Rotation type hydraulic ship unloader

A ship unloader and rotary technology, which is applied in the field of hydraulic ship unloading device for bulk materials, can solve the problems of ship unloader paralysis, material spreading, and affecting the normal operation of the wharf, and achieve the effect of controlling dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

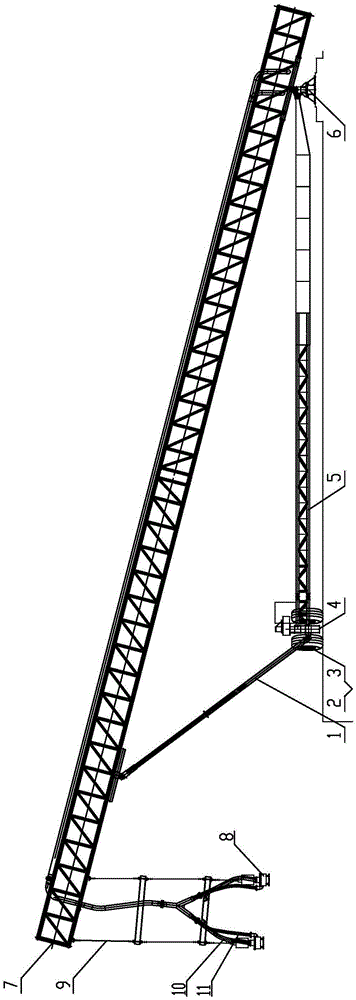

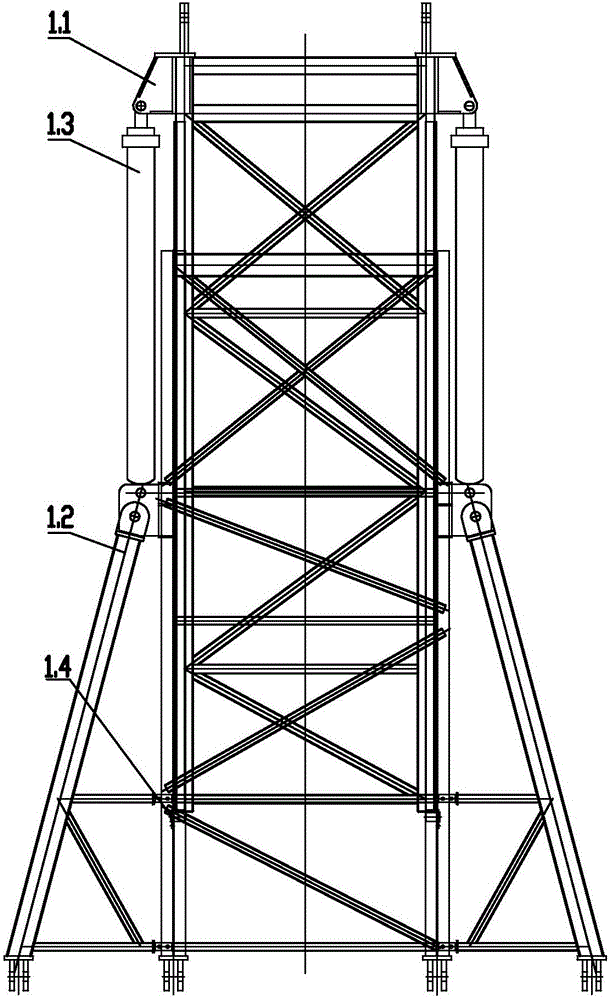

[0049] Such as Figure 1-Figure 18 As shown, a rotary hydraulic ship unloader, including

[0050] The pitch mechanism 1 includes a moving frame 1.1, a turret 1.2 and a hydraulic system 1.3 connecting the moving frame 1.1 and the turret 1.2,

[0051] Slewing mechanism, including driving wheel set 2, driven wheel set 3, balance beam 4, slewing frame 5 and slewing pivot 6,

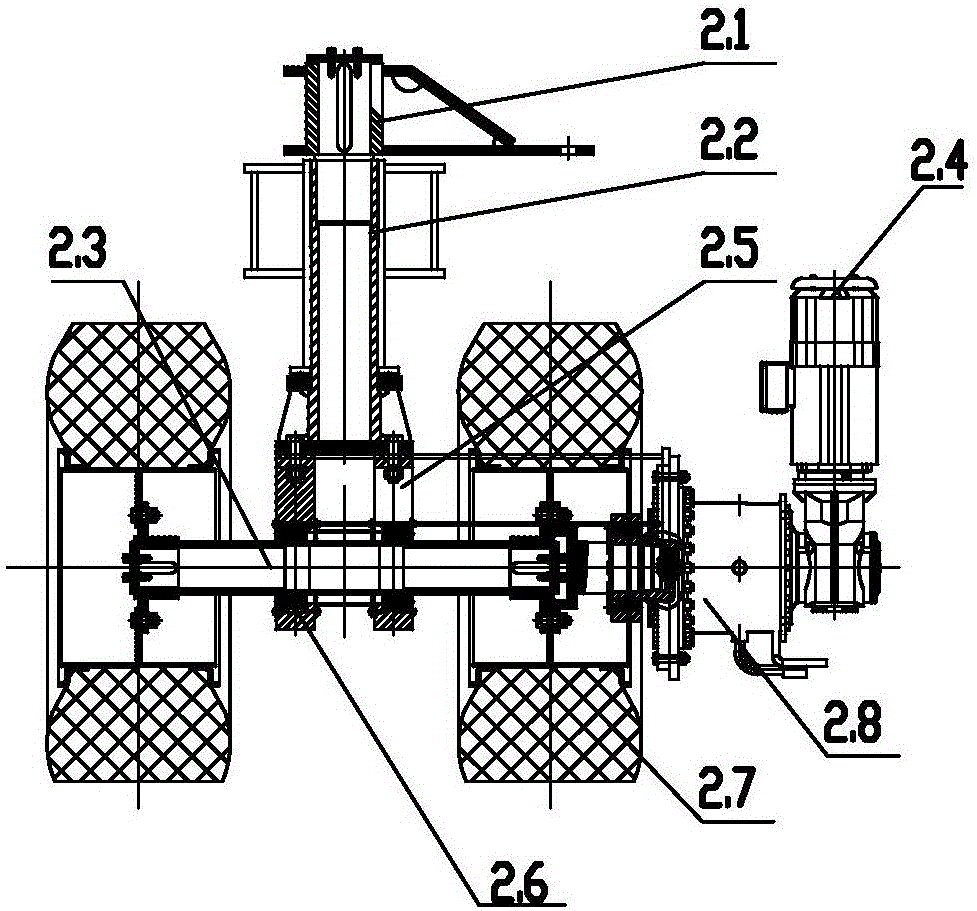

[0052] The driving wheel set 2 includes a driving wheel positioning sleeve 2.1, a driving wheel vertical shaft assembly 2.2, a driving wheel shaft assembly 2.3 and a driving wheel drive motor 2.4, and the driving wheel vertical shaft assembly 2.2 passes through the driving wheel bearing seat 2.5 and the driving wheel bearing 2.6 Connected with the driving wheel shaft assembly 2.3, the two ends of the driving wheel shaft assembly 2.3 are respectively provided with the driving wheel wheel assembly 2.7, and one end of the driving wheel shaft assembly 2.3 is connected to the driving wheel drive connecting shaft 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com