Dry-method sand making production line and method

A technology of production line and dry method, which is applied in the field of dry sand production line, can solve the problems that the quality of machine-made sand cannot be guaranteed and the influence of dust, etc., and achieve the effect of increasing humidity, reducing dust and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a dry sand production line, and more specifically relates to an improved dry sand production line, which improves the dry sand production line in the prior art, reduces dust and improves the quality of machine-made sand.

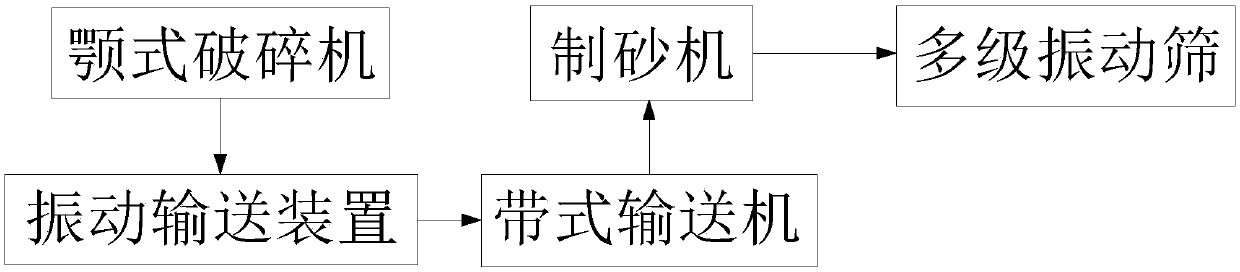

[0032] In this embodiment, the dry sand production line includes a jaw crusher, a vibrating conveying device, a sand making machine and a multi-stage vibrating screen.

[0033] Wherein, the jaw crusher is used to crush large stones into crushed stones with a diameter of 20-60mm, and the discharge port of the jaw crusher is connected to the feed hopper of the vibrating conveying device.

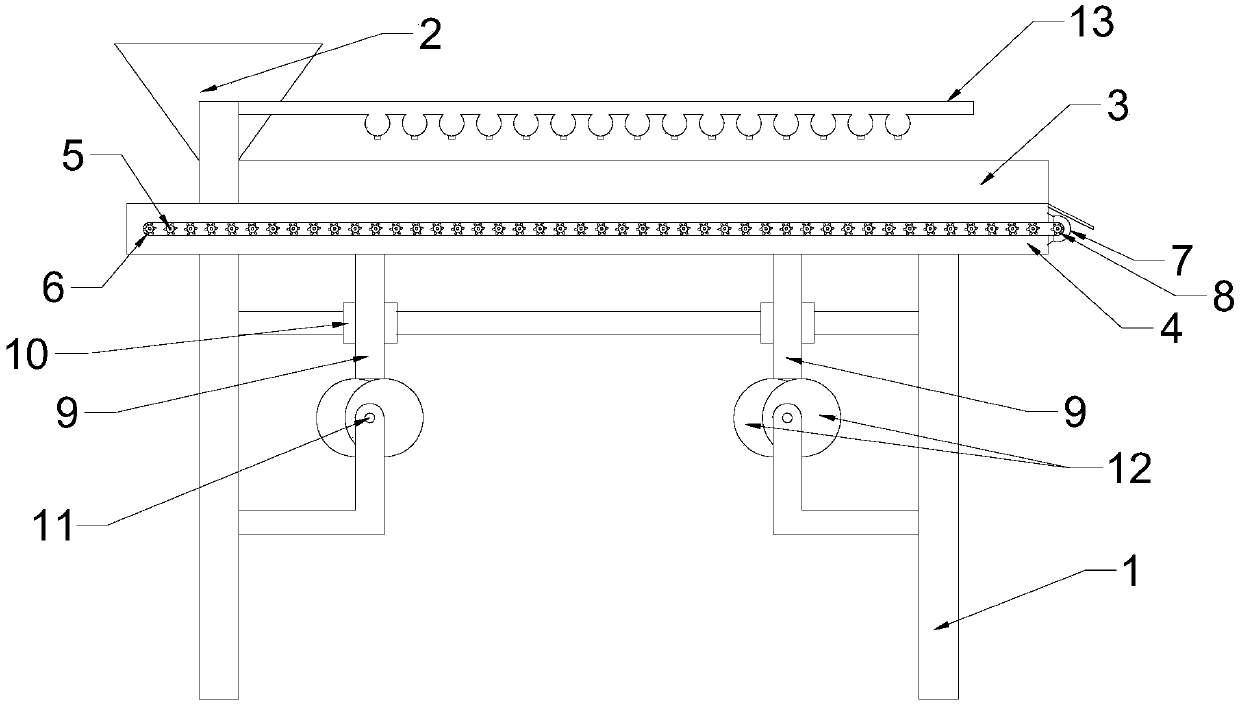

[0034] In this embodiment, the vibrating conveying device includes a frame 1 and a feed hopper 2 arranged at one end of the frame, and both sides of the frame 1 are provided with baffles 3, preferably, the baffles 3 Inclined settings from top to bottom.

[0035] The frame 1 is provided with a first conveying mechanism and a second conveying m...

Embodiment 2

[0050] This embodiment provides a dry sand making method, and more specifically relates to an improved dry sand making method, which can be produced by using the dry sand making production line described in Example 1, and includes:

[0051] S10. Crushing the large stones produced in the quarry into crushed stones with a diameter of 20-60 mm, and transporting the crushed stones to the vibrating conveying device.

[0052] S20. The vibrating conveying device vibrates the crushed stones, adjusts the pose of the crushed stones, and sprays water on the crushed stones, so as to clean the powder and soil on the surface of the crushed stones and improve the final mechanism. Sand quality, on the other hand, produces less dust in the subsequent sand making process.

[0053] In this embodiment, during the water spraying process, the water spraying amount is greater than or equal to 20kg of water / 1 ton of gravel.

[0054] S30. The belt conveyor sends the wet crushed stones into the sand m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com