Water-borne transportation method for polymer pellets

A technology of polymer particles and conveying pipes, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of waste of packaging materials and poor efficiency, and achieve the effect of easy cleaning and improved operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

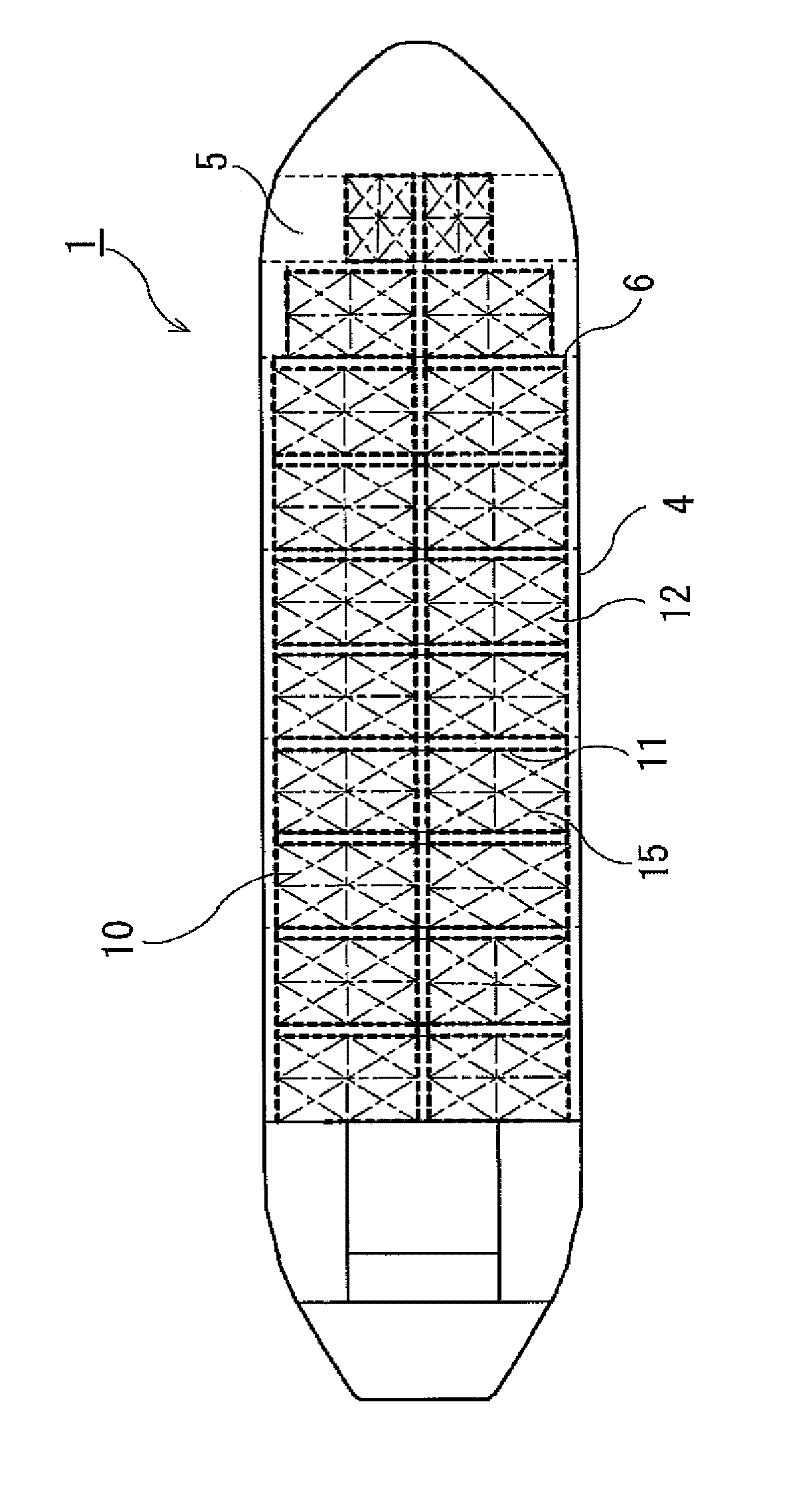

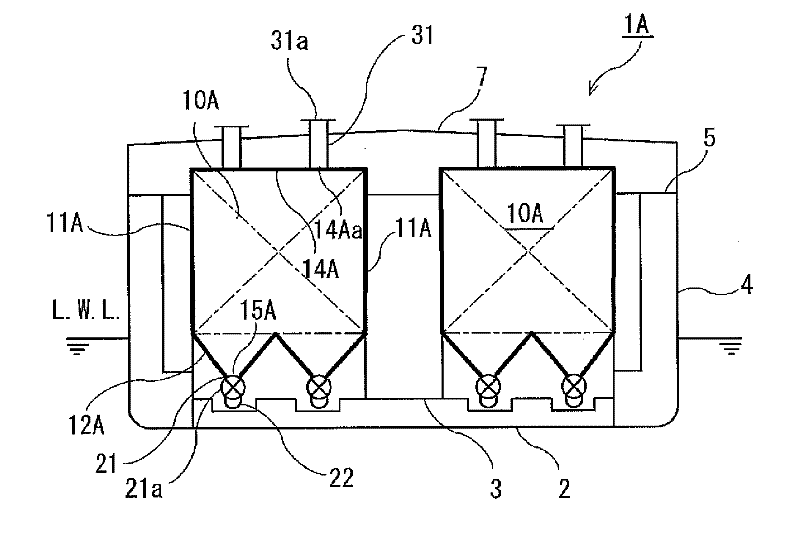

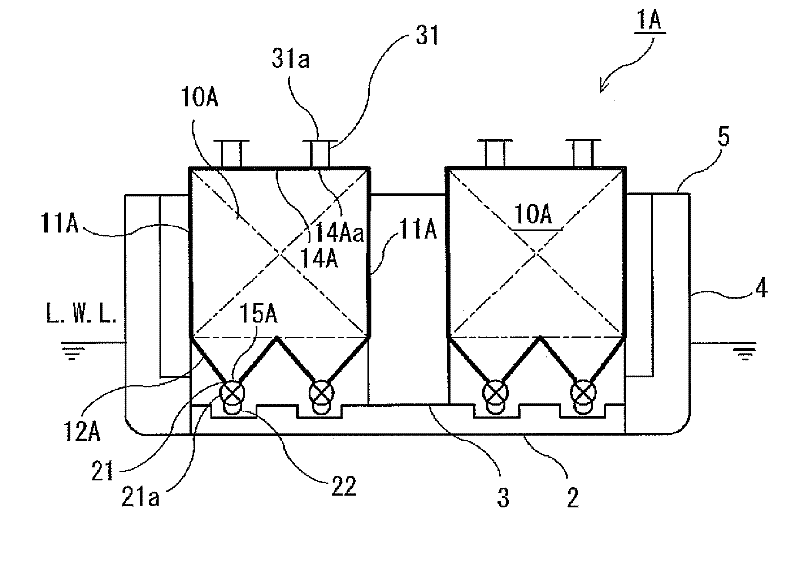

[0031] Hereinafter, the water transport method of the polymer particles according to the present invention will be described with reference to the drawings. In addition, although the bulk carrier which has a propulsion device is demonstrated here, this invention can be similarly employ|adopted also if the barge for bulk which does not have a propulsion device is used. In addition, the attached drawings are diagrams for explanation, and are not necessarily diagrams based on a ship type used in an actual ship and dimensions of a cargo warehouse. also, Figure 9 It is also a diagram used to illustrate the loading and unloading methods of goods. Figure 9 hull structure and Figure 1 to Figure 8 Compared with the hull structure, the hull structure is different in the shape of the cargo warehouse and the discharge port.

[0032] First, with regard to the bulk ship used in the water transportation method of polymer particles according to the embodiment of the present invention, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com