Detachable winding disc for pipe winding machine

A winder and detachable technology, applied in the field of detachable winder, can solve the problems of low space utilization rate of the winder and the inability to uniformly wind pipes, etc., and achieve the effect of convenient packaging and disassembly and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further technical details of the present invention in conjunction with the accompanying drawings and embodiments below.

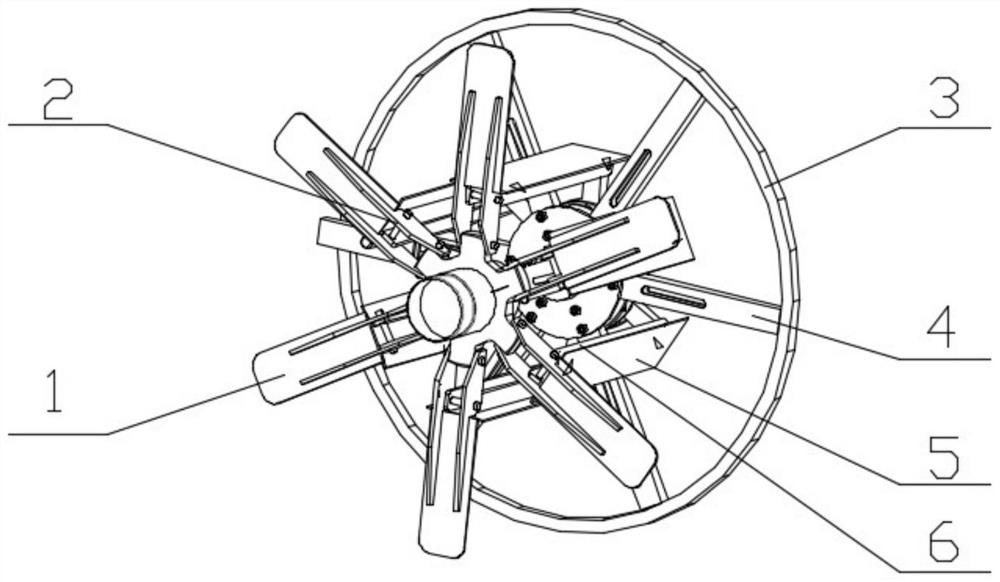

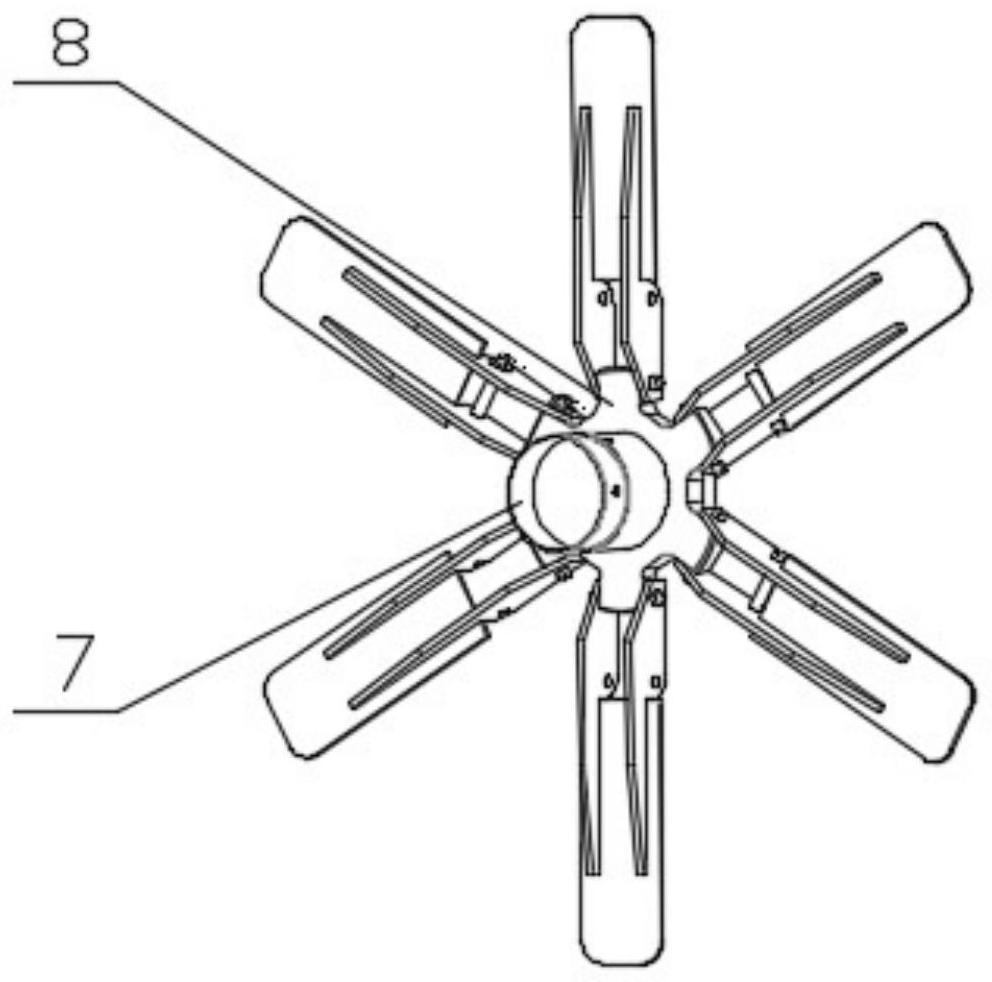

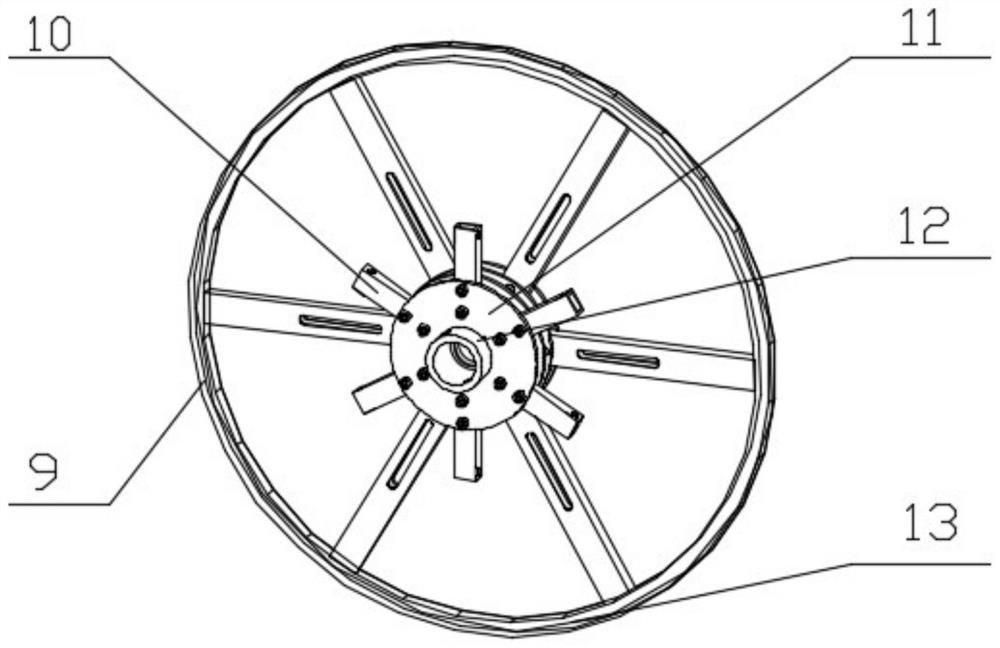

[0026] Detachable winding tube for winding disk machine, comprising a front plate and a winding disk after winding, such as figure 1 , figure 2 and image 3 , The front plate includes a front winding 8 wound stent, the stent circumferentially disposed baffles 8 1, the shutter 2 and the cradle 1 are connected by coil holder 8 around the front edge of the front wound by a bolt, the shutter 1 by bolts and support 2 is connected, the holder 2 for providing support for the baffle. Wound center front bracket 8 is provided with a linear bearing housing 16 is mounted within the linear bearing housing 16 linear bearings 14, linear bearings provided on the side plate 7 after the discharge wheel 14 away from the winding, the discharge side wheel is provided with a threaded hole, off wheel rolling can be completed with other detachable connection means by unloading s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com