Assembly and disassembly device and method of weight balancing arm for testing wind power pitch bearing

A technology for loading and unloading devices and pitch bearings, which is used in mechanical bearing testing, fluid pressure actuating devices, servo motor components, etc., can solve the problems of low production efficiency and automation level, poor safety, etc. The effect of unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, patent of the present invention is described further.

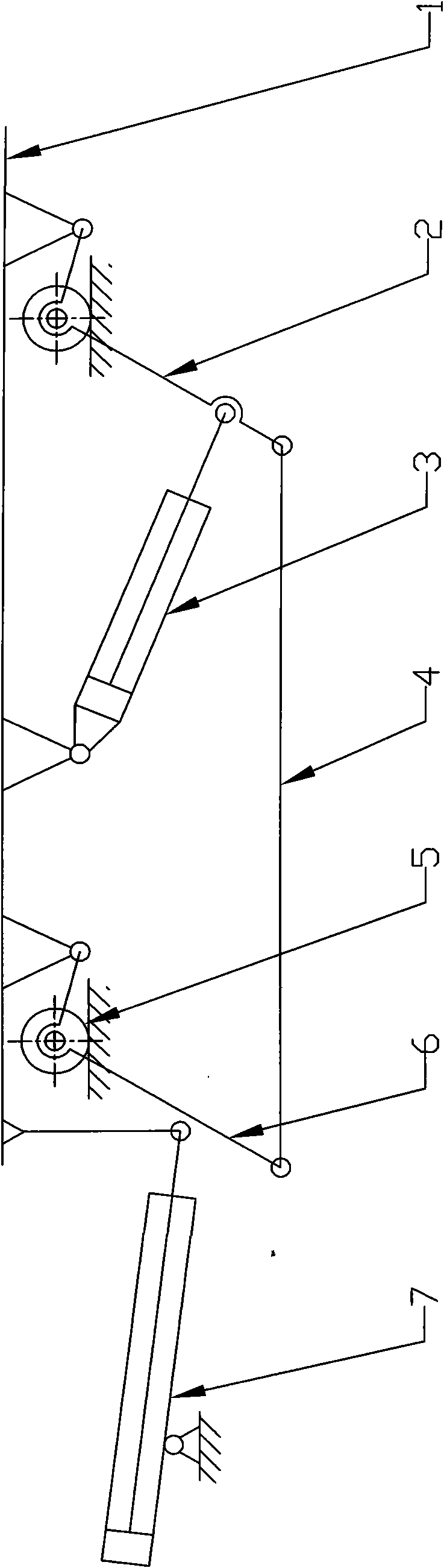

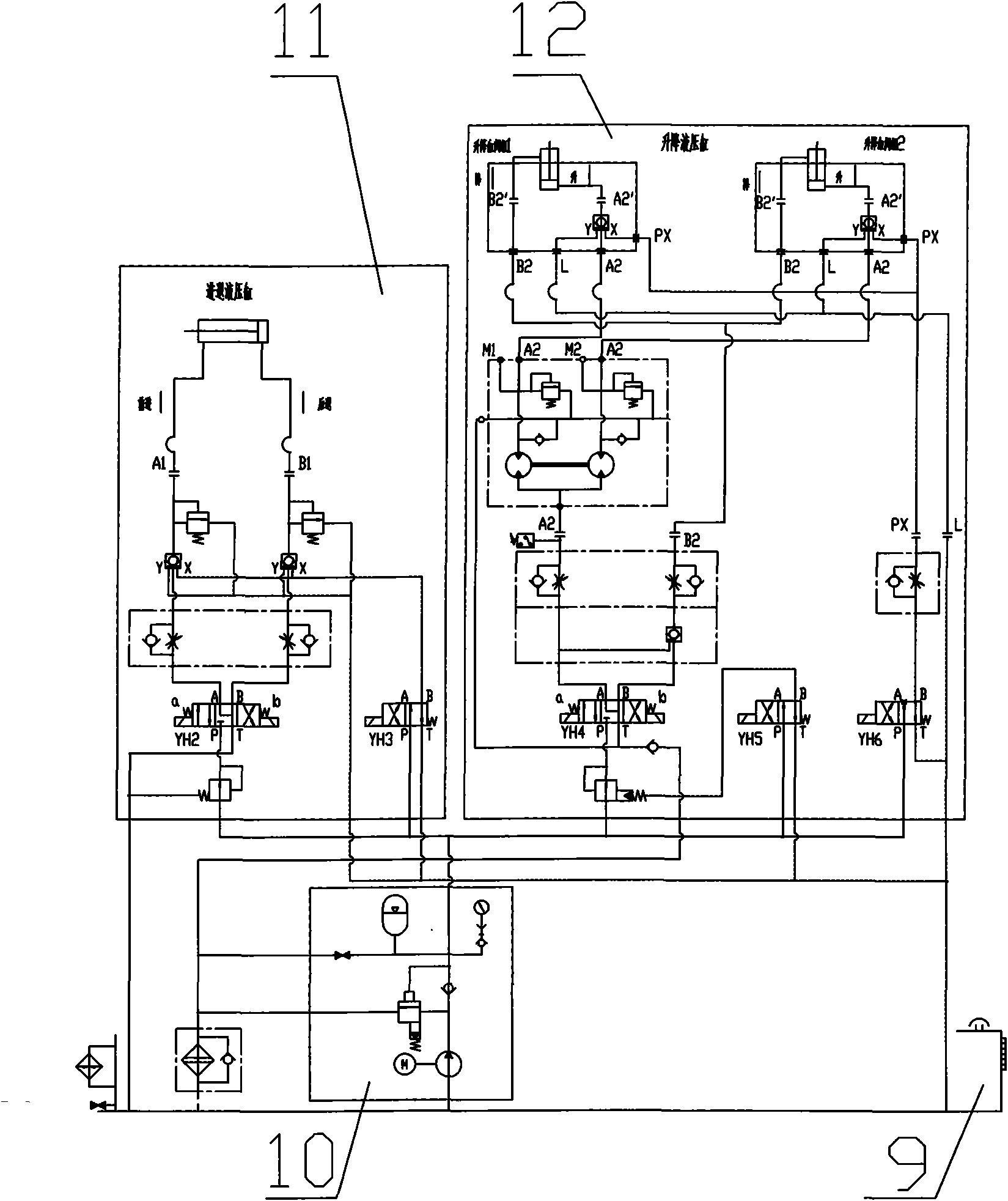

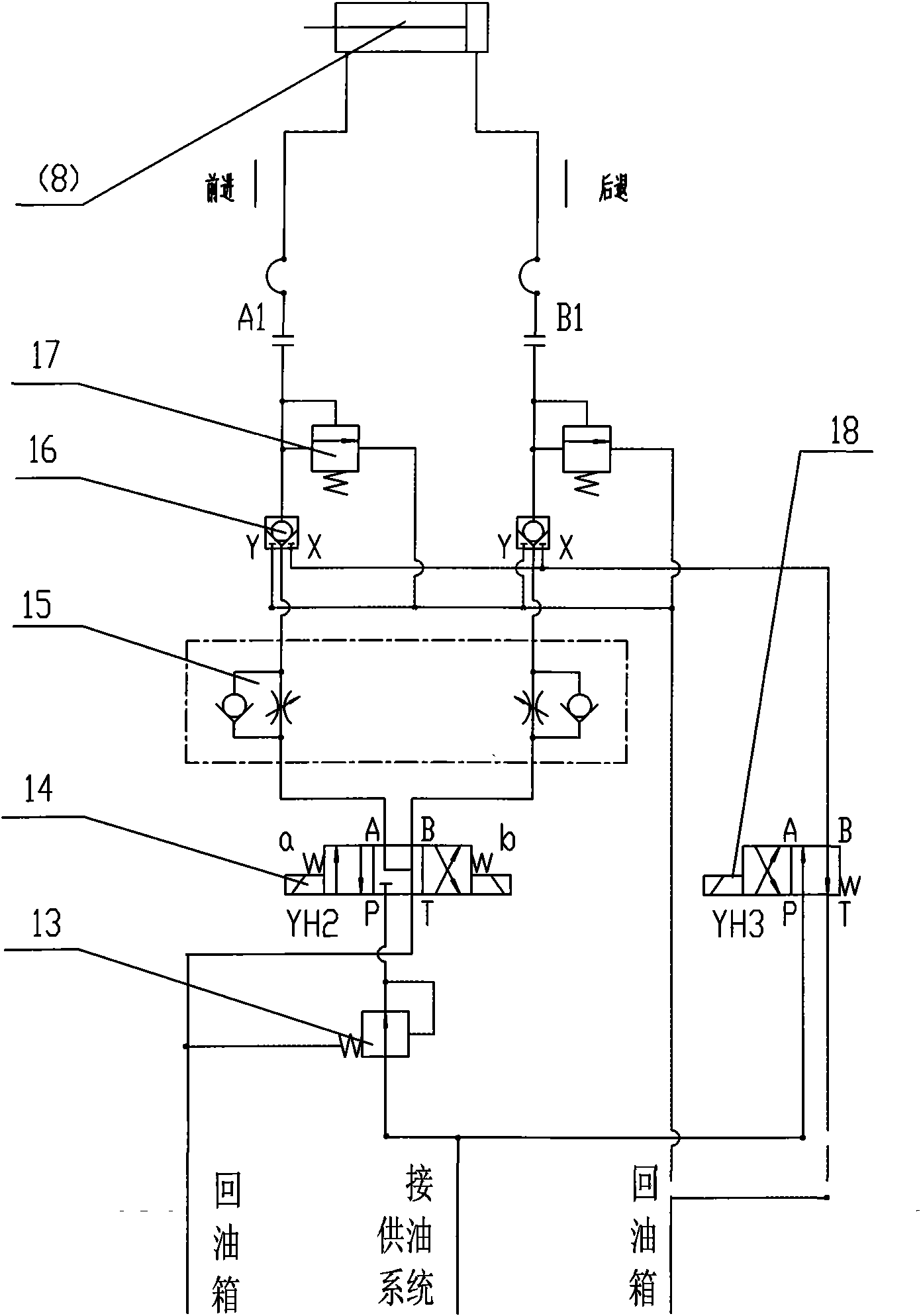

[0024] As shown in the accompanying drawings, the counterweight arm loading and unloading device and loading and unloading method for the wind power pitch bearing test include a counterweight arm loading and unloading device and a hydraulic control system. The counterweight arm loading and unloading device consists of a base 1 and two sets of symmetrically arranged traveling wheels I 2 , driving arm 3, lifting hydraulic cylinder 4, pull rod 5, traveling wheel II 6, swing arm 7, advance and retreat hydraulic cylinder 8, etc., traveling wheel I 2, traveling wheel II 6 are installed on the fixed track, and traveling wheel I 2 is installed on the shaft There is a driving arm 3, and a swinging arm 6 is housed on the traveling wheel II 6 axle, and the question between the driving arm 3, the swinging arm 7 and the wheel shaft is supported by a rolling bearing, and one end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com