Patents

Literature

79results about How to "Efficient loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

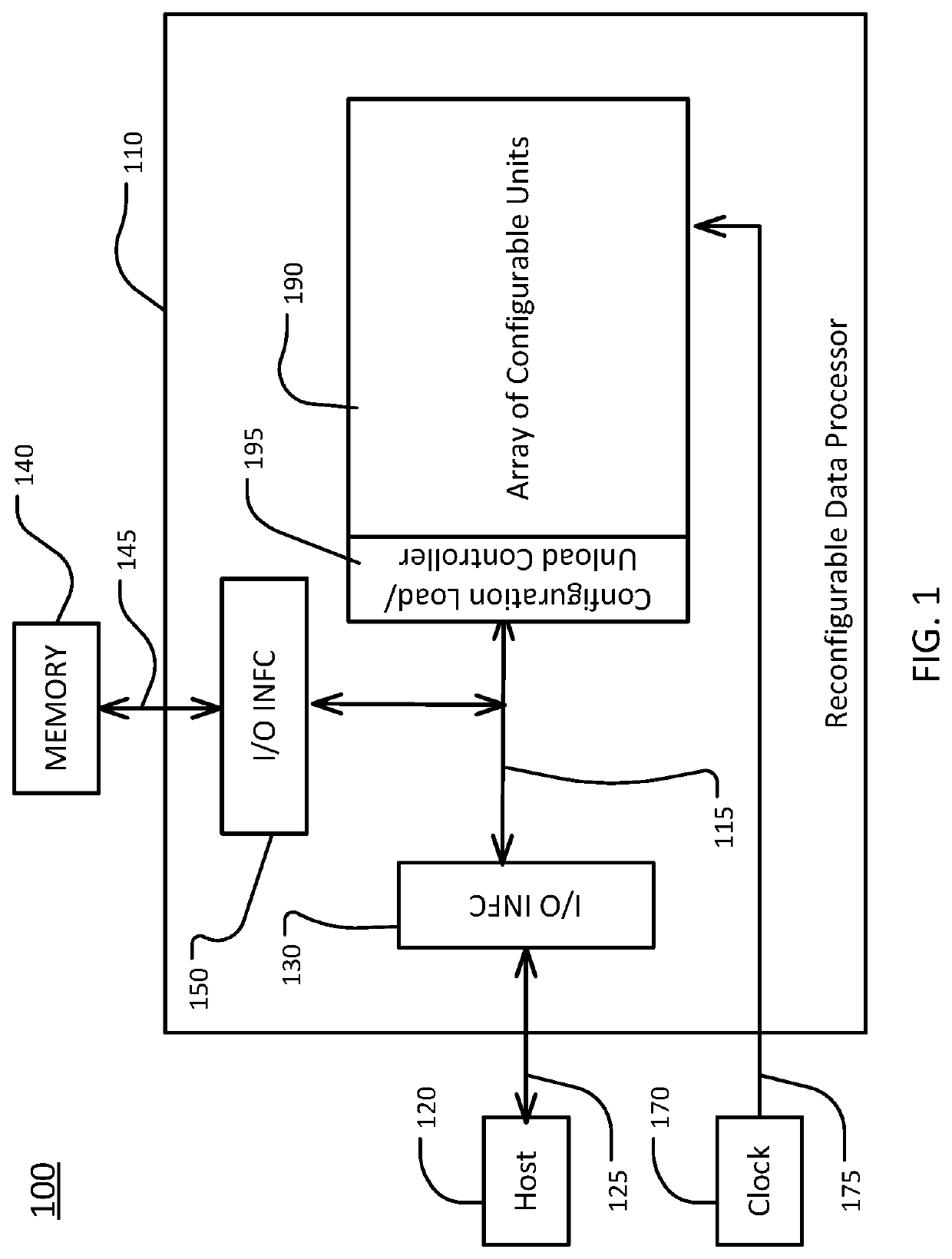

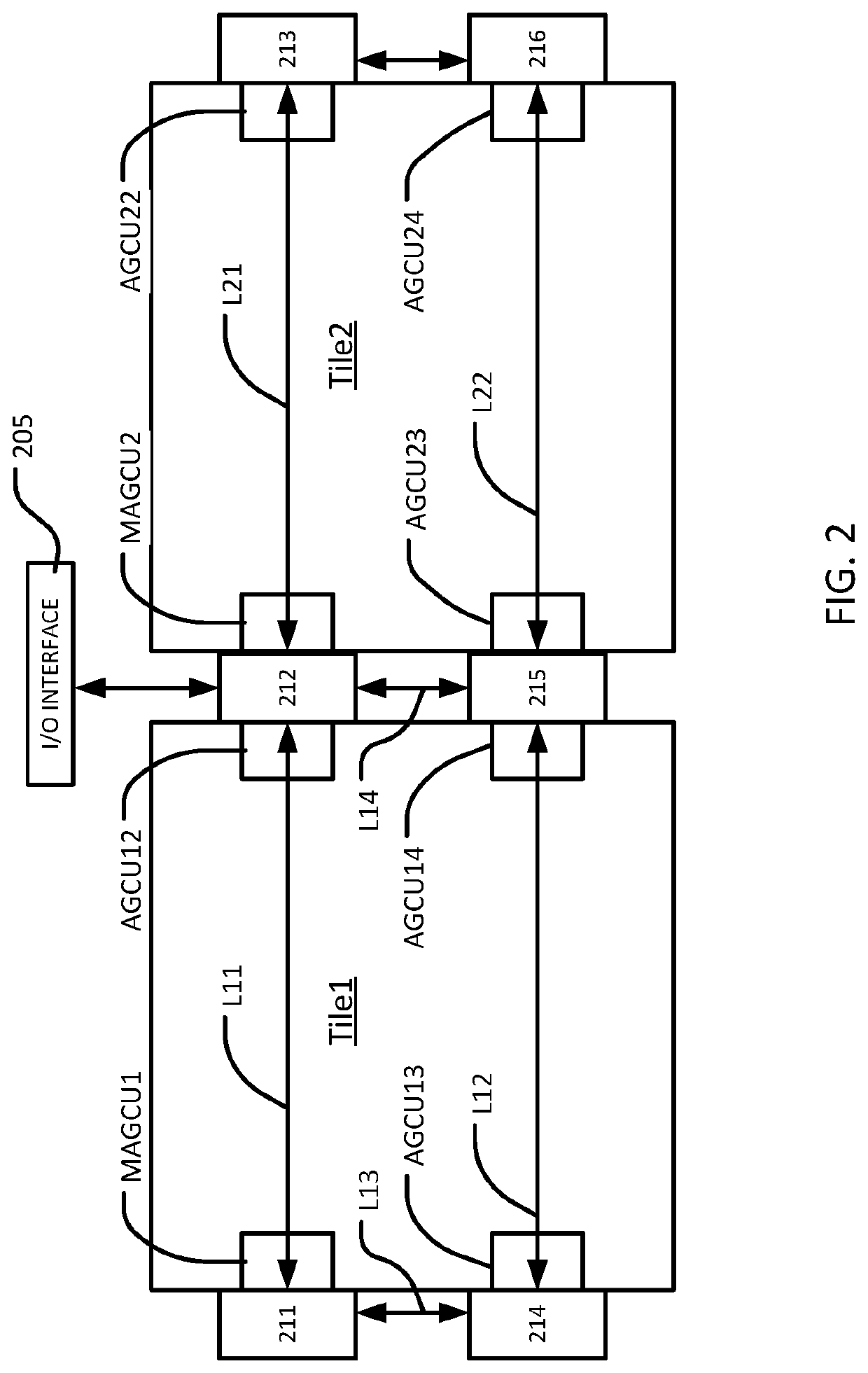

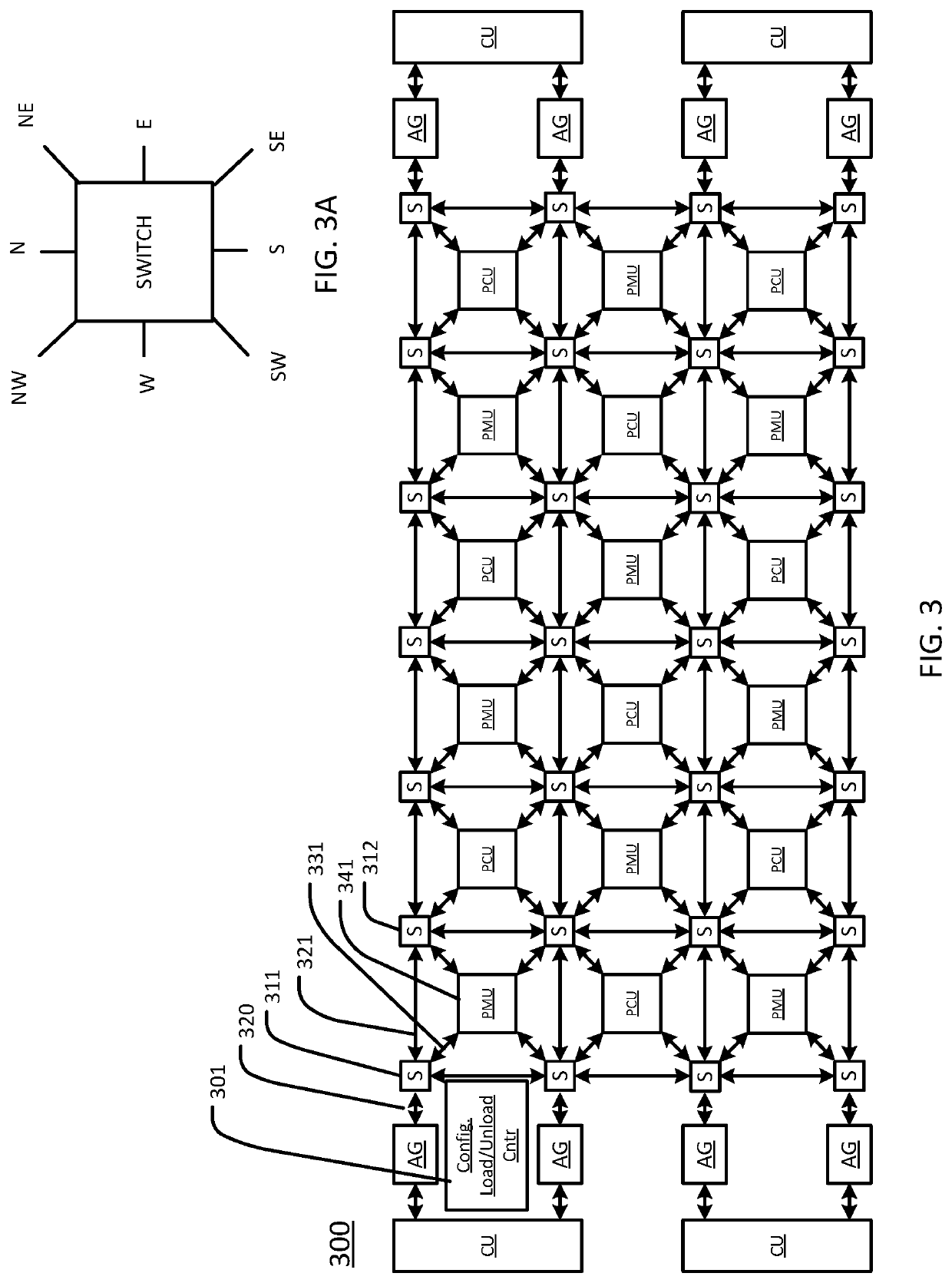

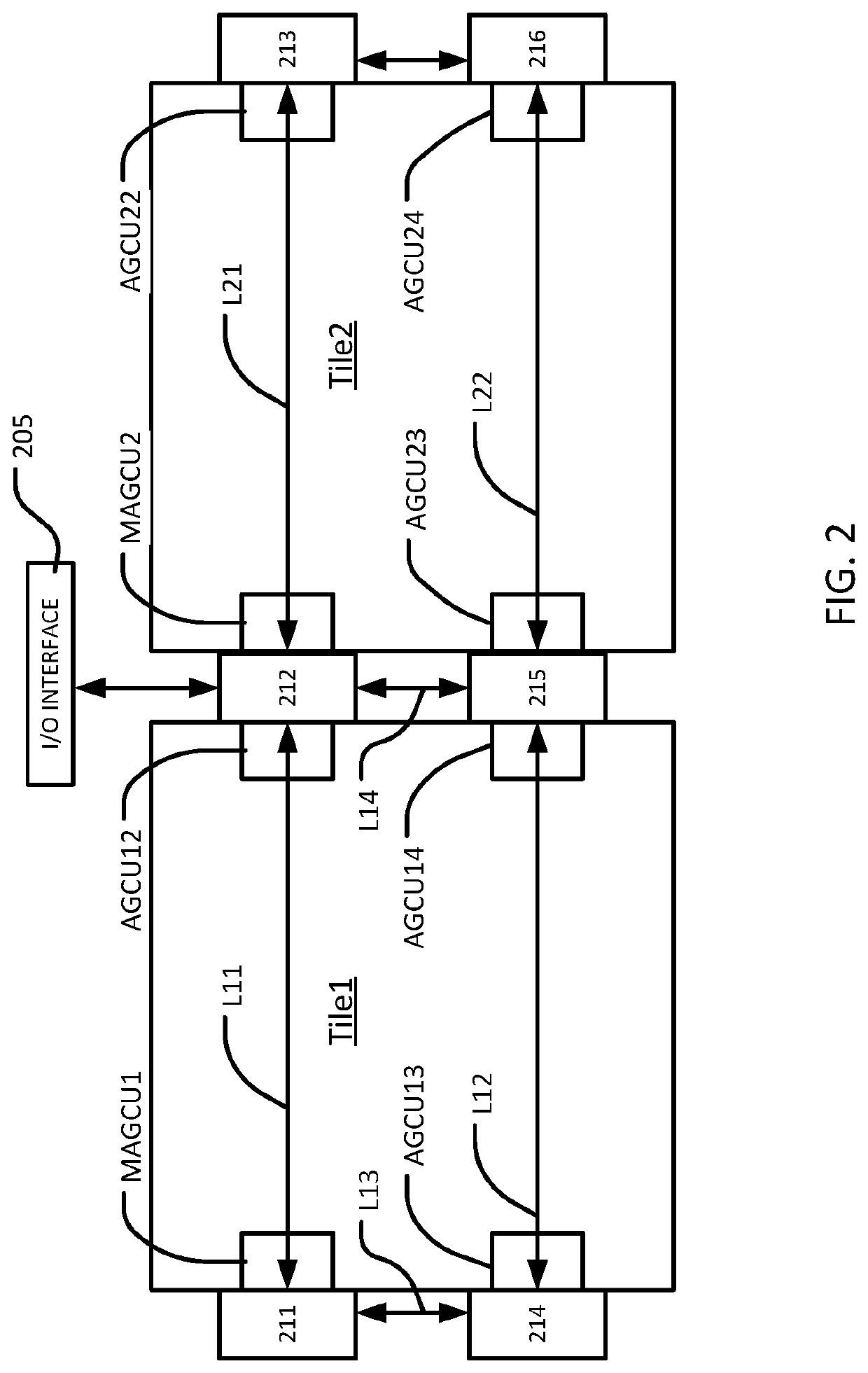

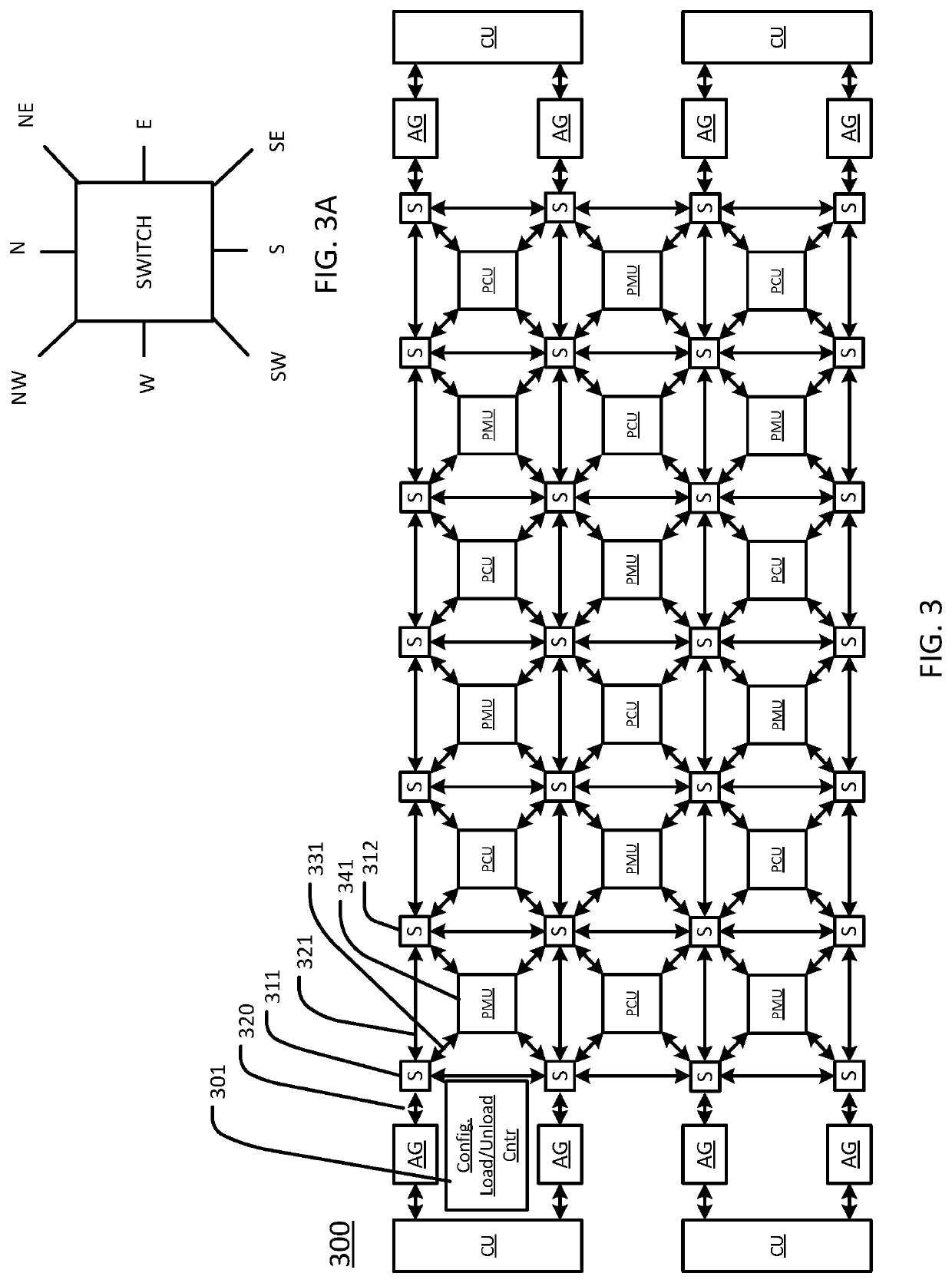

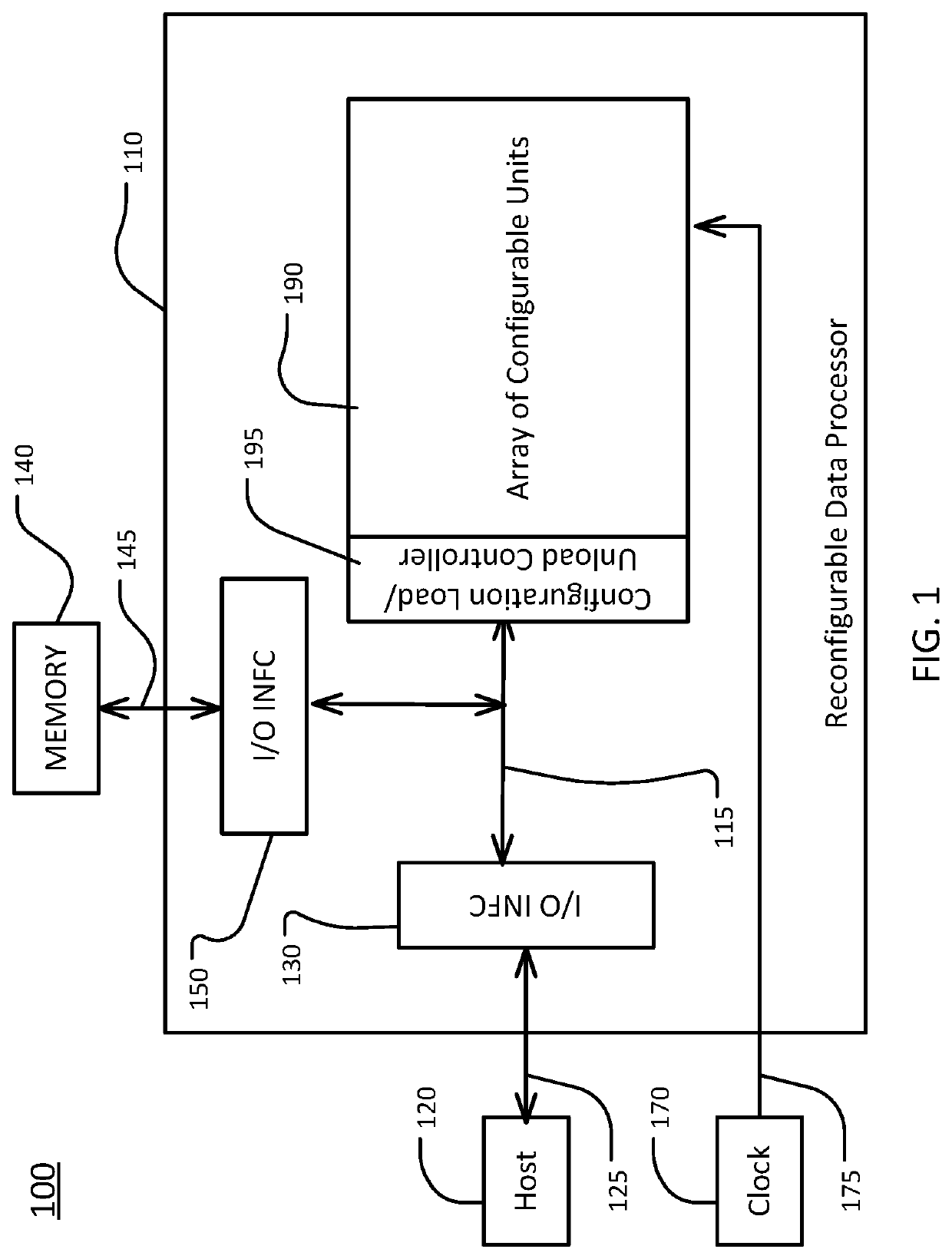

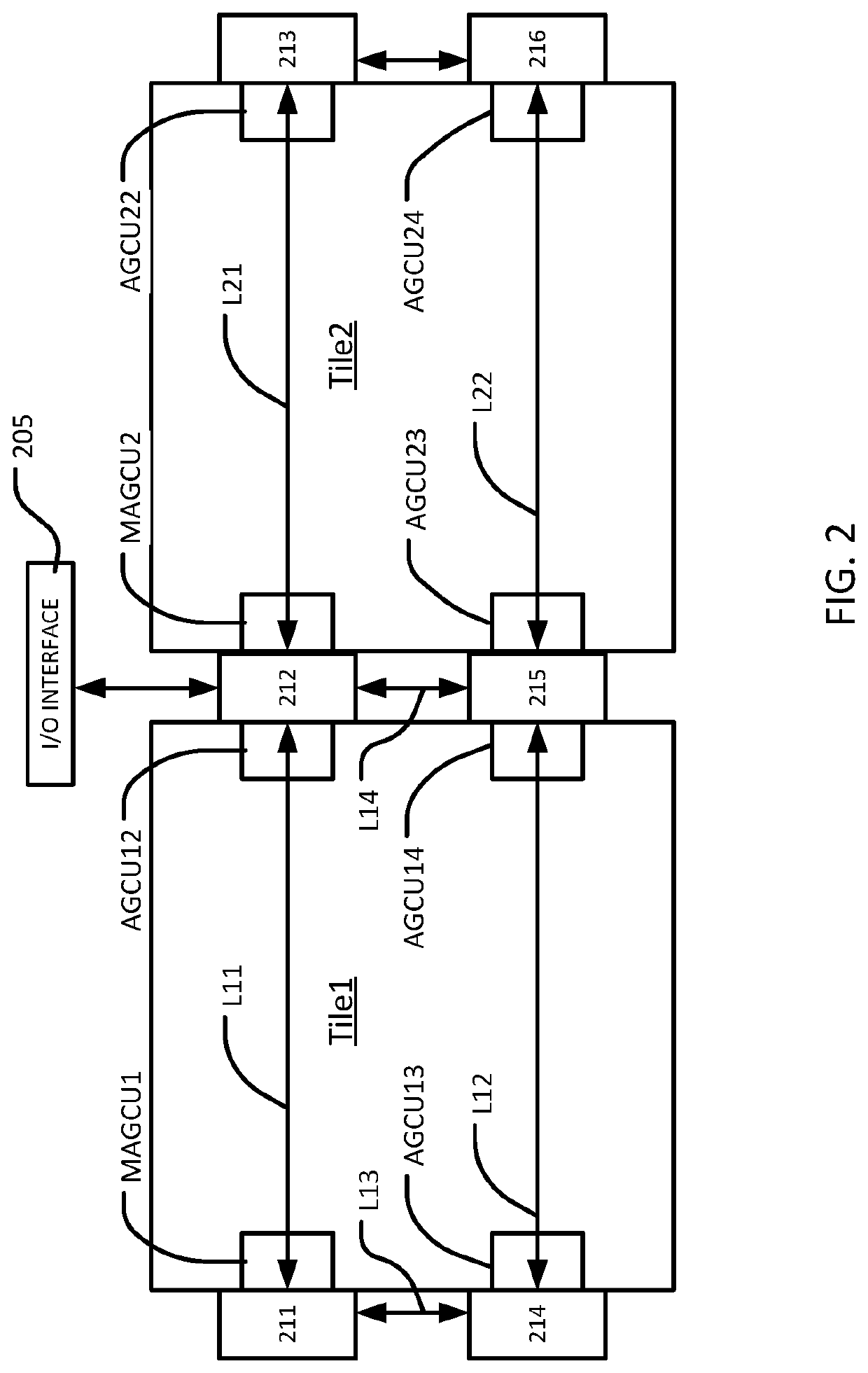

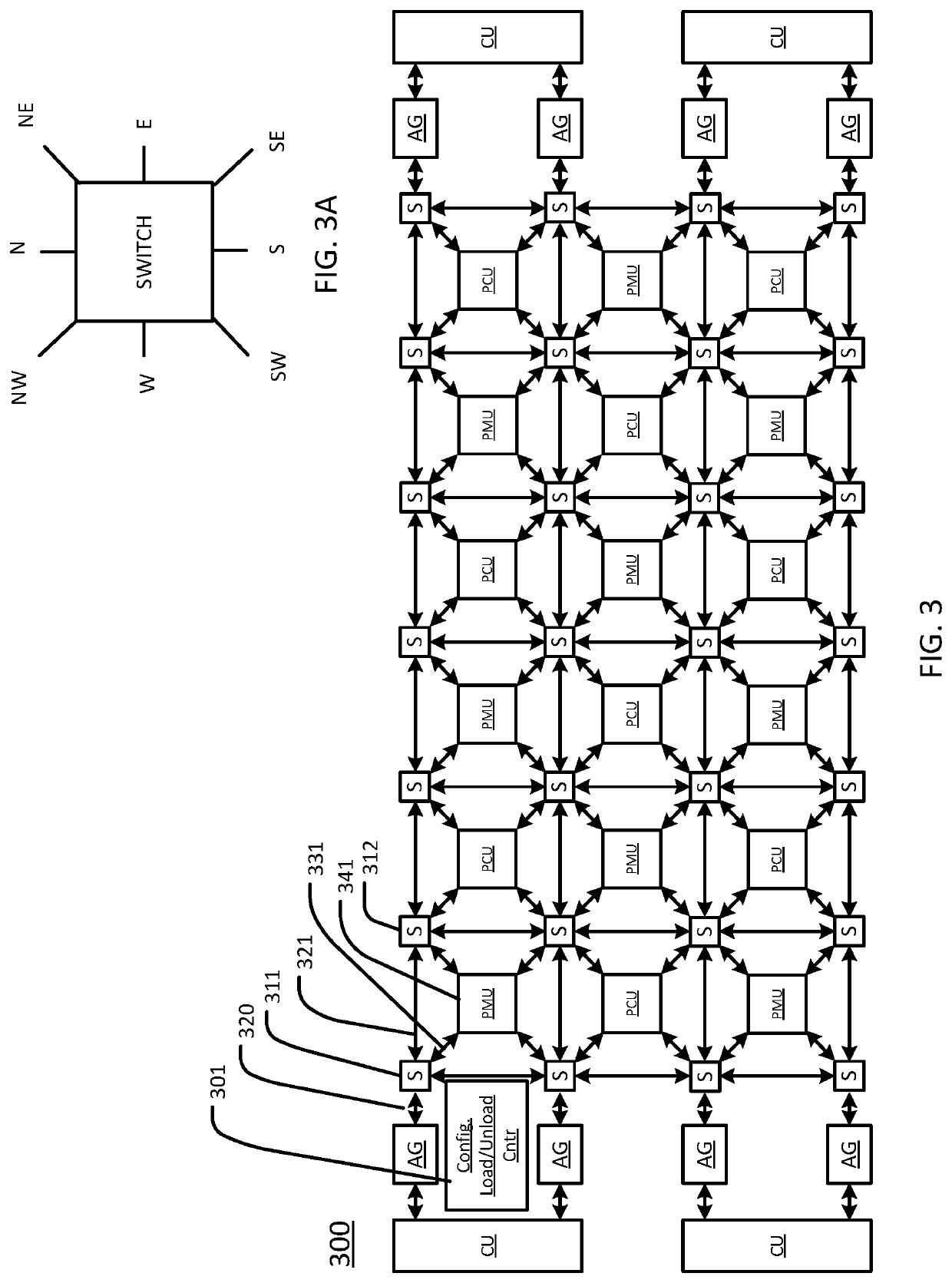

Configuration load of a reconfigurable data processor

ActiveUS20200159544A1Efficient unloadingEfficient loading and unloadingDigital computer detailsProgram loading/initiatingEngineeringData memory

A reconfigurable data processor comprises a bus system, and an array of configurable units connected to the bus system, configurable units in the array including configuration data stores to store unit files comprising a plurality of sub-files of configuration data particular to the corresponding configurable units. Configurable units in the plurality of configurable units each include logic to execute a unit configuration load process, including receiving via the bus system, sub-files of a unit file particular to the configurable unit, and loading the received sub-files into the configuration store of the configurable unit. A configuration load controller connected to the bus system, including logic to execute an array configuration load process, including distributing a configuration file comprising unit files for a plurality of the configurable units in the array.

Owner:SAMBANOVA SYST INC

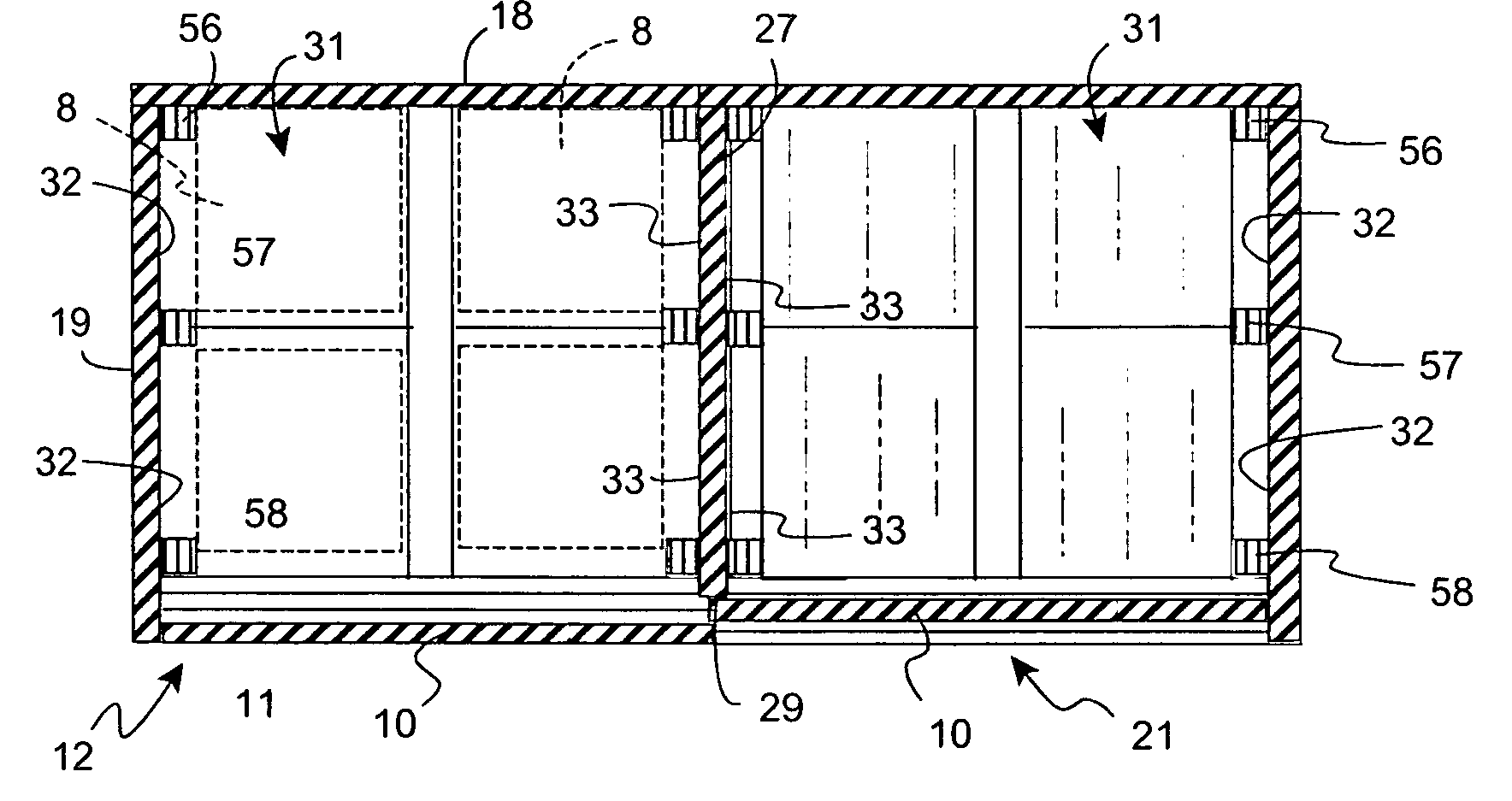

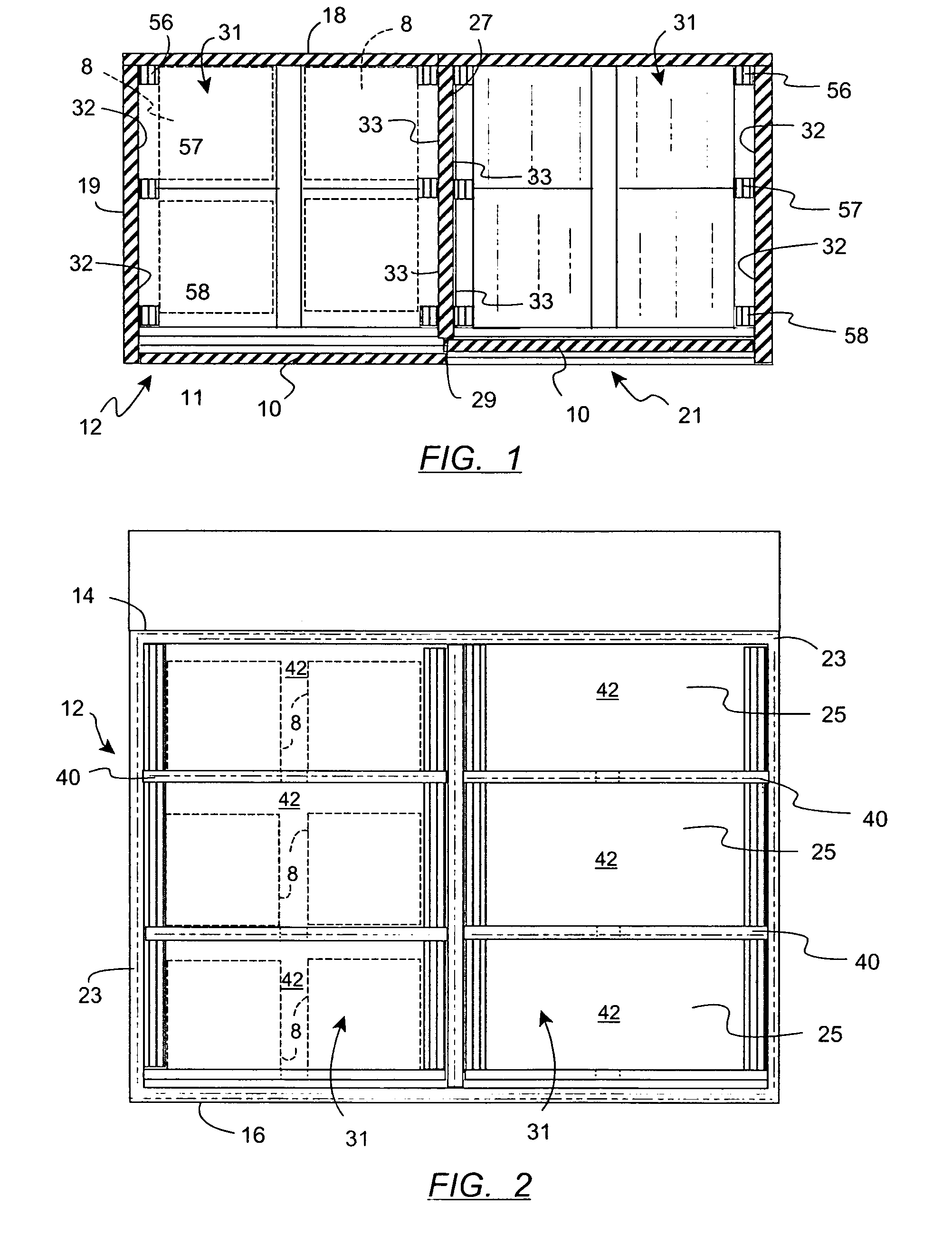

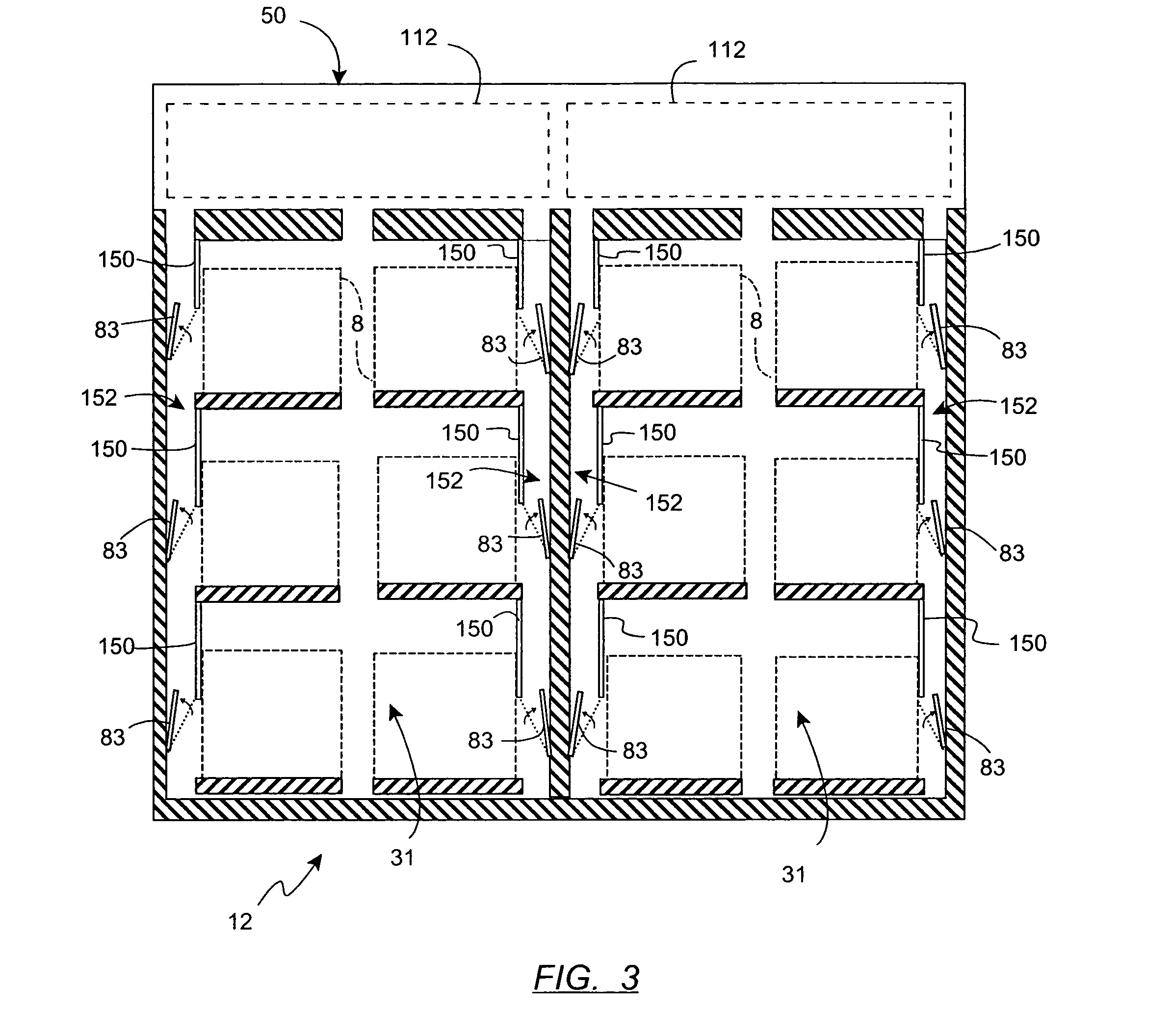

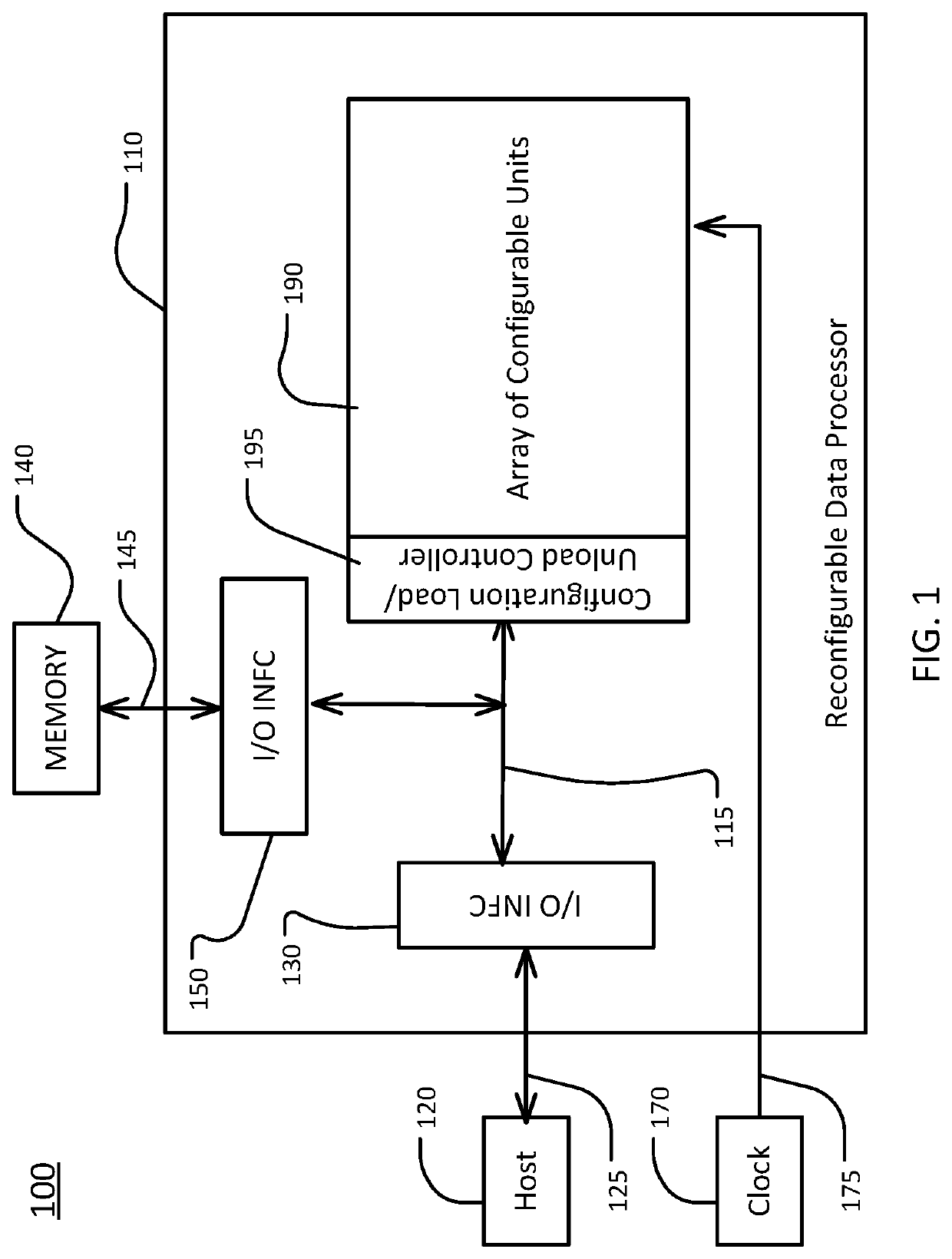

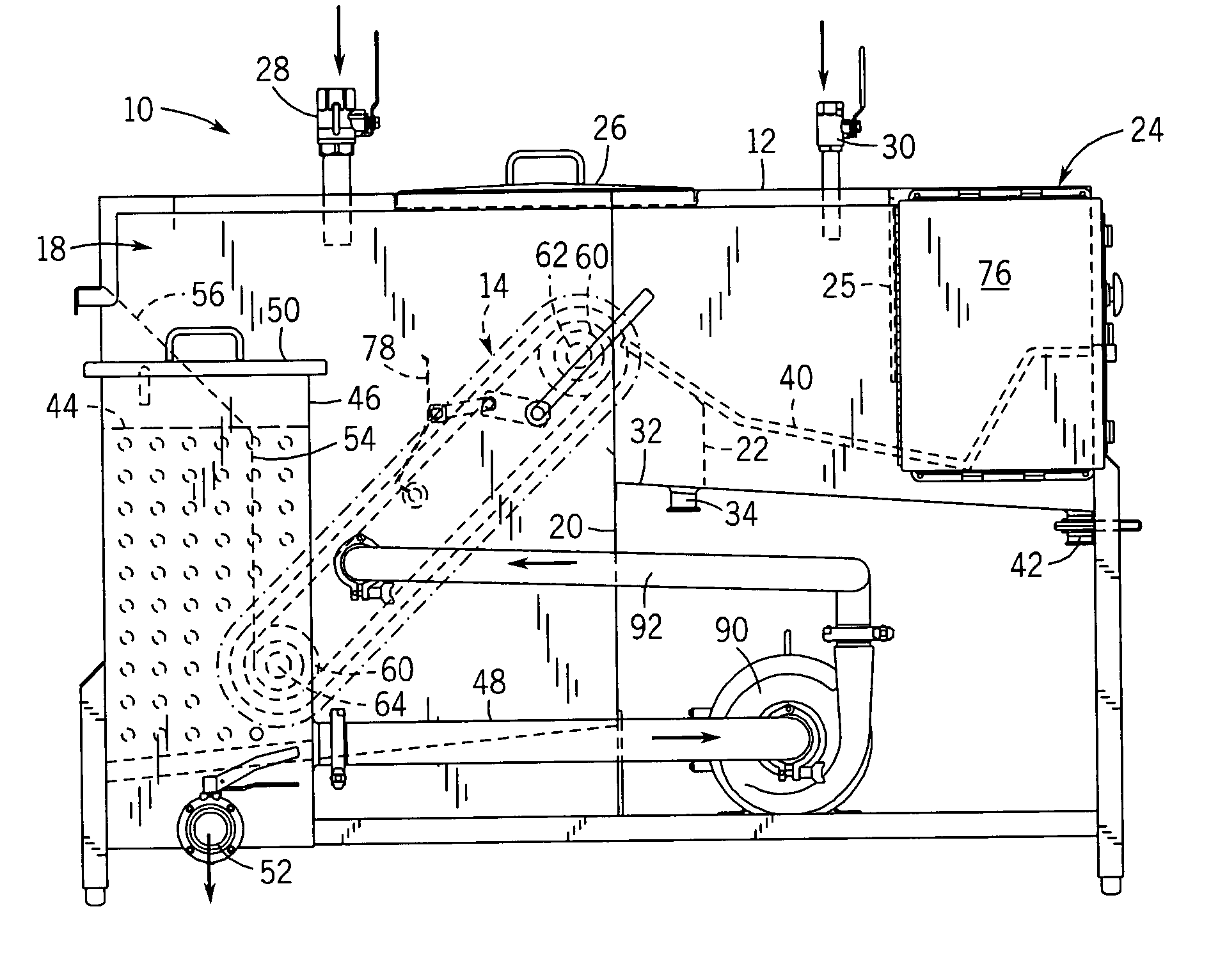

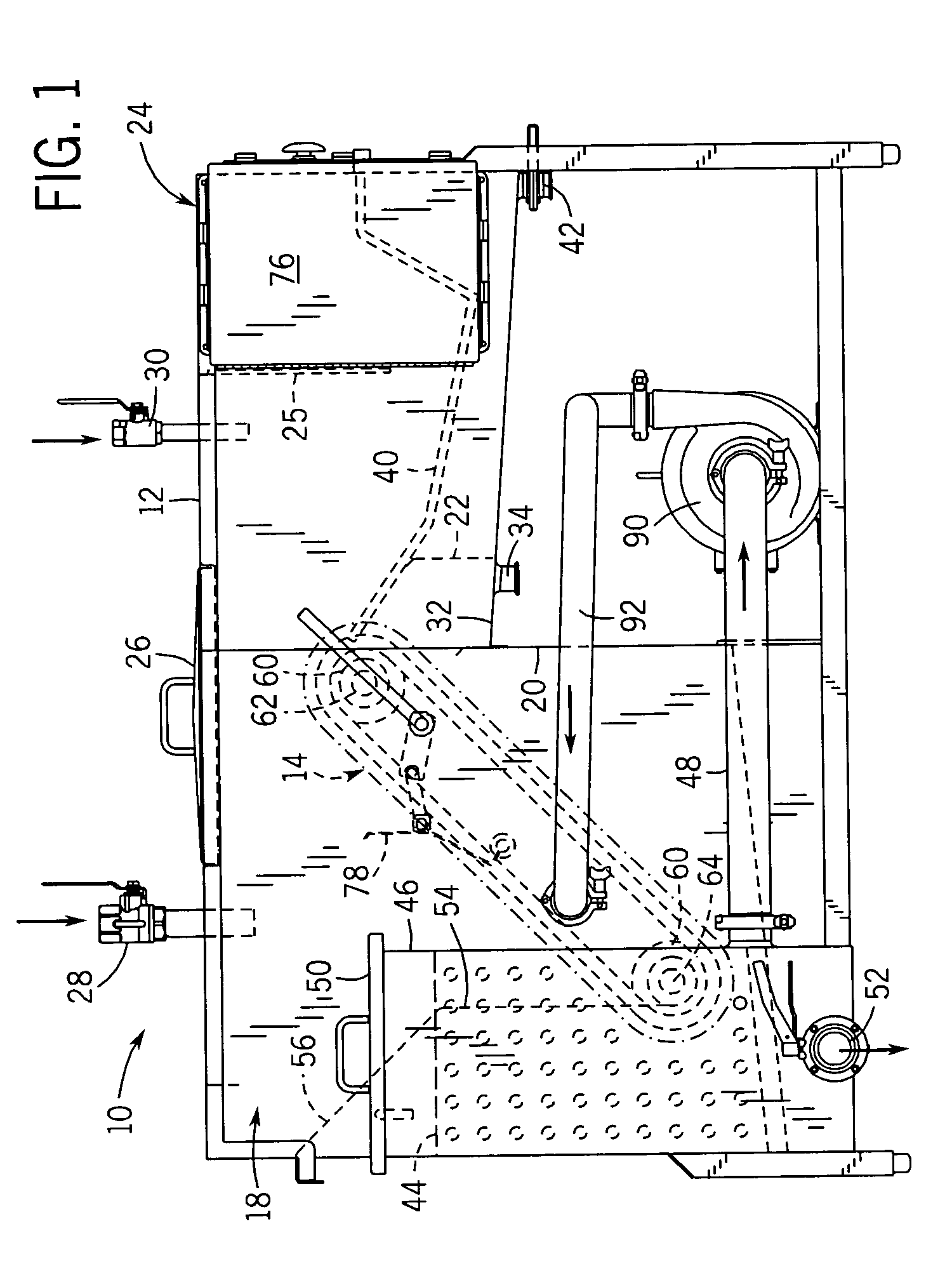

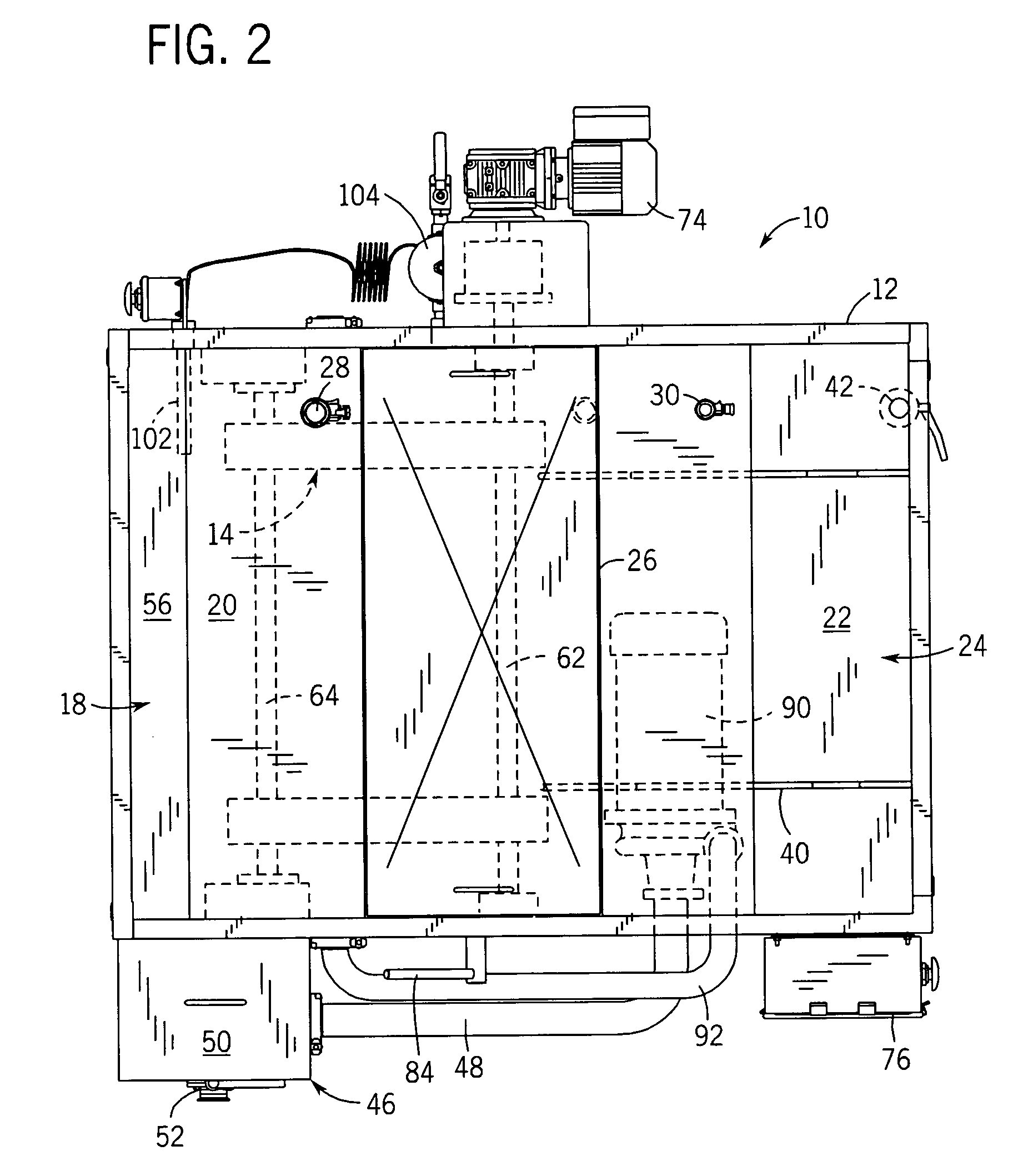

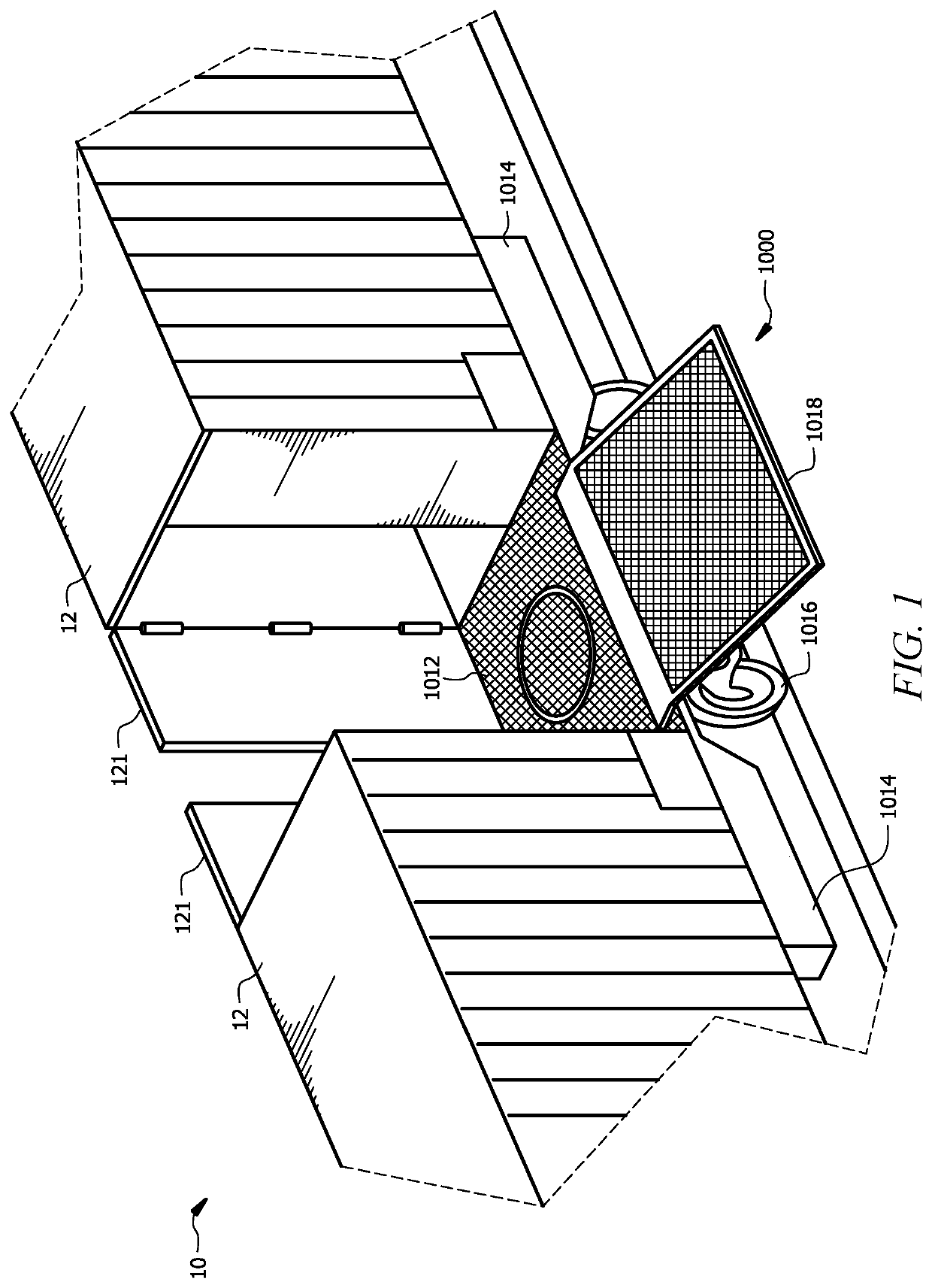

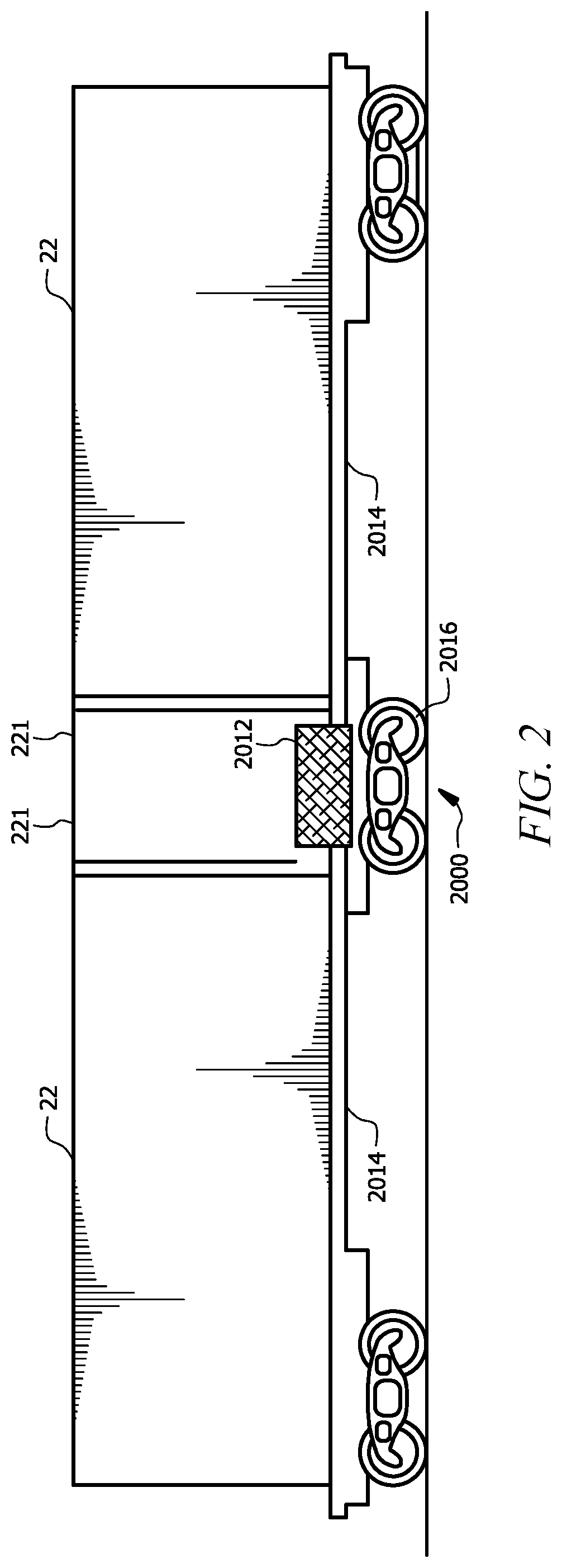

Environmentally controlled storage and ripening apparatus

InactiveUS6901768B1Easy to transportEfficient unloadingAir-treating devicesFruit and vegetables preservationModular unitModularity

A self-contained apparatus for maintaining perishable produce in a controlled environment has a novel air vent and damper system to provide optimal airflow within the apparatus to maintain and ripen perishable produce. An arrangement of seals within insulated compartments cooperate with the physical dimensions of palletized produce inserted therein to direct air flow therethrough to achieve optimal air flow characteristics. The air vent and damper system of the invention allows the apparatus to operate at peak efficiency regardless of the number of pallets present in the apparatus. The apparatus also includes a horizontal push back cart system which does not interfere with the seal arrangement by using an elastic biasing means instead of prior art gravity feed methods. The self-contained apparatus can be used as a modular unit, and encompasses all the equipment necessary for installation while offering temperature stability, simplified maintenance requirements, and ultimately, precise control of ripening.

Owner:WINDECKER ROBERT J

Configuration unload of a reconfigurable data processor

ActiveUS20200159692A1Efficient unloadingEfficient loading and unloadingProgram loading/initiatingArchitecture with single central processing unitEngineeringData memory

A reconfigurable data processor comprises a bus system, and an array of configurable units connected to the bus system, configurable units in the array including configuration data stores to store unit files comprising a plurality of sub-files of configuration data particular to the corresponding configurable units. Configurable units in the plurality of configurable units each include logic to execute a unit configuration load process, including receiving via the bus system, sub-files of a unit file particular to the configurable unit, and loading the received sub-files into the configuration store of the configurable unit. A configuration load controller connected to the bus system, including logic to execute an array configuration load process, including distributing a configuration file comprising unit files for a plurality of the configurable units in the array.

Owner:SAMBANOVA SYST INC

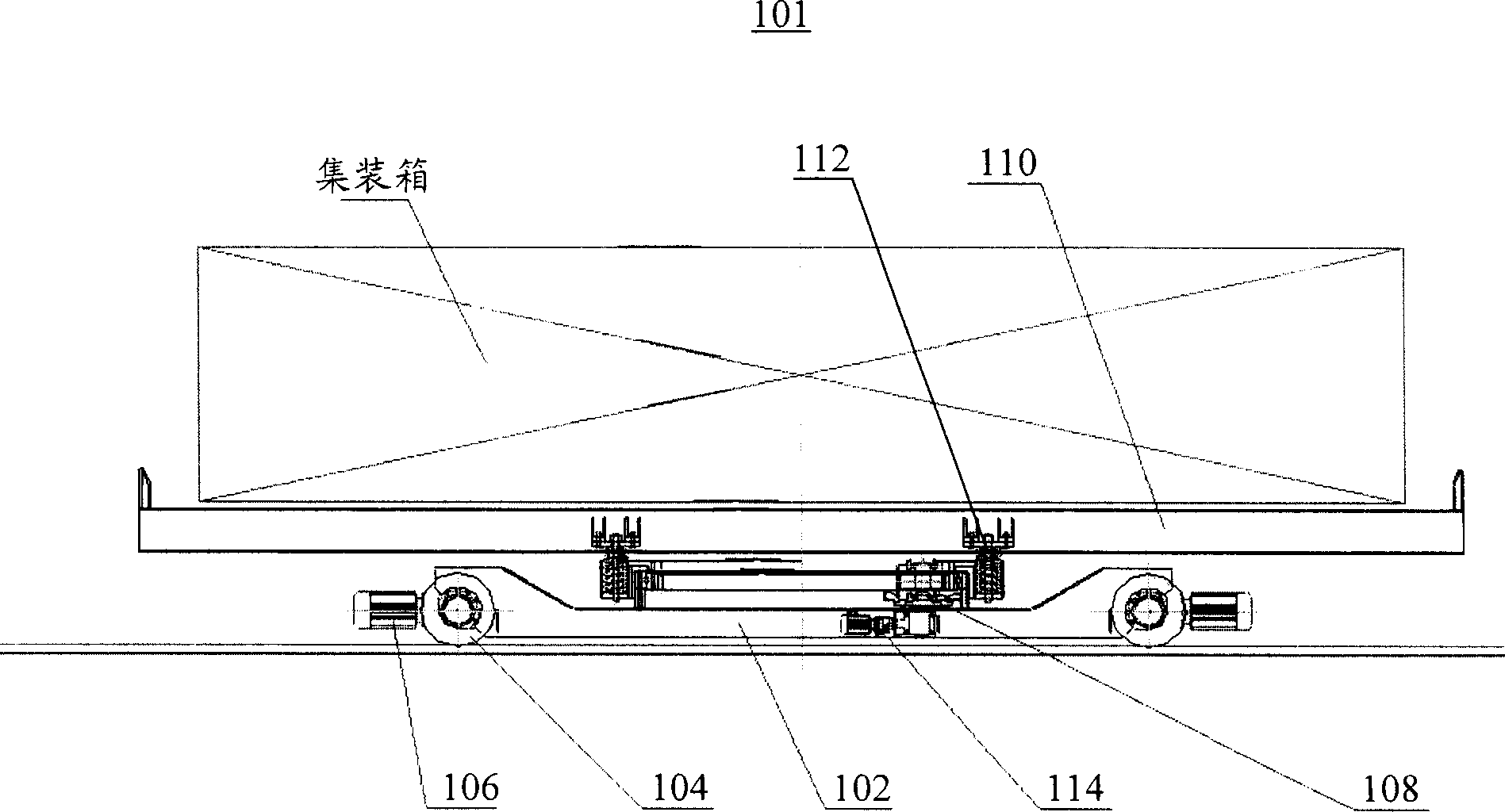

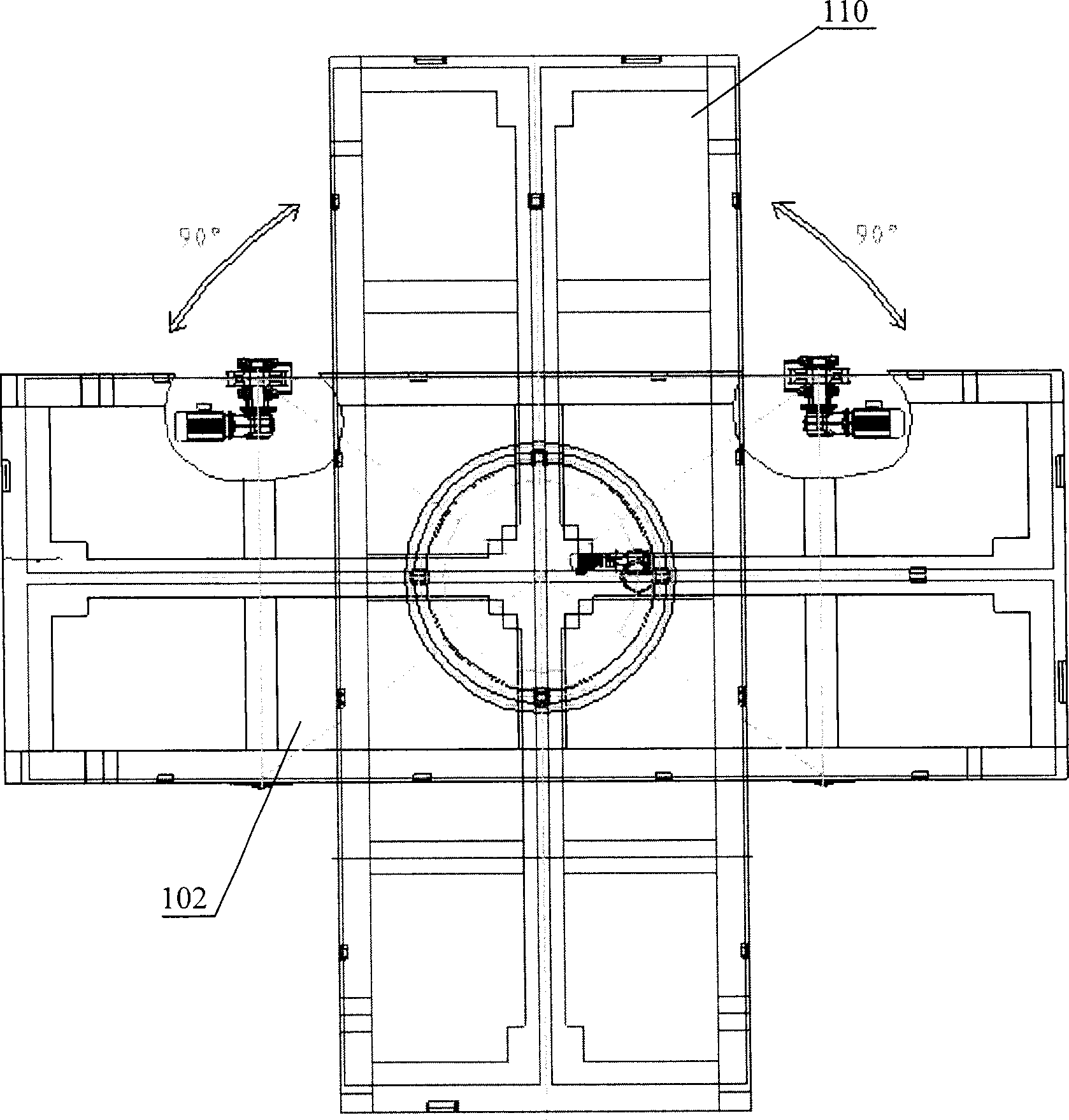

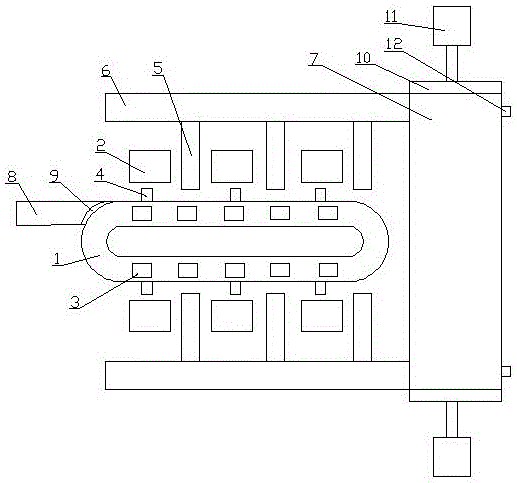

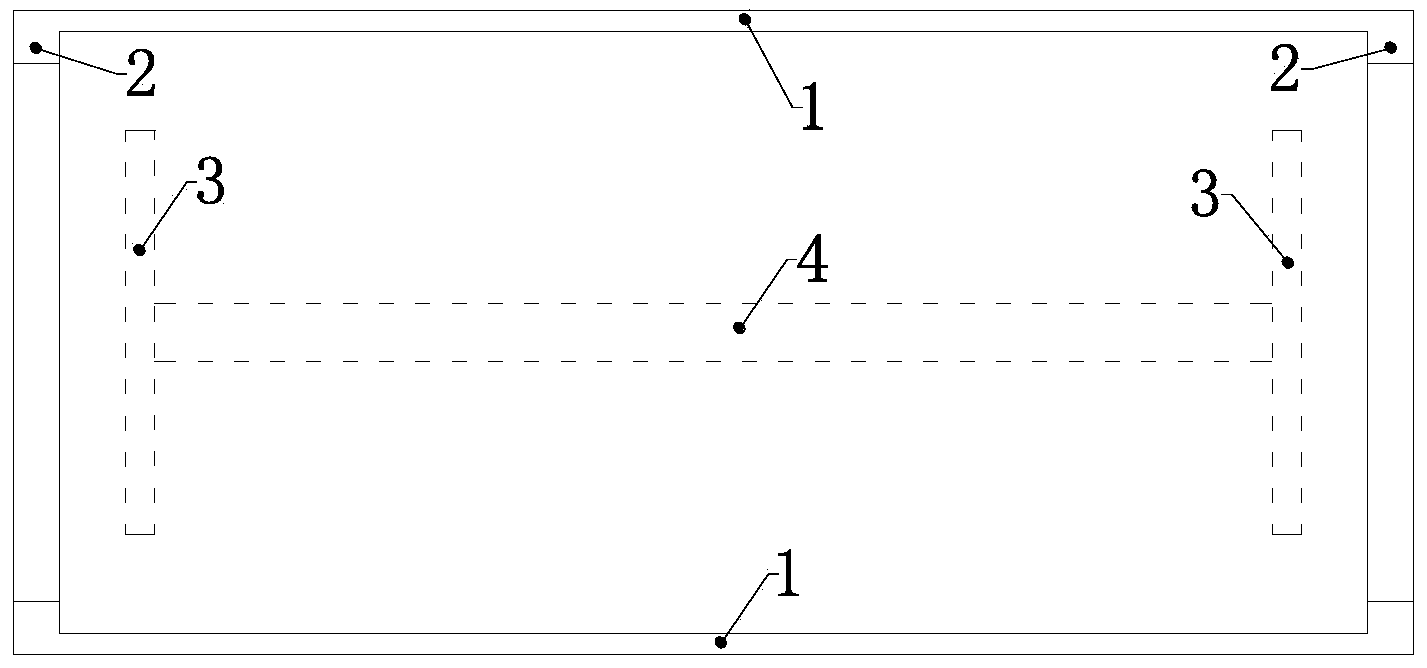

Scheme for laying container terminal and assemble and unassembled flow

InactiveCN1872643AImprove horizontal transport speedImprove efficiencyIC reciprocating piston engine transmissionStorage devicesCarrier systemTruck

An arrangement scheme for the container dock features that the arranging direction of the containers in stack field is perpendicular to that of the containers on ship. Its system is composed of coast hoister, the low bridge unit consisting of track, flat trucks, and monkey for loading or unload of said flat trucks, the transfer carrier system consisting of track and transfer carrier, and the hoister for stack field.

Owner:SHANGHAI ZHENHUA HEAVY IND +1

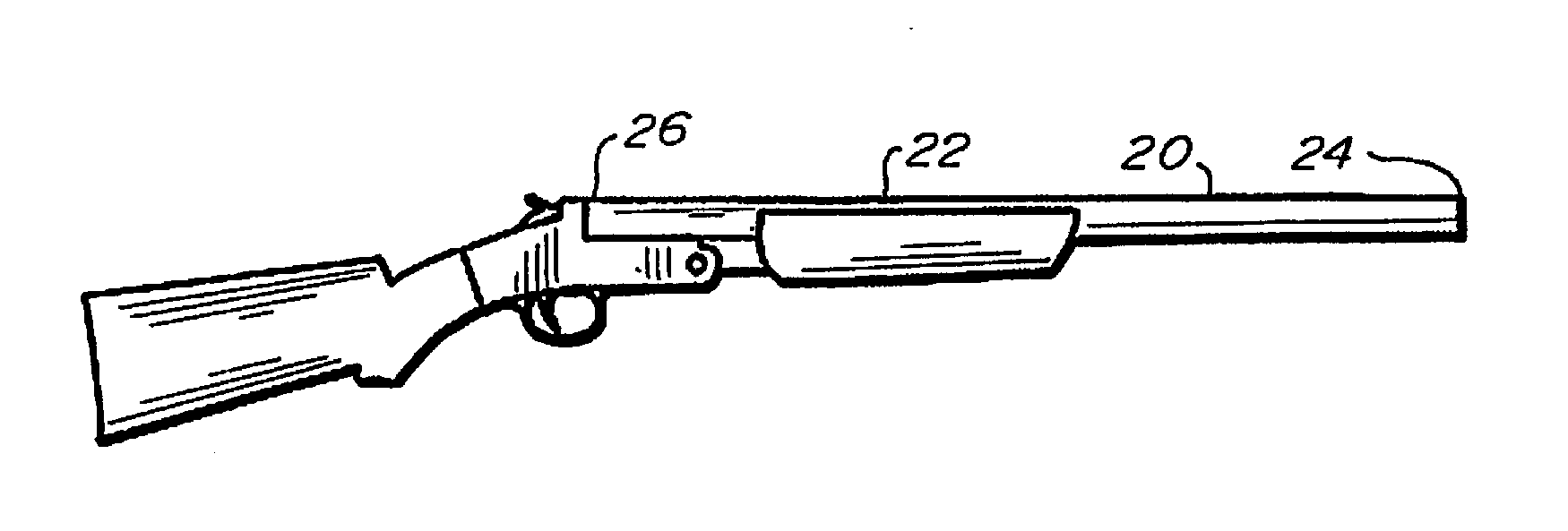

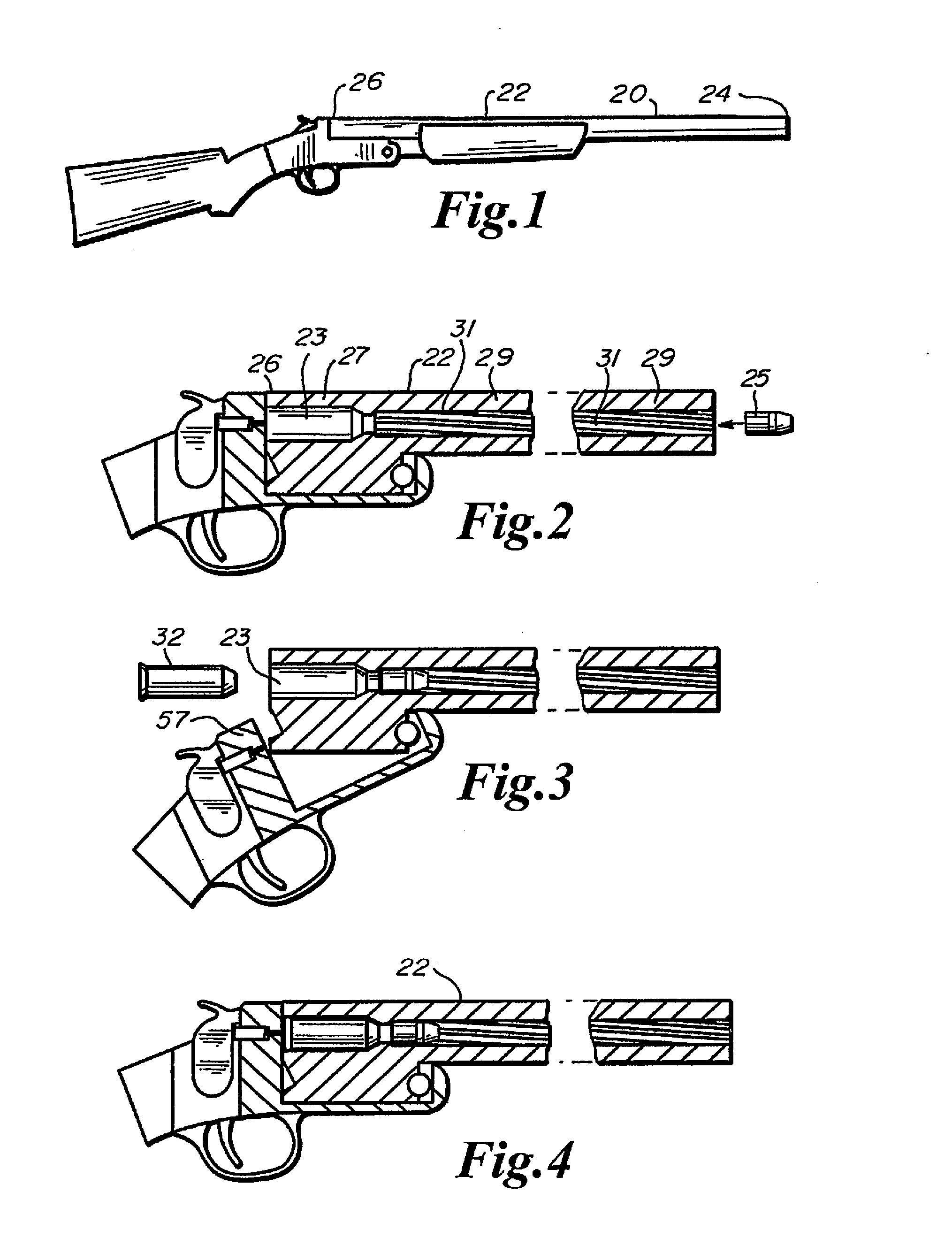

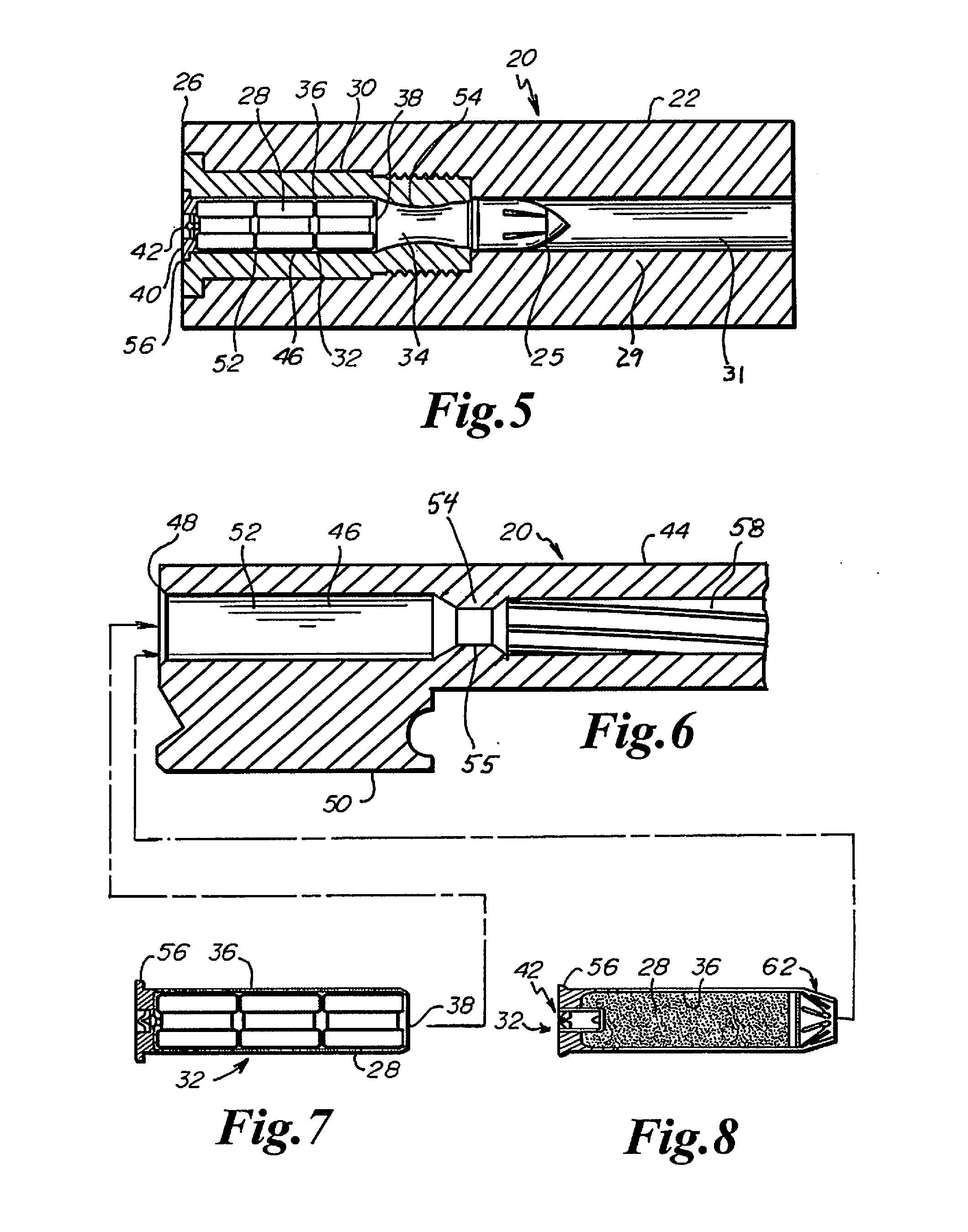

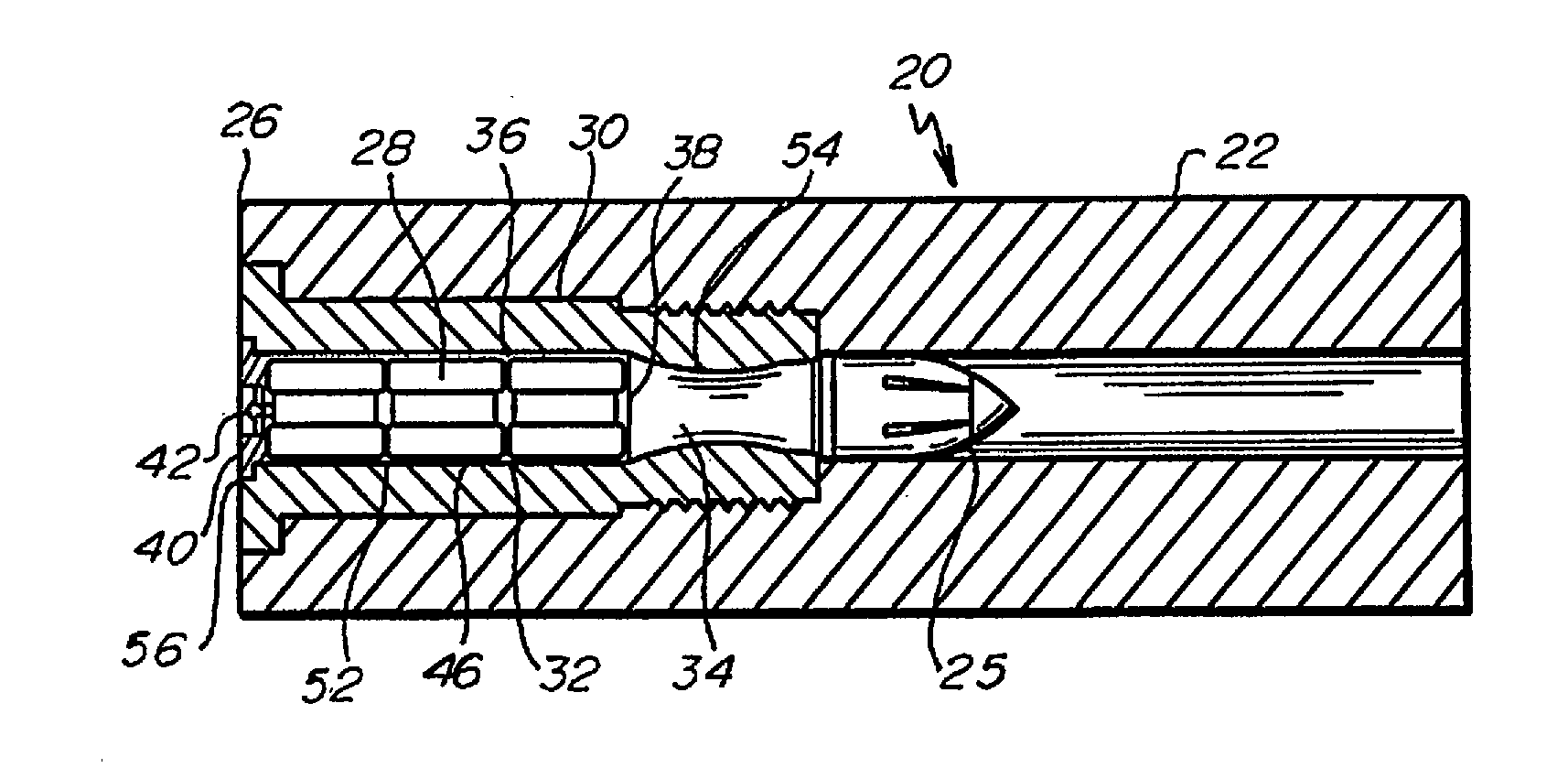

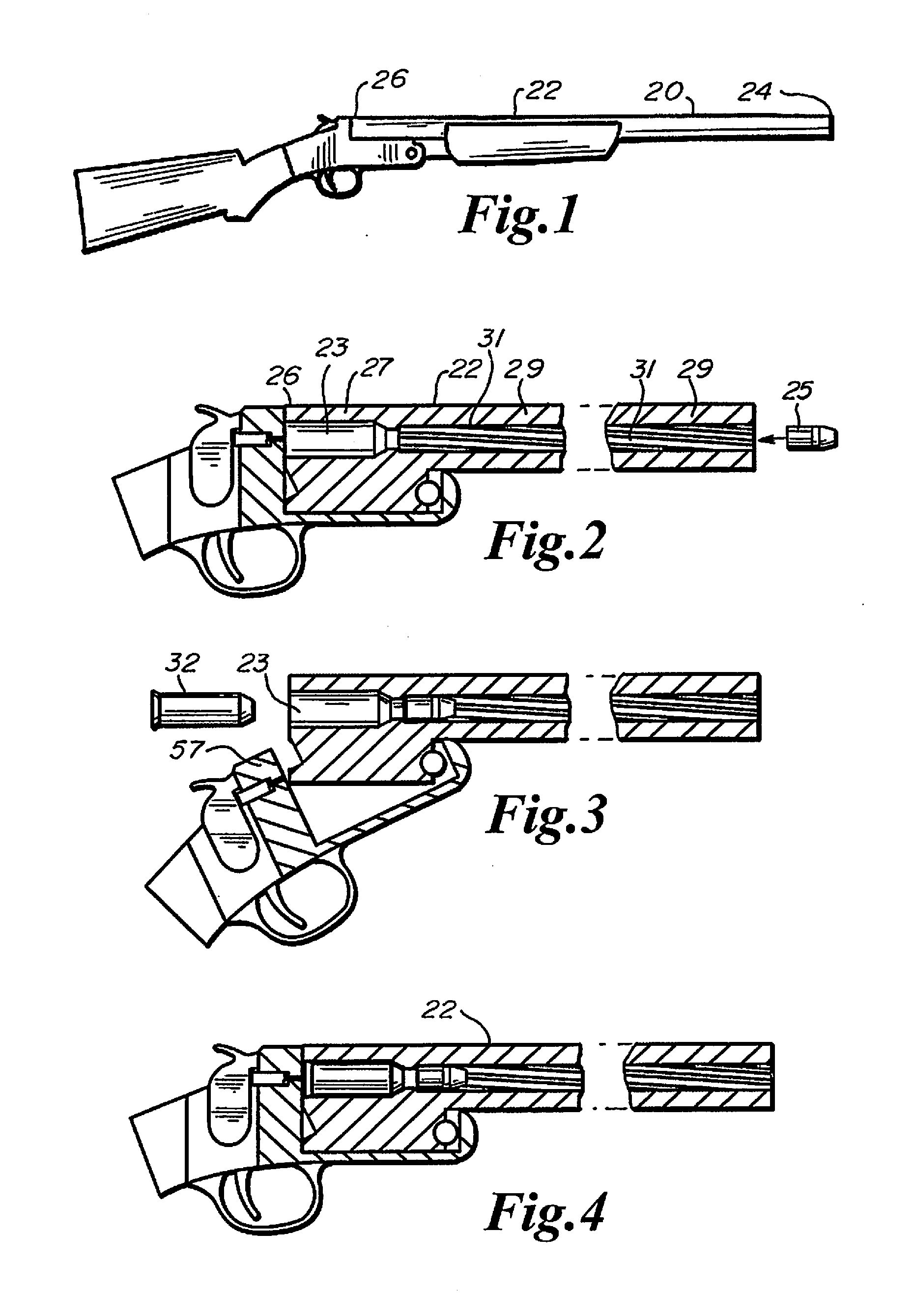

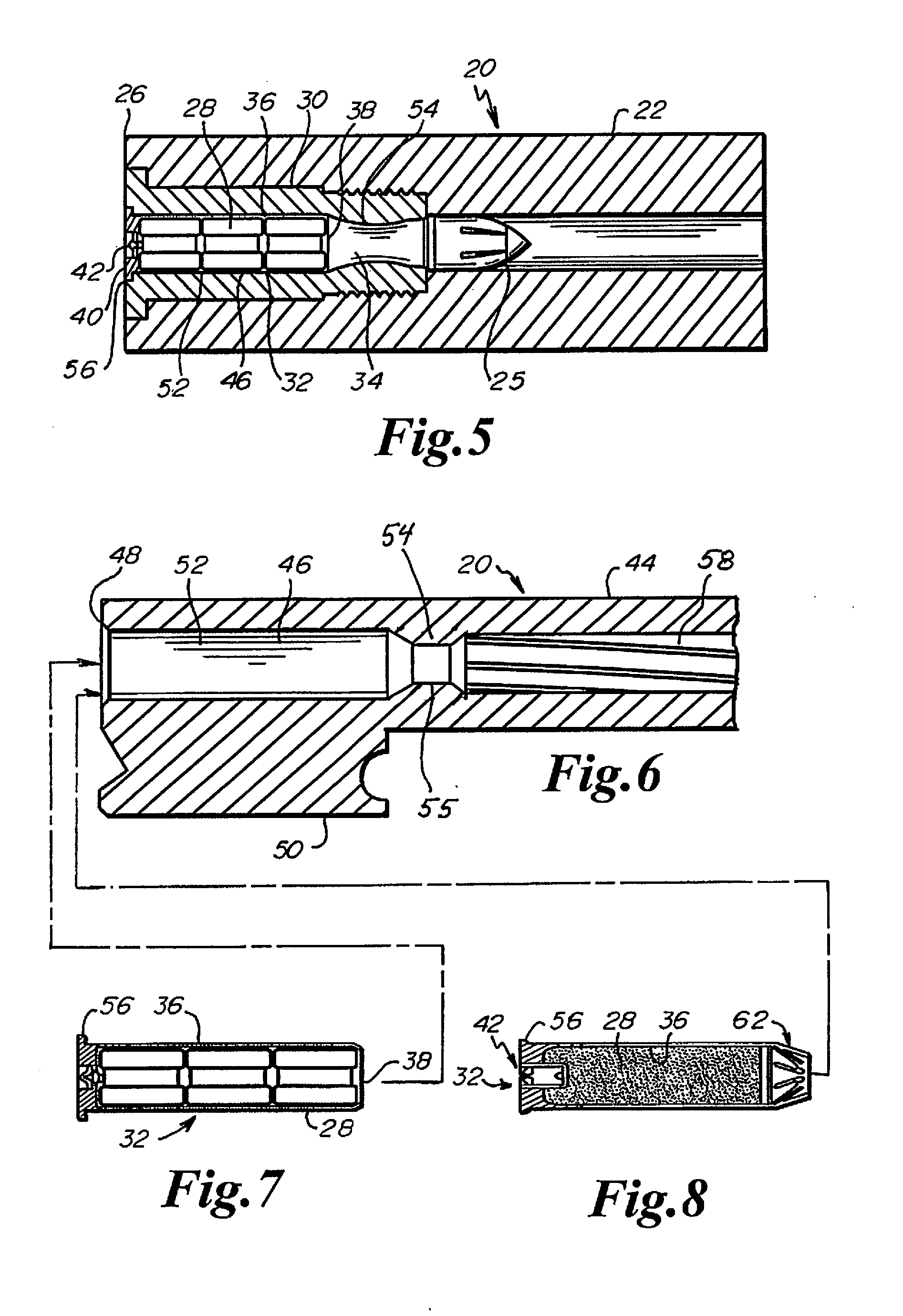

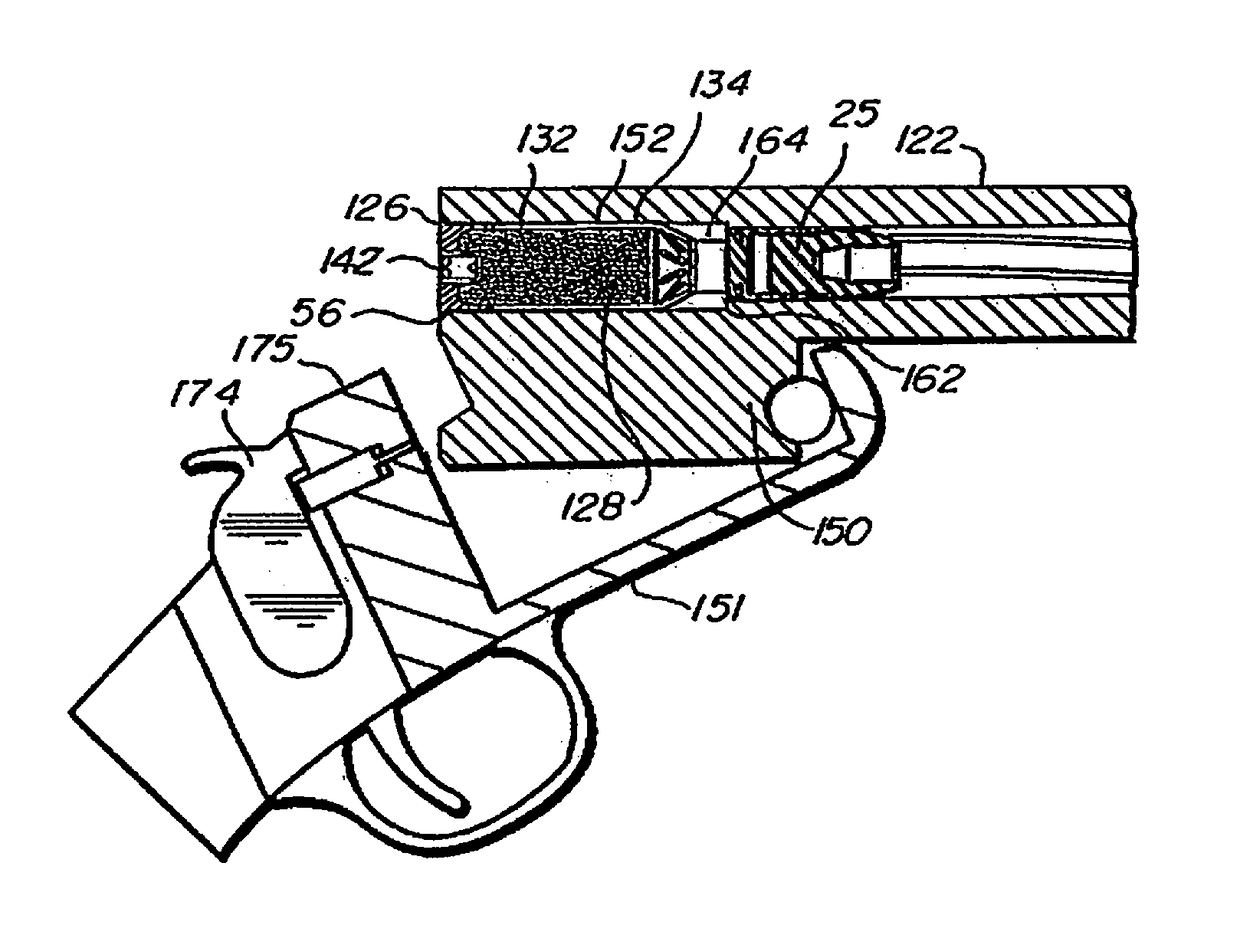

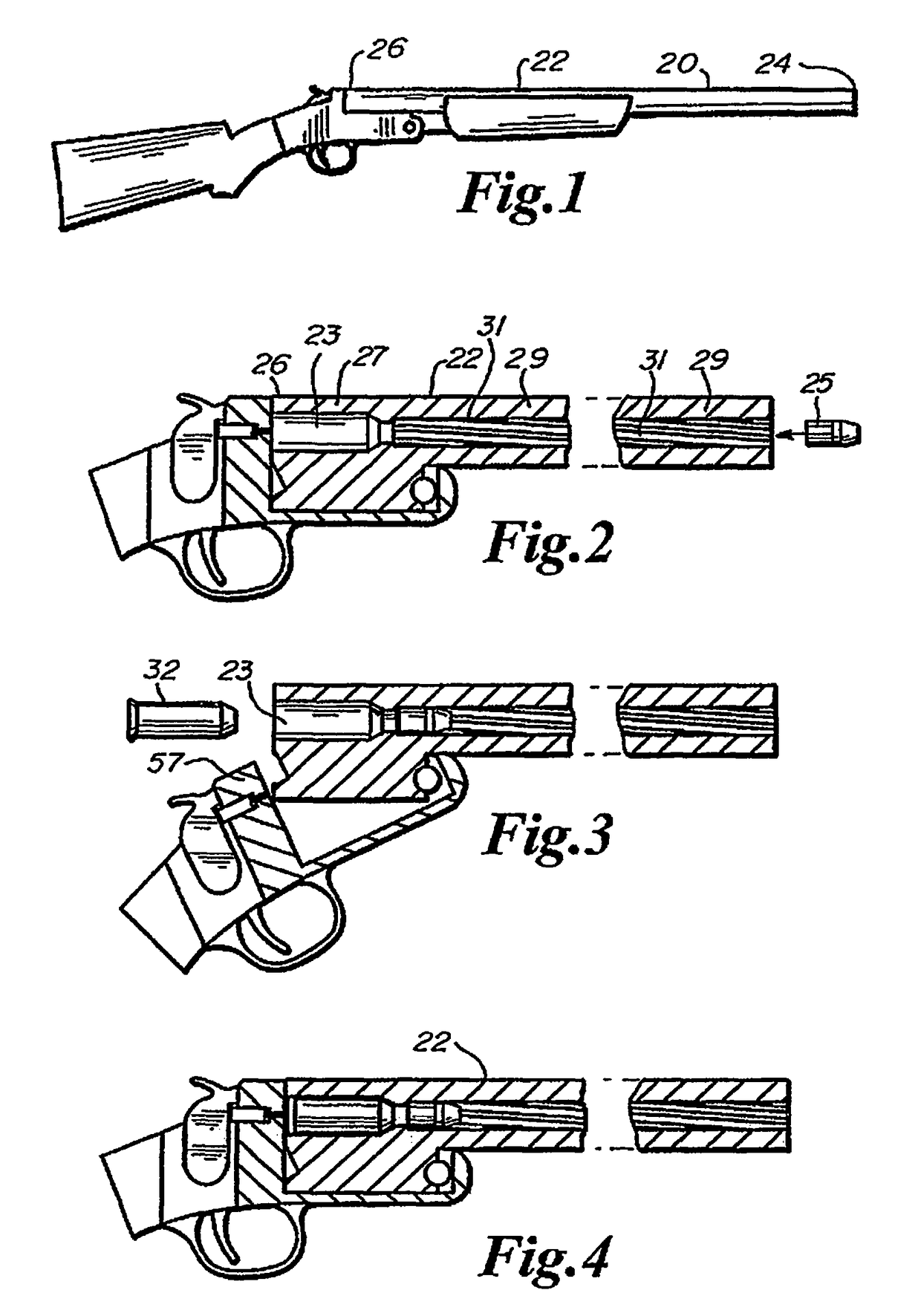

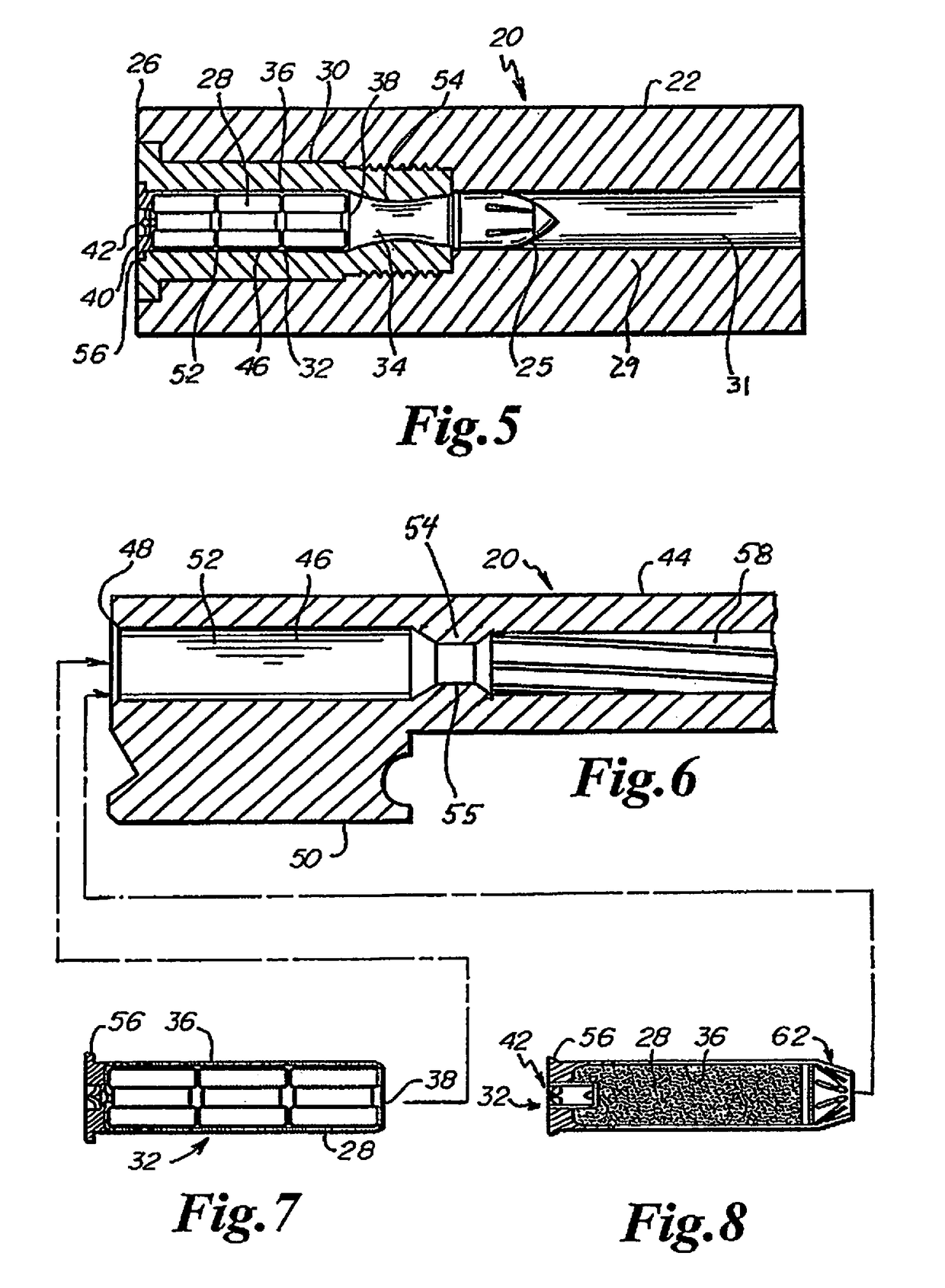

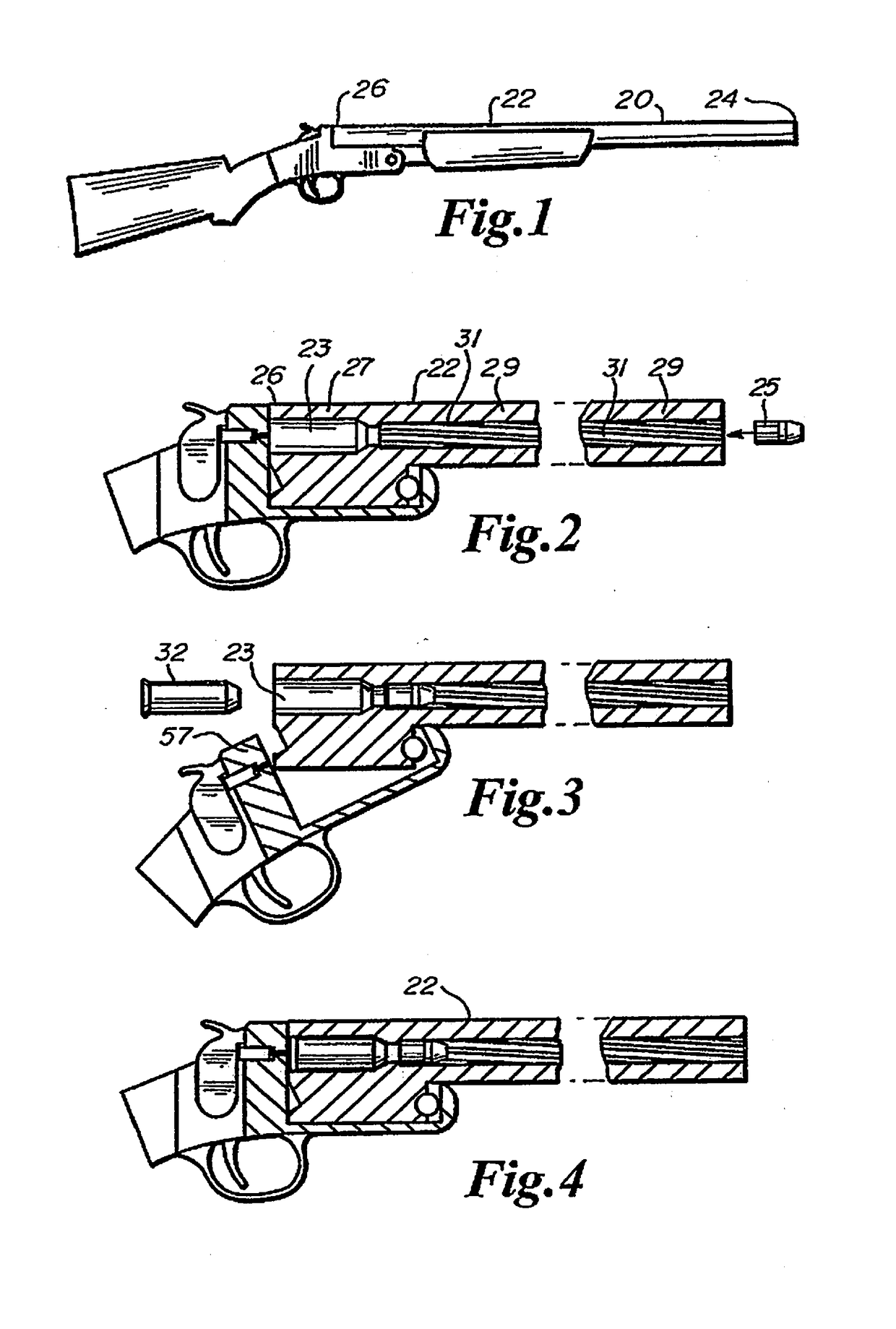

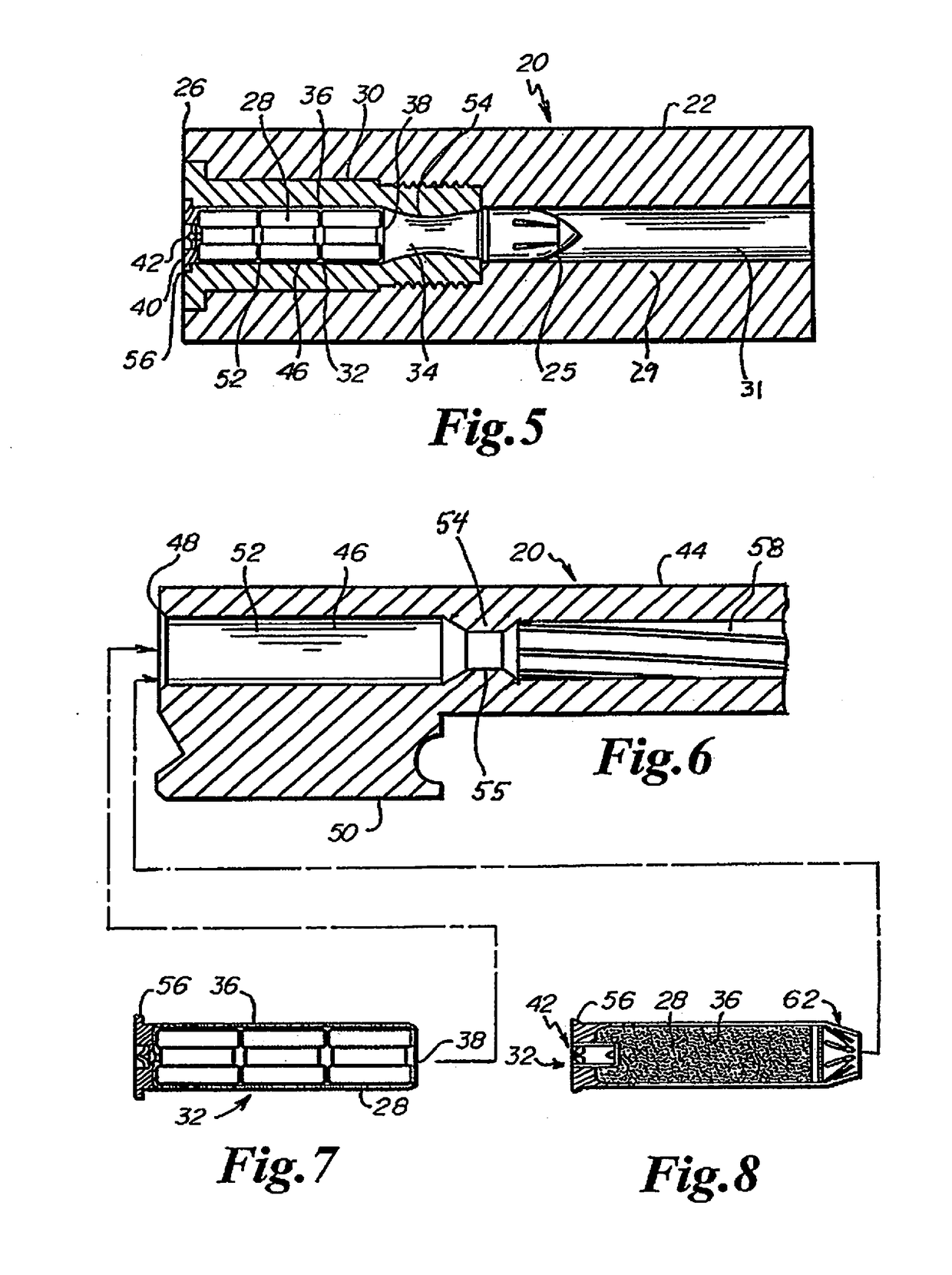

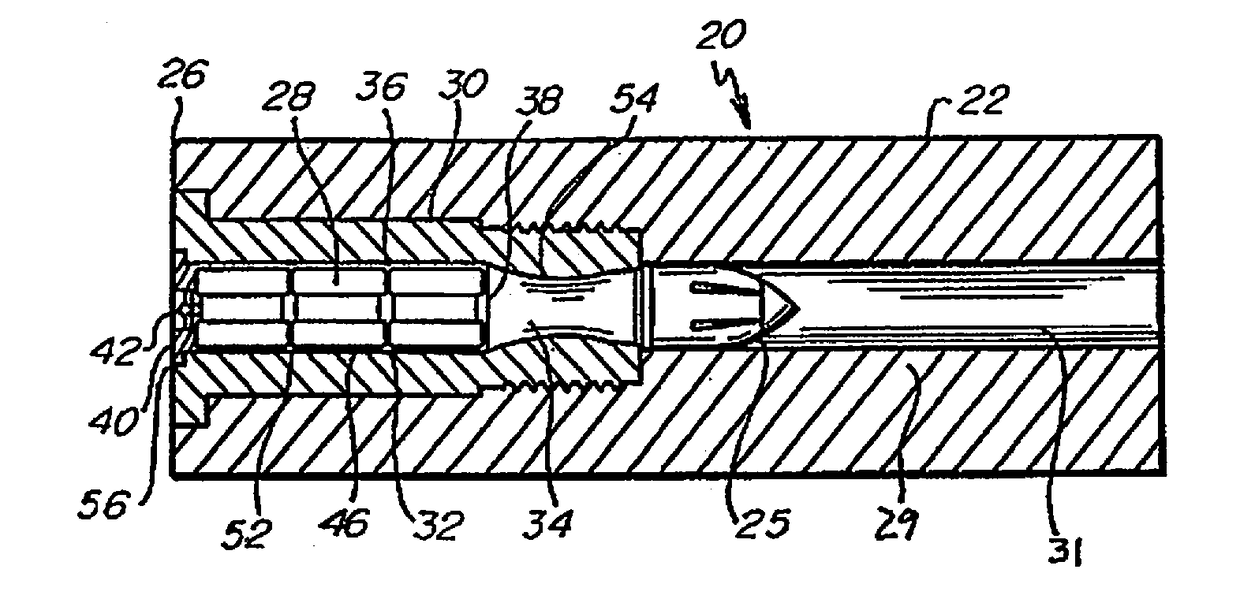

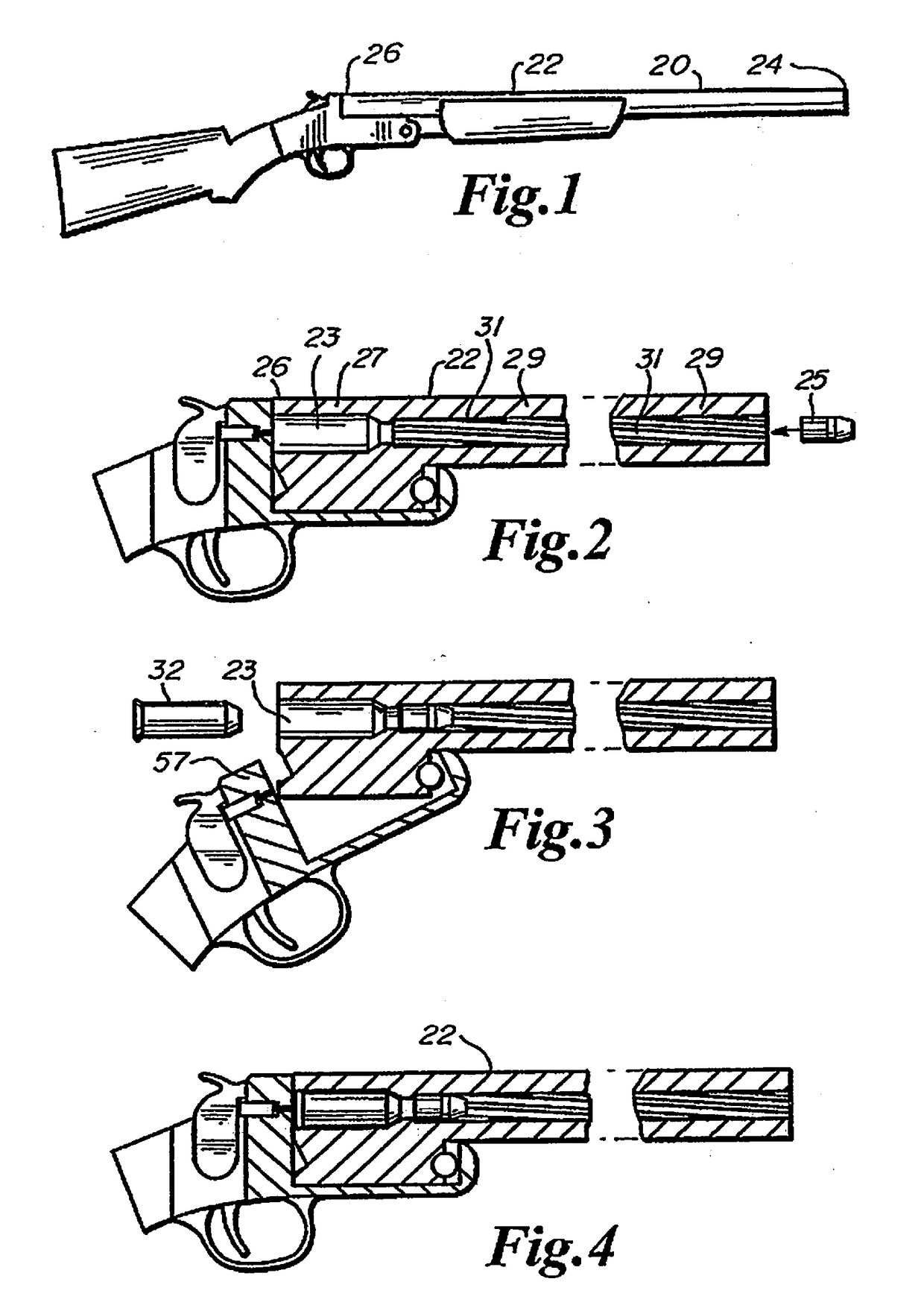

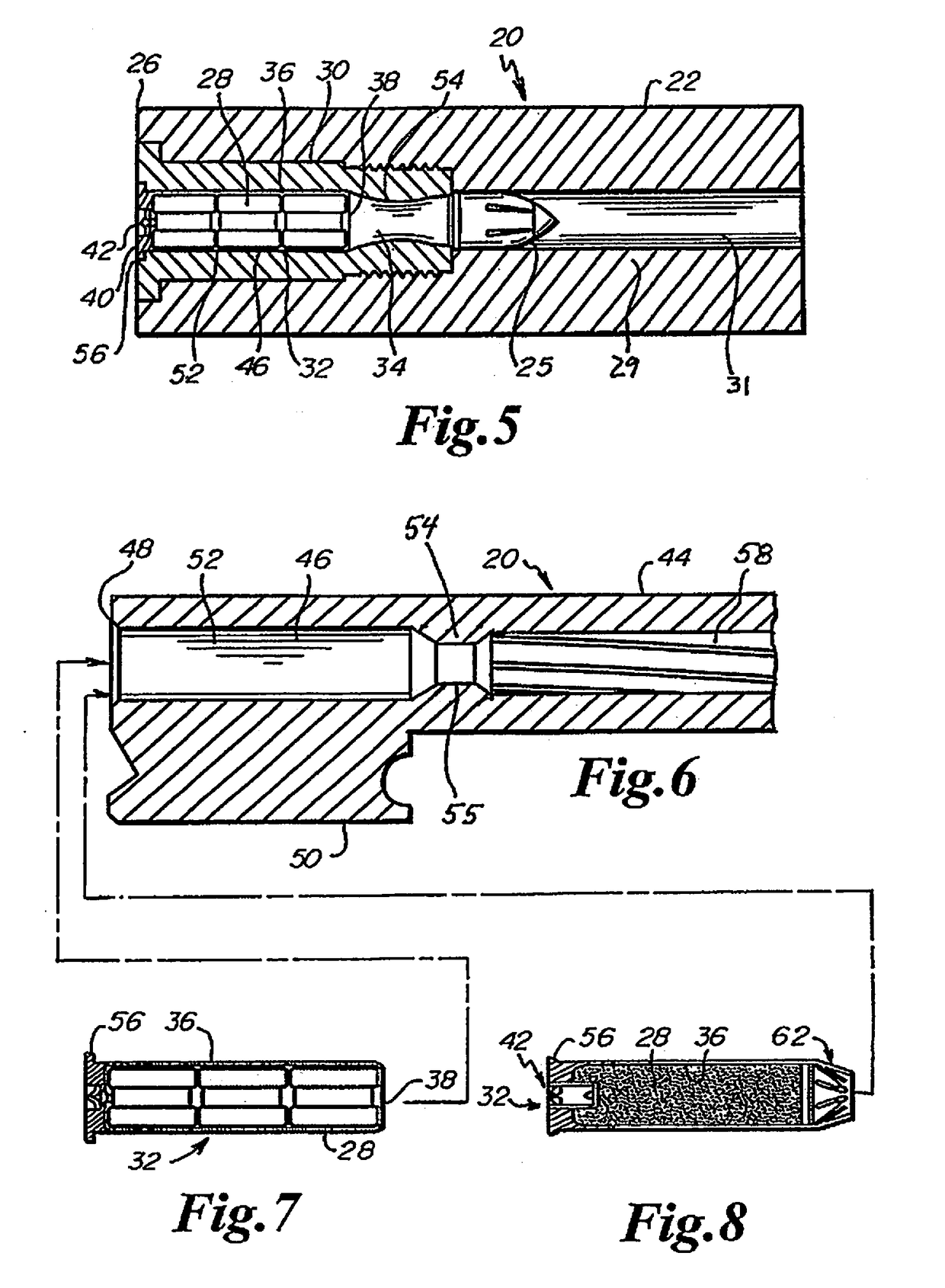

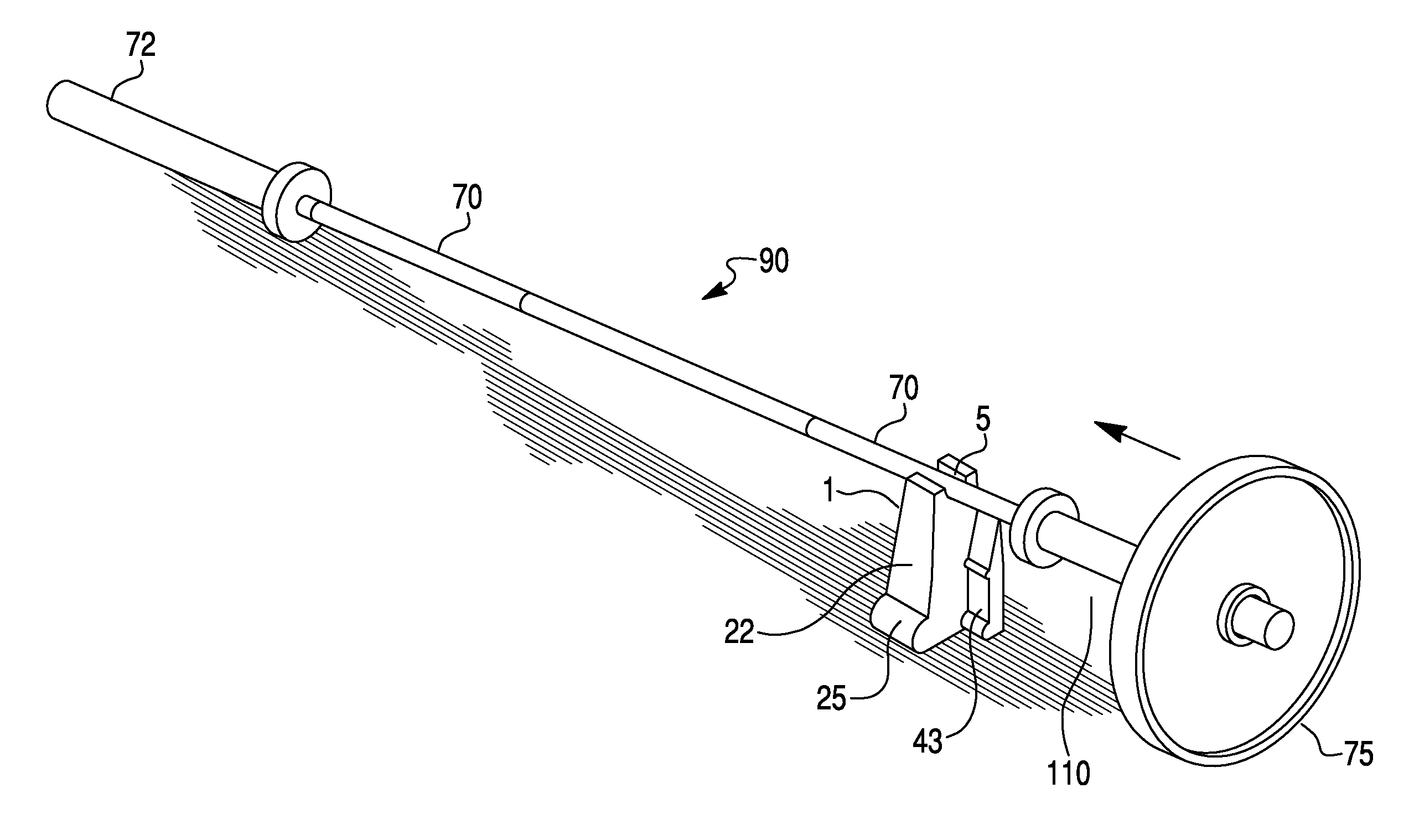

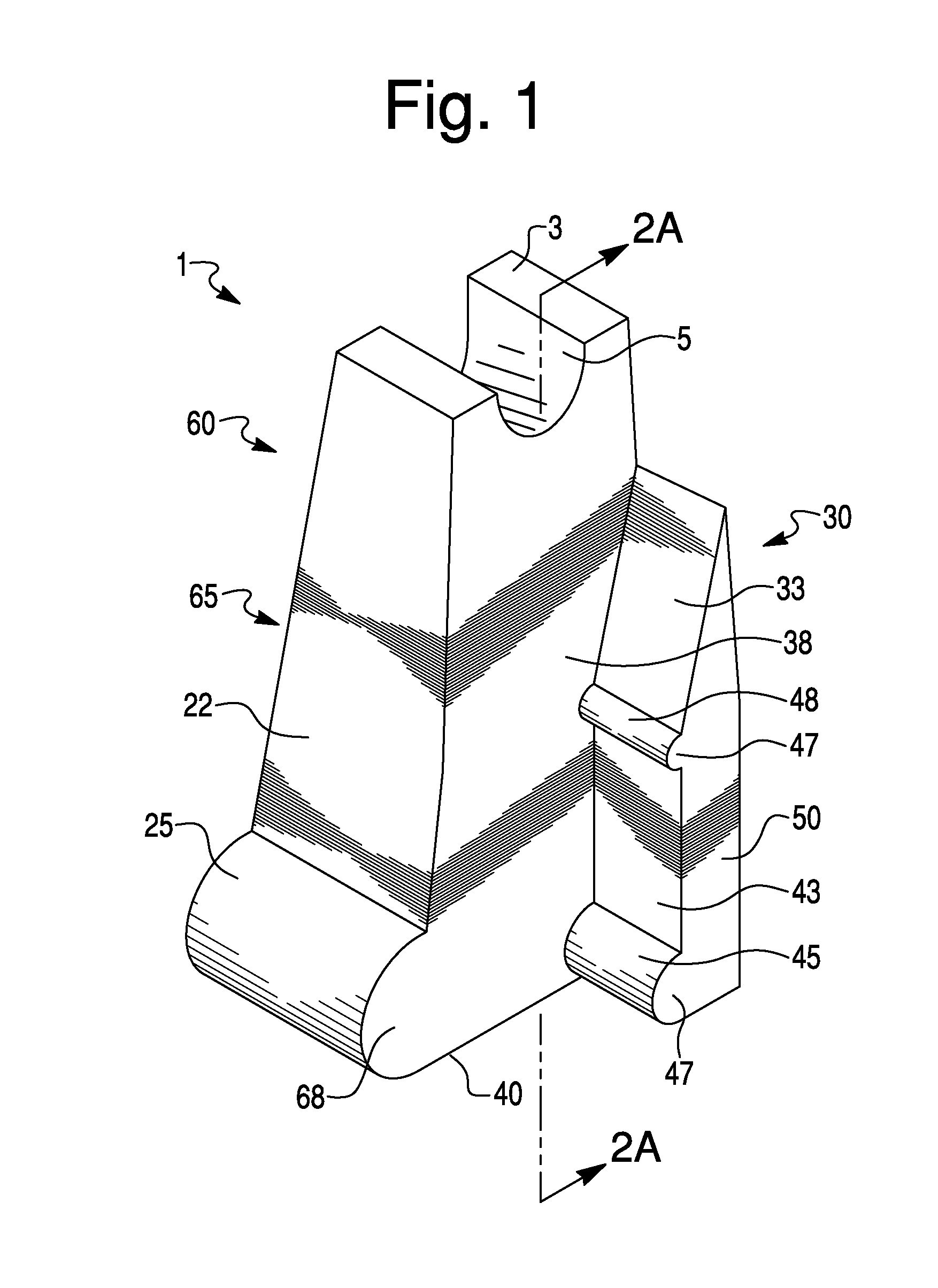

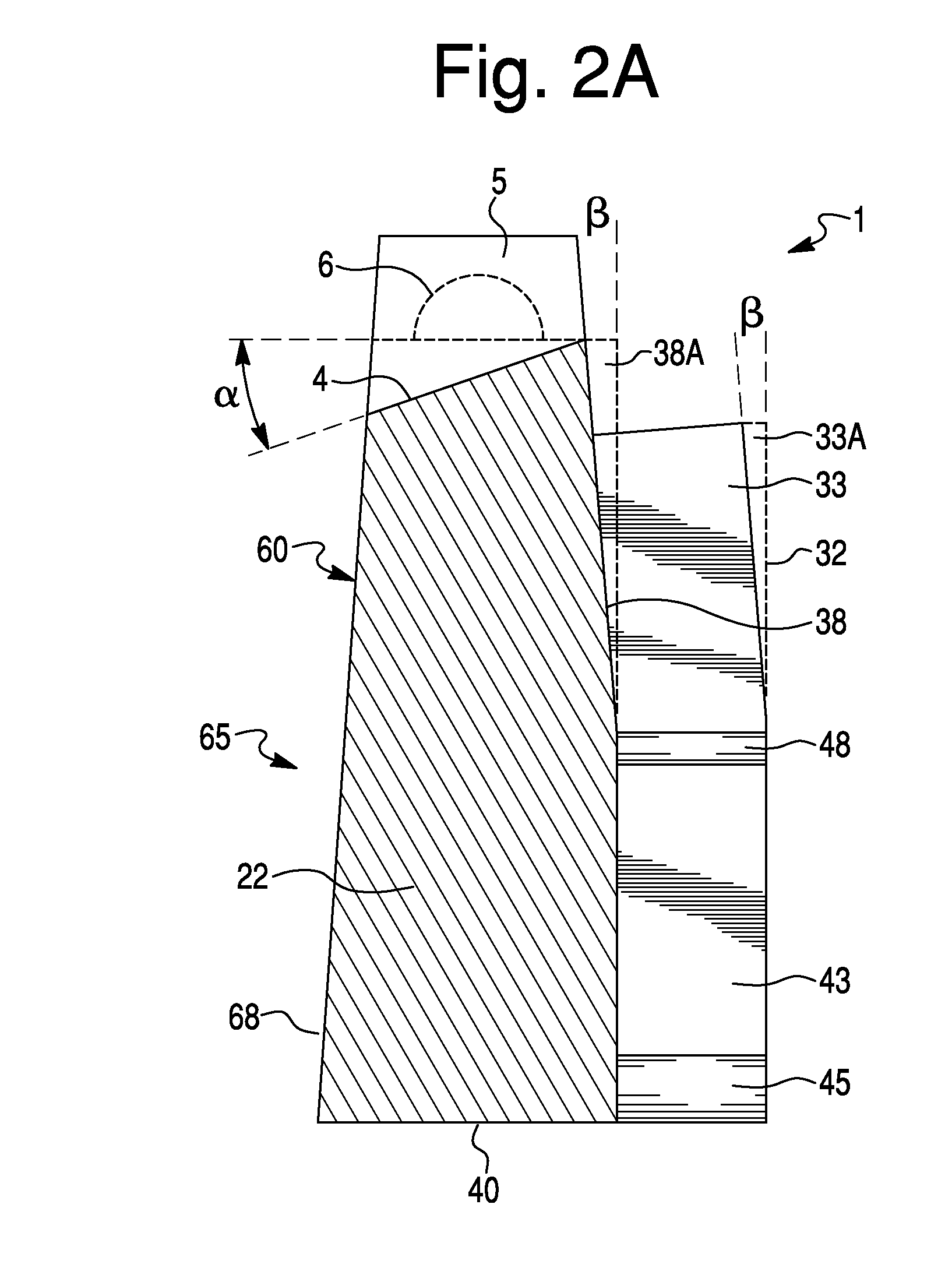

Muzzleloader systems

ActiveUS20140090284A1Efficient unloadingImprove sealing propertiesAmmunition projectilesShotgun ammunitionEngineeringUllage

Muzzleloader systems include a pre-packaged propellant charge and primer for providing efficient loading and unloading of the muzzleloader. The breech end accepts the propellant and means are provided to prevent breech loading of the projectile. A propellant cartridge conforms to a constriction portion to minimize ullage. A projectile is inserted in the muzzle end seats on the constriction portion. The propellant cartridge may be received in a removable breech plug. The constriction portion may be part of the breech plug or a separate component secured in the barrel by way of the breech plug. The cartridge may have a primer mechanism integrated into a proximal end. Projectiles have sliding components that have an axial elongate position and an axial shortened position and may be loaded with a ramrod having an engagement portion for each of the two pieces whereby the projectile doesn't prematurely collapse.

Owner:FEDERAL CARTRIDGE

Configuration load of a reconfigurable data processor

ActiveUS10831507B2Efficient loading and unloadingEffective meanDigital computer detailsProgram loading/initiatingEngineeringData memory

A reconfigurable data processor comprises a bus system, and an array of configurable units connected to the bus system, configurable units in the array including configuration data stores to store unit files comprising a plurality of sub-files of configuration data particular to the corresponding configurable units. Configurable units in the plurality of configurable units each include logic to execute a unit configuration load process, including receiving via the bus system, sub-files of a unit file particular to the configurable unit, and loading the received sub-files into the configuration store of the configurable unit. A configuration load controller connected to the bus system, including logic to execute an array configuration load process, including distributing a configuration file comprising unit files for a plurality of the configurable units in the array.

Owner:SAMBANOVA SYST INC

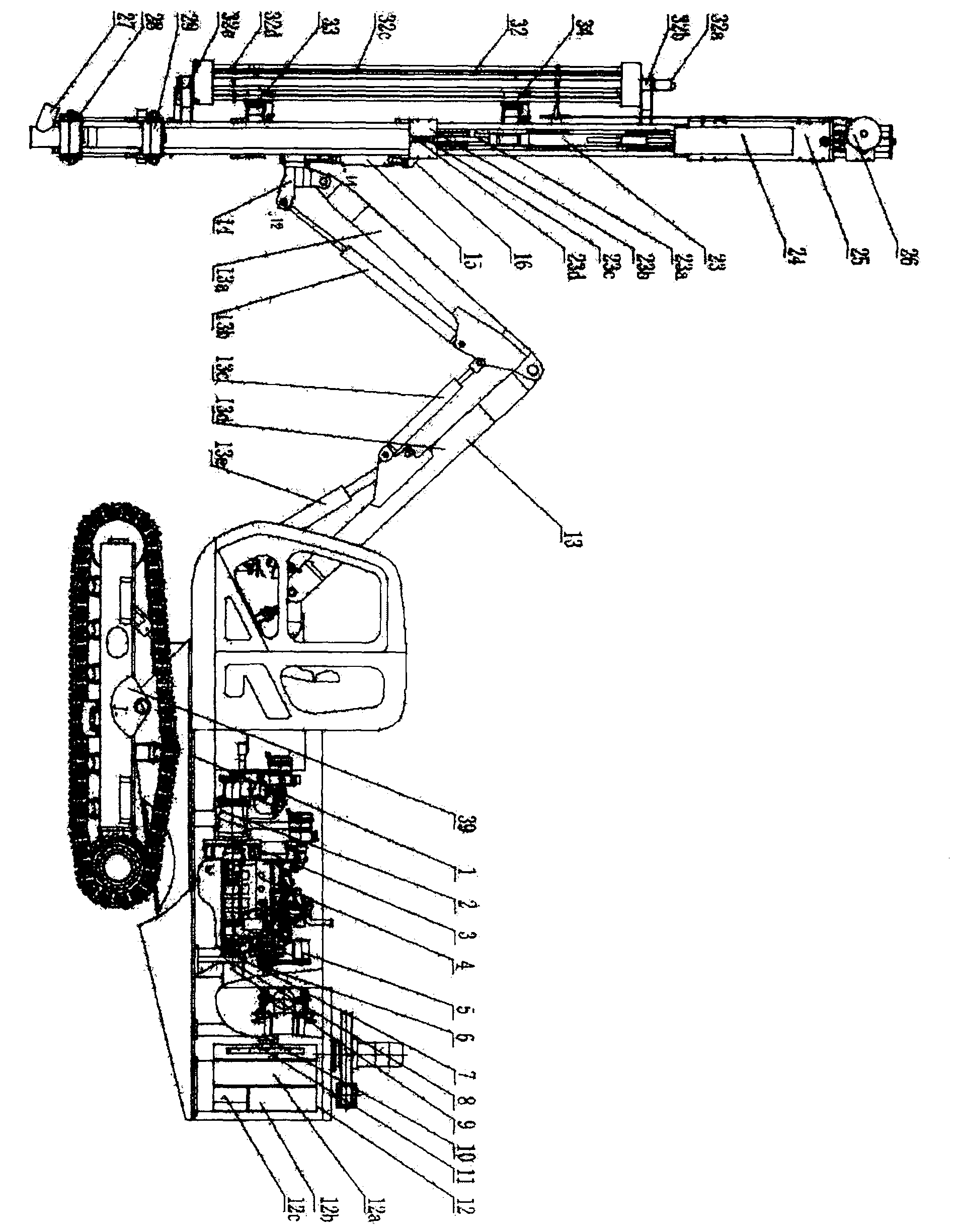

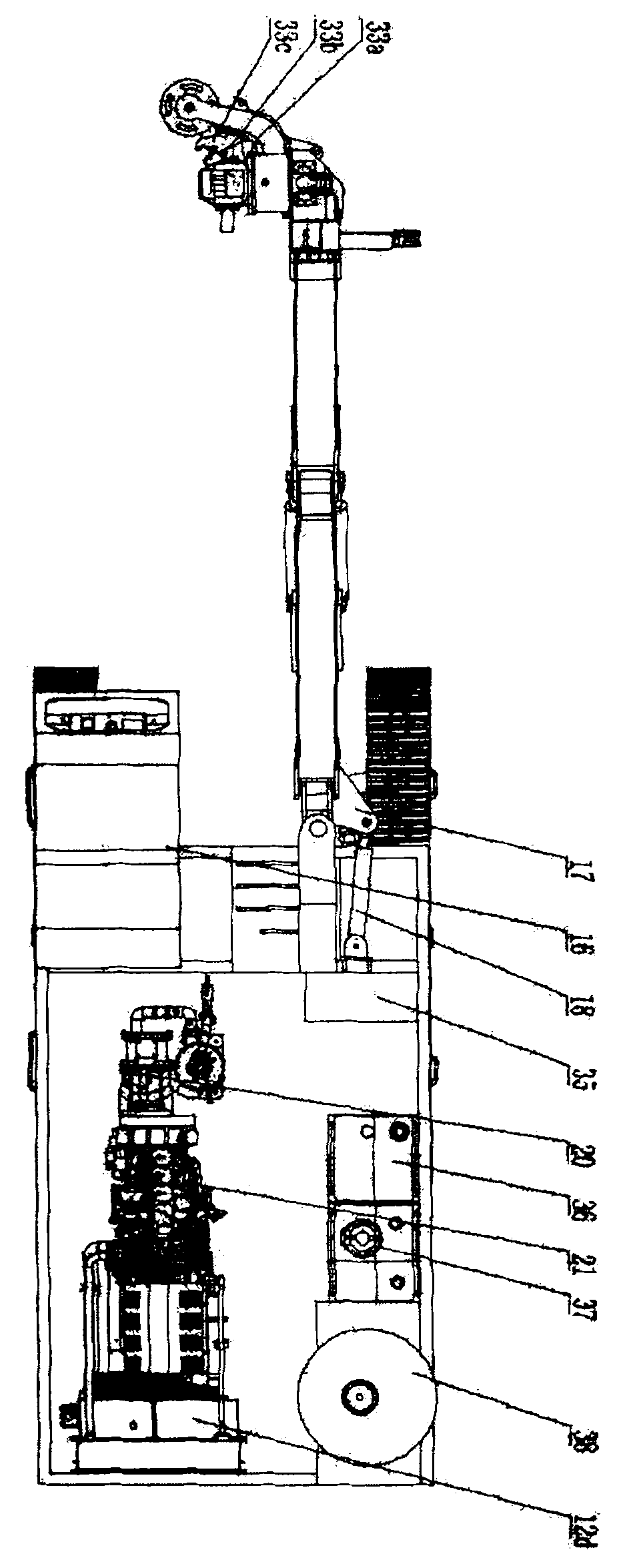

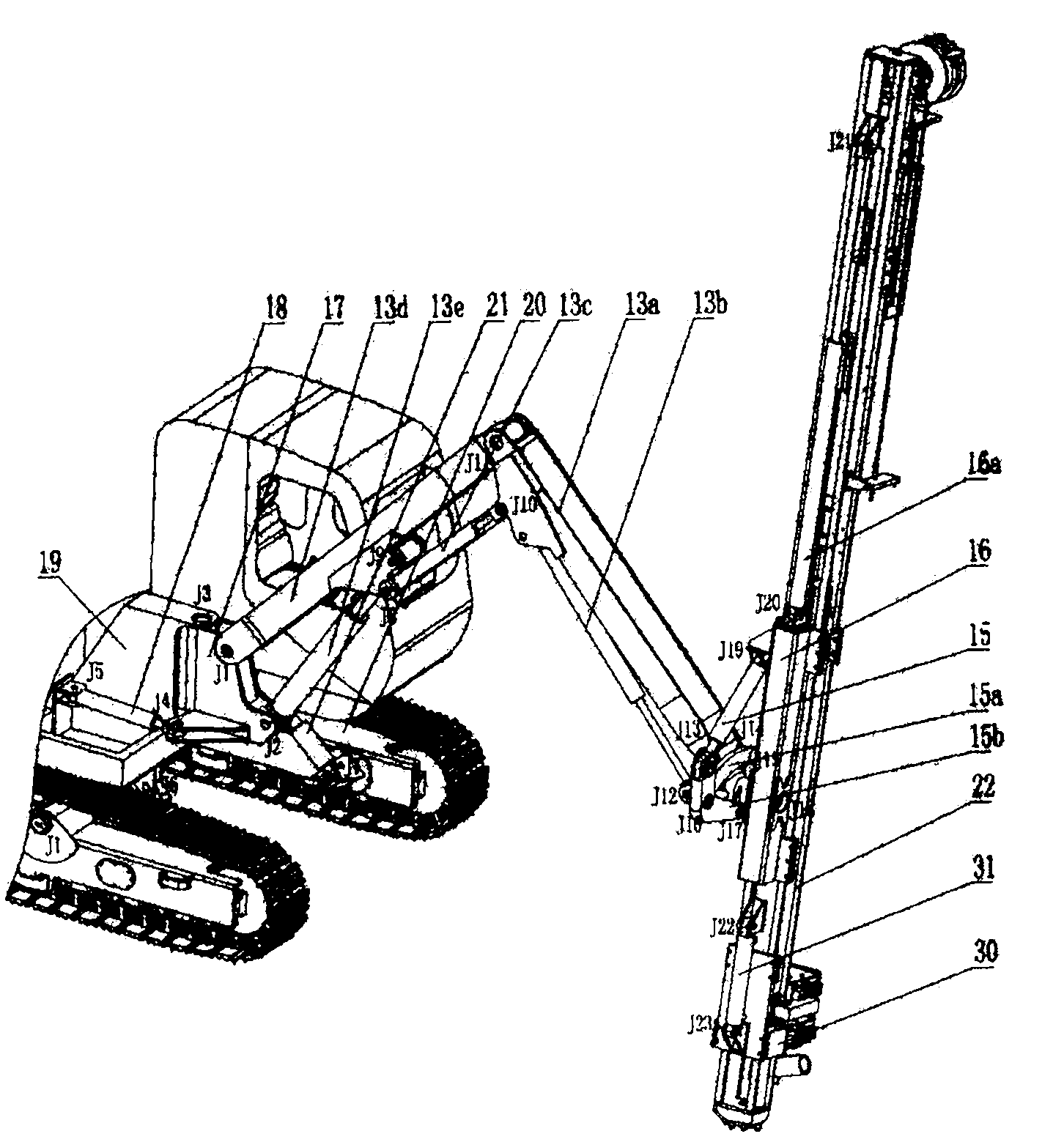

Multidirectional hydraulic rock drilling machine with integrated drives

InactiveCN102003143ACompact structureImprove energy efficiencyDrilling rodsDerricks/mastsElectronic control systemControl system

The invention relates to a multidirectional hydraulic rock drilling machine with integrated drives, and discloses multidirectional hydraulic rock drilling equipment with the integrated drives, which is composed of a rack, a drilling mechanism, a rod breaker mechanism, a drill hole angle adjustment mechanism, a crawler-type walking mechanism, an air compressor, an engine, a hydraulic system, an electronic control system, a dust removing system and the like, wherein, the crawler-type walking mechanism of a track frame the angle of which can be oscillated and is arranged below the rack; the air compressor, a hydraulic control system, an electrical apparatus control system, a power system and the dust removing system are arranged on the rack; the right front end of the rack is provided with afolded arm rack or a flexible arm rack; the front end of the arm rack is provided with a rotary head and the drilling mechanism; and the rod breaker mechanism, a pipe reeling mechanism, a propelling mechanism and a hydraulic rock drilling machine are arranged on a drilling rack of the drilling mechanism. The multidirectional hydraulic rock drilling machine integrating drive of the invention integrates the drives, can drill holes in multidirection, simultaneously has low energy consumption, high efficiency, compact structure and light and flexible operation, and is simple and convenient for maintenance.

Owner:吴亦舟

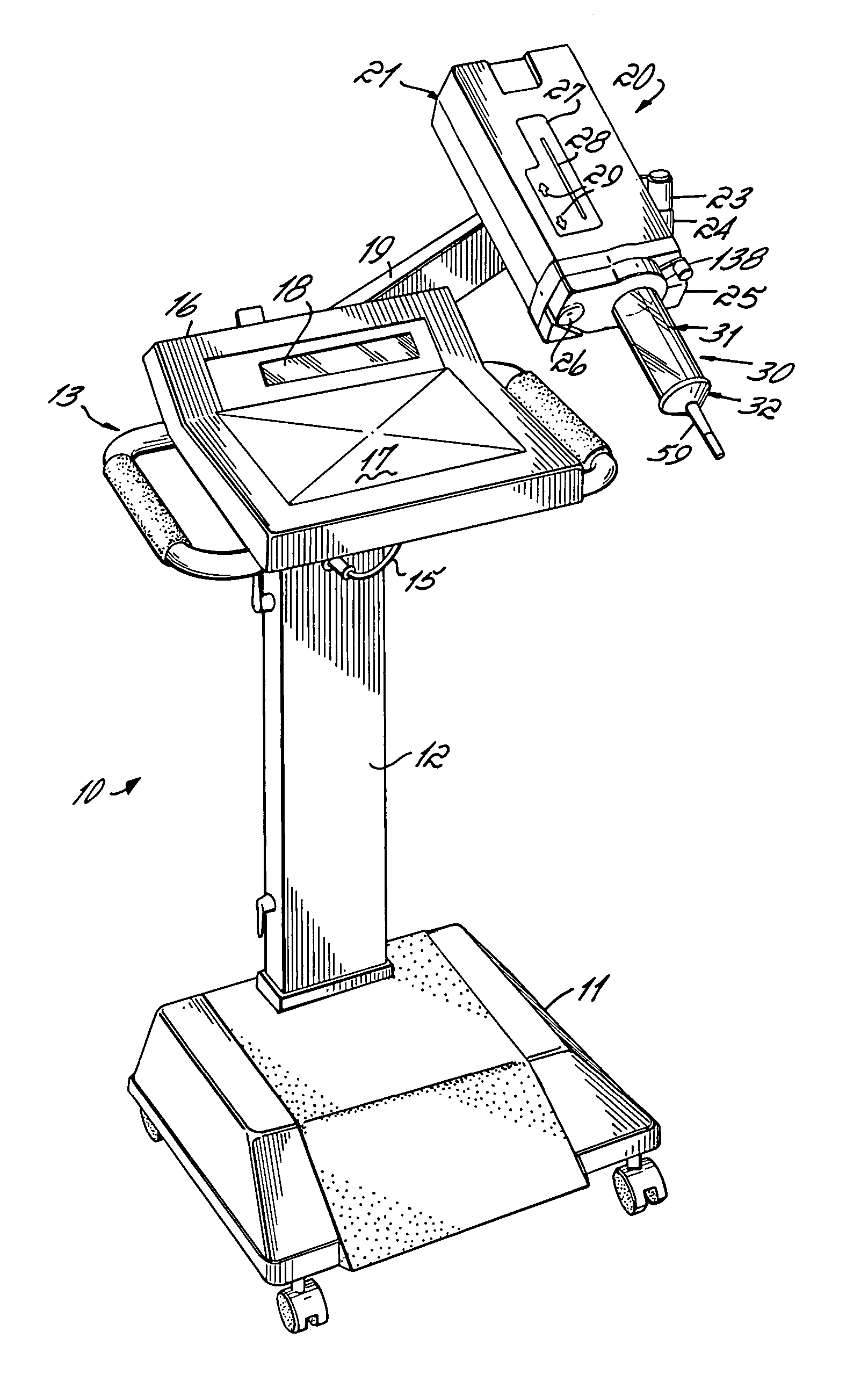

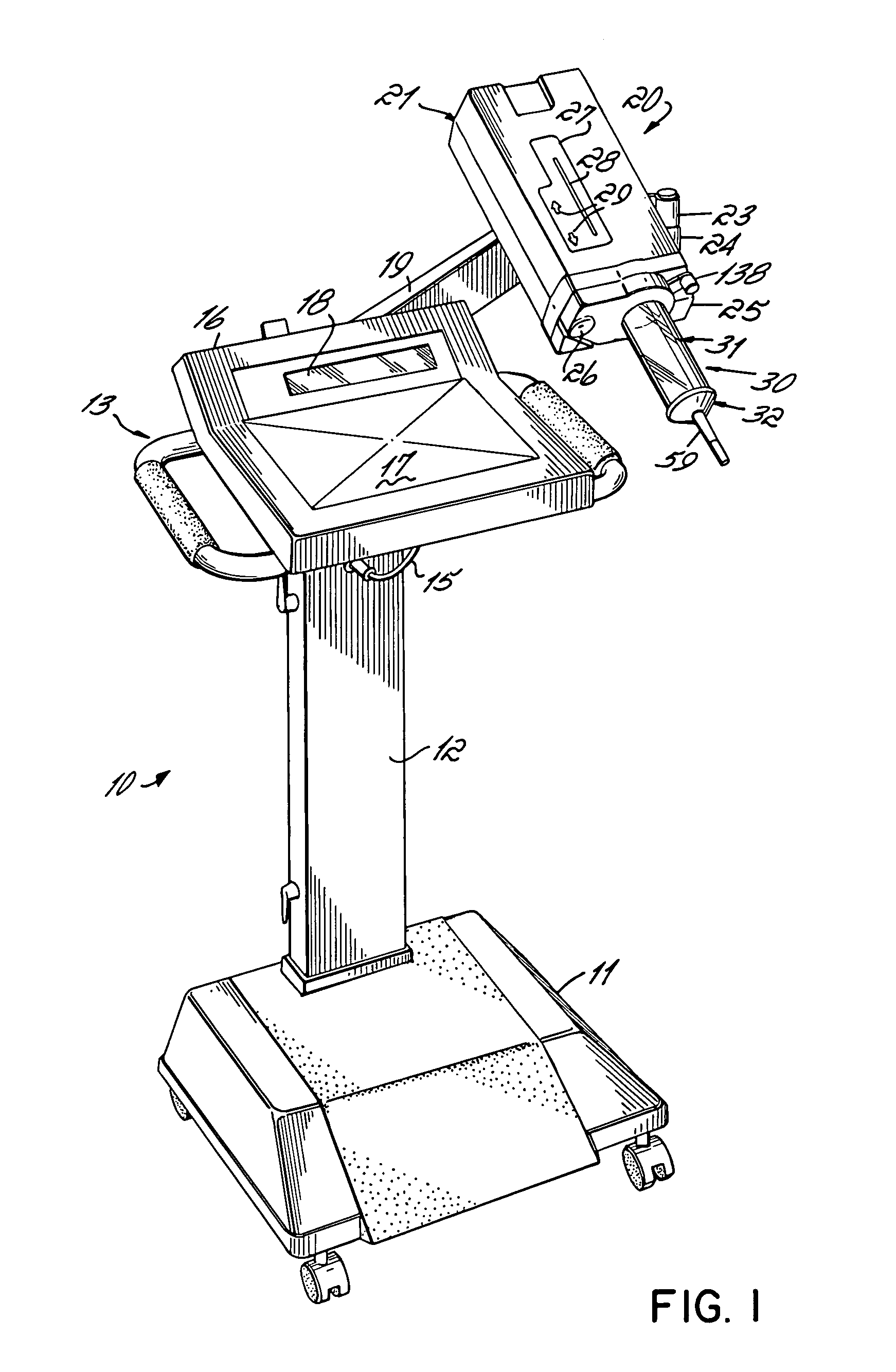

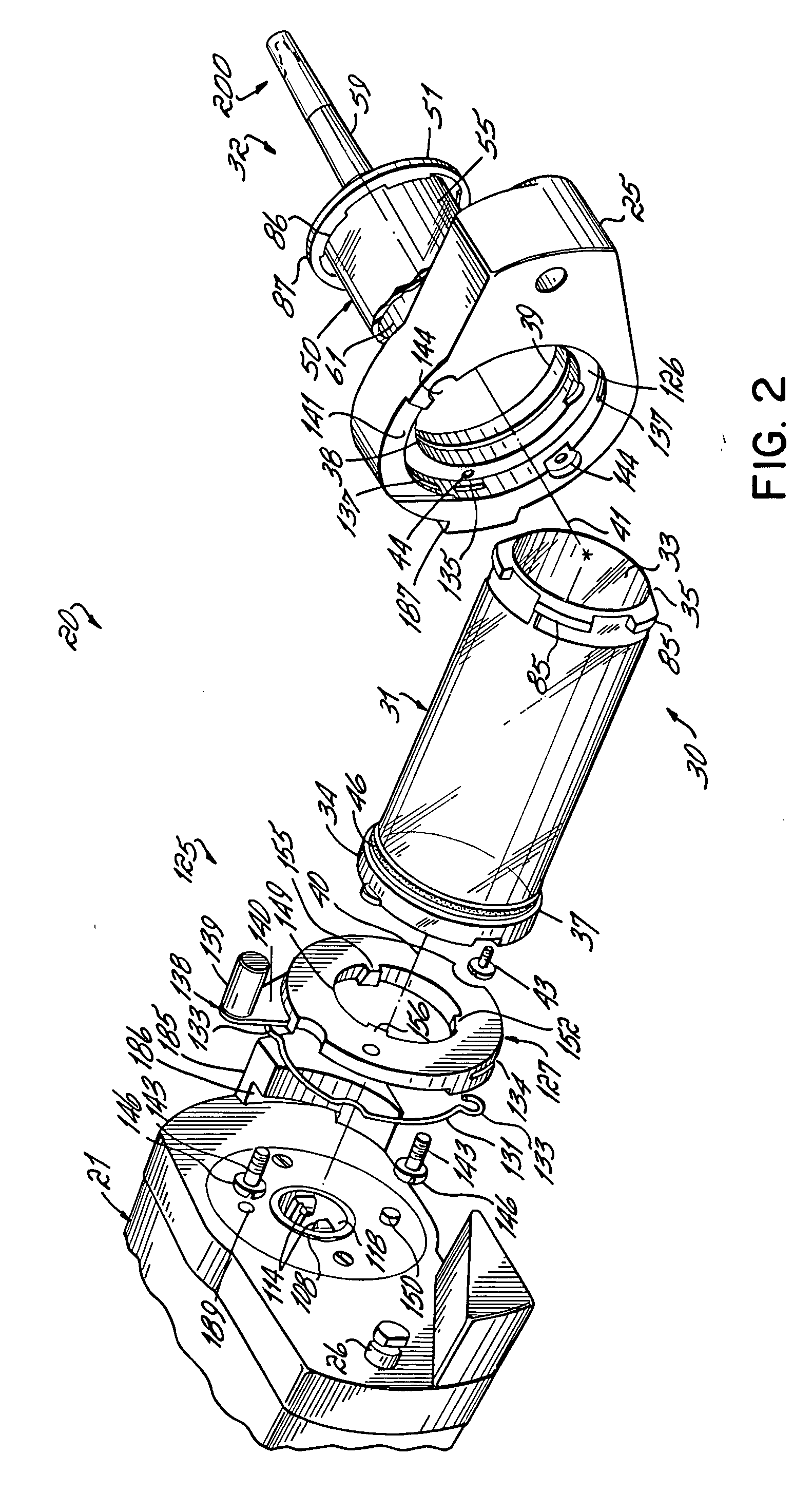

Disposable front loadable syringe and injector

InactiveUS20060106347A1Fast loadingPrevention and elimination of leakInfusion syringesMedical devicesEngineeringBiomedical engineering

A syringe for an injector that has at its nozzle end a connection to the fluid delivery tubing that prevents, reduces, or eliminates fluid leaks, by virtue of a ridge on the external surfaces of the connector which engage to tubing. Furthermore, the syringe and injector are configured to permit the syringe to be oriented in more than one manner on the injector.

Owner:MALLINCKRODT INC

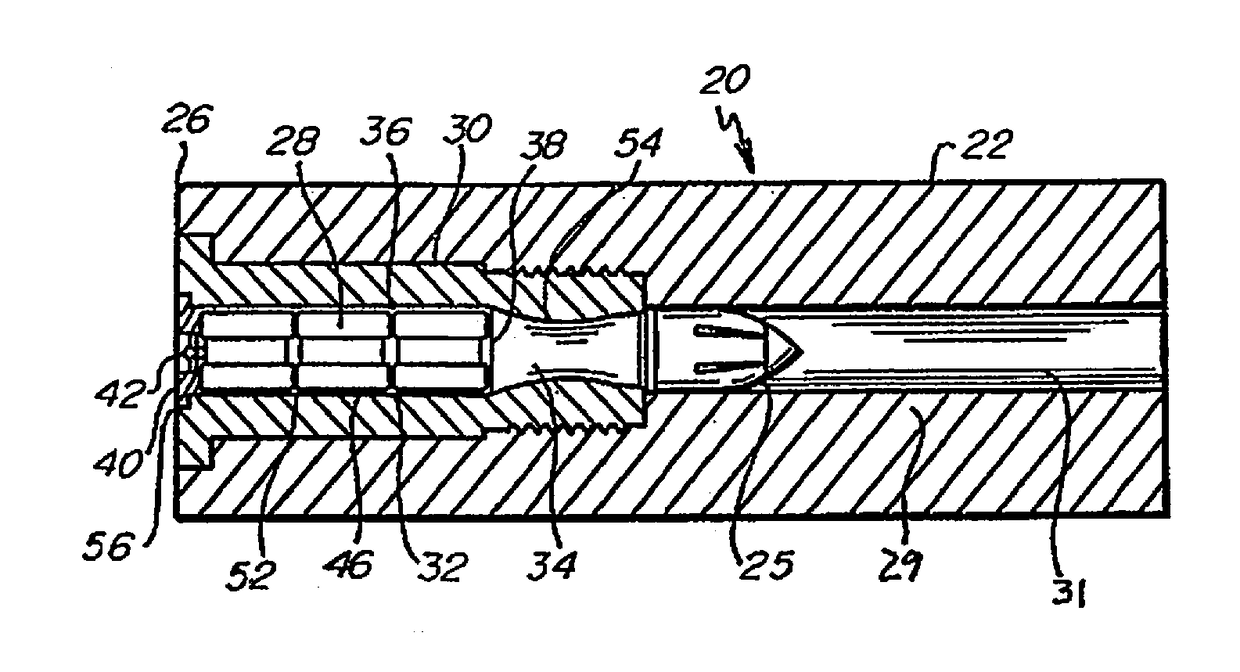

Muzzleloader and propellant system

InactiveUS20140090285A1Efficient unloadingReduce the overall diameterAmmunition projectilesCartridge extractorsEngineeringMechanical engineering

A muzzle-loader bullet system includes a pre-packaged propellant charge and primer for providing efficient loading and unloading of the muzzleloader. The muzzleloader accepts in the breech end the propellant containment vessel that abuts against a constriction portion with a reduced diameter portion. The propellant containment vessel having an end portion with a tapered surface that conforms to the constriction portion surface. A projectile is inserted in the muzzle end and seats against the constriction portion. The propellant containment vessel may be received in a removable breech plug. The constriction portion may be part of the breech plug or a separate component secured in the barrel by way of the breech plug. The containment vessel further comprises a primer mechanism that may be integrated into the proximal end of the containment vessel.

Owner:VISTA OUTDOOR OPERATIONS

Muzzleloader systems

ActiveUS10030956B2Efficient loading and unloadingFacilitate loading powderAmmunition projectilesTraining ammunitionEngineeringMechanical engineering

Muzzleloader systems include a pre-packaged propellant charge and primer for providing efficient loading and unloading of the muzzleloader. The muzzleloader accepts in the breech end the propellant containment vessel that abuts against a constriction portion with a reduced diameter portion. The propellant containment vessel having an end portion with a tapered surface that conforms to the constriction portion surface. A projectile is inserted in the muzzle end and seats against the constriction portion. The propellant containment vessel may be received in a removable breech plug. The constriction portion may be part of the breech plug or a separate component secured in the barrel by way of the breech plug. The containment vessel further comprises a primer mechanism that may be integrated into the proximal end of the containment vessel.

Owner:FEDERAL CARTRIDGE

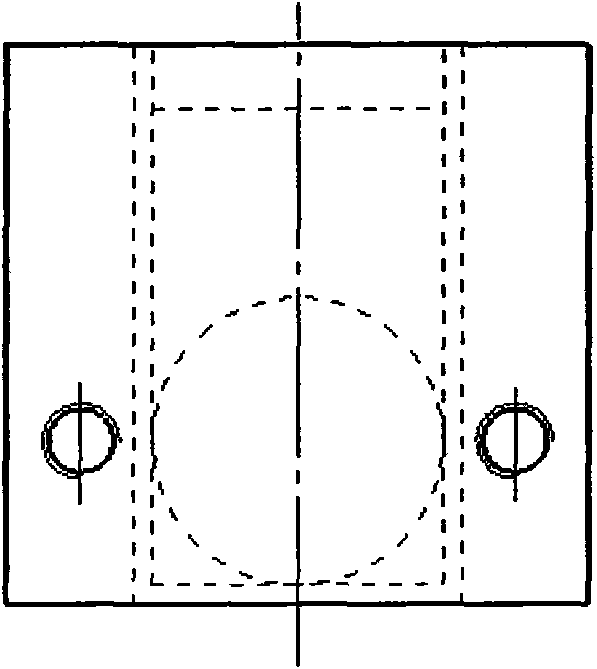

Full-diameter core resistivity clamp

InactiveCN102520214AAccurate measurementCompact and reasonable structureResistance/reactance/impedenceMeasurement instrument housingElectrical connectionStructural engineering

The invention relates to the technical field of a core resistivity measuring device, in particular to a full-diameter core resistivity clamp. The clamp comprises a holding cylinder, a movable plug cap, a fixed plug cap and a lead pedestal, wherein the axis of the holding cylinder is in the horizontal direction; the left part and the right part of the holding cylinder are fixedly provided with the movable plug cap and the fixed plug cap respectively; the lower part of the holding cylinder is fixedly arranged on the lead pedestal; a holding cavity capable of holding a core column is formed in the holding cylinder; a power supply electrode and a measuring electrode are fixed on the inner wall of the holding cavity; the measuring electrode can be used for measuring the resistivity of the core column; a connecting slot in which a connecting terminal is arranged is formed on the lead pedestal; and the connecting terminal is electrically connected with the measuring electrode through a wire. The clamp has a rational and compact structure and is convenient to use; the core column is protected from being influenced by external environment through the holding cylinder, the movable plug cap and the fixed plug cap; the core resistivity can be accurately measured and the core temperature can be monitored; a core is convenient and fast to assemble and disassemble; and the clamp has the characteristics of high measuring accuracy, easiness and convenience, and high efficiency.

Owner:CNPC XIBU DRILLING ENG

Single-conveyor elongated object cleaning system

InactiveUS20050087214A1Easy to cleanEfficient loading and unloadingHollow article cleaningLiquid processing with progressive mechanical movementRinse waterEngineering

A system for cleaning elongated objects uses a single inclined conveyor with a lower end adjacent a back stop disposed inside a tank containing cleaning solution. The elongated objects pile up between the back stop and the conveyor and a jet manifold sprays a lower side of the pile where pusher flights on the conveyor pick off the objects one at a time. A flip back plate strips the objects from the conveyor to continuously circulate the objects in the cleaning solution from the bottom to the top of the pile. The plate is retracted to allow the conveyor to deliver the objects to a rinse water basin where the clean objects are rinsed and then removed.

Owner:SANI MATIC

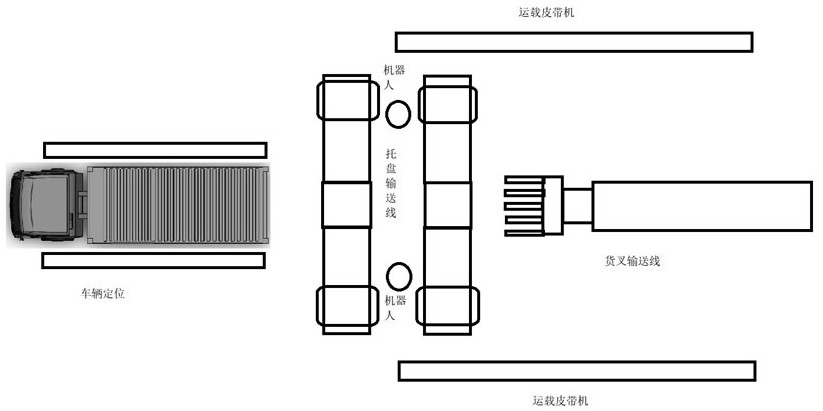

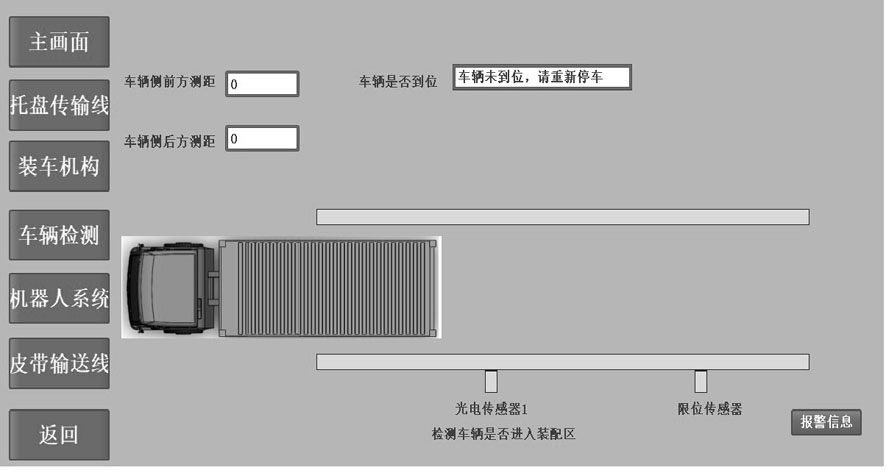

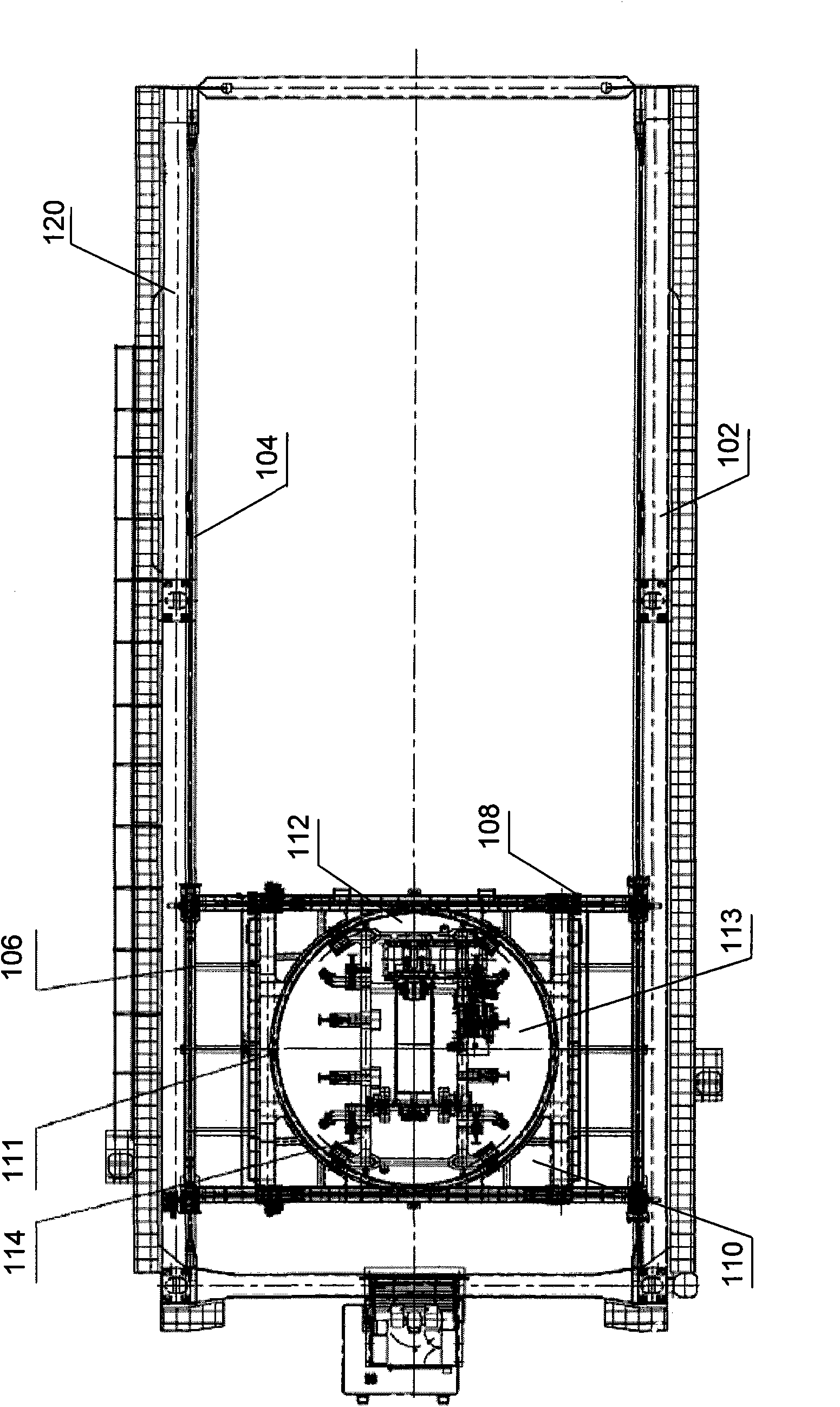

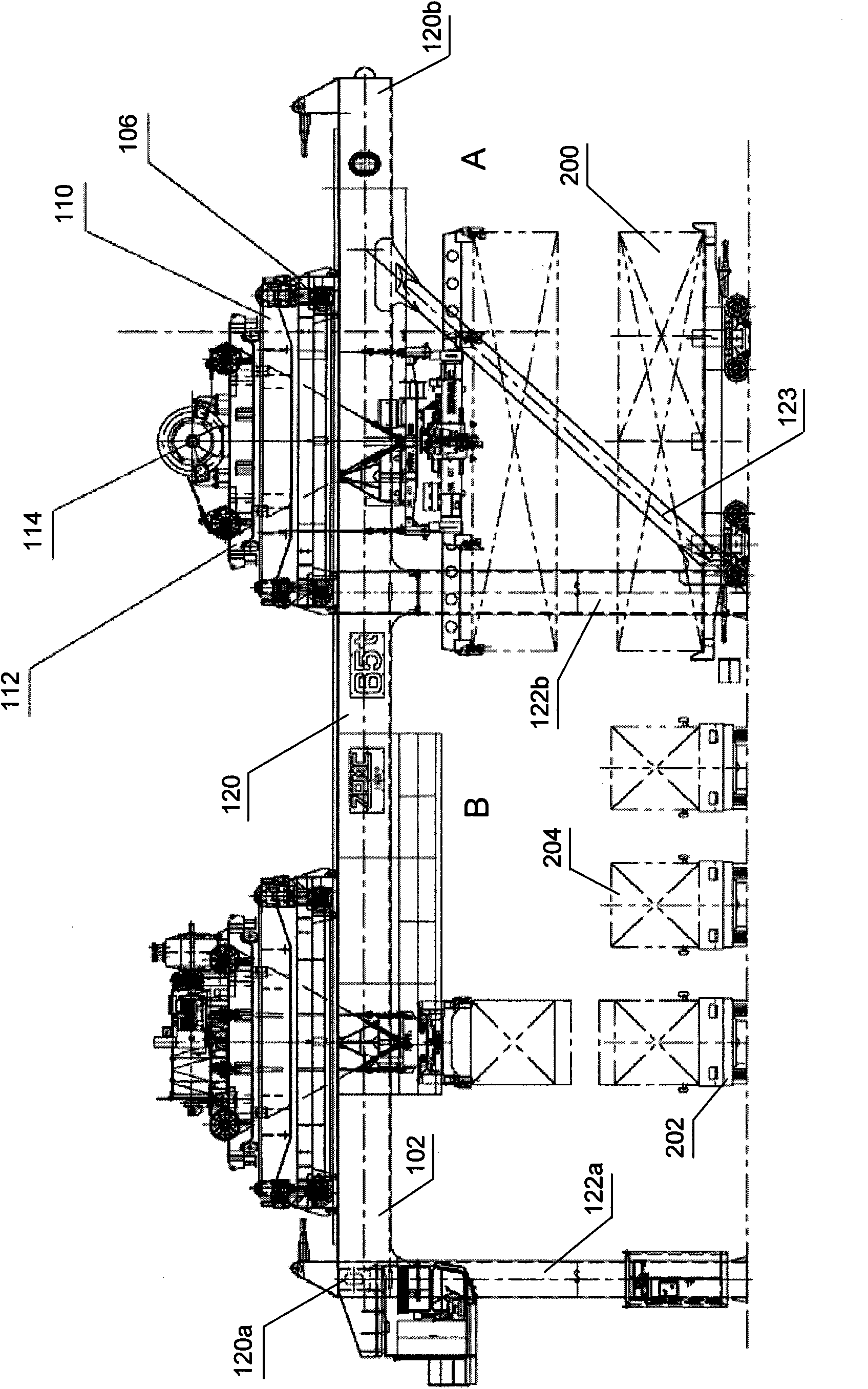

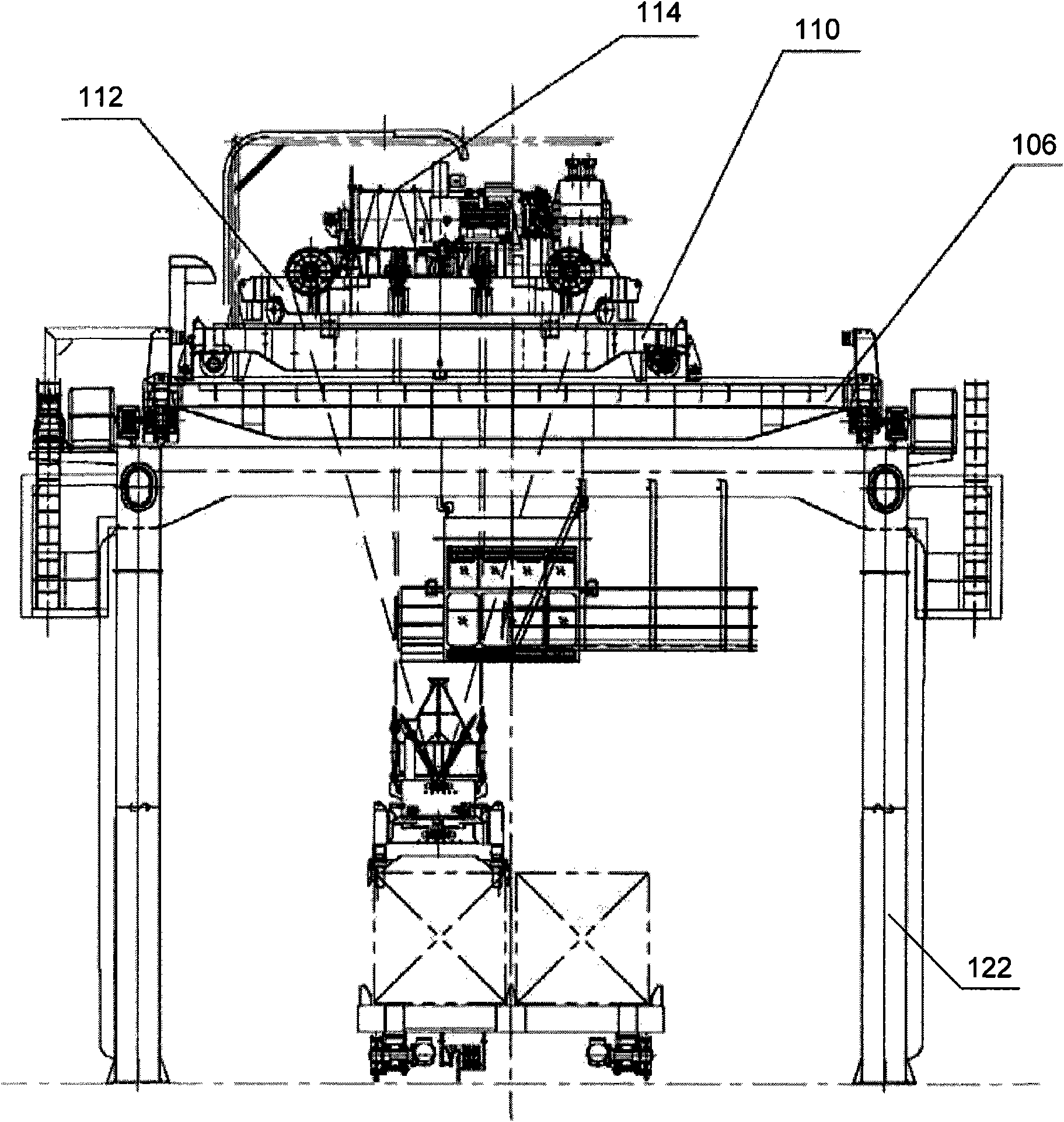

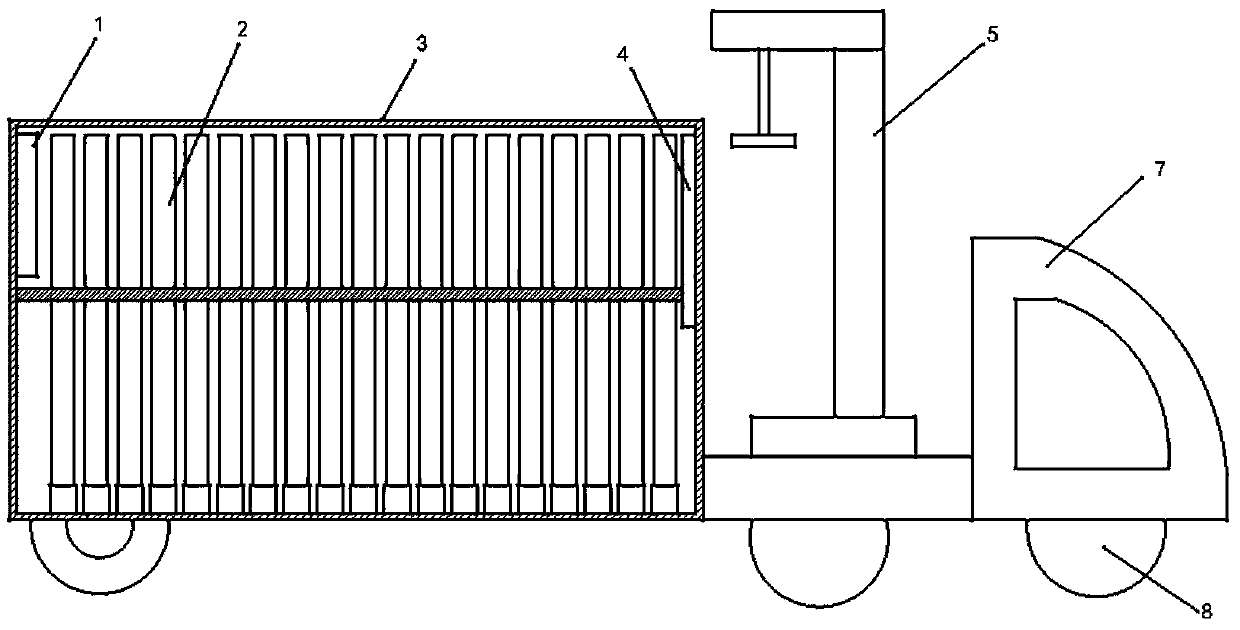

Container type automatic carriage loading system

PendingCN112441432AEfficient loading and unloadingReduce labor costsControl devices for conveyorsLoading/unloadingAutomotive engineeringRobot control system

The invention relates to a container type automatic carriage loading system, and belongs to the technical field of industrial automation. The system comprises a vehicle positioning system, a tray conveying line system, a carrying belt conveyor system, a robot control system and a pallet fork conveying line system, wherein the tray conveying line system is arranged between the vehicle positioning system and the pallet fork conveying line system, the robot control system is arranged on the two sides of the tray conveying line system, the carrying belt conveyor system is arranged on the two sidesof the tray conveying line system and the pallet fork conveying line system, and a transport vehicle stops on the vehicle positioning system. The automatic carriage loading system has the beneficialeffects that cargos are efficiently loaded and unloaded, the labor cost and the labor intensity are reduced, and work safety is improved.

Owner:ANHUI MINING ELECTROMECHANICAL EQUIP

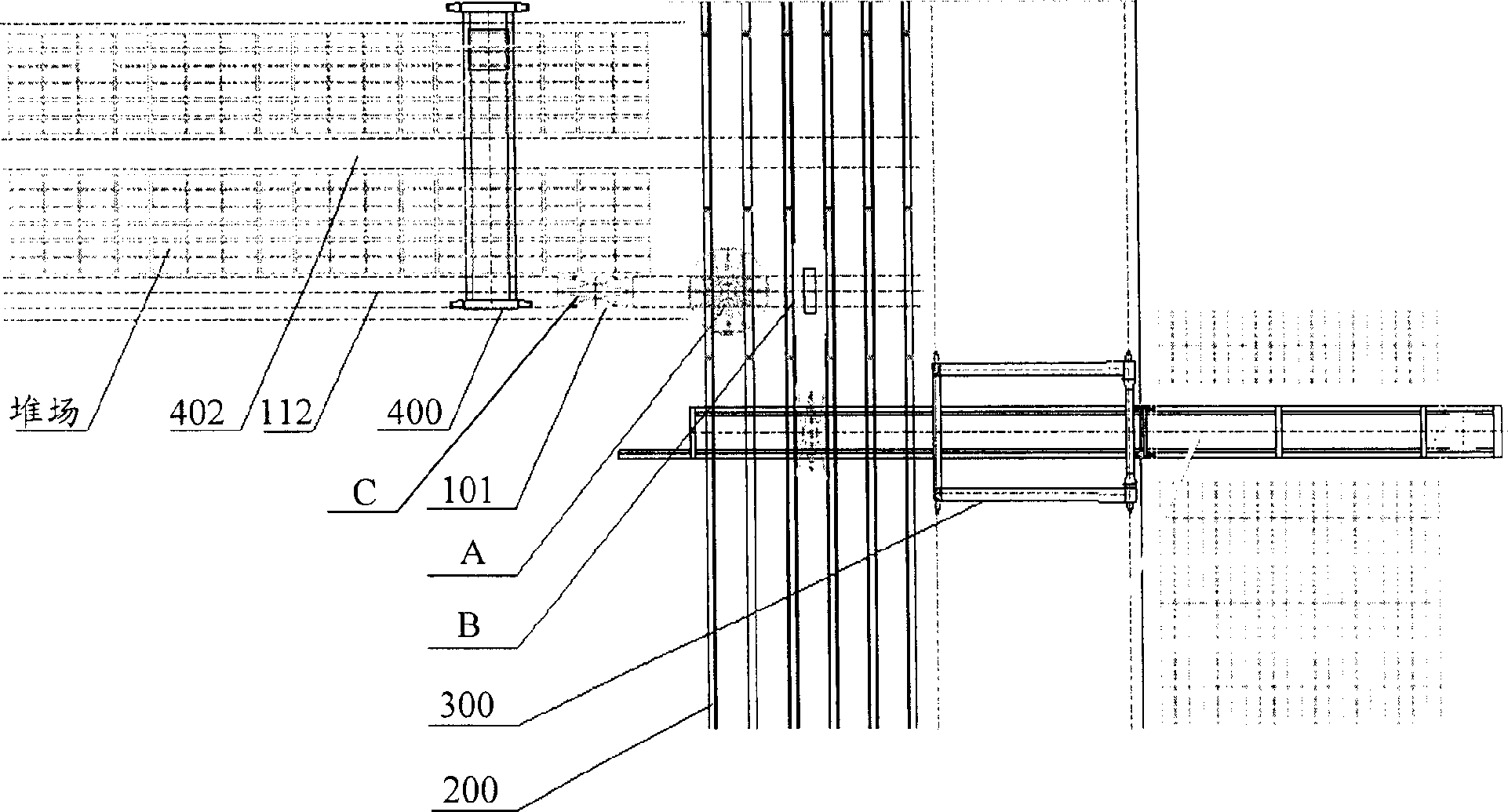

Crane in rear storage yard for automated container terminal

InactiveCN101920912AImprove operational efficiencyEfficient loading and unloadingBase supporting structuresBraking devices for hoisting equipmentsYardTruck

The embodiment of the invention discloses a crane in a rear storage yard for an automated container terminal, comprising a bracket, a second trolley track, a second trolley, a first trolley track, a first trolley, a swing mechanism and a lifting mechanism, wherein the bracket comprises a girder arranged in the second direction and a stand column supporting the girder as well as the girder covers the trolley tracks on the ground of the automated container terminal and a loading and unloading region of trucks; the second trolley track is arranged on the girder; the second trolley runs along the second trolley track; the first trolley runs along the first trolley track; the swing mechanism is arranged on the first trolley and has the capacity of swinging at least 90 degrees; and the lifting mechanism is arranged on the swing mechanism, rotates with the swing mechanism together, and comprises a lifting appliance for lifting containers. The crane in the rear storage yard in the automated container terminal provided by the invention can preferably match with the automated container terminal and can realize efficient loading and unloading of the containers with haulage trucks.

Owner:SHANGHAI ZHENHUA HEAVY IND

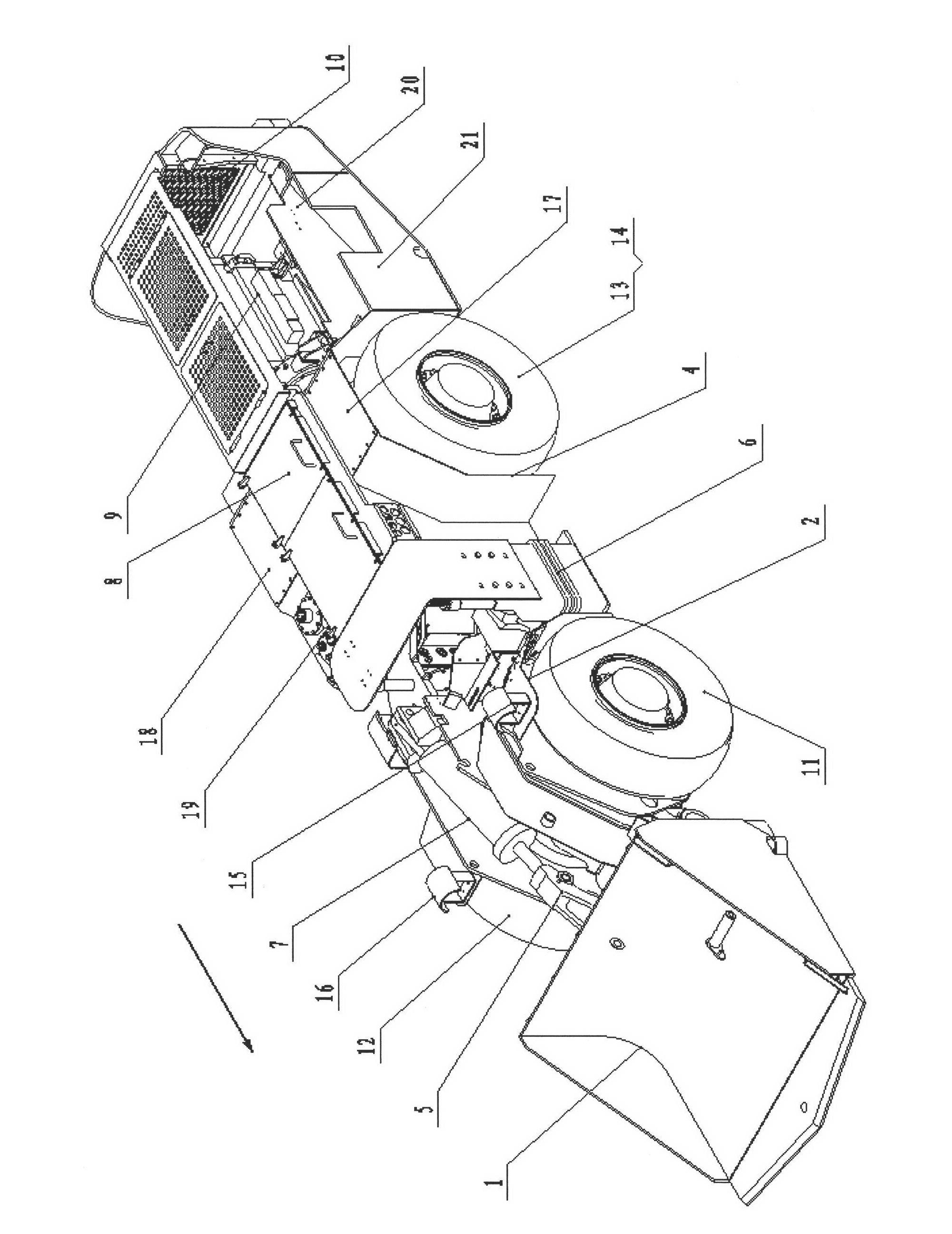

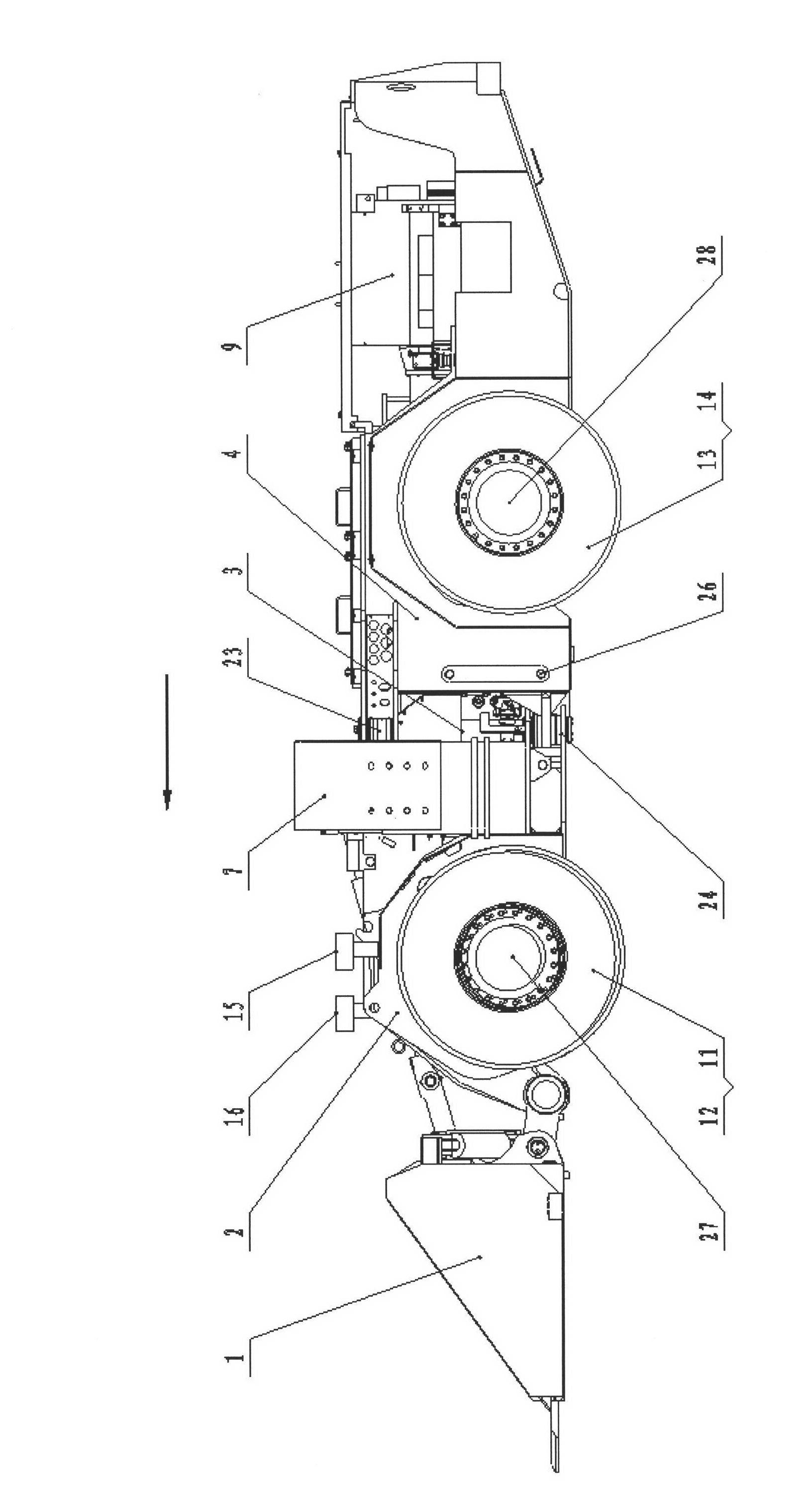

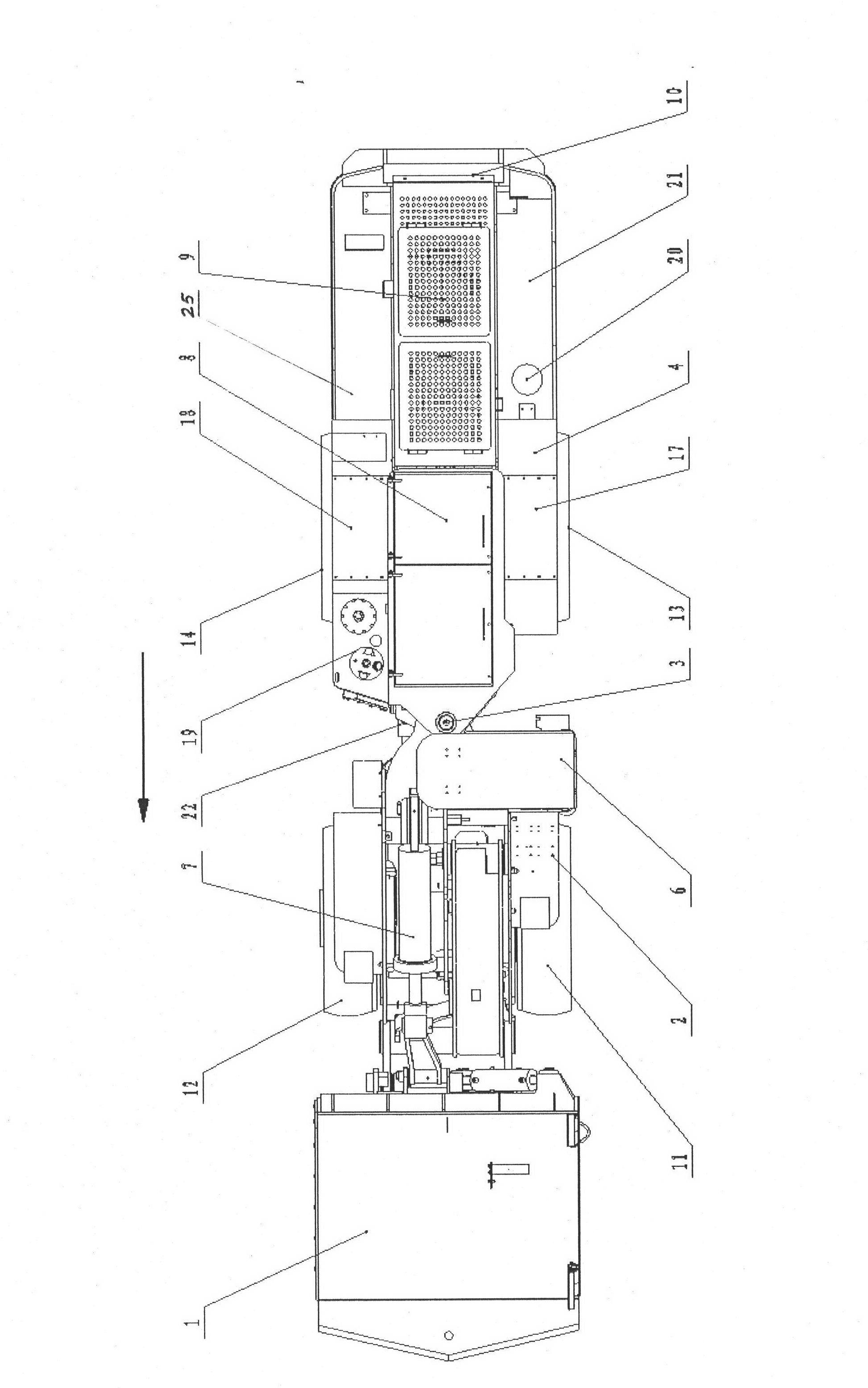

Low narrow multifunctional explosion-proof diesel scraper

InactiveCN102278139AEasy to useReduce pollutionMechanical machines/dredgersEarth drilling and miningFuel tankDiesel engine

The invention relates to a low and narrow multifunctional explosion-proof diesel scraper, the main structure of which consists of a bucket, a front frame, a rear frame, a splicing mechanism, a loading and unloading mechanism, a cab, an explosion-proof diesel engine, a gearbox, a radiator, Composed of diesel tank, hydraulic oil tank, exhaust gas treatment tank, front wheels, rear wheels, front axle, and rear axle; it is designed for the actual situation of narrow and low coal mine underground roadways. It uses explosion-proof diesel engines as power, and the loading and unloading mechanism uses connecting rods. The structure adopts single lifting oil cylinder + tilting oil cylinder, and the loading and unloading is faster. The splicing mechanism adopts fixed splicing + floating splicing, which makes the splicing safer and more reliable. Quickly change a variety of accessories to meet various transportation needs. The height of the vehicle is 1.75 meters, the width is 1.6 meters, and the load is 4t. It is suitable for handling various small equipment, tools and materials. This design is advanced and reasonable, compact in structure, safe and stable. Reliable, easy to operate and use, it is an ideal low and narrow multi-purpose scraper.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

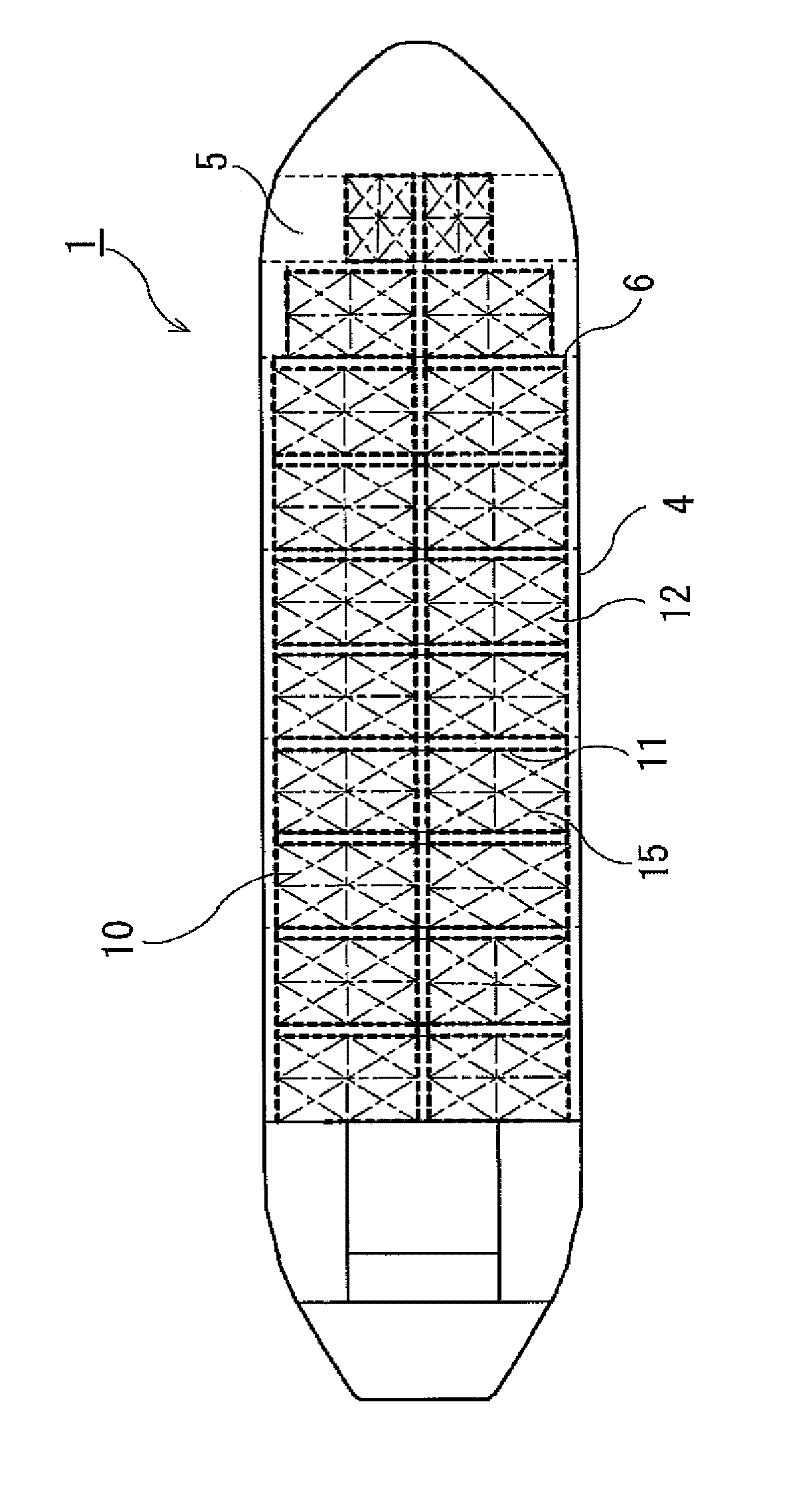

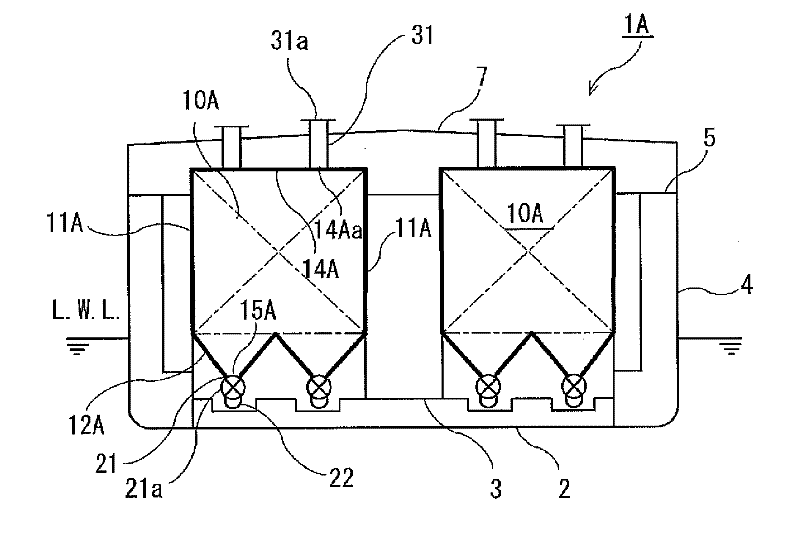

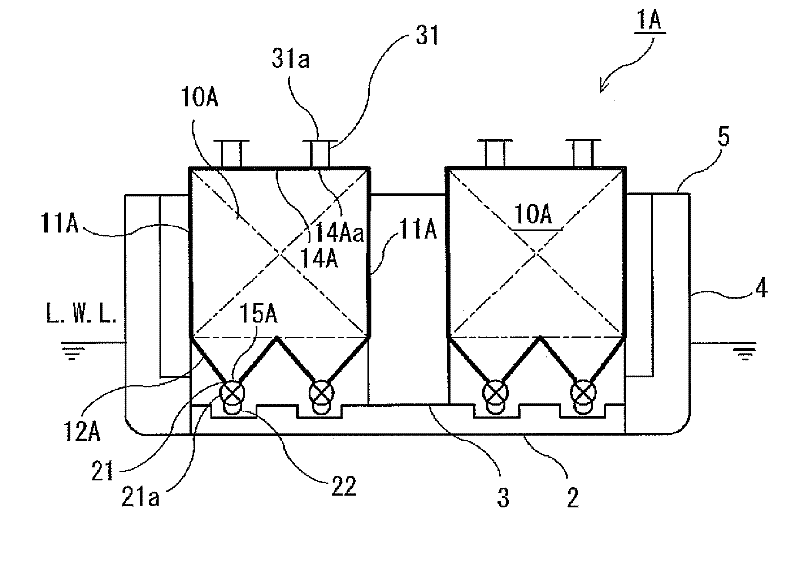

Water-borne transportation method for polymer pellets

InactiveCN102596704AEfficient loading and unloadingAvoid damageCargo handling apparatusPassenger handling apparatusEngineeringMoisture

Provided is a water-borne transportation method for polymer pellets whereby it is possible to efficiently transport polymer pellets powder particles for which damage, contamination, or moisture is unfavorable. Polymer pellets (B) are transported over water by being stowed in bulk in a cargo hold of a ship (1 or 1A) or a barge. Furthermore, for the purpose of preventing the surfaces of the polymer pellets (B) from being damaged by colliding with support members in the cargo hold, the polymer pellets (B) are transported by being stowed in bulk in a cargo hold (10 or 10A) wherein the walls with which the polymer pellets (B) are in contact are formed smoothly without being provided with support members protruding inside the cargo hold (10 or 10A).

Owner:MITSUI ENG & SHIPBUILD CO LTD +1

Muzzleloader systems

ActiveUS20180321022A1Efficient loading and unloadingEasy loadingAmmunition projectilesTraining ammunitionEngineeringMechanical engineering

Muzzleloader systems include a pre-packaged propellant charge and primer for providing efficient loading and unloading of the muzzleloader. The muzzleloader accepts in the breech end the propellant containment vessel that abuts against a constriction portion with a reduced diameter portion. The propellant containment vessel having an end portion with a tapered surface that conforms to the constriction portion surface. A projectile is inserted in the muzzle end and seats against the constriction portion. The propellant containment vessel may be received in a removable breech plug. The constriction portion may be part of the breech plug or a separate component secured in the barrel by way of the breech plug. The containment vessel further comprises a primer mechanism that may be integrated into the proximal end of the containment vessel.

Owner:FEDERAL CARTRIDGE

Muzzleloader systems

ActiveUS20170307347A1Efficient loading and unloadingFacilitate loading powderAmmunition projectilesTraining ammunitionEngineeringMechanical engineering

Muzzleloader systems include a pre-packaged propellant charge and primer for providing efficient loading and unloading of the muzzleloader. The muzzleloader accepts in the breech end the propellant containment vessel that abuts against a constriction portion with a reduced diameter portion. The propellant containment vessel having an end portion with a tapered surface that conforms to the constriction portion surface. A projectile is inserted in the muzzle end and seats against the constriction portion. The propellant containment vessel may be received in a removable breech plug. The constriction portion may be part of the breech plug or a separate component secured in the barrel by way of the breech plug. The containment vessel further comprises a primer mechanism that may be integrated into the proximal end of the containment vessel.

Owner:FEDERAL CARTRIDGE

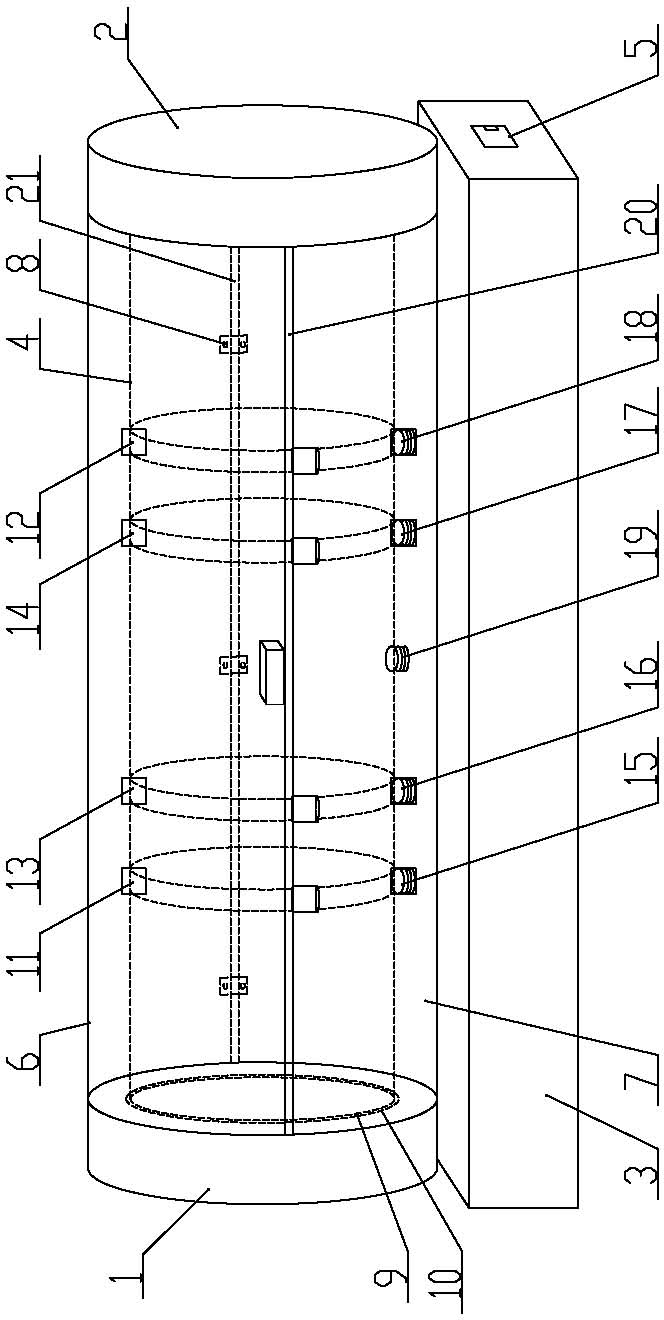

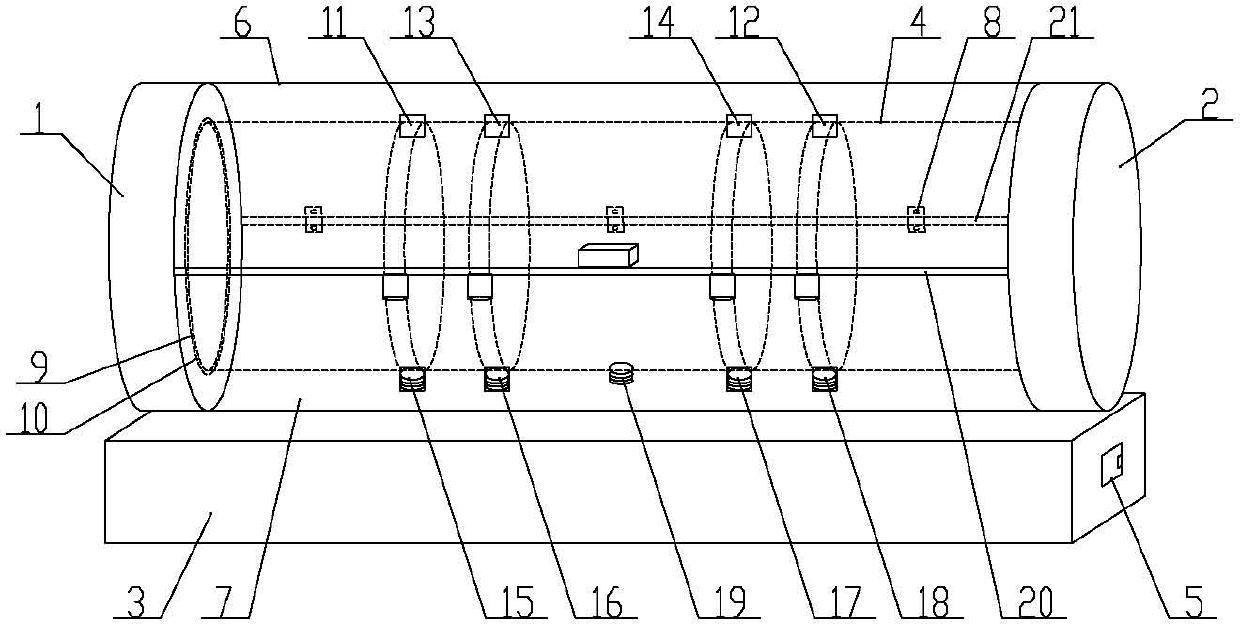

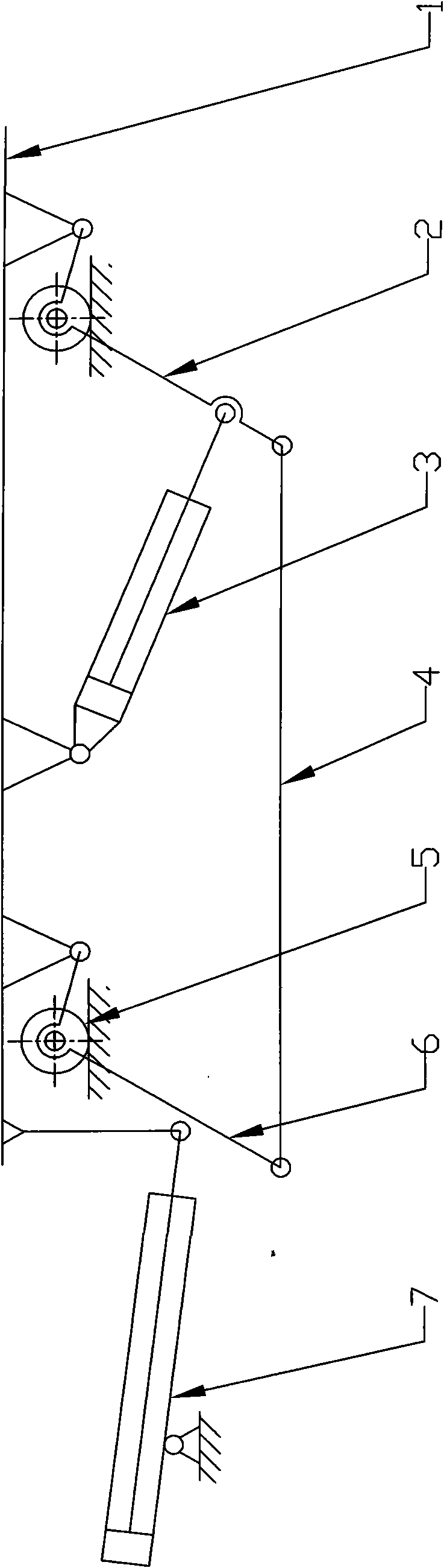

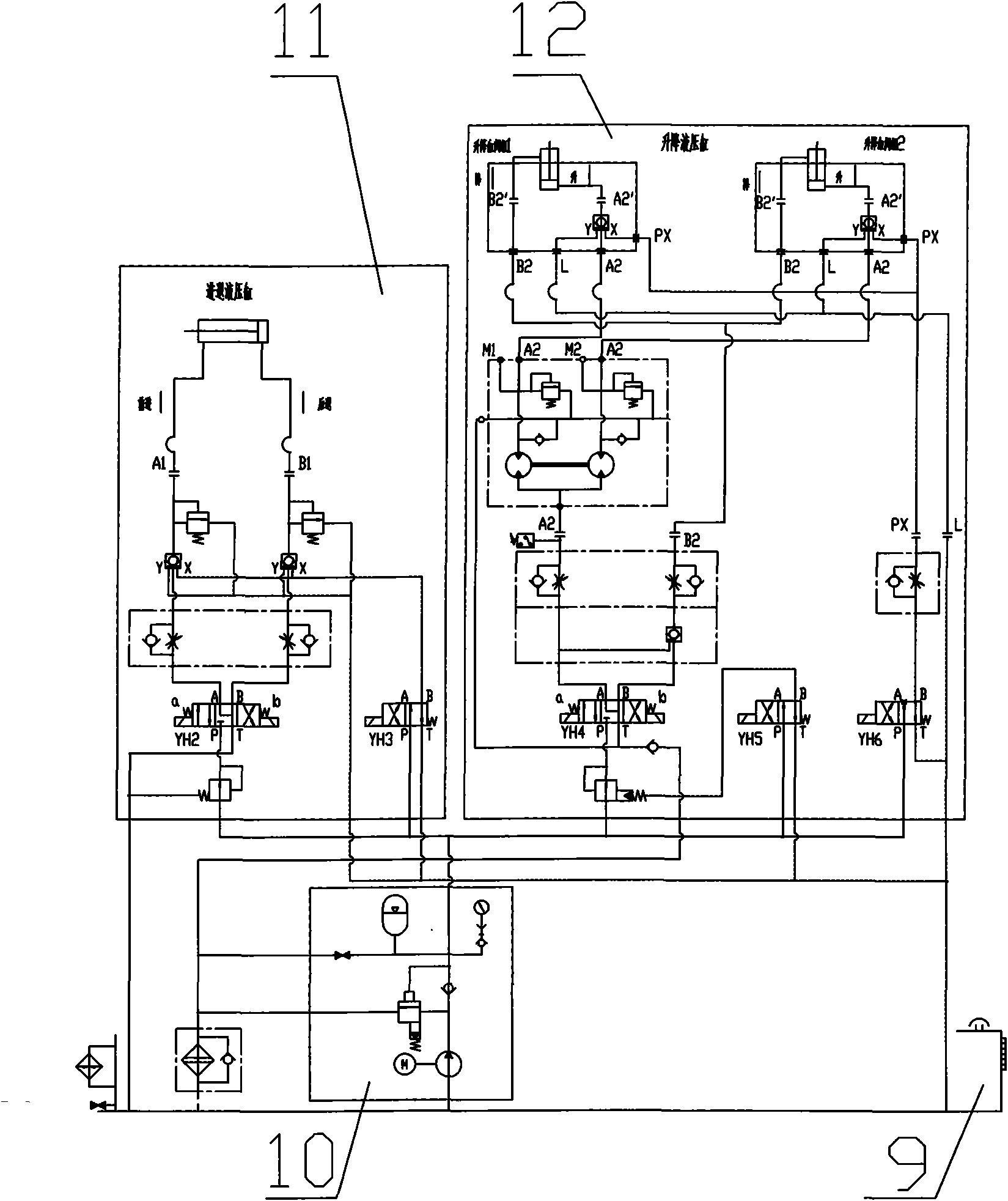

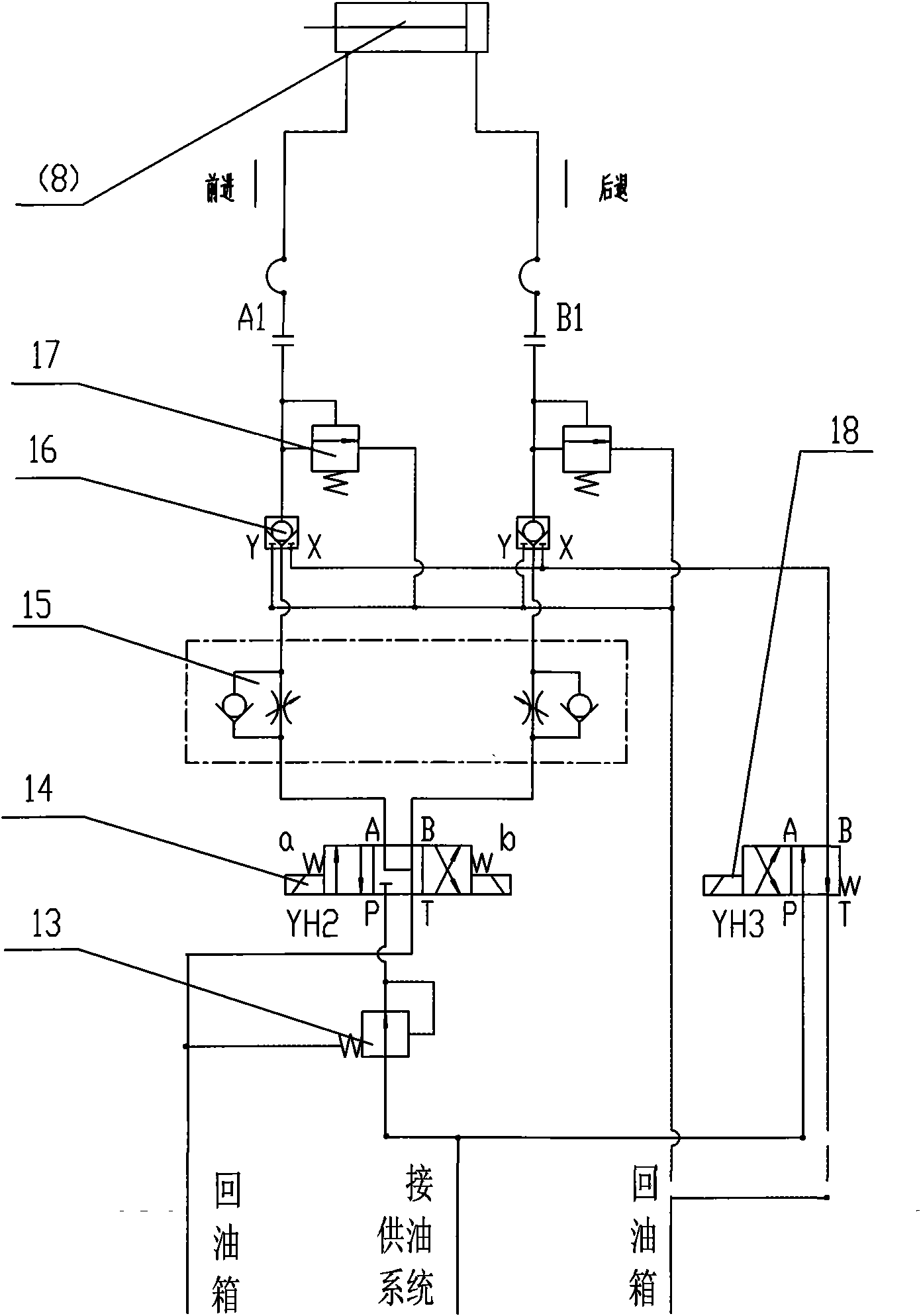

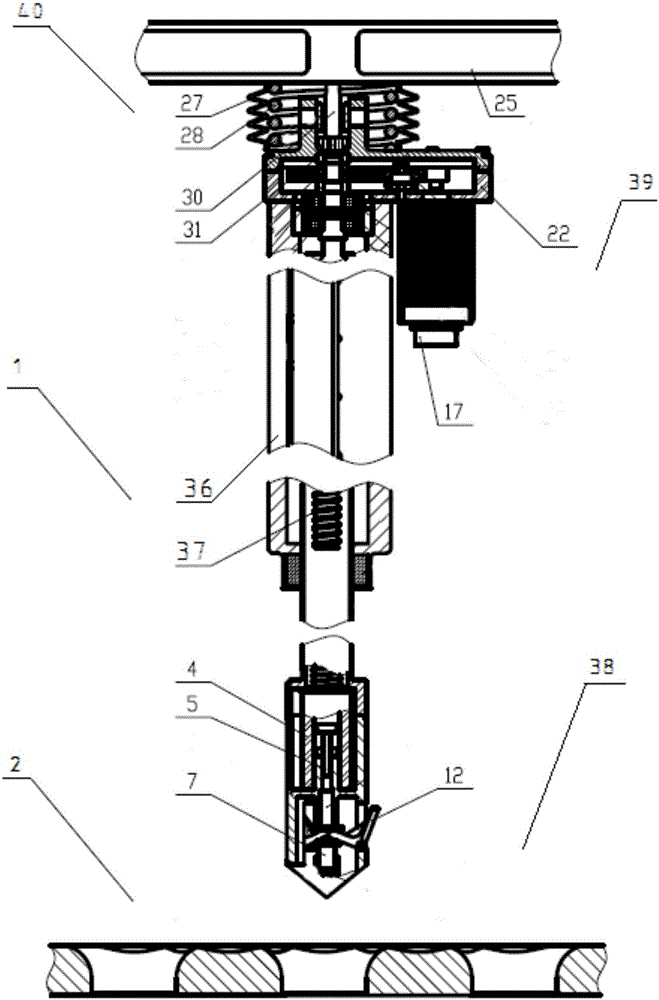

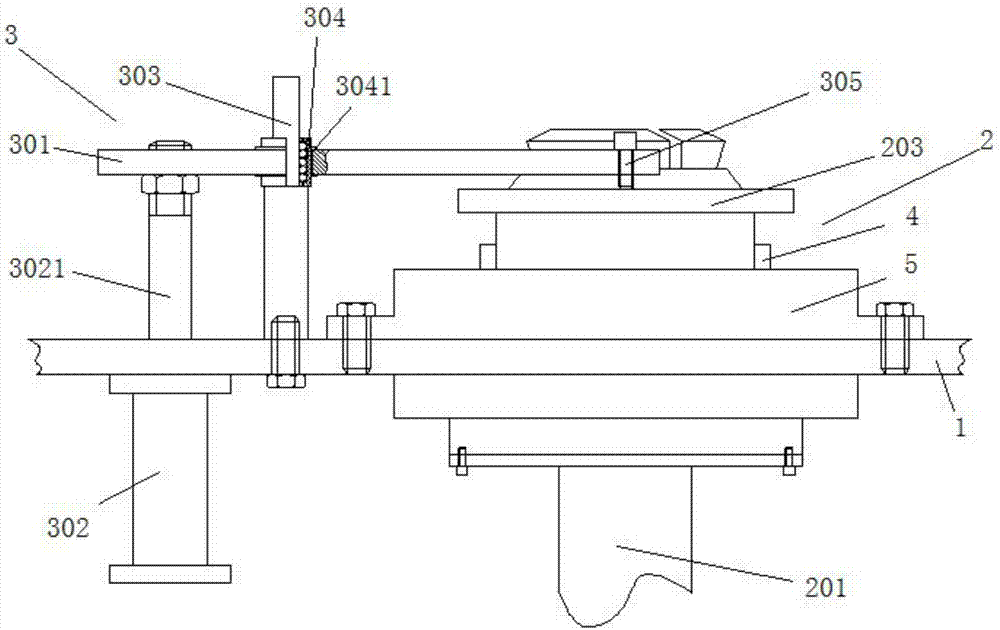

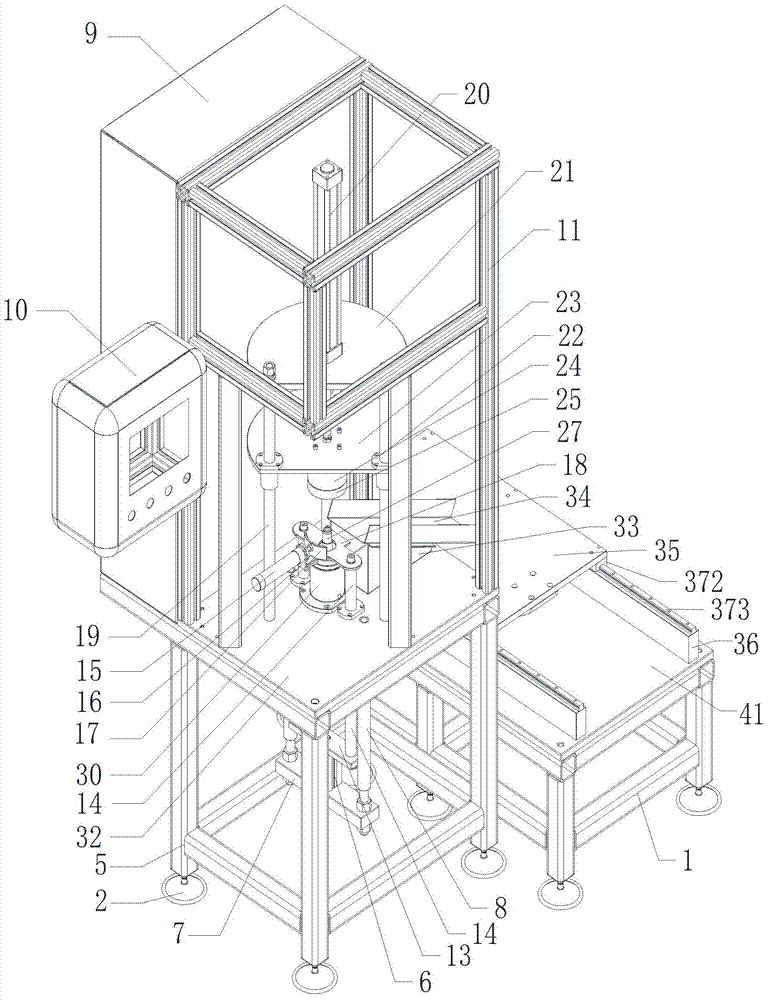

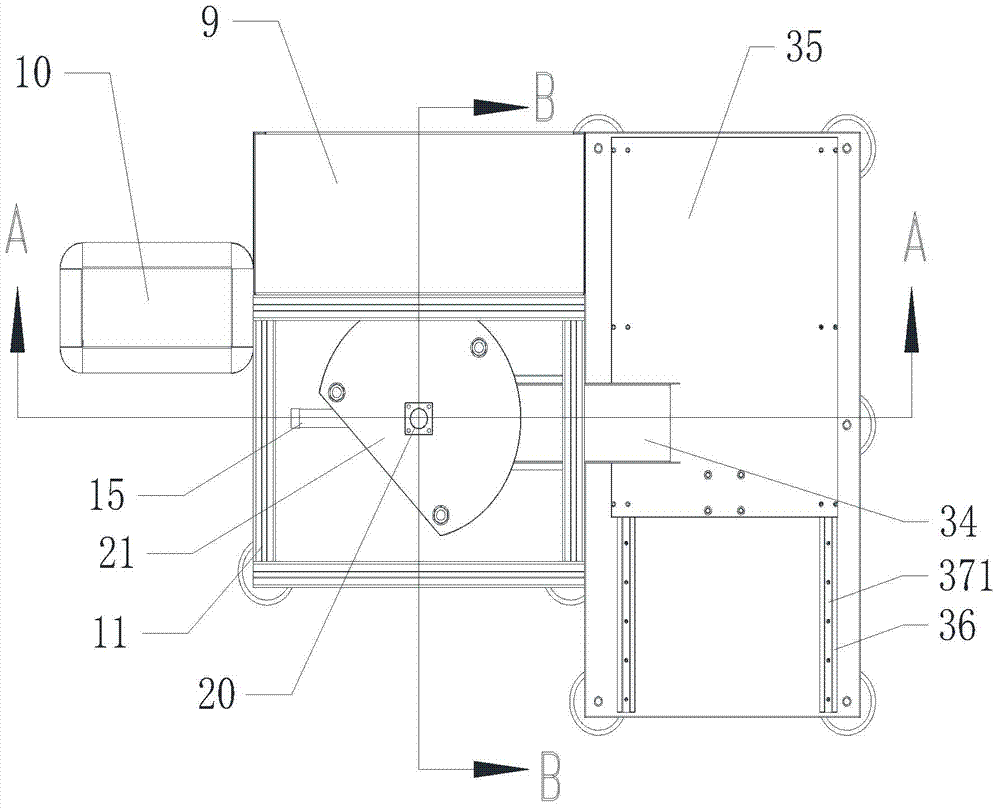

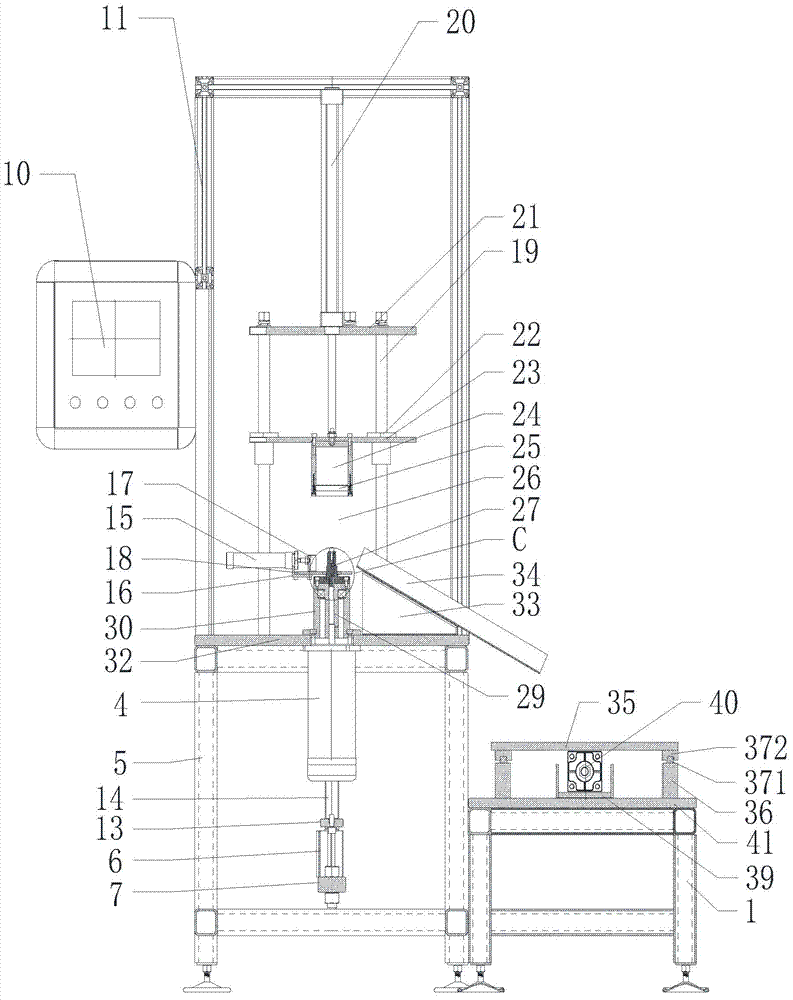

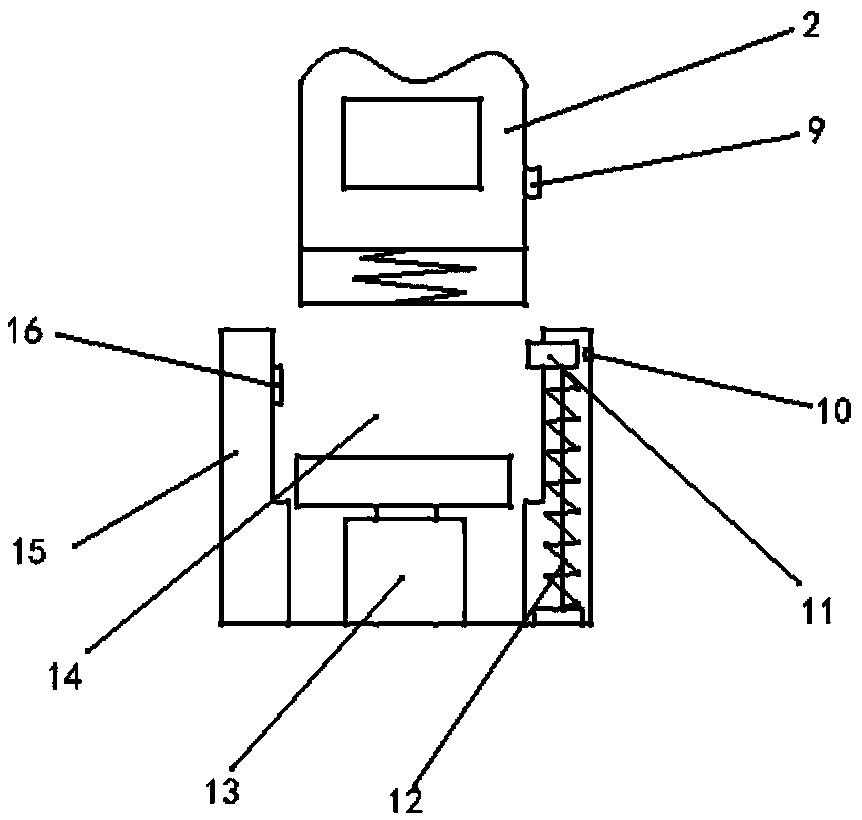

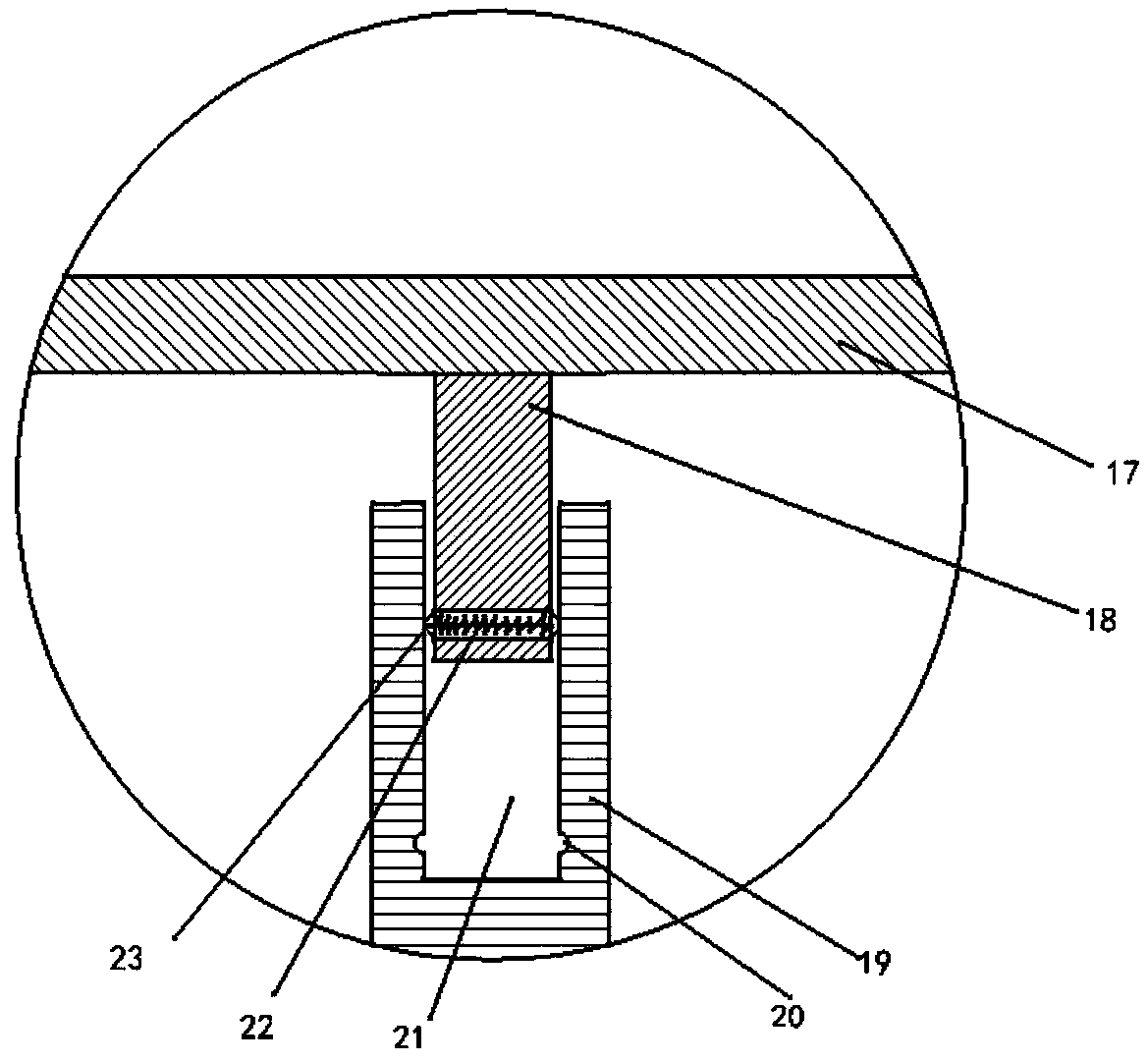

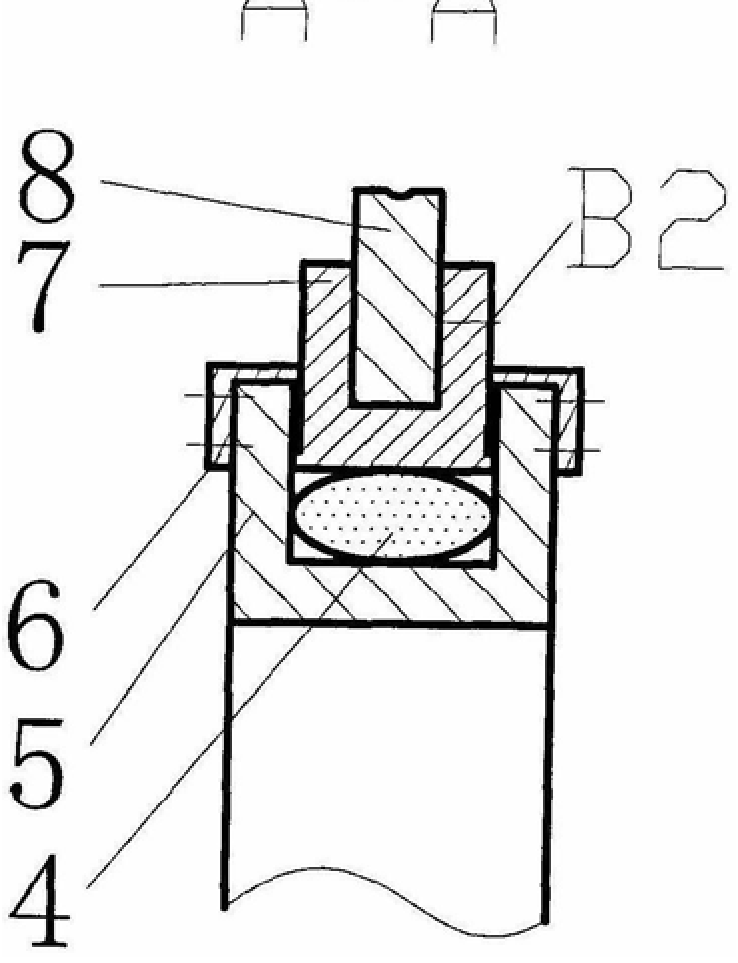

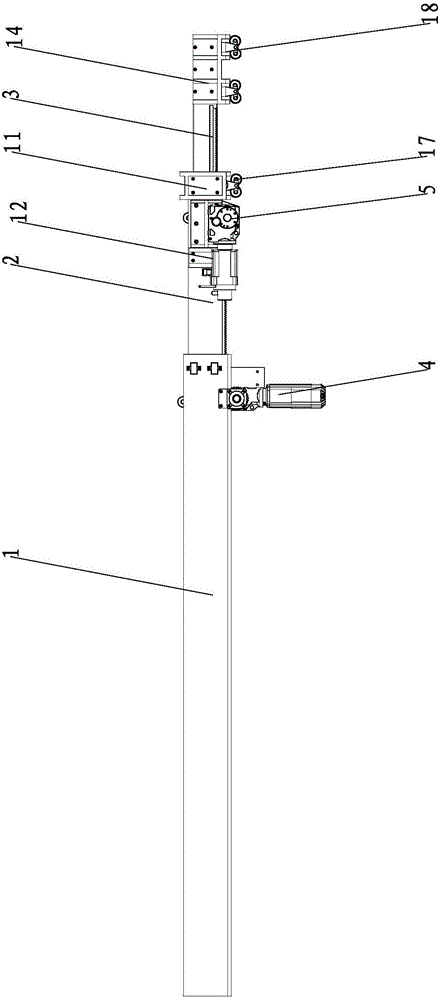

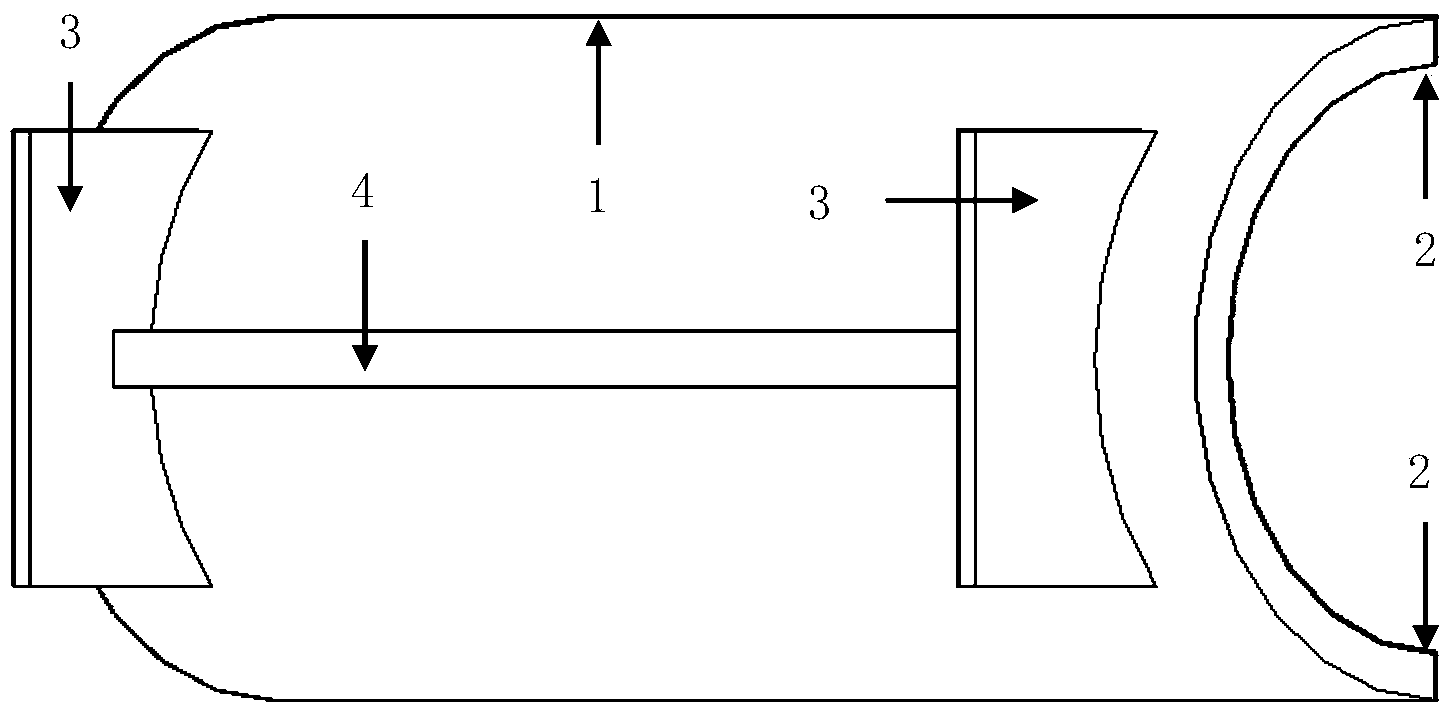

Assembly and disassembly device and method of weight balancing arm for testing wind power pitch bearing

InactiveCN102313647AEfficient loading and unloadingLoading and unloading safetyMachine bearings testingServomotor componentsHydraulic cylinderControl system

The invention discloses an assembly and disassembly device and an assembly and disassembly method of a weight balancing arm for testing a wind power pitch bearing. The device comprises a weight balancing arm assembling and disassembling device and a hydraulic control system, wherein a travelling wheel I and a travelling II are arranged on a fixed rail; a driving arm is arranged on a shaft of the travelling wheel I; a swing arm is arranged on a shaft of the travelling wheel II; a parallelogram mechanism is formed by a pull rod and a base; a lifting hydraulic cylinder is arranged between the base and the driving arm; an advancing and retreating hydraulic cylinder is arranged on a fixed support on a foundation through a lug shaft, and the head part of the advancing and retreating hydraulic cylinder is connected with the base; the hydraulic control system consists of an oil tank component, an oil supply system, an advancing and retreating oil cylinder hydraulic system and a lifting oil cylinder hydraulic system; the advancing and retreating oil cylinder hydraulic system is used for controlling the weight balancing arm to advance and retreat and making the assembly and disassembly device floated; and the lifting oil cylinder hydraulic system is used for controlling the assembly and disassembly device of the weight balancing arm to ascend and descend and keeping pressure, so that the synchronous action of the two hydraulic cylinders is ensured, and low pressure and system pressure in the lifting process can be switched for two times. The device and the method have the advantages of efficient, safe and automatic weight balancing arm assembling and disassembling processes.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

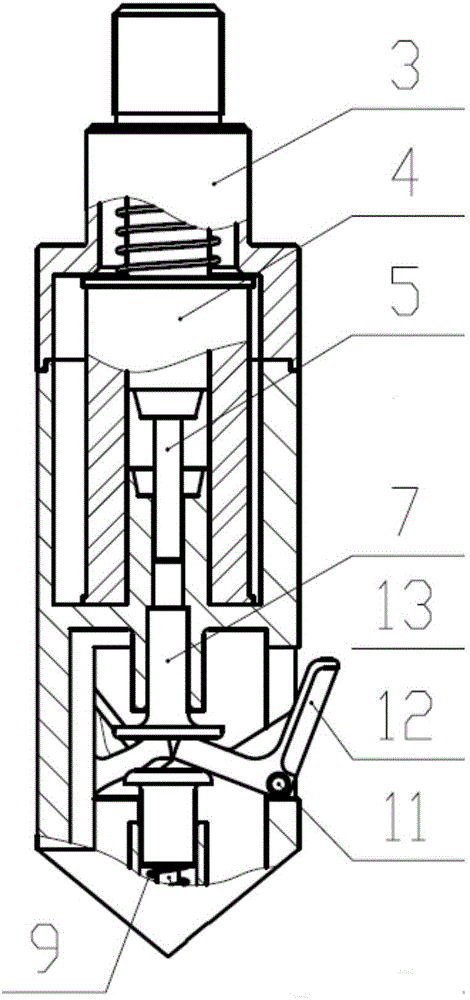

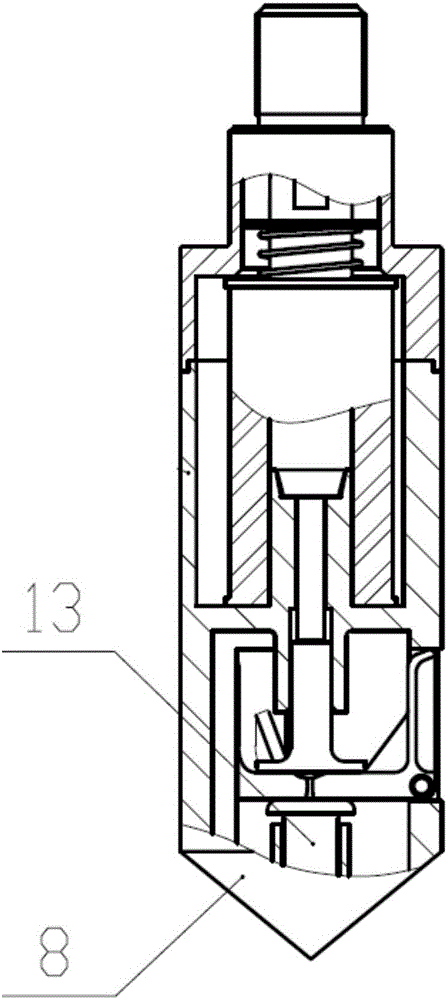

Ship-borne unmanned helicopter harpoon system

ActiveCN106184799AReduce stressReduce Angular UncertaintyGround installationsLow noiseSystems design

The invention discloses a ship-borne unmanned helicopter harpoon system, comprising a harpoon controller, an anchoring fork, a retraction actuating cylinder and a body connecting device, wherein the retraction actuating cylinder is mounted at the bottom of an unmanned helicopter through the body connecting device, the anchoring fork is connected with the bottom end of the retraction actuating cylinder, and the anchoring fork and the retraction actuating cylinder are driven and controlled by the harpoon controller. The ship-borne unmanned helicopter harpoon system has the advantages of simple structure, light weight, obvious locking effect and easy loading and unloading on the helicopter or on a deck; in comparison to pneumatic drive and hydraulic drive, the system designed by the invention needs not additionally matched weight-increasing devices such as a pneumatic supply and a hydraulic system in the body, and a driving power supply can directly use an on-board power supply, thereby greatly reducing the total weight; and the ship-borne unmanned helicopter harpoon system has the advantages of high precision, high environmental protection level, low noise and the like.

Owner:NO 60 RES INST OF GENERAL STAFF DEPT PLA

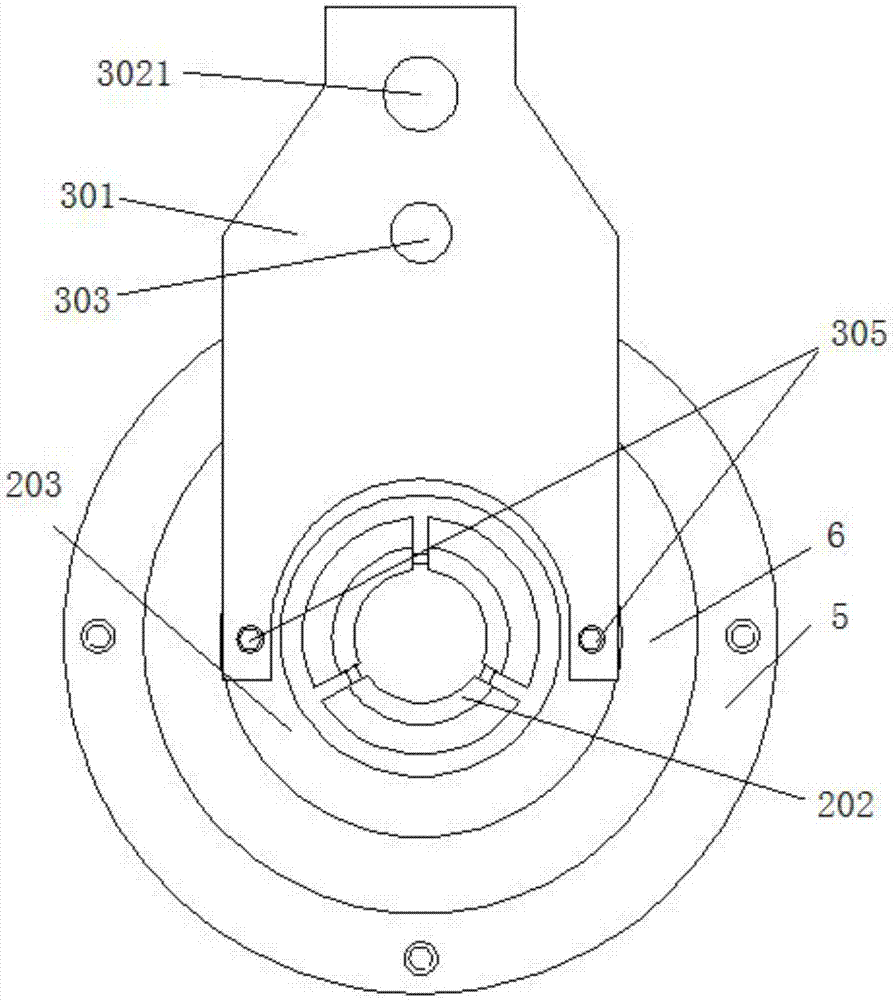

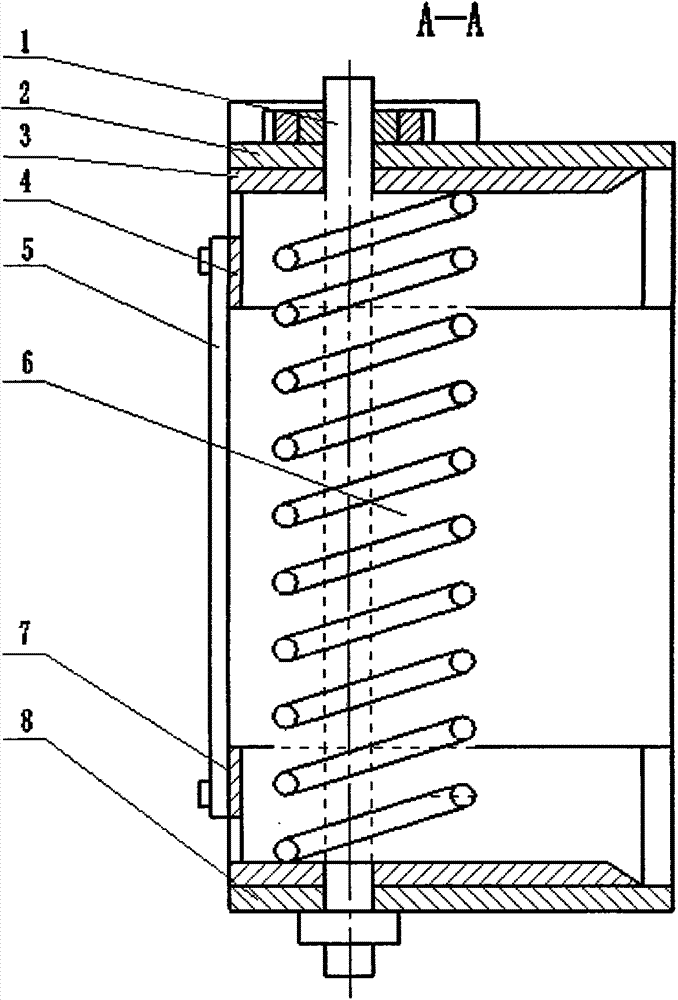

Capacitor aluminum casing clamping rotating device

ActiveCN107331540ASmooth rotationEfficient loading and unloadingThin/thick film capacitorStacked capacitorsMovement controlAluminium

The invention provides a capacitor aluminum casing clamping rotating device which comprises a workbench. A rotary clamping mechanism is arranged in the workbench. A pressure applying mechanism is arranged outside the rotary clamping mechanism. The pressure applying mechanism controls clamping and releasing of the rotary clamping mechanism through the movement of a cylinder. According to the invention, a workpiece rotation mode is adopted; a girdling or sealing device can finish aluminum casing girdling and sealing processing by moving close to a workpiece along a straight line track; the workpiece clamping rotation is stable; and the workpiece is efficiently loaded and unloaded from a rotating body.

Owner:TONGLING CITY START ELECTRONICS MFG

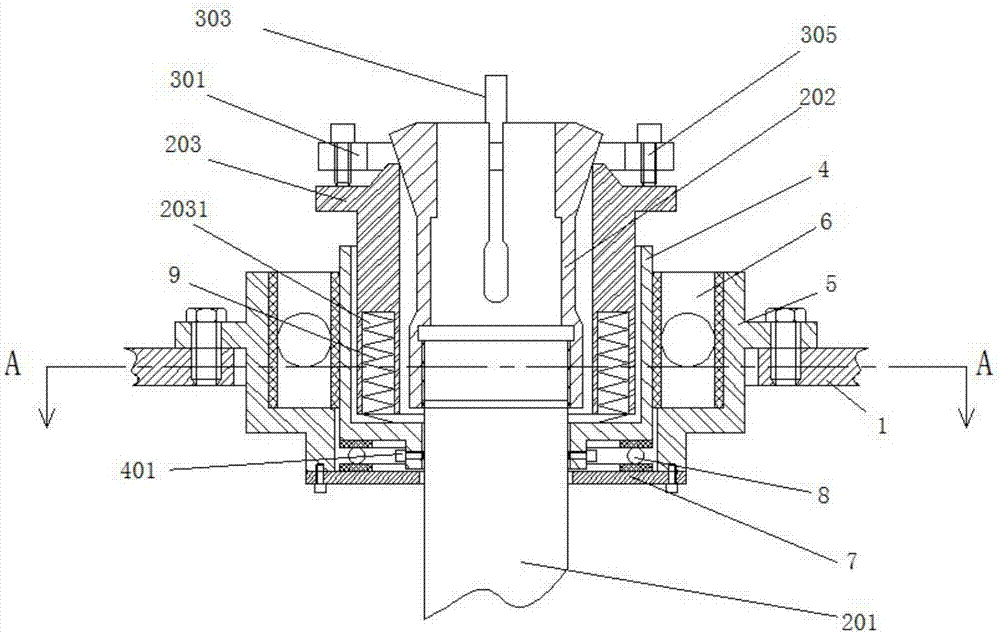

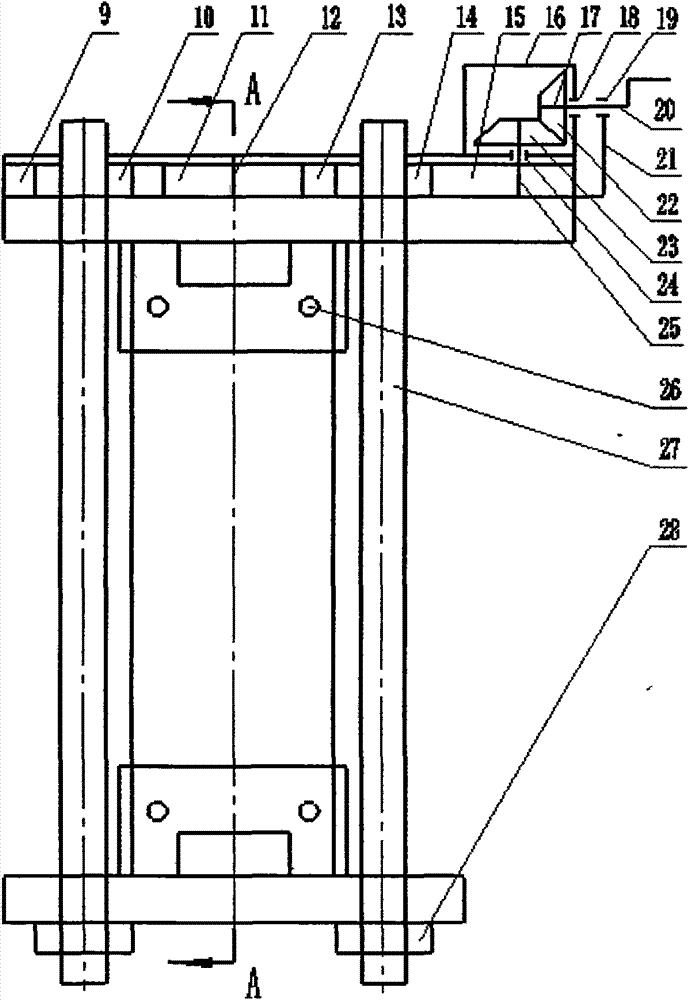

Automatic detecting instrument for retaining ring check ring of constant velocity universal joint three-pivot shaft

ActiveCN103940603AImprove efficiencyReduce labor intensityMachine part testingElectricityUniversal joint

The invention provides an automatic detecting instrument for a retaining ring check ring of a constant velocity universal joint three-pivot shaft. The automatic detecting instrument comprises a machine rack, wherein a workpiece installing mandrel for installing a workpiece and a driving mechanism I for driving the workpiece installing mandrel to rotate axially and connected with the workpiece installing mandrel are arranged on the machine frame, wherein the workpiece installing mandrel is provided with a positioning structure for positioning the workpiece, a sensor assembly is arranged above the workpiece installing mandrel and provided with an annular portion and a sensor, and the sensor is located on the inner wall of the annular portion. A driving mechanism II for driving the sensor assembly to be vertically lifted so as to close to or away from the workpiece installing mandrel is arranged on the machine rack, and the workpiece on the workpiece installing mandrel finally extends into the annular portion of the sensor assembly in the process that the sensor assembly is close to the workpiece installing mandrel. An electrical control system is arranged on the machine rack, the driving mechanism I and the driving mechanism II are electrically connected with the electrical control system, and the sensor is in electrical or signal connection with the electrical control system.

Owner:ZHEJIANG ODM TRANSMISSION TECH

Barbell Safety Device

InactiveUS20150157894A1Safe removalSafely securedMuscle exercising devicesEngineeringBiomedical engineering

Owner:FISHMAN JAI WEI

Multifunctional refrigerating carrier vehicle with lifting arm

ActiveCN109572527AEfficient loading and unloadingIncrease the use of functionsVehicles with cranesRefrigerated goods vehicleTowerTruck

The invention discloses a multifunctional refrigerating carrier vehicle with a lifting arm. The multifunctional refrigerating carrier vehicle comprises a tractor car, a box body and a mechanical arm,wherein the tractor car and the mechanical arm are positioned in front of a truck bed; the mechanical arm is positioned between the truck bed and the tractor car; the truck bed is connected to the tail end of the tractor car; the mechanical arm is mounted on the tractor car; and the mechanical arm is equipped with the lifting arm, a balance arm, a tower cap, upper and lower supporting bases, a tower body and a pedestal. The mechanical arm is additionally arranged on the refrigerating carrier vehicle, so that goods is conveniently, quickly and efficiently loaded and unload, vehicles and workersfor loading and unloading do not need to use, and time and labor cost for loading and unloading is reduced. A using function of the carrier vehicle is increased, so that the multifunctional refrigerating carrier vehicle further can be used as a relief vehicle when other vehicles have small accidents.

Owner:NANNING UNIV

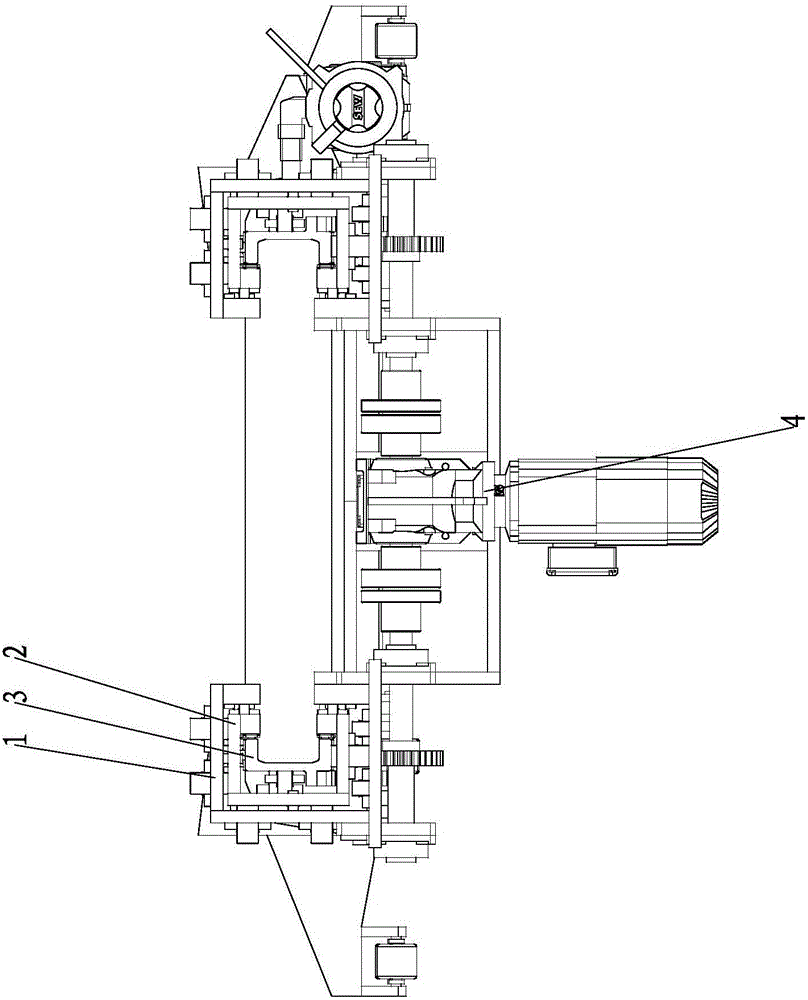

Large-sized pressure spring loading and unloading machine

InactiveCN104511742AAxial positioning is accurateImprove wear resistanceMetal working apparatusGear wheelWear resistant

The invention discloses a large-sized pressure spring loading and unloading machine. A left lead screw cylinder shaft is connected with an upper spring fixing seat, a lower spring fixing seat, a left lead screw nut and a nut; a right lead screw cylinder shaft is connected with the upper spring fixing seat, the lower spring fixing seat, a right lead screw nut and a nut; the upper spring fixing seat and the lower spring fixing seat are provided with a wear-resistant lining; an upper spring pushing support plate is connected with the wear-resistant lining and the upper spring fixing seat; a lower spring pushing support plate is connected with the wear-resistant lining and the lower spring fixing seat; a left lead screw gear is connected with the upper spring fixing seat and the left lead screw nut and is engaged with a middle gear; a right lead screw gear is connected with the right lead screw nut and is engaged with a driving gear. The driving bevel gear is engaged with a driven bevel gear. A spring pulling plate is connected with the upper spring pushing support plate and the lower spring pushing support plate; a gearbox casing is connected with the upper spring fixing seat.

Owner:王荣

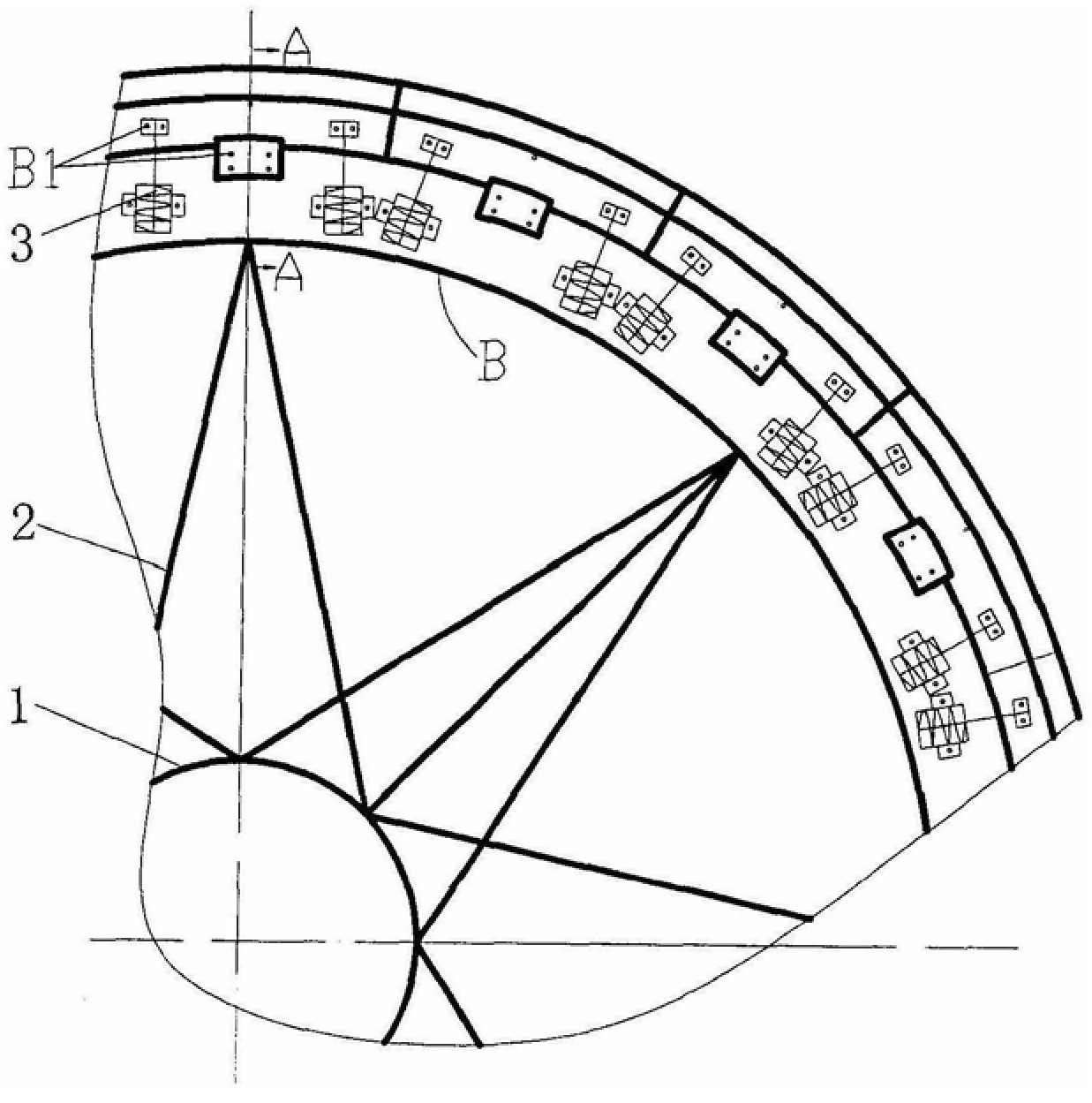

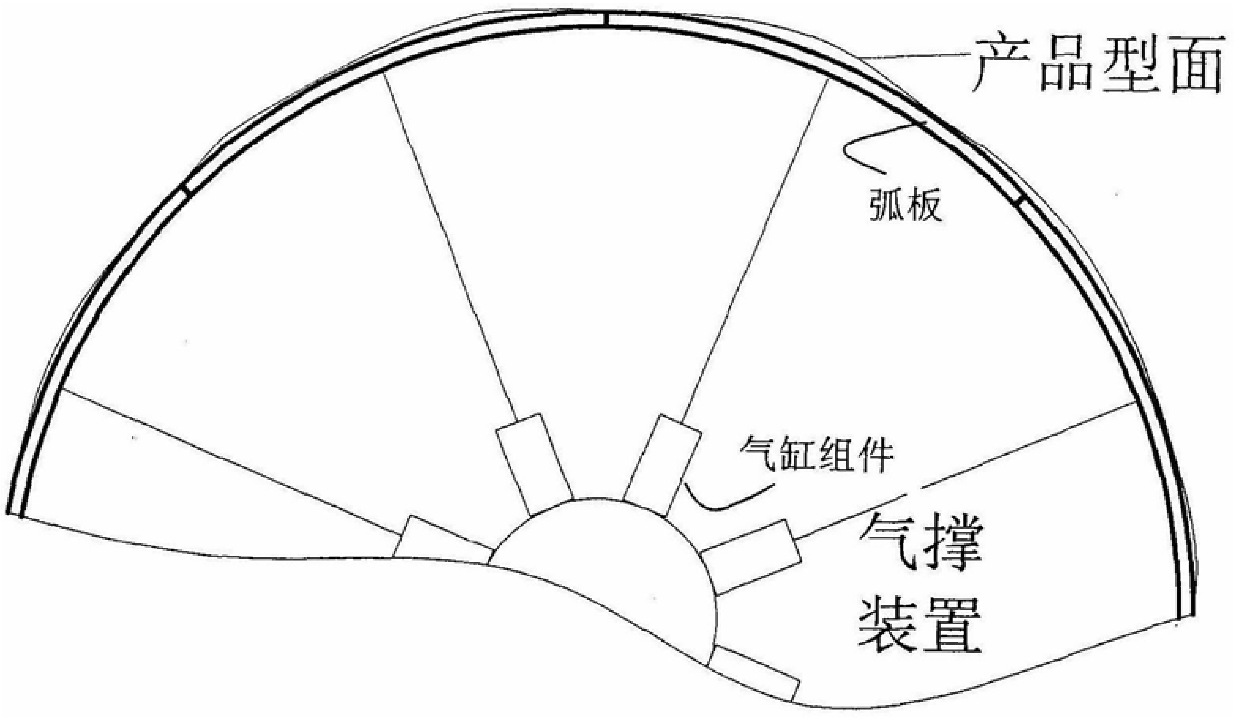

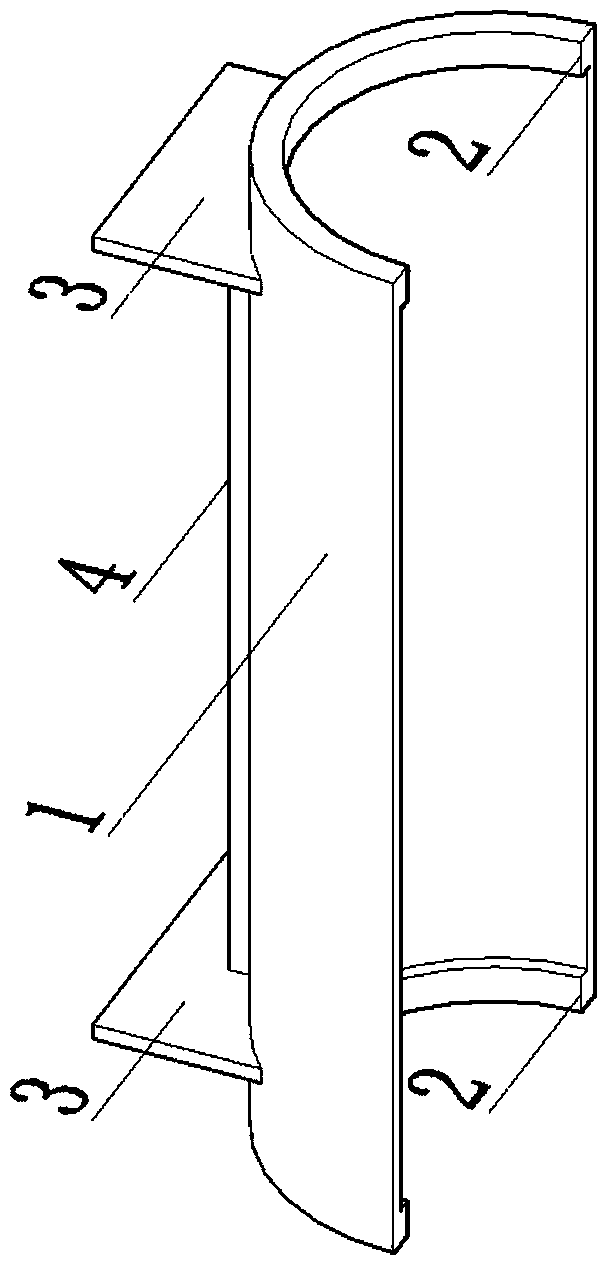

Circumferential seam welding support device for arrow body barrel section of launch vehicle

InactiveCN106342017BShorten the lengthIncrease the number ofWelding/cutting auxillary devicesArc welding apparatusRocketLaunch vehicle

The invention relates to rocket body manufacturing equipment for a launch vehicle, and discloses a support device for welding the circular seam of the rocket body barrel section of a launch vehicle, comprising a plurality of auxiliary supports [2] radially arranged around an inner frame [1] , the outer end of the auxiliary support [2] is provided with an integral frame [5] and an arc-shaped support plate [7] in turn, and an integral airbag [4] is provided at the internal connection of the two, and the position is limited by the limit block [6]; Welding breakout plate [8] is embedded in the outer end of arc brace plate [7]. The invention achieves the beneficial effects of effectively, uniformly, neatly and quickly stretching apart the workpiece to be welded, and good bonding.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Welding line for automotive chassis parts

InactiveCN106736068AEfficient loading and unloadingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringChassis

The invention aims to provide a welding line for automotive chassis parts. The welding line comprises a long-strip-shaped annular conveying line performing clockwise conveying, wherein at least three welding benches located in the same straight line are horizontally distributed on each of the front side and the rear side of the annular conveying line; transfer tools are conveyed on the annular conveying line; a discharge plate is arranged in the position, close to each welding bench, of the annular conveying line; a feed plate is arranged on the right side of each welding bench; the sides, far from the annular conveying line, of the feed plates on the right sides of the working benches on the same side are jointly connected with a discharge conveying line; right sides of the two discharge conveying lines are jointly connected with a collecting plate. To-be-welded workpieces are conveyed by the annular conveying line, the discharge plates are arranged to allow workers on the welding benches to perform discharge, workpieces after welding are conveyed to the discharge conveying lines through the feed plates and finally conveyed to the collecting plate for centralized collection, internal pushing cylinders are arranged for assisting collection, and welded workpieces can be fed and discharged efficiently and rapidly.

Owner:WUHU POWER TECH

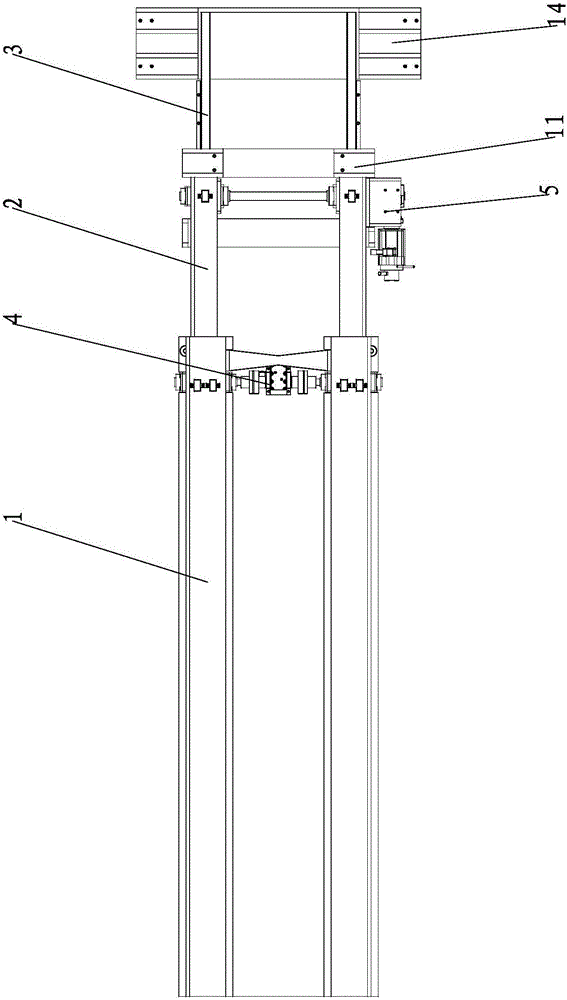

Self telescopic sleeve type load bearing rail

ActiveCN105731104AEasy to processEasy to disassemble and carryLifting devicesLoading/unloadingAutomatic gain controlAutomation

The invention relates to a load bearing rail, in particular to a self telescopic sleeve type load bearing rail, and belongs to the technical field of robot rail equipment. The self telescopic sleeve type load bearing rail comprises a primary rail assembly, a secondary rail assembly, a tertiary rail assembly, a secondary rail driving assembly and a tertiary rail driving assembly, wherein the secondary rail driving assembly is arranged on a secondary rail driving assembly installing frame; the inner side of the primary rail assembly is glidingly connected with the secondary rail assembly; the tertiary rail driving assembly is arranged between two secondary rails; the inner side of the secondary rail assembly is glidingly connected with the tertiary rail assembly. The self telescopic sleeve type load bearing rail is a load bearing rail for an automatic loading and unloading system; the engagement between a loading and unloading platform and a container is completed; the free shuttling of a forklift in the rail is realized, so that the container lorry loading and unloading automation is realized; the rail is applied to the field of automatic loading and unloading, and completely overturns the original AGC (automatic gain control) loading and unloading mode; the loading and unloading coordinate control is realized, so that the vehicle loading and unloading becomes simple, efficient and energy-saving.

Owner:朱红蔚

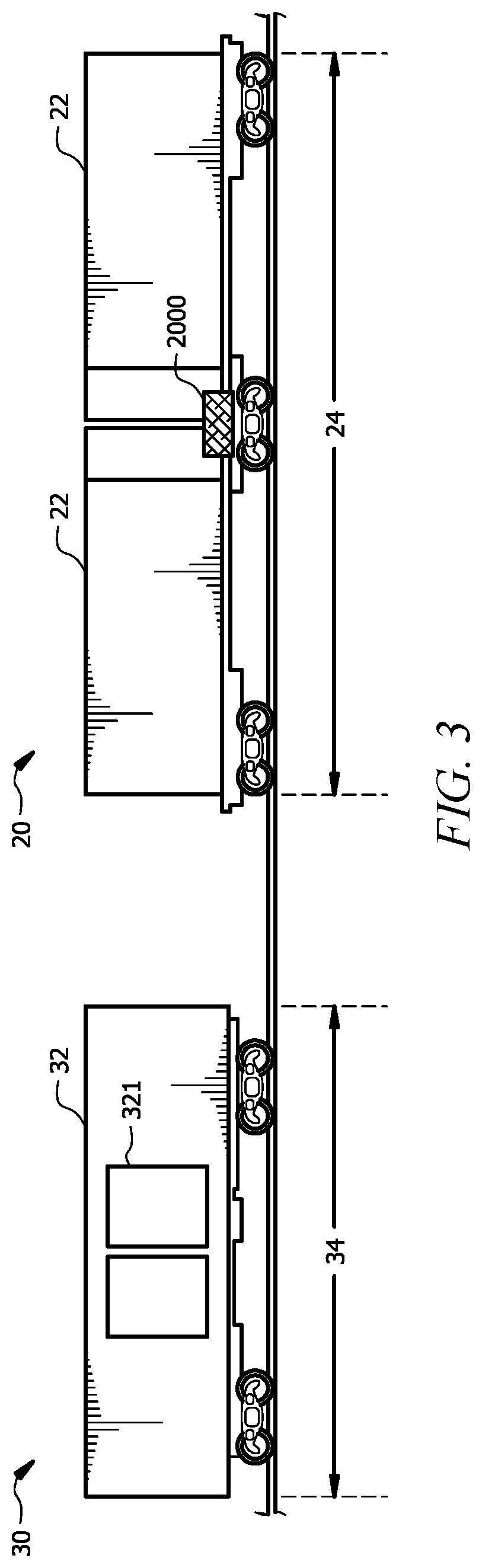

Multimodal Platform for Railcar

InactiveUS20200062281A1Improve efficiencyIncrease unloading optionFire rescueDoor arrangementMultimodal transportChassis

A multimodal platform is provided for a railcar. The multimodal platform includes a first underframe, a second underframe, a loading platform, and rail wheels. The first underframe carries a first container and the second underframe carries a second container. The second underframe is coupled to the first underframe and coupling the first underframe and the second underframe provides an articulation point. The loading platform is disposed above the articulation point and between a first end of the first container proximate the second container and a second end of the second container proximate the first container. The rail wheels are disposed under the loading platform and coupled to the first underframe and the second underframe. The rail wheels are configured to transport the multimodal platform on rails of a railway.

Owner:TRINITY RAIL GRP

Coiling block rubber sleeve assembling and disassembling tool and assembling and disassembling method

InactiveCN104339140AEasy loading and unloadingImprove loading and unloading efficiencyMetal working apparatusMetal-working hand toolsEngineering

The invention discloses a coiling block rubber sleeve assembling and disassembling tool and an assembling and disassembling method. The coiling block rubber sleeve assembling and disassembling tool comprises an arc-shaped tank body, wherein a rubber sleeve baffle ring for limiting the cross section of a rubber sleeve is arranged at at least one end of the tank body; a fixing mechanism for mounting and fixing the tank body is arranged at the bottom of the tank body. As the rubber sleeve is positioned inside the tank body and does not deform, the phenomenon that the rubber sleeve is blocked when being mounted is avoided; when being assembled and disassembled, the rubber sleeve is limited and stressed through the rubber sleeve baffle ring at one end of the tank body and is uniformly stressed in the axial direction, the assembling and dissembling operation on the rubber sleeve is simplified, and the rubber sleeve is prevented from being damaged when being assembled and disassembled; when the coiling block rubber sleeve assembling and disassembling tool cooperates with a steel coil trolley, a baffle and a positioning clamping plate are arranged at the bottom of the tank body so as to fix the tank body, so that the processing is easy, the operation is simple and rapid, and the manufacturing cost is low; when the rubber sleeve is disassembled by using the method disclosed by the invention, the possibility of blockage is low, the rubber sleeve assembling and disassembling efficiency is improved, the service life of the rubber sleeve is prolonged, and the production cost is lowered.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com