Multimodal Platform for Railcar

a multi-modal platform and railcar technology, applied in the field of platforms, can solve the problems of time and resource-intensive task of loading or unloading cargo from containers on the railcar, and achieve the effect of increasing the loading and unloading options and improving the efficiency of loading or unloading cargo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

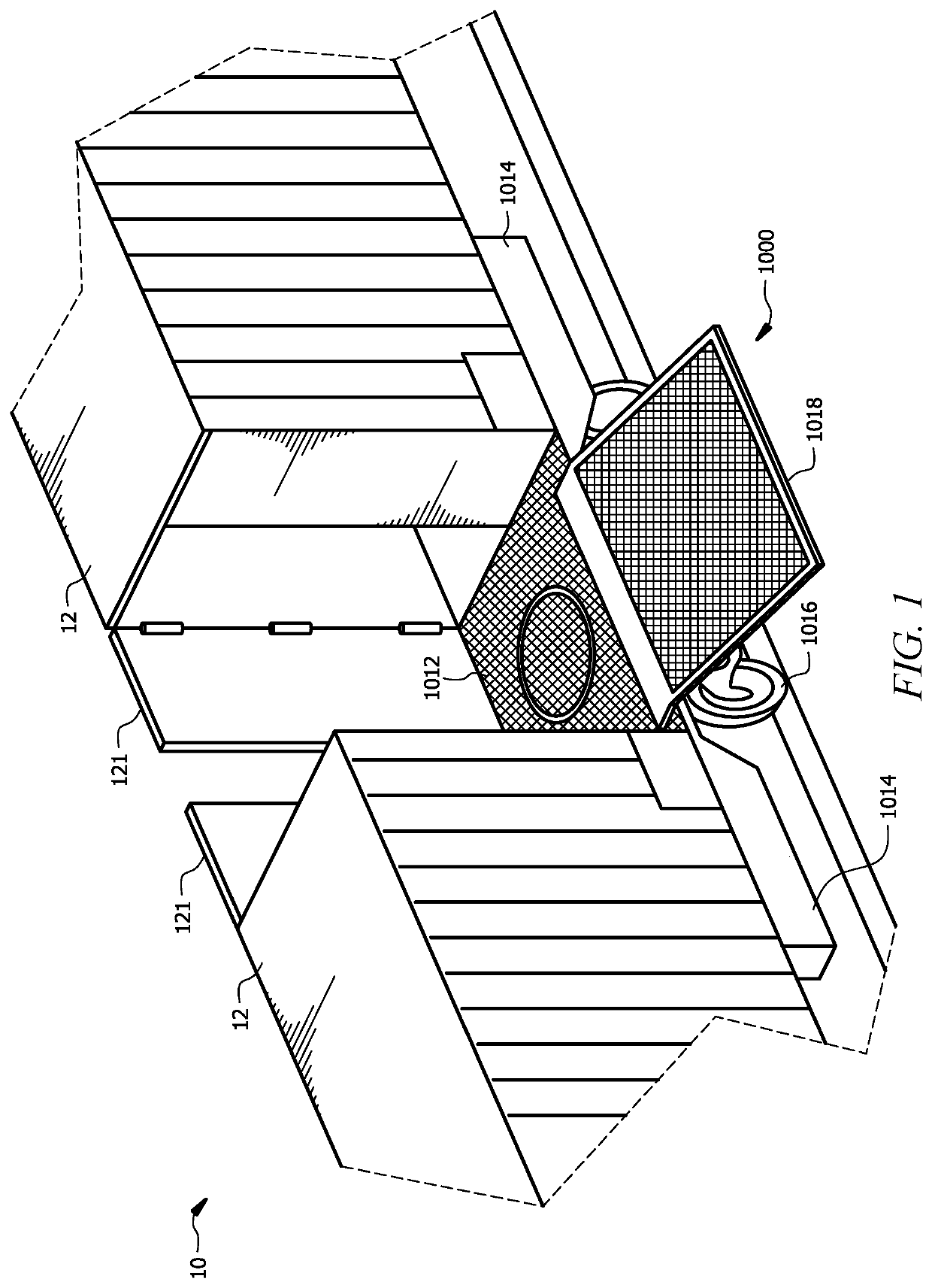

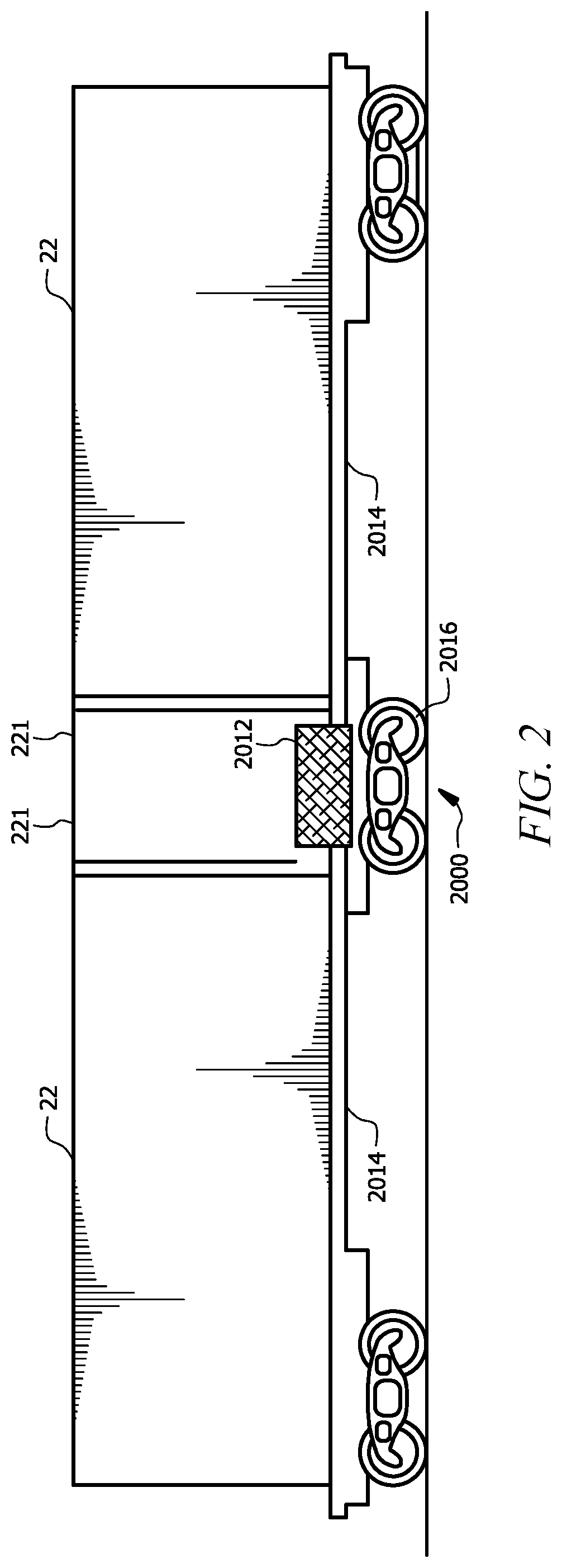

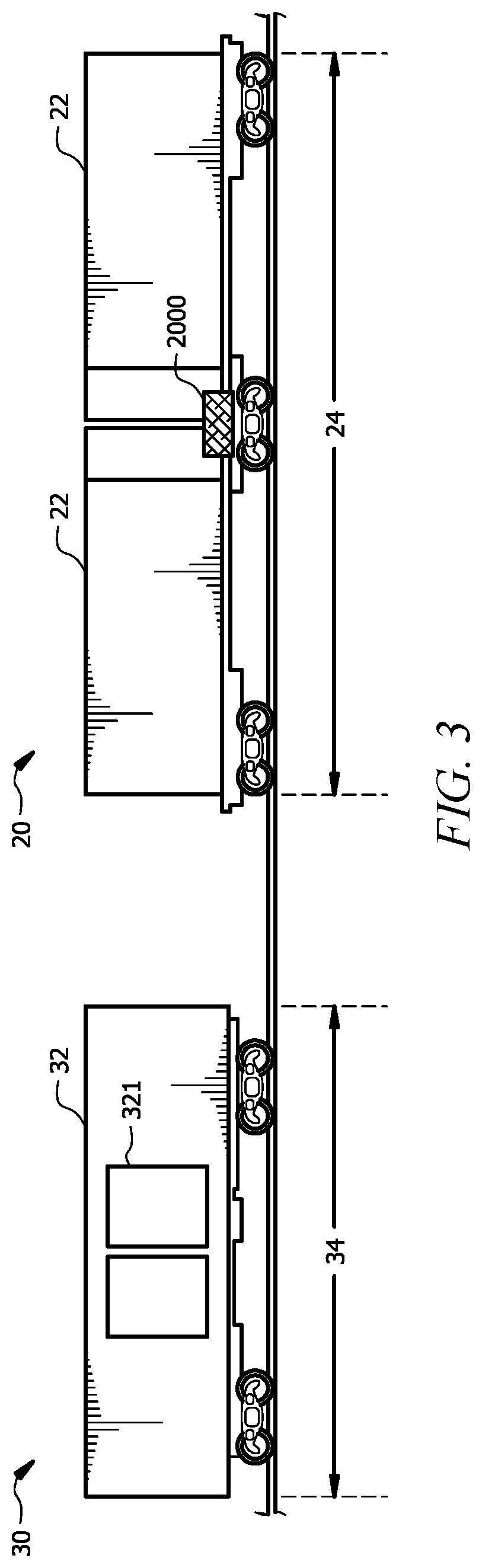

[0027]Certain embodiments of the present disclosure and inventive concepts, and their features and advantages, may be understood by referring to FIGS. 1 to 30, like numerals being used for corresponding parts in the various drawings.

[0028]Particular embodiments include a multimodal platform using approved containers that can be loaded or unloaded in a manner similar to a conventional rail boxcar and then transferred to other modes in the same package. The multiplatform platform, which may articulate two or more underframes with containers, allows a forklift truck loading over its loading platform into two or more standard ISO or domestic container boxes with end doors. This provides an adaptation of fixed infrastructures at origin and destination, where both of the origin and the destination are served by the rail carrier and rail logistics network.

[0029]FIG. 1 illustrates an example railcar 10 loaded with multiple containers 12, in accordance with certain embodiments. In particular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com