Patents

Literature

101results about How to "Efficient unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

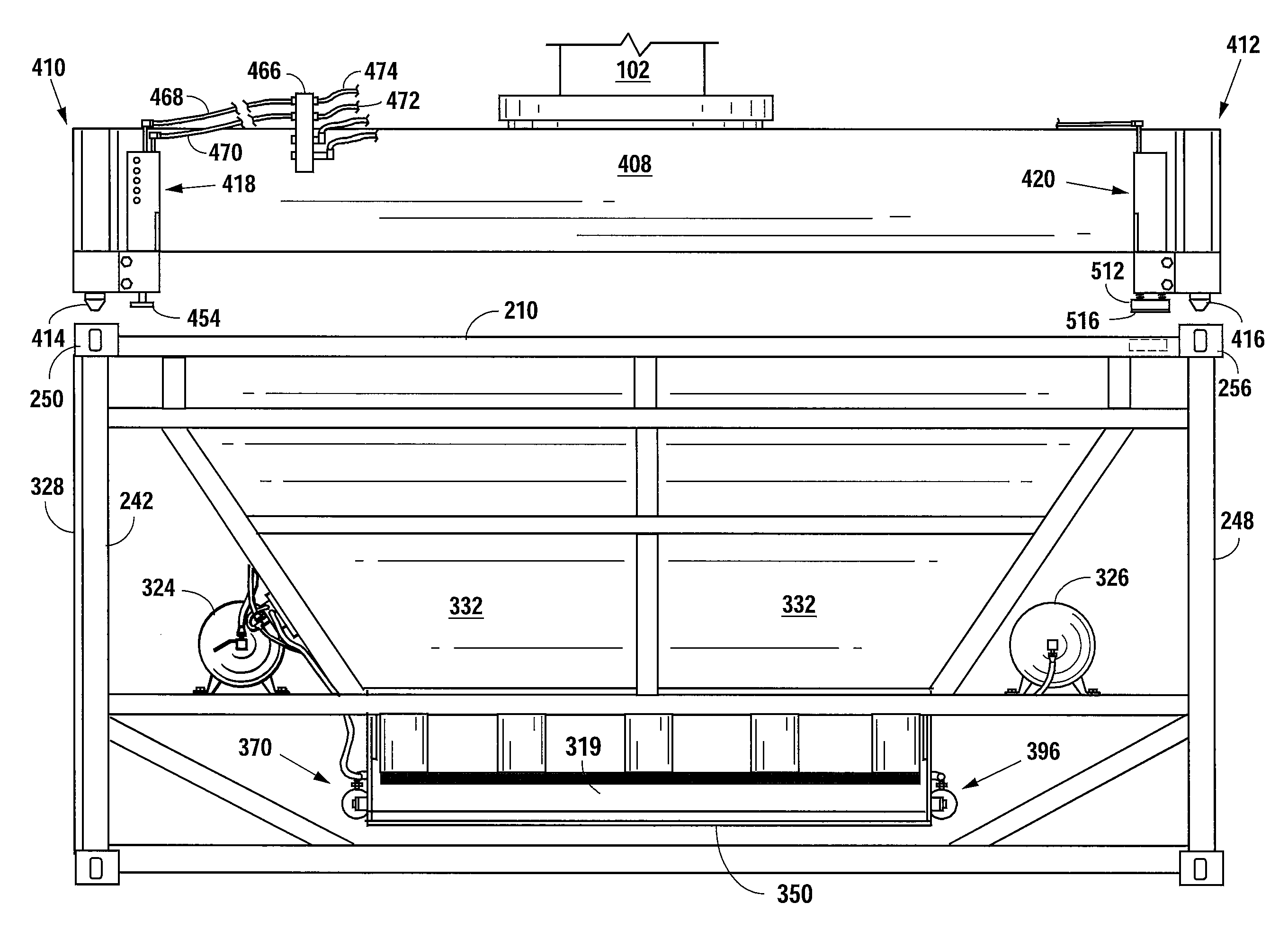

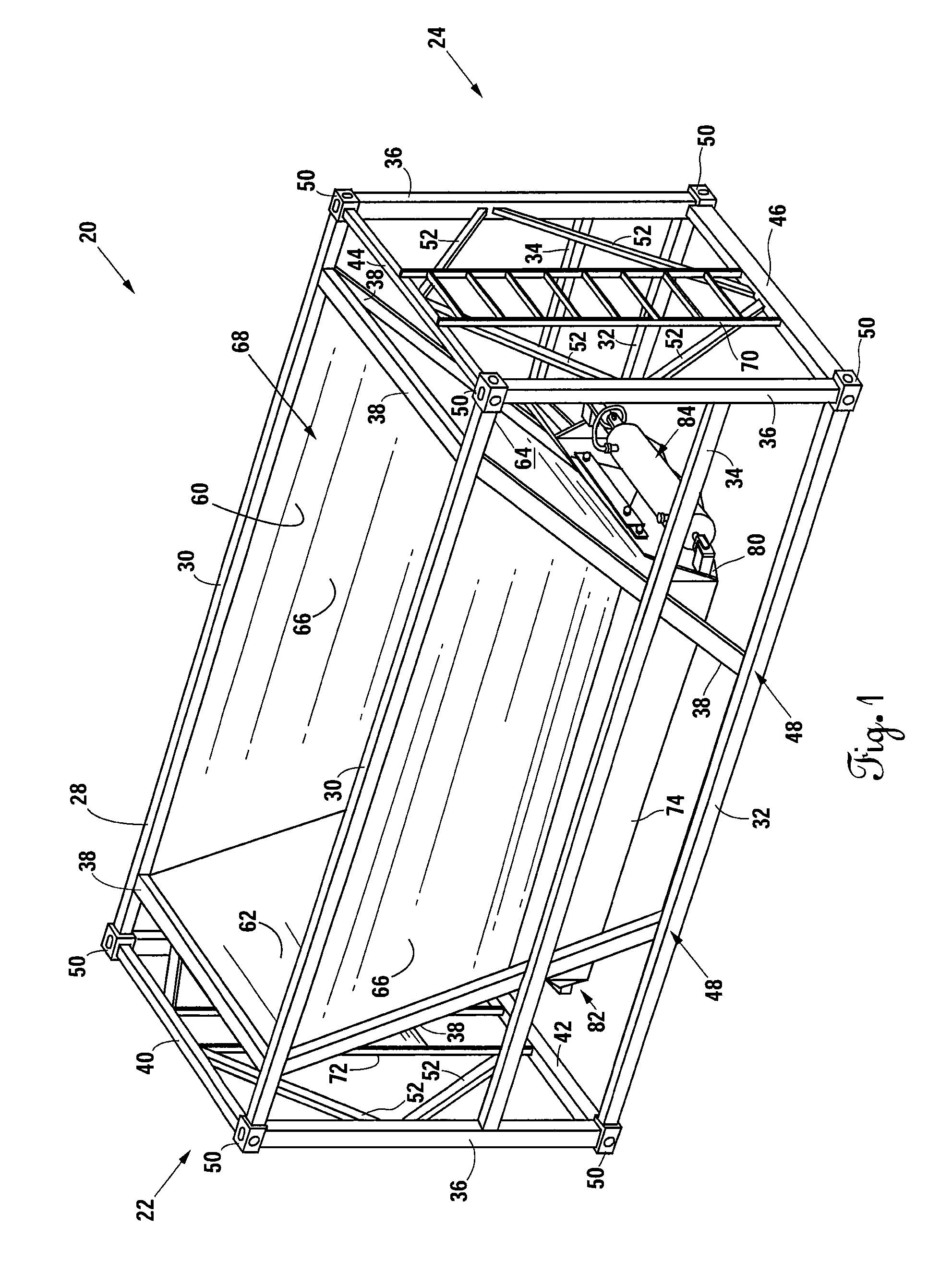

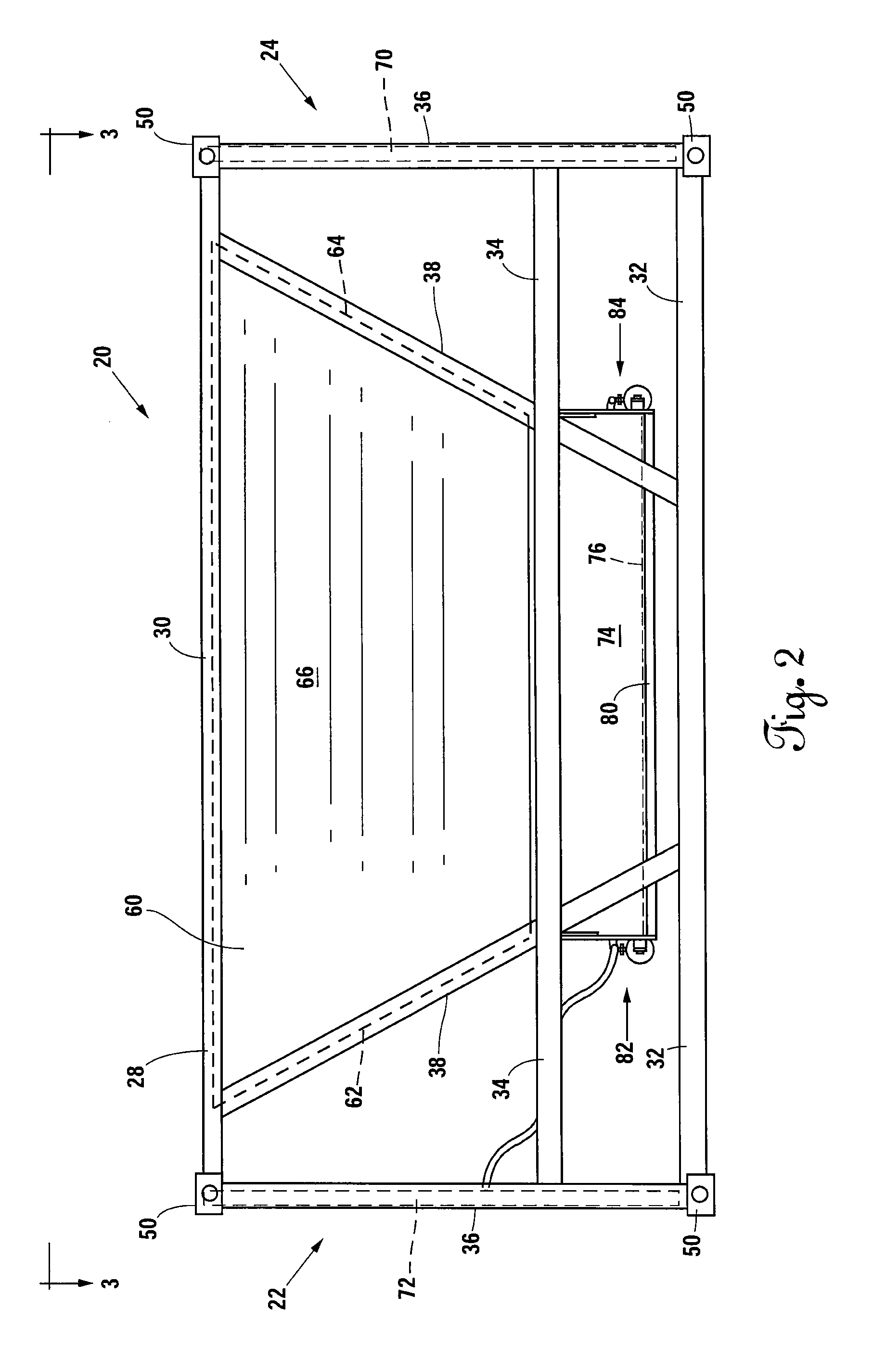

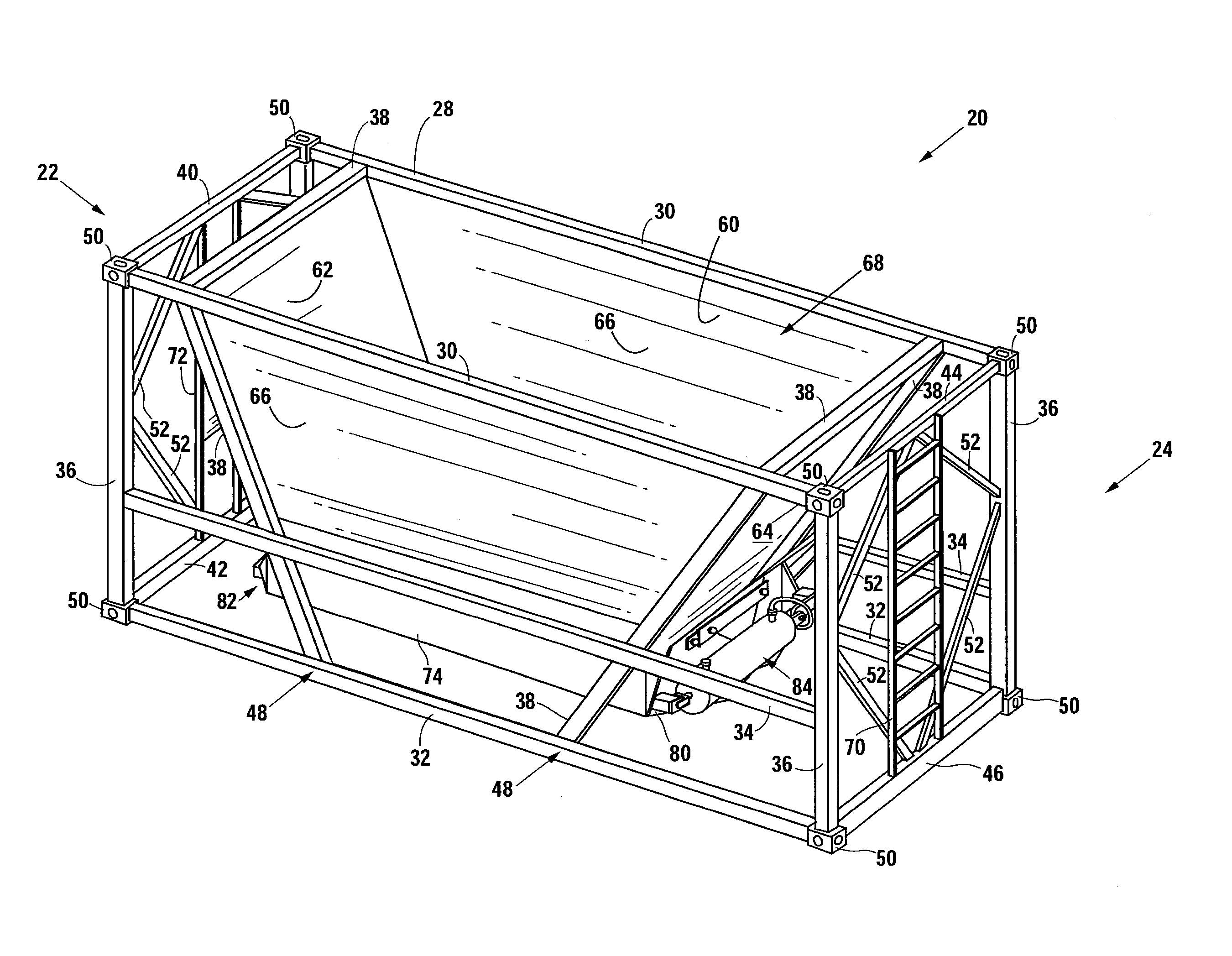

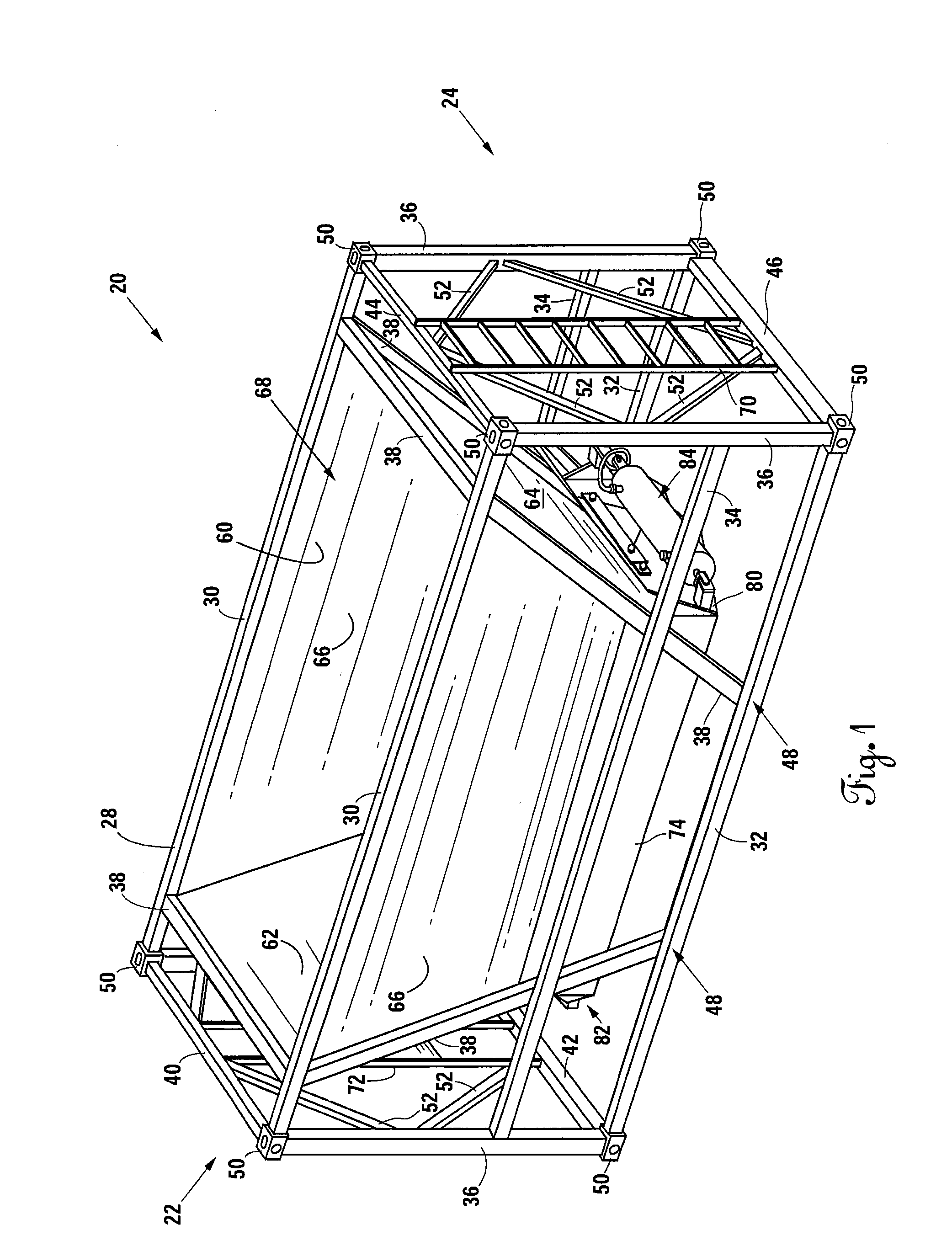

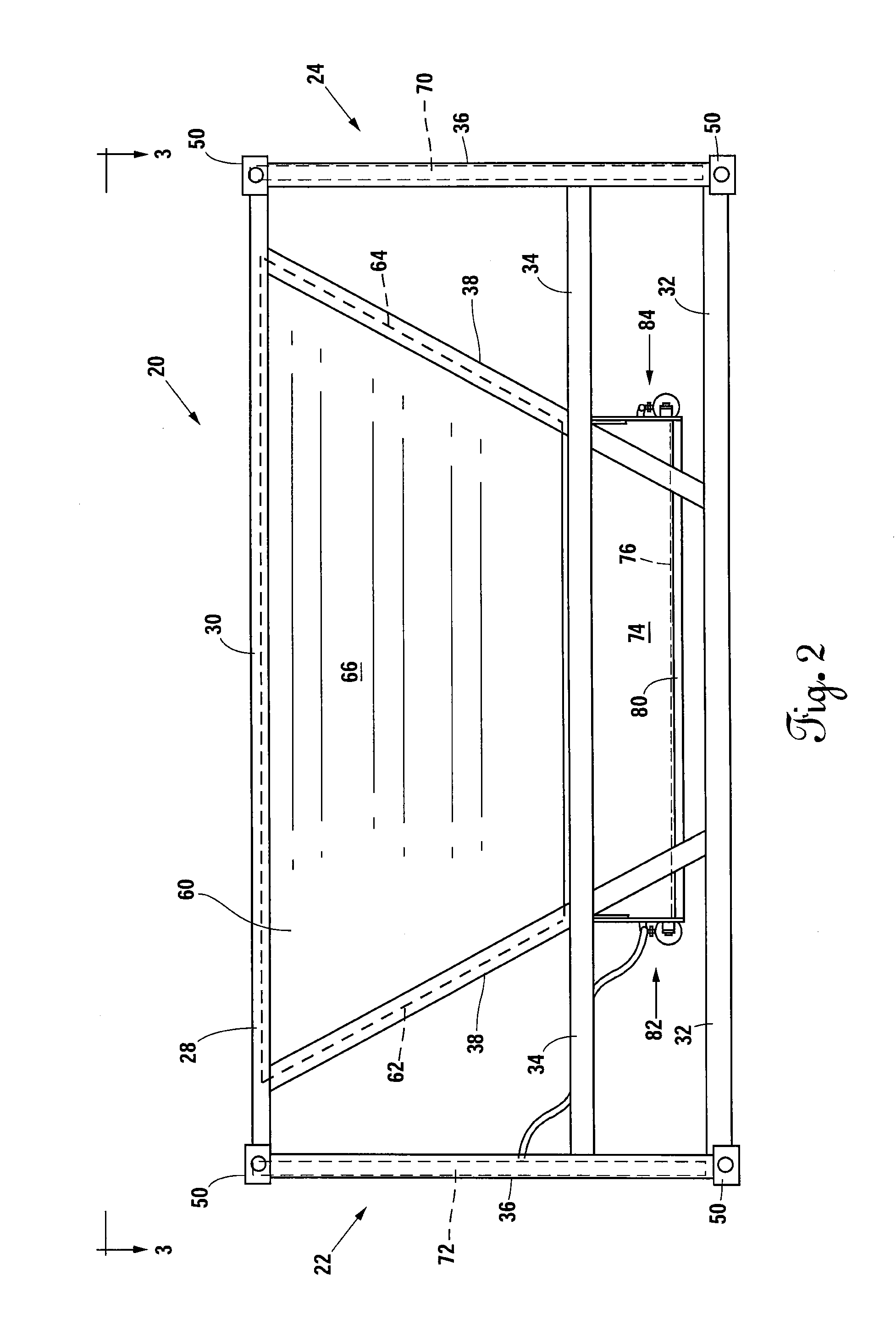

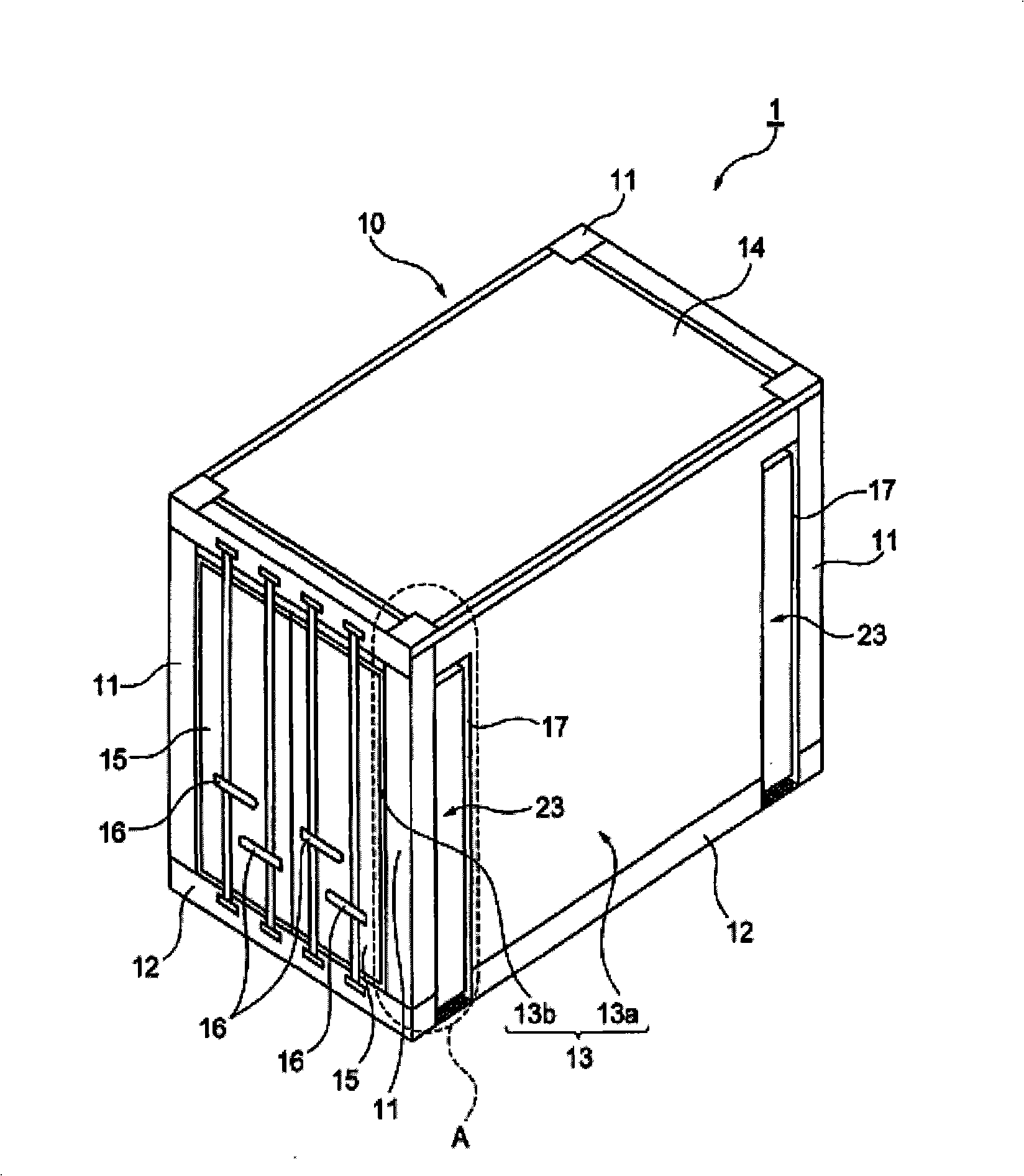

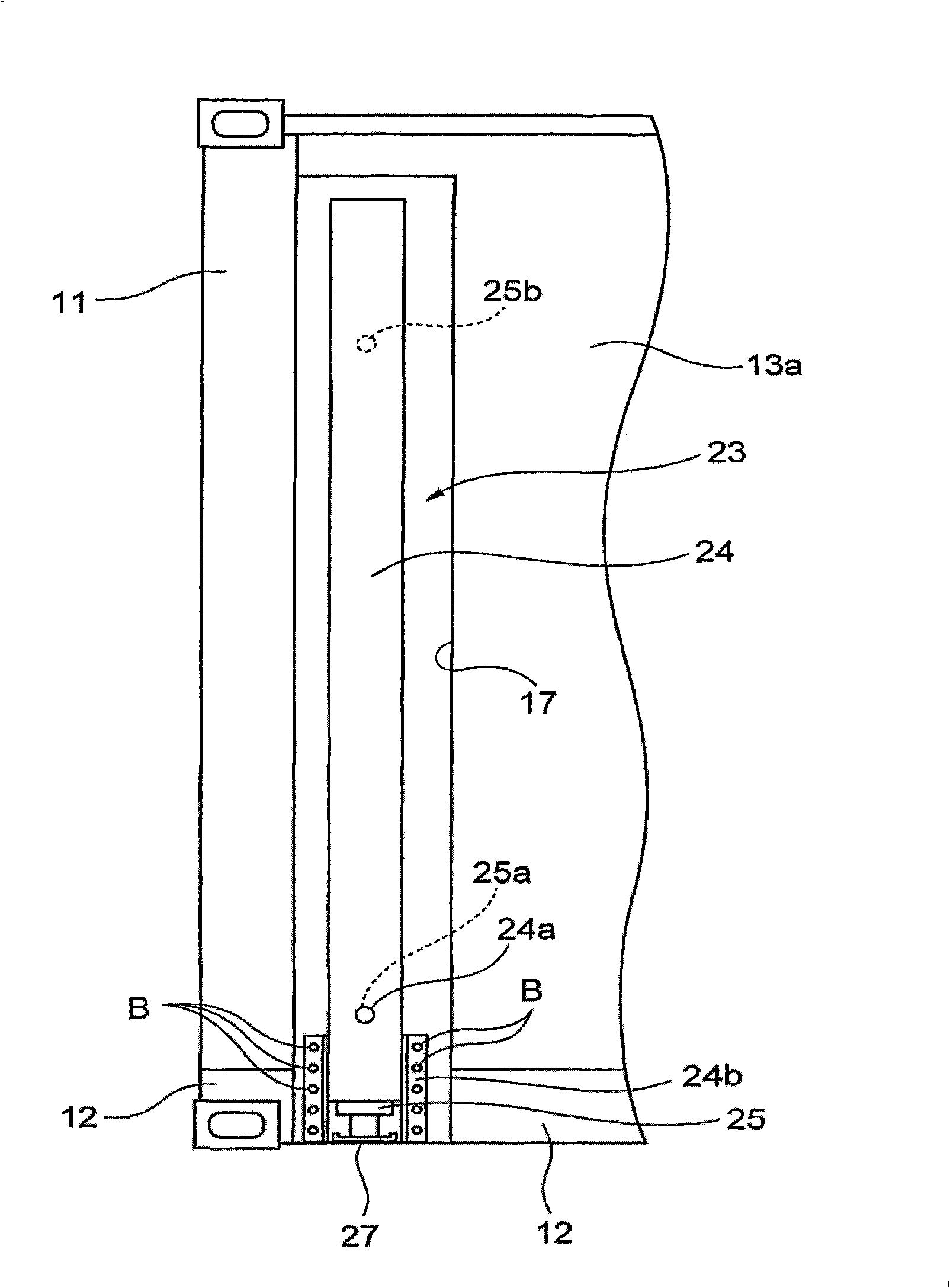

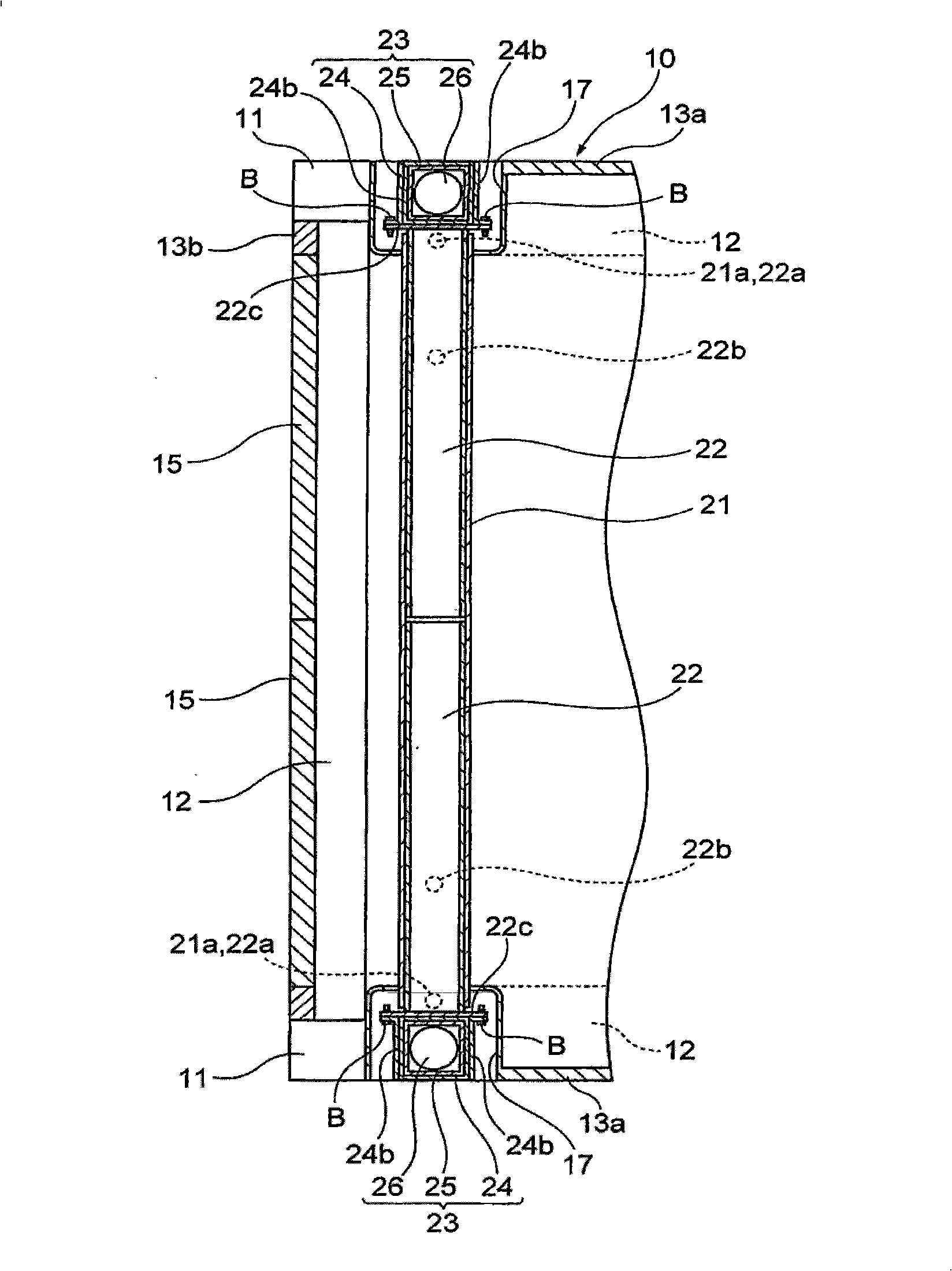

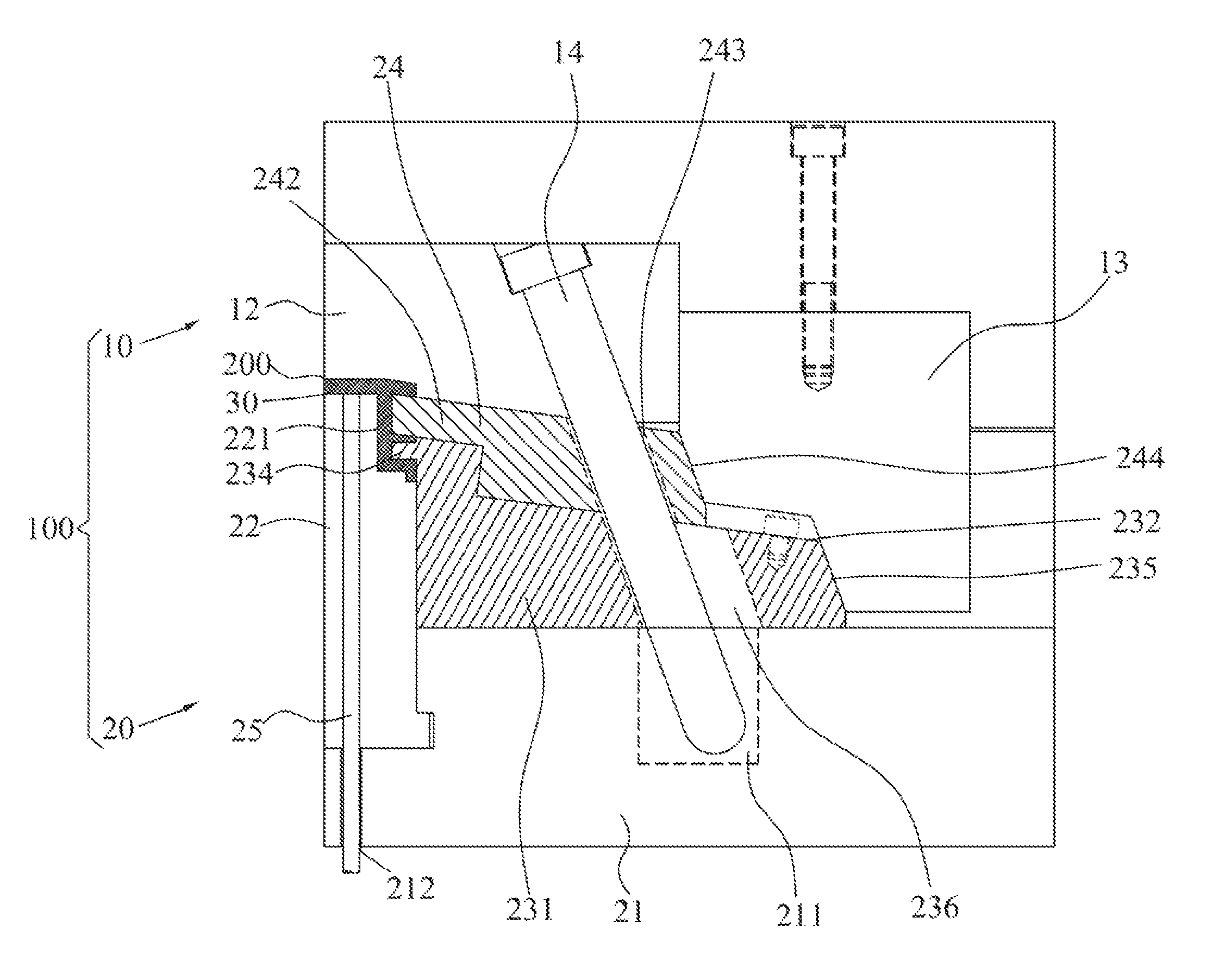

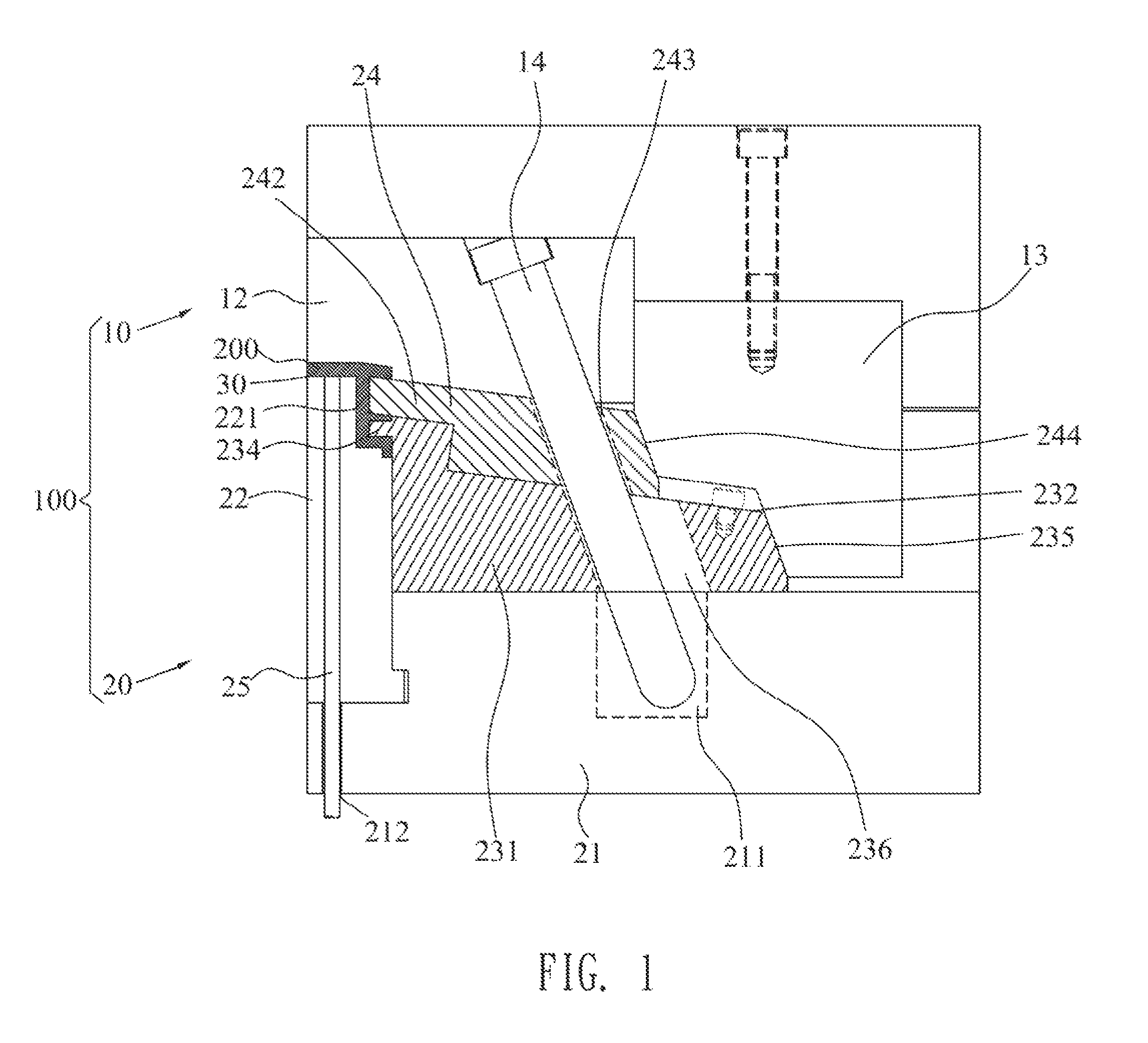

Belly-dump intermodal cargo container

ActiveUS9309064B2Efficient unloadingMinimize chargesLarge containersLoading/unloadingTerrainTransfer system

A container comprising a frame conforming to ISO intermodal container dimensions, a hopper attached within the frame; the hopper defining a chute having a first opening and a second opening, at least one door pivotally attached to the hopper proximal to the second opening; at least one gate assembly attached to the at least one door; a connector apparatus panel mounted to the frame; and at least one actuating fluid or electrical line connected between the at least one gate and the connector apparatus panel. An alternative embodiment includes at least one air tank connected to the container and filled through an air transfer system and a plunger system to cause actuation of container doors for releasing of materials into a second receptacle and where the air transfer and plunger systems reside partially on a rough terrain container handler vehicle.

Owner:LOGICHAUL LOGISTICS LLC

Belly-Dump Intermodal Cargo Container

ActiveUS20150368052A1Reduce in quantitySave a lot of costLarge containersArticle unpackingTerrainTransfer system

A container comprising a frame conforming to ISO intermodal container dimensions, a hopper attached within the frame; the hopper defining a chute having a first opening and a second opening, at least one door pivotally attached to the hopper proximal to the second opening; at least one gate assembly attached to the at least one door; a connector apparatus panel mounted to the frame; and at least one actuating fluid or electrical line connected between the at least one gate and the connector apparatus panel. An alternative embodiment includes at least one air tank connected to the container and filled through an air transfer system and a plunger system to cause actuation of container doors for releasing of materials into a second receptacle and where the air transfer and plunger systems reside partially on a rough terrain container handler vehicle.

Owner:LOGICHAUL LOGISTICS LLC

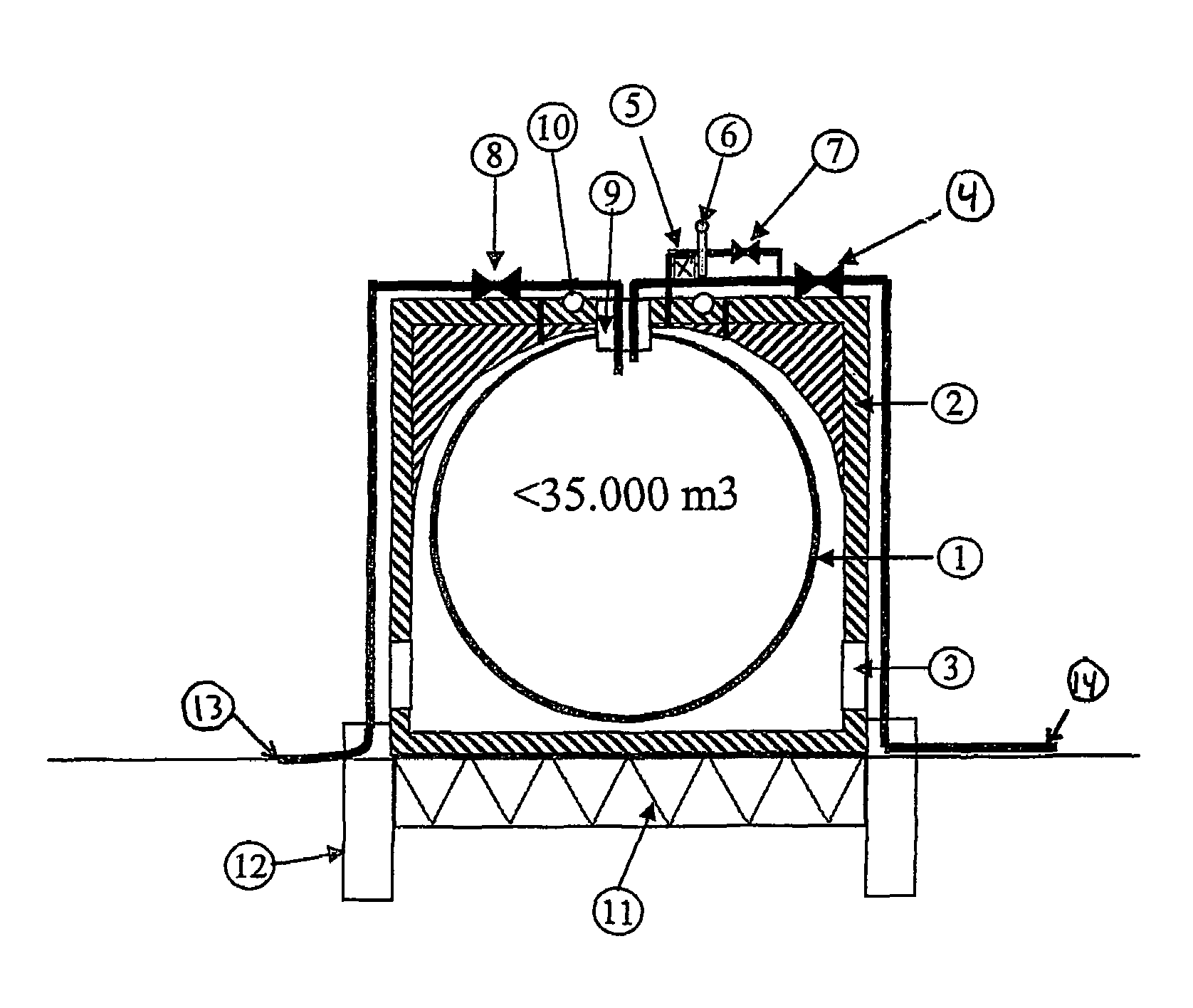

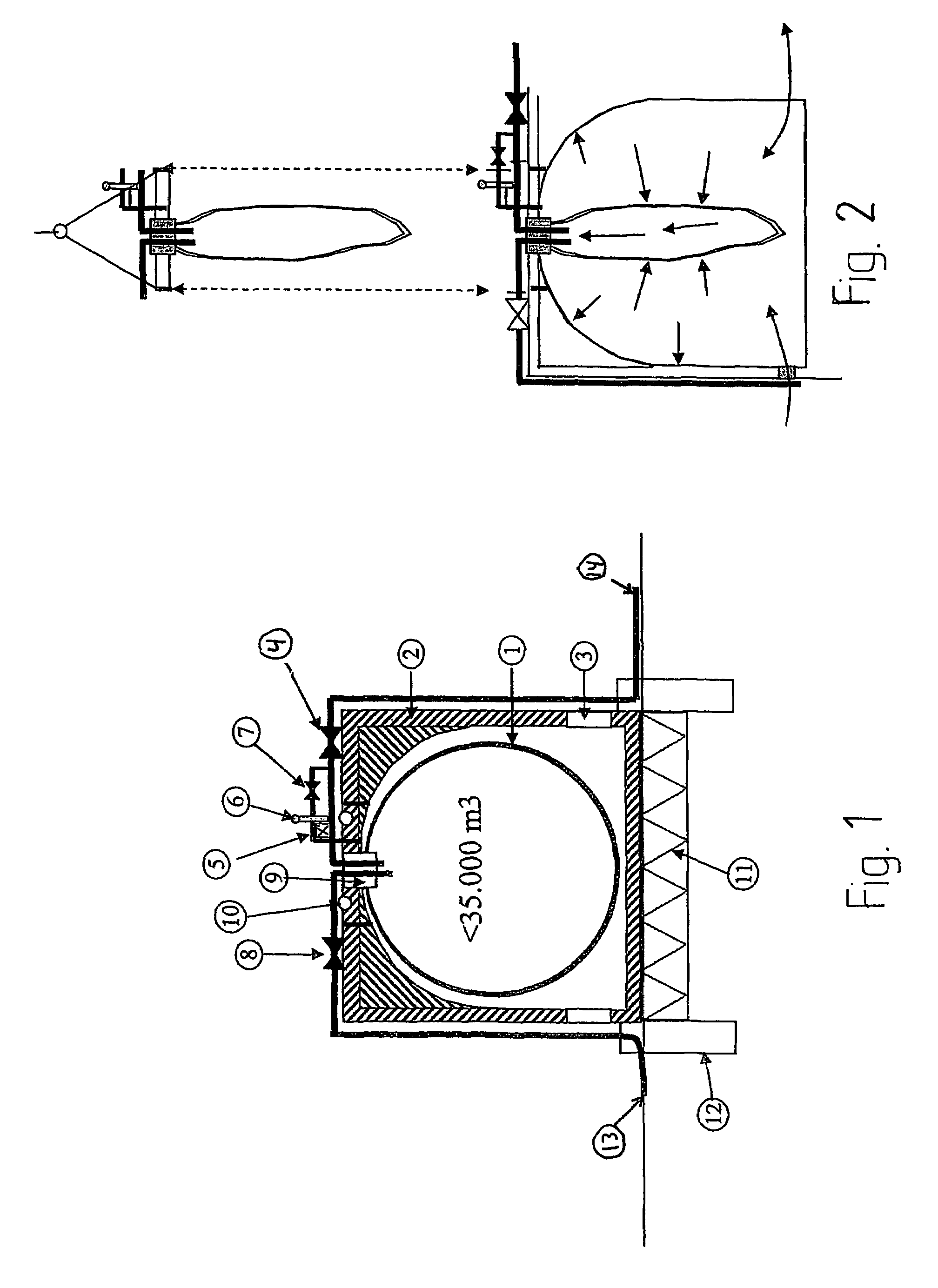

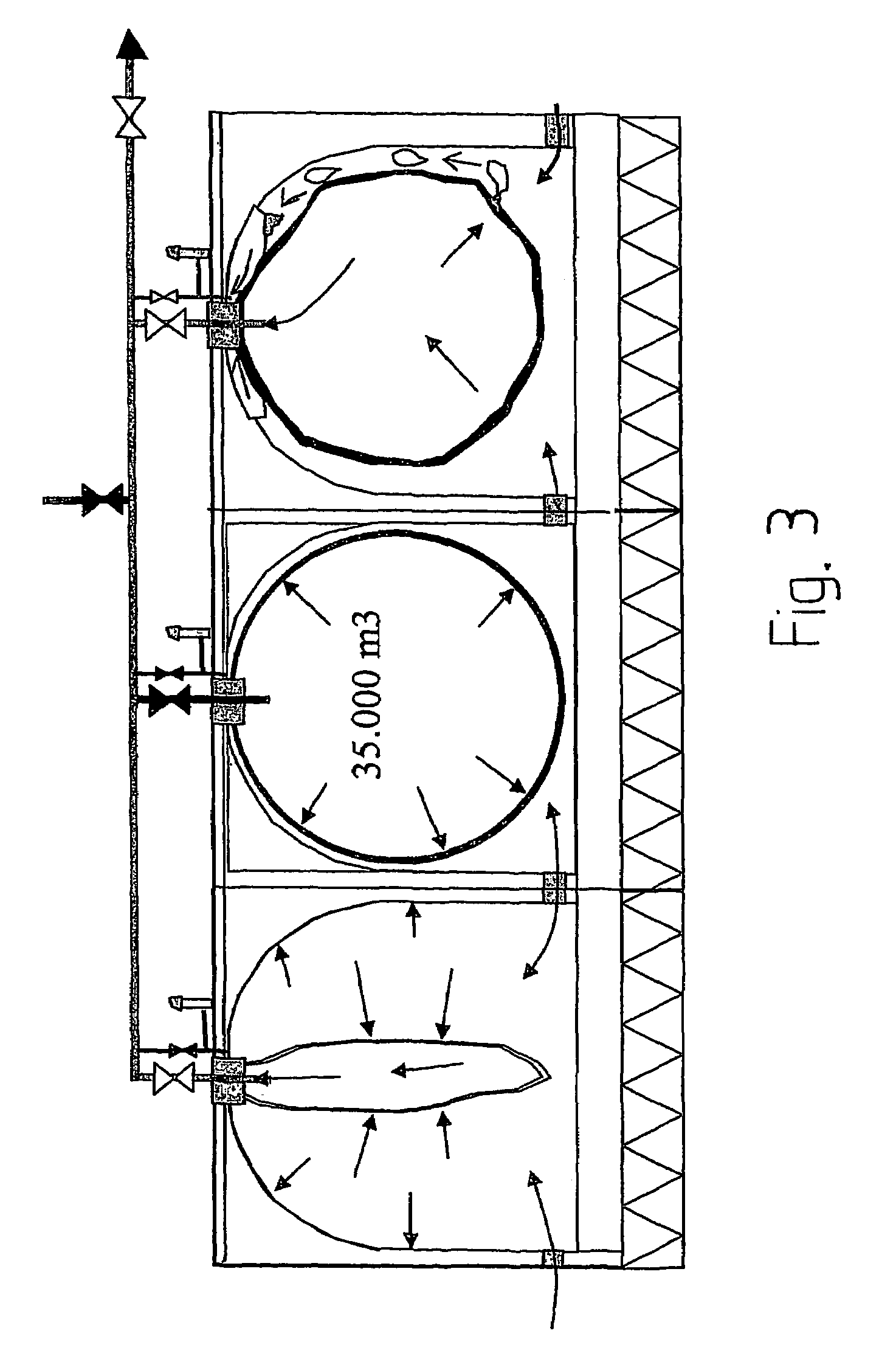

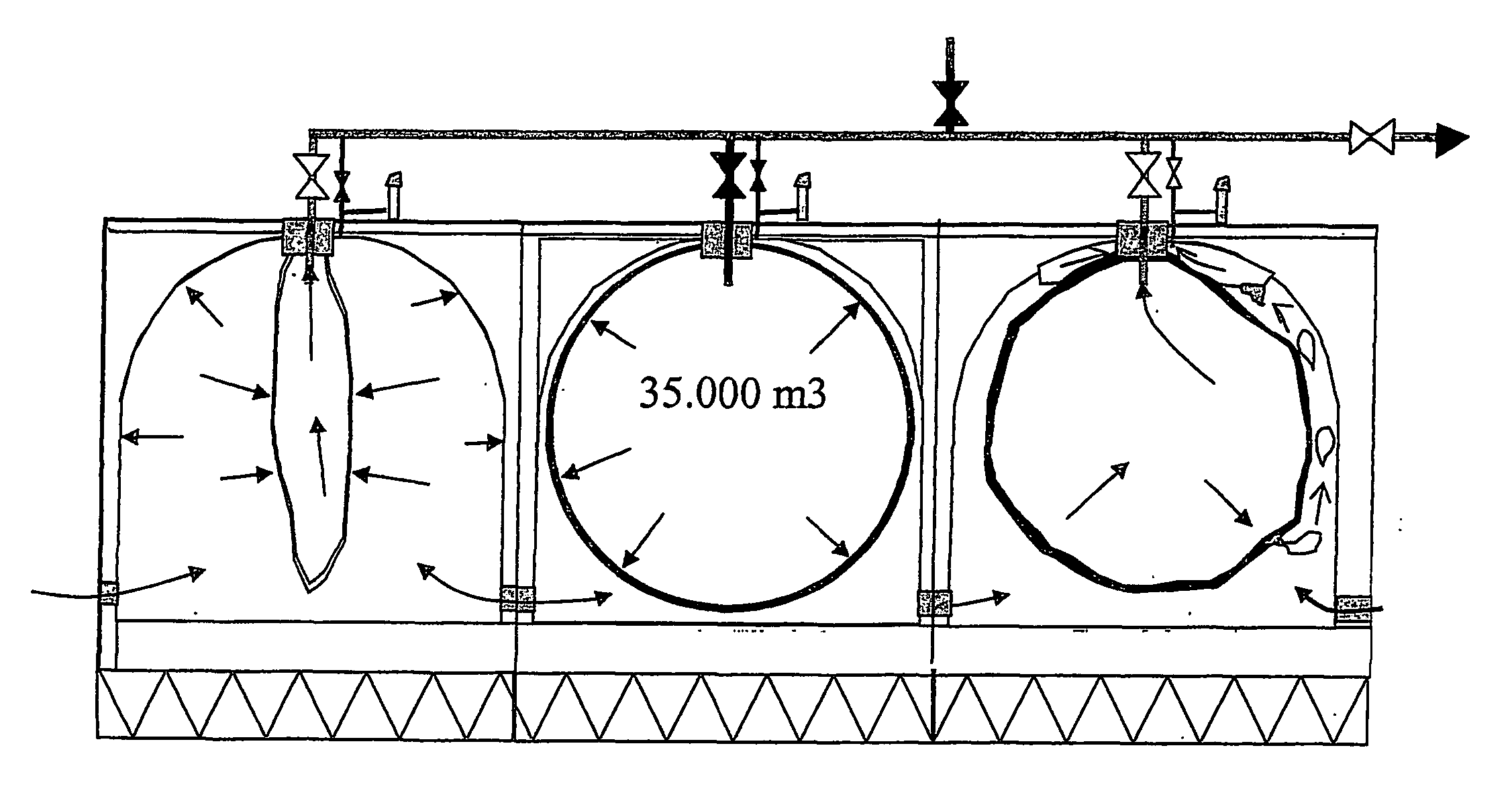

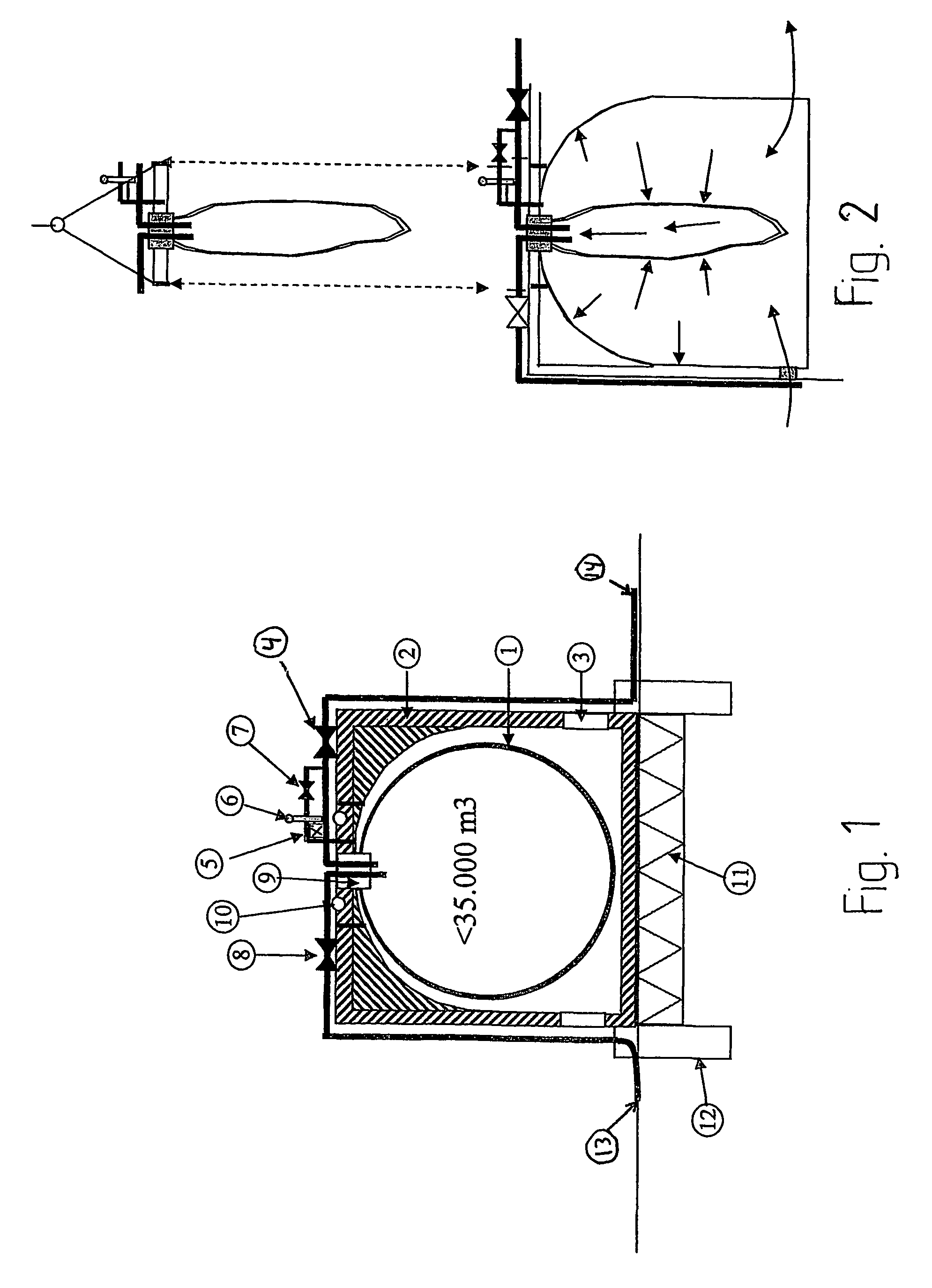

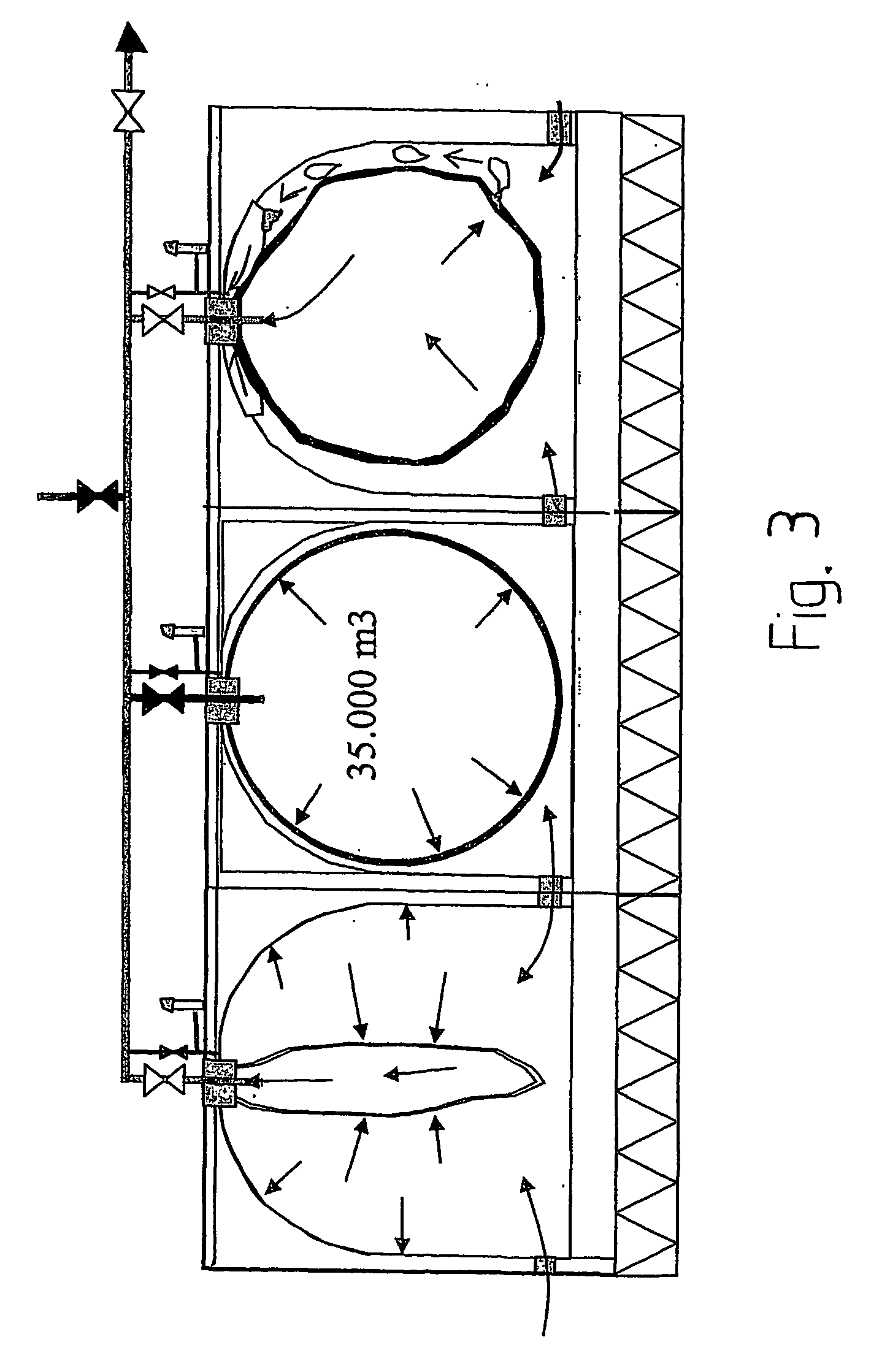

Seabed located storage

Seabed located storage for crude oil or other fluid, distinguished in that it is comprising a storage section in form of an oil and waterproof cloth formed as a flexible balloon that can be filled with, store and emptied for a storage fluid, a structure section formed as an external casing over the storage section, which structure section is closed in the upper part such that an upward close volume of size at least corresponding to the volume of the storage section is formed, but with openings to the surroundings in the lower part, an anchoring section formed as a substructure between the structure section and the seabed, with means for anchoring to or stable placement on the seabed, and a transfer section comprising pipes and valves for loading and unloading of a storage fluid, arranged in substance exterior to the upper part of the storage.

Owner:NOV PROCESS & FLOW TECH AS

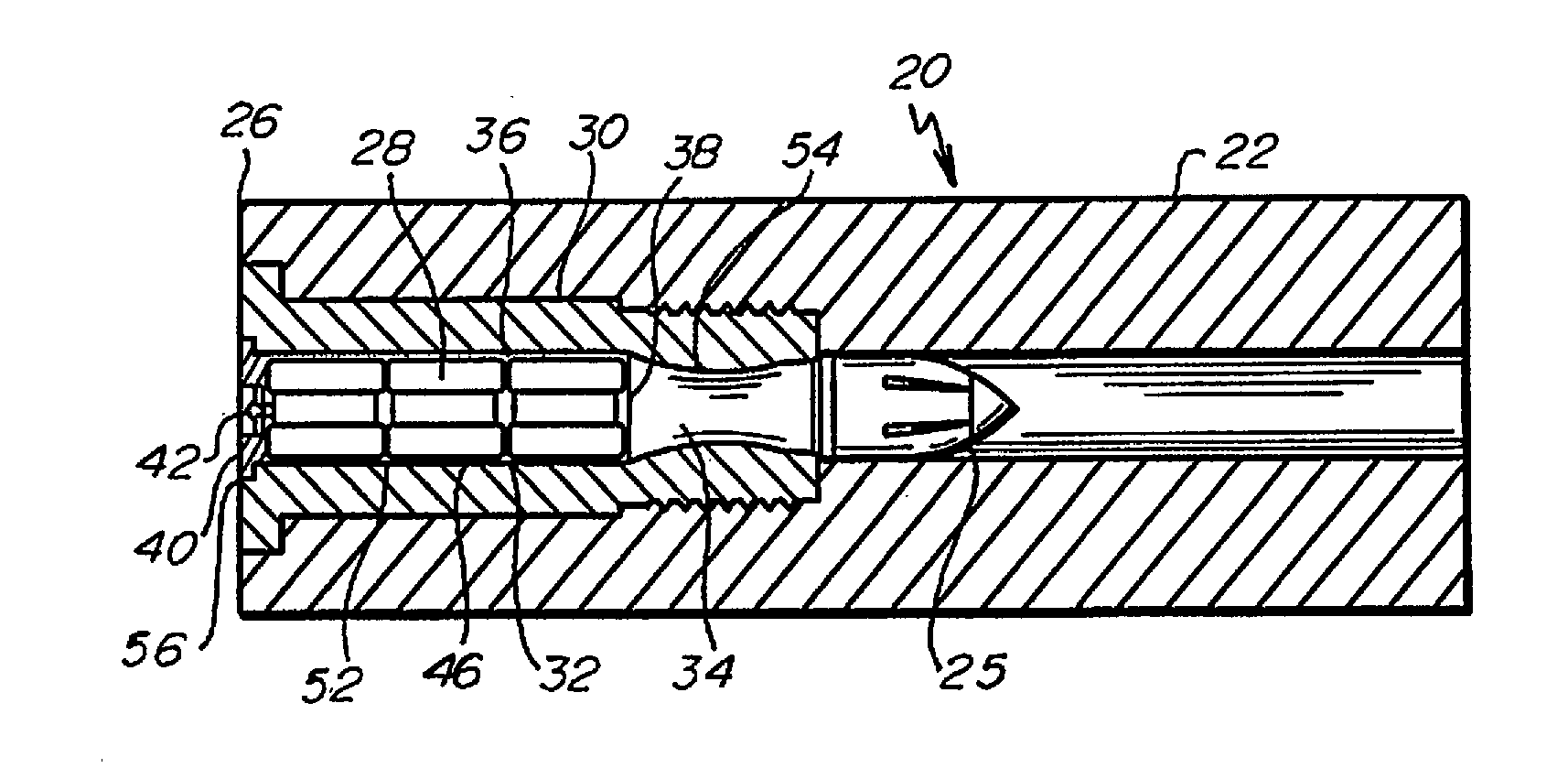

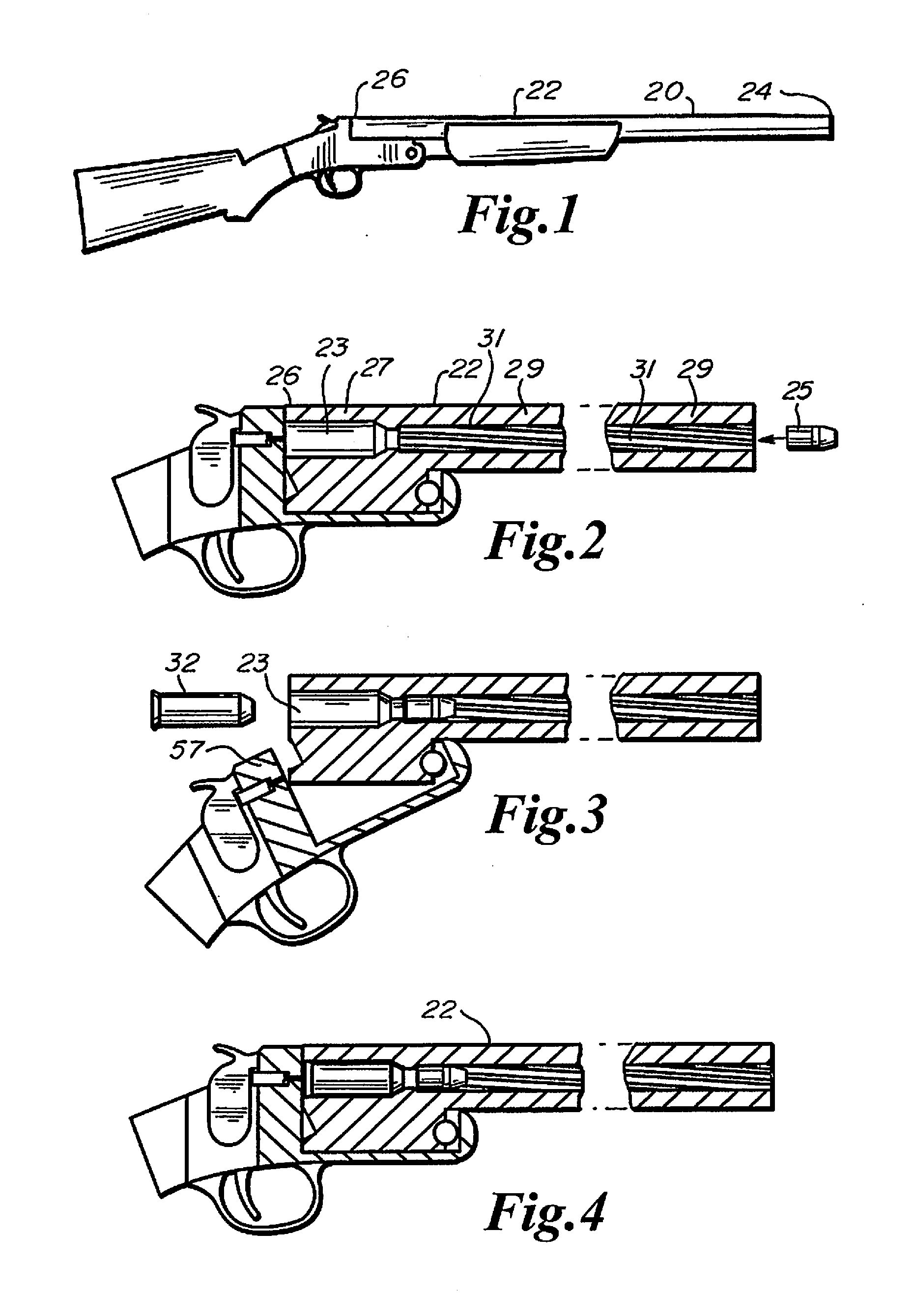

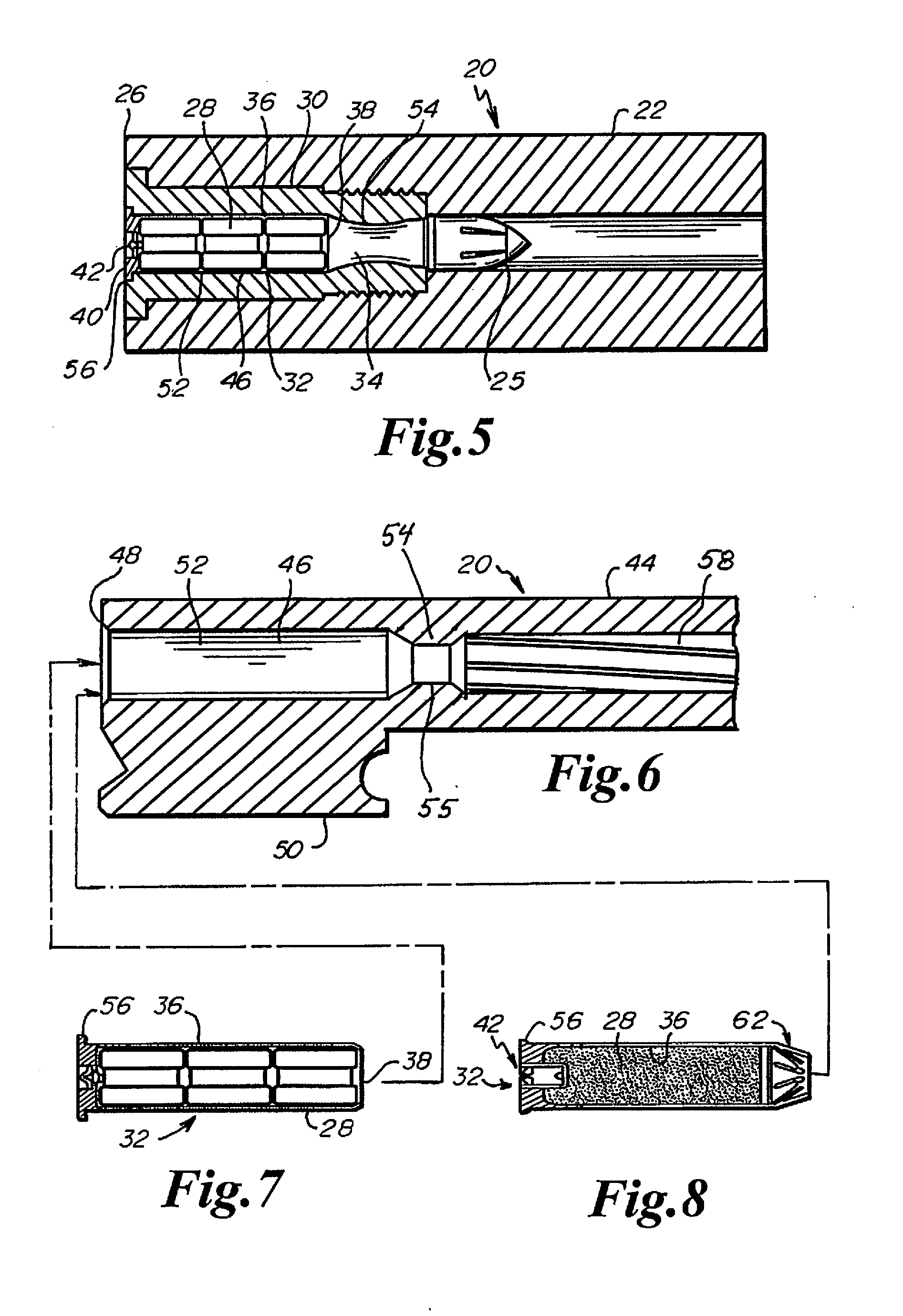

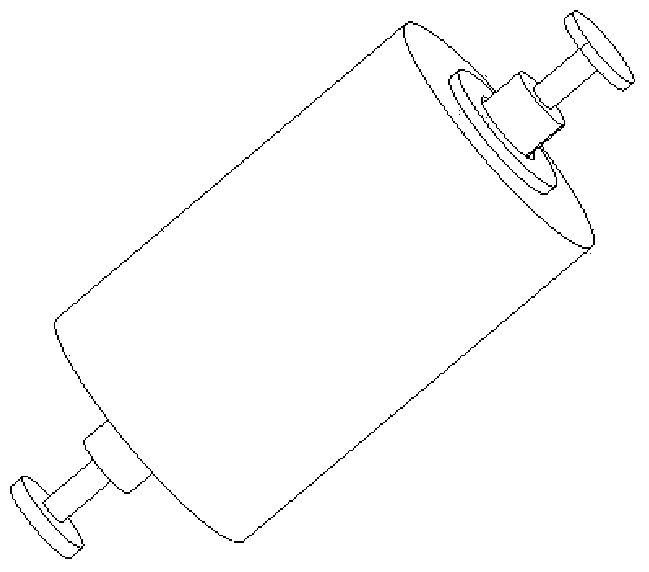

Muzzleloader and propellant system

InactiveUS20140090285A1Efficient unloadingReduce the overall diameterAmmunition projectilesCartridge extractorsEngineeringMechanical engineering

A muzzle-loader bullet system includes a pre-packaged propellant charge and primer for providing efficient loading and unloading of the muzzleloader. The muzzleloader accepts in the breech end the propellant containment vessel that abuts against a constriction portion with a reduced diameter portion. The propellant containment vessel having an end portion with a tapered surface that conforms to the constriction portion surface. A projectile is inserted in the muzzle end and seats against the constriction portion. The propellant containment vessel may be received in a removable breech plug. The constriction portion may be part of the breech plug or a separate component secured in the barrel by way of the breech plug. The containment vessel further comprises a primer mechanism that may be integrated into the proximal end of the containment vessel.

Owner:VISTA OUTDOOR OPERATIONS

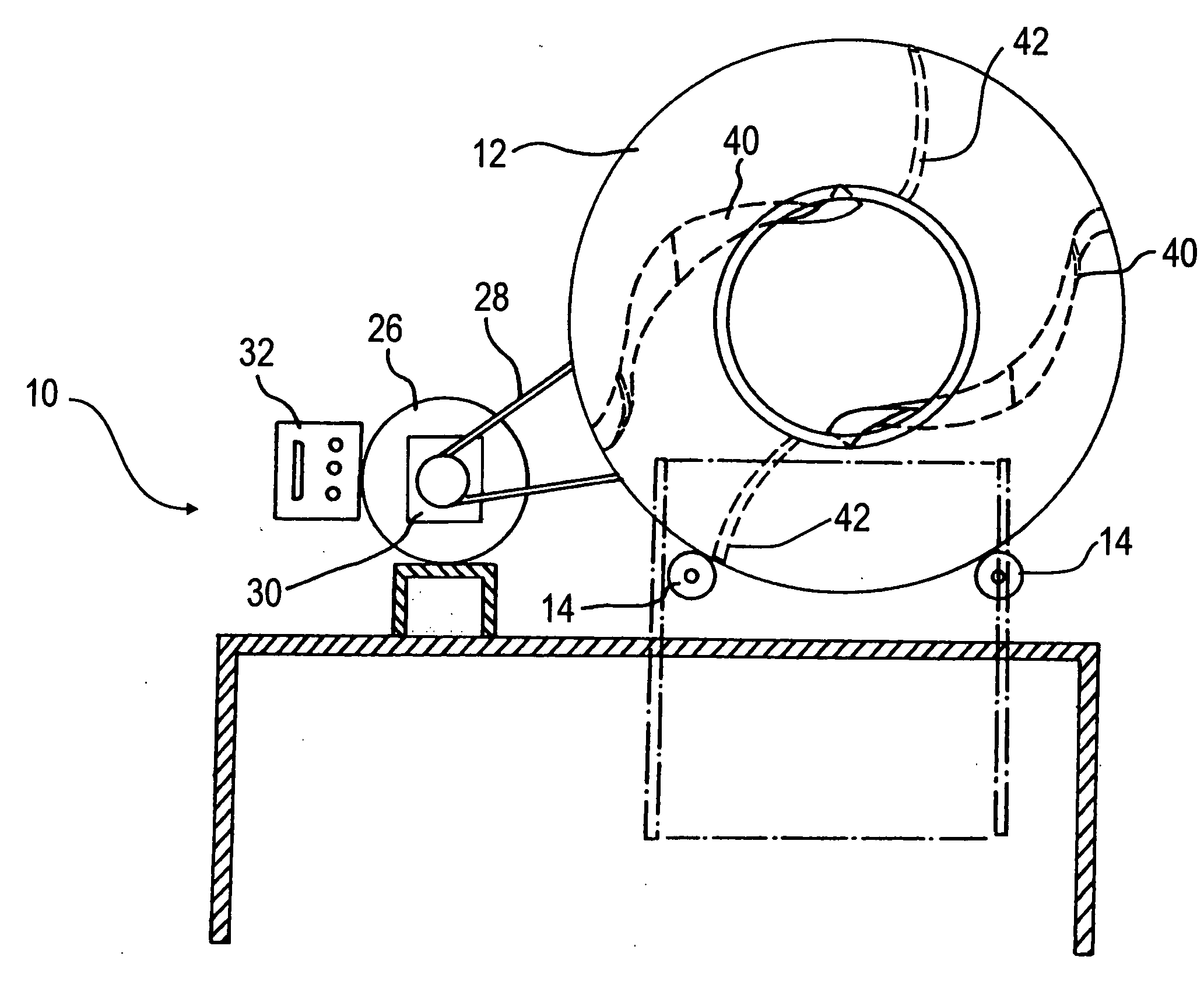

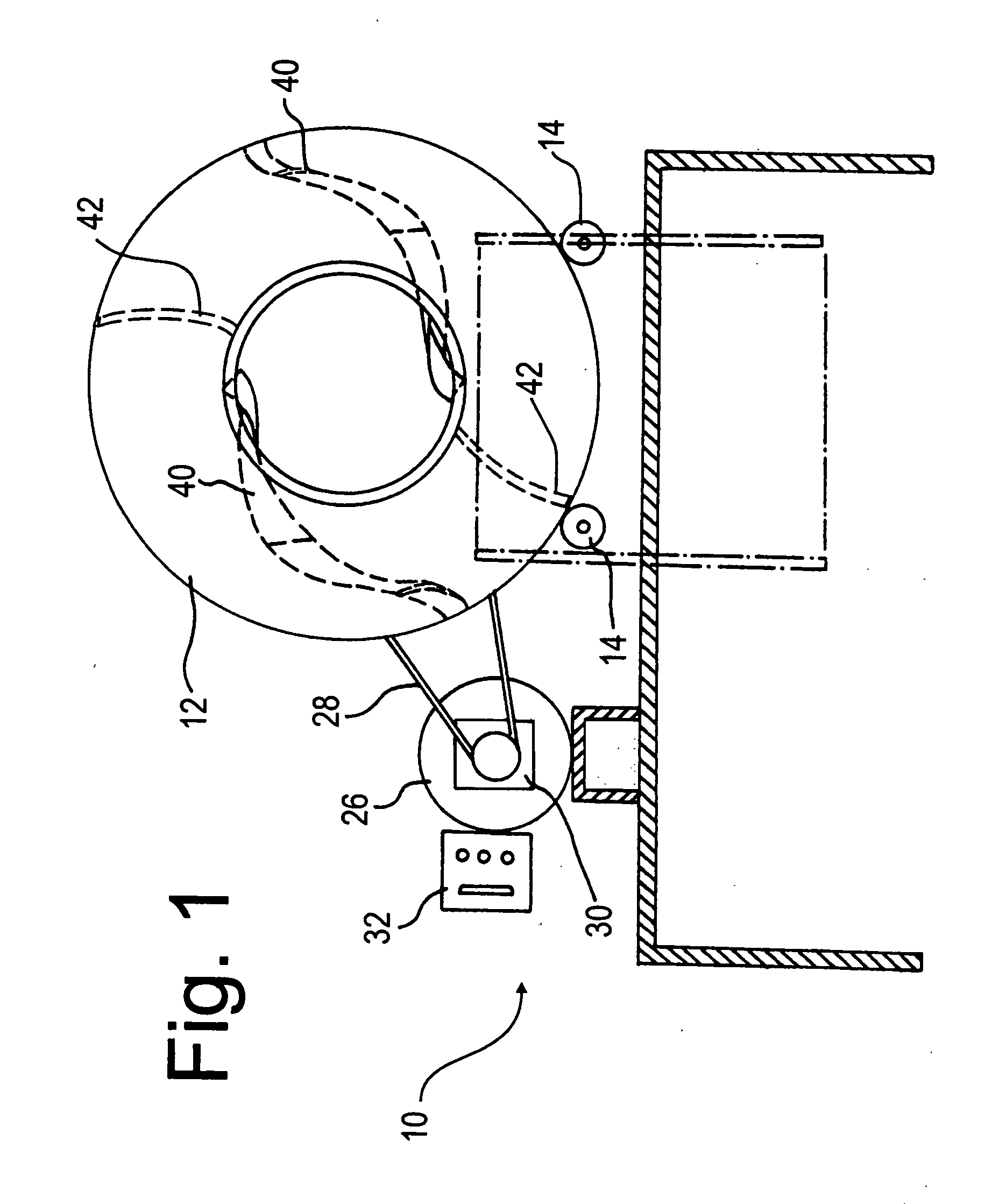

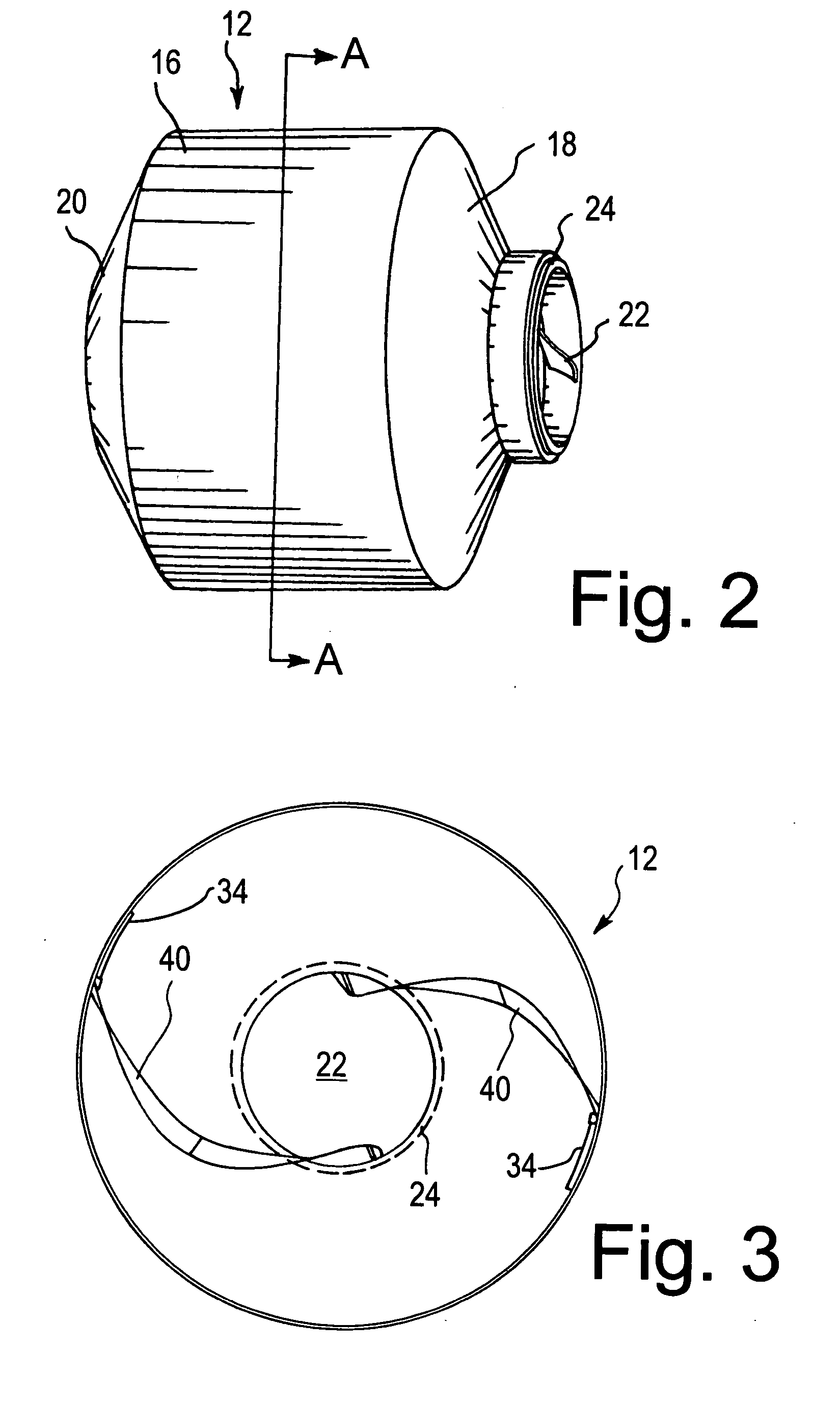

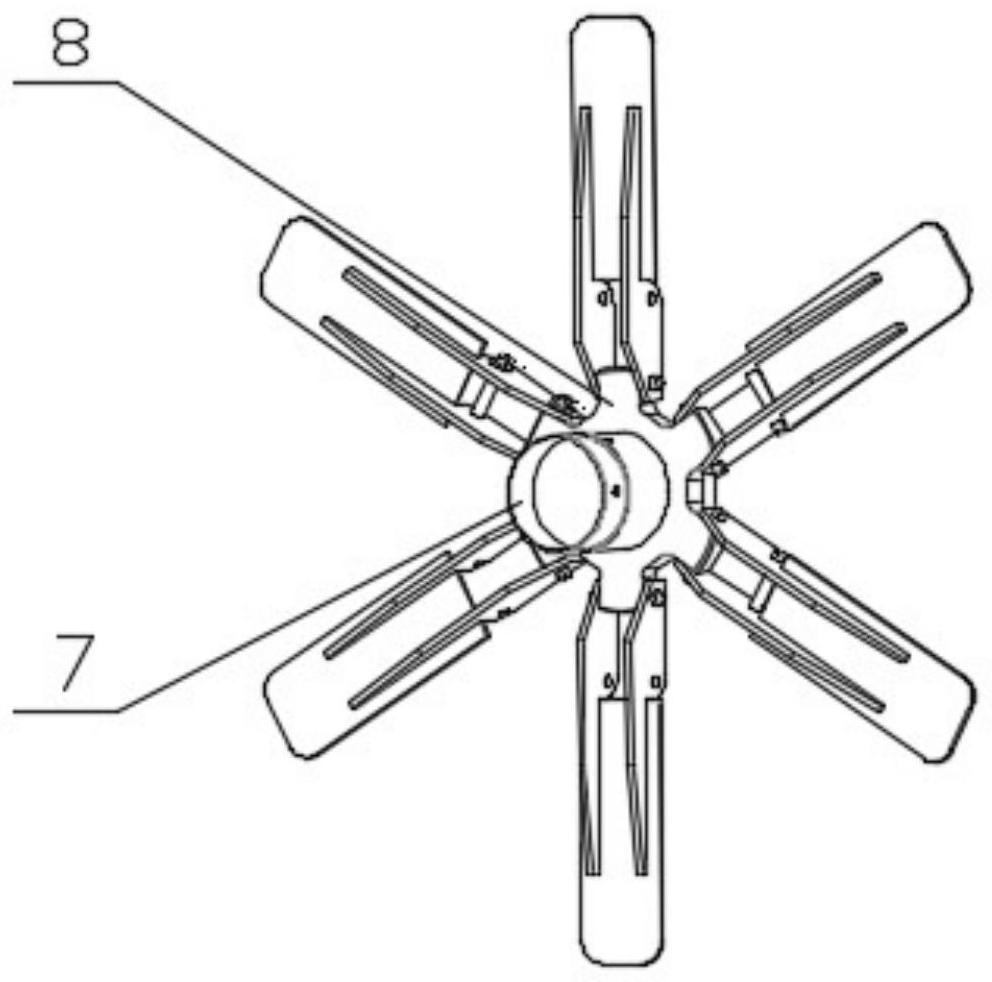

Rotary drum for tablet coating with reverse-direction unloading

InactiveUS20050152217A1Minimal damageEfficient unloadingRotating receptacle mixersTransportation and packagingMechanical engineeringRotating drum

A mixing device for tablets includes a rotating drum including front and rear end walls, with the front end wall having a central mouth to receive and discharge the drum contents. One or more ribbon-like baffles are mounted to the inside surface of the front wall, with the baffle having a distal end which partly occludes the drum opening. The baffles are mounted at an angle such that when the drum is rotating in one direction they tend to direct the contents of the drum towards the opening of the drum to discharge the drum contents in a series of successive drum rotations, while when the drum is rotated in the opposite direction the baffles tend to direct the contents of the drum away from the drum opening. One or more curved ribs mounted to the inside surface of the drum body at an angle may be provided to cooperate in the tablet mixing and discharge phases.

Owner:OHARA DAVID

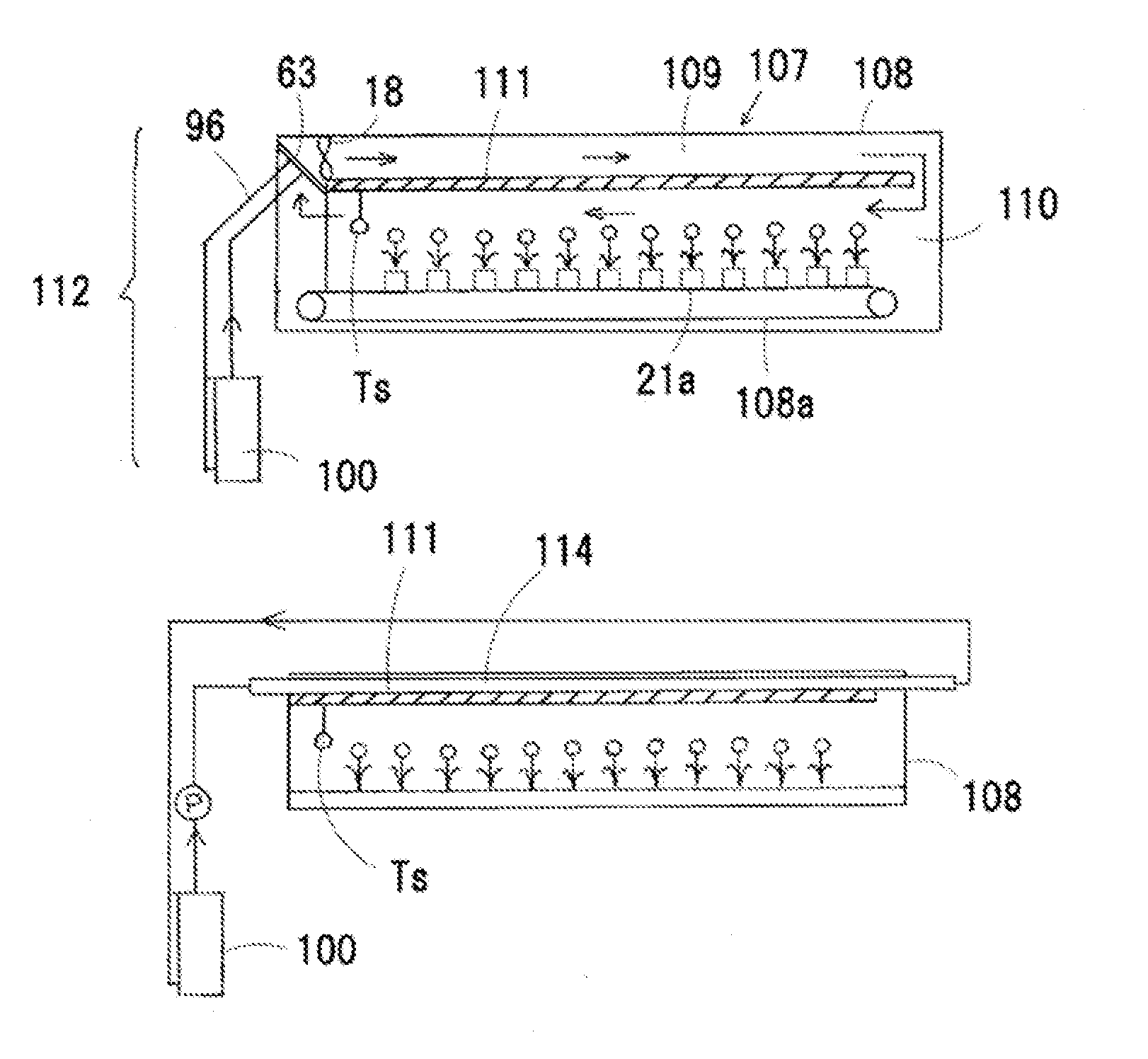

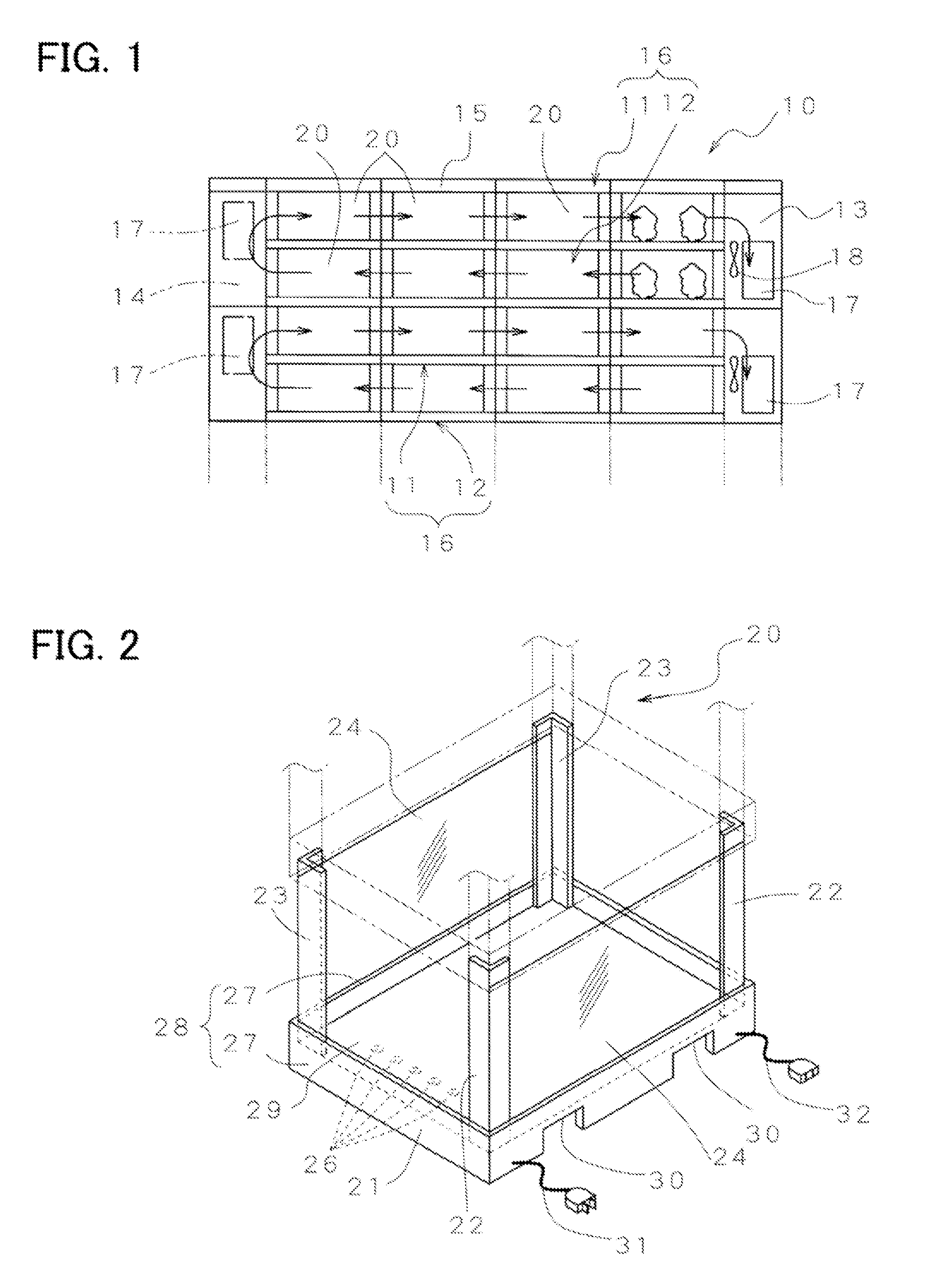

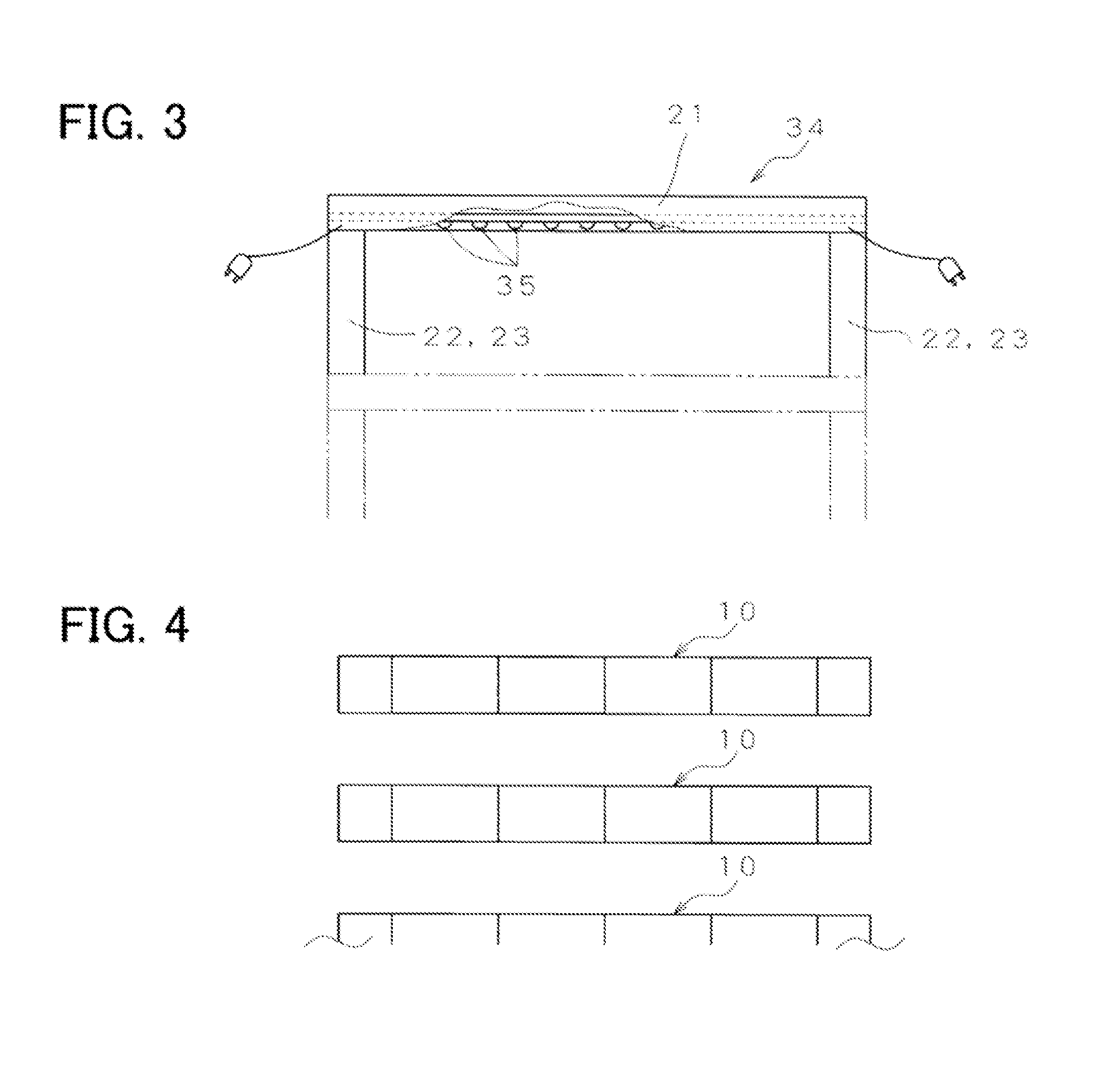

Plant cultivation apparatus

InactiveUS8984806B2Efficient unloadingEasy to trainClimate change adaptationAgriculture gas emission reductionPlant cultivationInstrumentation

The present invention discloses an apparatus to simplify an air supply path without damaging the merit of conventional culture apparatus. The apparatus is a culture apparatus which includes a row of a plurality of box-shaped containers for plant cultivation, and a row of lower stage containers arranged in the lower portion of the row, holding the upper stage container spaced as high as the height after growth of the plants to be cultivated. In each container, a support, a blocking film stretched between front and rear, right and left supports of the container are provided. In the one end of the rows of the containers, an air conditioner is arranged, and in another end, a turnaround chamber is provided.

Owner:UCHIYAMA HISAKAZU

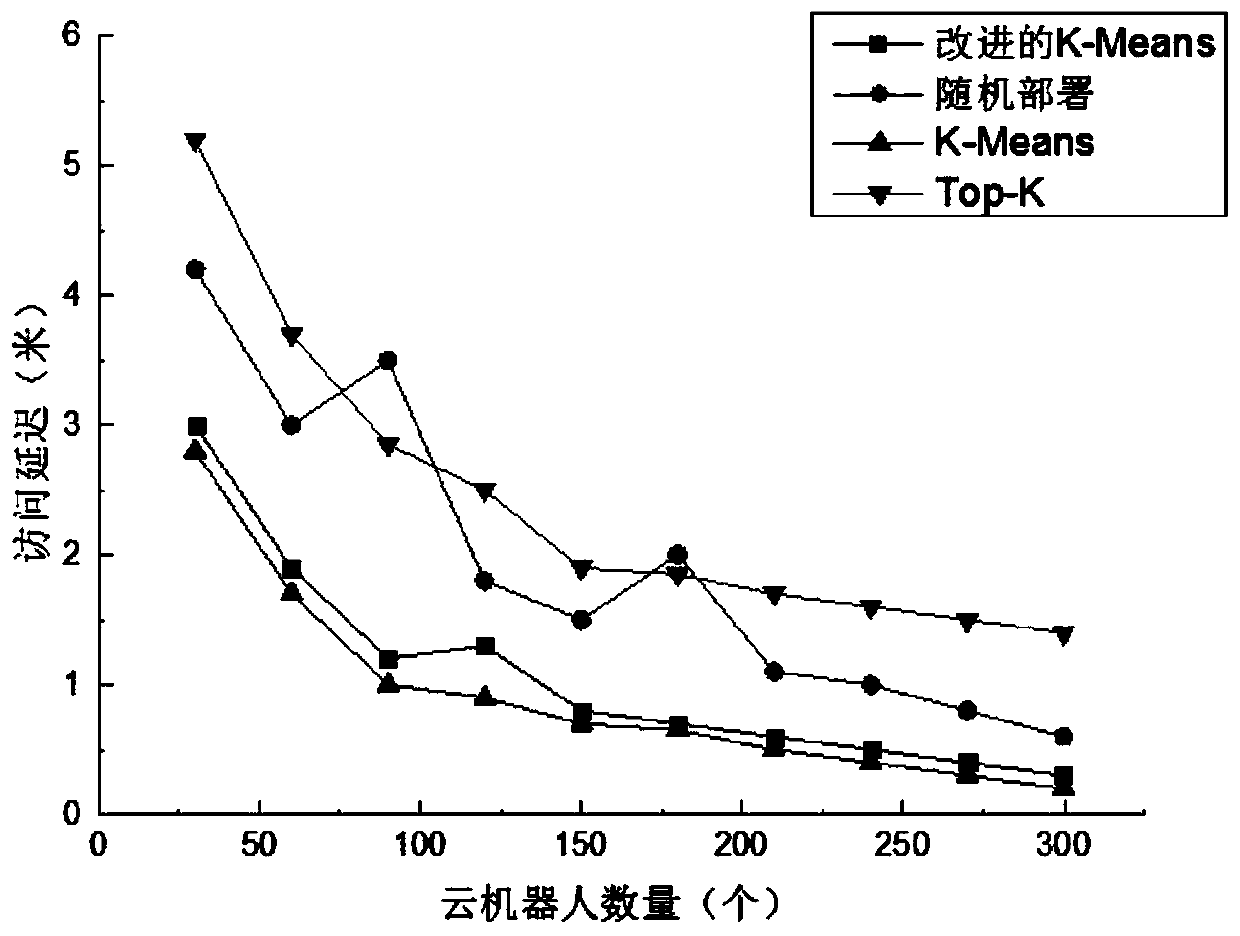

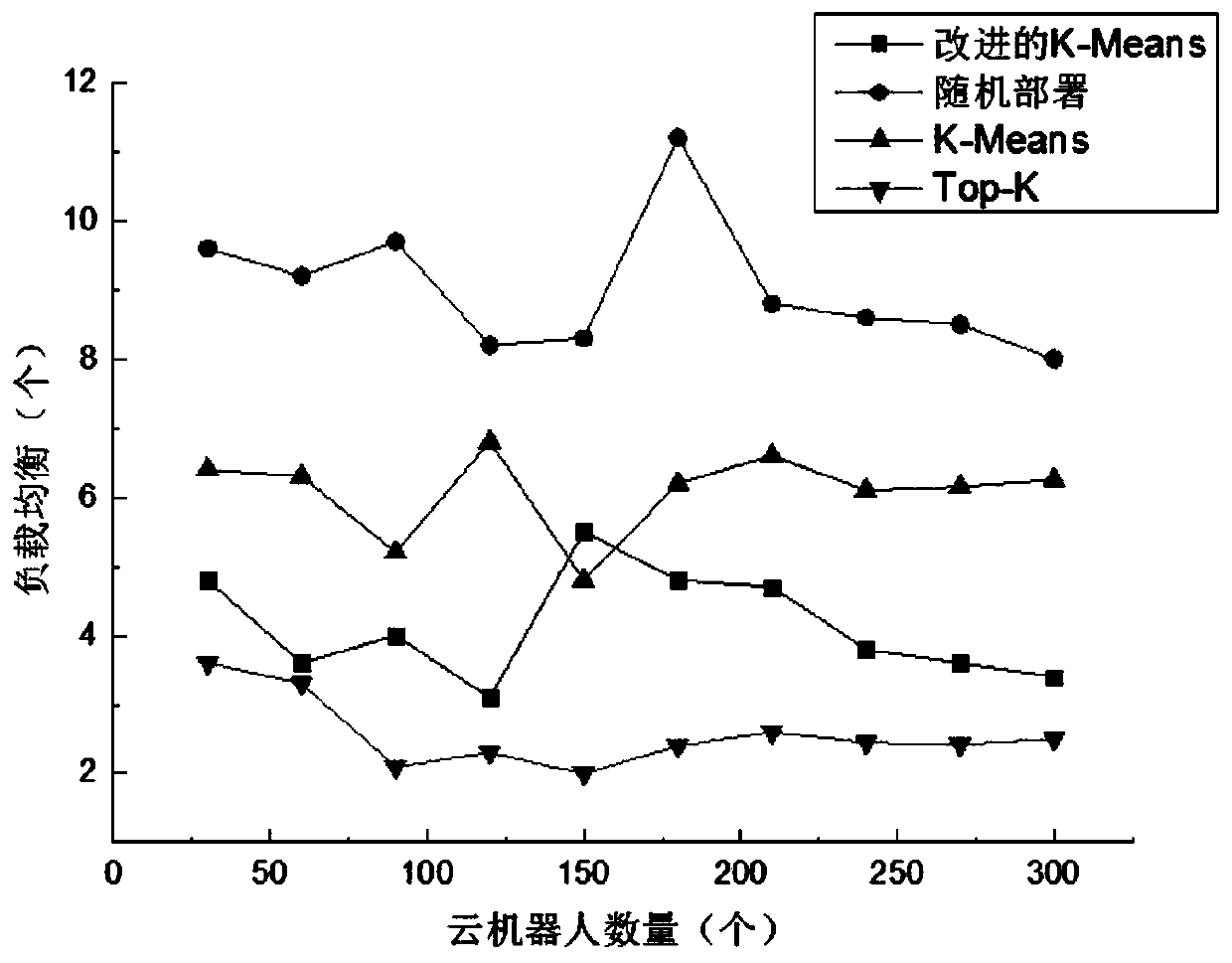

Cloud robot edge computing unloading model and unloading method thereof

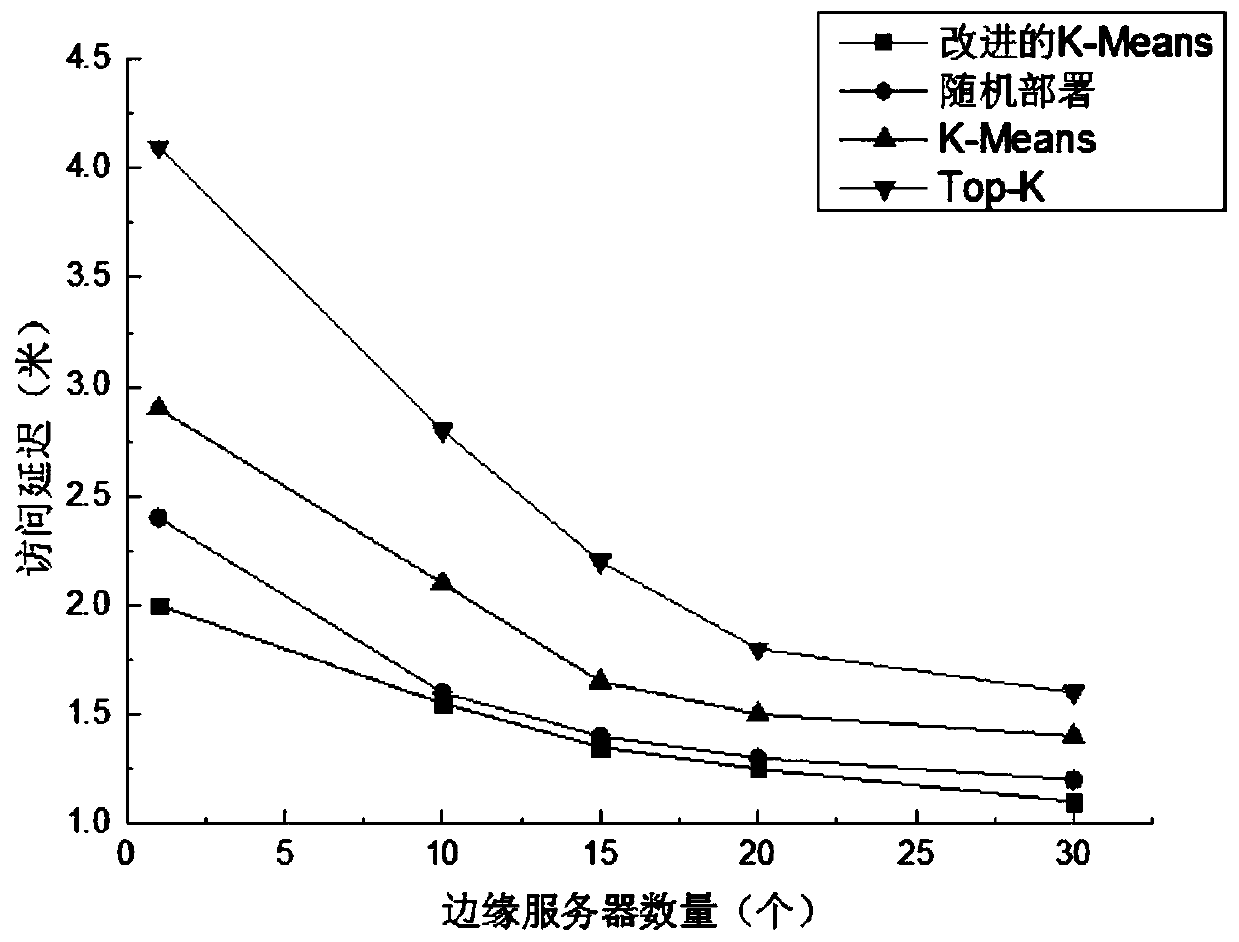

ActiveCN111522666AReasonable placementOptimize starting positionResource allocationCharacter and pattern recognitionEdge serverAlgorithm

The invention relates to a cloud robot edge computing unloading model and an unloading method thereof. According to the technical scheme provided by the invention, the method comprises the steps thatfirstly, an edge server placement model is established, then local and edge server task processing models are established, and then a game theory model is established; an initial clustering center isdetermined; clustering is performed according to the target function; and unloading is carried out by a task unloading method based on an improved game theory algorithm. On one hand, research is carried out from the placement problem of the edge server, an improved k-means algorithm is provided in a many-to-many scene of the cloud robot and the edge server, and the problems that the workload pressure of a single edge server is too large and the task processing efficiency is low are solved; and on the other hand, on the basis of edge server placement research, for the problem of partial task unloading of the heterogeneous cloud robot, fine-grained segmentation is carried out on the tasks, an improved game theory algorithm is provided, an optimal unloading strategy is researched, the energyconsumption of the cloud robot is reduced, and the task completion time is shortened.

Owner:XIAN TECHNOLOGICAL UNIV

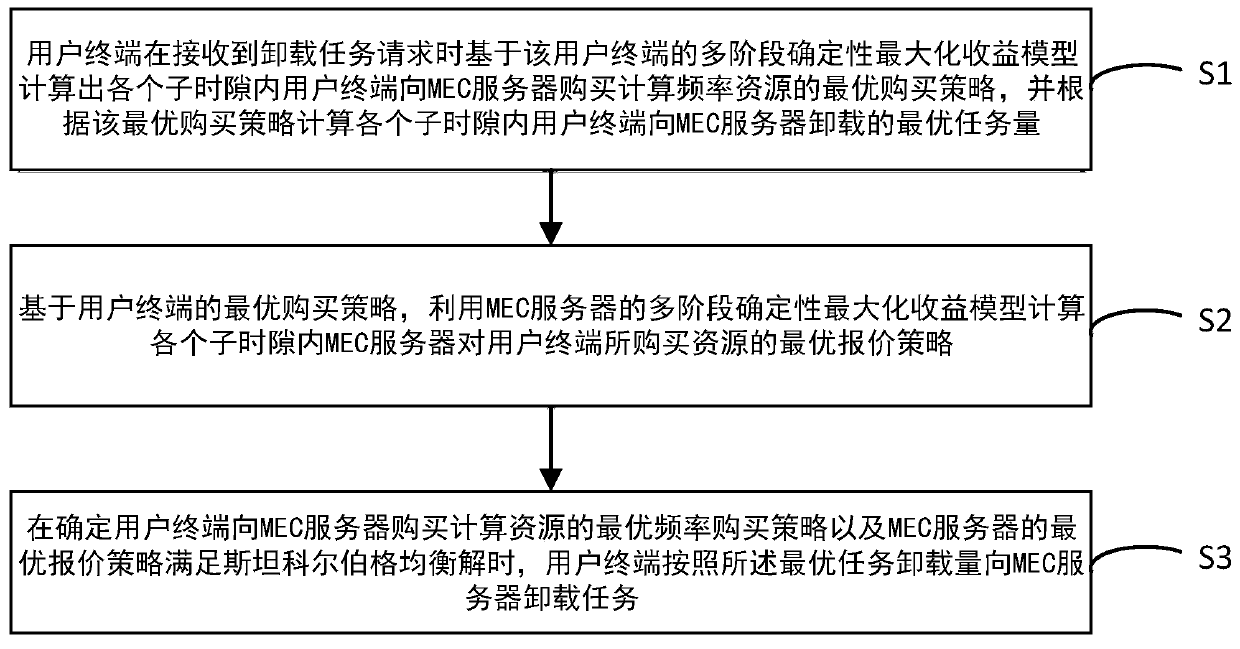

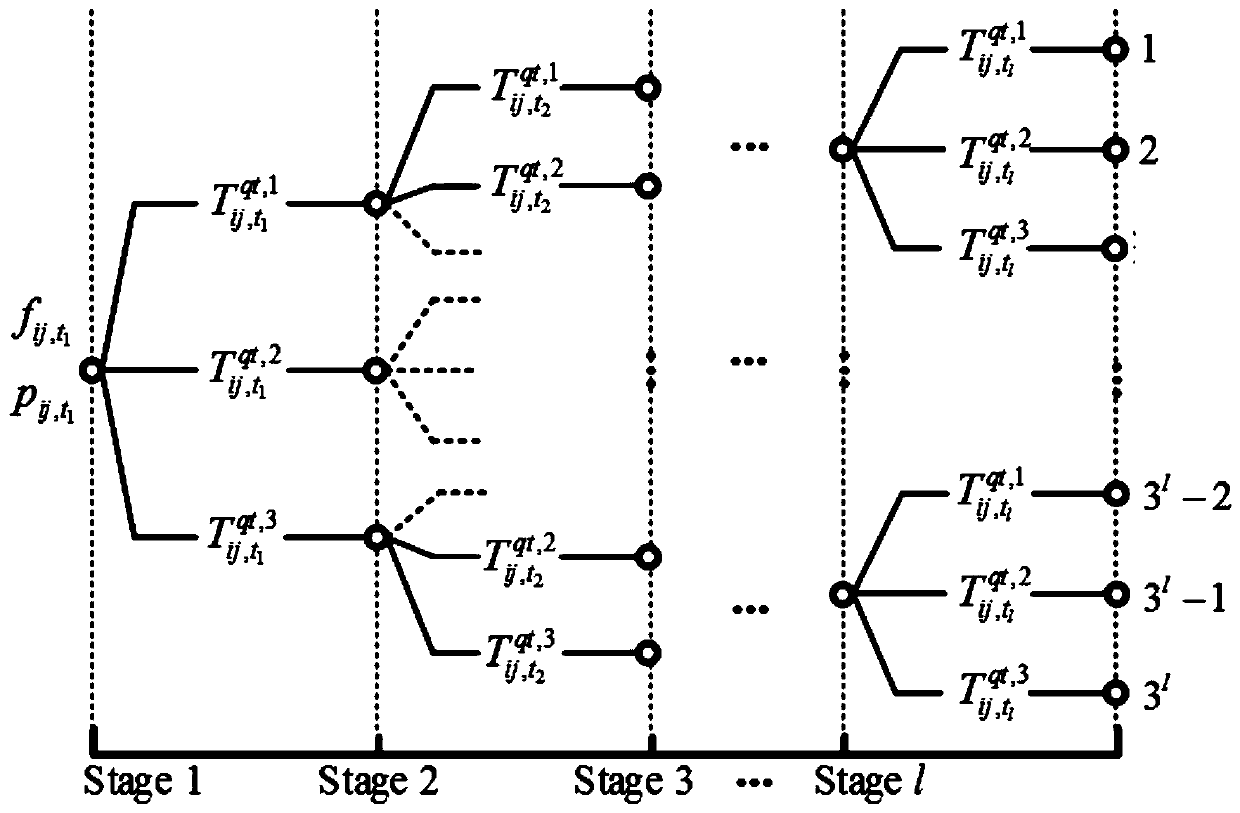

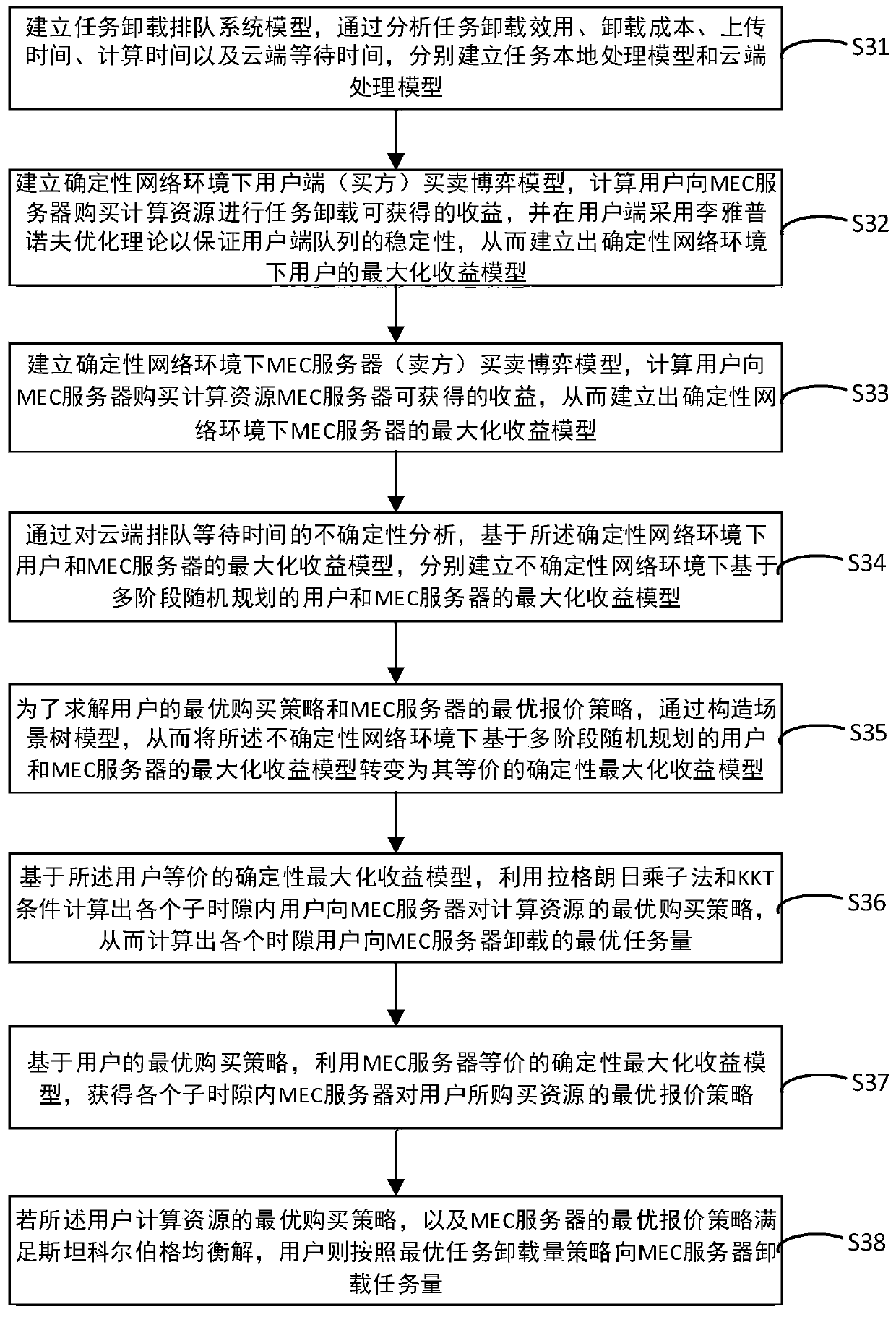

Dynamic task unloading method in uncertain environment in mobile edge computing

ActiveCN111401744AResolve uncertaintyEfficient unloadingResourcesTransmissionInternet of ThingsServer-side

The invention discloses a dynamic task unloading method in an uncertain environment in mobile edge computing. According to the invention, the method gives full consideration to the uncertainty of thecloud task queuing waiting time and the randomness and explosiveness generated by massive Internet of Things equipment tasks in an actual distributed Internet of Things environment. According to the method, a buying and selling game model is adopted, a user side is defined as a buyer, a server side is defined as a seller, a multi-stage stochastic programming model is introduced, the uncertainty problem of cloud queuing waiting time delay is solved, efficient task unloading can be carried out in an uncertainty environment, and the success rate of task unloading can be effectively improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

Self-lifting/lowering transport container

Owner:TATSUMI

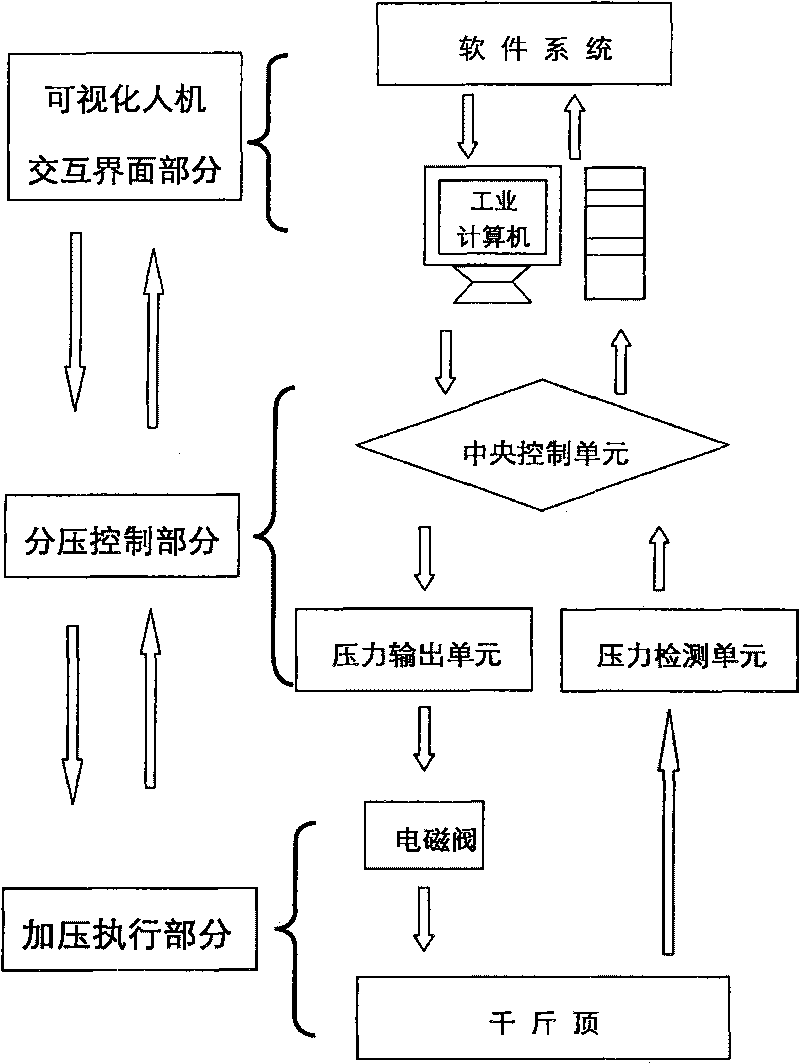

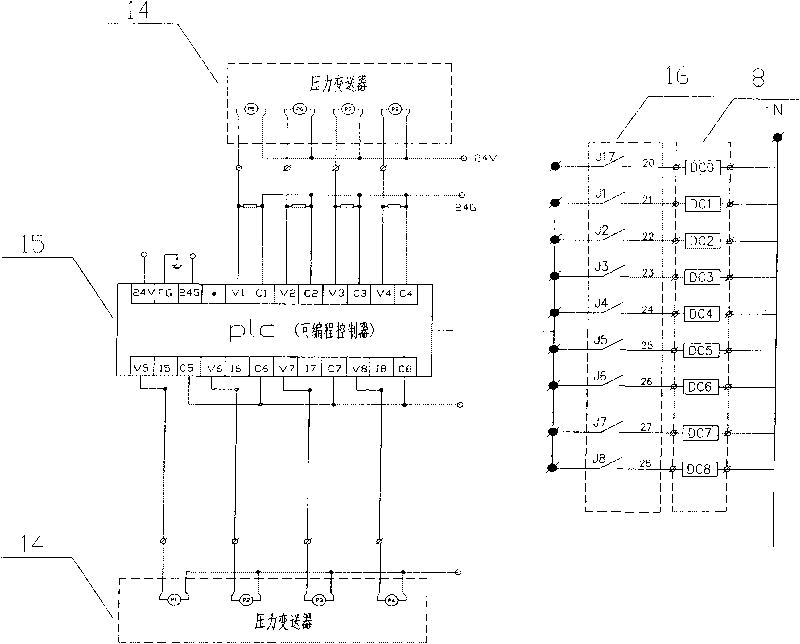

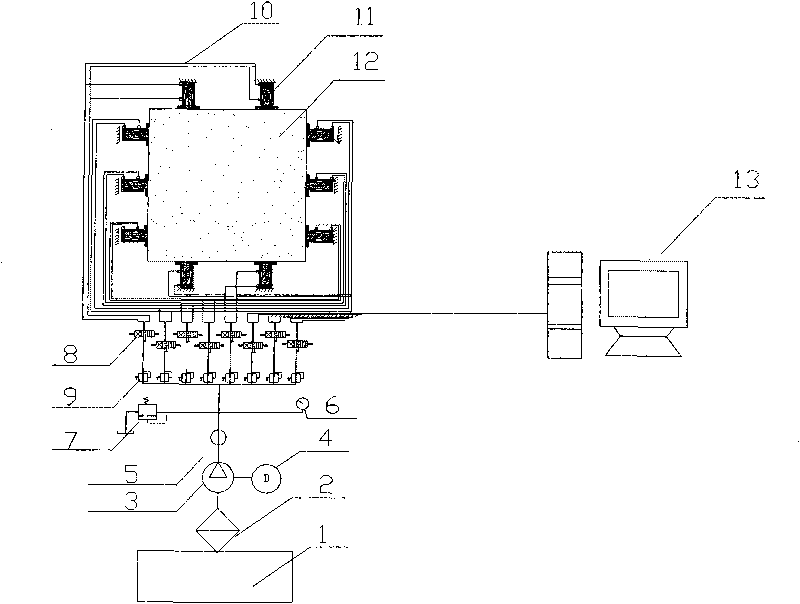

CNC pressurizing system for model test and control method thereof

InactiveCN101726440AGo digitalRealize visualizationServomotorsMaterial strength using tensile/compressive forcesSoftware systemInteraction interface

The invention relates to a CNC pressurizing system for a model test and a control method thereof. The CNC pressurizing system for the model test comprises a partial pressure control part, a pressurization performing part and a visible human-computer interaction interface part, wherein the partial pressure control part comprises a pressure detection unit, a central control unit and a control output unit; the pressurization performing part comprises various control valves and various pressurization jack; the visible human-computer interaction interface part comprises a loading software system and an industrial computer system; a digital pressurization control part inputs a pressurizing command via the visible human-computer interaction interface; the partial pressure control part processes and converts obtained pressure information to generate an electric signal and inputs the electric signal to the pressurization performing part so as to carry out load output; and meanwhile, a partial pressure control system dynamically monitors the output load and feeds the output load to a visible human-computer interaction interface system for real-time display, storage and adjustment. The CNC pressurizing system for the model test and the control method thereof can realize digitization, visualization and intelligence of model loading in underground engineering model tests in the fields of hydroelectric power, transportation, energy source, resources and defense construction.

Owner:SHANDONG UNIV

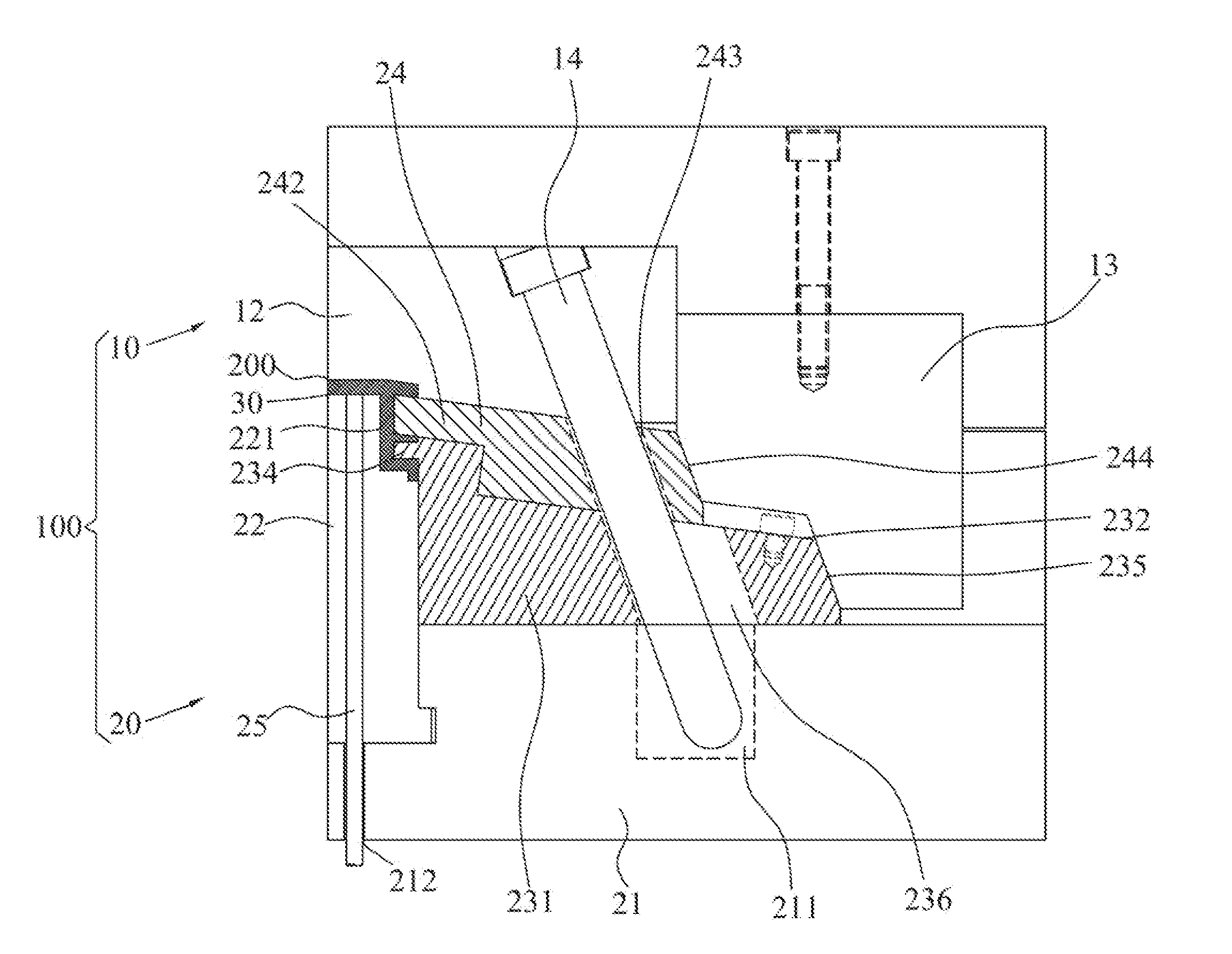

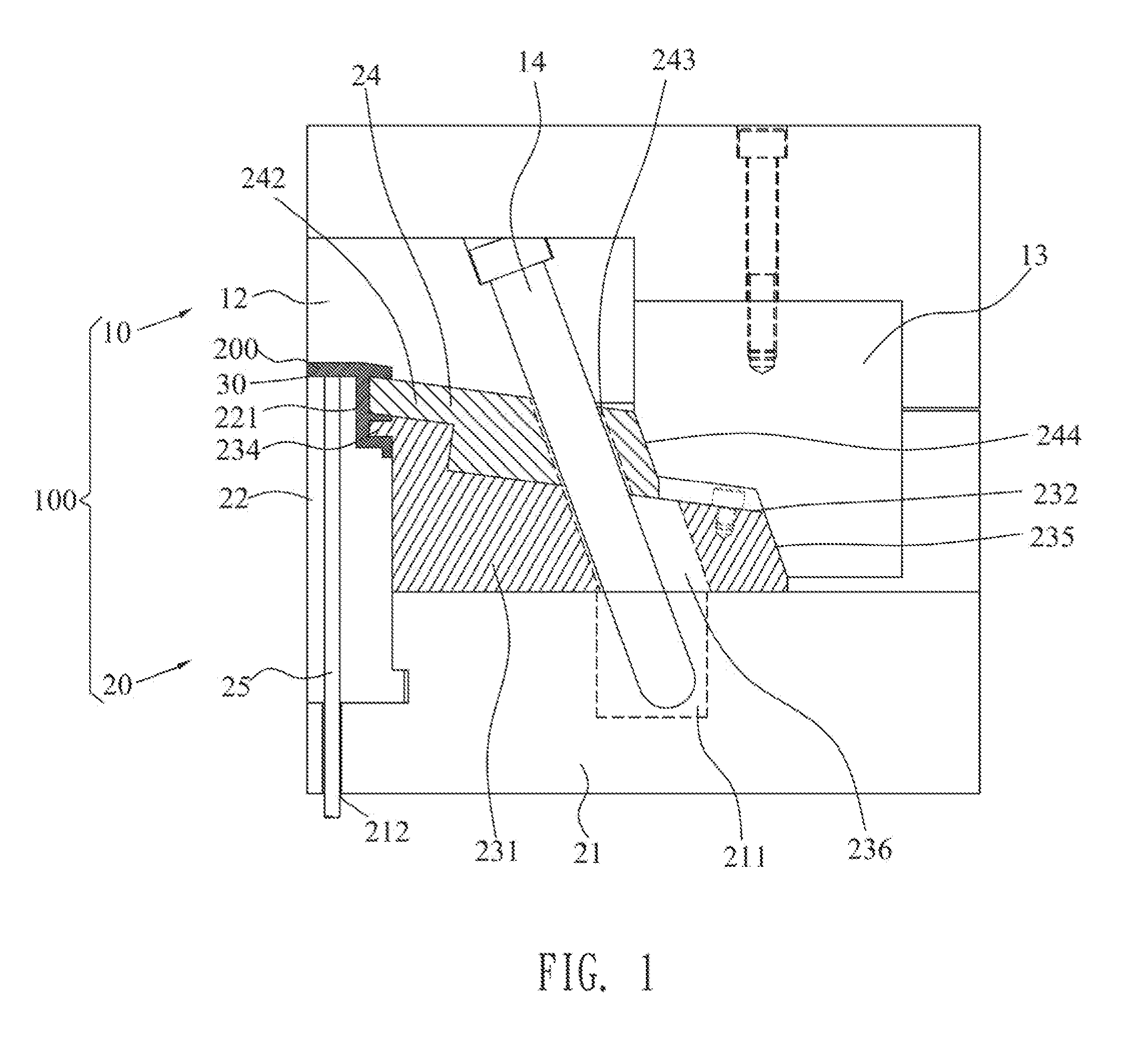

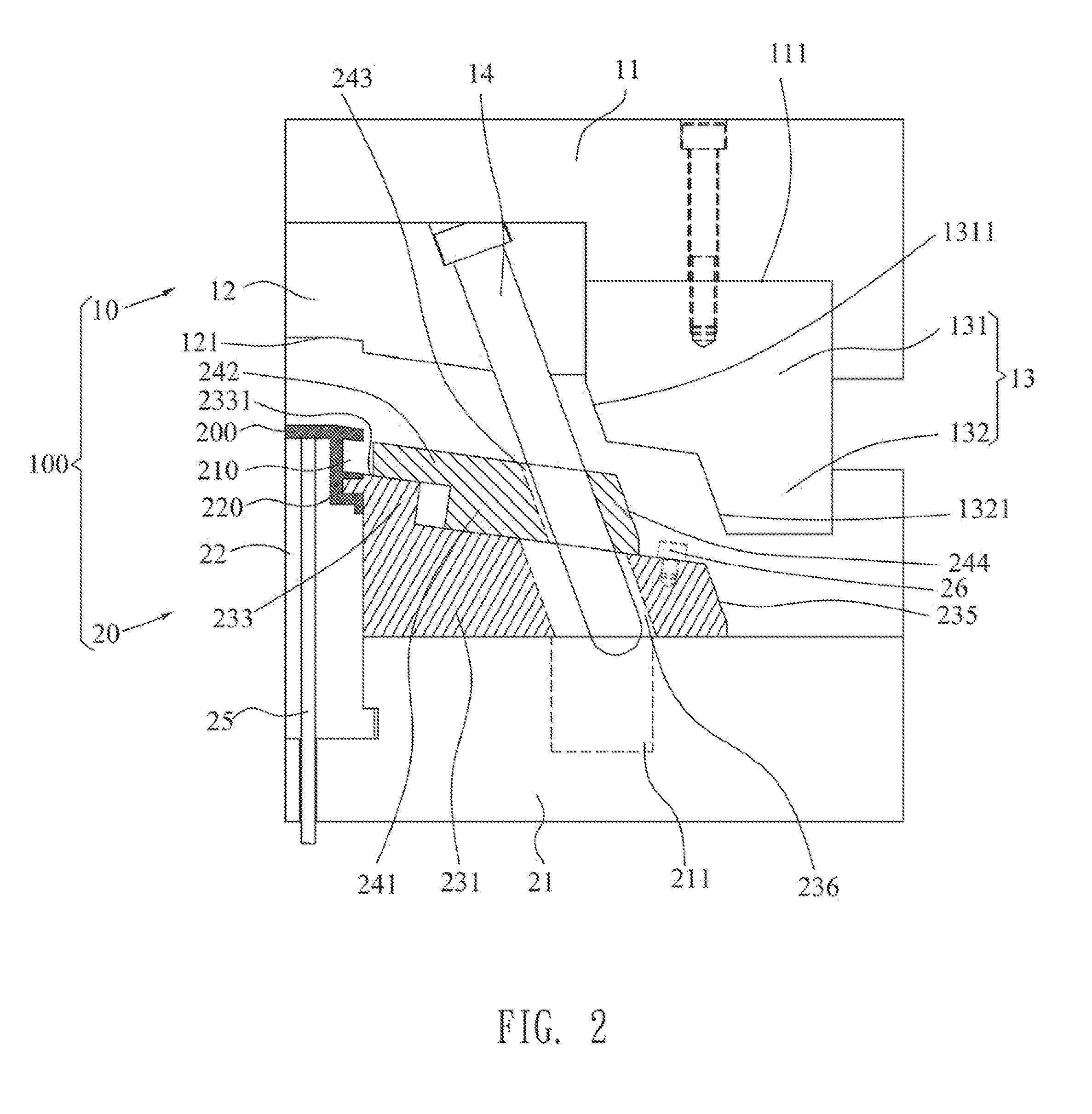

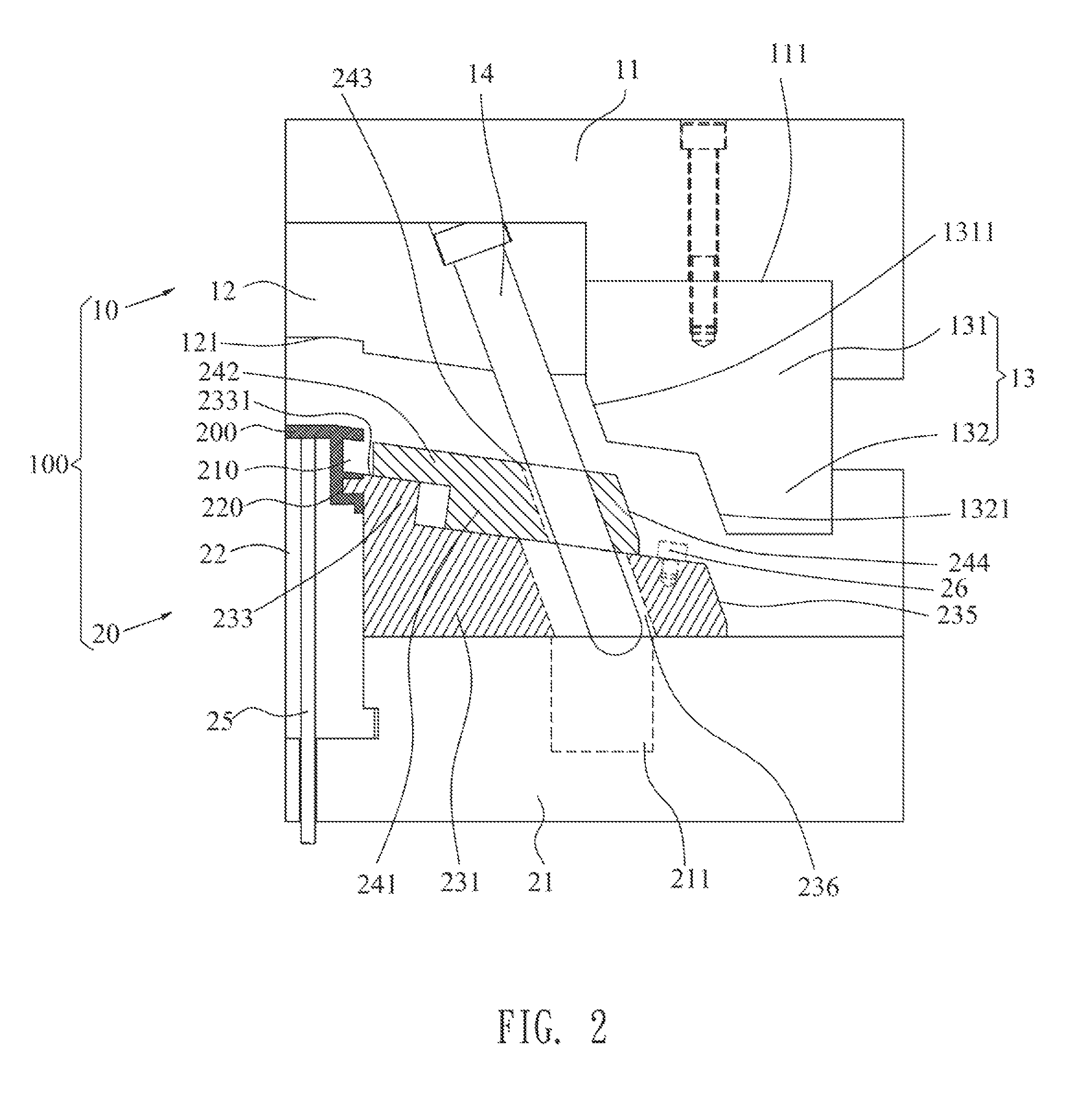

Injection mold

InactiveUS20130101693A1Reduce defective rateReduce manufacturing costAuxillary shaping apparatusMaterials scienceEngineering

Owner:CHENG UEI PRECISION IND CO LTD

User-centered distributed multi-user computing task unloading method

The invention provides a user-centered distributed multi-user computing task unloading method. The method is characterized by comprising the following steps: uniformly abstracting multiple fog computing nodes into an access point with a servers, wherein the access point has both computing and communication capabilities; when any user generates a computing task, comprehensively considering the unloading decisions of other users; and choosing to compute locally or to unload the computing task into one of other computing nodes according to an unloading decision under a current time slot in orderto minimize own overhead. Through adoption of the user-centered distributed multi-user computing task unloading method provided by the invention, stable and efficient computing task unloading among multiple users can be realized in a distributed execution way. A user satisfactory result can be achieved, and relatively high overall performance of the system can be ensured (compared with the optimalstrategy of the system).

Owner:SHANGHAI TECH UNIV

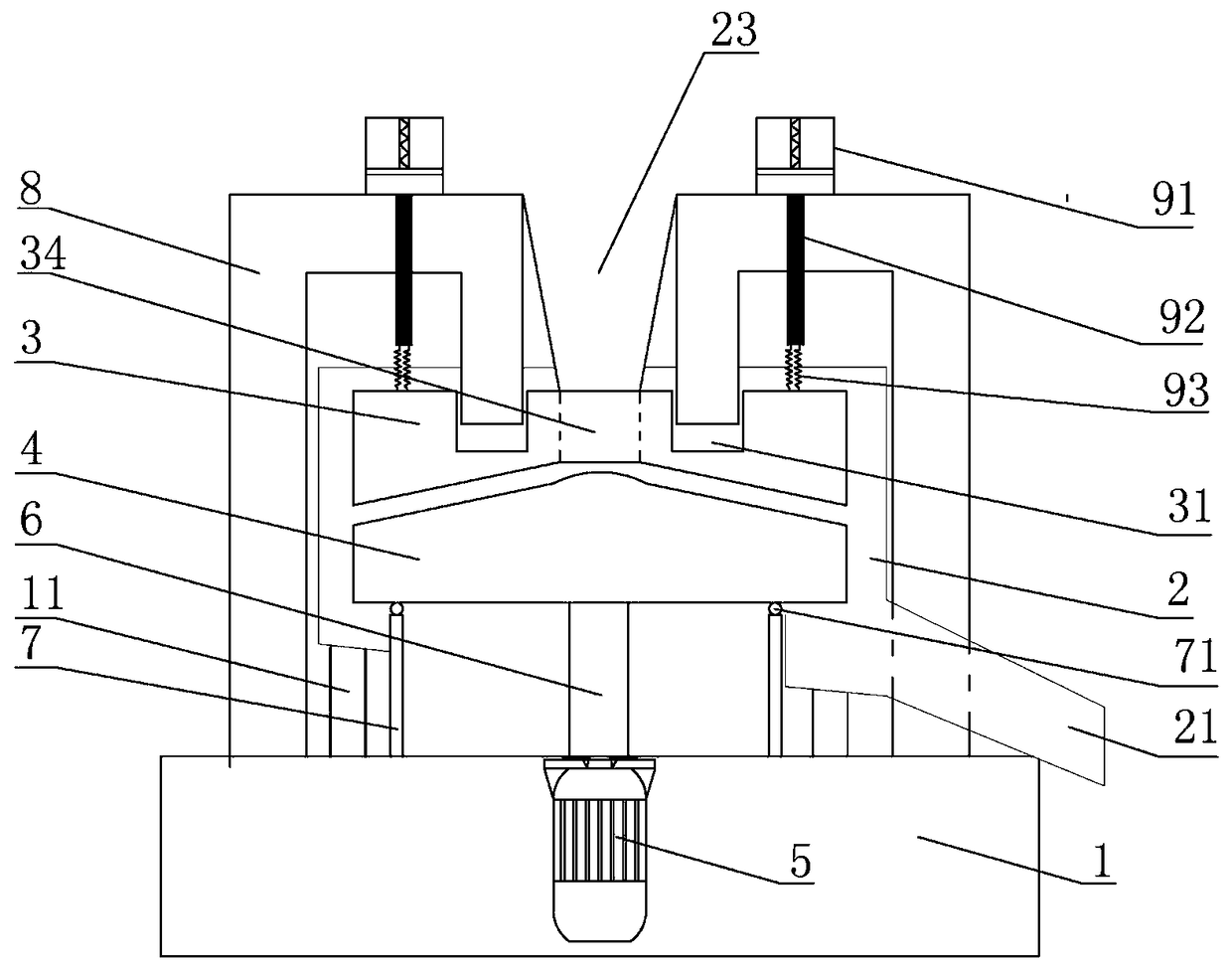

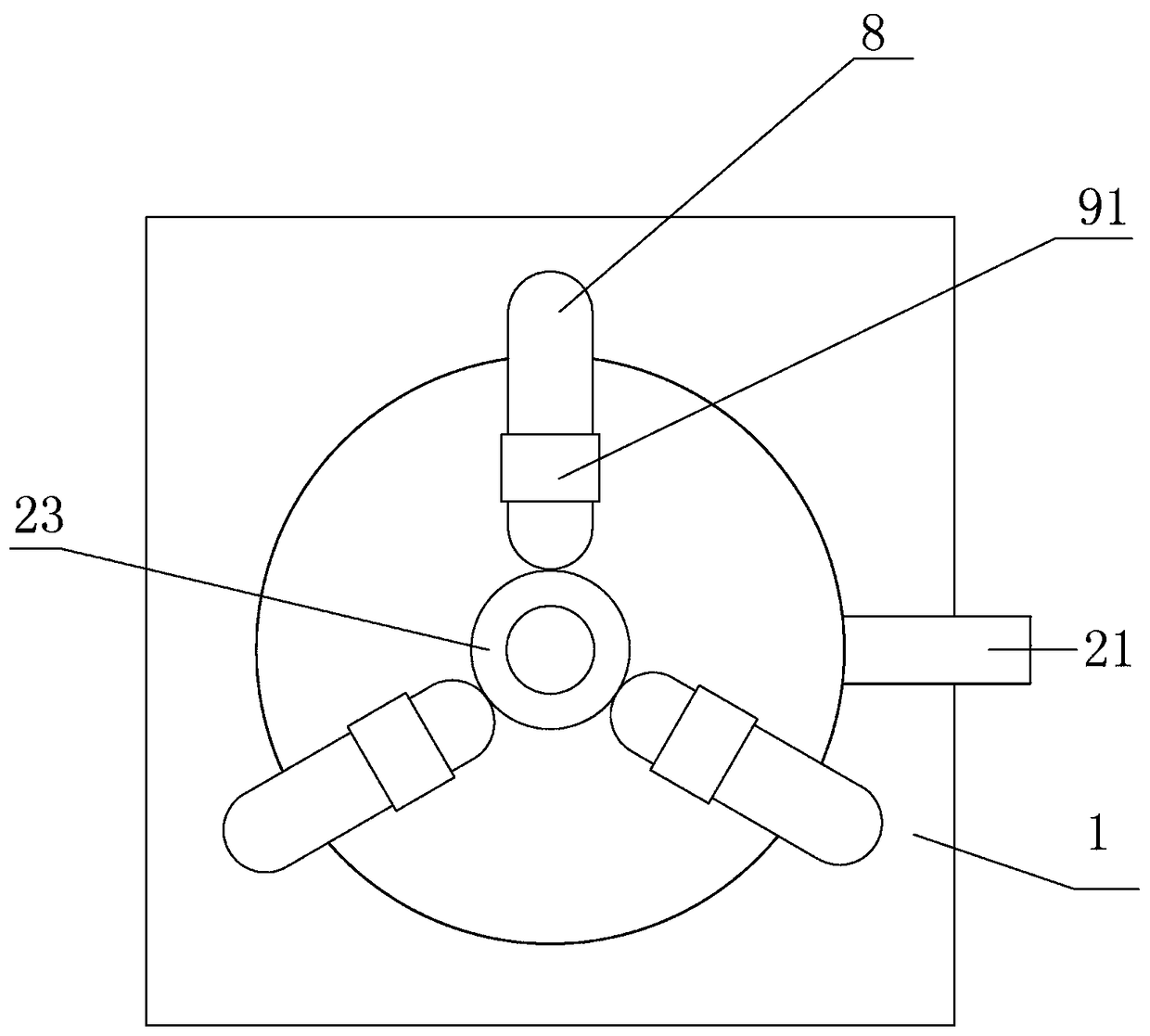

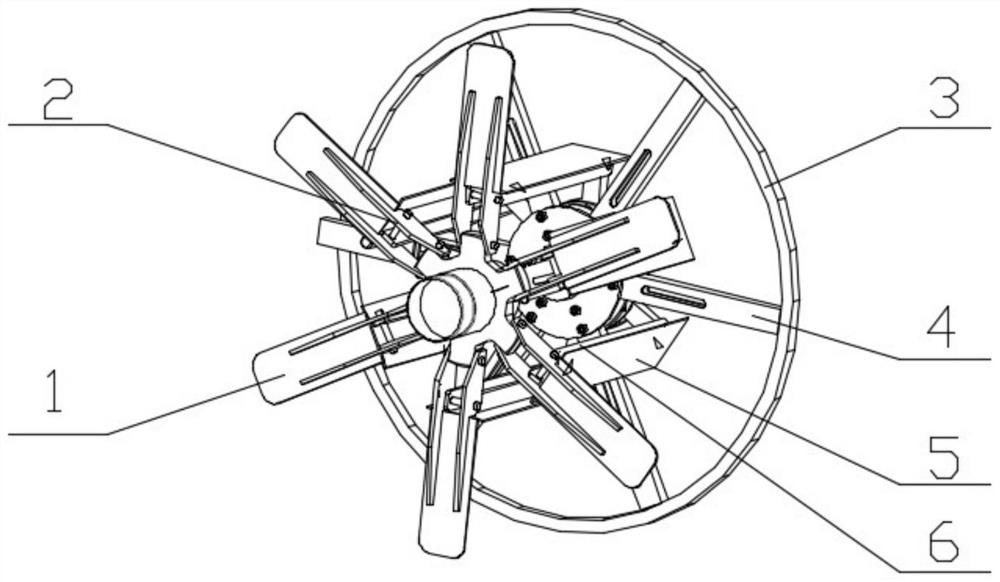

Cone-disc type waste concrete regenerated coarse aggregate mortar stripping device

ActiveCN109012867AWeaken protruding cornersReduce mud contentCocoaGrain treatmentsMetallurgyConstruction aggregate

The invention discloses a cone-disc type waste concrete regenerated coarse aggregate mortar stripping device. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device comprises a base, a material collection bin and a cone-disc type grinding disc, wherein the cone-disc type grinding disc is composed of an upper grinding disc and a lower grinding disc, the grinding surface of the lower grinding disc is of a convex cone type, the grinding surface of the upper grinding disc is of a concave cone type, and the grinding surface of the upper grinding disc is in fit with that of the lower grinding disc; the base is provided with a plurality of reverse-hook-shaped supports, the disc surface of the upper grinding disc is correspondingly provided with position-limiting holes, and reverse hooks of all the reverse-hook-shaped supports penetrate into the corresponding position-limiting holes to restrict the upper grinding disc to be only capable of sliding up and down; ahydraulic force transmitting device is arranged between the upper grinding disc and all the reverse-hook-shaped supports, and ascending and descending of the upper grinding disc are controlled through stretching and contracting adjustment of the hydraulic force transmitting device; and the center of the upper grinding disc is provided with a material inlet, the material inlet penetrates out of the top of the material collection bin, and the lower portion of the material collection bin is provided with a material outlet. The cone-disc type waste concrete regenerated coarse aggregate mortar stripping device is simple in structure, the aggregate mortar stripping effect is good, and the original particle size of coarse aggregate can be maintained to make the performance of the coarse aggregate be close to natural aggregate, so that the workability, strength and durability of freshly-mixed waste concrete are improved.

Owner:CHINA UNIV OF MINING & TECH

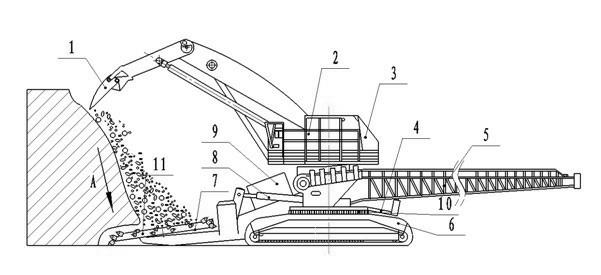

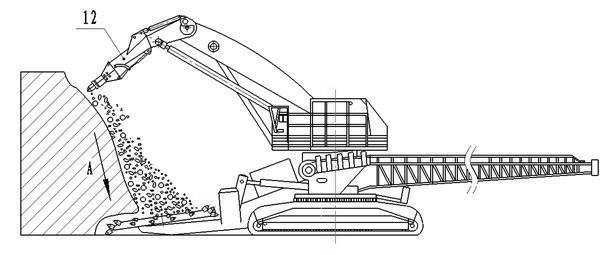

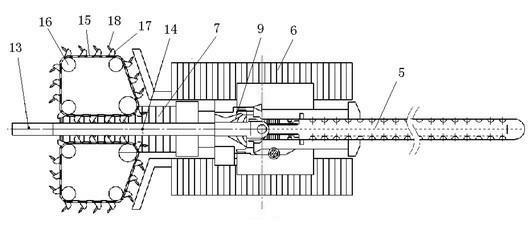

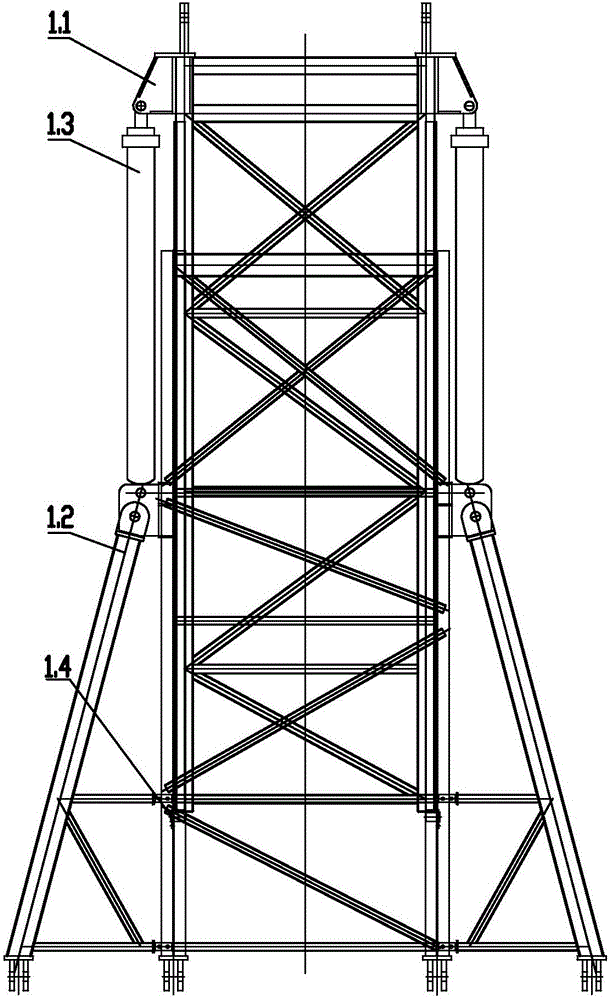

Strip mining machine for mine

InactiveCN102691503AImprove stabilityImprove compactnessSlitting machinesOpen-pit miningIntegrated operationsMechanical engineering

A strip mining machine for a mine belongs to technical field of mining equipment, and is applied to integral strip mining of surrounding rock and mineral of an open-pit mine. The technical scheme is that the strip mining machine comprises a cutting, slotting and scraper type loading part, a raking down part, a scratch board transporting device, a crushing device, a rubber belt transporting device, a rotating and elevating system, a walking part and a rotating part, wherein the cutting, slotting and scraper type loading part is arranged at the front end of the strip mining machine; the scratch board transporting device is mounted at the lower part of the cutting, slotting and scraper type loading part; the back end of the scratch board transporting board device is connected to the crushing device; the crushing device is connected to the rubber belt transporting device; the rotating and elevating system is mounted at the lower part of the rubber-belt transporting device; the transporting belt of the rubber belt transporting device is mounted in the middle of the track of the walking part; the raking down part is arranged above the cutting, slotting and scraper type loading part; and the rotating part is mounted above the walking part. The strip mining machine can realize the integrated operation of continuous strip mining, crushing, transshipping and transporting for the open-pit mine, thereby greatly improving the strip mining efficiency and the productivity of the mine.

Owner:TIANDI TANGSHAN MINING TECH

Plate bending system

ActiveCN110153240AAchieve bendingReduce threatMetal-working feeding devicesStripping-off devicesPunchingEngineering

The invention relates to a plate bending system, and relates to the technical field of plate bending. When an existing bending machine is used for bending plates, one side of the plate can be upwardswarped, and potential safety hazards to surrounding operators are caused. The plate bending system comprises a bending machine which comprises a punching head and a lower die. One side of the bendingmachine is provided with a supporting assembly, a first driving assembly and a second driving assembly, wherein the supporting assembly is used for attracting the plates, the first driving assembly isused for driving the supporting assembly to move in the vertical direction, and the second driving assembly is used for driving the supporting assembly to be close to or far away from the bending machine in the horizontal direction. The supporting assembly comprises a fixed plate, a movable plate, a first connecting rod set, a second connecting rod set and attracting parts, wherein the first connecting rod set is connected between the fixed plate and the movable plate, the second connecting rod set is connected between the fixed plate and the movable plate, and the attracting parts are installed on the side, far away from the fixed plate, of the movable plate. According to the plate bending system, the probability of harming the operators due to upward warping of the edges of the plates can be reduced.

Owner:杭州东盛五金电器有限公司

Seabed located storage

ActiveUS20060225633A1Easy to uninstallEasy to moveLarge containersFluid removalEngineeringSubstructure

Seabed located storage for crude oil or other fluid, distinguished in that it is comprising a storage section in form of an oil and waterproof cloth formed as a flexible balloon that can be filled with, store and emptied for a storage fluid, a structure section formed as an external casing over the storage section, which structure section is closed in the upper part such that an upward close volume of size at least corresponding to the volume of the storage section is formed, but with openings to the surroundings in the lower part, an anchoring section formed as a substructure between the structure section and the seabed, with means for anchoring to or stable placement on the seabed, and a transfer section comprising pipes and valves for loading and unloading of a storage fluid, arranged in substance exterior to the upper part of the storage.

Owner:NOV PROCESS & FLOW TECH AS

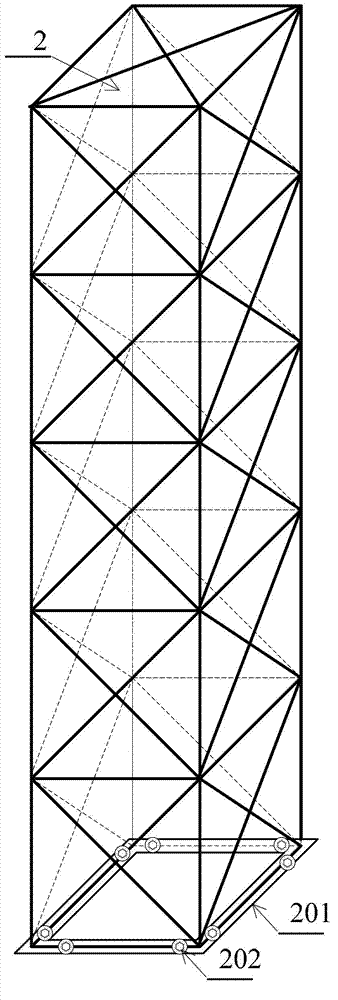

Shoal sea area rescue operational ship with pile driving and pulling device and ship body fixing method

ActiveCN102815374ASafe removalSafe and efficient loading and unloadingSpecial purpose vesselsAnchoring arrangementsSeabedShoal

The invention relates to a shoal sea area rescue operational ship with a pile driving and pulling device. A through hole allowing driving and pulling of a pile is arranged on a deck of an operational ship body, a hollow hoisting truss is fixedly connected on the ship body deck at the upper edge of the through hole, the vertical pile is suspended in the hoisting truss, racks are symmetrically and longitudinally arranged on the lateral side of the outer surface of the pile, and a lifting mechanism which drives the pile to reciprocate longitudinally and enable the pile to be driven in or pulled out of the seabed is meshed with the racks. By means of driving of the pile by the pile driving and pulling device arranged on the ship body, the ship body can be stably fixed to a shoal sea area to set rescue equipment, personnel and corresponding goods and materials down, and after rescue is finished, the ship body can be unfixed to sail freely by means of pulling of the pile by the pile driving and pulling device. The deck of the fixed rescue ship body can serve as a reliable operating platform.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

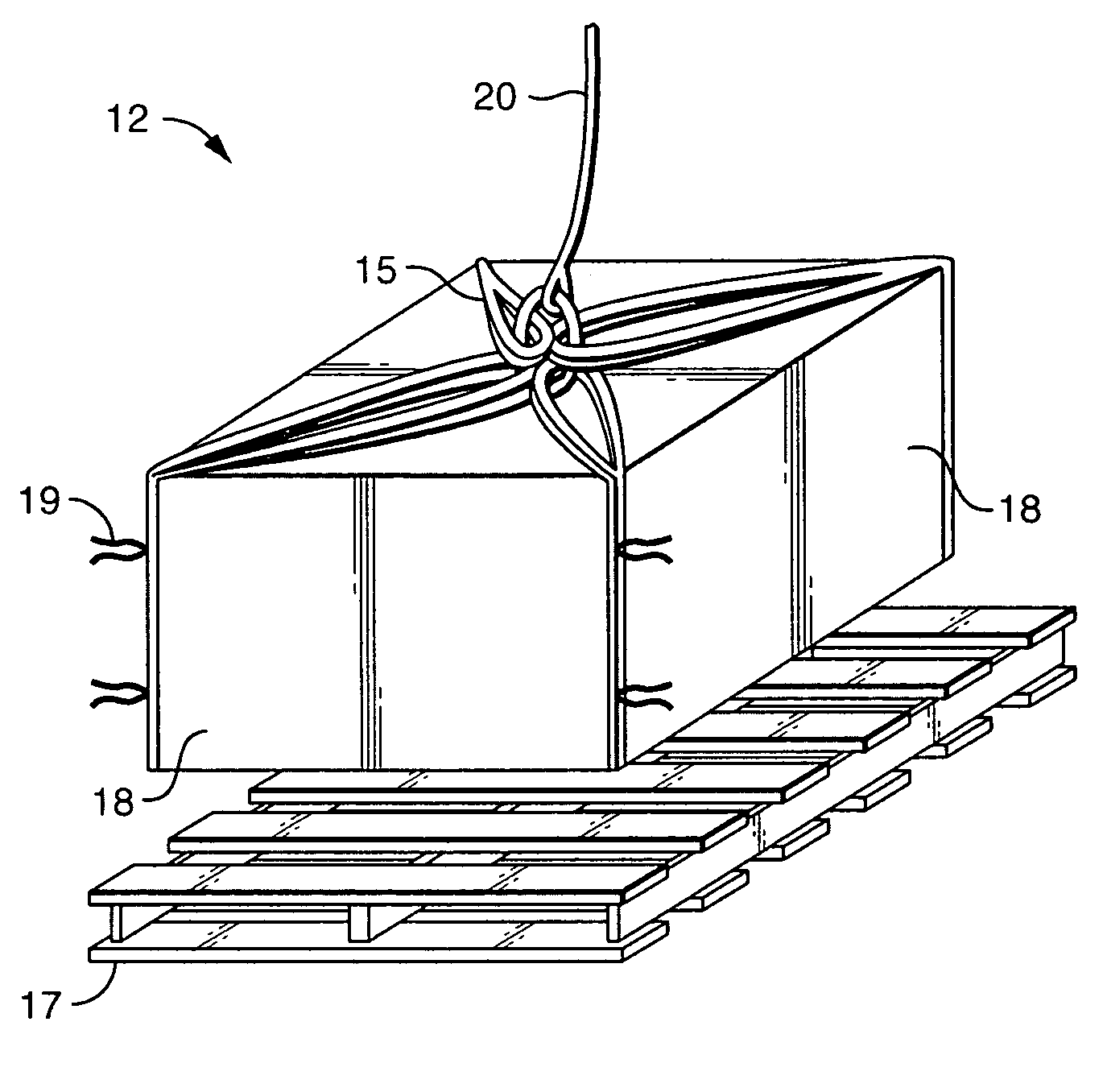

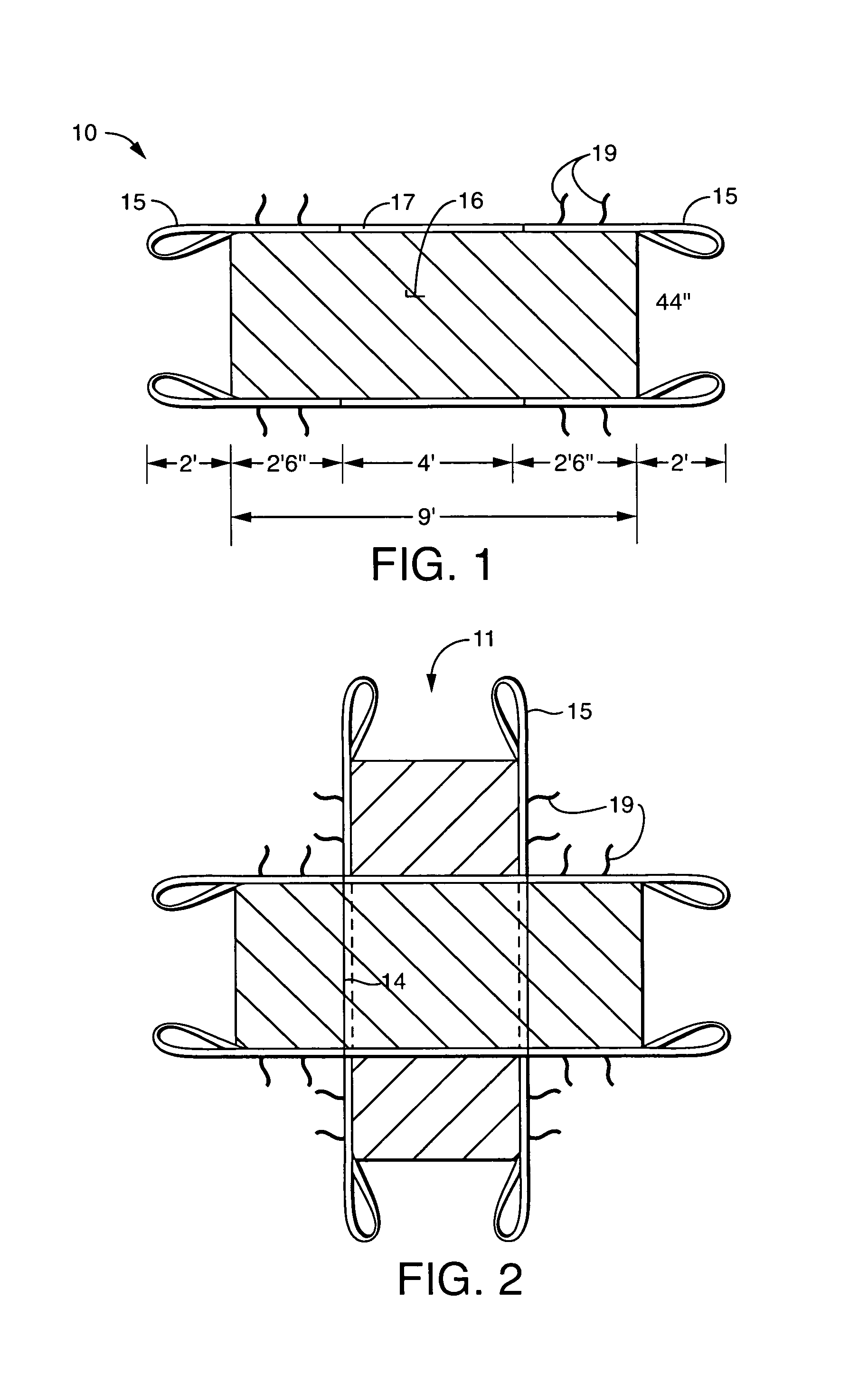

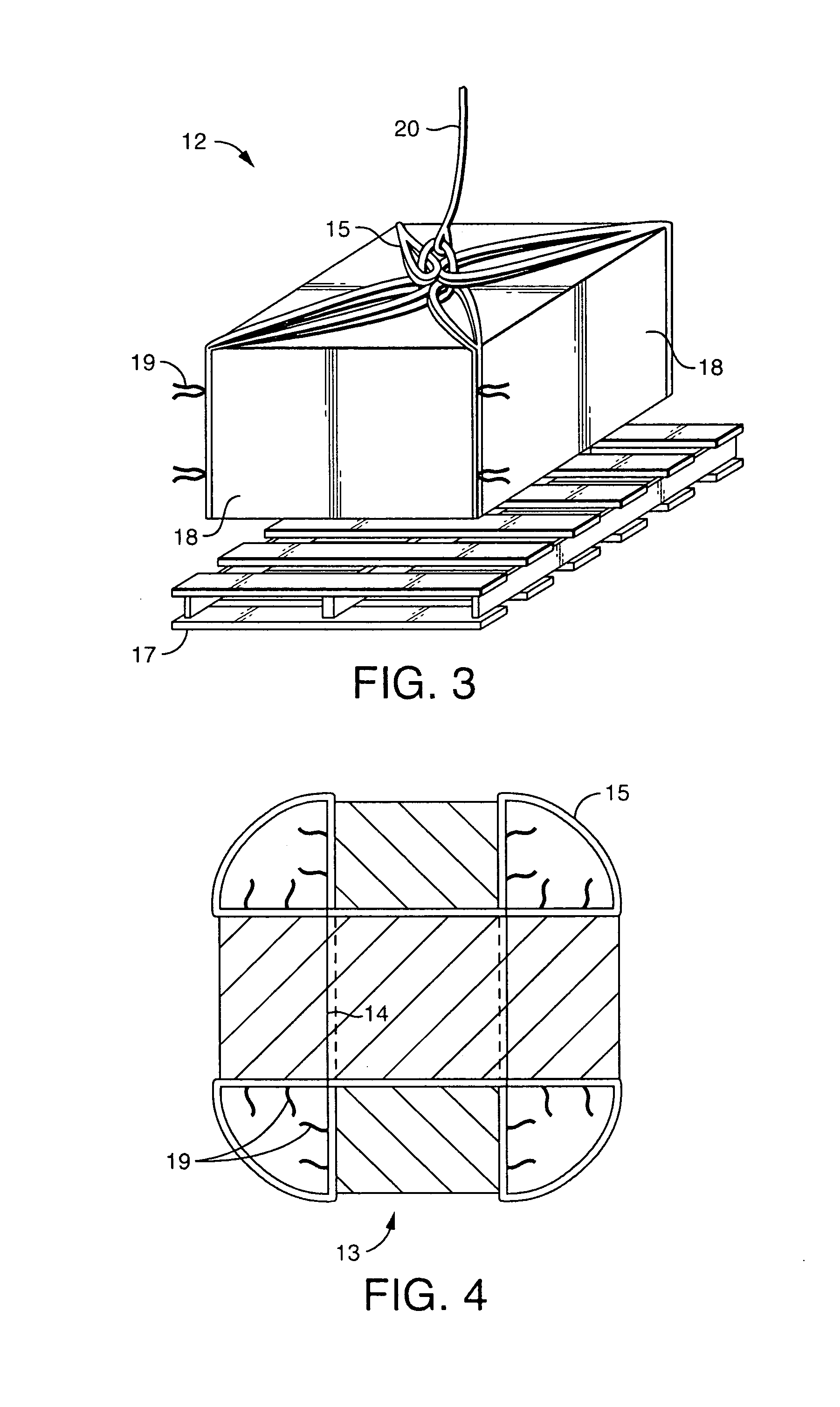

Pallet loading and unloading sling

Owner:QUIKRETE INT

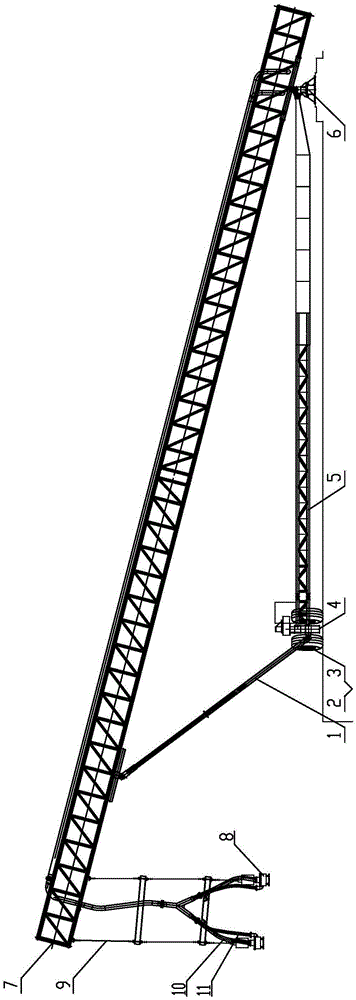

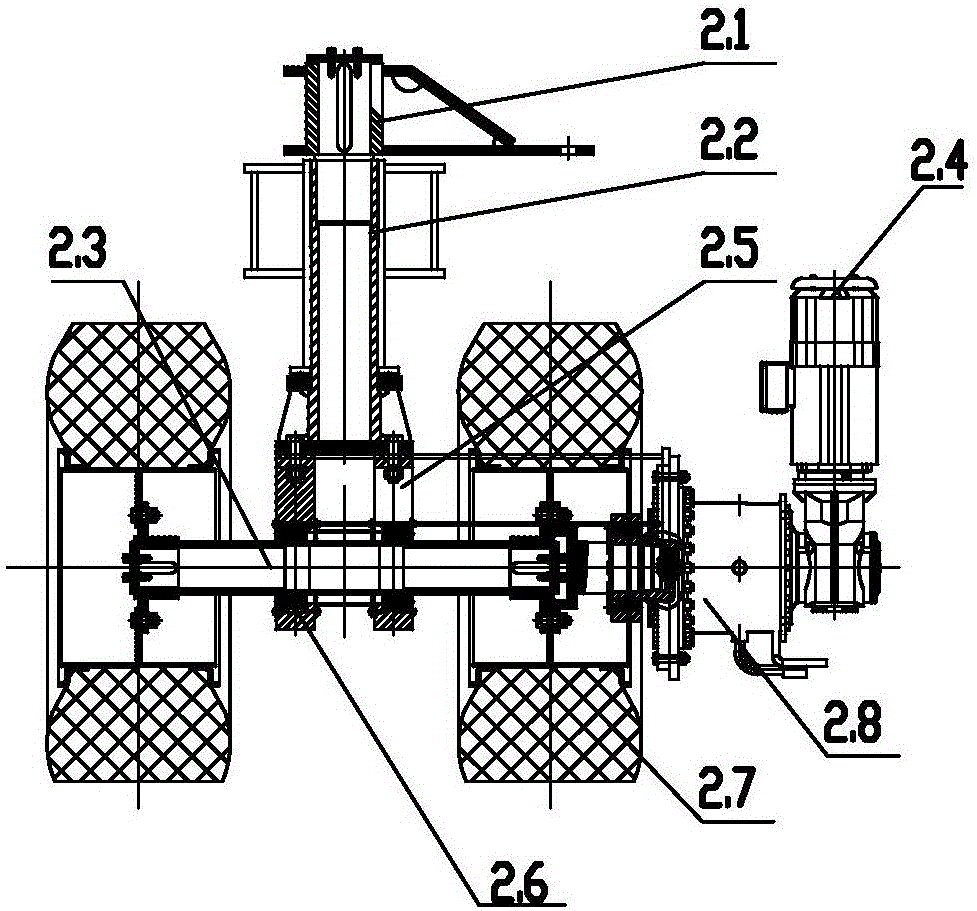

Rotation type hydraulic ship unloader

ActiveCN106429532APollution controlRealize dust-free unloadingLoading/unloadingMarine engineeringVessel type

The invention discloses a rotation type hydraulic ship unloader. The rotation type hydraulic ship unloader comprises a pitching mechanism, a rotation mechanism and a boom. The boom is at least provided with a slime pump. The boom is connected with one end of the rotation mechanism and connected with the other end of the rotation mechanism through the pitching mechanism. Each slime pump is provided with a slime pipeline system and a clean water pipeline system. In the work state, the pitching mechanism and the boom can be driven by the rotation mechanism to rotate around a rotating shaft of the rotation mechanism. The hydraulic manner never adopted in a traditional ship unloader is adopted for ship unloading, dustless unloading can be achieved by utilizing hydraulic power for bulk material ship unloading, and the phenomenon of dust pollution of bulk material wharfs is effectively controlled. The purposes of mechanical production and efficient ship unloading can be achieved in cooperation with the rotation mechanism and the pitching mechanism, the rotation type hydraulic ship unloader can adapt to ship types different in size through changing of the pitching angle, and compared with the traditional ship unloader, the rotation type hydraulic ship unloader is more suitable for unloading bulk materials large in specific gravity, high in water content and small in particle.

Owner:大连华锐国际工程有限公司 +1

Injection mold

InactiveUS8517716B2Reduce defective rateReduce manufacturing costMouldsConfectioneryMaterials science

Owner:CHENG UEI PRECISION IND CO LTD

Self-control cotton collecting box

The invention relates to a self-control cotton collecting box, belonging to the technical field of harvesting and storing facilities of agricultural products. One side which is adjacent to the open end of a cotton collecting box boy of the cotton collecting box is articulated and supported on a chassis frame through a support cantilever, the support end of a lifting oil cylinder is articulated and supported on the chassis frame, the telescopic end of the lifting oil cylinder is articulated and supported on the cotton collecting box boy, the support cantilever is articulated with one branch of a V-shaped direction-changing rod which is articulated and supported on the cotton collecting box body, the other branch of the V-shaped direction-changing rod is articulated with one end of a pull rod, the other end of the pull rod is articulated with one end of a dislocation and conveying chain, the other end of the dislocation and conveying chain is linked with a positioning and conveying chain, and the positioning and conveying chain is positioned on the bottom side of the cotton collecting box body. According to the self-control cotton collecting box disclosed by the invention, an ascending dislocation action of the cotton collecting box body can be realized through the ingenious and reasonable structure, and reasonable linkage of the conveying chains is further realized, so that high-efficient cotton unloading can be further realized; and furthermore, transfer and transportation equipment can be positioned below the cotton collecting box body, so that cotton can be prevented from falling onto the ground.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

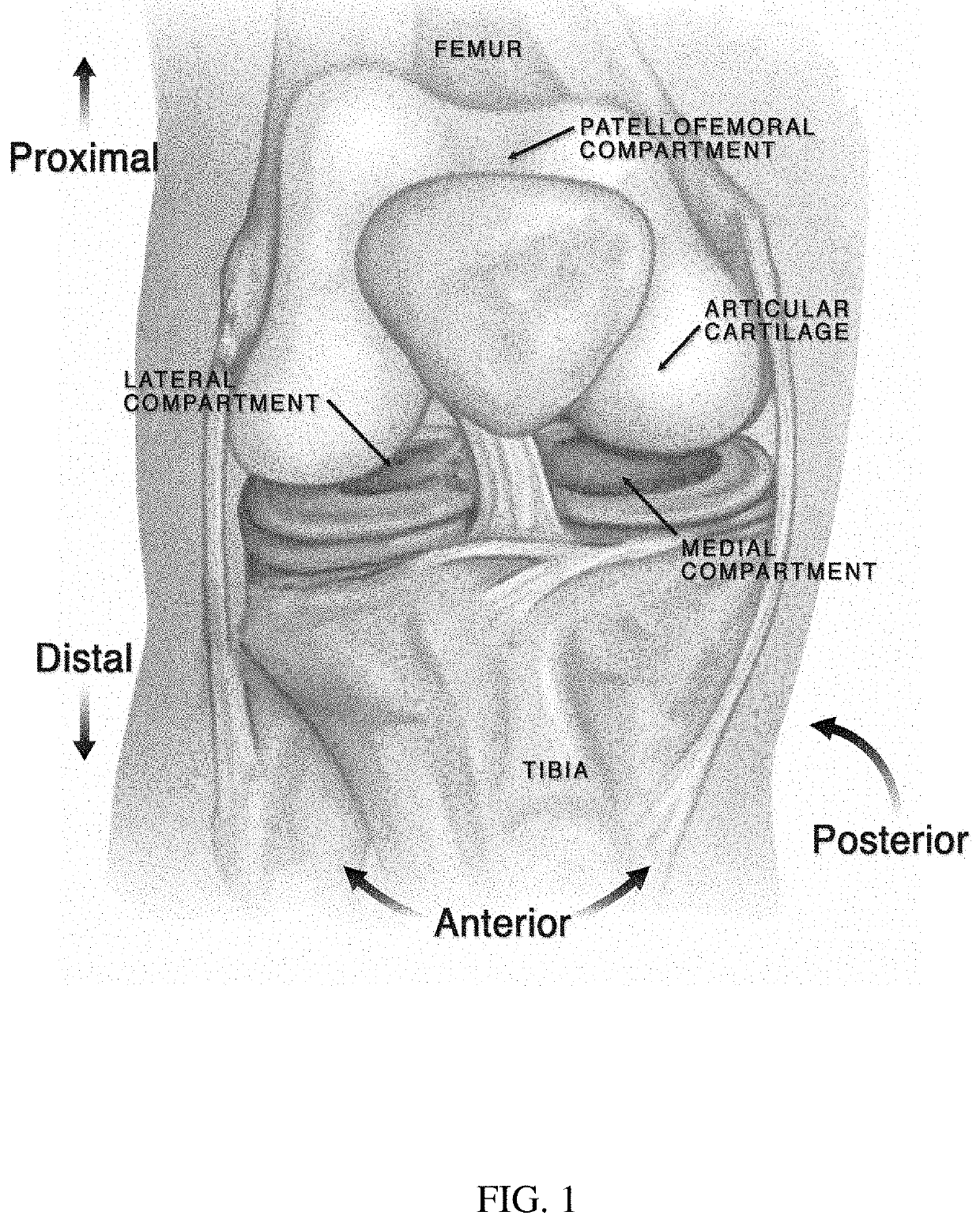

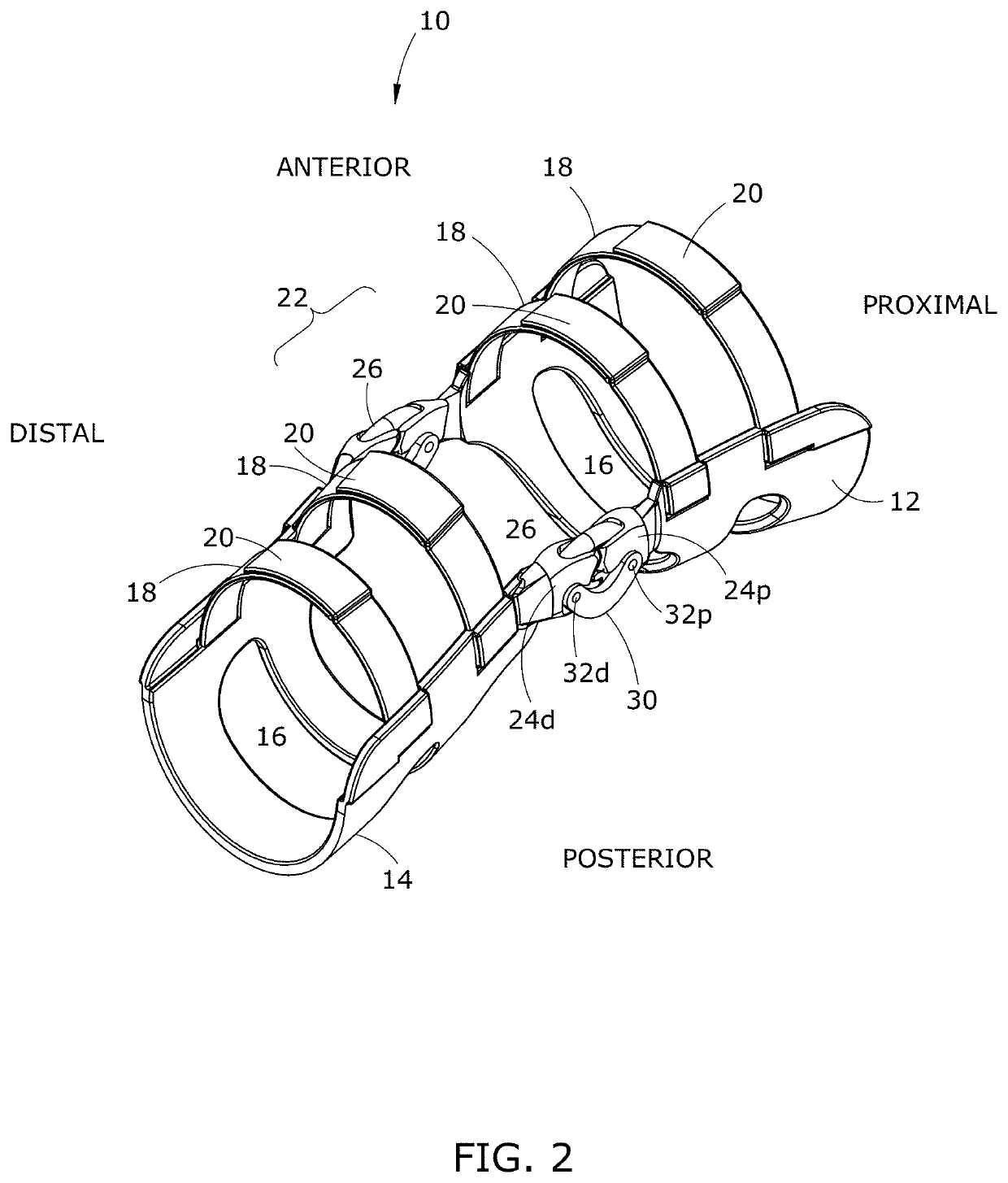

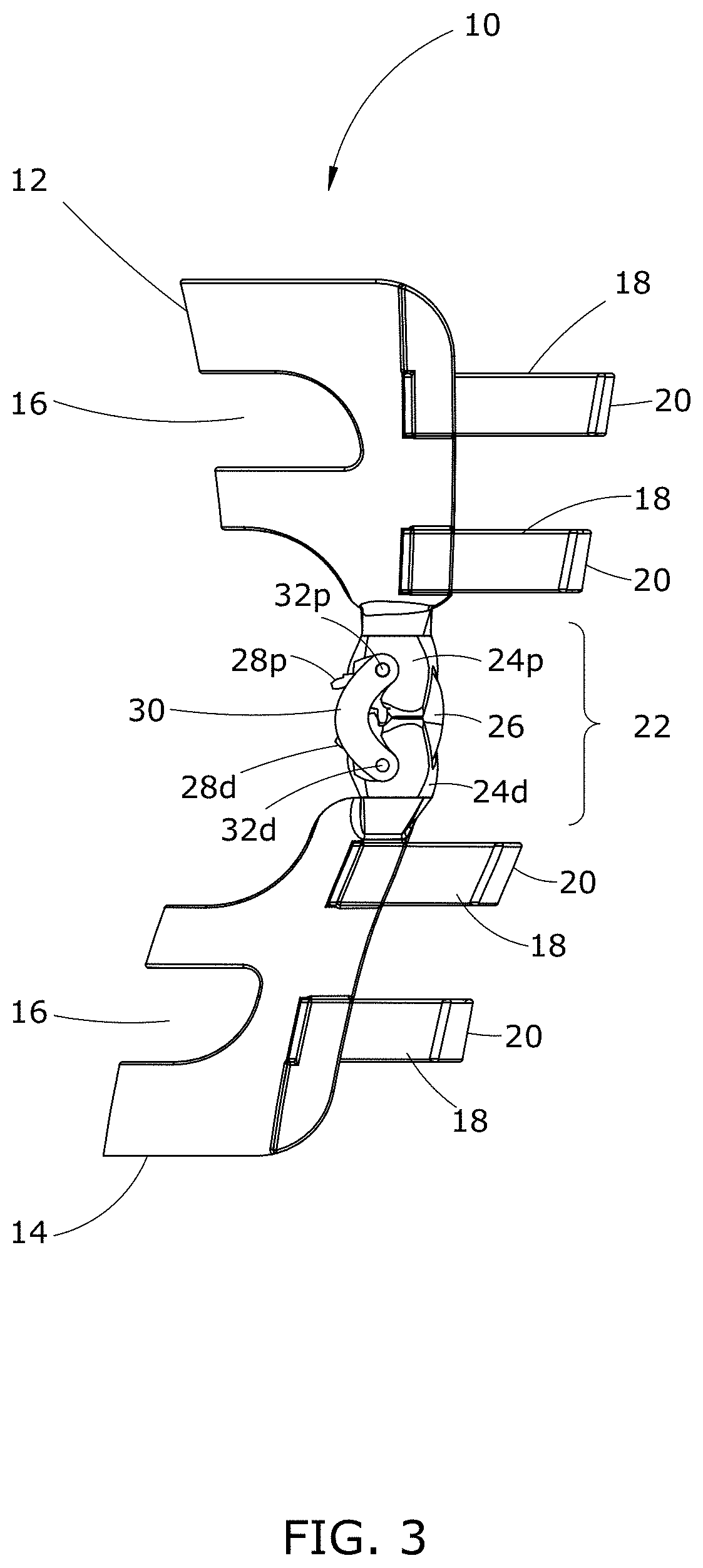

Unloading knee brace apparatus

ActiveUS10806619B1Relieve painReduce frictionNon-surgical orthopedic devicesPhysical medicine and rehabilitationKnee Joint

An adjustable tension knee brace for unloading weight from a knee joint afflicted with osteoarthritis, thus reducing pain and improving mobility, comprising: an upper and lower rigid posterior portion, anterior straps, and a tension adjustable geared hinge assembly. Four embodiments are disclosed of hinge assemblies useable with the knee brace, or other types of braces. The hinge assemblies comprise: two subunits housing intermeshed gears, and at least one elastic band extending between the hinge subunits over a cam surface above the gears. In three embodiments, U-shaped connectors secure the subunits and gears together, and the subunits may comprise a user mechanism that adjusts the elastic band's tension and thus the amount of weight unloaded, then releases it. Another embodiment comprises a core bracket to protect the band(s) and a mechanism to compress the elastic band at various points to increase the amount of tension, and with a quick release mechanism.

Owner:ICARUS MEDICAL LLC

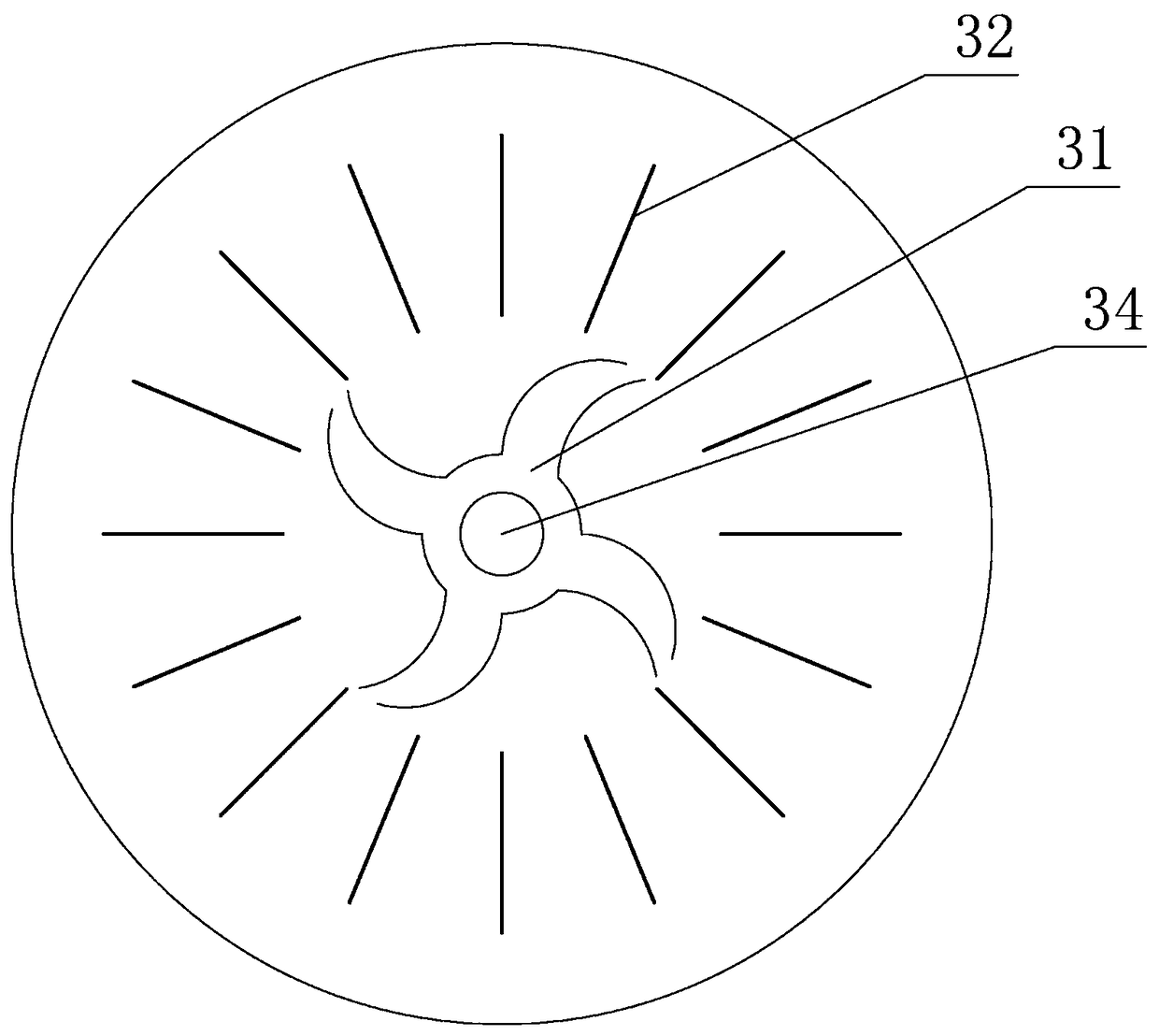

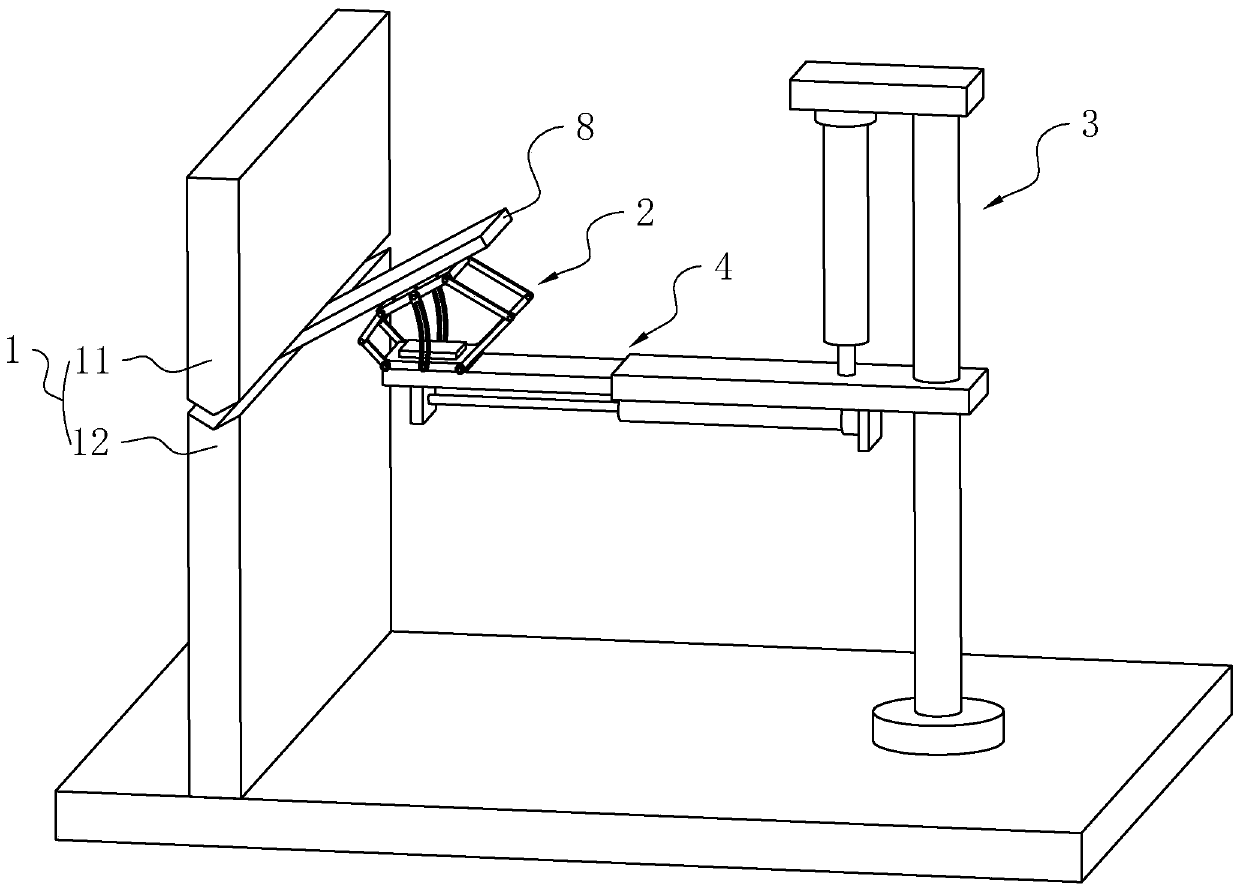

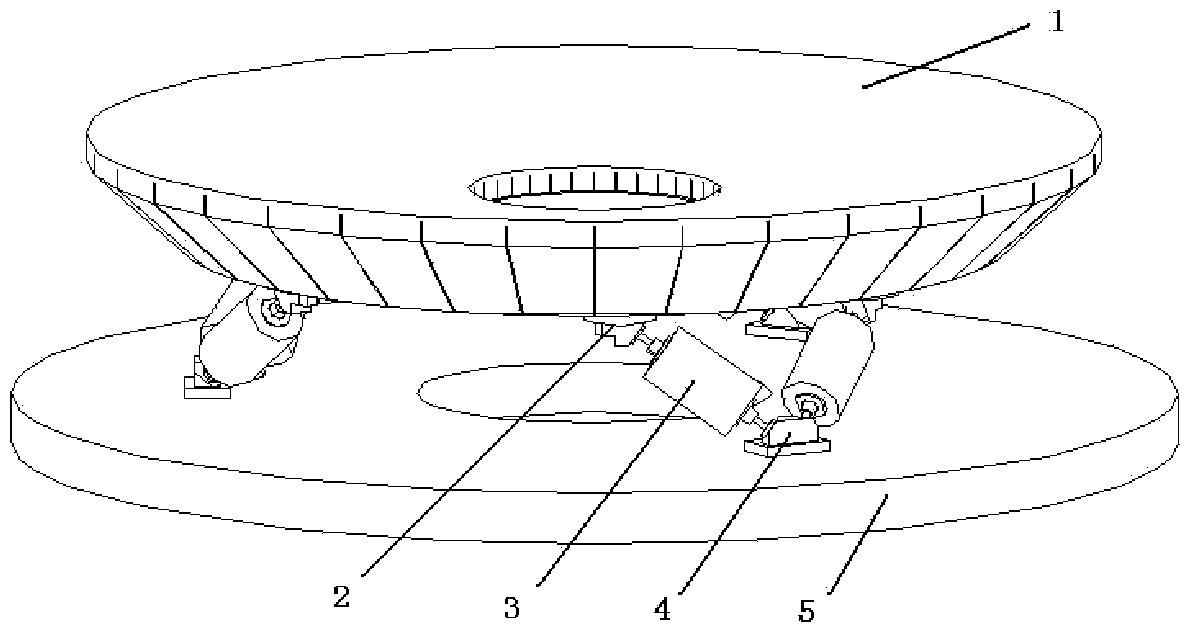

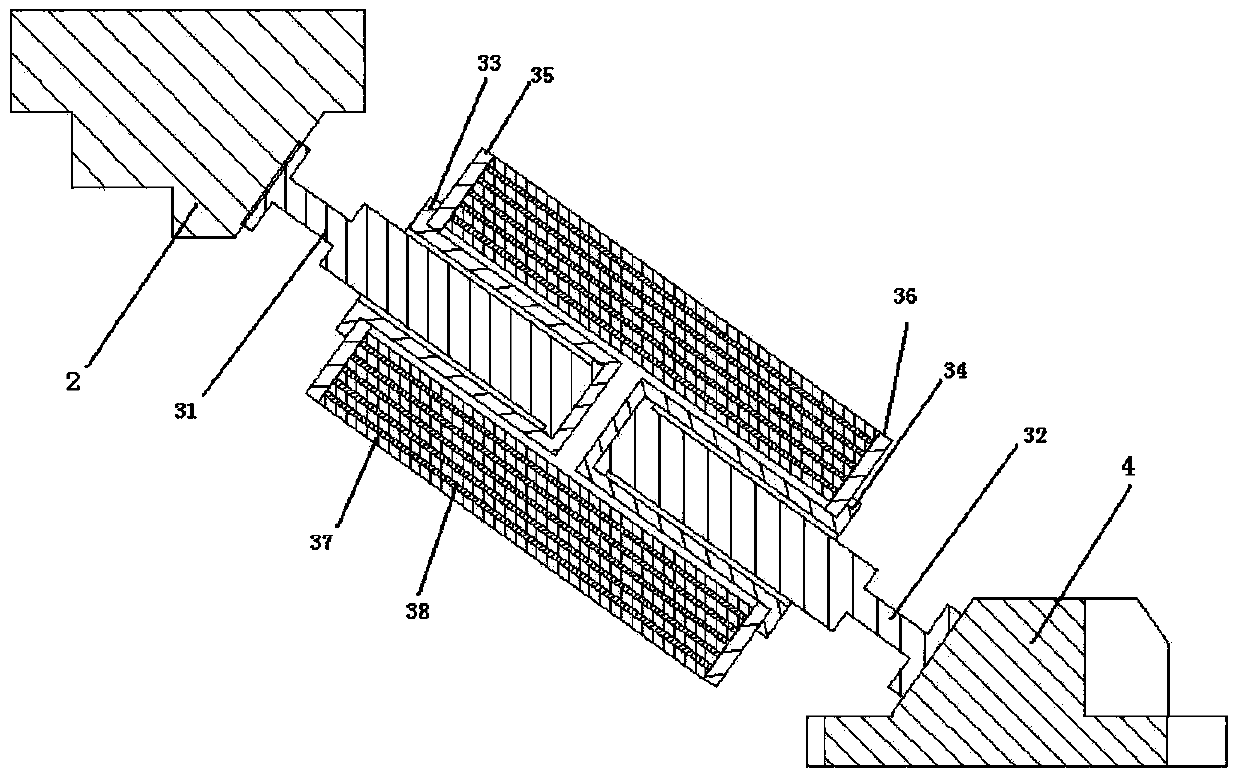

Zero-expansion flexible damping supporting device of space reflector

ActiveCN103472566AGuaranteed high-precision surfaceReduce response magnificationMountingsExpansion factorThermal deformation

Provided is a zero-expansion flexible damping supporting device of a space reflector. The zero-expansion flexible damping supporting device of the space reflector comprises reflector connection blocks (2), zero-expansion flexible damping rod assemblies (3) and substrate connection connectors (4), wherein the zero-expansion flexible damping rod assemblies (3) are in six groups, every two groups of the zero-expansion flexible damping rod assemblies form a bipod configuration, the included angle of 120 degrees is formed between every two bipod configurations, and the bipod configurations are distributed on the bottom face of the reflector (1). Each zero-expansion flexible damping rod assembly (3) comprises an upper connection rod (31), a lower connection rod (32), an upper sleeve (33), a lower sleeve (34), an upper connection board (35), a lower connection board (36), a damping barrel (37) and a damping rubber layer (38). The supporting device achieves good unloading of quasi-static and fixed support on the assembly errors and thermal deformation through the zero-expansion flexible design, and meanwhile through the operation of materials of different expansion factors, approximately-zero deformation of flexible rods is achieved under different temperature working conditions; the response magnification times of the reflector (1) are reduced by damping, and the structural intensity is prevented from being damaged and losing efficacy.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

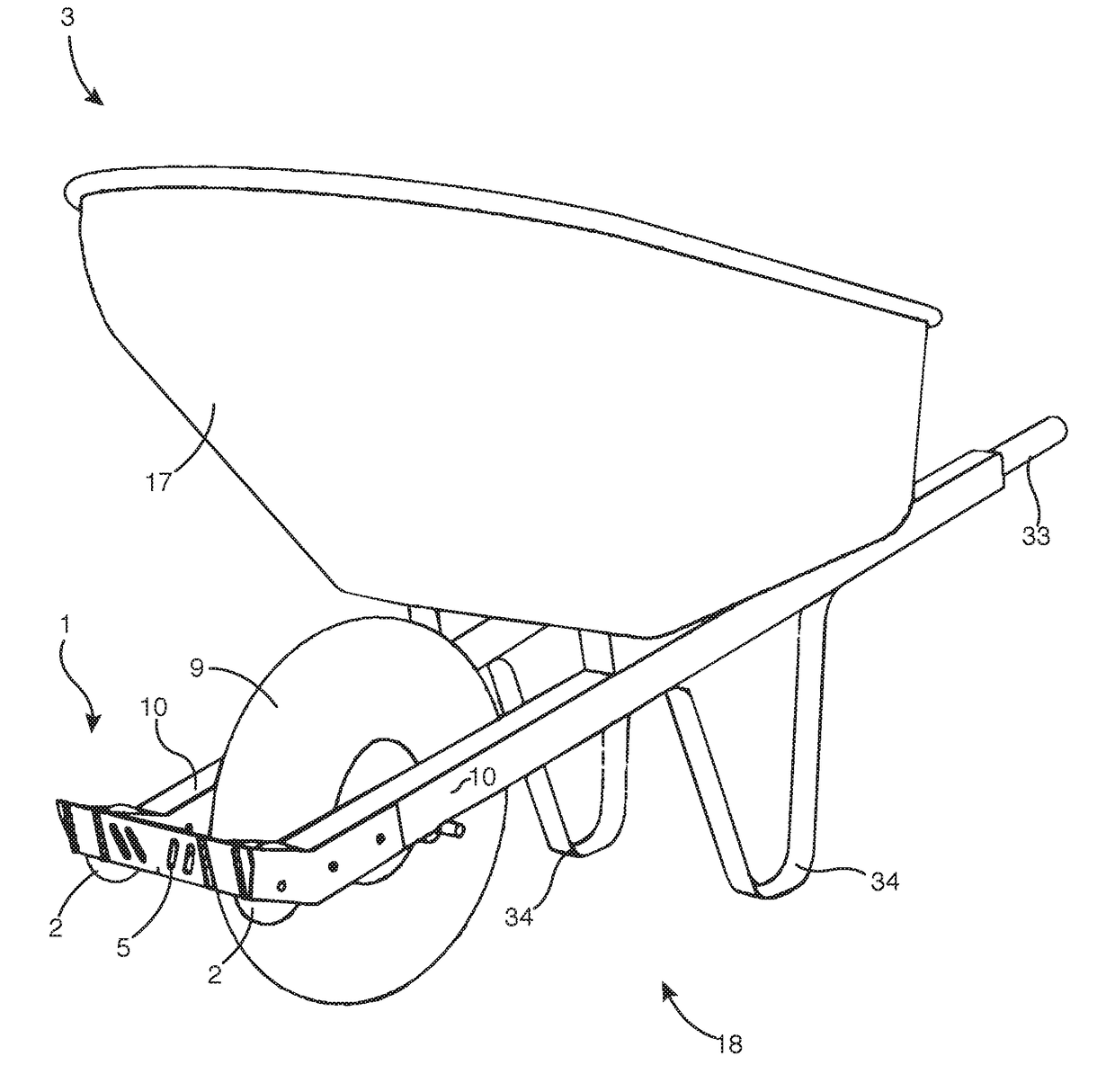

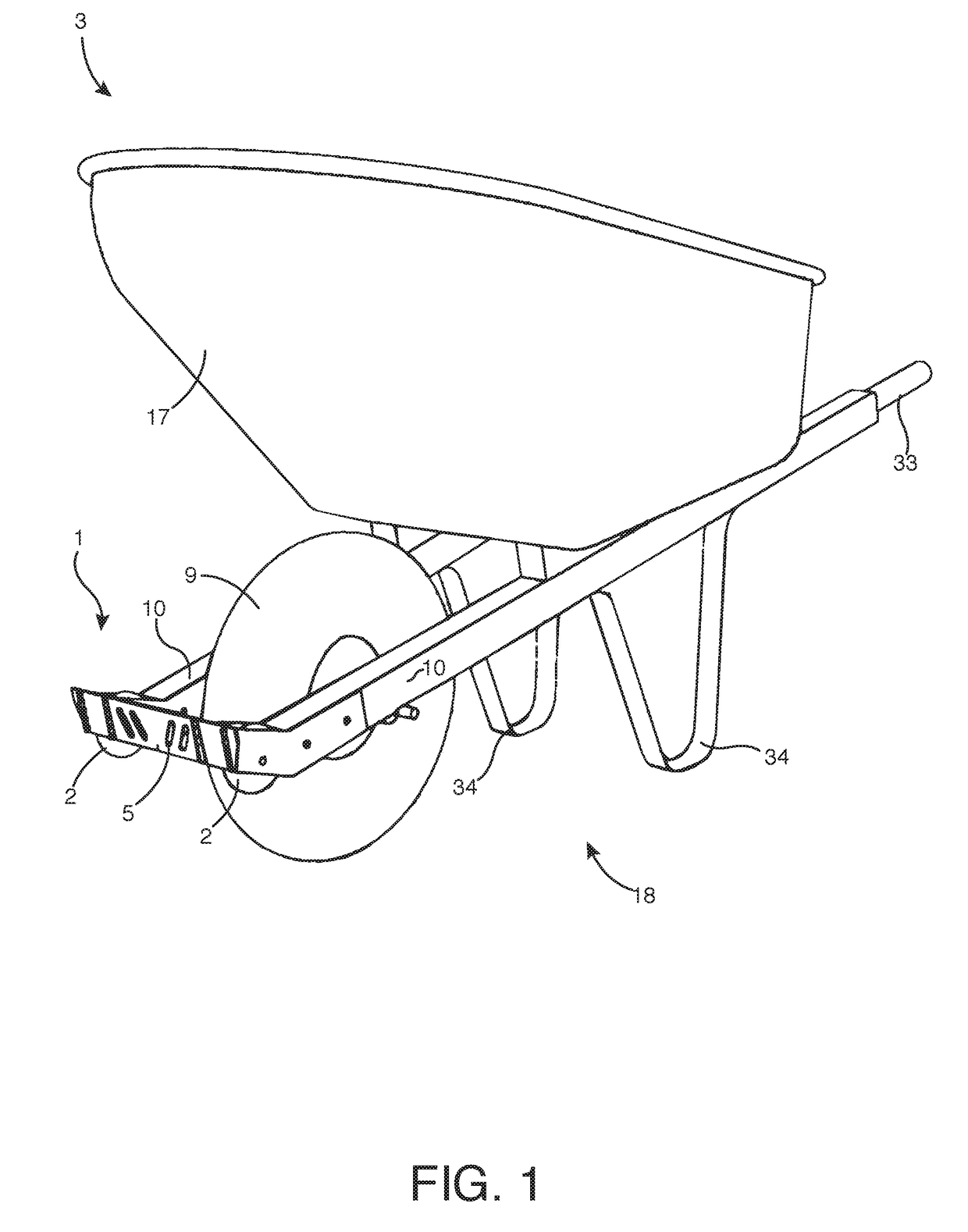

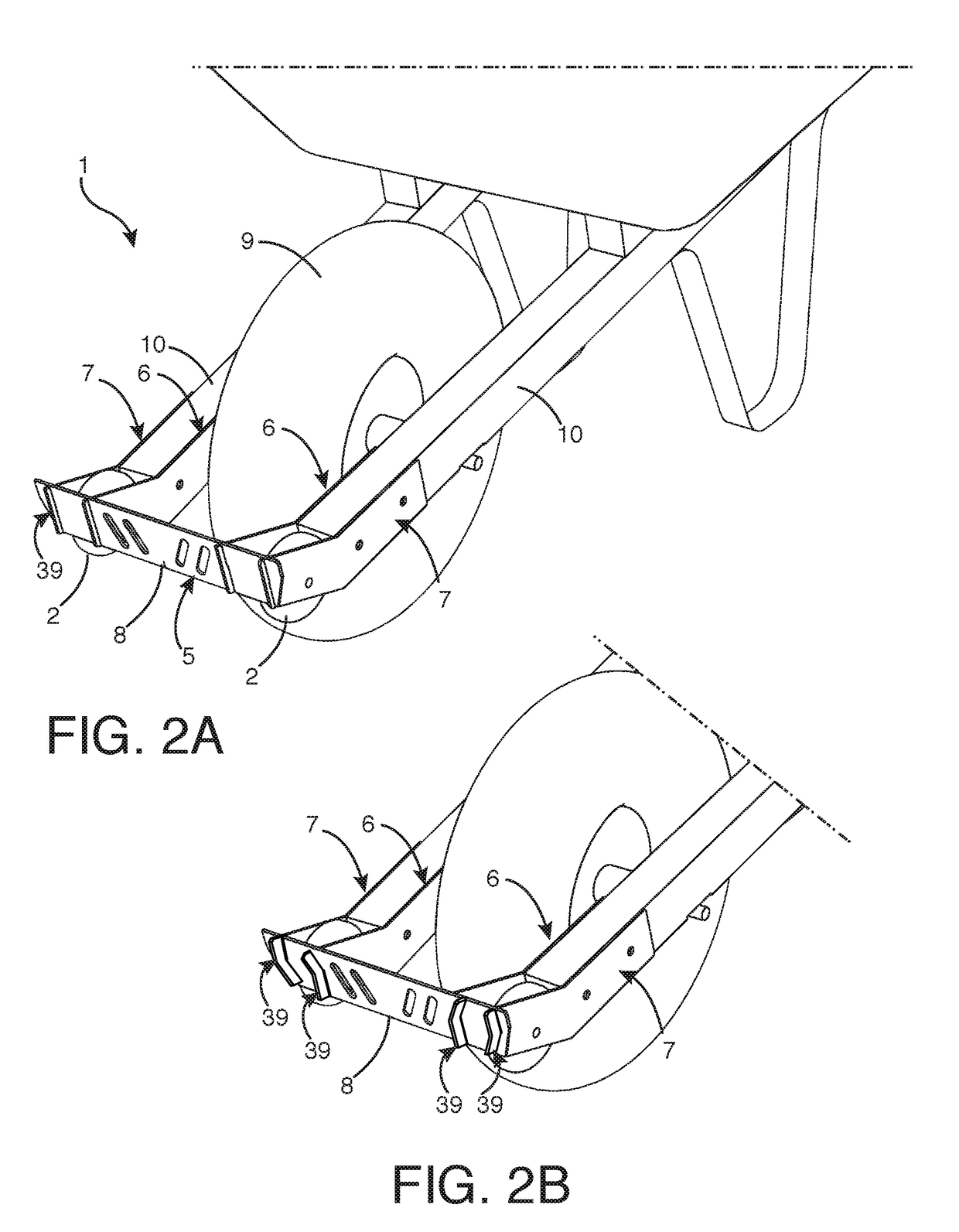

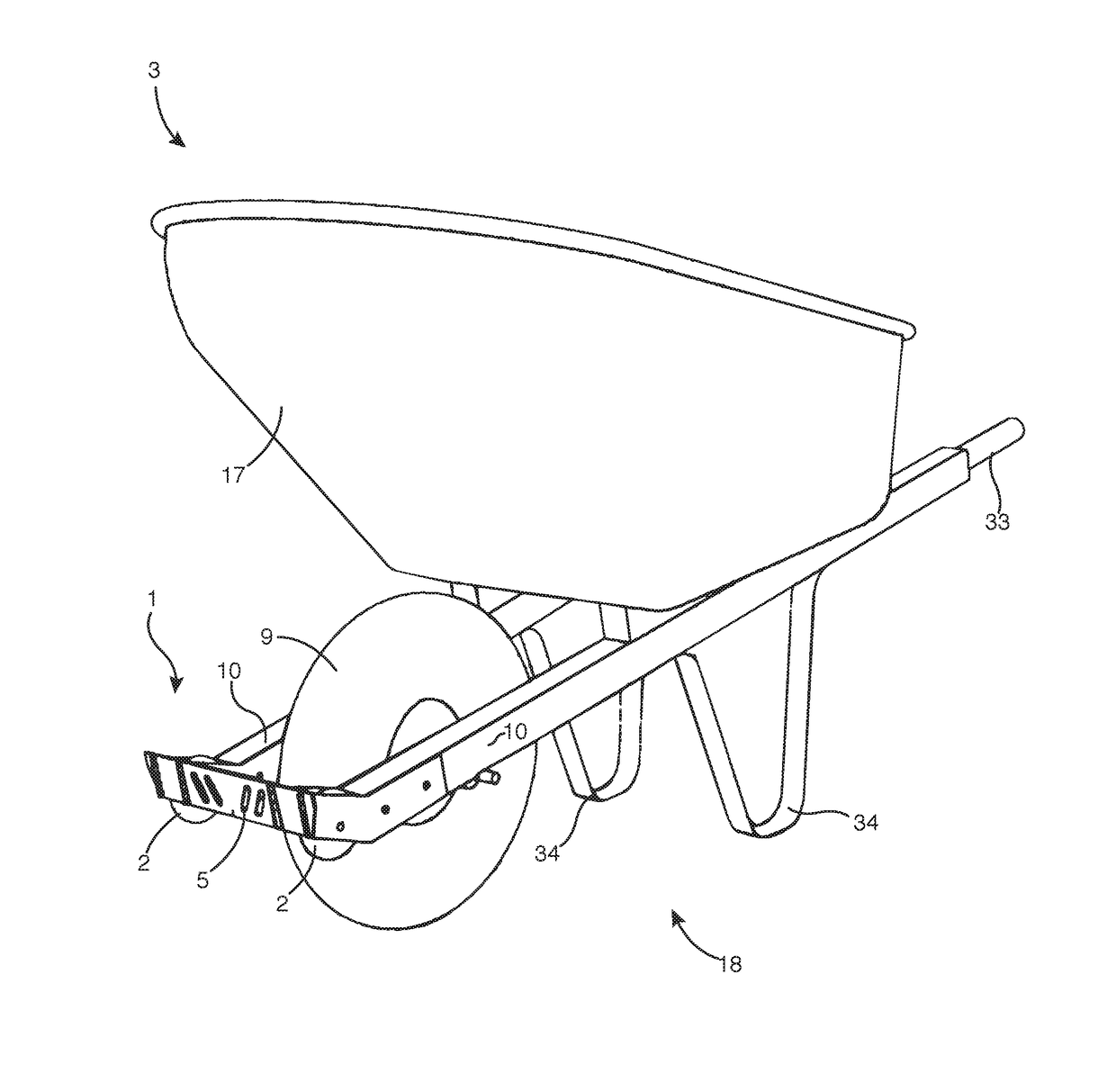

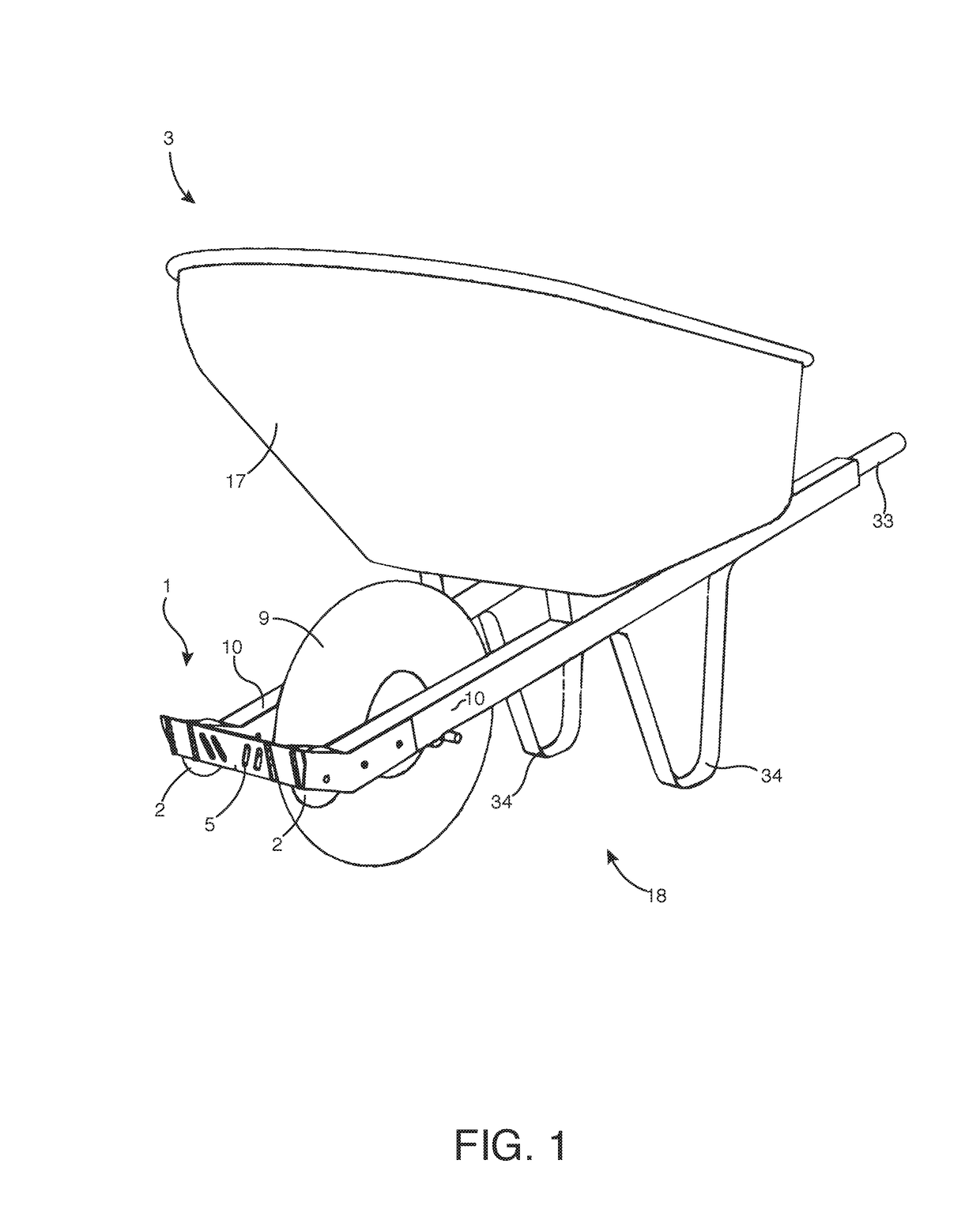

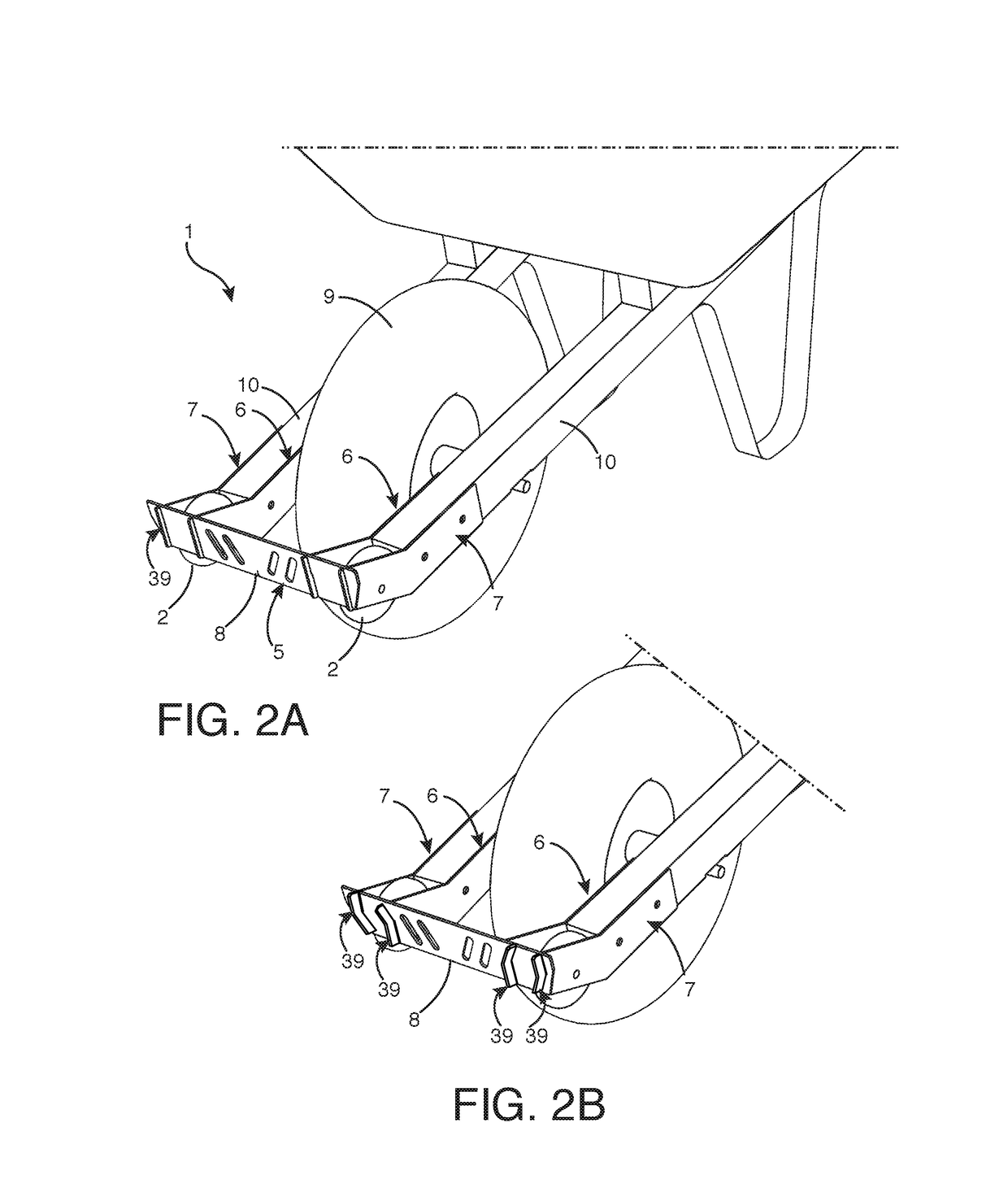

Method and apparatus for wheelbarrow front end protection

ActiveUS20170282947A1Reduce generationPrevent unintentional tipping of a wheelbarrowSledge wheelsSupporting partsEngineeringWeight-bearing

Embodiments of the invention are designed to be improvements over existing wheelbarrows. Certain embodiments comprise a frame, one or more weight-bearing wheels, and a pan. In certain embodiments, a wheelbarrow comprises a bight or a bumper having wheels. The wheels on the bight or bumper are located to the sides of a weight-bearing wheel. In certain embodiments, wheels located on each side of a bight or bumper portion allow a user to maneuver a wheelbarrow up or down a curb, or navigate stairs without causing damage to surfaces. Certain embodiments of the invention allow more efficient unloading of the contents of a wheelbarrow bed. Certain embodiments are designed to retrofit on existing wheelbarrows.

Owner:VECTION LTD

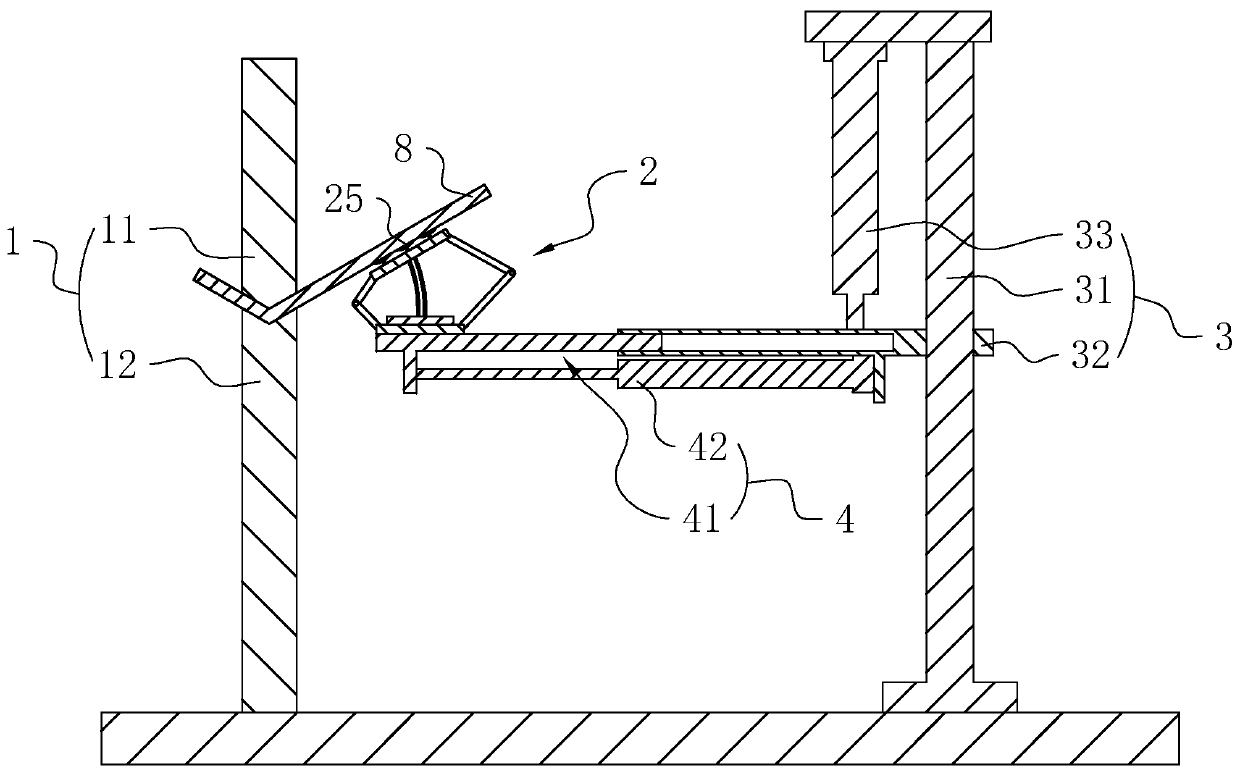

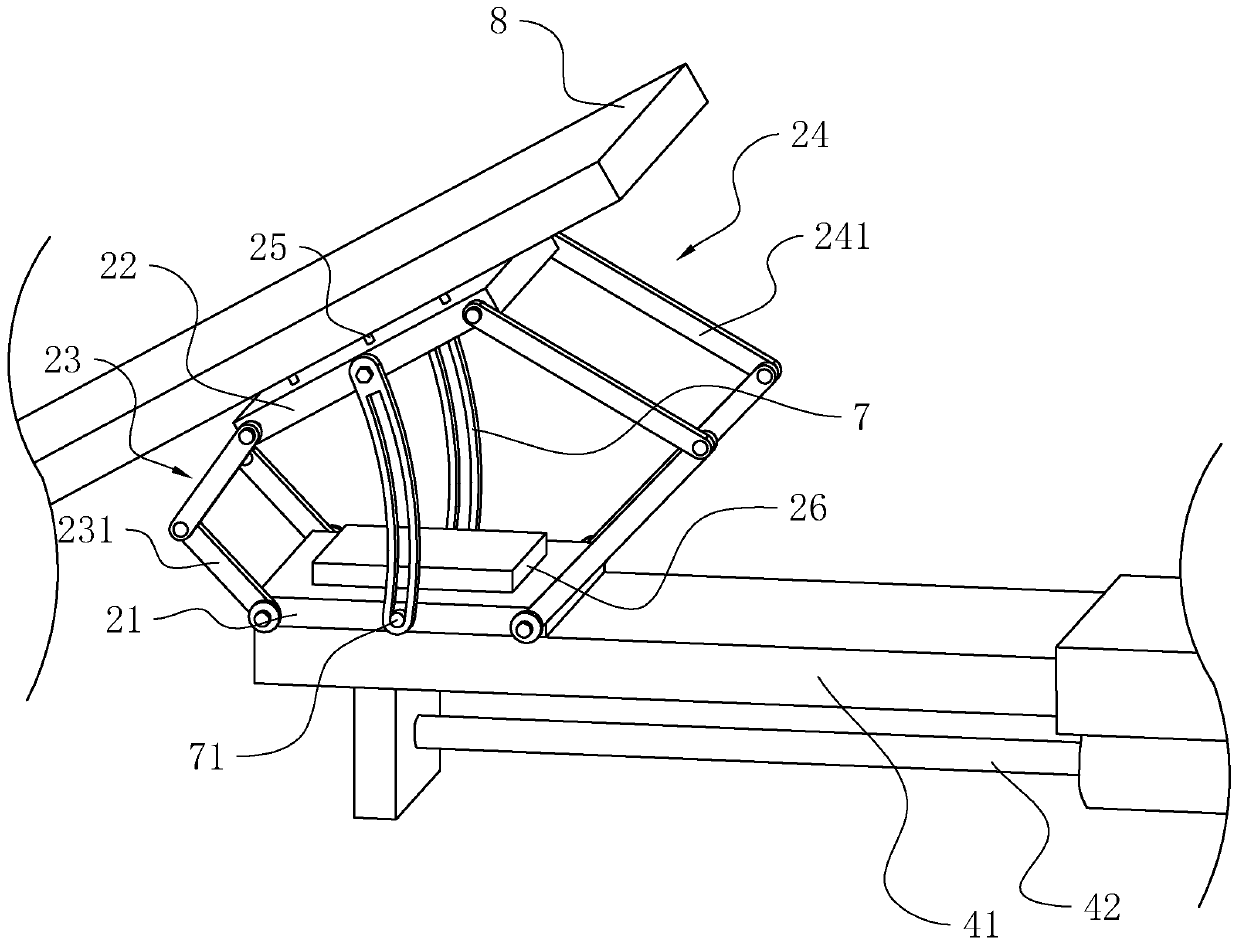

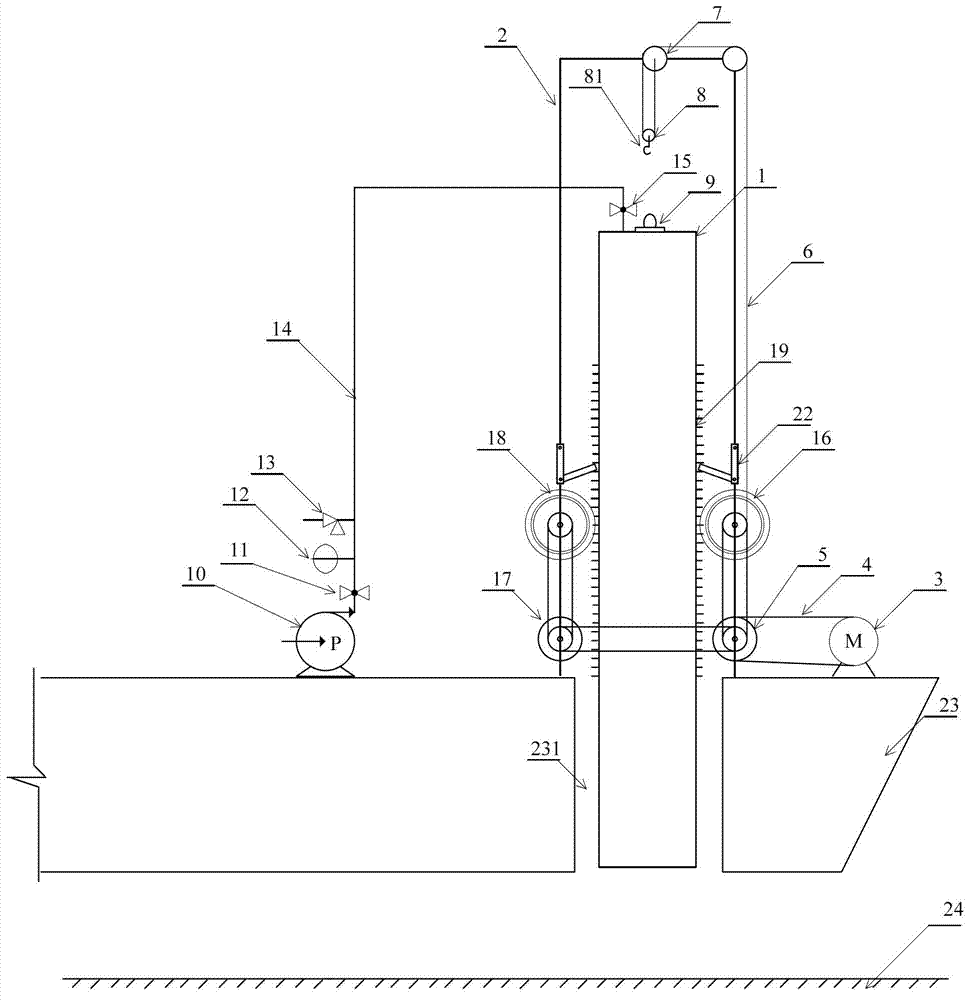

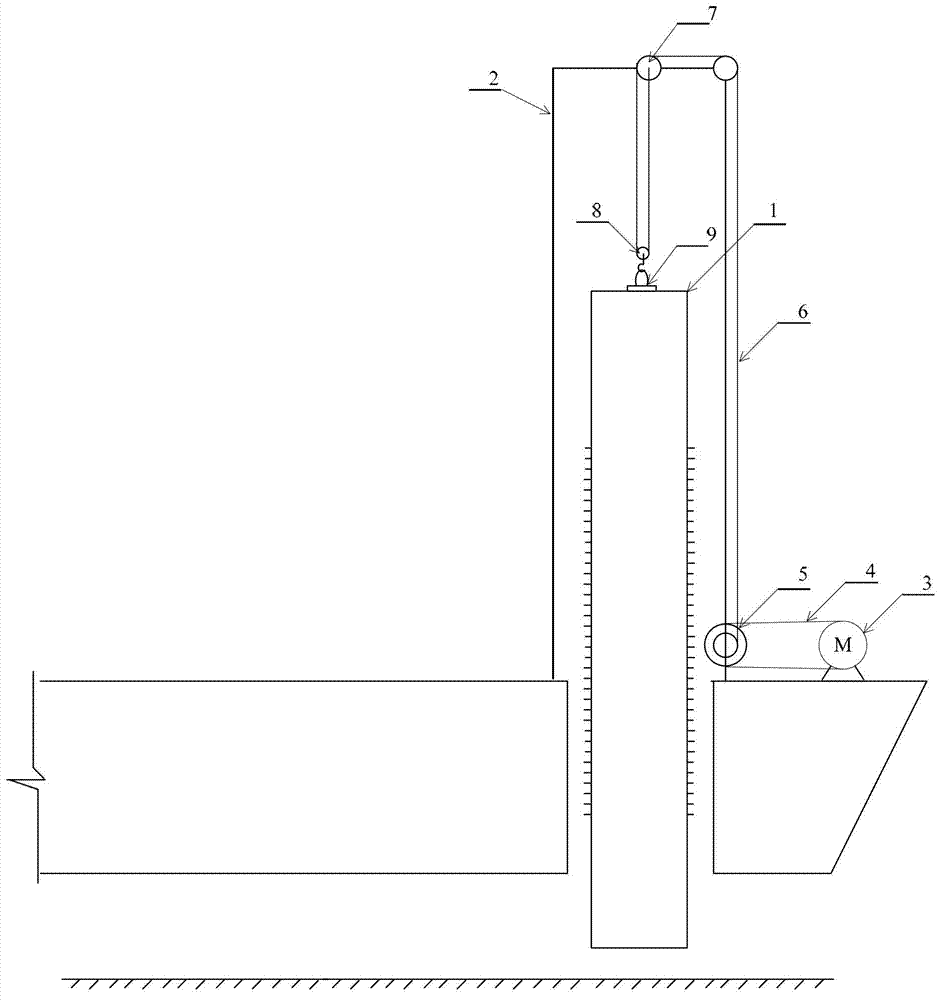

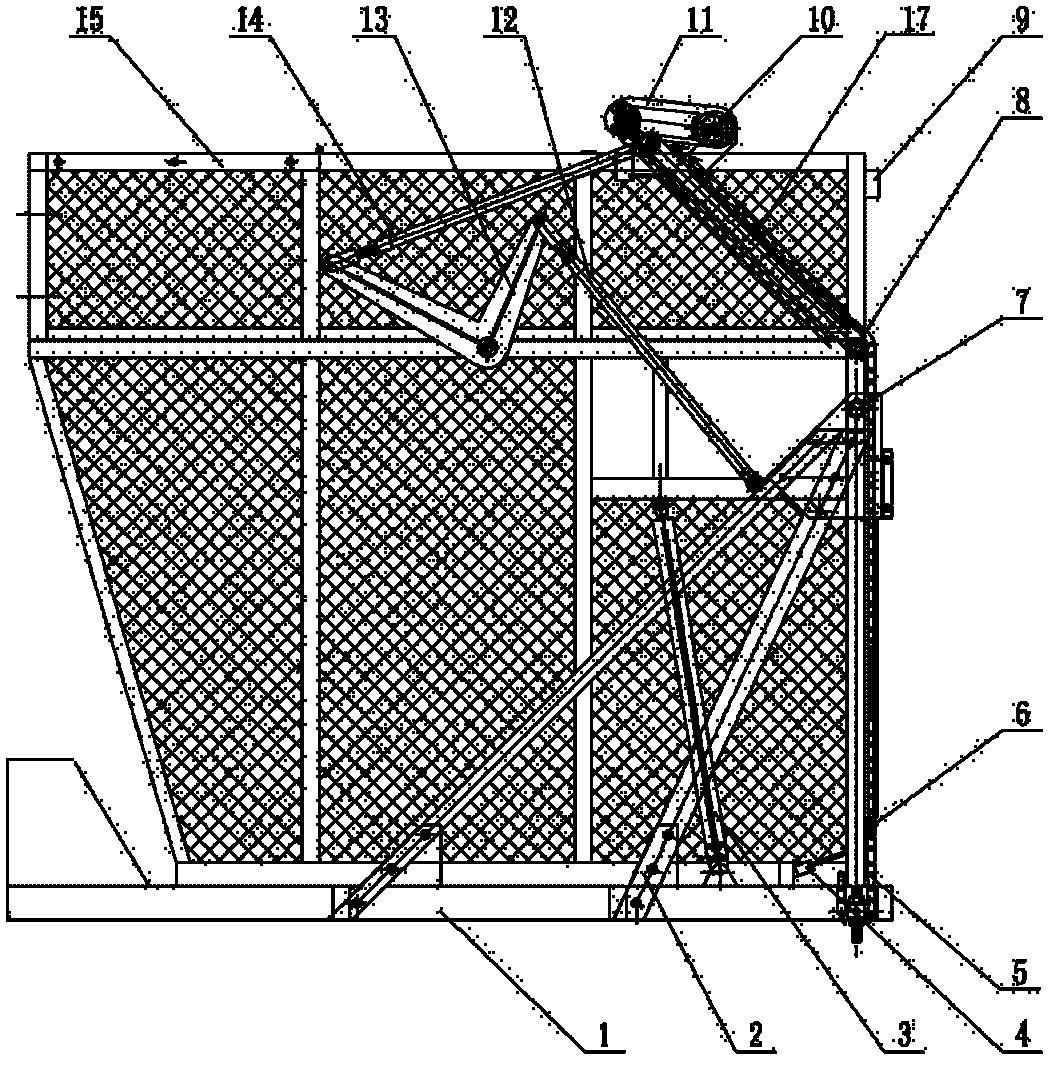

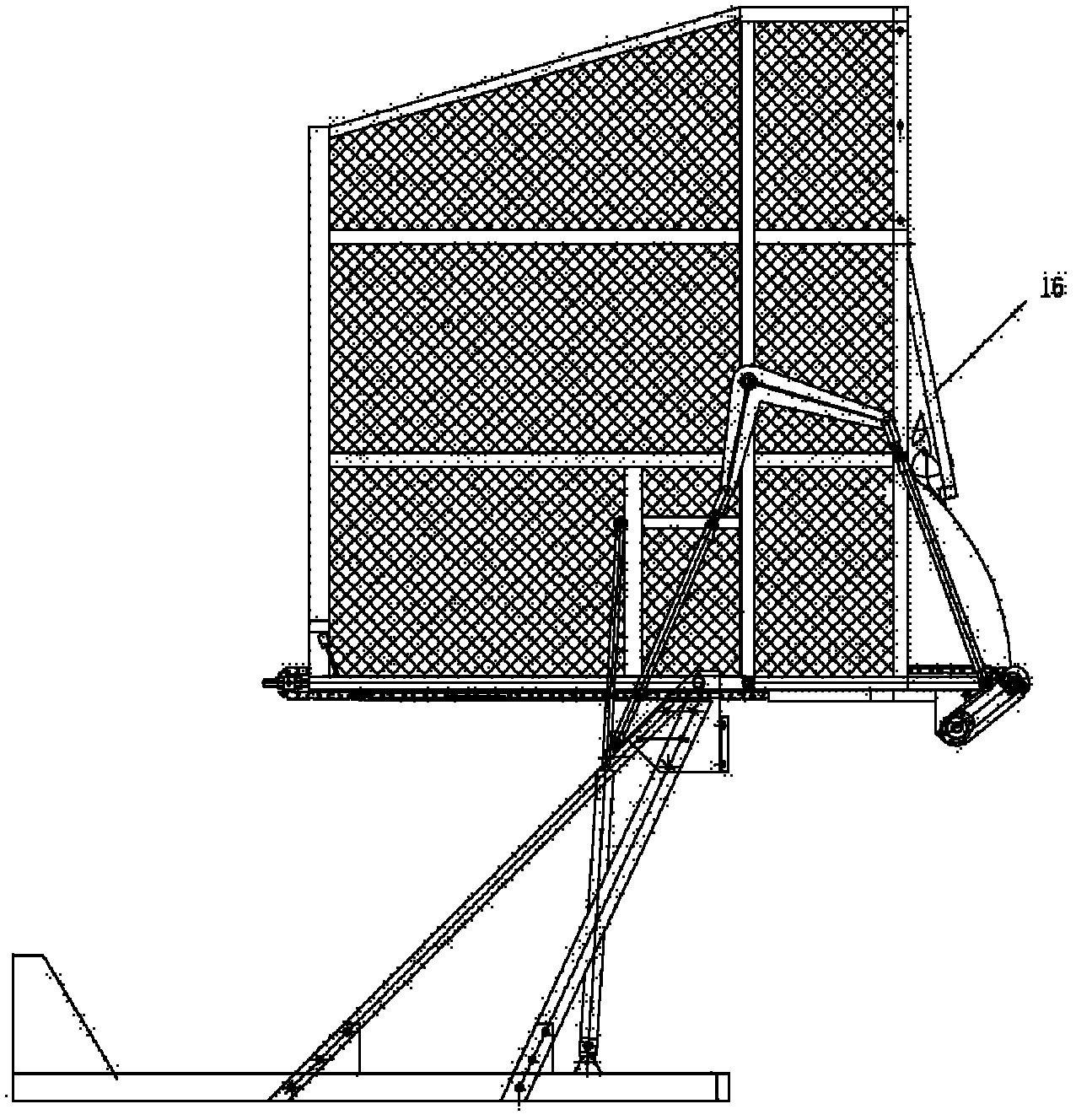

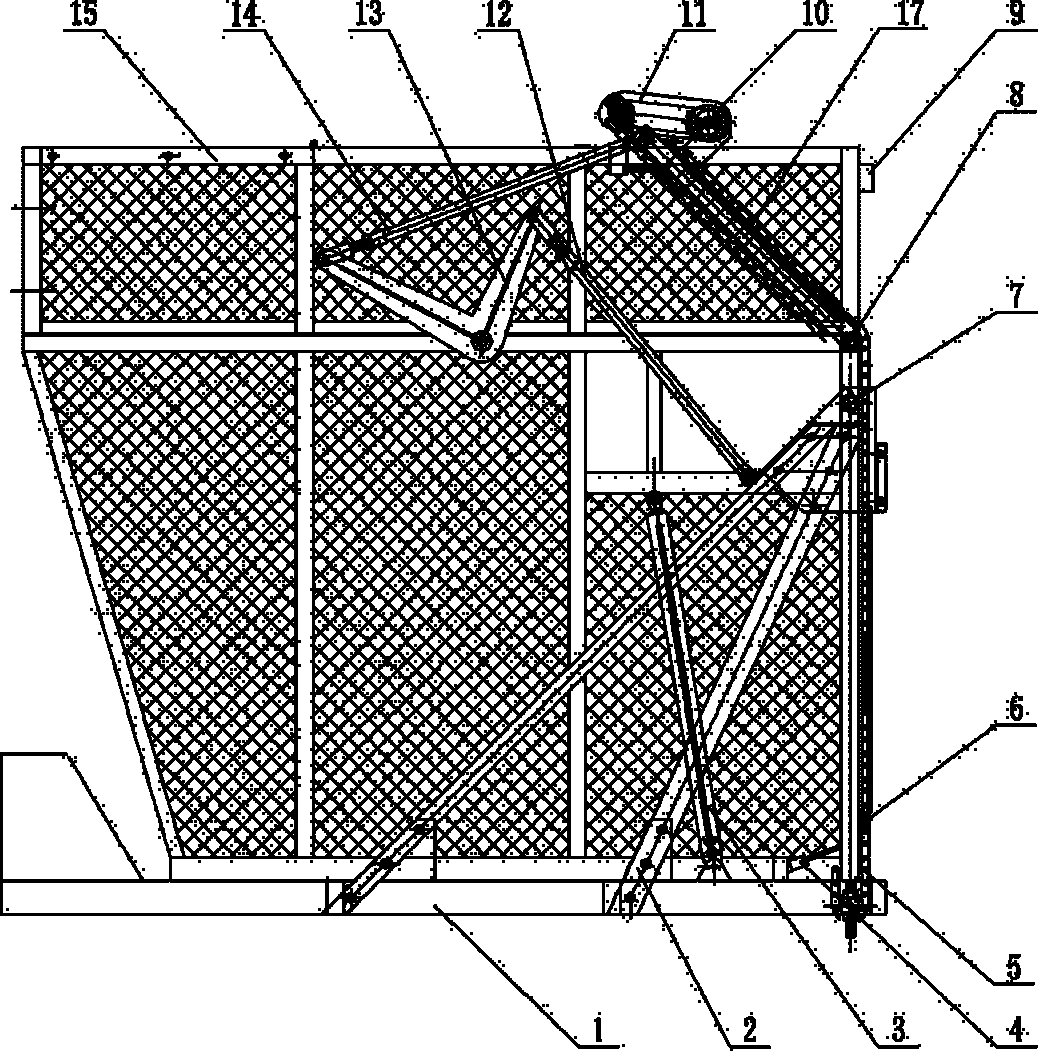

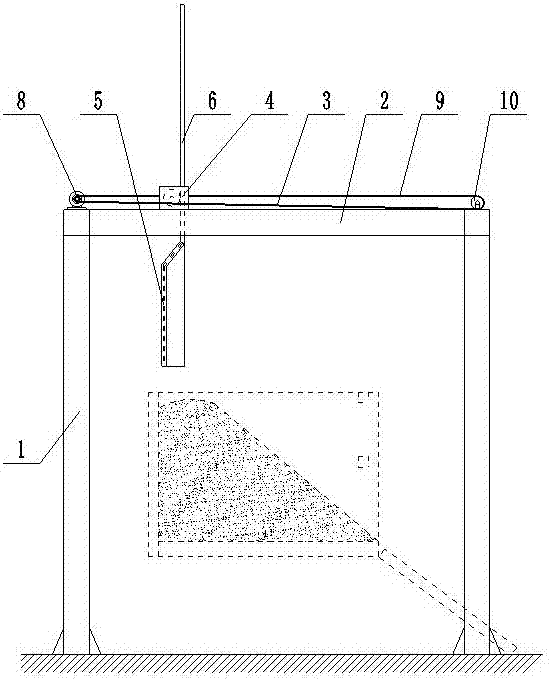

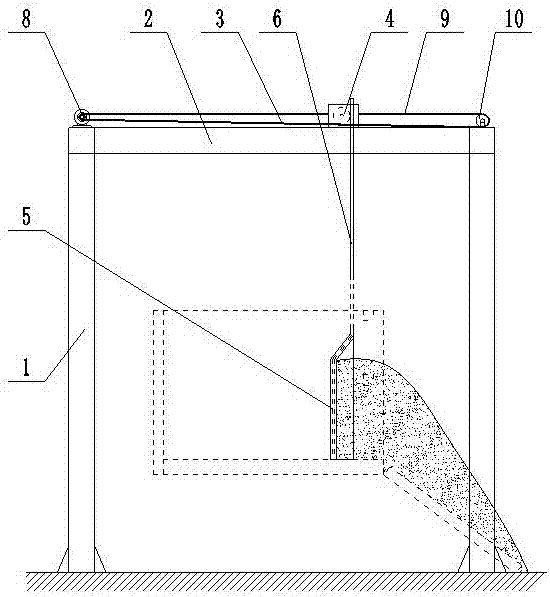

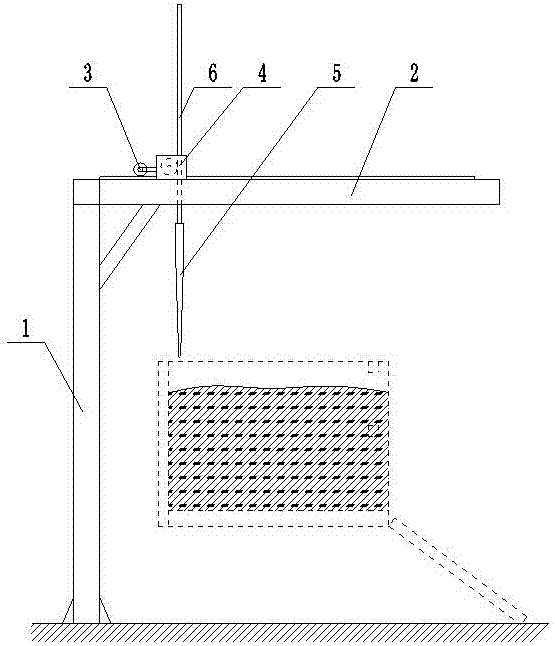

Fixed-point unloading mechanism

PendingCN106946060AReduce labor intensityConvenient and flexible unloadingLoading/unloadingMaterial transport

The fixed-point unloading mechanism of the present invention belongs to the technical field of material transportation; the technical problem to be solved is: to provide a fixed-point unloading mechanism, which is convenient and flexible to use, has low cost, reduces the labor intensity of workers, and improves the efficiency of unloading; the adopted technology The scheme is: a fixed-point unloading mechanism, including a frame body, a beam, a horizontal transmission mechanism, a vertical transmission mechanism, a discharge plate and a controller. The frame body is fixed on the ground, and the beam is fixed on the upper part of the frame body. The transmission mechanism, the vertical transmission mechanism is movably installed on the beam and realizes the lateral movement on the beam through the horizontal transmission mechanism. The vertical transmission mechanism is connected with the upper connecting rod of the discharge plate to realize the up and down movement of the discharge plate. The controller controls the operation of the horizontal transmission mechanism and the vertical transmission mechanism; the invention is mainly used for transporting and unloading materials such as grain and cotton.

Owner:高伟

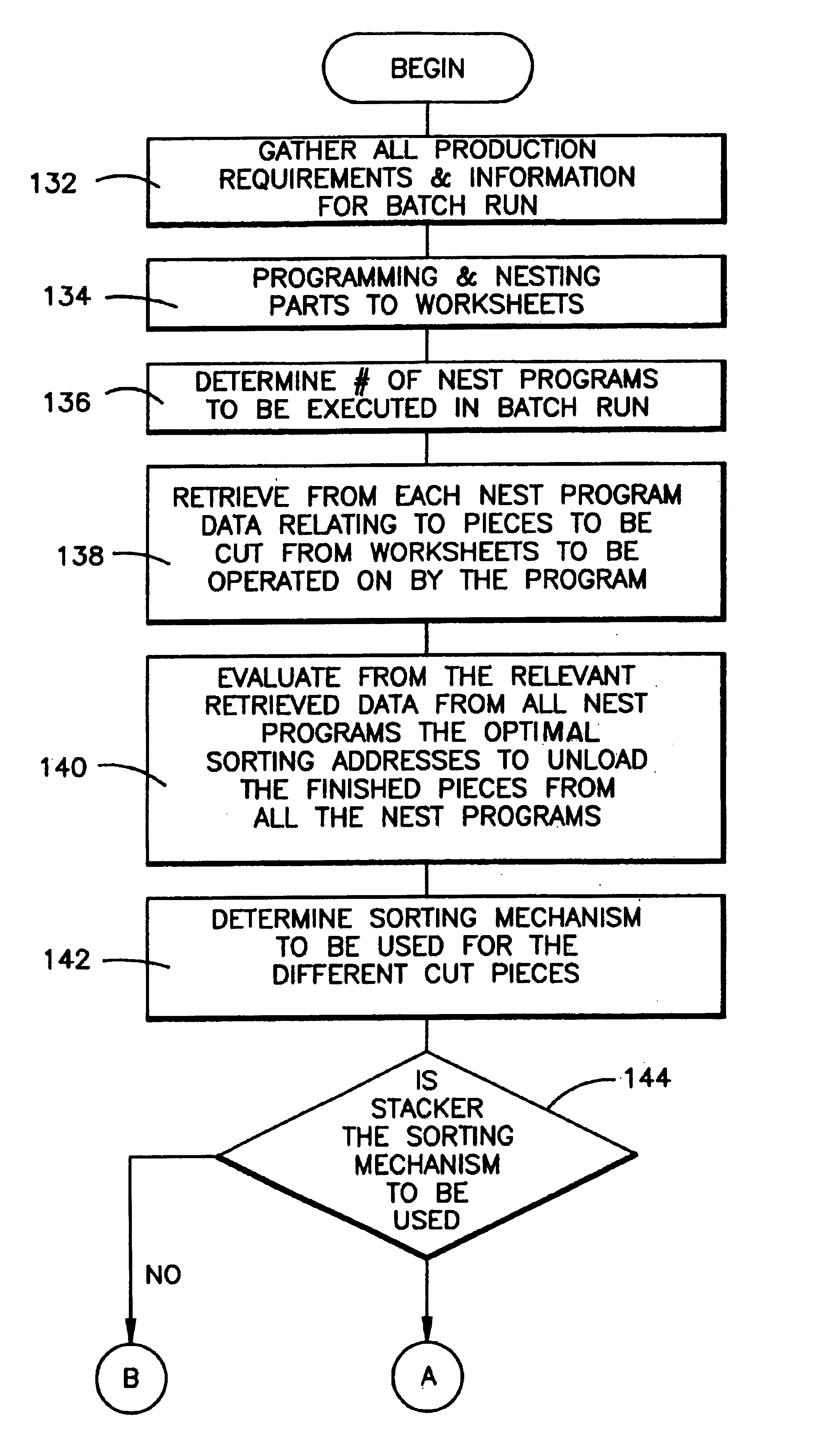

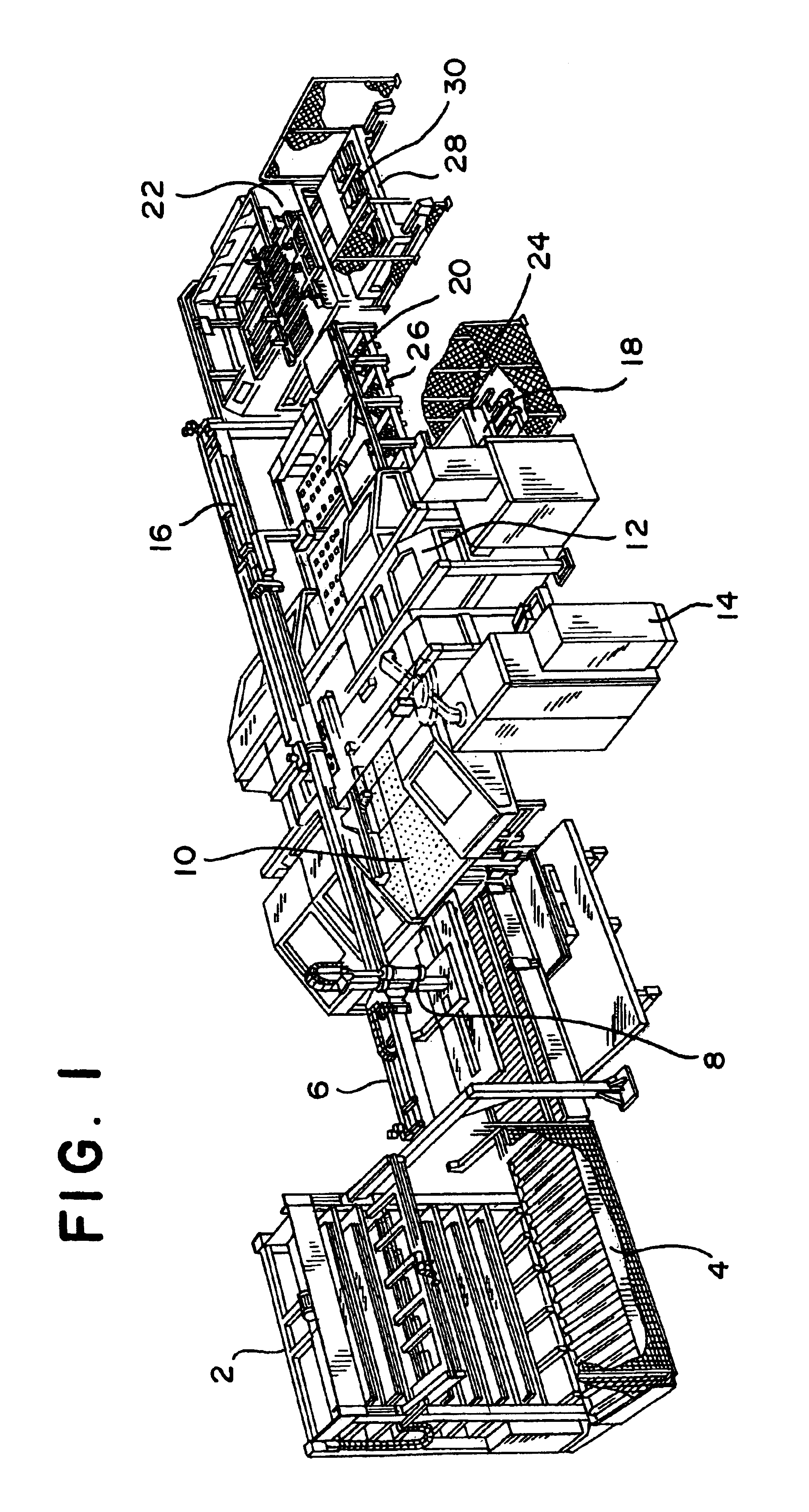

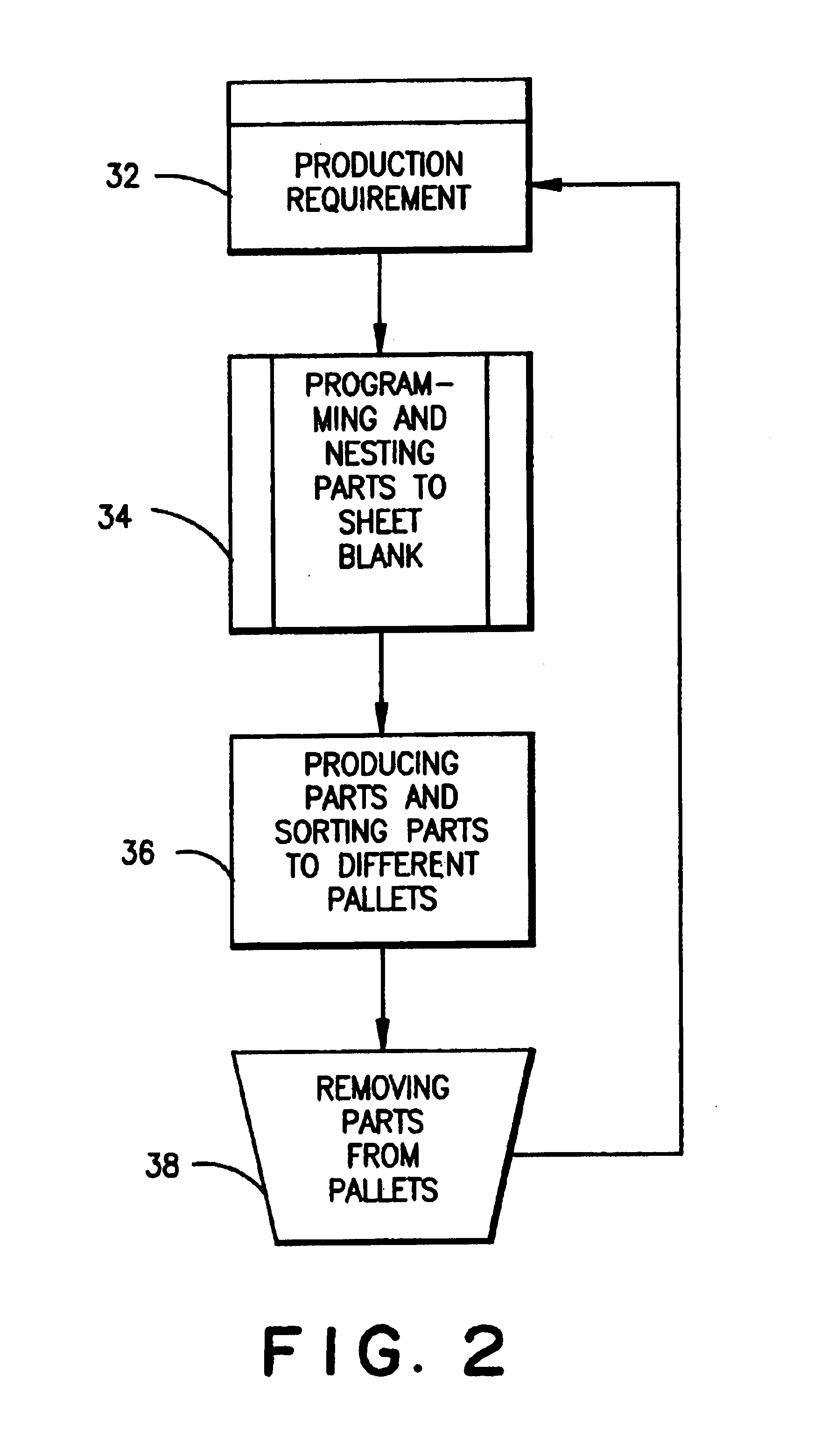

System and method of flexibly sorting and unloading finished parts during part manufacturing process

InactiveUS6788995B1Large capacityReduce setup timeDigital data processing detailsForecastingEngineeringMechanical engineering

The present invention relates to a system and method therefor of sorting and unloading various pieces cut from sheet blanks which have different dimensions in a sheet metal fabricating environment. To achieve this end, prior to the production run, the various program routines whose operations for effecting the cutting of the sheet blanks are retrieved and the data relevant to the to be cut pieces are grouped and analyzed so that pieces of different dimensions cut in accordance with the different program routines are respectively allocated to the corresponding sorting addresses for unloading. Accordingly, different pieces with the same dimension cut from different program routines during the same production run are unloaded to the same location of the unloader area. Optimization of the unloading process and optimal utilization of the available loading space are thereby achieved.

Owner:FINN POWER INT

Method and apparatus for wheelbarrow front end protection

ActiveUS10124820B2Reduce generationPrevent unintentional tipping of a wheelbarrowSledge wheelsSupporting partsEngineeringWeight-bearing

Embodiments of the invention are designed to be improvements over existing wheelbarrows. Certain embodiments comprise a frame, one or more weight-bearing wheels, and a pan. In certain embodiments, a wheelbarrow comprises a bight or a bumper having wheels. The wheels on the bight or bumper are located to the sides of a weight-bearing wheel. In certain embodiments, wheels located on each side of a bight or bumper portion allow a user to maneuver a wheelbarrow up or down a curb, or navigate stairs without causing damage to surfaces. Certain embodiments of the invention allow more efficient unloading of the contents of a wheelbarrow bed. Certain embodiments are designed to retrofit on existing wheelbarrows.

Owner:VECTION LTD

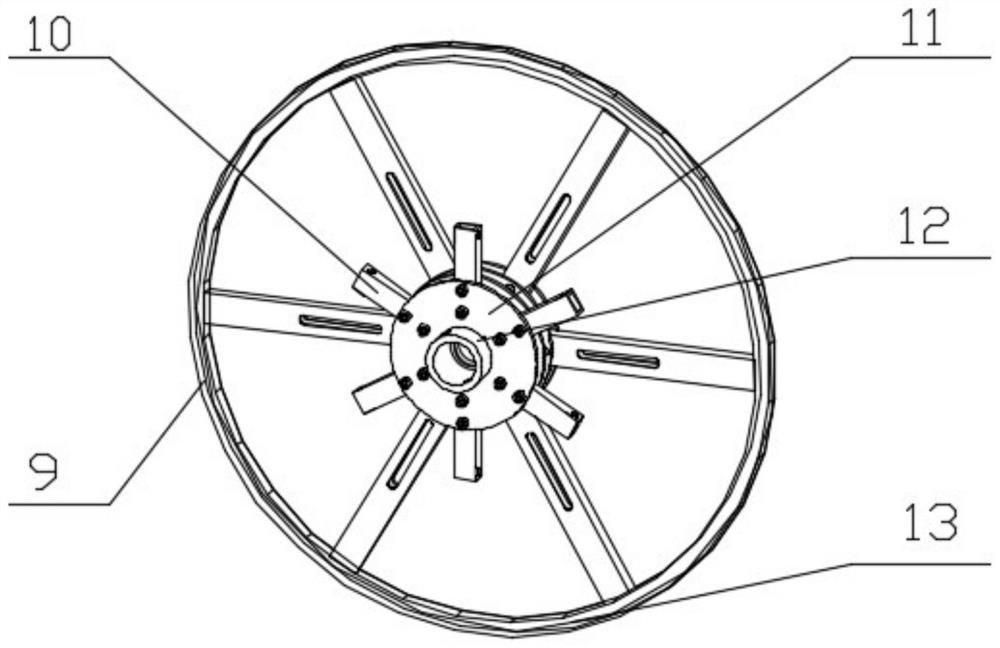

Detachable winding disc for pipe winding machine

The invention discloses a detachable winding disc for a pipe winding machine. The detachable winding disc comprises a front winding disc and a rear winding disc, a flaky flat plate is arranged between the front winding disc and the rear winding disc, a plastic pipe is wound on the flat plate, the flat plate is connected with the front winding disc and the rear winding disc through bolts, and the detachable winding disc is convenient to assemble. After winding is completed, coil discharging can be completed by detaching a discharging wheel on the front winding disc and a bolt on a support or the bolt on the rear winding disc. The diameter of the front winding disc is the same as that of the rear winding disc, pipe overflowing and loosening caused by overlarge rolling diameter can be avoided, and the front winding disc is not provided with an outer ring and is convenient to pack and disassemble.

Owner:JIANGSU UNIV OF SCI & TECH

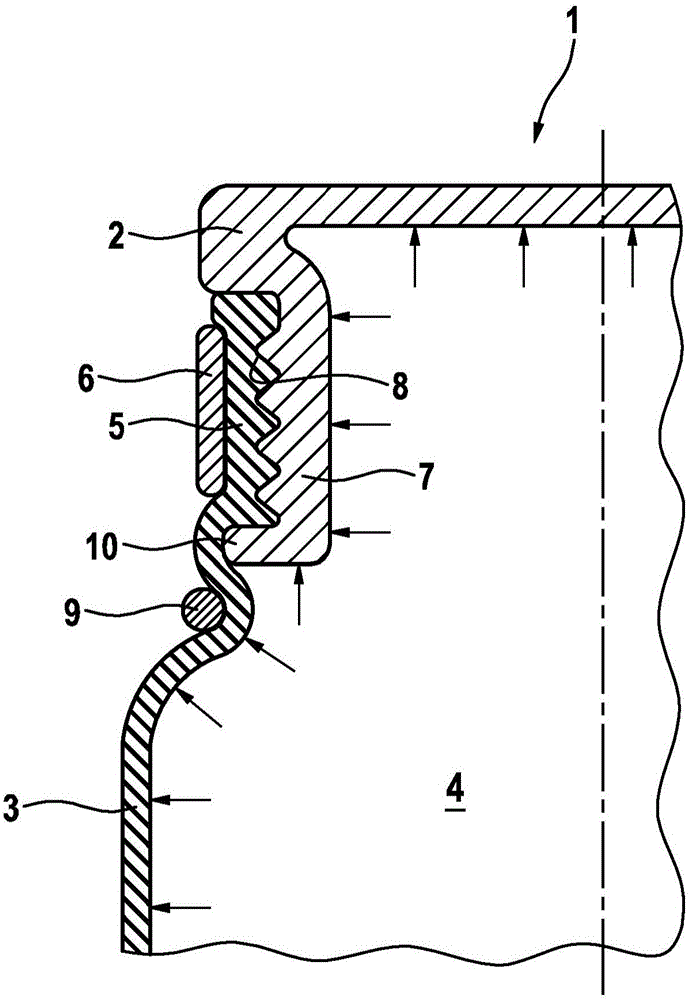

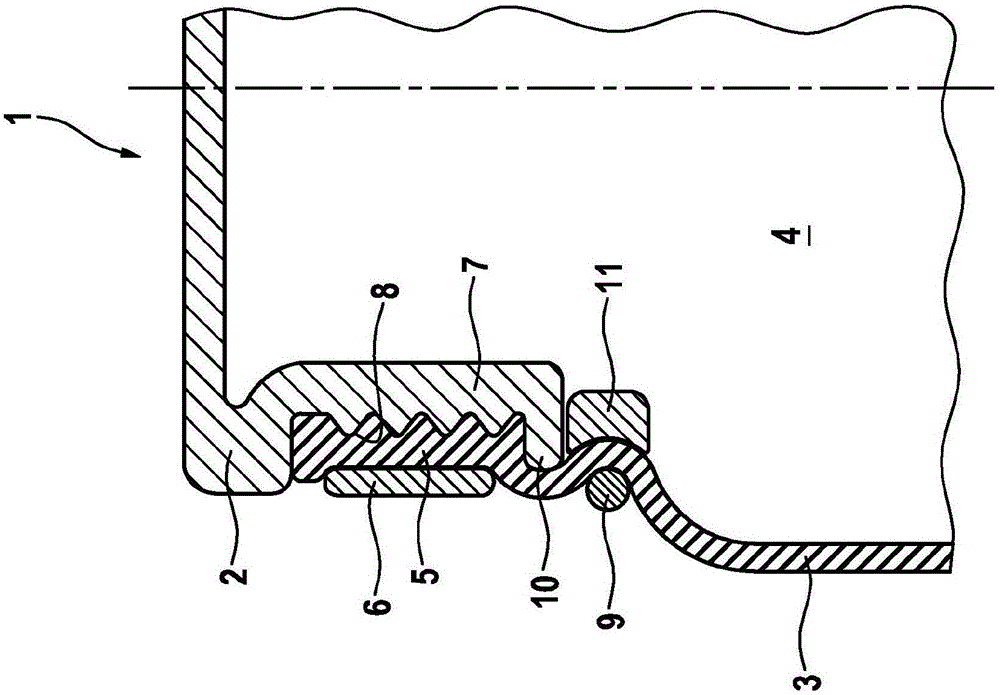

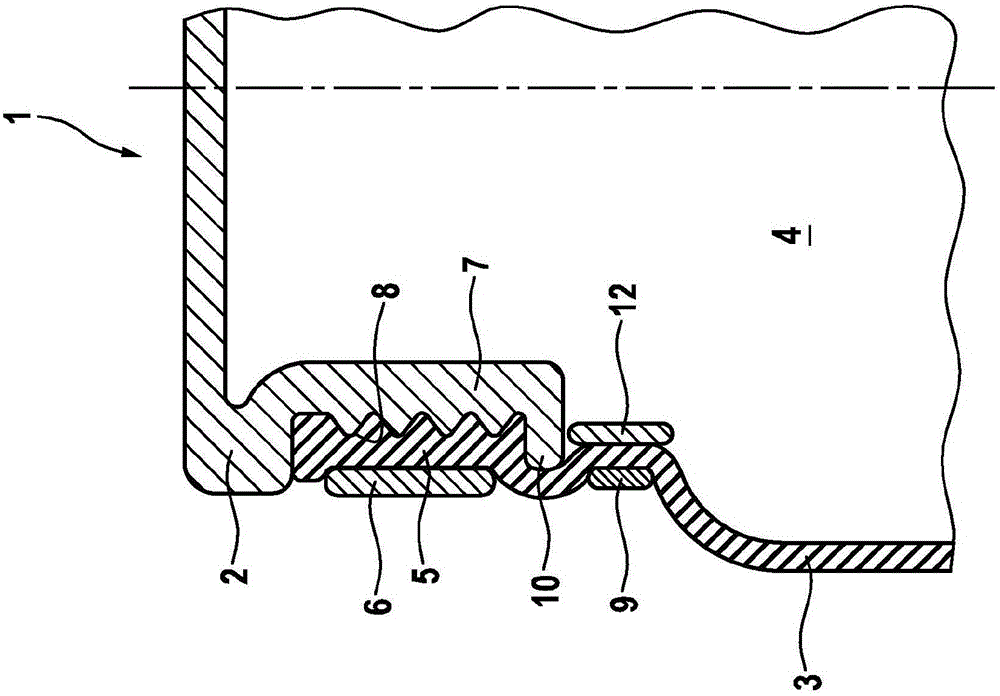

Air spring, in particular for vehicles

InactiveCN105102845AEfficient unloadingCompression does not lowerSpringsResilient suspensionsAir springCompressed air

The invention relates to an air spring (1), in particular for vehicles, which is clamped with an air spring piston and an air spring cover (2) between the chassis and the vehicle body of a motor vehicle, comprising an air spring bellows (3), which is sealingly fixed on the air spring cover (2) and air spring piston, is made of an elastomeric material, at least partially delimits a working chamber (4) filled with compressed air, and which unrolls so as to form at least one rolling fold on the air spring piston, wherein an end region (5) of the air spring bellows (3) is secured on a clamping section (7) of the air spring cover (2) by means of a clamping ring (6). An additional ring (9) is provided, which is arranged in the end region (5) of the air spring bellows (3) and outside the clamping section (7) in order to relieve the clamping ring (6), wherein the inner diameter thereof substantially corresponds to an inner diameter of the clamping ring (6).

Owner:CONTINENTAL TEVES AG & CO OHG

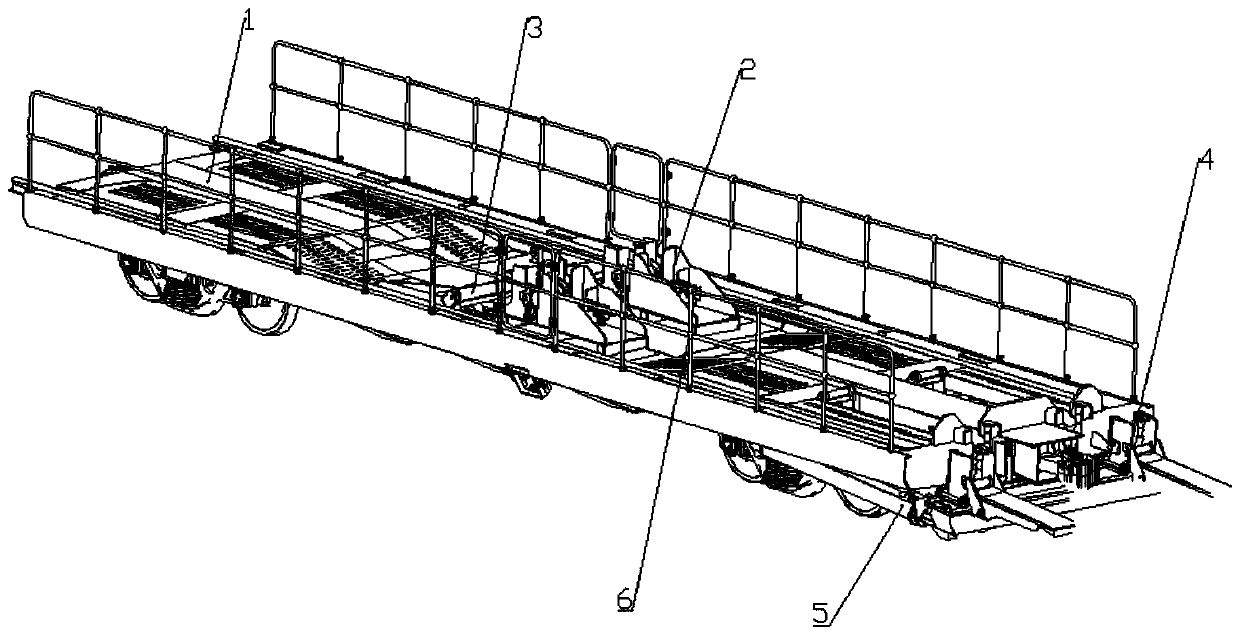

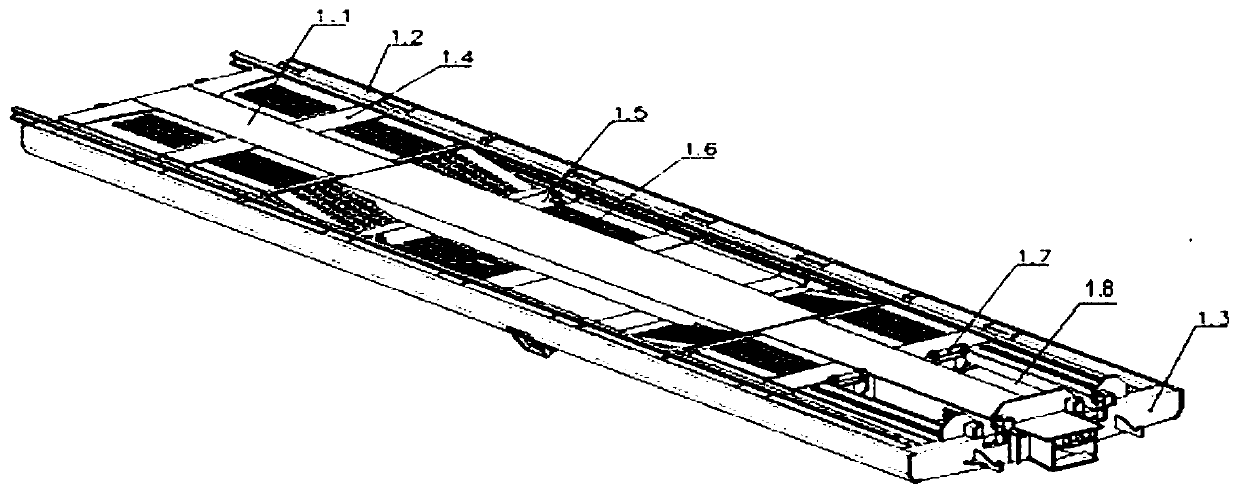

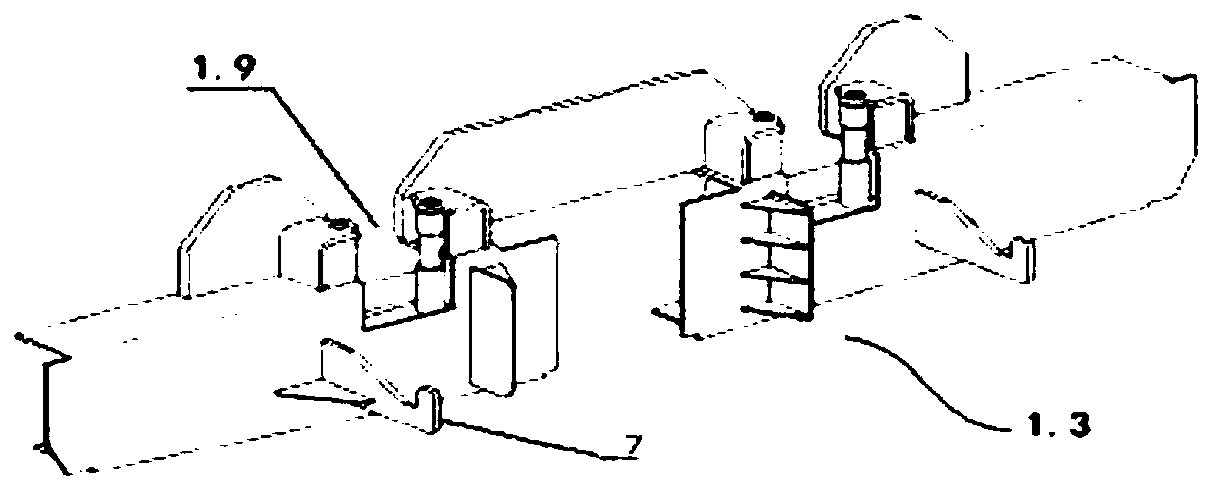

Long steel rail transport loading and unloading vehicle and transportation vehicle set composed thereof

PendingCN111559394AGood transportHigh degree of automationWagons/vansCargo supporting/securing componentsAutomotive engineeringRail transportation

The invention discloses a long steel rail transportation loading and unloading vehicle and a transportation vehicle set. The long steel rail transportation loading and unloading vehicle comprise a chassis assembly arranged on a wheel set and a bogie. Two sets of steel rail transportation loading fixing mechanisms are respectively arranged along the two sides of the center line of the chassis assembly, and a steel rail unloading mechanism is arranged at the tail end of the chassis assembly; and each steel rail transporting loading fixing mechanism comprises an adjustable support assembly, a steel rail braking device, a transverse roller, a guide rail groove and a rail loading and unloading opening which are sequentially arranged in the axial direction of a chassis. A steel rail unloading system is composed of an unloading operation trolley and a trolley driving guide mechanism of the unloading operation trolley. The transportation vehicle set comprises a blocking vehicle, a loading andunloading vehicle, a clamping vehicle, two transition vehicles, four bearing vehicle set units and a spanning type lifting vehicle which are connected. The transportation loading fixing mechanisms canadjust the height of the steel rail and lift the operation trolley to improve the operation automation degree, safety and stability and can match the height needed during steel rail unloading to meetthe requirement for multi-layer steel rail unloading; and the extending distance of the unloading operation trolley as well as the operation space is reduced.

Owner:CRRC MEISHAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com