Anti-cracking mortar powder for thin plastering and leveling of inner walls and preparation method of anti-cracking mortar powder

An anti-cracking mortar and thin plastering technology, which is applied to the field of thin plastering and leveling anti-cracking mortar powder for interior walls and its preparation field, can solve the problem of mildewing of surface coatings and putty of interior walls, no quality control of on-site mixing ratio, and poor quality control. The performance of wet-mixed mortar is single and other problems, so as to avoid the abnormal state of the mortar, improve the construction feel, and avoid shrinkage and cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

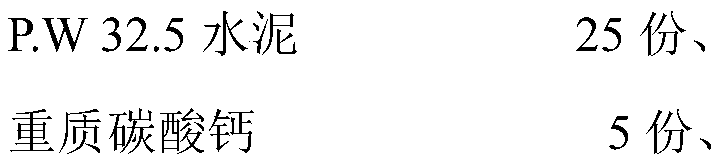

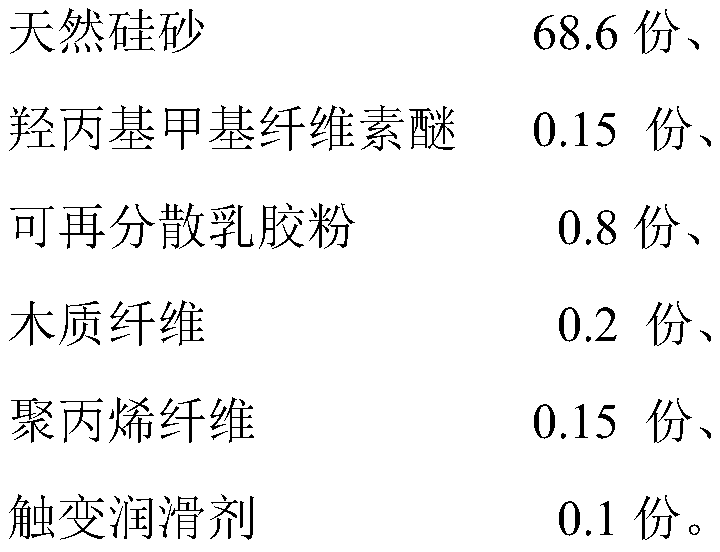

[0021] 1.1 Composition of thin plastering and leveling anti-cracking mortar powder for interior walls

[0022] Proportion by weight is composed of:

[0023]

[0024]

[0025] 1.2 Preparation method

[0026] Using integrated equipment and computer weighing and feeding, according to the description in 1.1, put the raw materials into 3m according to the proportion 3 In the mixing chamber, stir at a speed of 120 rpm for 180-240 seconds to mix evenly, and discharge the material after the stirring is completed.

[0027] 1.3 How to use

[0028] Put the inner wall thin plastering leveling anti-cracking mortar powder prepared in 1.2 and water in a container at a weight ratio of 4 to 4.5:1, stir with a hand-held electric mixer at a medium-low speed for 2 to 3 minutes, and then stop for 1 Minutes, and then stir for 1 to 2 minutes to mix the mortar. The mortar should be constructed within 2 hours. It should not be used when it is out of date, and no water or powder can be added i...

Embodiment 2

[0030] 2.1 Composition of thin plastering and leveling anti-cracking mortar powder for interior walls

[0031] Proportion by weight is composed of:

[0032]

[0033] 2.2 Preparation method

[0034] Using integrated equipment computer weighing and feeding, according to the 2.1, the raw materials are put into 3m according to the ratio 3 In the mixing chamber, stir at a speed of 120 rpm for 180-240 seconds to mix evenly, and discharge the material after the stirring is completed.

[0035] 2.3 How to use

[0036] Put the inner wall thin plastering leveling anti-cracking mortar powder prepared in 2.2 and water in a container at a weight ratio of 4 to 4.5:1, stir with a hand-held electric mixer at a medium-low speed for 2 to 3 minutes, and then stop for 1 Minutes, and then stir for 1 to 2 minutes to mix the mortar. The mortar should be constructed within 2 hours. It should not be used when it is out of date, and no water or powder can be added in the middle; the method of manu...

Embodiment 3

[0038] 3.1 Composition of thin plastering and leveling anti-cracking mortar powder for interior walls

[0039] Proportion by weight is composed of:

[0040]

[0041] 3.2 Preparation method

[0042] Using integrated equipment computer weighing and feeding, according to 3.1, the raw materials are put into 3m according to the ratio 3 In the mixing chamber, stir at a speed of 120 rpm for 180-240 seconds to mix evenly, and discharge the material after the stirring is completed.

[0043] 3.3 How to use

[0044] Put the inner wall thin plastering leveling anti-cracking mortar powder prepared in 3.2 and water in a container at a weight ratio of 4 to 4.5:1, stir with a hand-held electric mixer at a medium-low speed for 2 to 3 minutes, and then stop for 1 Minutes, and then stir for 1 to 2 minutes to mix the mortar. The mortar should be constructed within 2 hours. It should not be used when it is out of date, and no water or powder can be added in the middle; the method of manual b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com