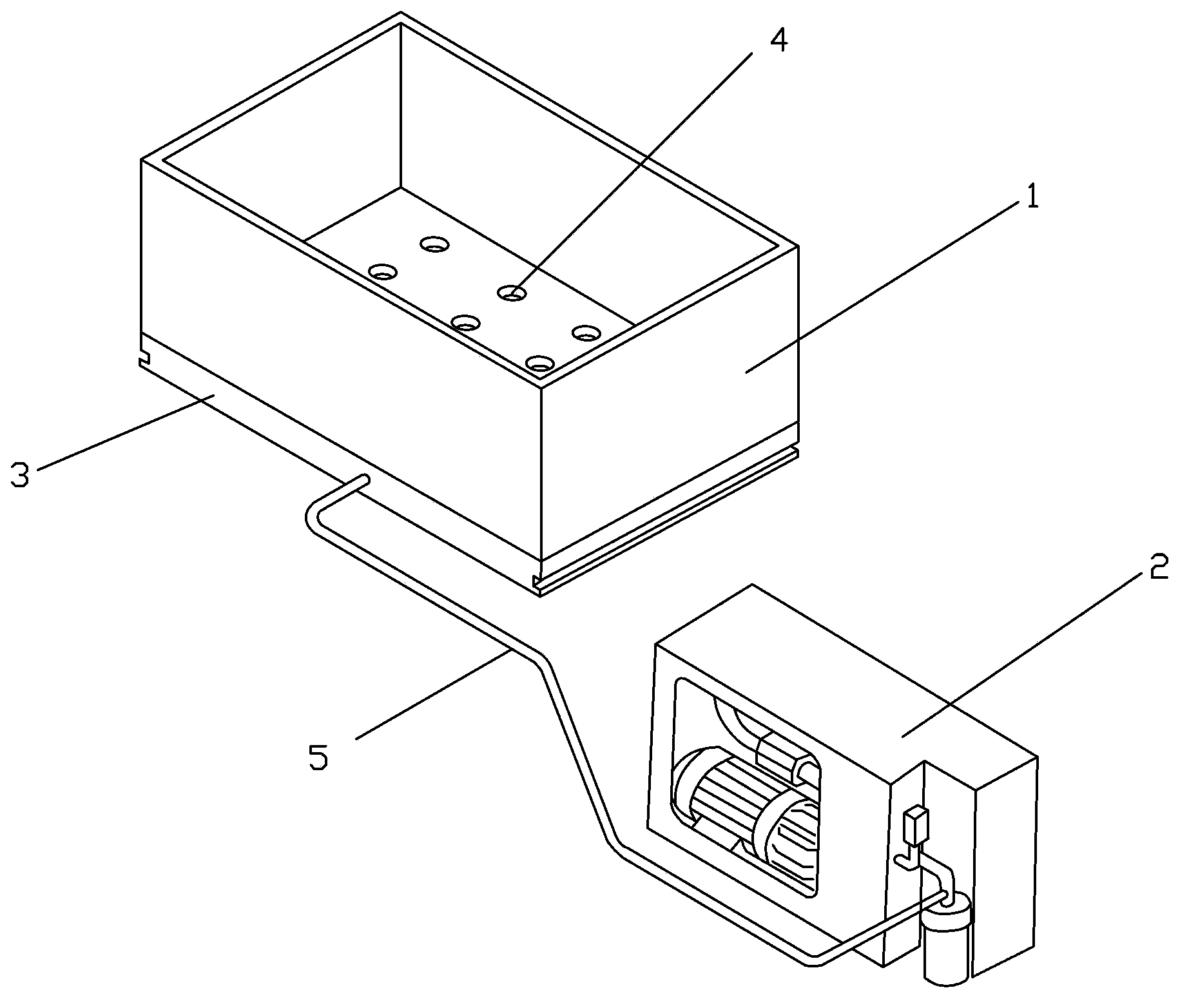

Polymerized plate vacuum adsorption device and polymerized plate manufacturing technology

InactiveCN103657949ANo pollution in the processNo damagePretreated surfacesCoatingsManufacturing technologyEngineering

The invention relates to the technical field of heat-preservation fireproof material manufacturing, and particularly relates to a polymerized plate vacuum adsorption device and a polymerized plate manufacturing technology. The vacuum adsorption device comprises a box body for containing plates and a vacuum pump, wherein a vacuum groove is formed in the bottom of the box body; the vacuum groove is communicated with a cavity of the box body through liquid flowing holes and also communicated with the vacuum pump through a vacuum pipe. A polymerized plate is manufactured by means of re-polymerizing an extruded plate with various fireproof environment-friendly and heat-preservation materials through new technology treatment, so that not only are the original various physical indexes of the extruded plate kept, but also the problems such as inflammability, toxic smoke release and melt-dripping of the extruded plate are solved. The polymerized plate is an incombustible material meeting grade-A fireproof requirements and the fire endurance of the polymerized plate surpasses that of inorganic materials such as rock wool, glass wool and foamed glass. The polymerized plate is high in production efficiency, low in cost, convenient to construct, free of environment pollution, free of breakage in transportation, safe to load and unload, and low in labor intensity.

Owner:天津市裕华玻璃钢有限公司

Grinding device with quick-disassembly structure

InactiveCN103433844APrecise positioningNot easy to fall offGrinding wheel securing apparatusEngineeringMechanical engineering

The invention discloses a grinding device with a quick-disassembly structure. The grinding device comprises a grinding head and a grinding cutter, wherein a driving rod is arranged in the grinding head; a cutter bar is arranged in the driving rod and comprises a cutter bar body, and a plurality of through holes are formed in the front end of the cutter bar body along the circumference; a locking device is arranged in the cutter bar and comprises an upper locking piece and a lower locking piece; an accommodating space is reserved between the upper locking piece and the lower locking piece; a plurality of balls are arranged in the accommodating space; an upper fixing ring is arranged in a middle hole of the grinding cutter; a tapered hole matched with the cutter bar is formed in the upper fixing ring; an annular limiting bulge is arranged in the middle of the tapered hole; and an annular positioning groove matched with the balls is formed below the limiting bulge. The grinding device can realize quick connection and disassembly between the cutter and the grinding head, is difficult to wear, can save more space, is convenient to maintain, saves the cost, and improves the efficiency.

Owner:JIANGSU HAIJIAN

Forklift work device with steel pipe clamp

The invention provides a forklift work device with a steel pipe clamp. The forklift work device comprises a door frame. The door frame is provided with a rotator. The rotator is arranged on the door frame in a vertical sliding manner through sliding parts on the two sides. The rotator is provided with a fork frame. The fork frame is rotationally arranged on the door frame through the rotator. The lower end of the fork frame is connected with the rotator. A push-pull air cylinder is arranged between the upper end of the fork frame and the rotator. The fork frame is provided with two sliding guiding devices. A distance adjusting device is arranged between the two sliding guiding devices. Each sliding guiding device is connected with a pallet fork. Each pallet fork is provided with a plurality of bending joints used for adjusting the shape of the pallet fork. Fastening bolts are arranged at the two ends of each bending joint. Sliding rails are arranged on the two inner sides of the door frame. A rotating shaft is arranged between the two sliding rails and connected with the steel pipe clamp. The steel pipe clamp is provided with an operation air cylinder. The forklift work device with the steel pipe clamp is convenient to operate and repair, complete in function and safe and reliable in operation, the accident rate is reduced, the device has multiple purposes, repeated equipment purchasing is reduced for users, and the cost is effectively reduced.

Owner:HEFEI HANDBAROW APPURTENANCES TECH

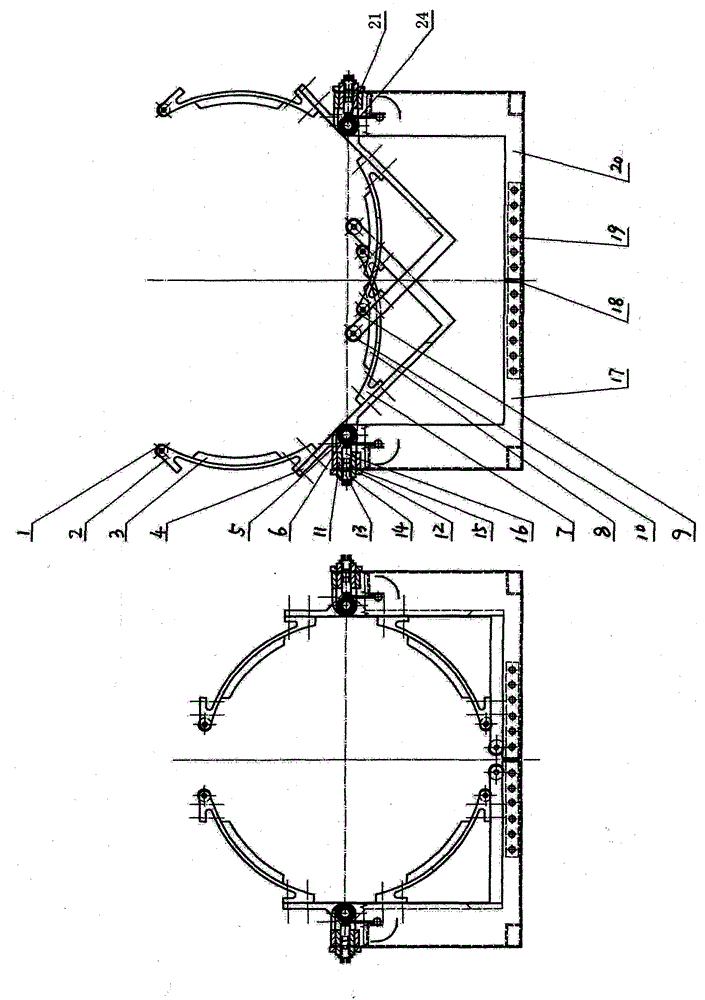

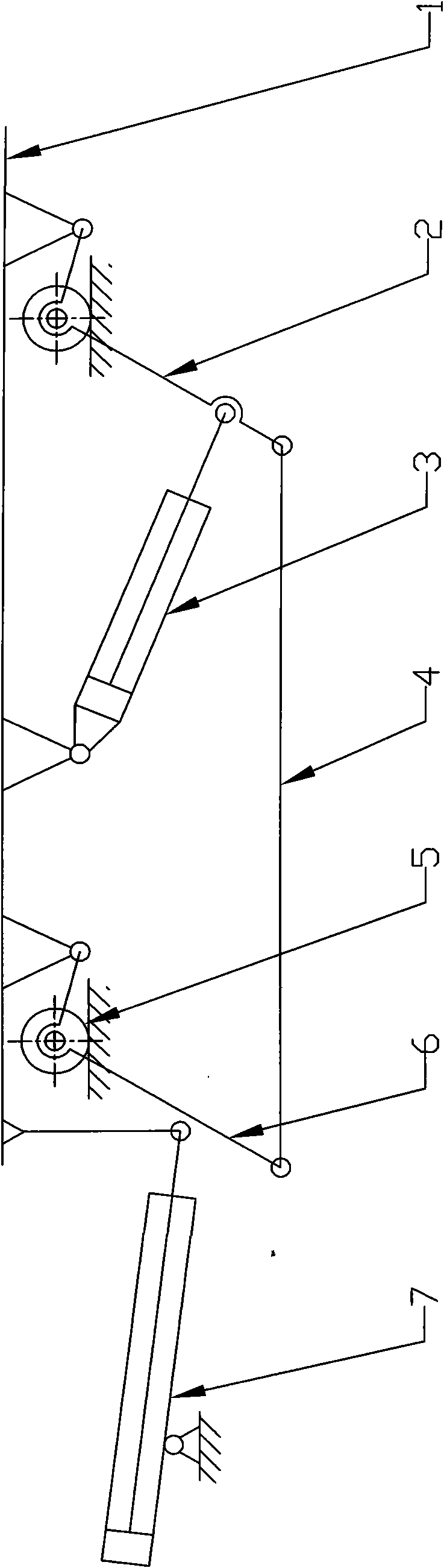

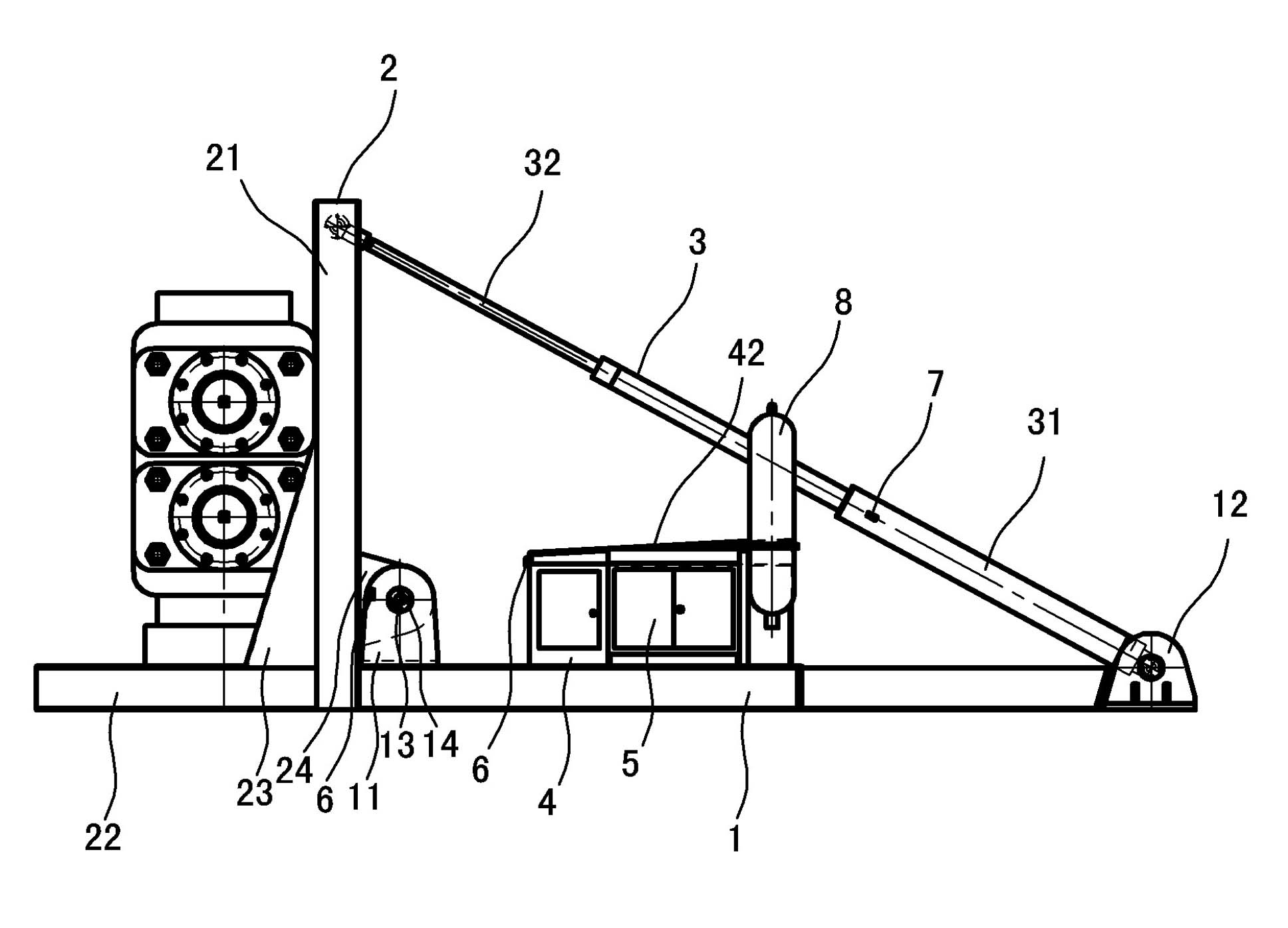

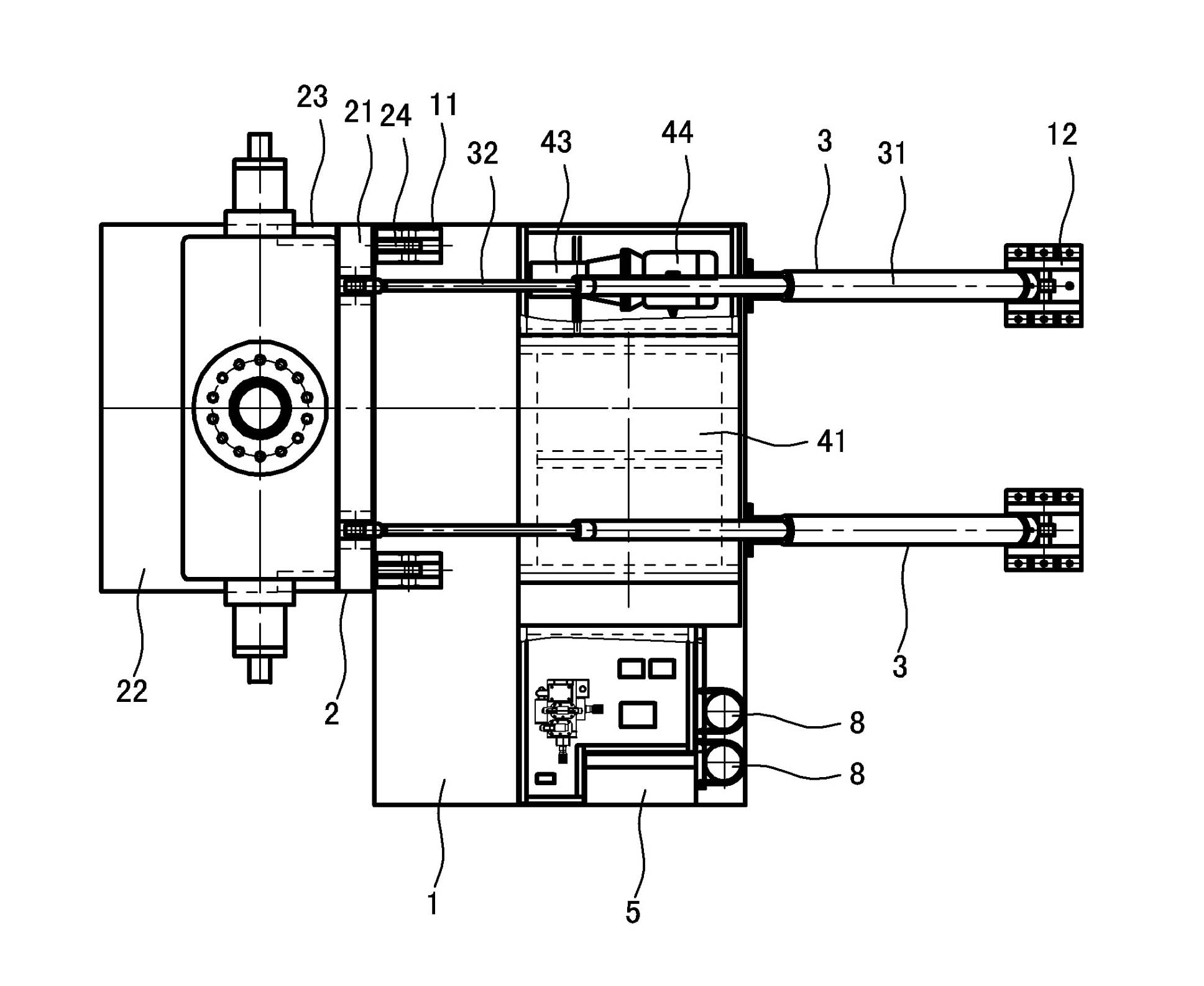

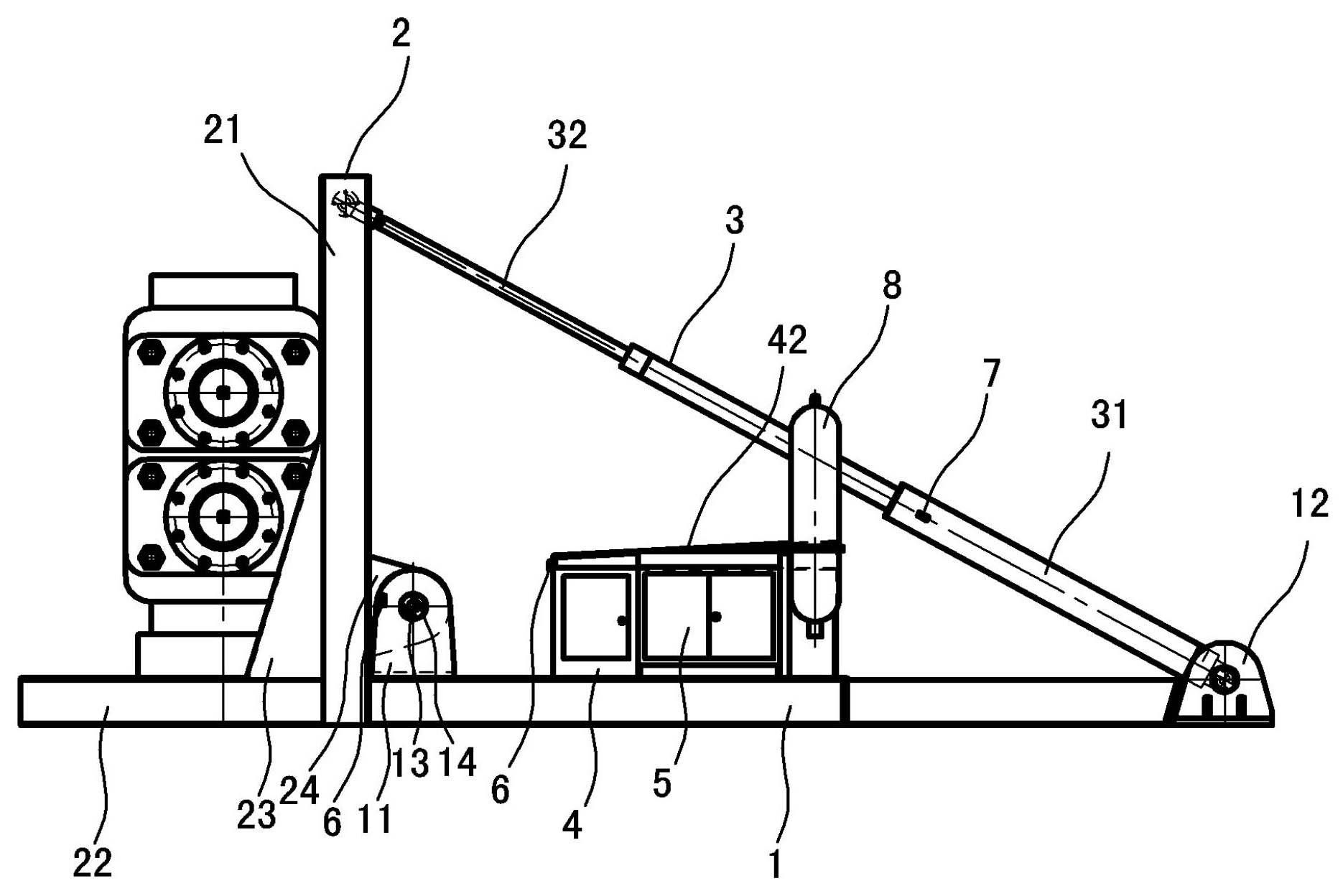

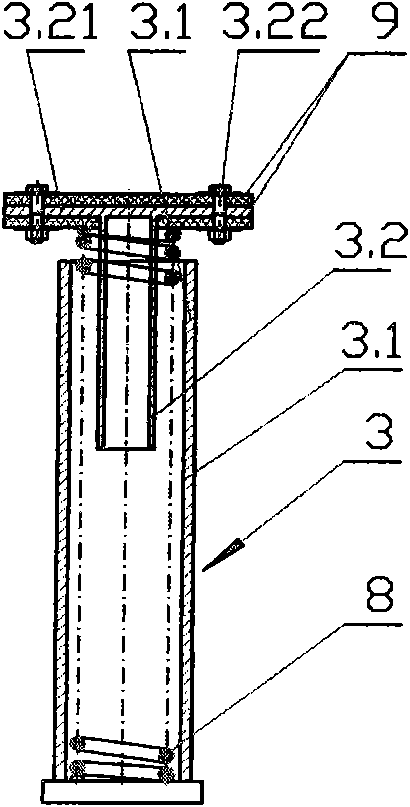

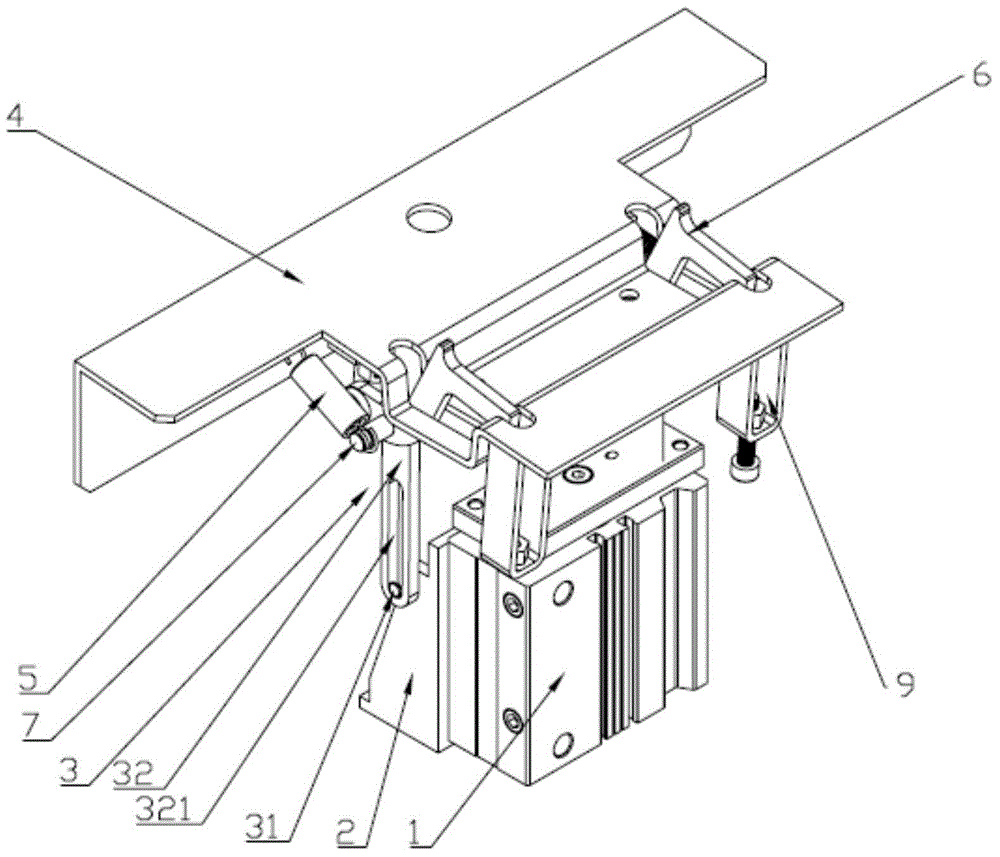

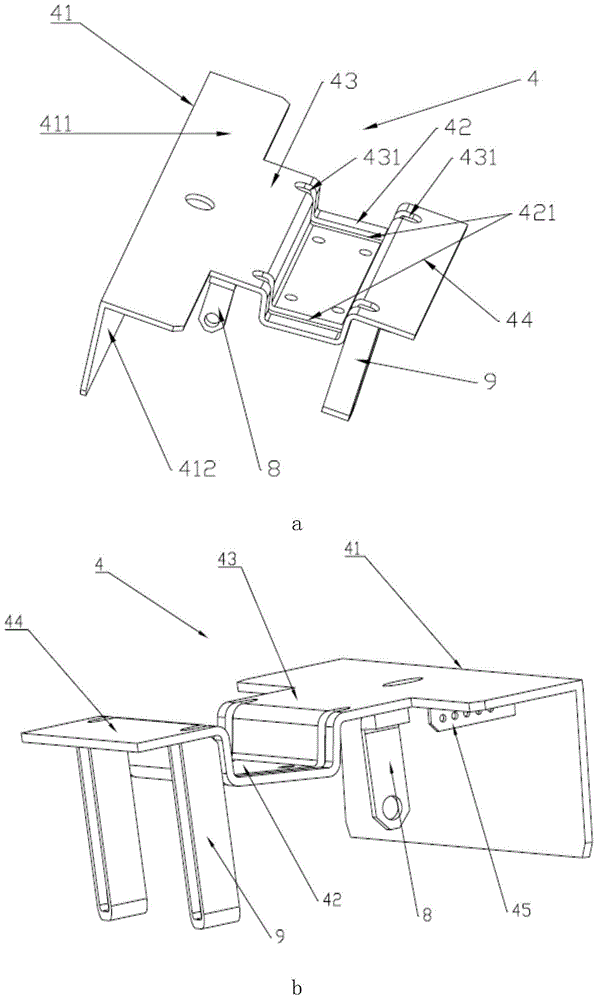

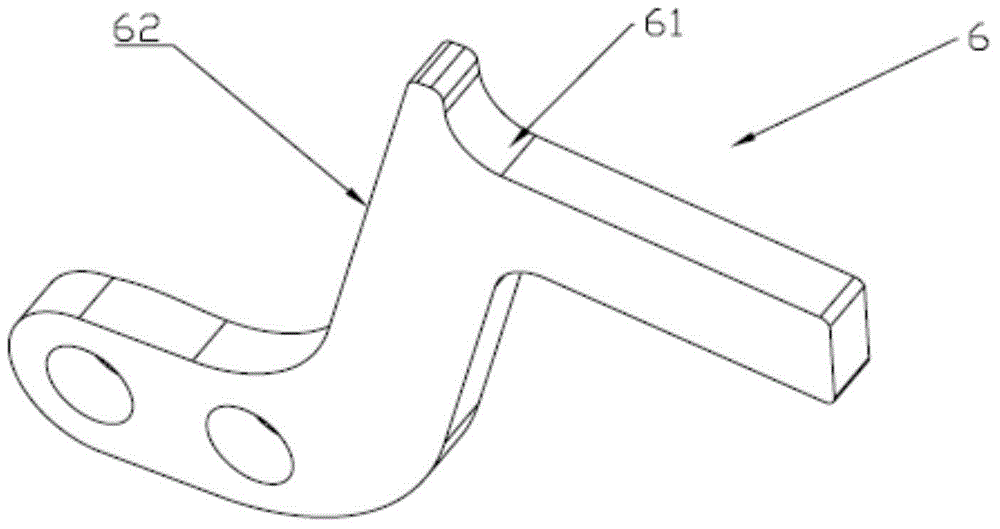

Blowout preventer turning system

InactiveCN101858204ASafe and reliable maintenanceSafe and reliable cleaningSealing/packingPush and pullTurning frames

The invention relates to a petroleum machinery maintenance device, in particular to a blowout preventer turning system for turning a blowout preventer during maintenance and cleaning. The blowout preventer turning system comprises a base (1), a bearing turning frame (2), a hydraulic tuning oil cylinder (3), a hydraulic station assembly (4) and an electric control device (5); the bearing turning frame (2) is transversely hinged on the base (1); the cylinder body (31) of the hydraulic tuning oil cylinder (3) is hinged on the base (1), and the end part of the piston rod (32) of the hydraulic tuning oil cylinder (3) is articulated with the bearing turning frame (2) to push and pull the bearing turning frame (2) to turn; the hydraulic tuning oil cylinder (3) is connected with the hydraulic station assembly (4) through a high-pressure oil pipeline; and the hydraulic station assembly (4) is connected with the electric control device (5). The blowout preventer turning system is time-saving and labor-saving to use, safely and reliably turns a ram preventer, a drill spool and other heavy devices in maintenance or cleaning, improves the production efficiency, ensures safe production and fills a blank in the blowout preventer maintenance field at home and abroad.

Owner:MUDANJIANG DONGXU MACHINERY

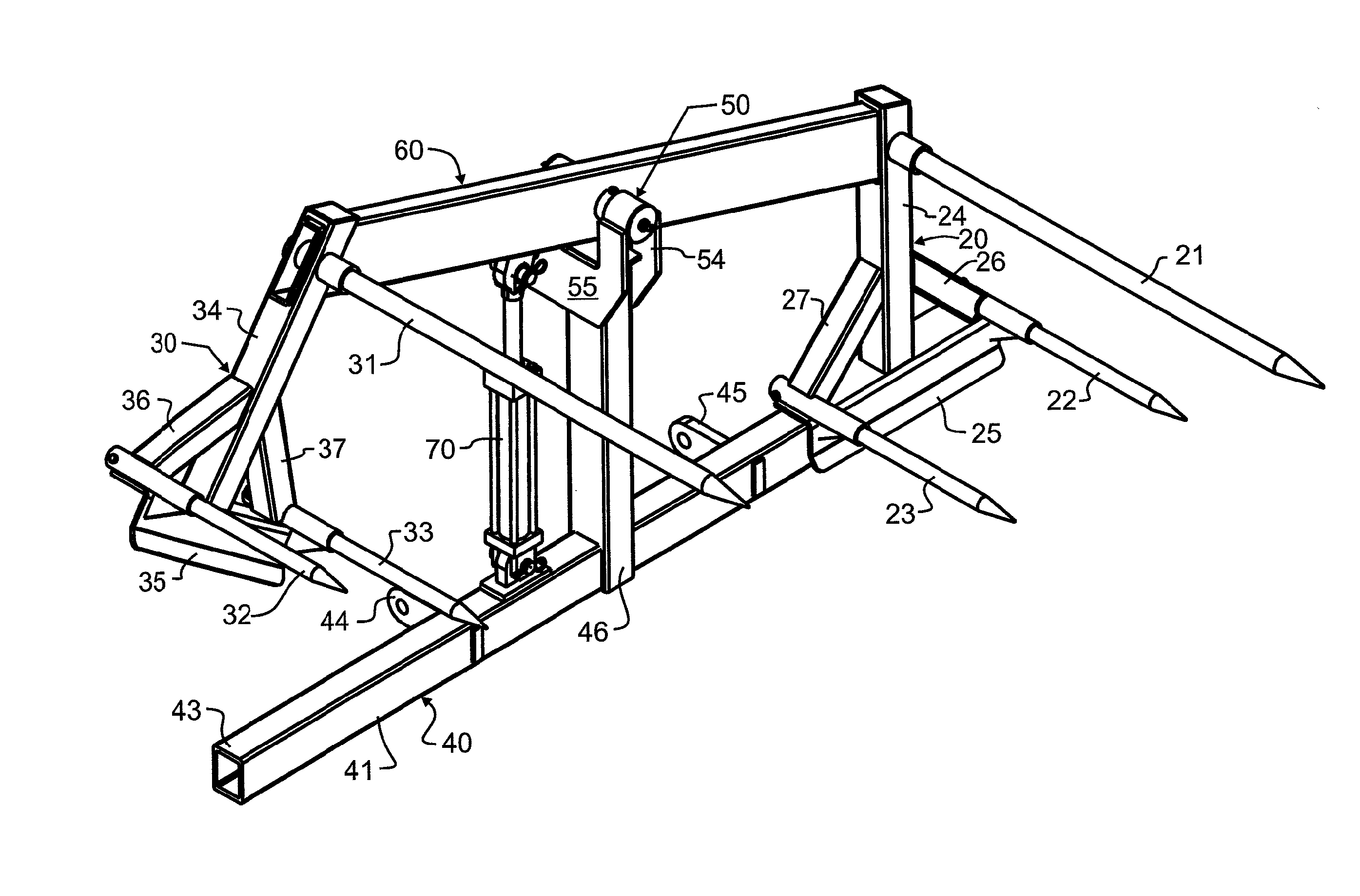

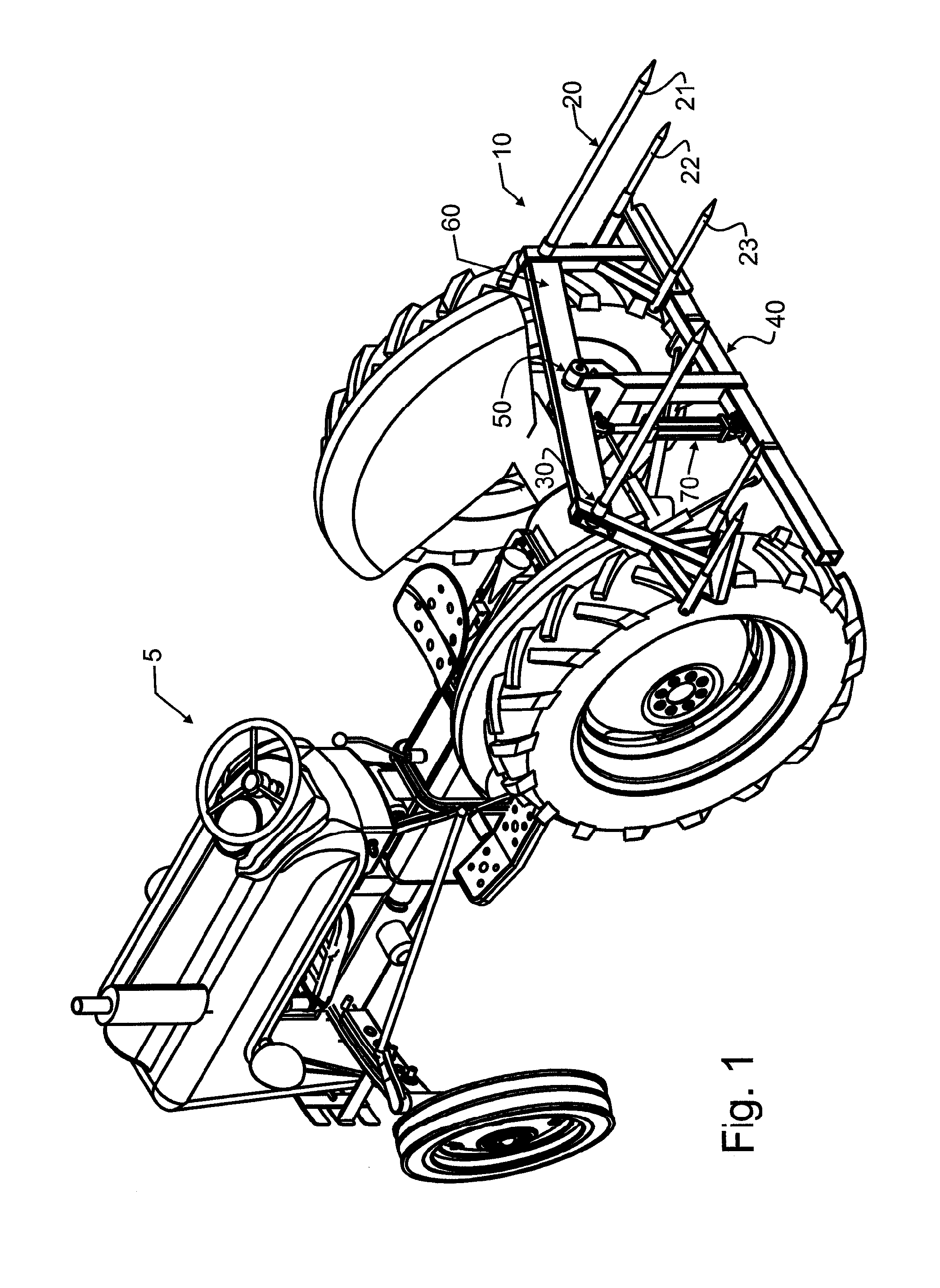

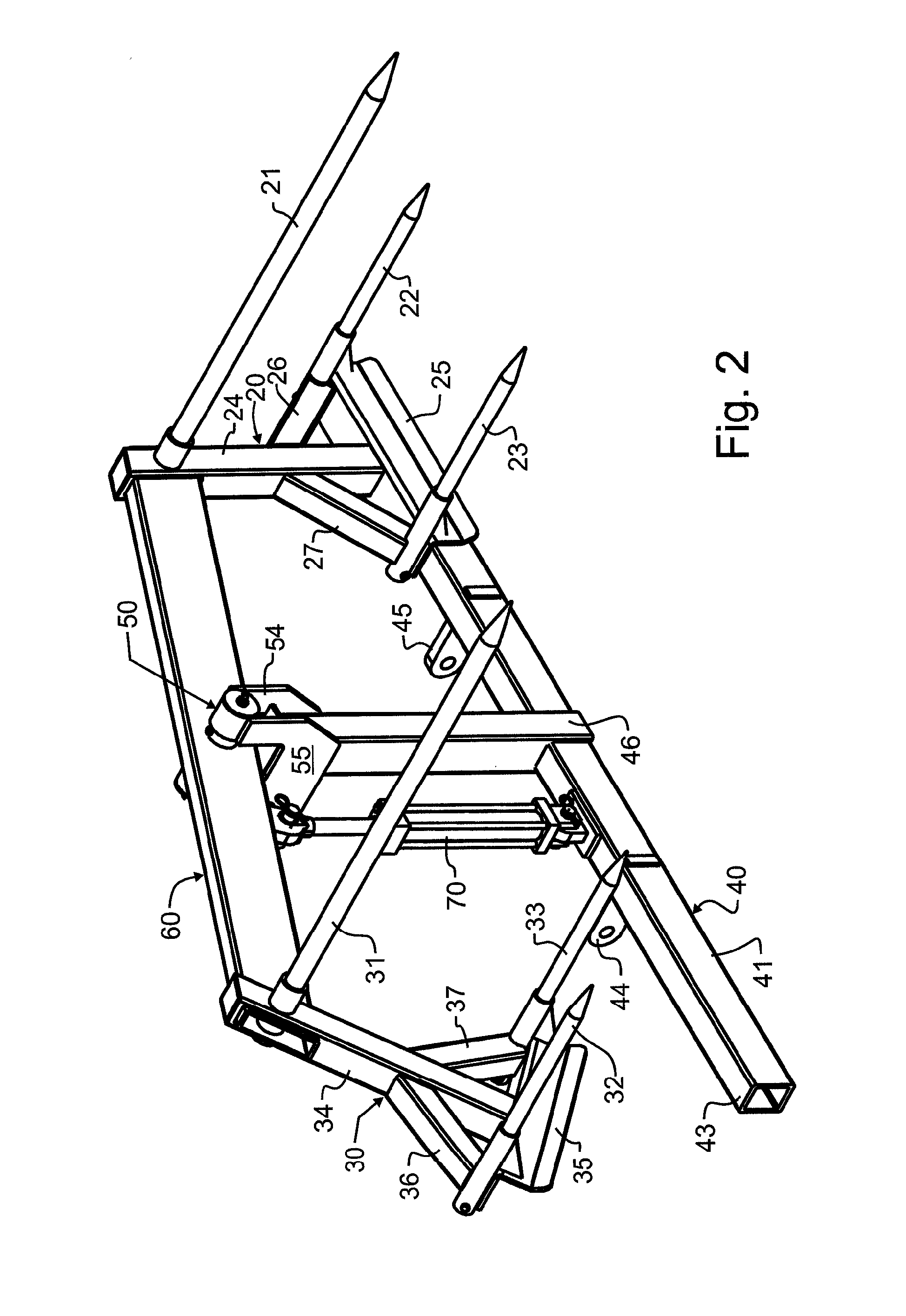

Dual bale lift with longitudinal and machinery pivots

A fork-type dual bale lift has both longitudinal and machinery pivots. A frame structure is mounted on a vertically swinging load support. A boom member is coupled to the frame structure through a pair of bearings and is pivotal about the longitudinal machine axis. At the ends of the boom member are bale supports that are operative to pierce and support a large bale for lifting and transport. A hydraulic cylinder is used to control the pivotal orientation of the boom about the longitudinal machine axis, and thereby allow an operator to selective raise one of the two bale supports while simultaneously lowering the other of the two bale supports. At the extremes of boom rotation, the lower of the two bale supports additionally engages with the frame structure to provide increased strength and stability during loading and unloading, and to reduce stress on the bearings during transport.

Owner:COLLOM LANGDON J

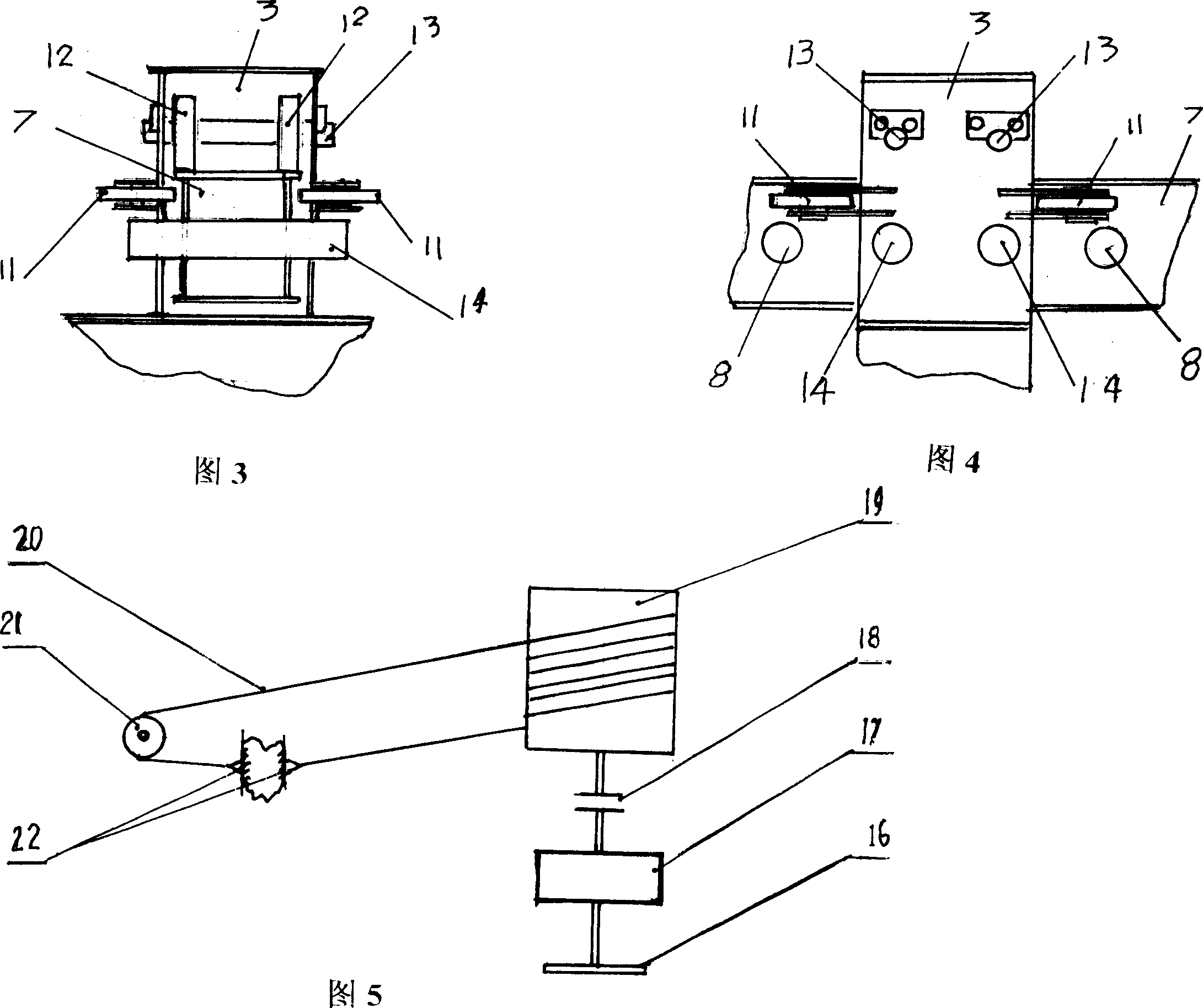

Large-sized pressure spring loading and unloading machine

InactiveCN104511742AAxial positioning is accurateImprove wear resistanceMetal working apparatusGear wheelWear resistant

The invention discloses a large-sized pressure spring loading and unloading machine. A left lead screw cylinder shaft is connected with an upper spring fixing seat, a lower spring fixing seat, a left lead screw nut and a nut; a right lead screw cylinder shaft is connected with the upper spring fixing seat, the lower spring fixing seat, a right lead screw nut and a nut; the upper spring fixing seat and the lower spring fixing seat are provided with a wear-resistant lining; an upper spring pushing support plate is connected with the wear-resistant lining and the upper spring fixing seat; a lower spring pushing support plate is connected with the wear-resistant lining and the lower spring fixing seat; a left lead screw gear is connected with the upper spring fixing seat and the left lead screw nut and is engaged with a middle gear; a right lead screw gear is connected with the right lead screw nut and is engaged with a driving gear. The driving bevel gear is engaged with a driven bevel gear. A spring pulling plate is connected with the upper spring pushing support plate and the lower spring pushing support plate; a gearbox casing is connected with the upper spring fixing seat.

Owner:王荣

Support for turning over coiled steel

ActiveCN101857148ASo as not to damageThere will be no shipping quality problemsLoading/unloadingState of artProne position

The invention discloses a support for turning over coiled steel, which is provided for overcoming the shortcomings that when the coiled steel is unloaded from a transport vehicle and shipped for transportation in the prior art, the standing posture needs to be turned over to the lying posture, the turning over occupies manpower and equipment and is easy to damage a carriage or the ground by collision, and a product is easy to deform and unsafe during the turning over process. A seesaw type turning plate is supported on a base, a support part which can lead the gradient of the upper surface to be consistent with the gradient of the bottom surface when hoisting the coiled steel and is positioned in the balance state during the empty load of the turning plate is fixedly arranged below one end of the turning plate, and cantilever beams which can support the coiled steel in the lying posture state when the turning plate is in the heavy load vertical state are arranged on two sides above the other end of the turning plate. As the coiled steel is turned over from the standing posture to the lying posture for shipping, only a hanging tool needs to be used for hanging the coiled steel onto one end mounting the cantilever beams on the turning plate of the support for turning over, the turning plate drives the coiled steel to automatically downwards turn over in place, then a fork truck can be used for transporting the coiled steel to a cabin for shipping, the turning over does not occupy the equipment and the manpower, the operation is convenient, time-saving and effort-saving, and the loading and unloading cost is low.

Owner:QINGDAO PORT GRP

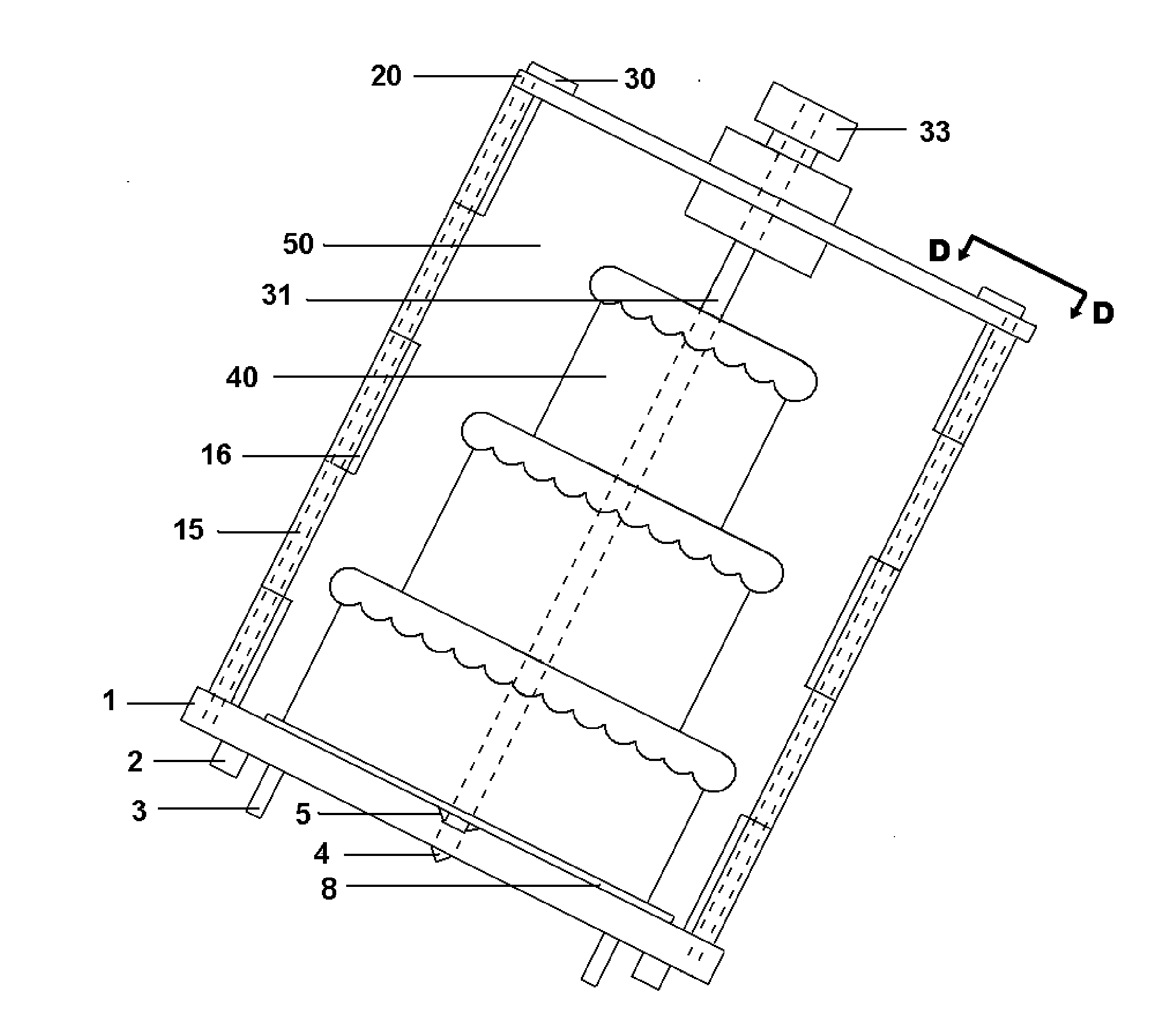

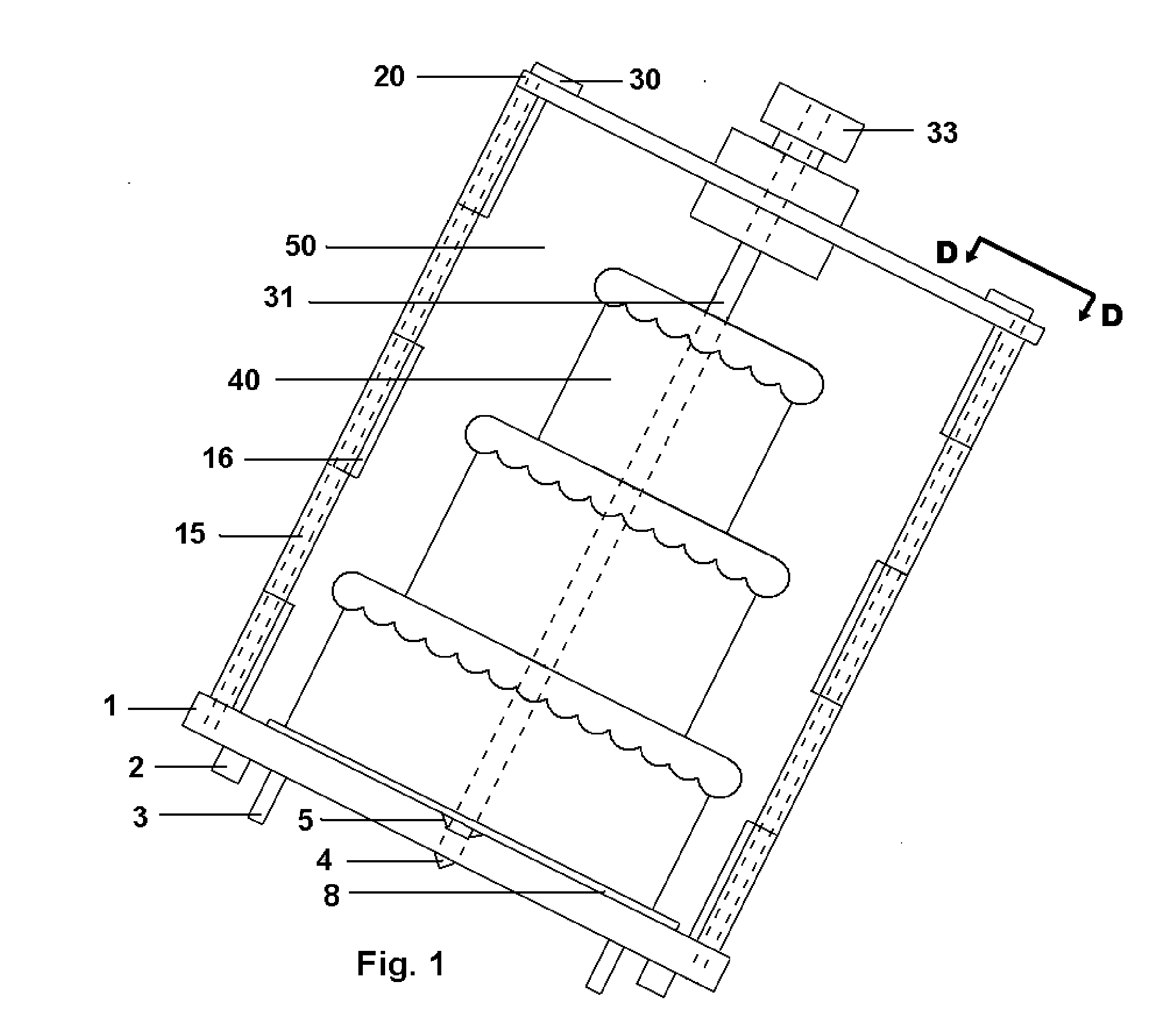

Transportable Cake Carrier

Disclosed is a transportable cake carrier that protects tall, multilayer pastry products from the perils of unexpected turns, uneven pavement, pot-holes and sudden stops of the vehicles doing the delivery. In addition to vehicle borne perils the new and unique carrier addresses ease of placement and removal of the pastry from the carrier, keeping the pastry refrigerated and placement and removal of the carrier from the vehicle. A unique combination of tying the top, base, pedestal and layer separators firmly together, with a sturdy, easy to clean and reusable housing and outstanding human engineering make transport damage a thing of the past. In addition this unique carrier fulfills the spirit of federal LEEDs sustainability requirements with completely reusable components and by keeping ruined product out of the landfills.

Owner:CHAPIN JULIANNE MARGOLIS +1

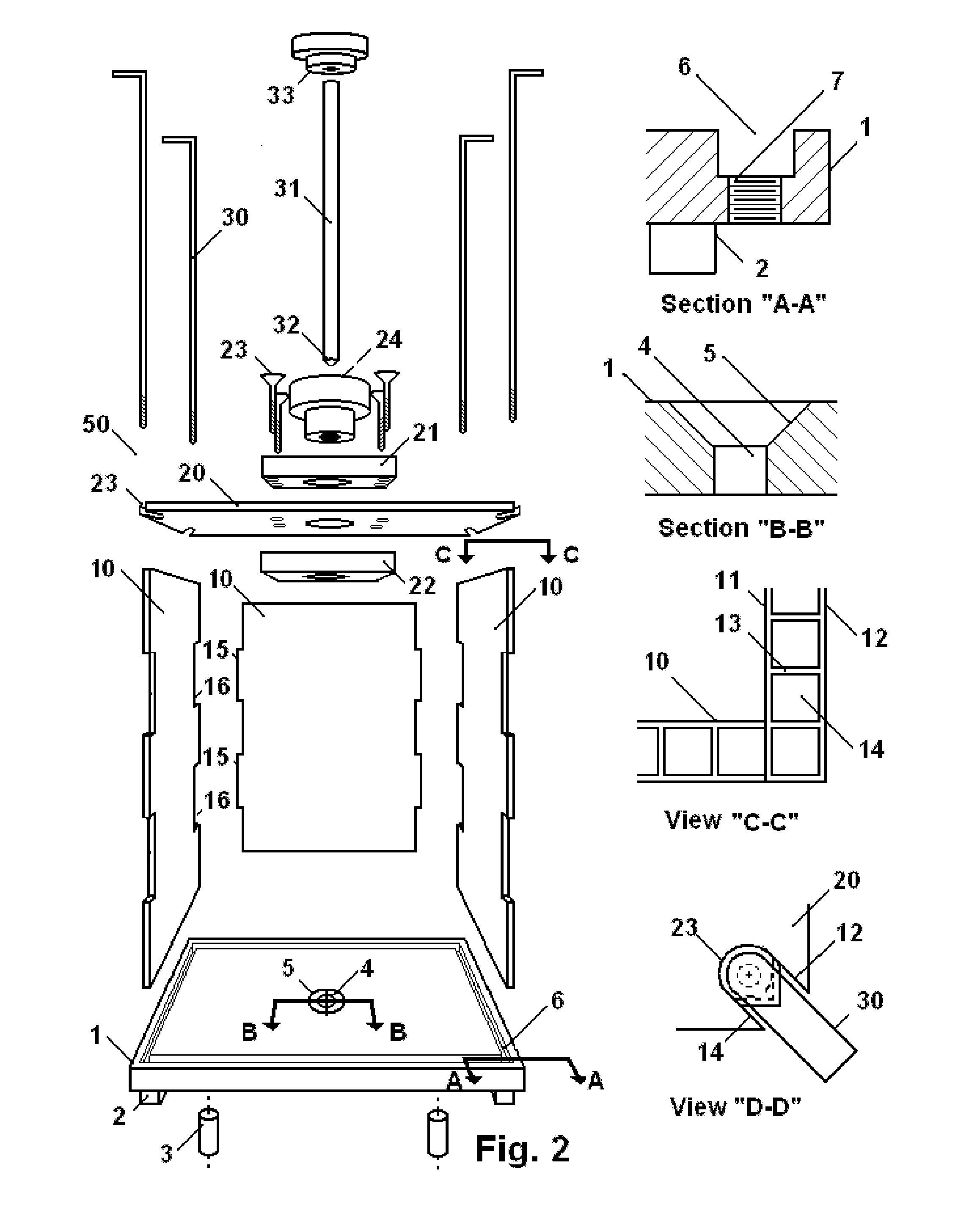

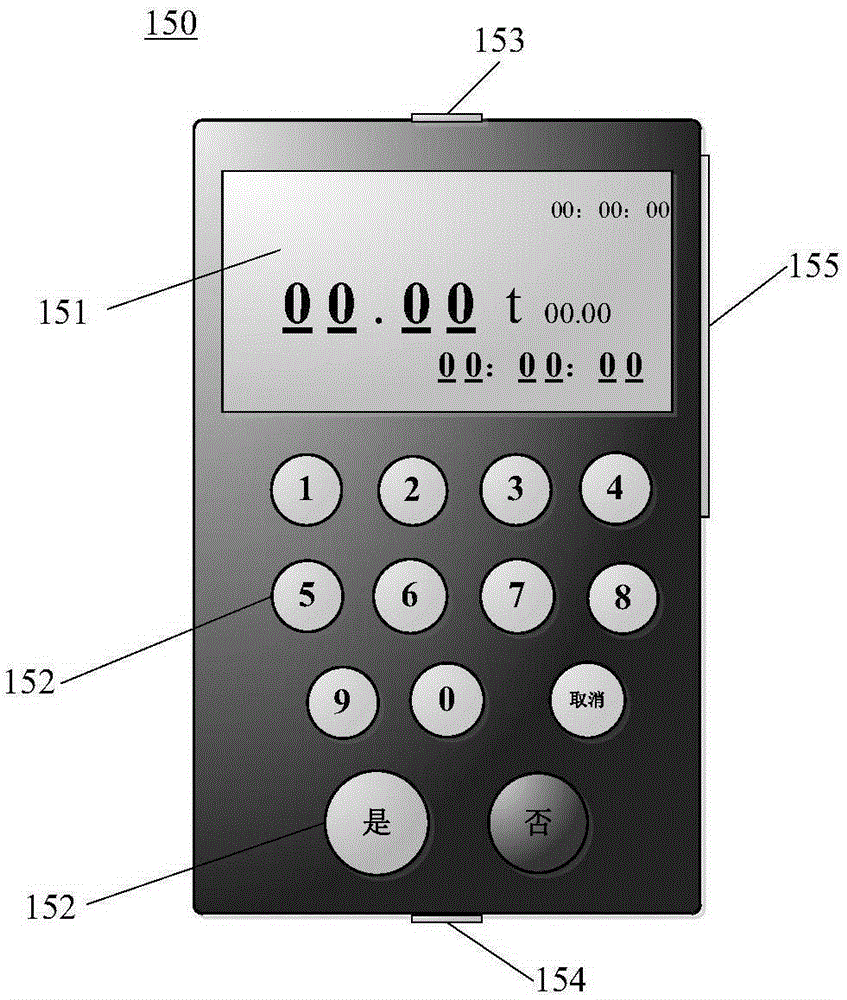

Dangerous chemical loading and unloading system

InactiveCN105240682ALoading and unloading safetyContainer filling methodsPressure vesselsElectricityClosure operation

The invention provides a dangerous chemical loading and unloading system, and belongs to the field of dangerous chemical transportation. The dangerous chemical loading and unloading system comprises an automotive transport tank wagon and a storage tank, wherein the storage tank is connected with the automotive transport tank wagon through a pipeline, and dangerous chemicals can be transferred between the storage tank and the automotive transport tank wagon through the pipeline. The dangerous chemical loading and unloading system further comprises a processor, an electric valve and a display controller, wherein the electric valve and the display controller are electrically connected with the processor. The electric valve is arranged in the pipeline, and is used for executing valve opening operation according to an opening instruction sent by the processor so as to enable the pipeline to be connected, and executing valve closing operation according to a closing instruction sent by the processor so as to enable the pipeline to be disconnected. The display controller is used for displaying operation prompting to a user according to the instructions of the processor, and forwarding operation execution confirmation data to the processor, wherein the operation execution confirmation data are inputted by the user who responds to the operation prompting. The processor judges whether the operation execution confirmation data are matched with pre-stored operation execution reference data or not, if yes, the opening instruction is sent to the electric valve, and if not, the closing instruction is sent to the electric valve.

Owner:谢玉勋 +1

Automatic feeding and discharging device of type rolling machine

The invention belongs to the technical field of machines, and provides an automatic feeding and discharging device of a type rolling machine. The device comprises a drive element, a drive element installation support, a limiting mechanism, a feeding mechanism, a reset mechanism and a discharging mechanism. The drive element controls the feeding mechanism and the discharging mechanism to move up and down in a reciprocating mode, the feeding mechanism and the discharging mechanism are rotationally connected, the feeding mechanism is connected with the drive element installation support in a sliding mode through the limiting mechanism, and the reset mechanism controls the discharging mechanism to return to the original position. By means of the arrangement of the feeding mechanism and the discharging mechanism, feeding and discharging are combined in the type material rolling process, time is saved, the work tact of the type rolling machine is reduced, materials can be pushed to be discharged through the discharging mechanism, the discharging mechanism also has a certain bearing function on the materials to be machined, discharging is accurate, consumed time is short, and efficiency is high; by means of the arrangement of the limiting mechanism and the reset mechanism, it is guaranteed that the automatic feeding and discharging device is safe, stable and high in reliability in the feeding and discharging processes.

Owner:TIANJIN WEIKE WODE TECH

Movable sludge material conveying box

PendingCN109516114AGuaranteed uptimeStrong conveying capacityLoading/unloadingMechanical conveyorsElectronic controllerDrive wheel

The invention provides a movable sludge material conveying box. The movable sludge material conveying box comprises rails, a material trolley, a sludge self-discharging material box and an electroniccontroller, wherein the rails are two parallel suspended steel rails; the material trolley comprises a driving device, a driven wheel set and a driving wheel set; the sludge self-discharging materialbox is fixed on the material trolley, an open feeding port is arranged at the top, discharging doors which are opened oppositely are arranged at the bottom, and a box body is symmetrically distributedwith respect to the rails on the two sides; a discharging door unit comprises a pair of the symmetrically distributed discharging doors and a reciprocating mechanism connected with the discharging doors, and the discharging doors synchronously move to two sides to be opened or synchronously move oppositely to be closed; and the electronic controller is connected with the driving device and the reciprocating mechanism, controls the material trolley to walk or stand still on the rails and controls opening and closing of the discharging doors. The movable sludge material conveying box has a large-volume conveying function, achieves material reciprocating conveying according to the line distance between the conveying starting point and the final point and achieves automatic running and operation. The discharging doors are closed and opened automatically, and discharging is thorough.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

A kind of domestic garbage crushing and air-selecting compression transport vehicle

ActiveCN106429121BEffective dockingOptimize collection routesRefuse vehiclesRefuse collectionWaste collection

The invention relates to a household garbage smashing, winnowing and compressing transportation car. The household garbage smashing, winnowing and compressing transportation car comprises a car chassis which is provided with a garbage collecting and compressing tank, an automatic charging device, a garbage can and a smashing and winnowing device; the garbage collecting and compressing tank is arranged on the tail portion of the car; the garbage can and the smashing and winnowing device are arranged between the head portion and the tail portion of the car; the automatic charging device used for grabbing a roadside garbage can is connected with the side edge of the car chassis below the garbage can; and the smashing and winnowing device used for smashing and classifying the garbage is connected with the garbage can and the garbage collecting and compressing tank. The household garbage smashing, winnowing and compressing transportation car has the beneficial effects that the garbage pretreatment function of garbage smashing and plastic thin film winnowing is achieved, the garbage is stored in different bins after being classified, the sealing performance is good, secondary pollution cannot be caused, the garbage smashing and compressing loading capacity is high, the automation level is high, loading and unloading are safe and reliable, and the work efficiency is high.

Owner:新疆思冀金巴环保科技有限公司

Method for packaging high-furnace cooling wall

InactiveCN101638160AStacking is safe and reliableTransportation safetyCooling devicesRigid containersEngineeringWater pipe

The invention relates to a method for packaging a high-furnace cooling wall, comprising the following steps: overlapping the outer walls of two high-furnace cooling walls back to back so that an inletand outlet pipe opening is protected by the two cooling walls; installing a prefabricated packaging bracket on a packaging cross arm of each cooling wall so that the two cooling walls form a firm integrity with an inward outer wall convex cambered surface inlet and outlet pipe opening and an outward inner wall concave cambered surface to ensure safety and reliable storage, transportation as wellas assembly and disassembly, wherein the packaging cross arm of each cooling wall is made of round steel or profile steel; the packaging cross arms of the two cooling walls are respectively arranged at the left side and the right side of the cooling wall with a space of 20-90 percent of the length of the cooling wall, and cast together with a high-furnace cooling wall body to ensure that the packaging bracket obtains a firm and effective fulcrum; the packaging bracket of the cooling wall is made of profile steel or the whole block of steel plate and welded with the packaging cross arm of the cooling wall or fastened together with a screw.

Owner:周传禄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com