Self-control cotton collecting box

A technology of collecting cotton and box body, which is applied in the fields of picking machines, agricultural machinery and implements, and applications, can solve the problems of uneconomical, short conveying distance, and high cost, and achieve the purpose of avoiding falling to the ground, reasonable connection, and efficient cotton unloading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

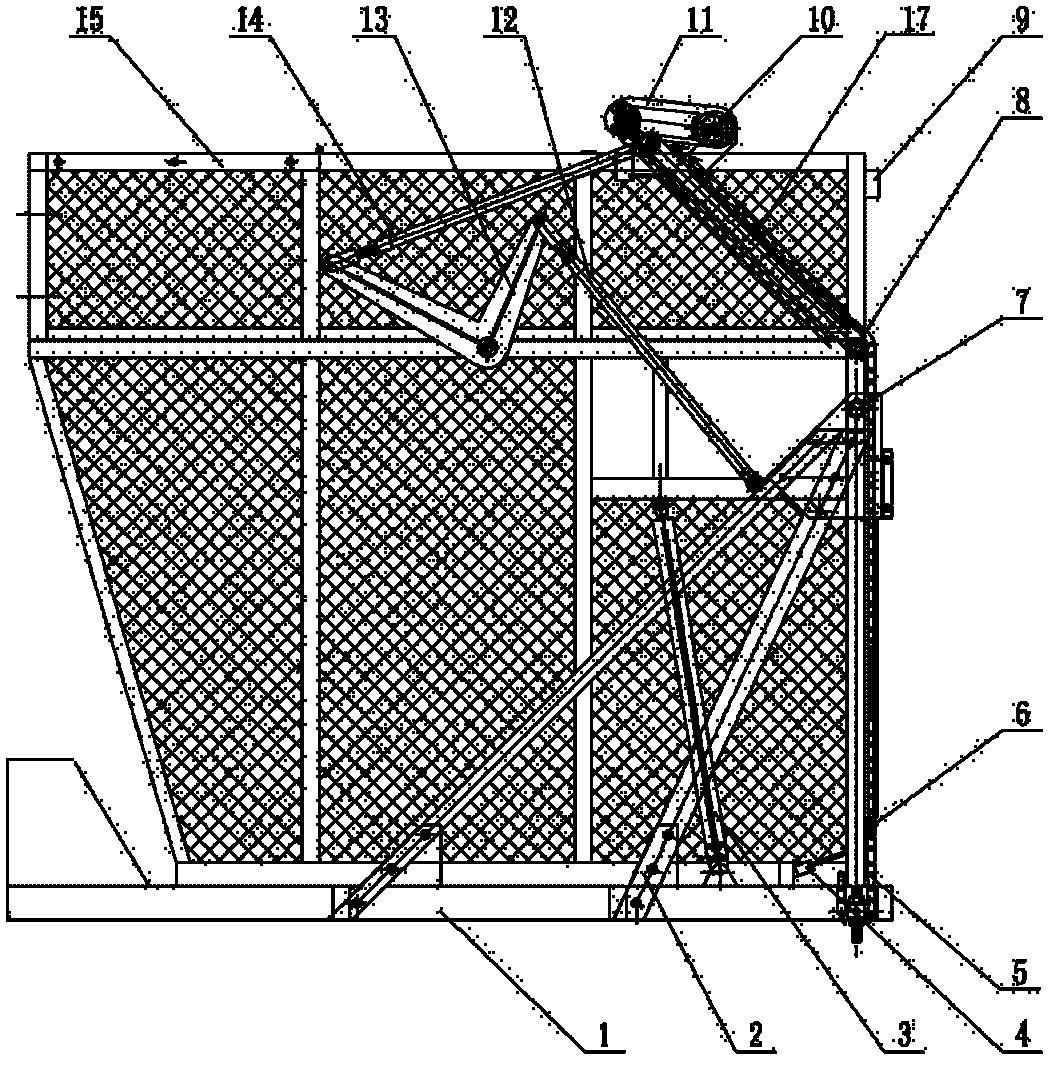

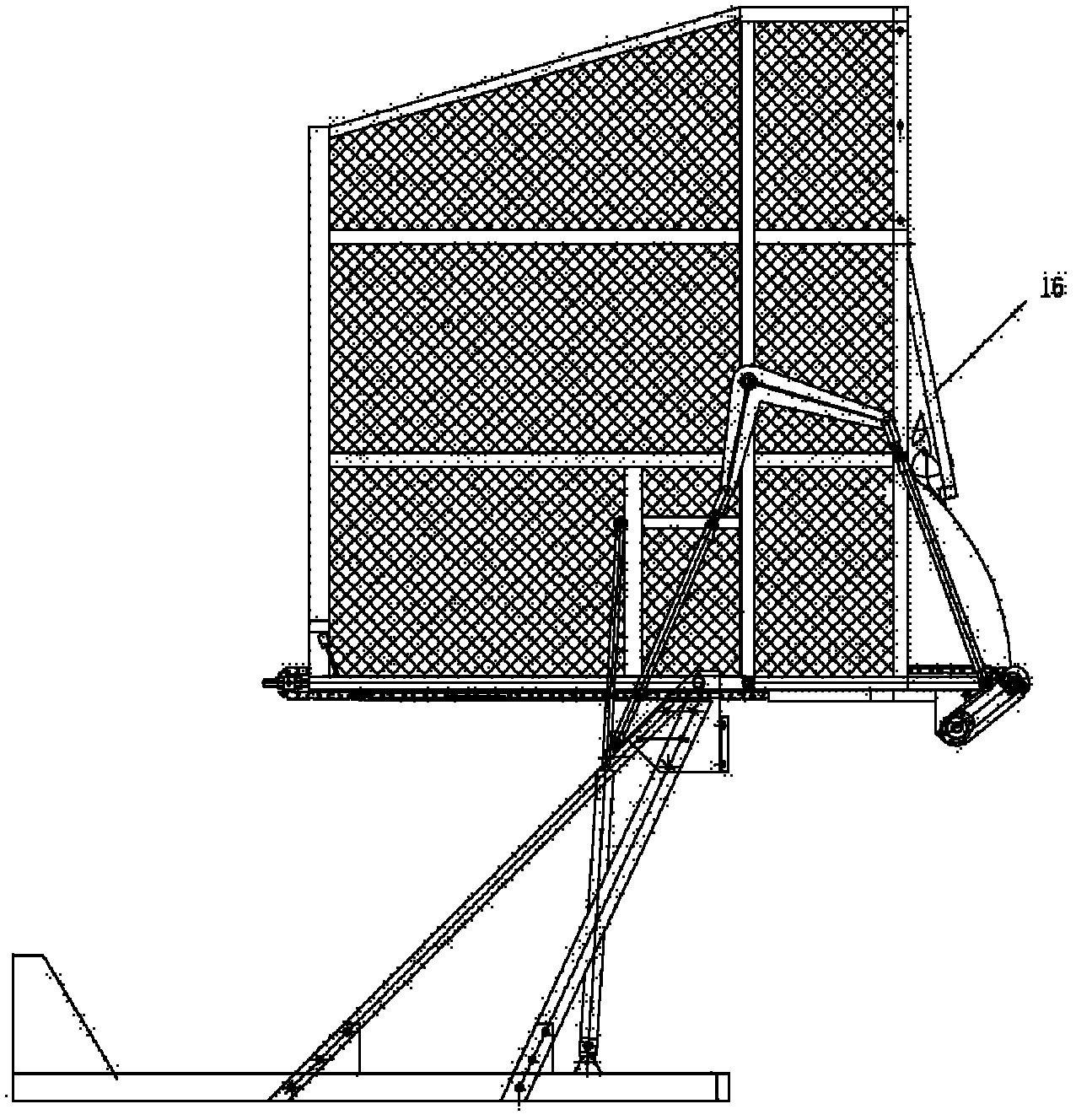

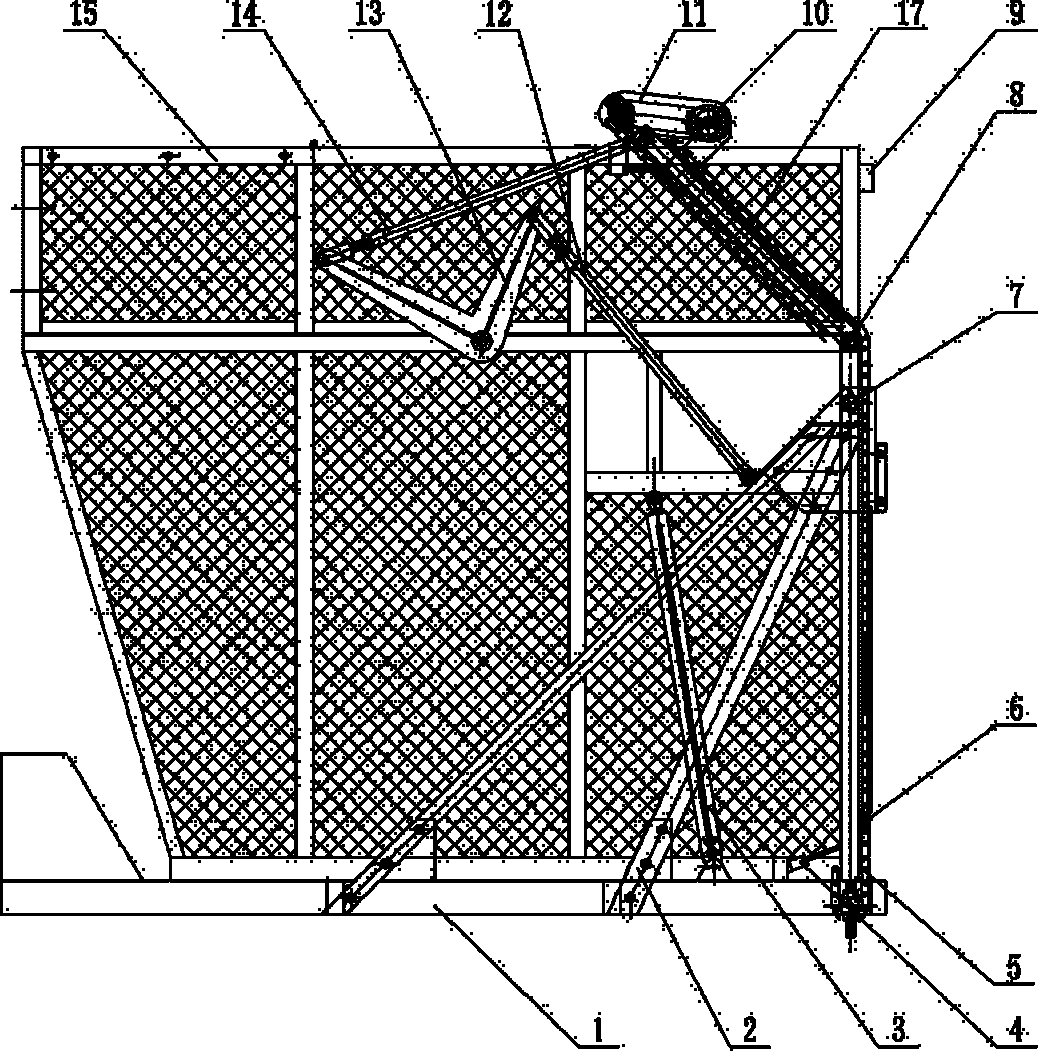

[0016] The self-control cotton collecting box of the present embodiment is as figure 1 As shown, it includes a cotton collection box 15 with an open end, and the side adjacent to the open end of the cotton collection box is hinged on the chassis frame 1 through an inverted V-shaped support cantilever 2 . The supporting end of the lifting oil cylinder 3 is hinged on the chassis frame 1, and the telescopic end of the lifting oil cylinder 3 is hinged on the cotton collecting box 15. The top of the support cantilever 2 is hinged with one end of the connecting rod 12, and the other end of the connecting rod 12 is hinged with one end of the V-shaped redirecting rod 13 hinged on the cotton box body, and the other end of the V-shaped redirecting rod 13 is hinged. The end is hinged with one end of the pull rod 14, and the other end of the pull rod 14 is hinged with one end of the indexing conveyor chain 17, which is driven by the hydraulic motor 10 on the tongue door 11, and the tongue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com