Cone-disc type waste concrete regenerated coarse aggregate mortar stripping device

A technology of waste concrete and recycled coarse aggregate, applied in the fields of cocoa, grain processing, food science, etc., can solve the problem of reduced surface binding ability of recycled coarse aggregate, no fundamental removal of hardened mortar, and reduced water absorption of recycled coarse aggregate, etc. problems, to achieve the effect of reducing the content of needle-like particles, fast and efficient discharge, and increasing the apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

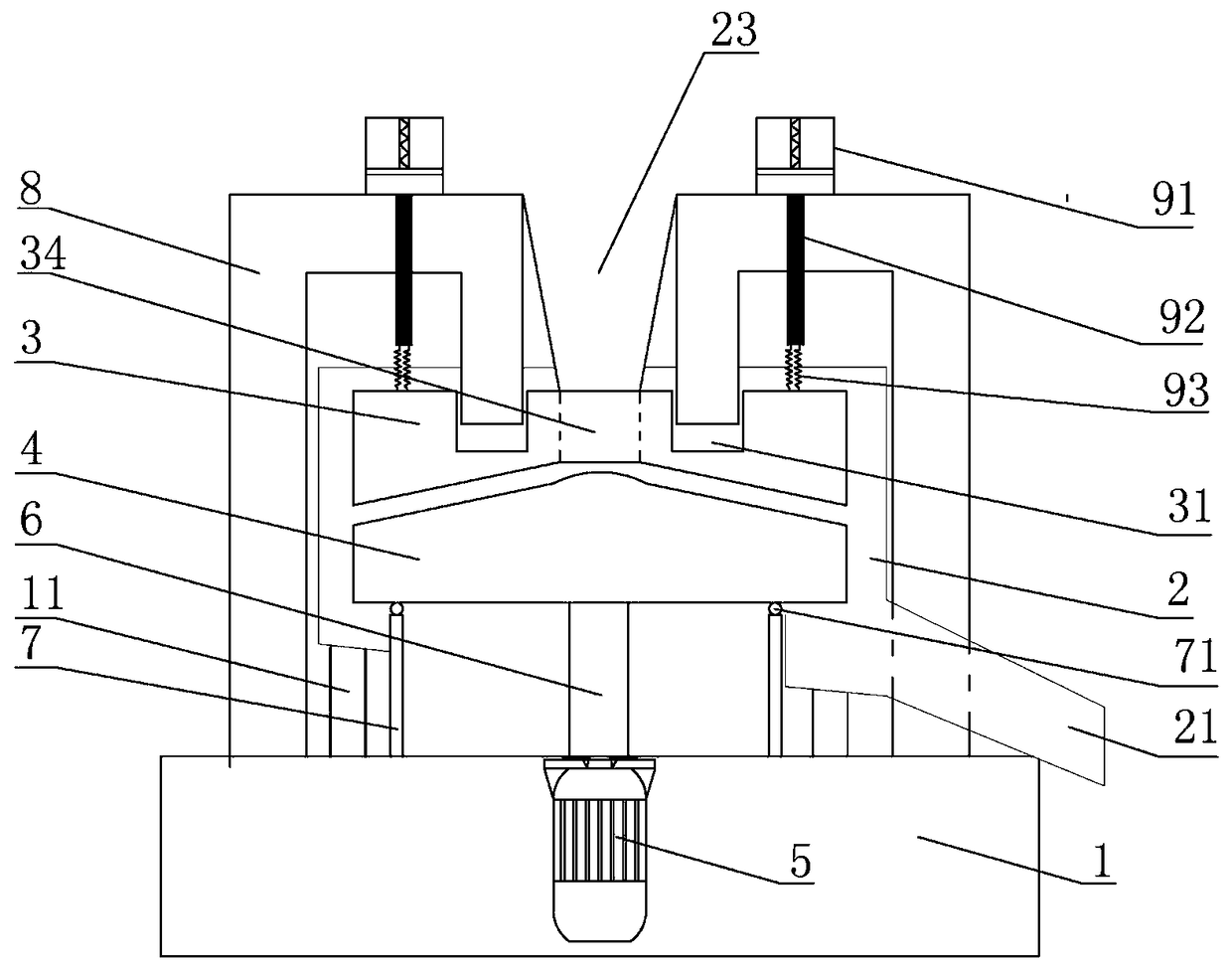

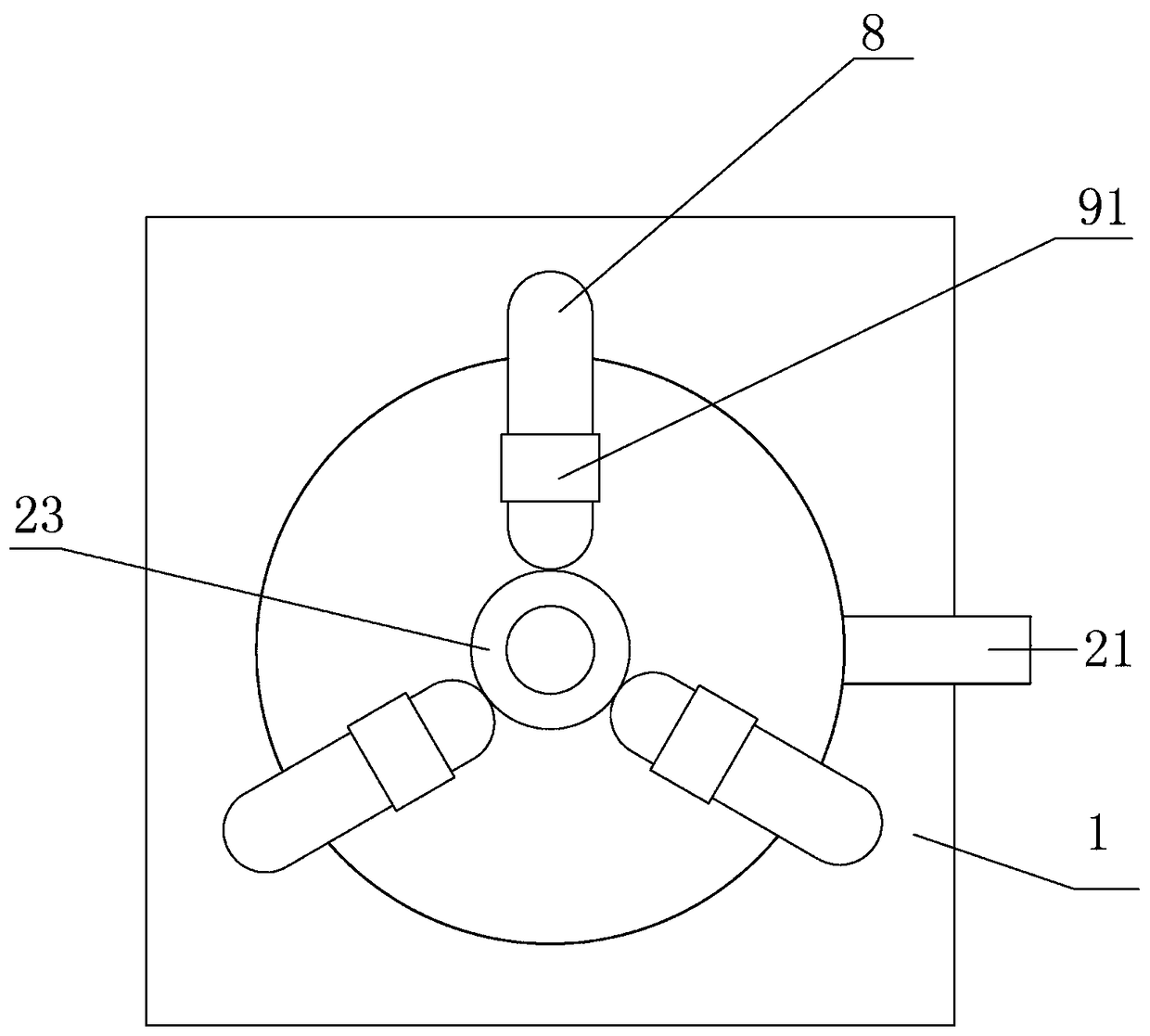

[0039] Such as figure 1 As shown, the cone-disk type waste concrete regenerated coarse aggregate mortar stripping device of the present invention includes a base 1, a collection bin 2 and a cone-disk grinding disc. Three support rods 11 are arranged on the base 1, and the collection bin 2 is supported above the base 1 by the three support rods 11, and the cone-disk type grinding disc is placed in the collection bin.

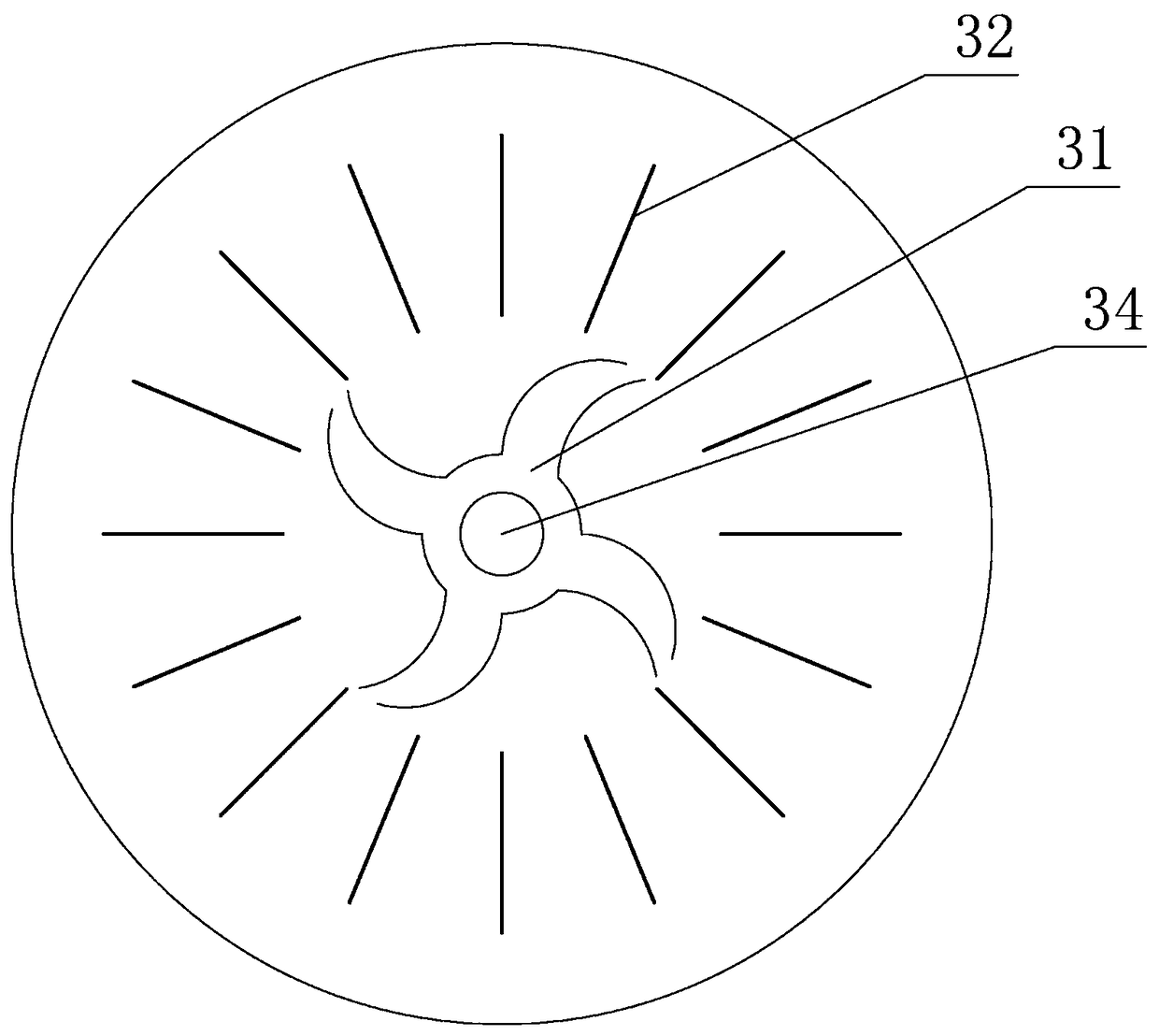

[0040] The conical disc type grinding disc is composed of an upper grinding disc 3 and a lower grinding disc 4 . The grinding surface of the lower grinding disc 4 is a convex cone type, the grinding surface of the upper grinding disc 3 is a concave cone type, and the grinding surfaces of the upper and lower grinding discs are bonded. Such as image 3 As shown, there is a windmill-shaped groove 31 around the feeding port of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com