CNC pressurizing system for model test and control method thereof

A pressurized system and model test technology, applied in the direction of fluid pressure actuation device, using stable tension/pressure test material strength, servo motor, etc. Man-machine interactive operation, no introduction of pressurization control methods, etc., to achieve long-term stability, broad application prospects, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

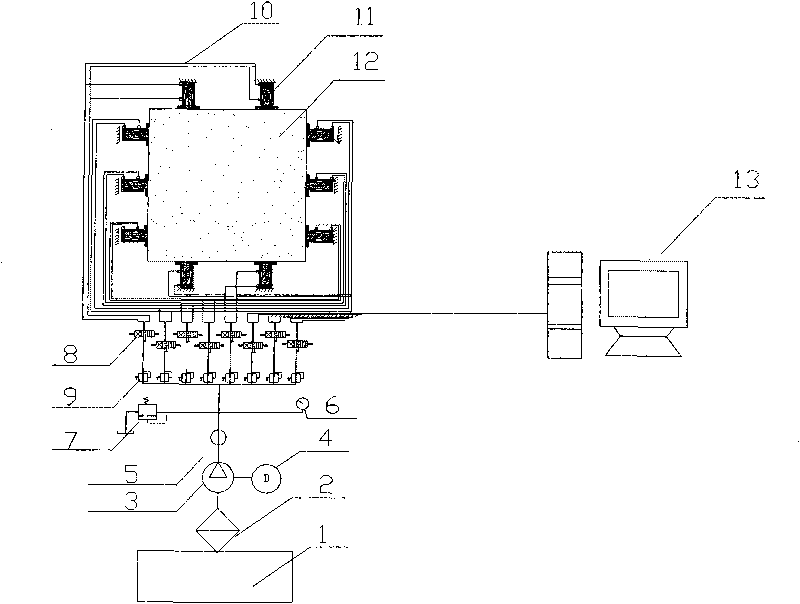

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

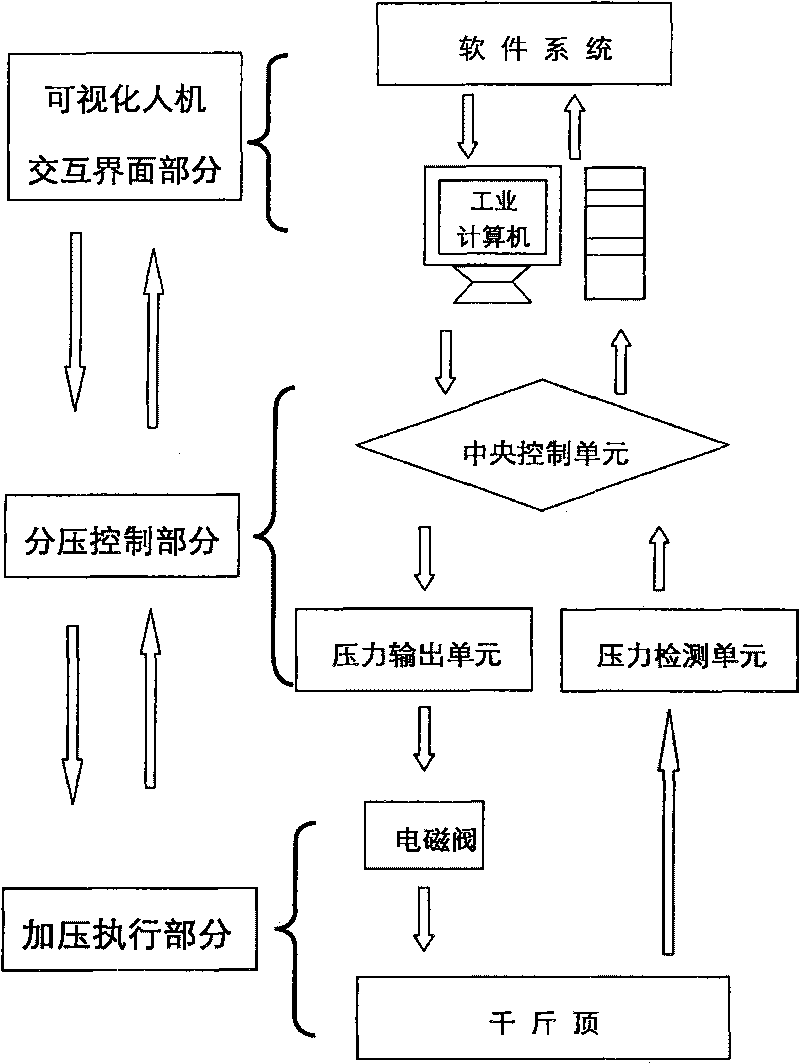

[0030] figure 1 Among them, the digital pressurization control system consists of a pressure division control part, a pressurization execution part and a visual human-computer interaction interface part. The voltage division control part is respectively connected with the visual human-computer interaction interface part and the pressurization execution part through electrical circuits. The operator realizes the control of the pressurization execution system through the part of the visual human-computer interaction interface.

[0031] The working principle of the entire digital pressurization control system: With the increase of the burial depth, the stress distribution of the rock around the underground cavern is nonlinear. In order to simulate the non-uniform distribution of in-situ stress around the cave, especially the horizontal tectonic stress σ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com