Patents

Literature

40results about How to "Stable uninstall" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

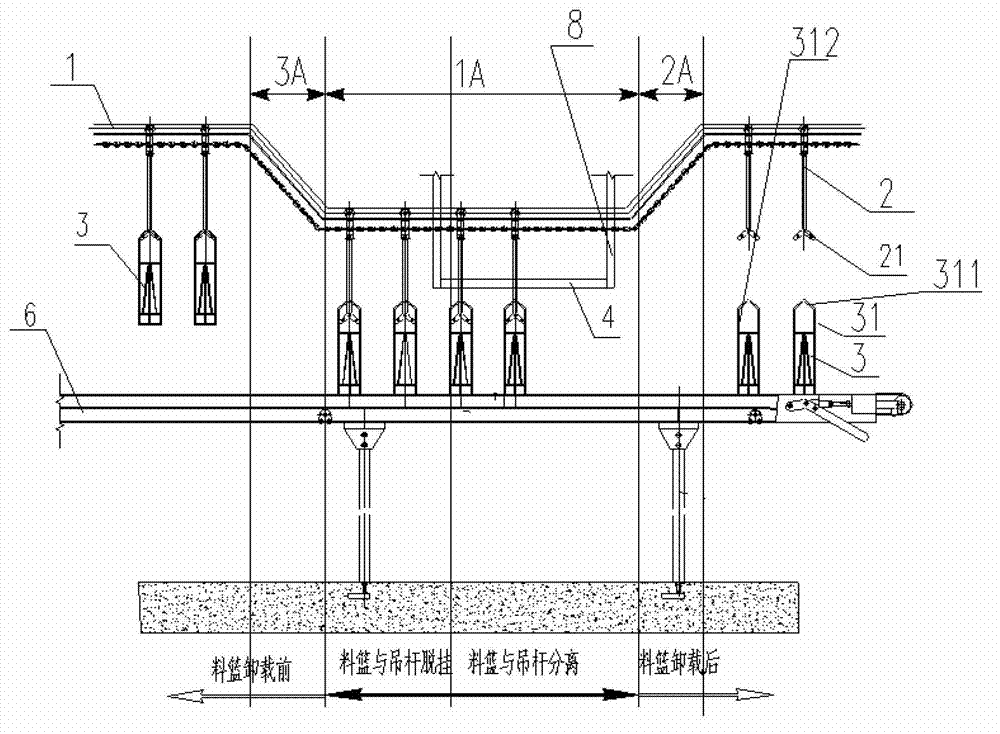

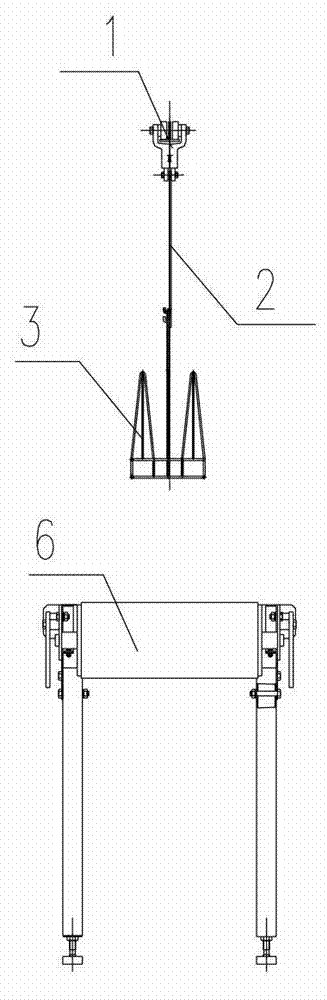

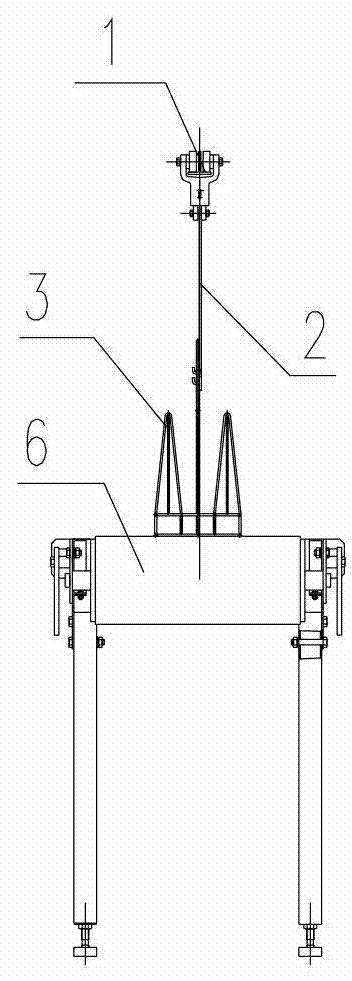

Automatic hanging and unloading system of material basket

The invention discloses an automatic hanging and unloading system of a material basket, which comprises a hanging conveying line, a material basket hanging rod, the material basket and a disengagement blocking rod, wherein the upper end of the material basket hanging rod is connected with the hanging conveying line, and the lower end of the material basket hanging rod is used for lifting through a hanging hook and a hanging ring on the material basket; the hanging conveying line is provided with a material basket disengagement conveying area; the disengagement blocking rod is arranged below the hanging conveying line and forms a horizontal included angle with the conveying direction of the hanging conveying line in the material basket disengagement conveying area; a material basket conveying device is arranged below the material basket disengagement conveying area and is parallel to the hanging conveying line in the material basket disengagement conveying area, and the material basket conveying device and the hanging conveying line are synchronously driven; the material basket conveyed into the material basket disengagement conveying area comes into contact with the material basket conveying device; the hanging hook is disengaged from the hanging ring and positioned in an area of the hanging ring, which is to be hung; the material basket is driven to convey by the material basket conveying device; and when the material basket hanging rod is conveyed to the tail end of the disengagement blocking rod, the hanging hook is moved out of the area of the hanging ring, which is to be hung, and the material basket is unloaded. According to the automatic hanging and unloading system of the material basket, smooth unloading of the material basket is realized, and the degree of automation is increased.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

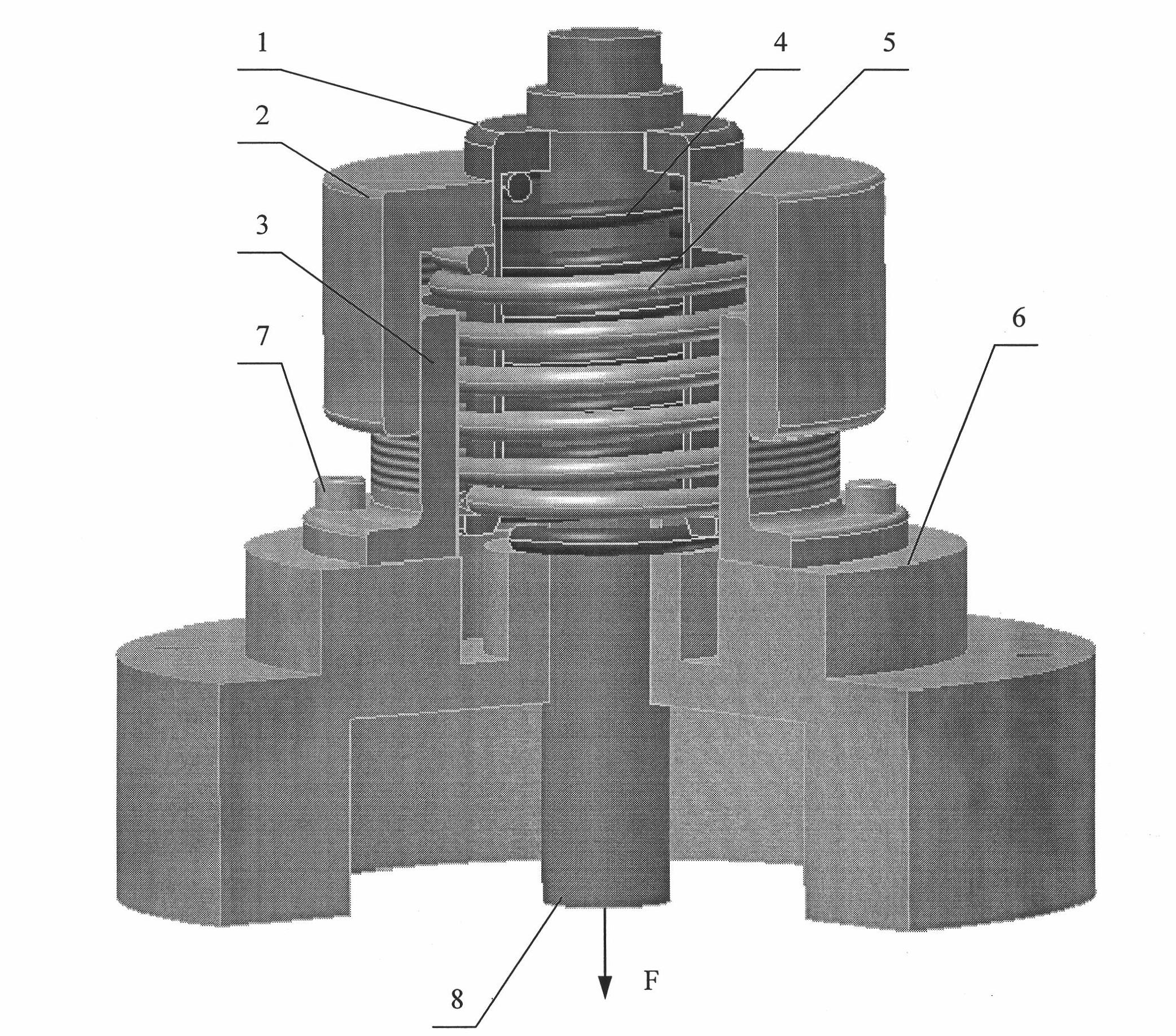

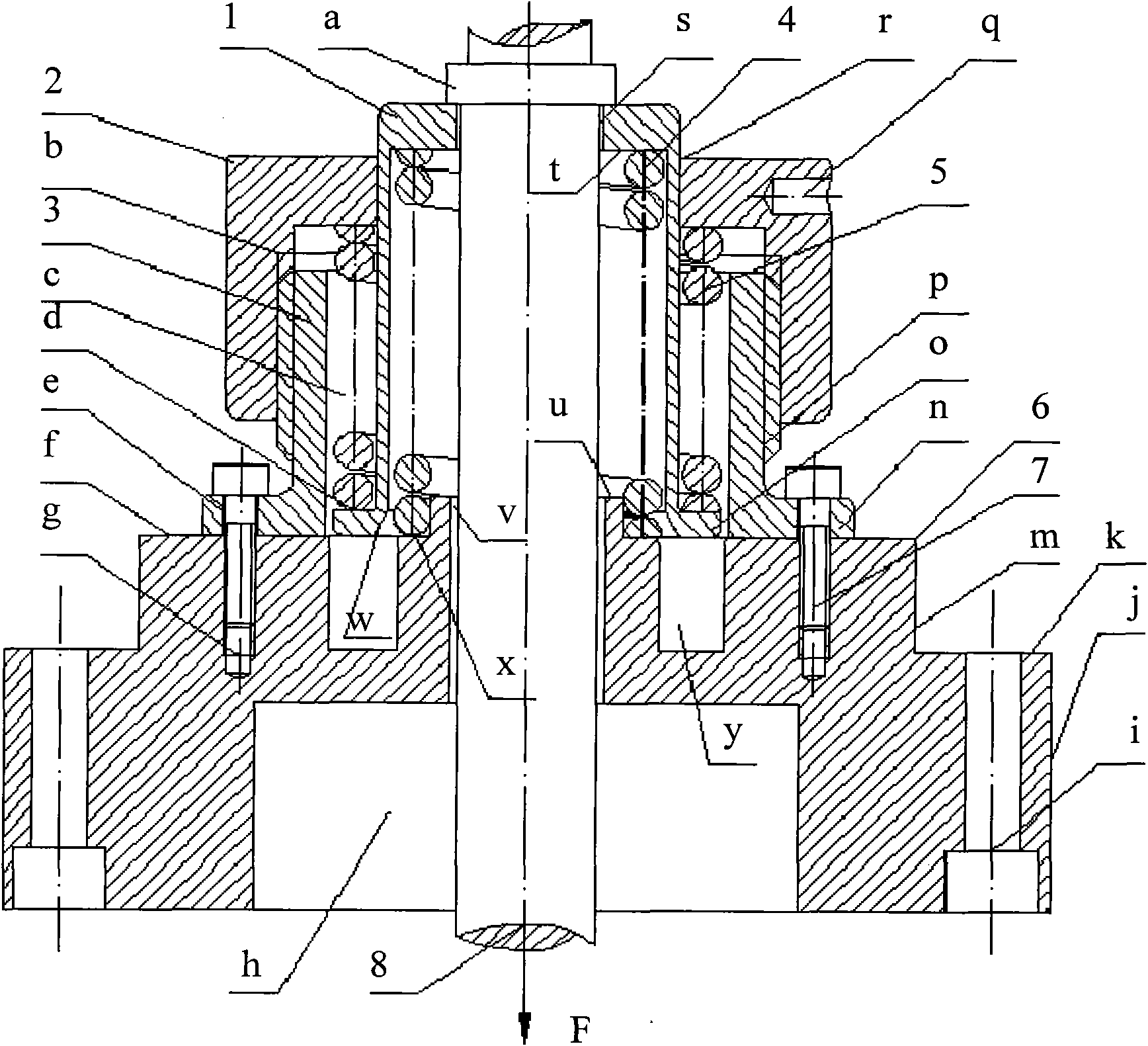

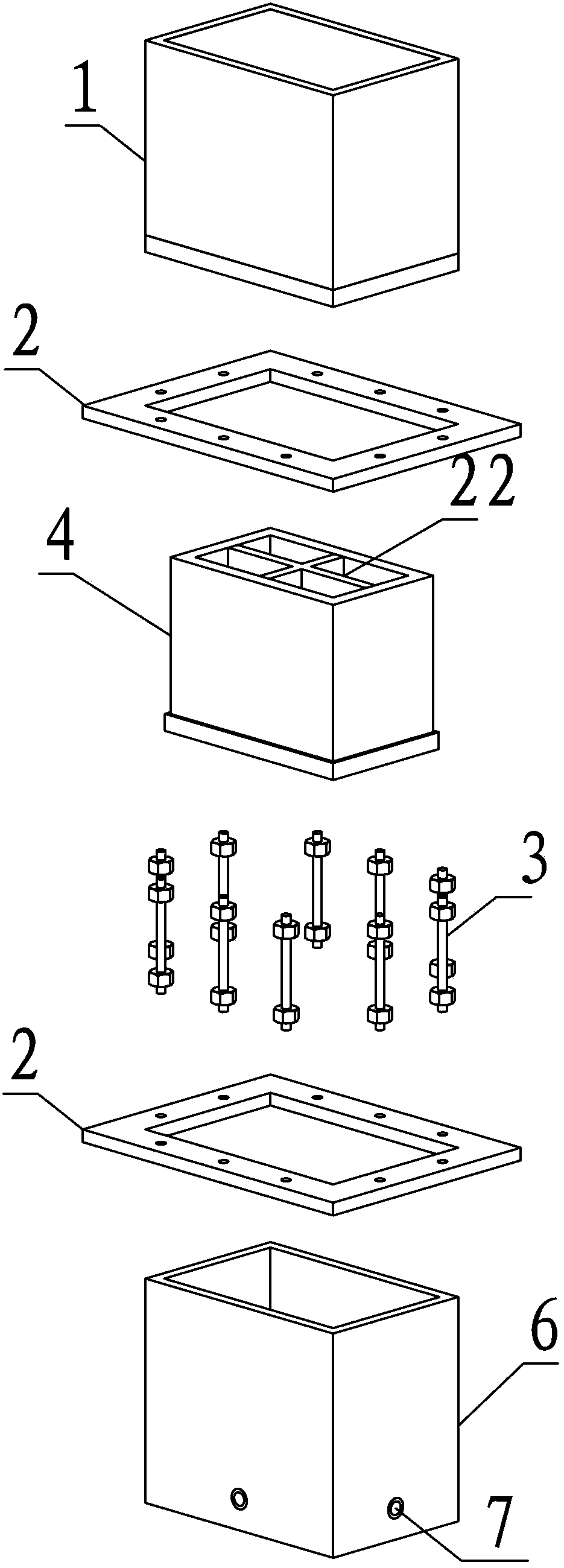

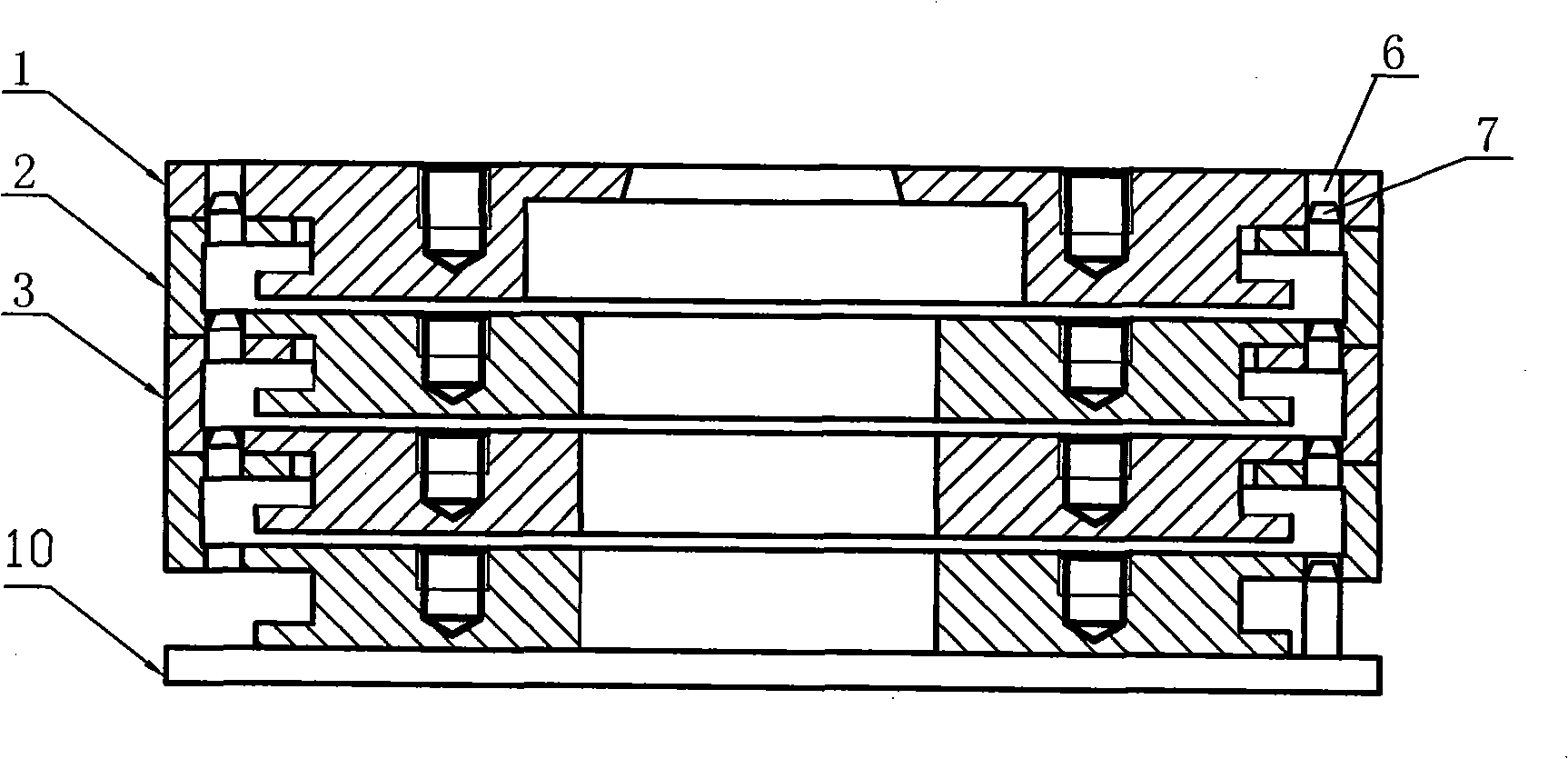

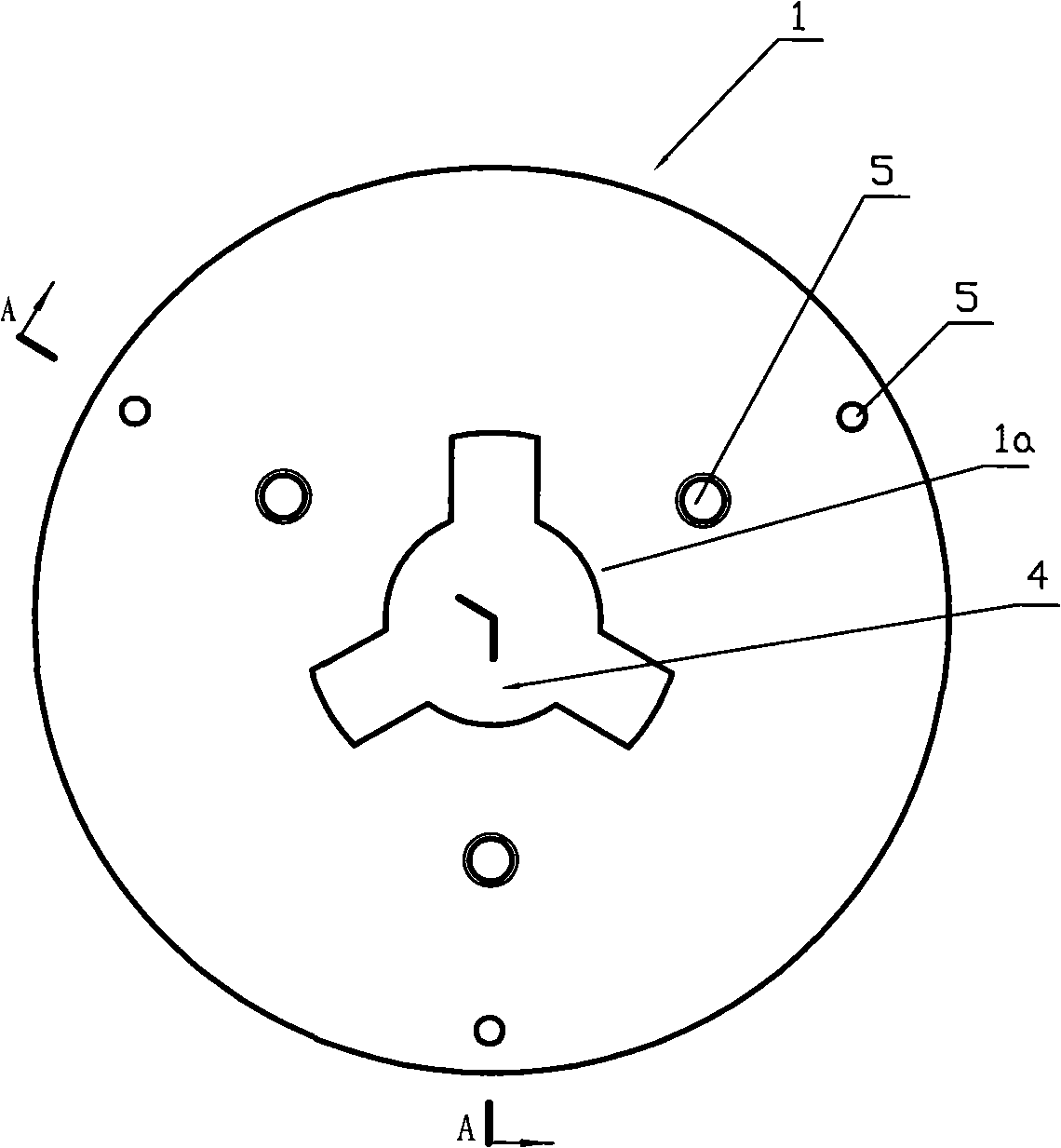

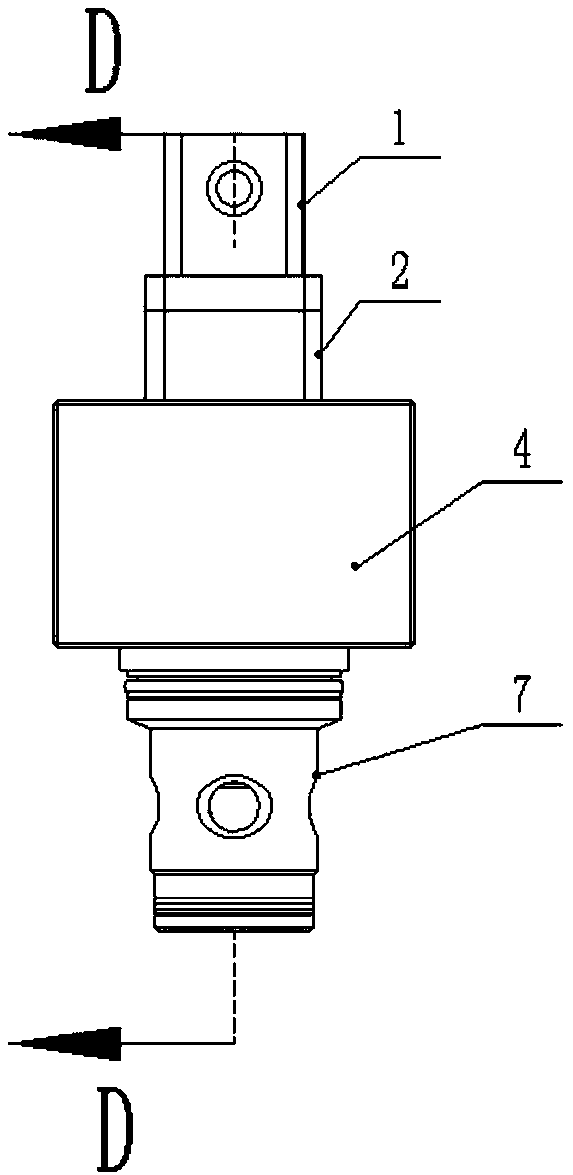

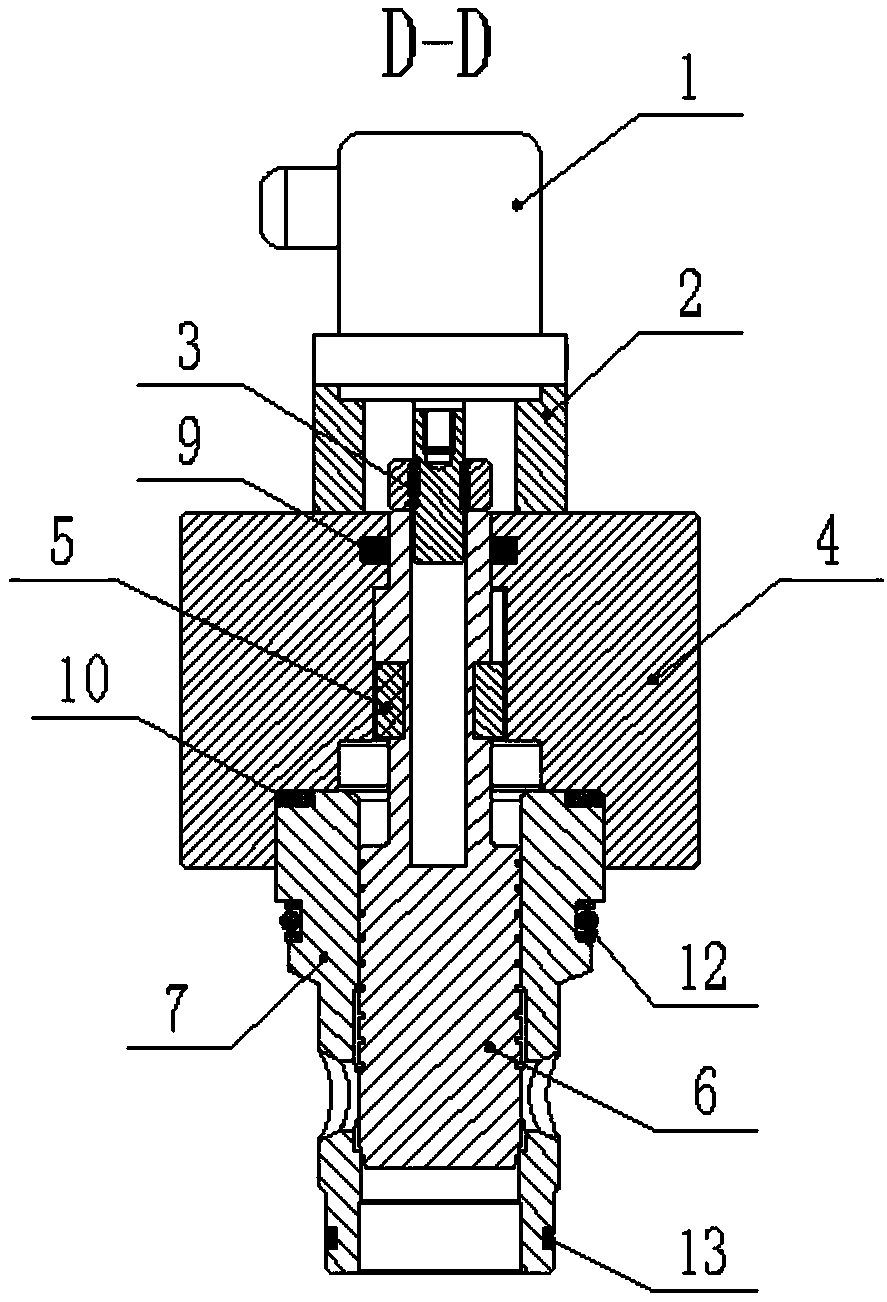

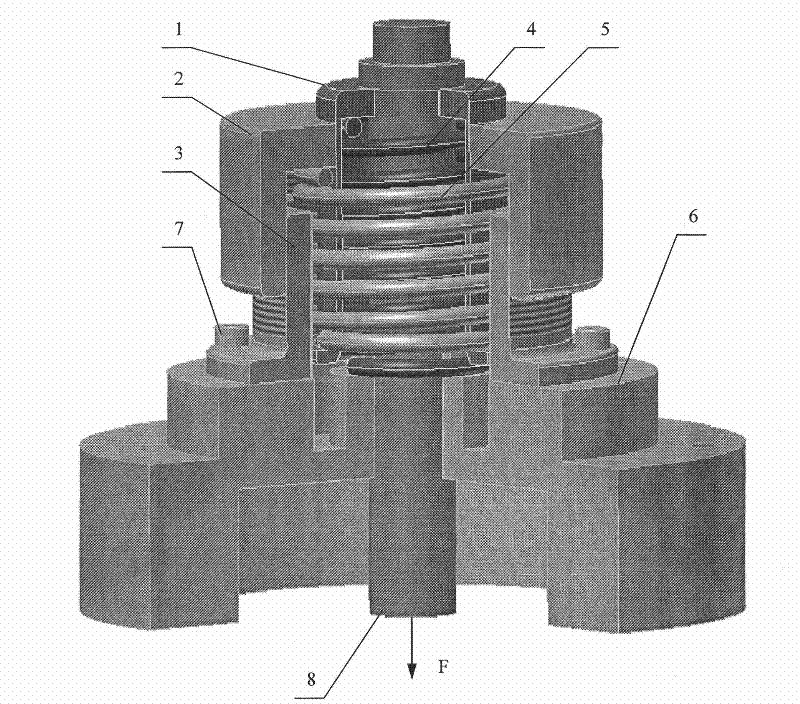

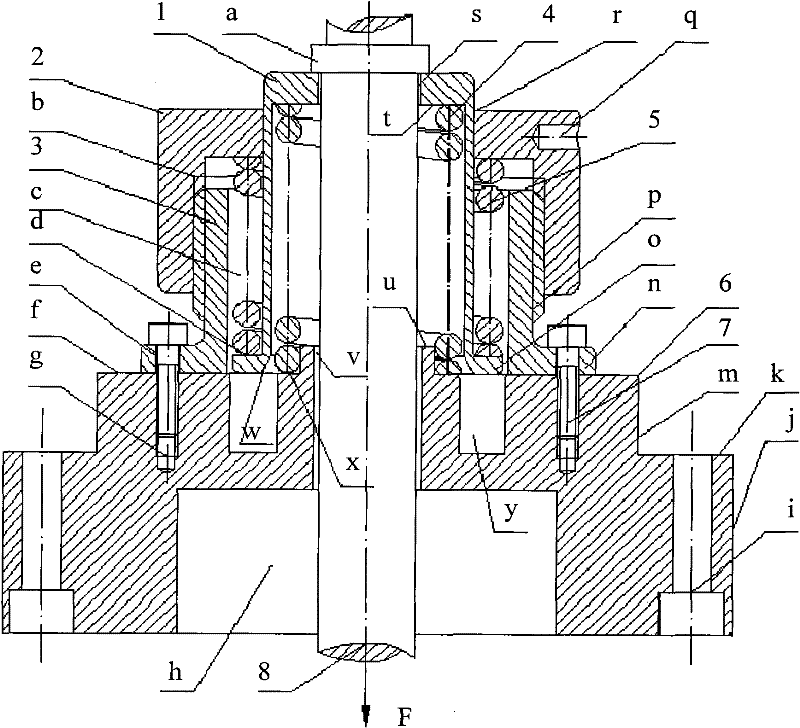

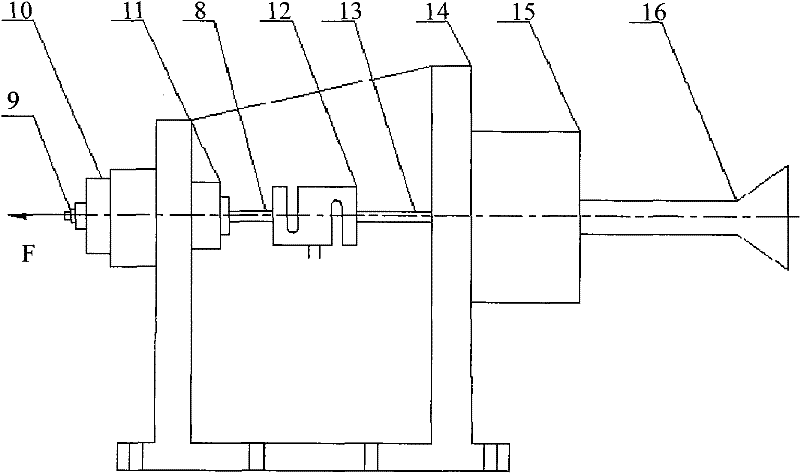

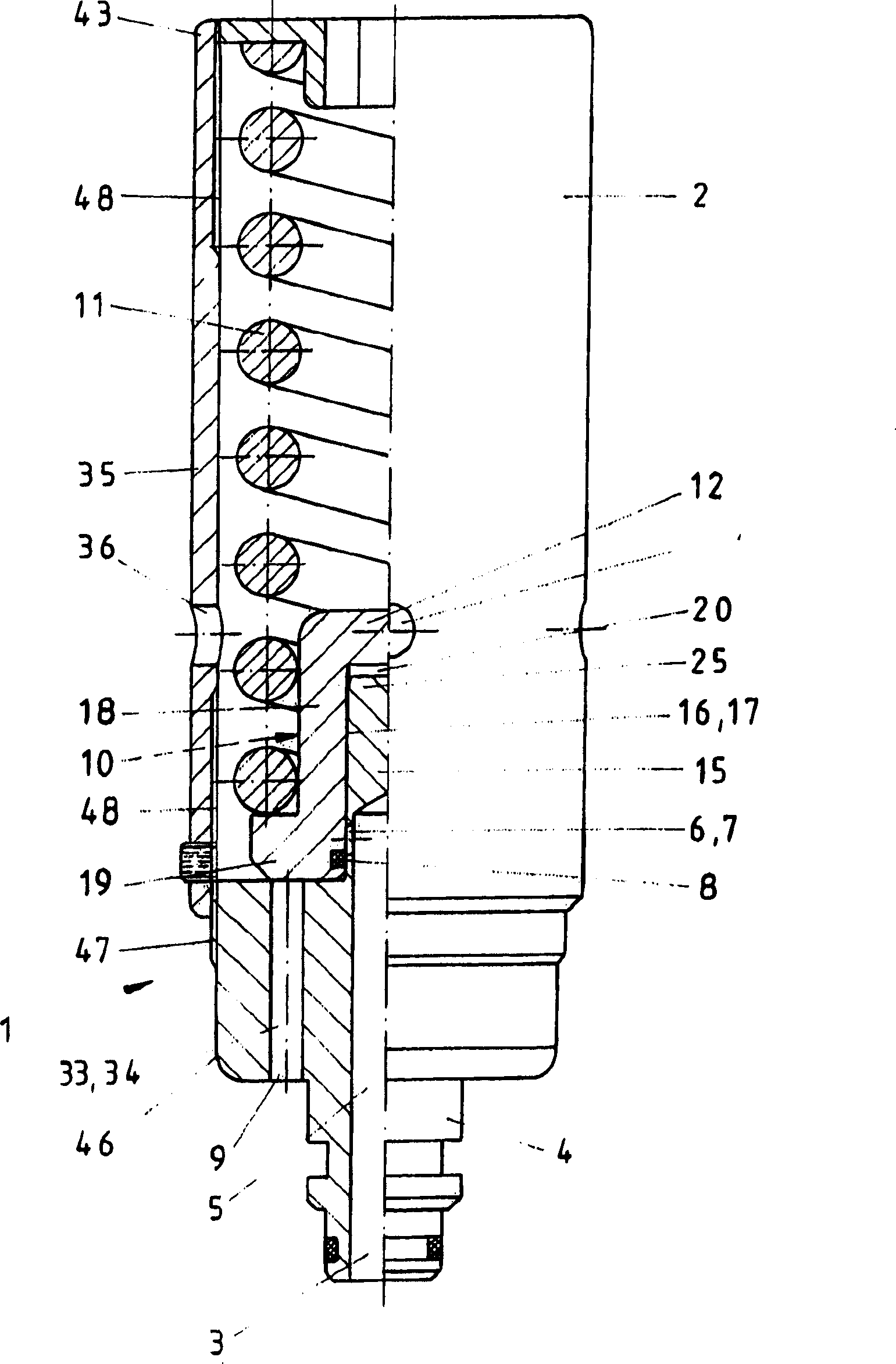

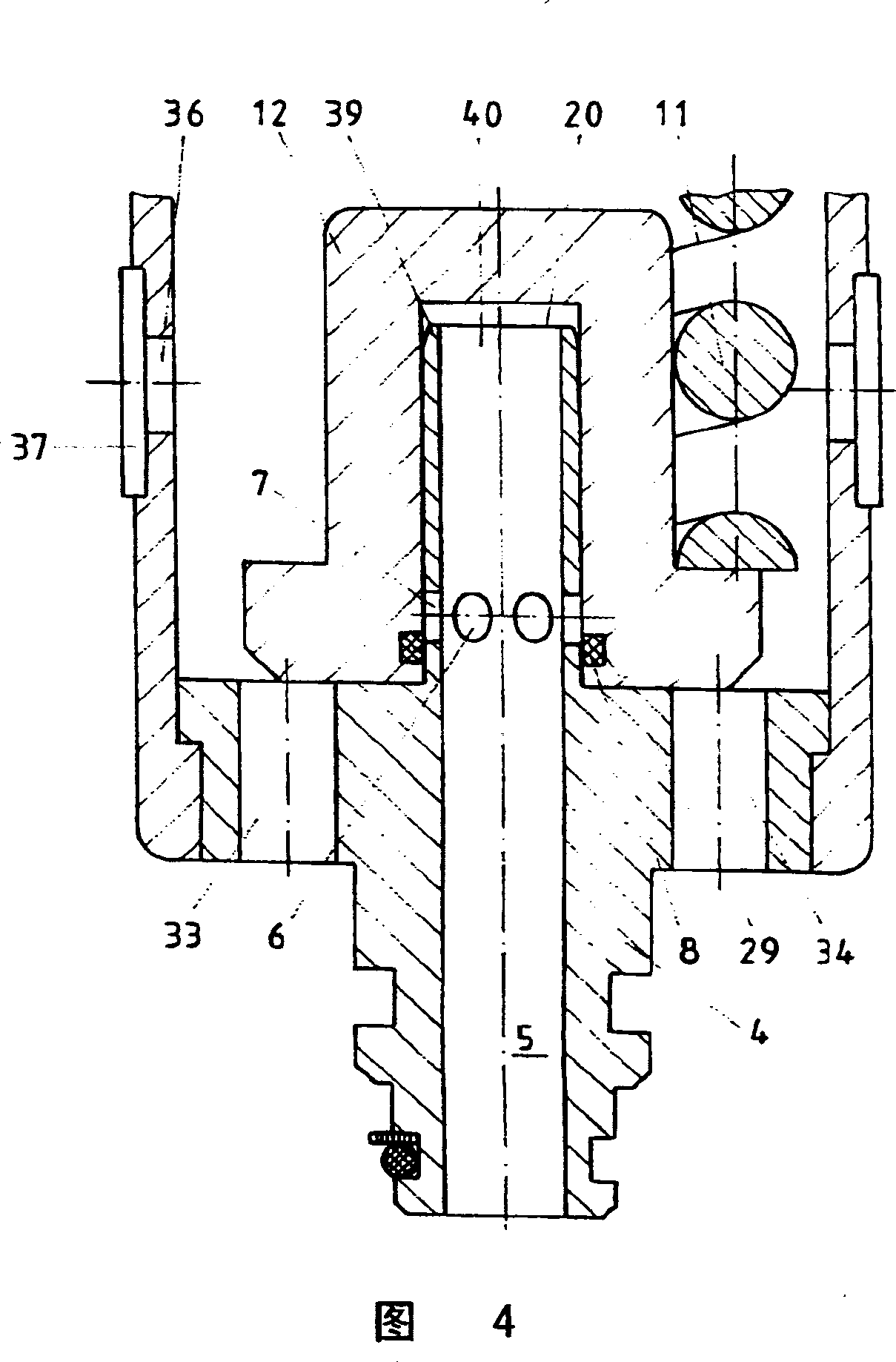

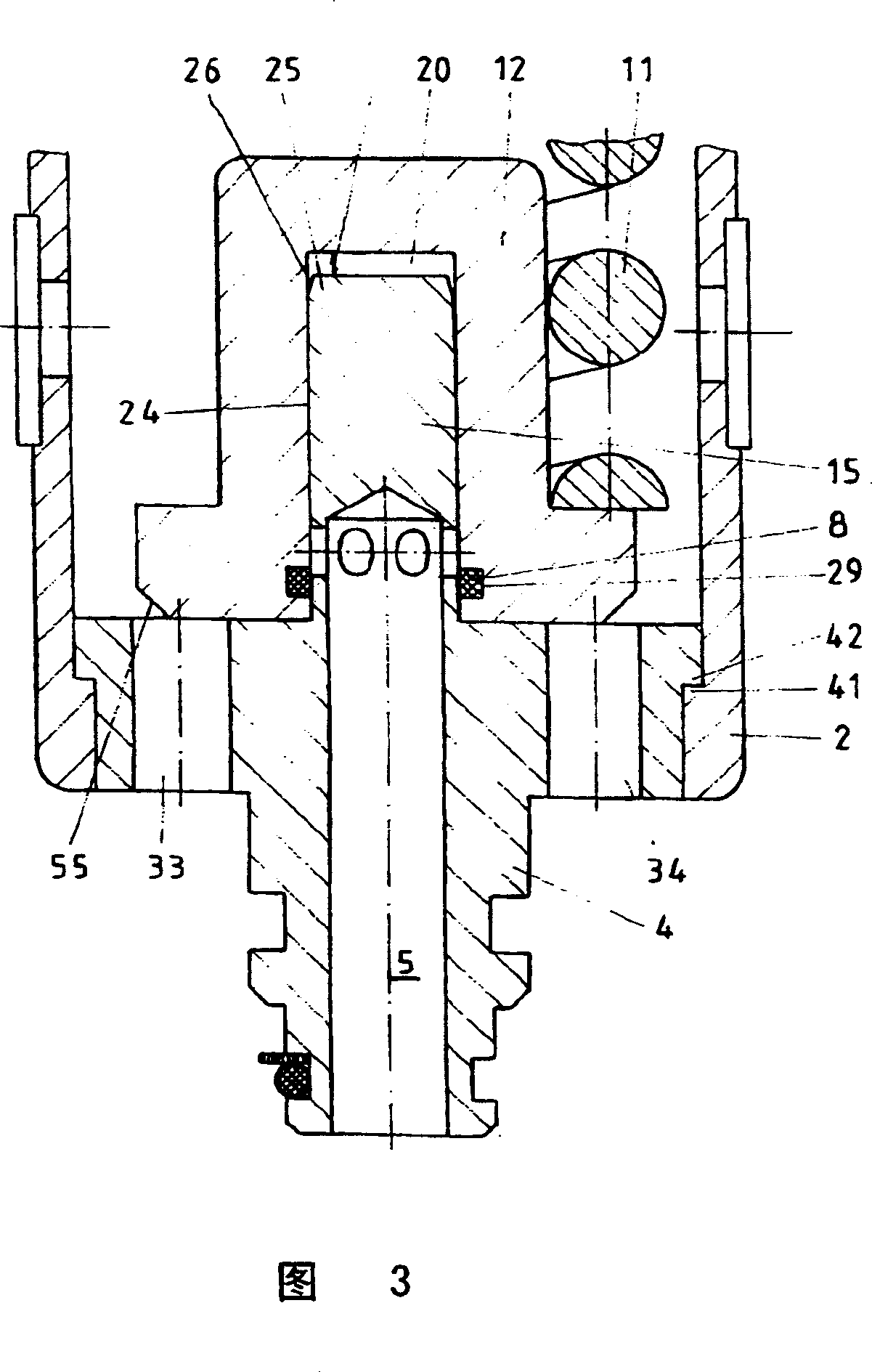

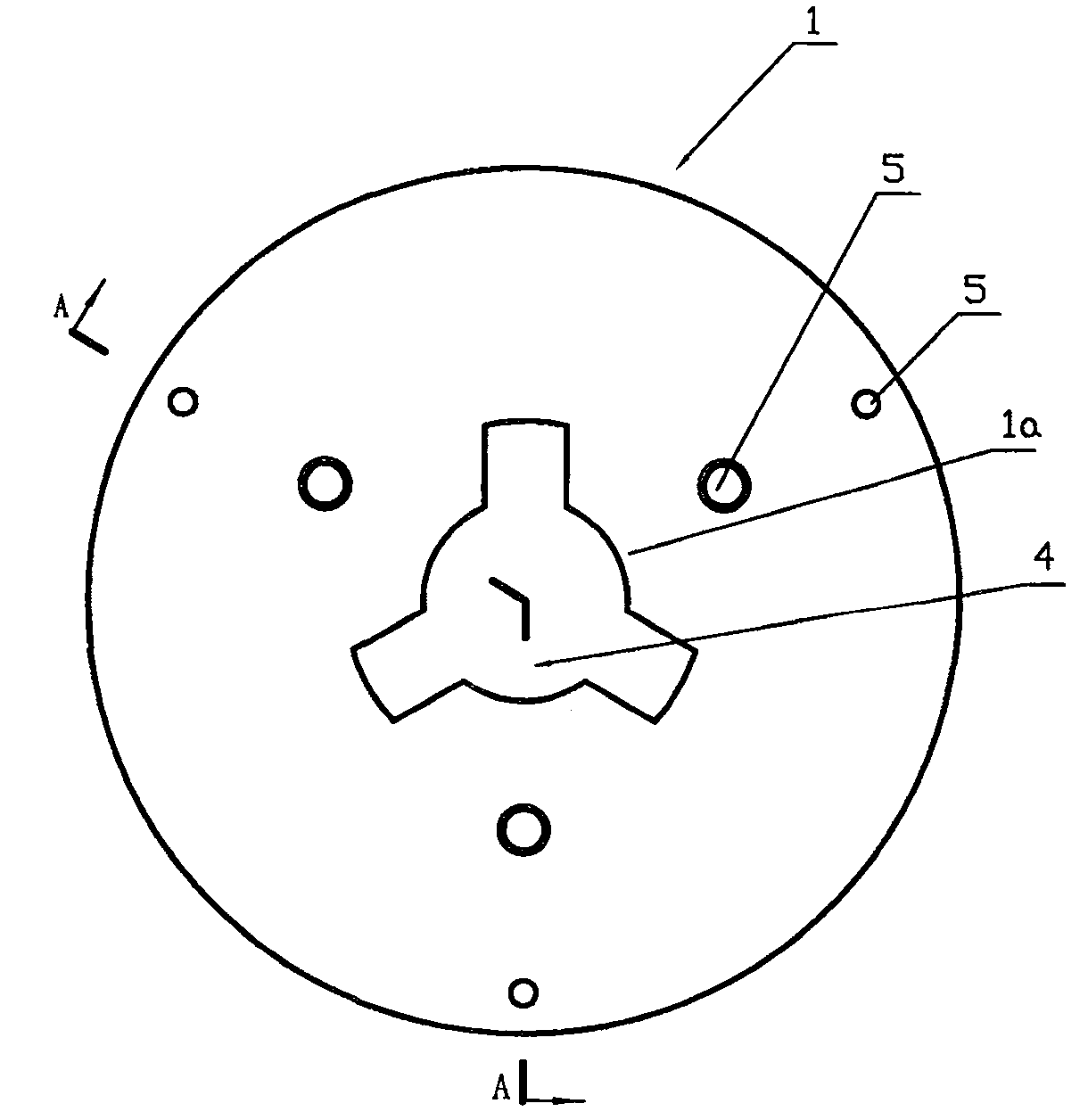

Device for unloading and buffering pull force

The invention relates to a device for unloading and buffering pull force, in particular to a static calibration device of a thrust test system of a rocket engine, belonging to the field of sensing measurement and control devices. The device adopts inner and outer dual pressure springs as unloading and buffering elements and comprises a cylinder, an upper cover, a base, an inner spring, an outer spring, a hydraulic cylinder supporting flange and a connecting bolt, wherein the hydraulic cylinder supporting flange used as a support is of a stepped revolving body structure provided with a central through hole; and the base is of a structure, which is provided with an outer surface tapped with screw threads and is provided with a central through hole of the base. The invention realizes the total unloading of loaded force during the in-situ calibration of a work sensor and effectively buffers the impact of the loaded force on the thrust test system and a hydraulic loading system during an unloading moment, and thus, hydraulic oil is prevented from being leaked, the unloading is also stabilized and return-trip calibration can be carried out accurately; and in addition, the device has the advantages of higher adaptability, wider usage range and certain popularization and use value.

Owner:DALIAN UNIV OF TECH

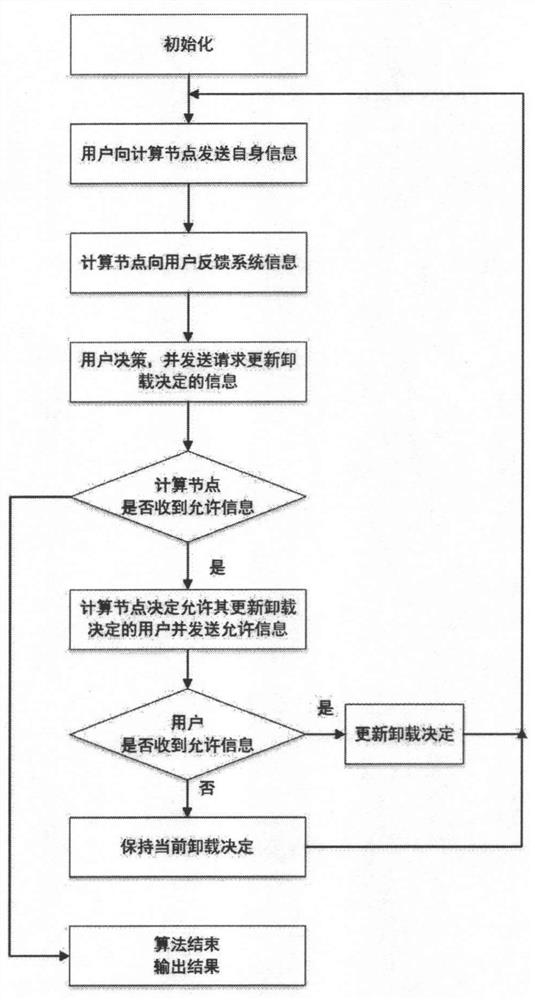

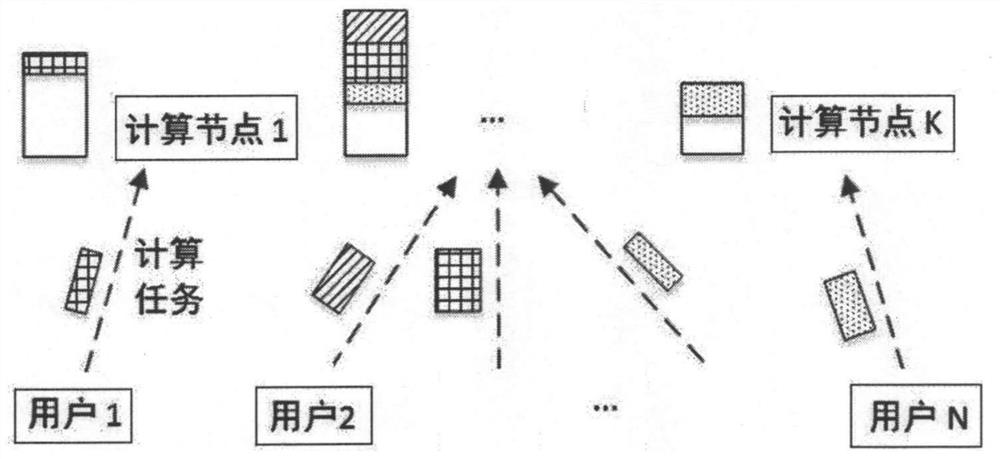

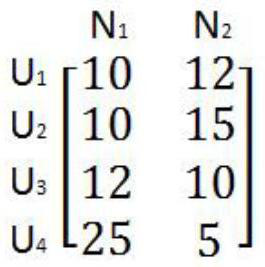

User-centered distributed multi-user computing task unloading method

The invention provides a user-centered distributed multi-user computing task unloading method. The method is characterized by comprising the following steps: uniformly abstracting multiple fog computing nodes into an access point with a servers, wherein the access point has both computing and communication capabilities; when any user generates a computing task, comprehensively considering the unloading decisions of other users; and choosing to compute locally or to unload the computing task into one of other computing nodes according to an unloading decision under a current time slot in orderto minimize own overhead. Through adoption of the user-centered distributed multi-user computing task unloading method provided by the invention, stable and efficient computing task unloading among multiple users can be realized in a distributed execution way. A user satisfactory result can be achieved, and relatively high overall performance of the system can be ensured (compared with the optimalstrategy of the system).

Owner:SHANGHAI TECH UNIV

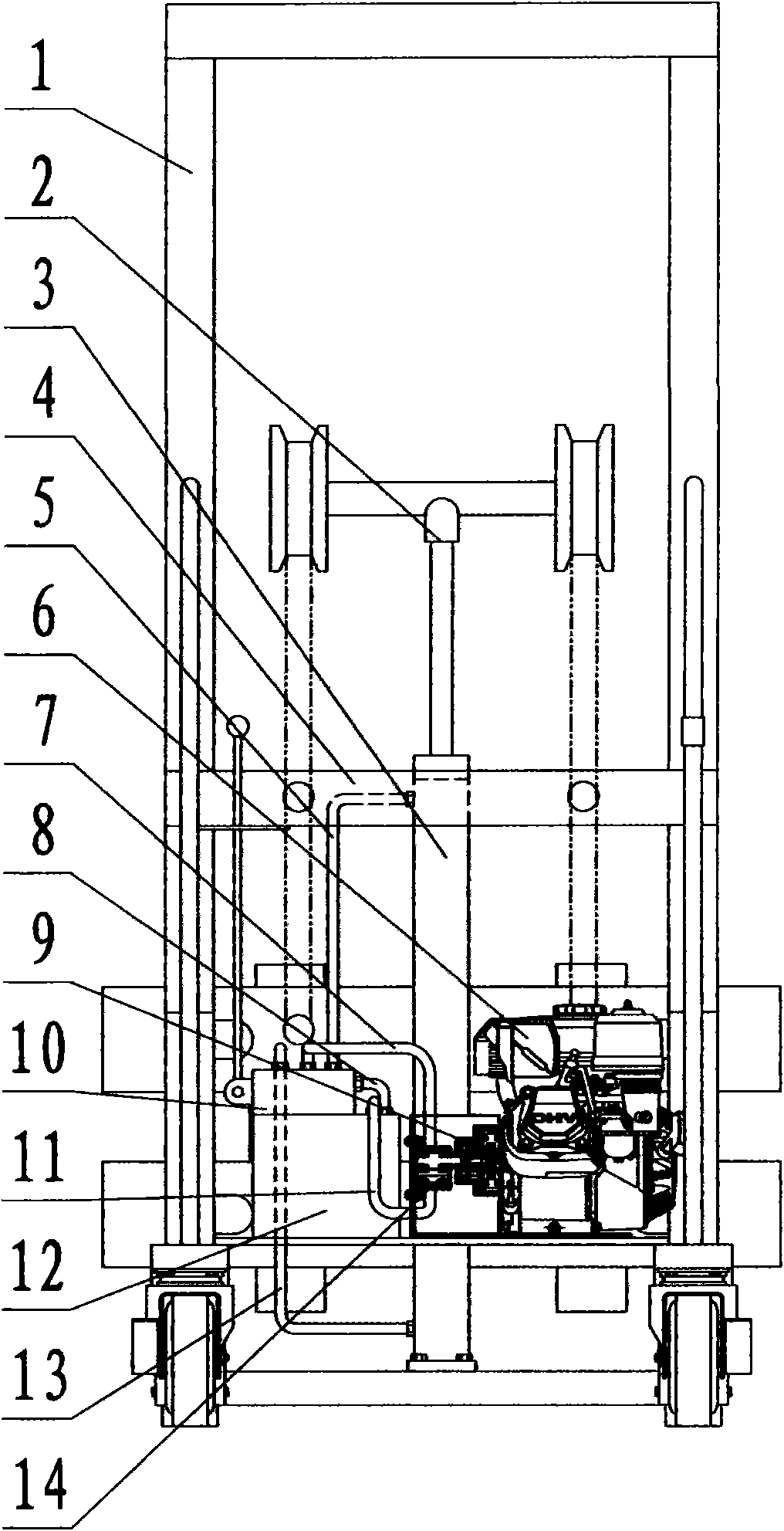

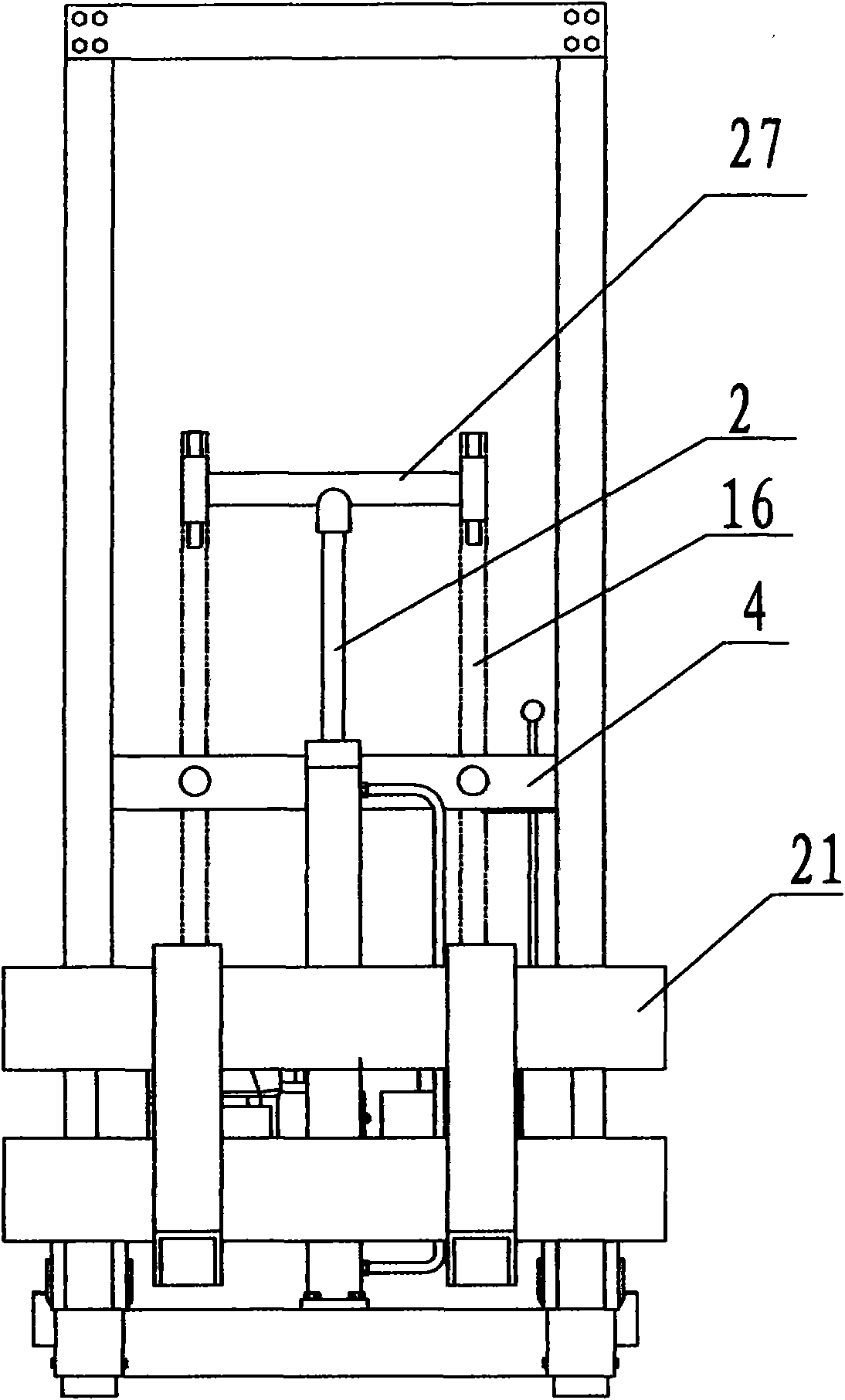

Straddle forklift

InactiveCN102050408ASimple structureReduce restrictionsLifting devicesHydraulic cylinderLifting capacity

The invention discloses a straddle forklift, which comprises a lifting and unloading device and a driving device, wherein the driving device comprises an engine and a hydraulic transmission device; the hydraulic transmission device comprises a hydraulic pump, a hydraulic oil tank, a reversing valve and a hydraulic cylinder; the hydraulic oil tank, the hydraulic pump, the reversing valve and the hydraulic cylinder are connected through hydraulic pipelines; the output shaft of the engine is connected with the input shaft of the hydraulic pump through a clutch to drive the hydraulic pump; the hydraulic cylinder is provided with an ejector rod capable of extending out of the hydraulic cylinder and stretching up and down; and the ejector rod is connected with the lifting and unloading device. The engine is used as driving motive power, so the straddle forklift is limited little by power and has high lifting efficiency and lifting capacity. The straddle forklift has low cost, can be used in all weathers, and is simple in structure, convenient to maintain, longer in service life, stable for unloading, safe and reliable.

Owner:陶青松

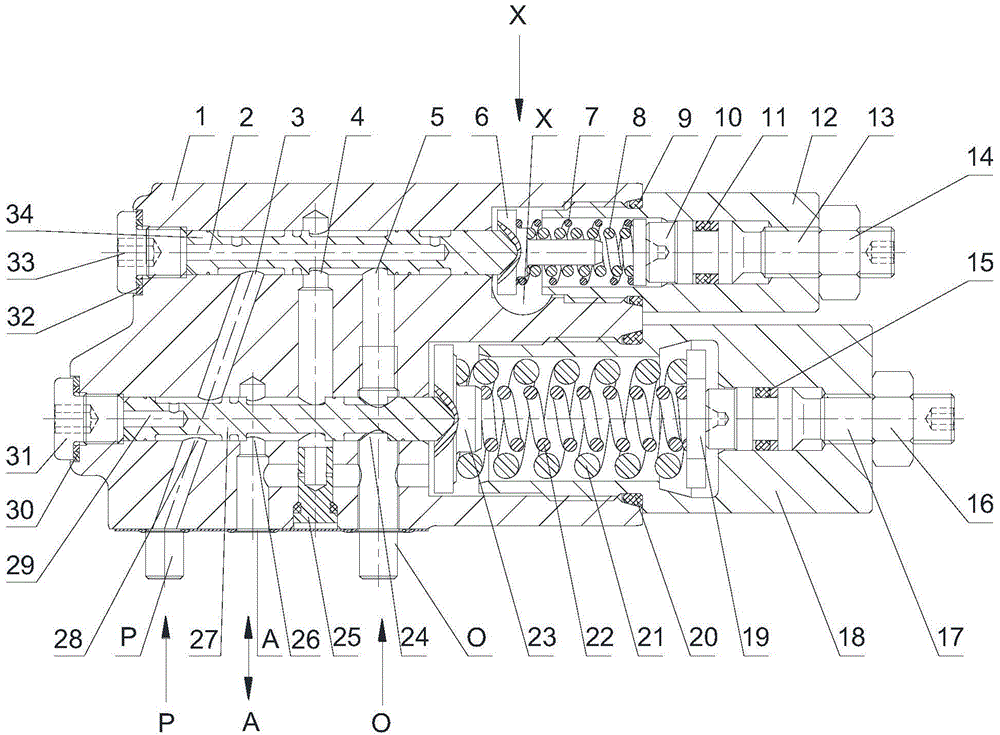

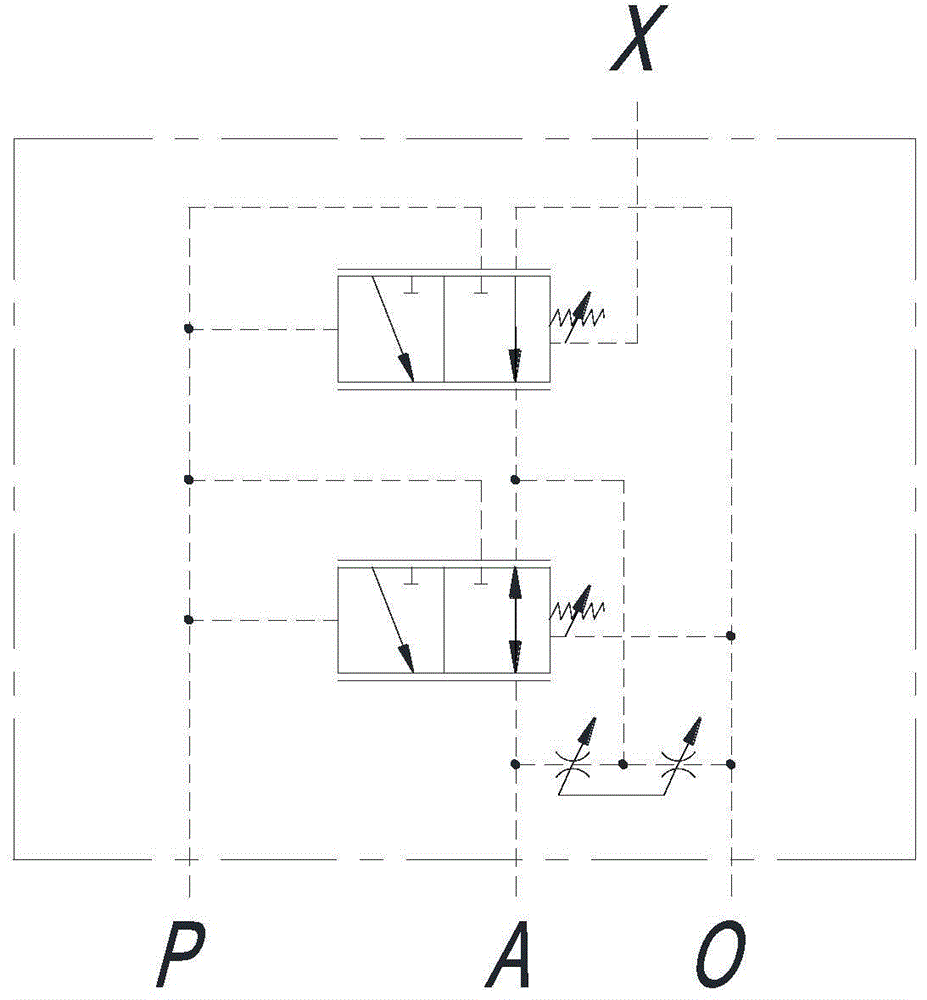

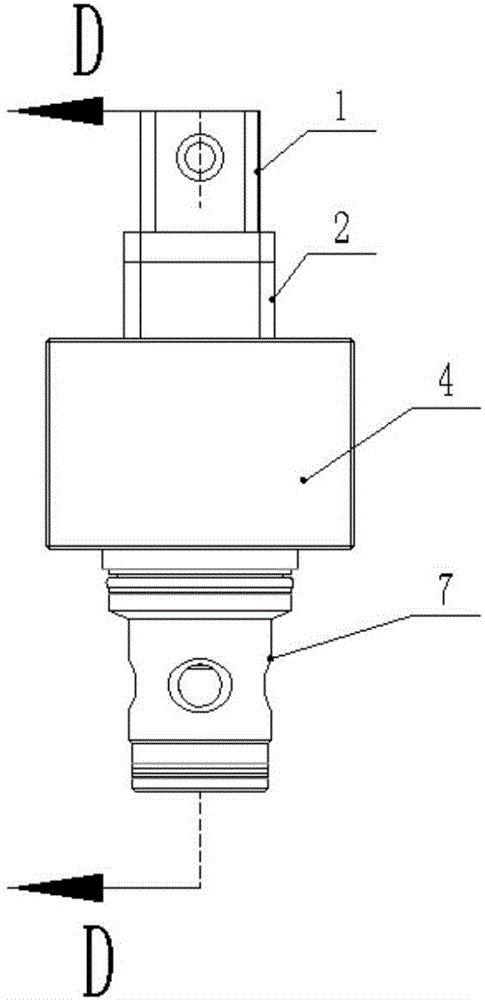

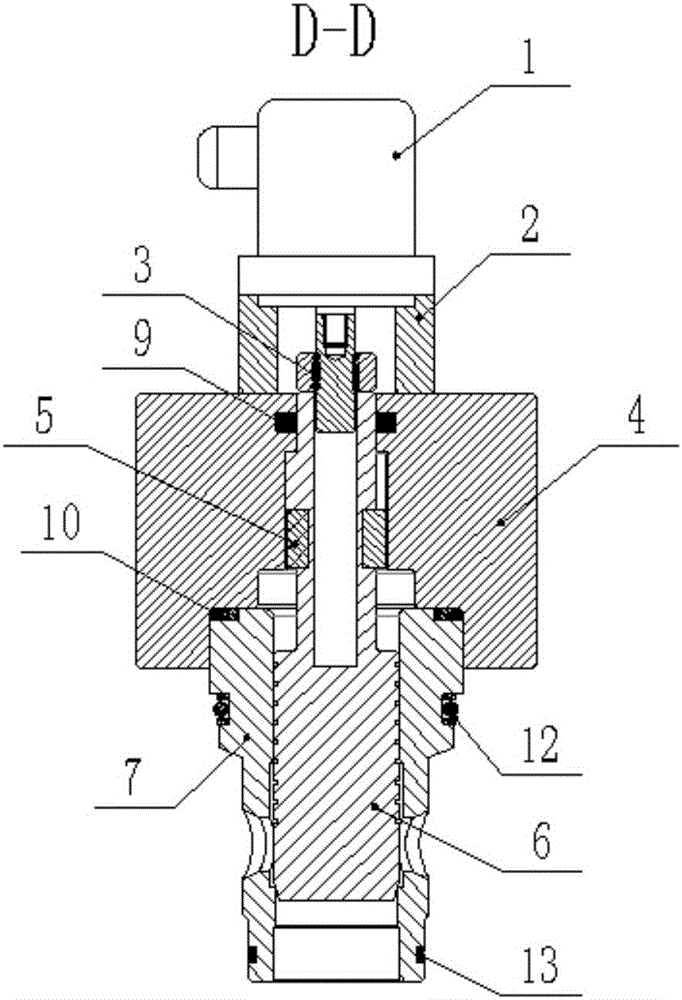

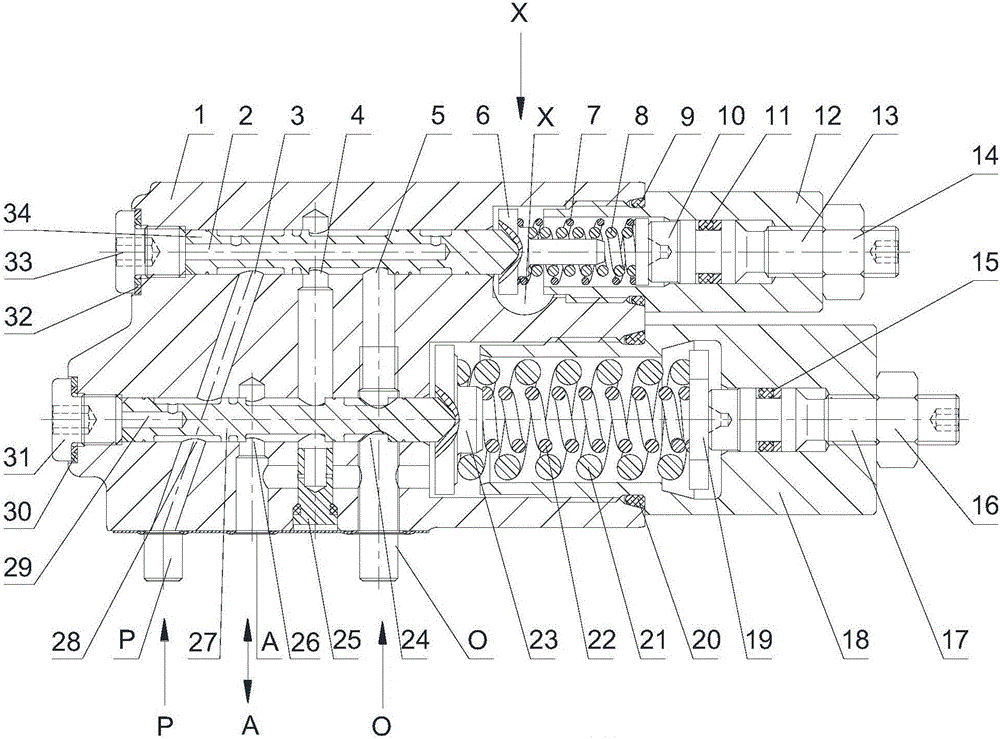

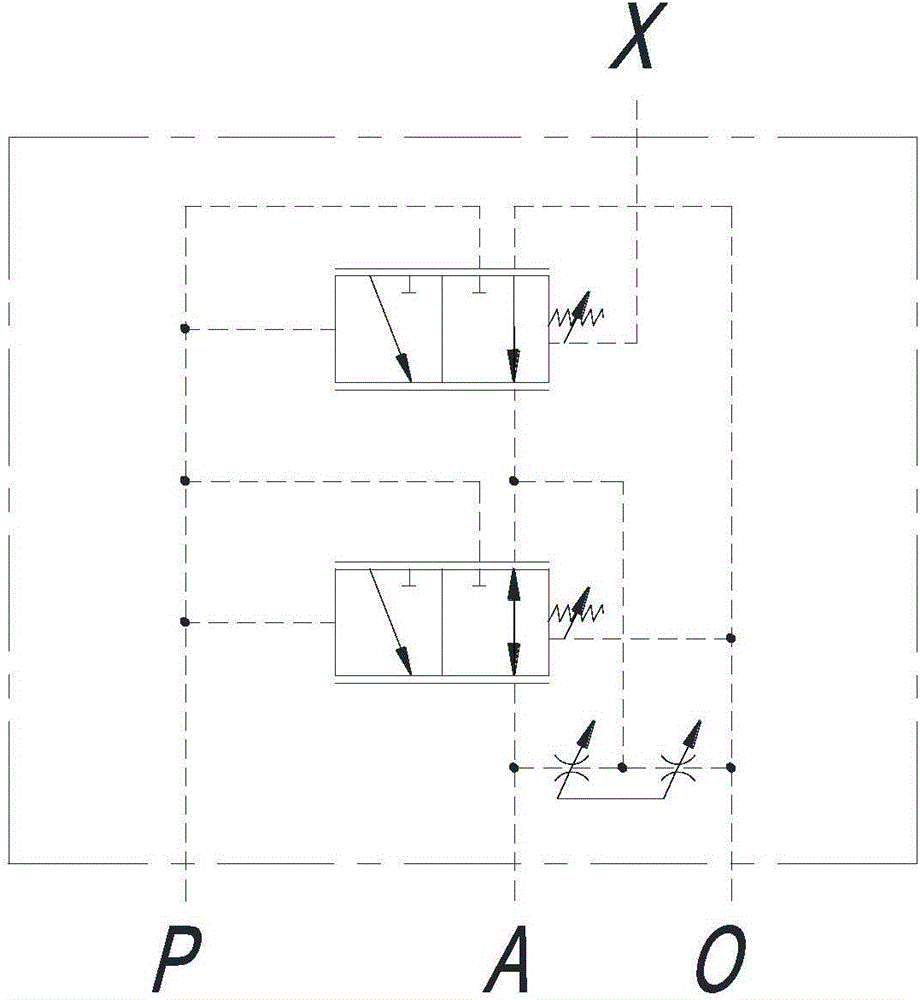

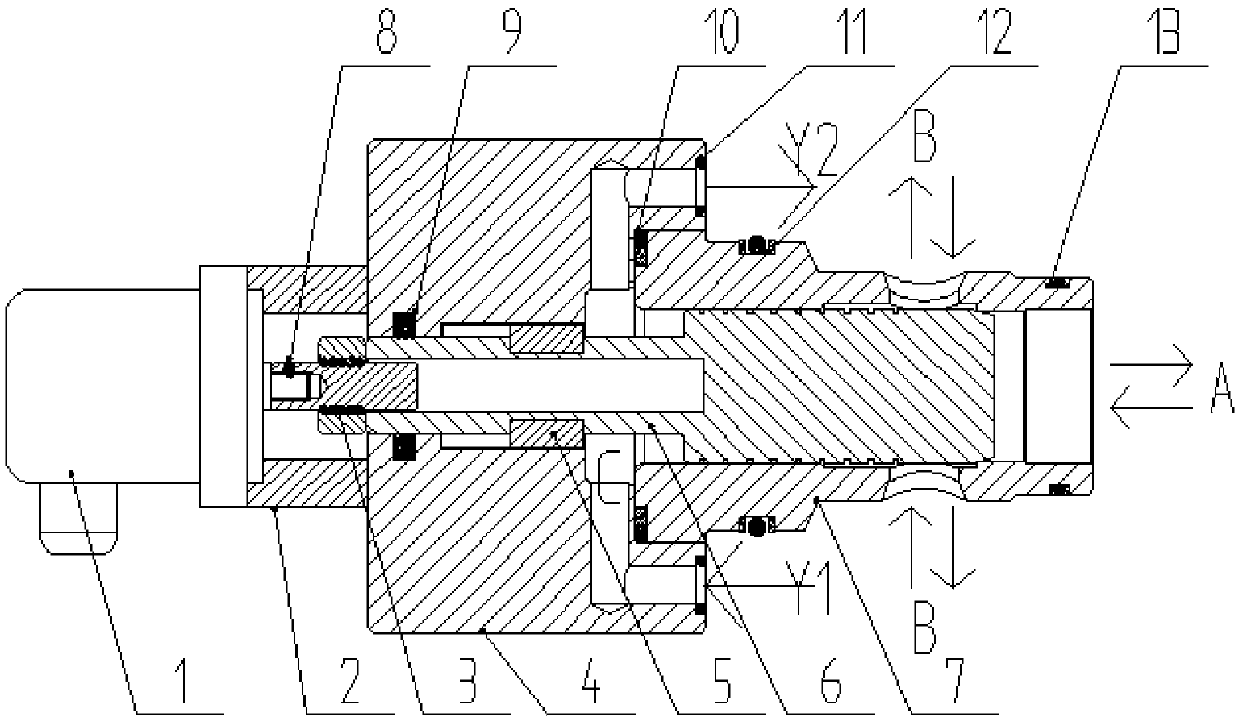

Flow and pressure control valve

InactiveCN105114665AEasy to useSimple structureServomotor componentsMultiple way valvesBrake torqueControl flow

The invention relates to a flow and pressure control valve. The flow and pressure control valve comprises a valve body in which a flow control valve and a pressure control valve are arranged; the flow control valve comprises a first valve element, a first spring cavity and a first-stage spring; the pressure control valve comprises a second valve element, a second-stage spring cavity and a second-stage spring. According to the flow and pressure control valve, by arranging the two control valves, stepping control over oil pressure is achieved, the first-stage flow control valve is mainly used for controlling flow through flow diversion, the second-stage pressure control valve is mainly used for controlling pressure through oil return unloading, the problem that after pressure is out of control, the pressure continuously rises, and consequently braking torque and oil liquid temperature fast raise is efficiently solved, and use is reliable.

Owner:SUZHOU SABO IND DESIGN

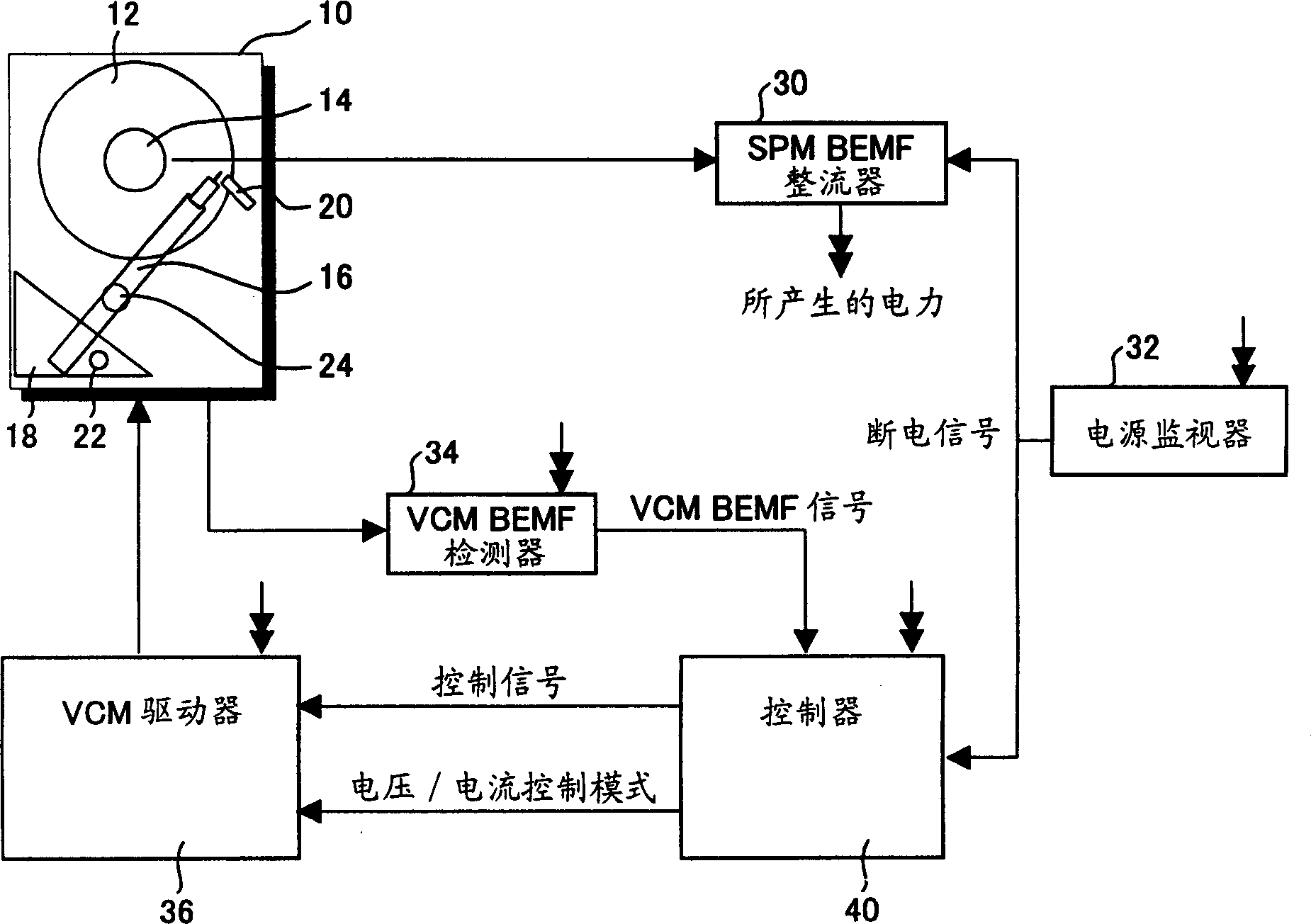

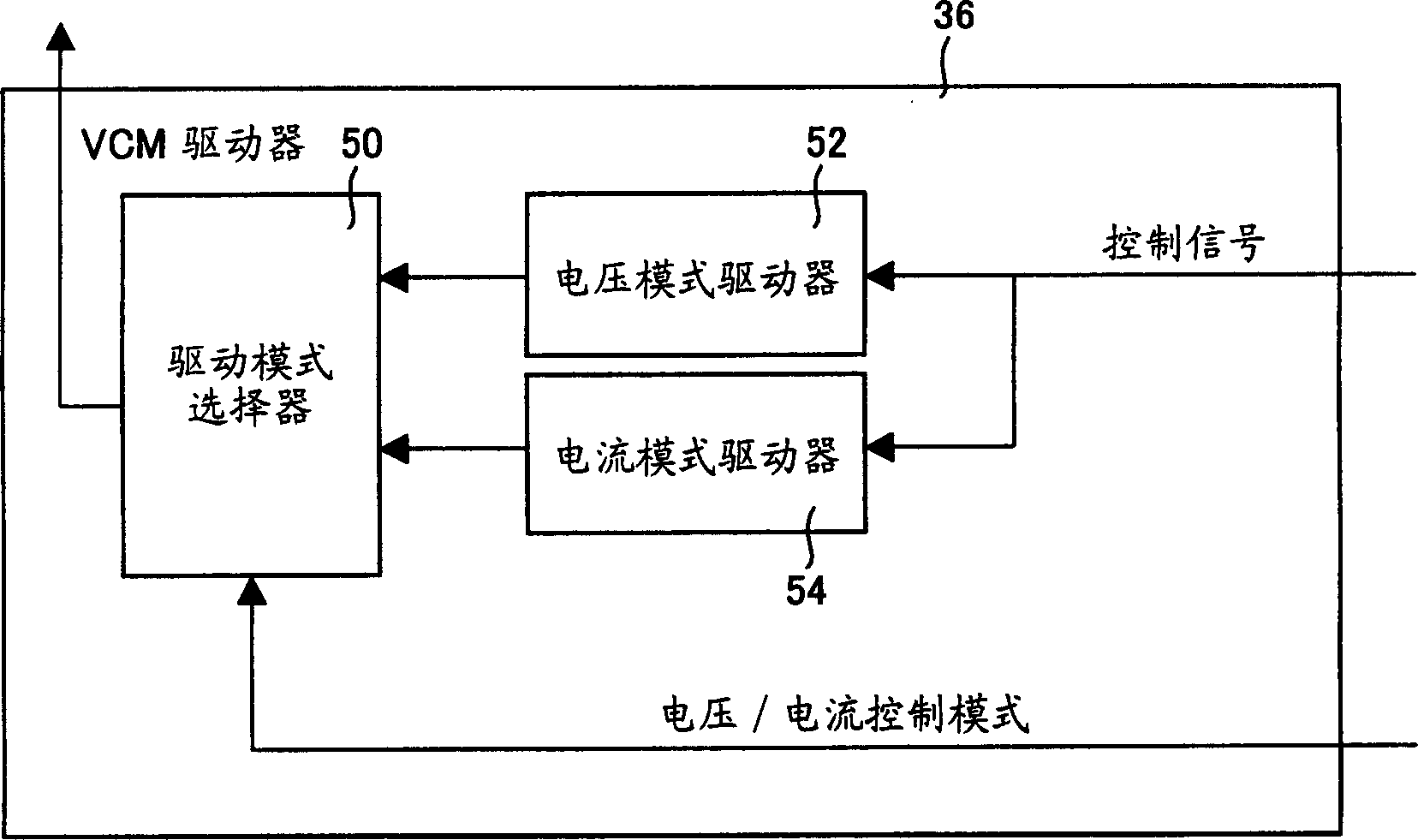

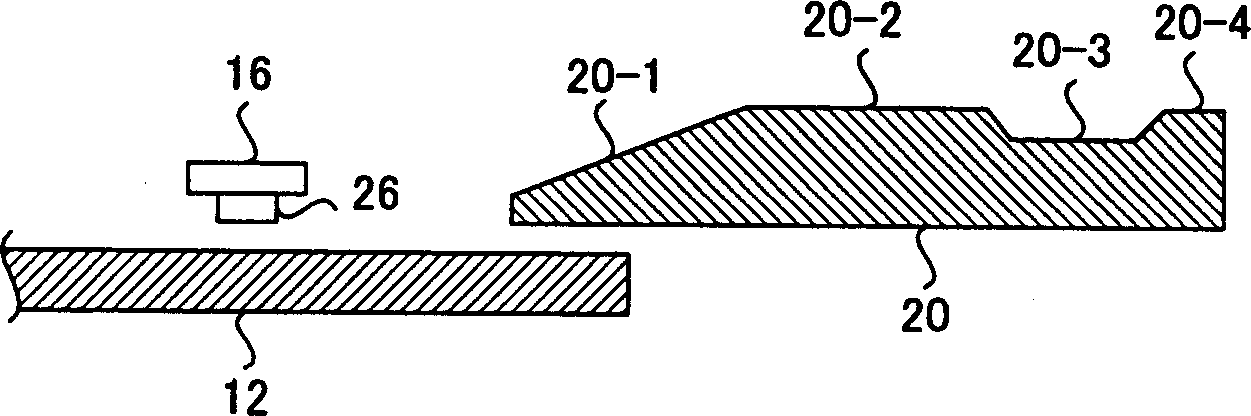

Method for disk drive

InactiveCN1501389AStable uninstallStable uninstall operationDisposition/mounting of recording headsDriving/moving recording headsControl theoryControl circuit

A head retracting method retracts a head to a retract position which is different from a disk to perform a stable unload operation when a power supply failure occurs, regardless the position and the velocity of the head. When the power supply failure occurs, controller controls that the head reaches the inner stopper, which is at a predetermined position in an opposite direction from, the ramp, so as to stop at the inner stopper at a predetermined position without receiving impact, regardless what position the head is and regardless what velocity the head is moving. The head is unloaded from the predetermined position by constant voltage driving, so the head contacts the ramp and climbs onto the ramp at a predetermined velocity.

Owner:FUJITSU LTD

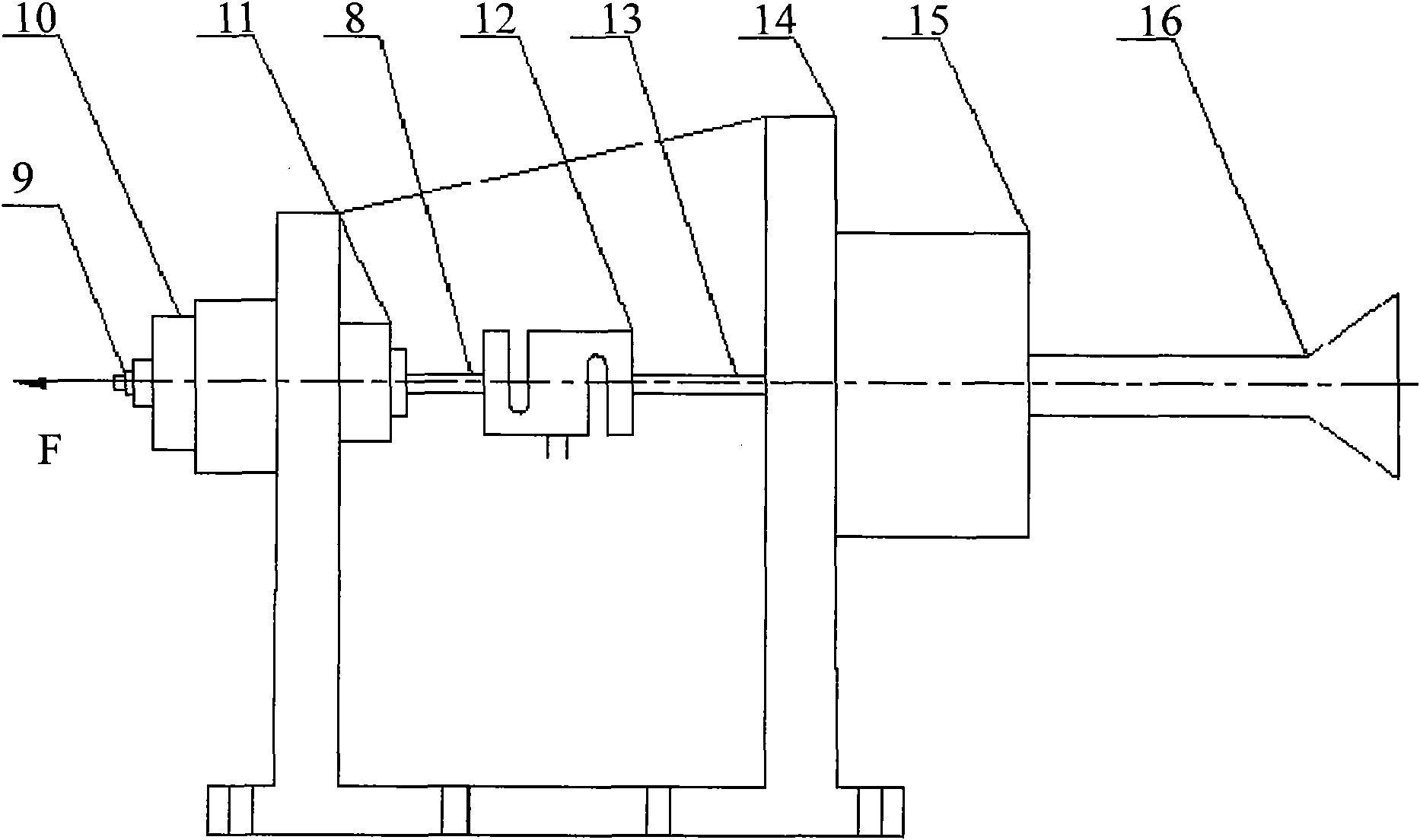

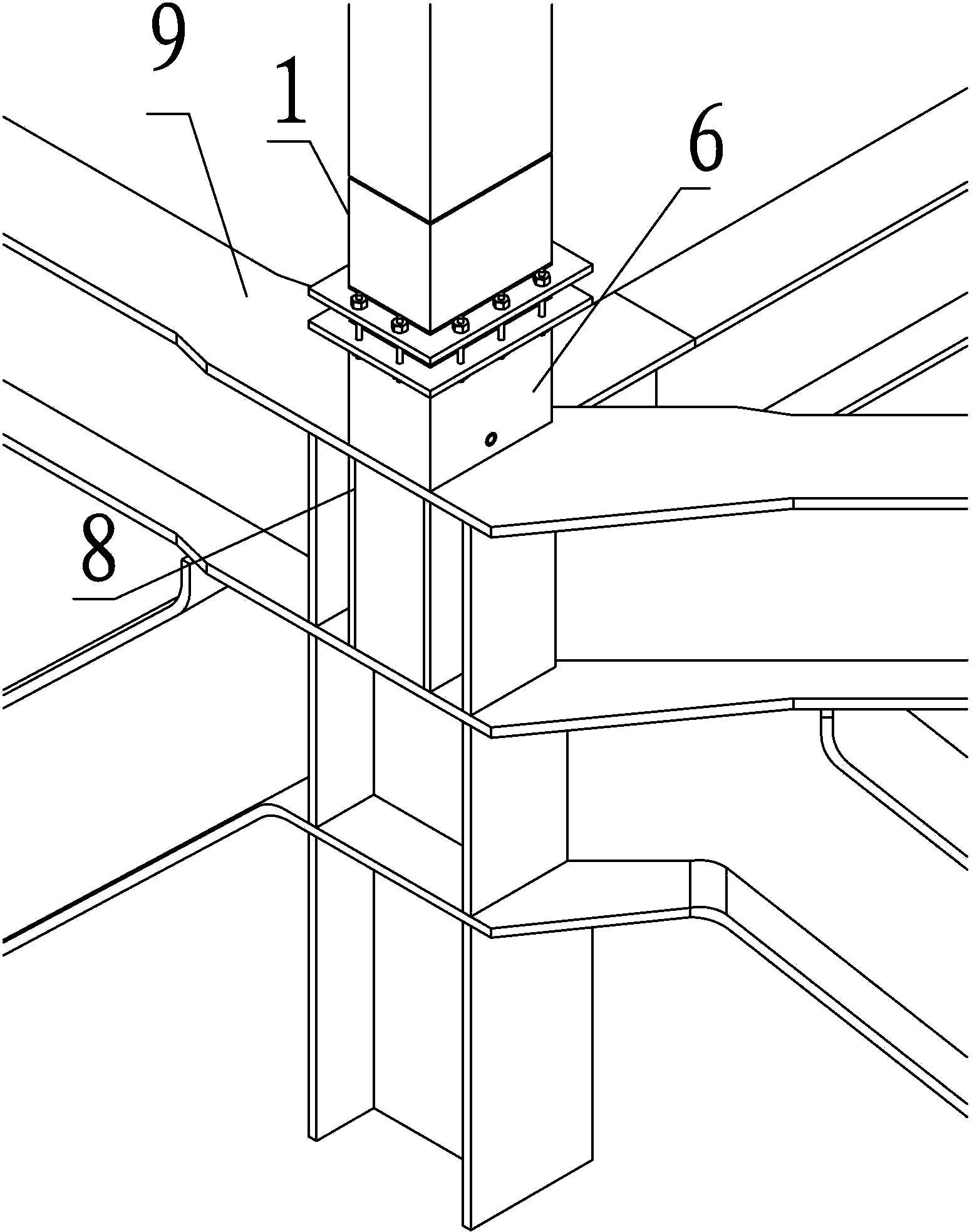

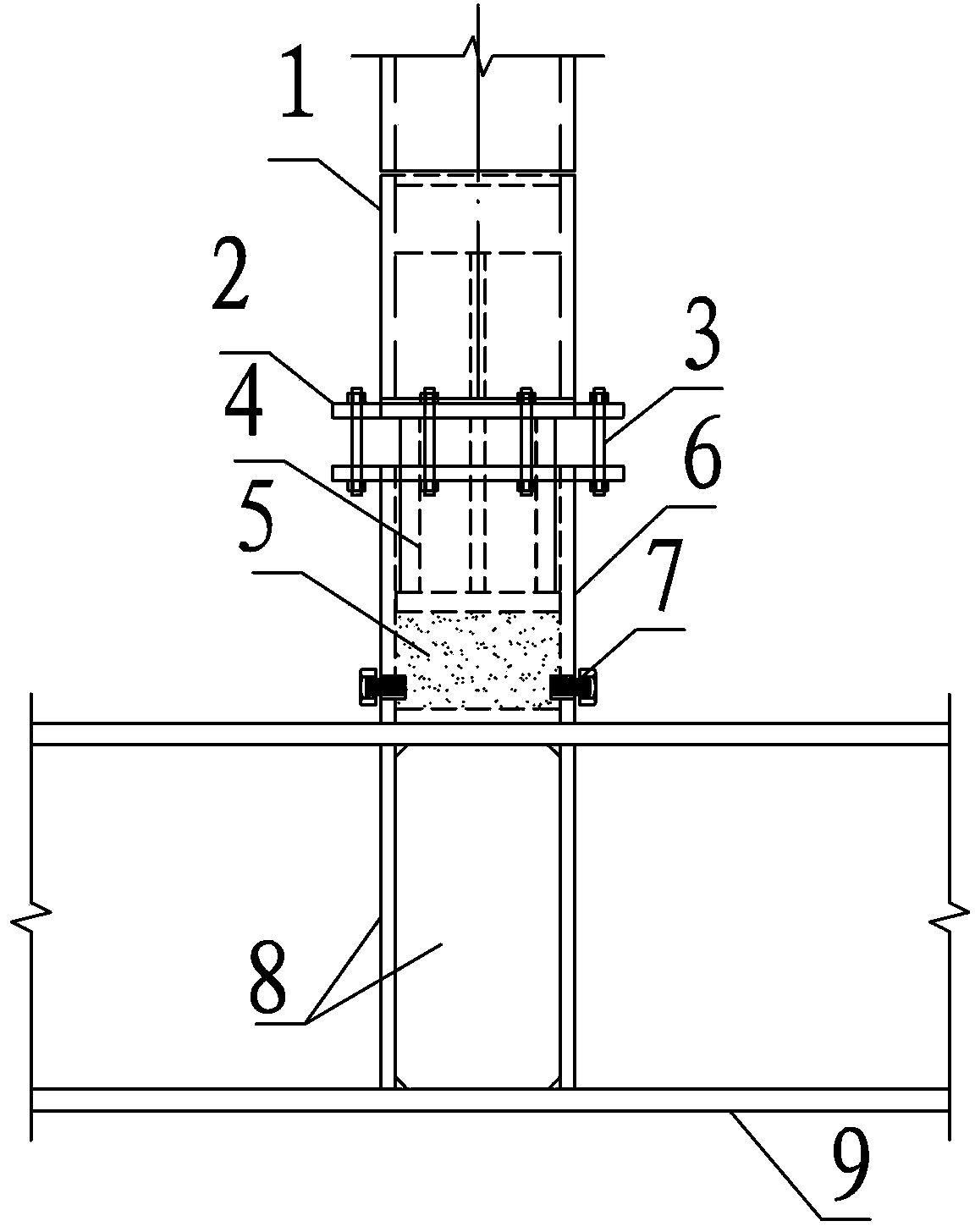

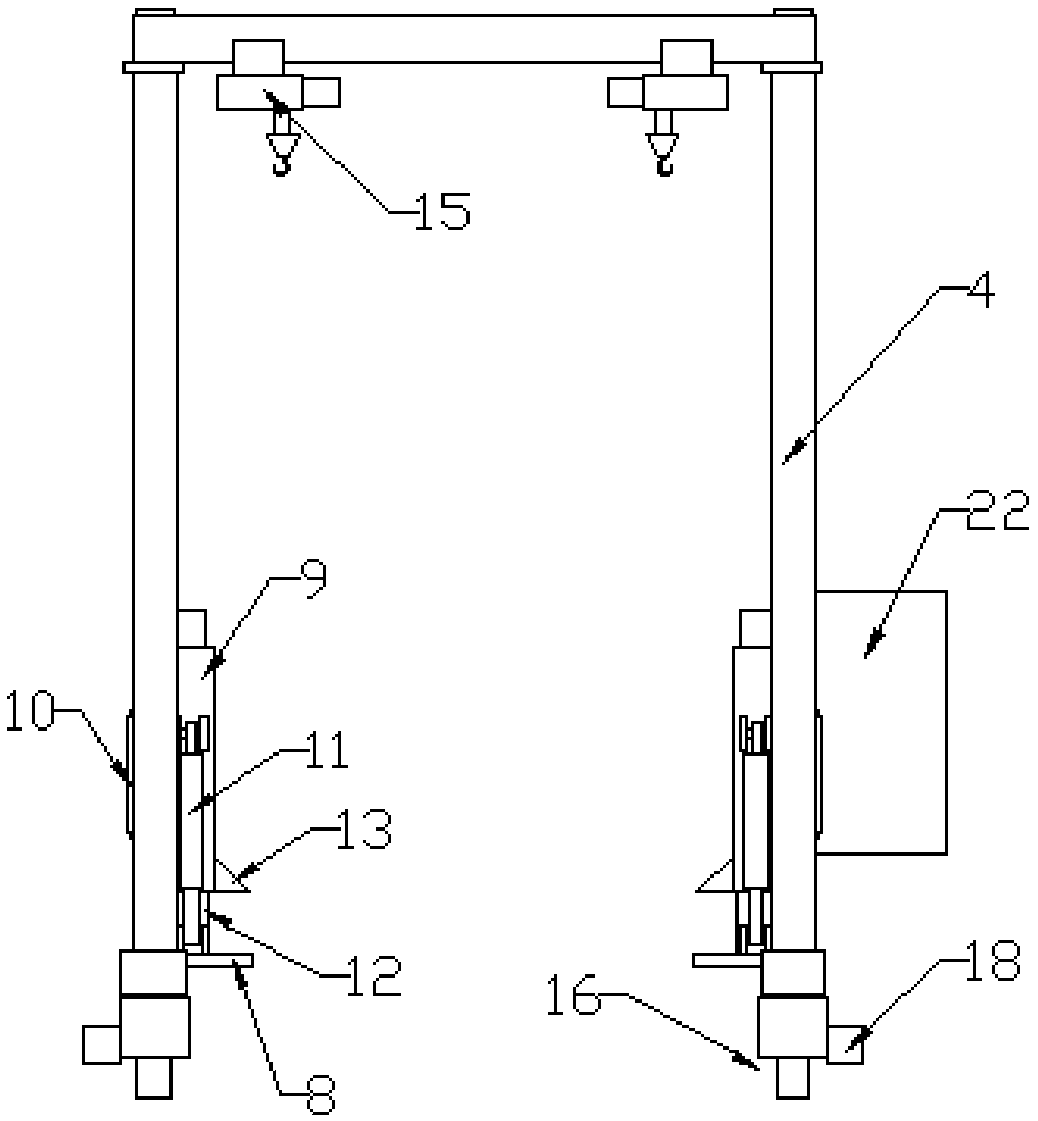

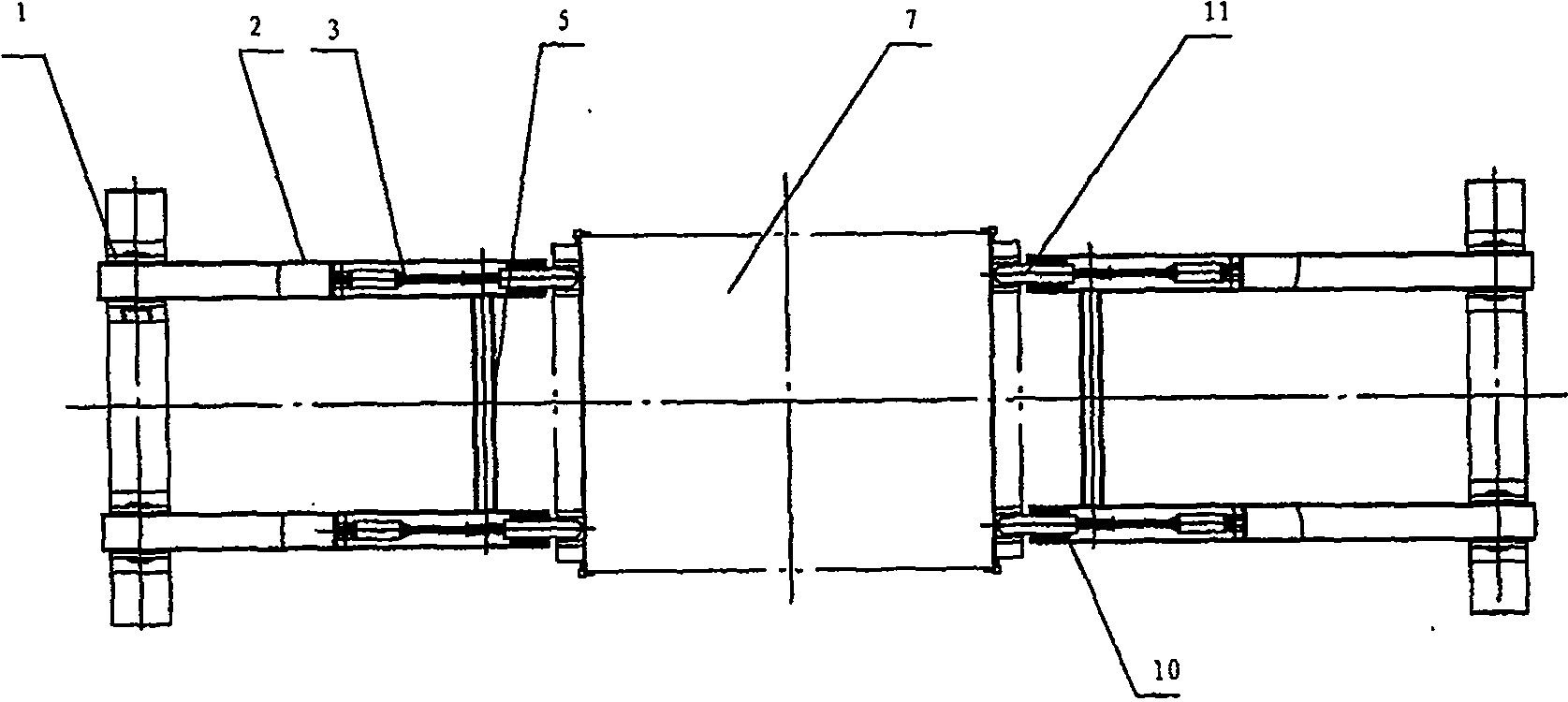

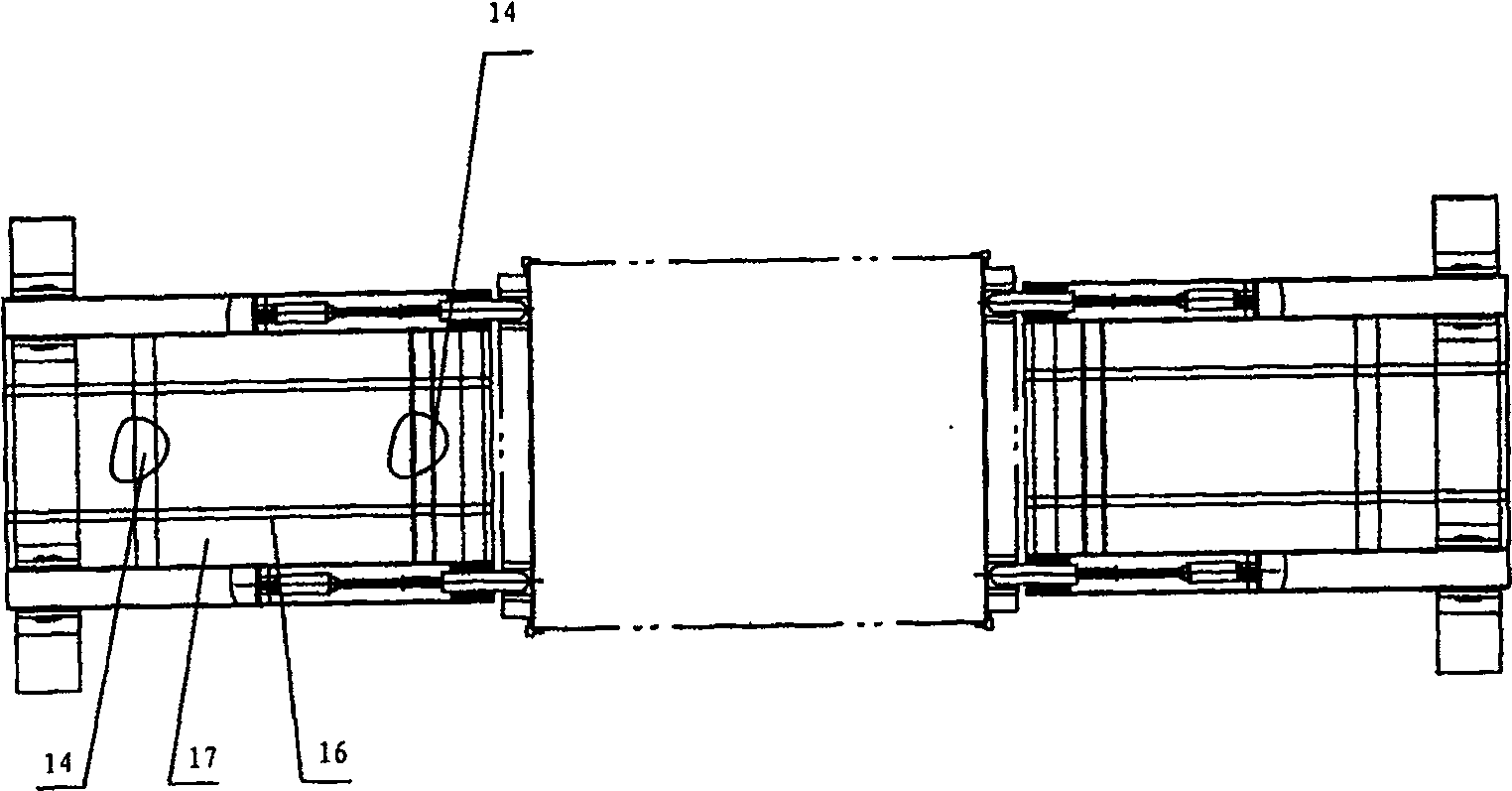

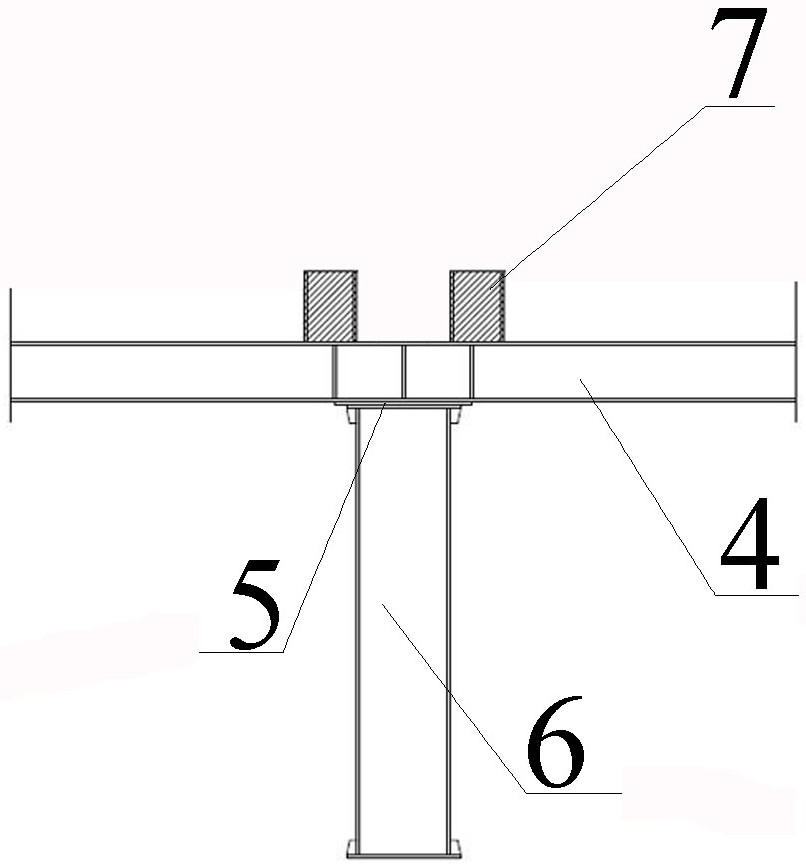

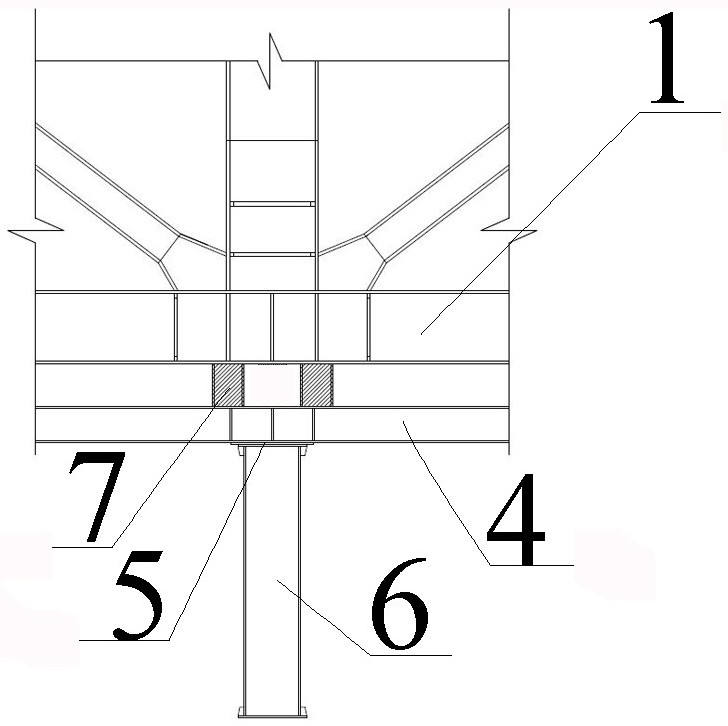

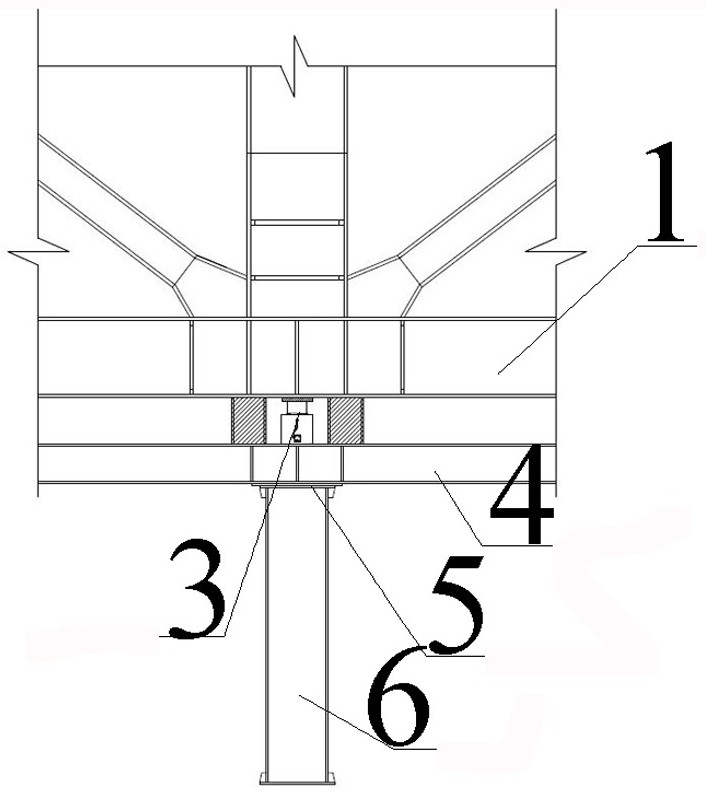

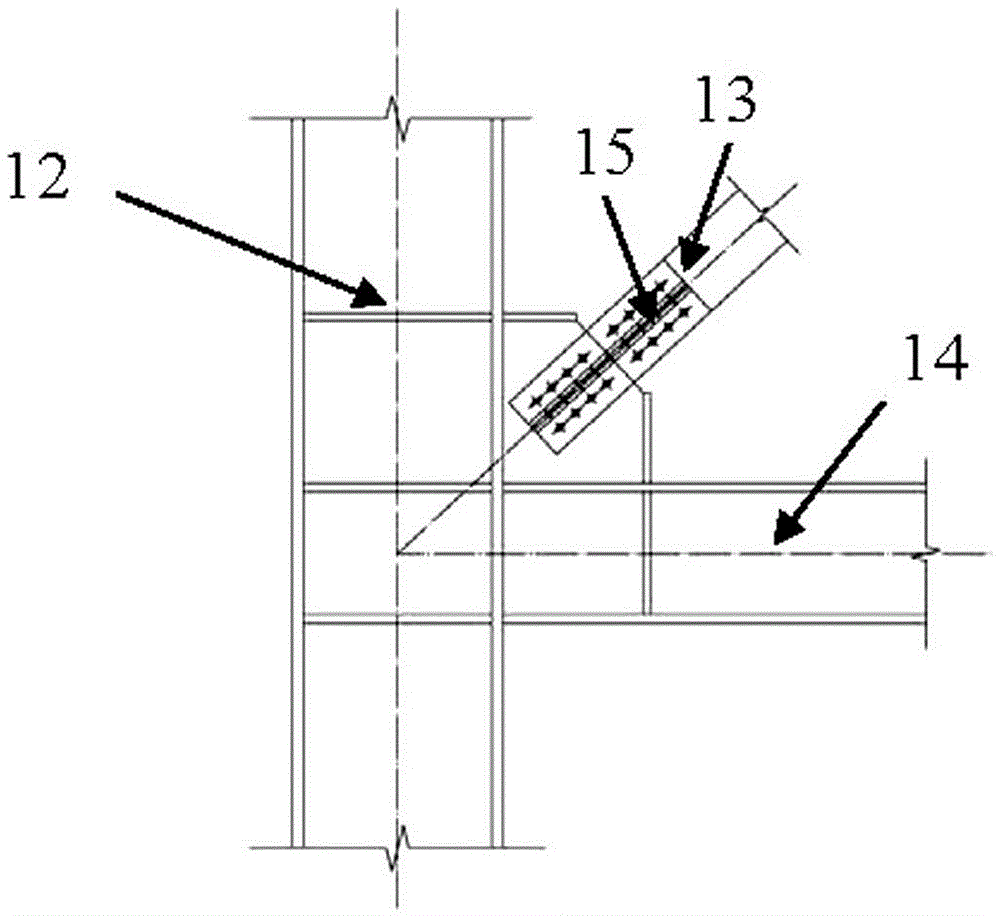

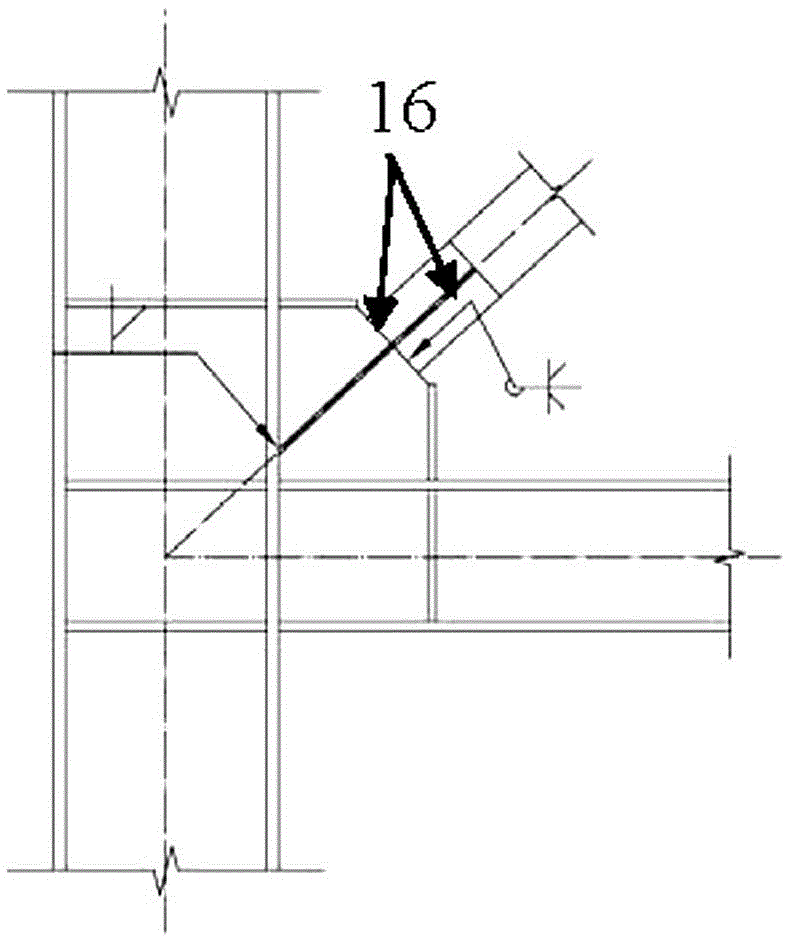

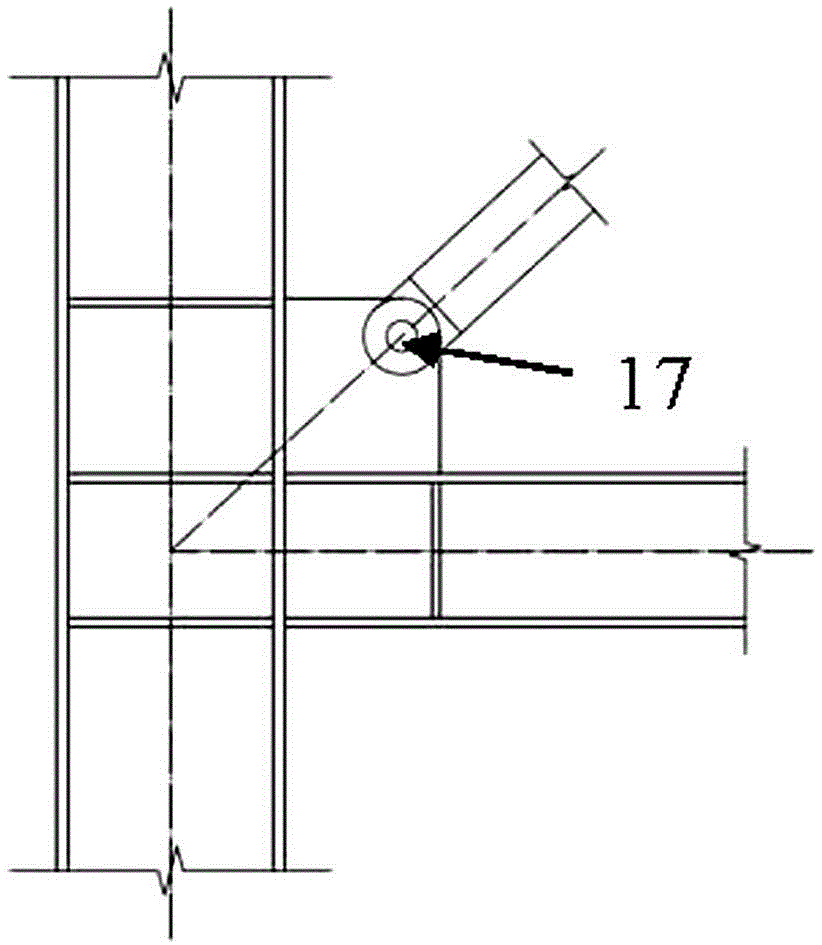

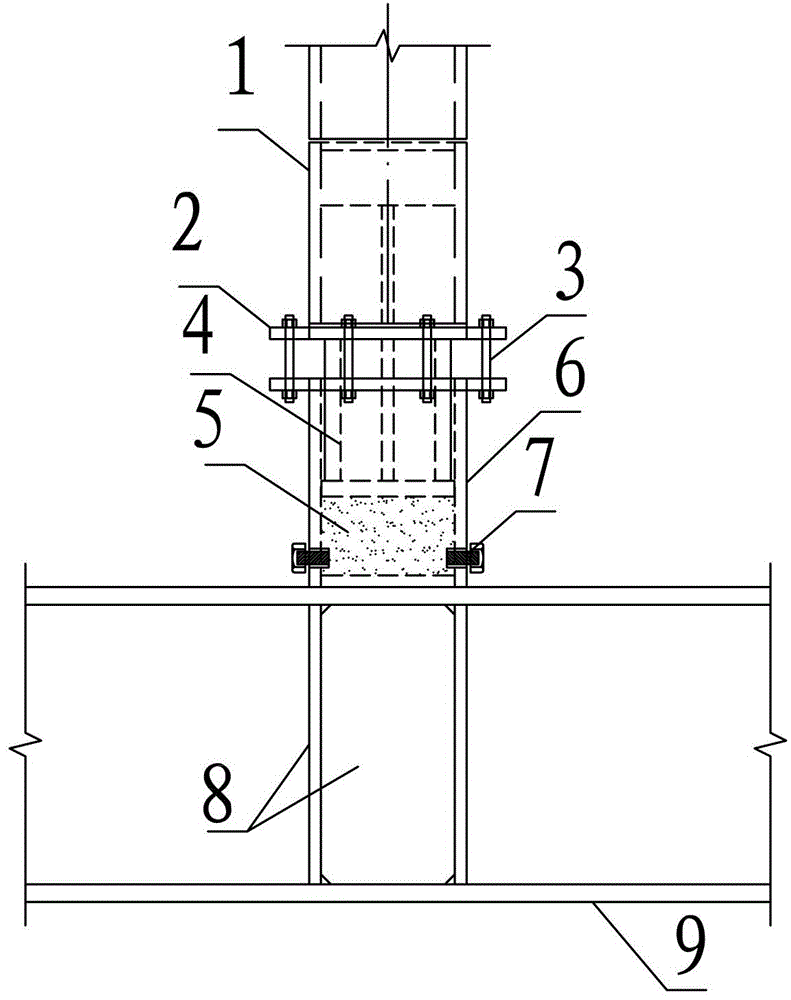

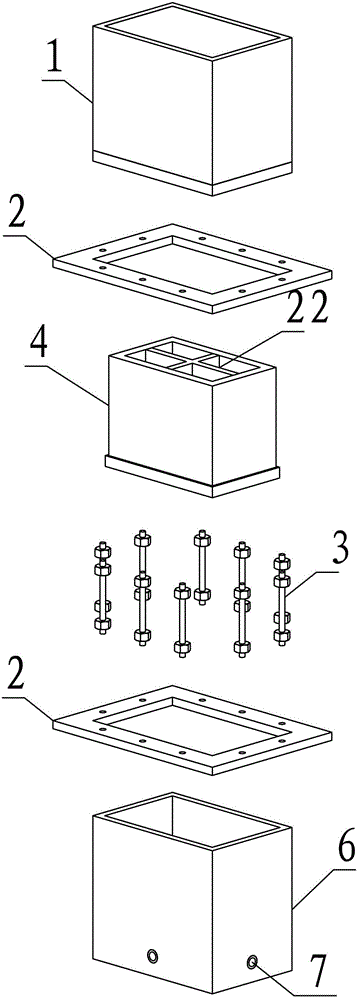

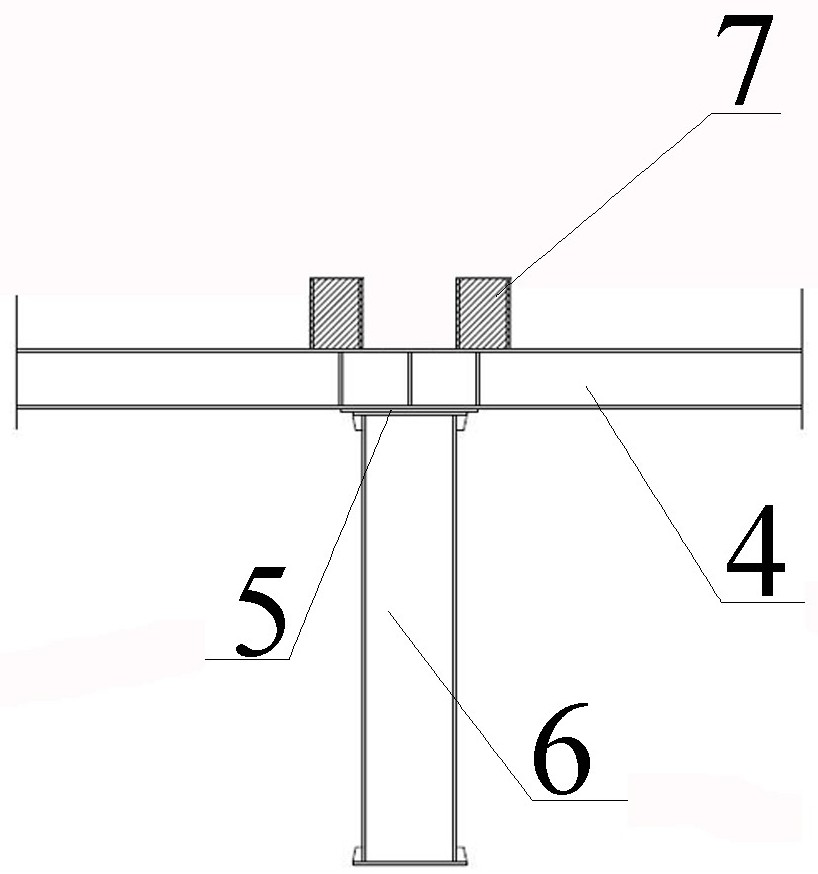

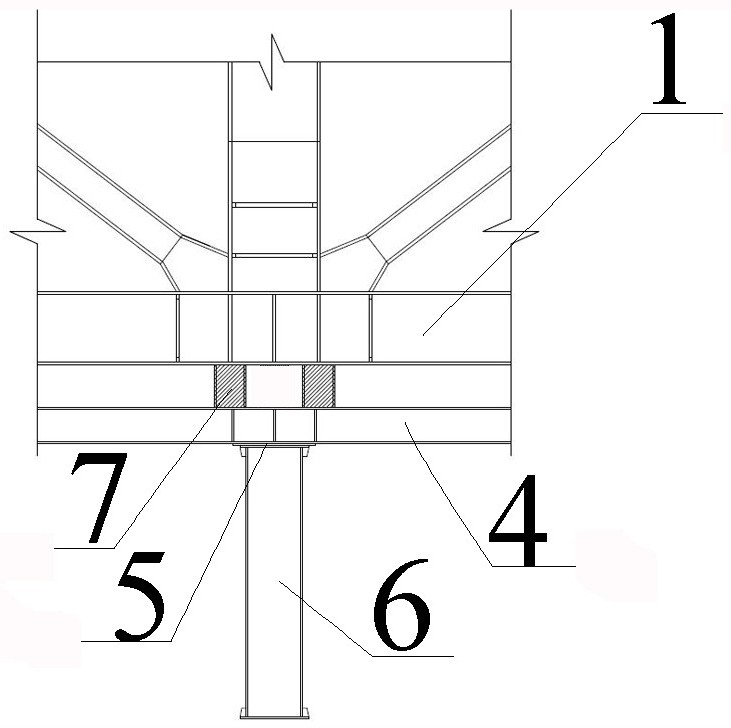

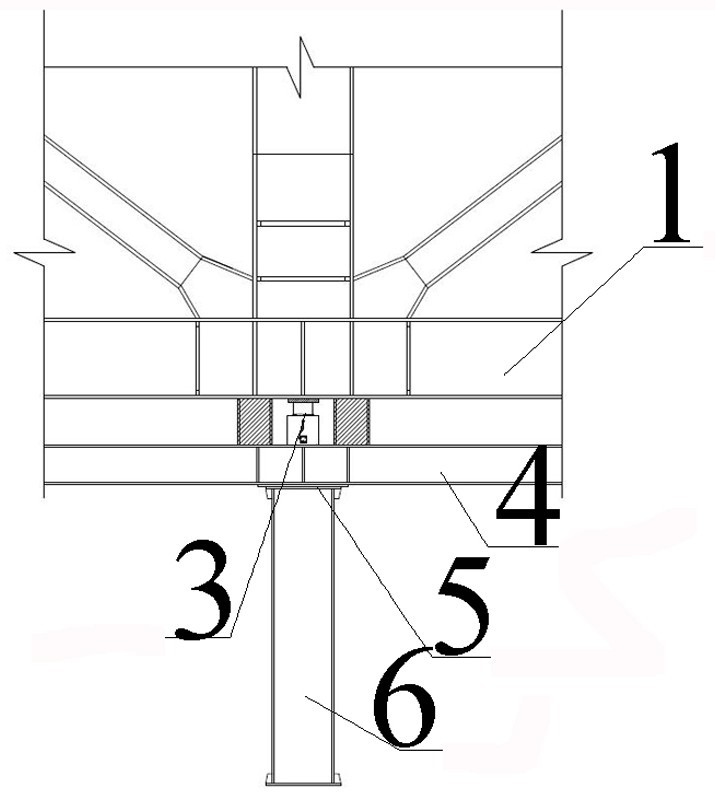

Method and equipment for sequentially constructing ultra-long hanging posts

ActiveCN103452326AEasy constructionImprove installation efficiencyBuilding material handlingPistonSteel frame

The invention mainly discloses a method and equipment for sequentially constructing ultra-long hanging posts in a high-rise structure. The method includes steps of firstly, mounting a bottom uninstalling device of the hanging posts, filling high-strength steel sand in the uninstalling device and screwing down temporary connecting rods; secondly, mounting the hanging posts and steel frame beams adjacent to the hanging posts until a hanging post top structure is completely constructed; thirdly, synchronously unscrewing pressure release valves on the periphery of the uninstalling device to uninstalling the hanging posts; fourthly, cleaning residual steal sand in the uninstalling machine after the hanging posts are completely uninstalled, removing the temporary connecting rods, cutting off temporary connecting annular plates, sealing gaps between a bottom piston of the hanging posts and the uninstalling device and performing anti-corrosion treatment on the gaps between the bottom piston of the hanging posts and the uninstalling device so as to completely constructing the hanging posts. The equipment comprises the uninstalling device, the pressure release valves, the two temporary connecting annular plates, the multiple temporary connecting rods, the bottom piston of the hanging posts and the high-strength steel sand. The method and the equipment have the advantages that construction temporary measures can be reduced, the installation efficiency can be improved, the construction period can be shortened, the hanging posts can be conveniently and quickly uninstalled, and efficient and high-quality uninstalling work can be implemented.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

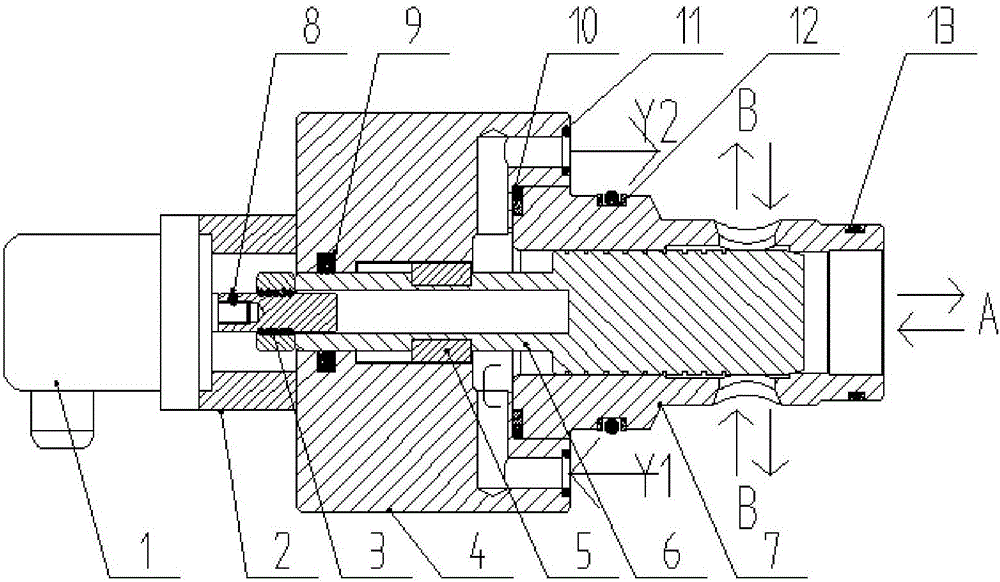

Servo quick forging valve and servo valve system

ActiveCN106762913AFast switching speedIncrease frequencyOperating means/releasing devices for valvesServomotor componentsBall screwProgrammable logic controller

The invention provides a servo quick forging valve and a servo valve system and relates to the field of quick forging hydraulic machines, in particular to the servo quick forging valve. The servo quick forging valve comprises a servo motor, a support, a guiding lubricating cover plate and a valve sleeve which are sequentially arranged from left to right, a ball screw assembly is installed in the centers of the support, the guiding lubricating cover plate and the valve sleeve in a penetrating mode, and an output shaft of the servo motor is connected with a lead screw of the ball screw assembly in a threaded mode; the guiding lubricating cover plate and the end face of the valve sleeve are tightly matched in a sealed mode and connected into an integrated structure, a servo valve core is installed in the valve sleeve, and the servo valve core and a bearing bolt of the ball screw assembly are connected to into an integrated structure; and a bearing of the ball screw assembly can be driven by the lead screw to vertically move to adjust opening and closing of a valve. The invention further relates to the servo valve system. The servo valve system comprises the servo quick forging valve and a programmable logic controller. Through the technical scheme of the servo quick forging valve and the servo valve system, the oil swapping phenomenon occurring in an existing servo quick forging valve is avoided.

Owner:青岛海德马克智能装备有限公司

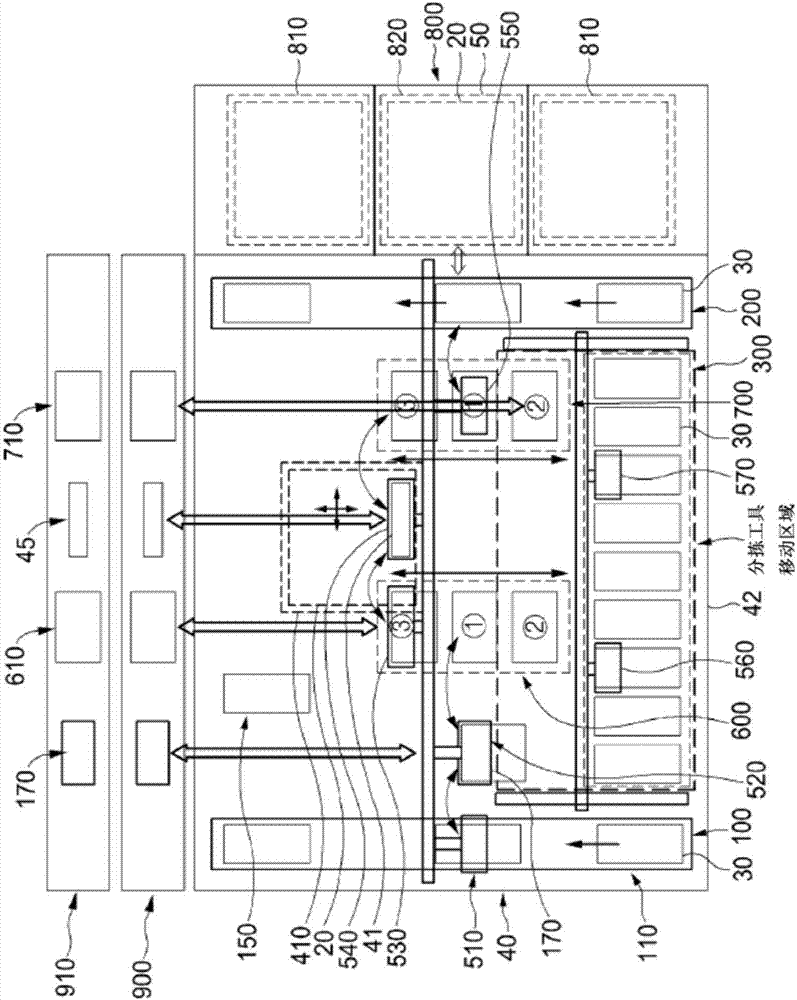

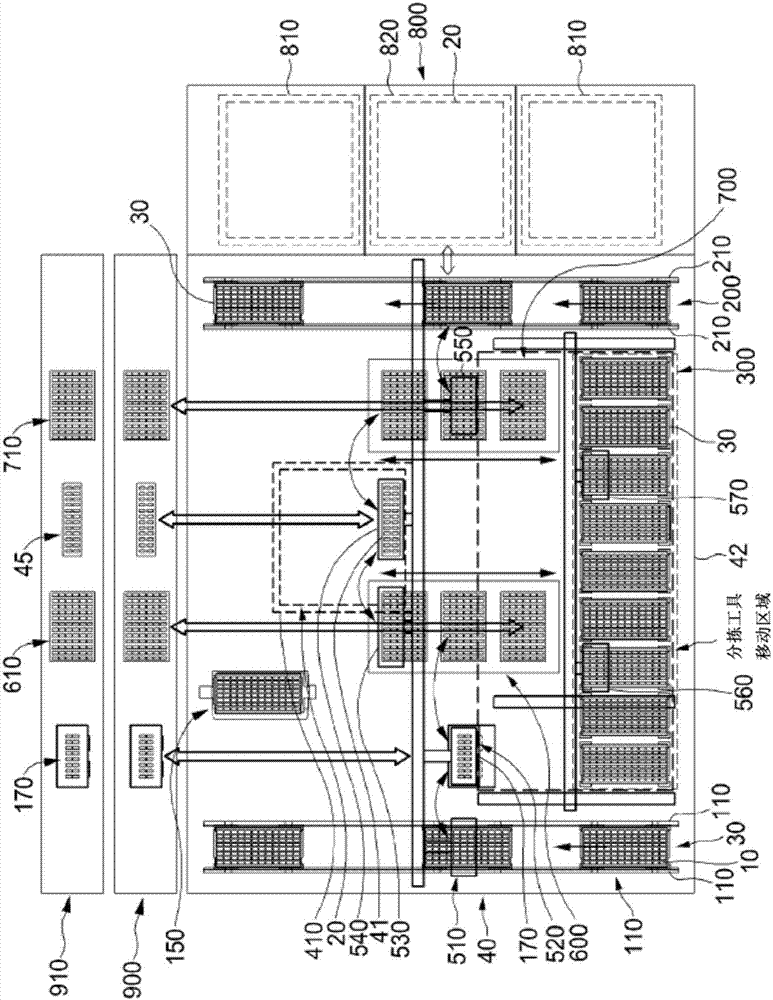

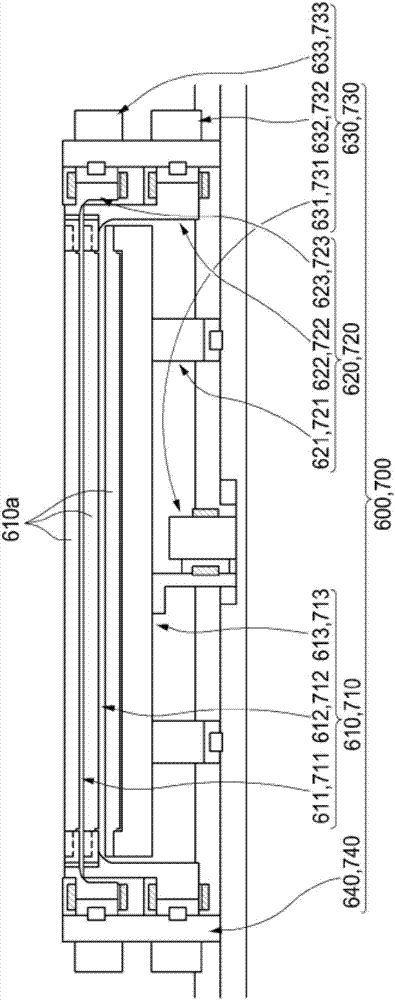

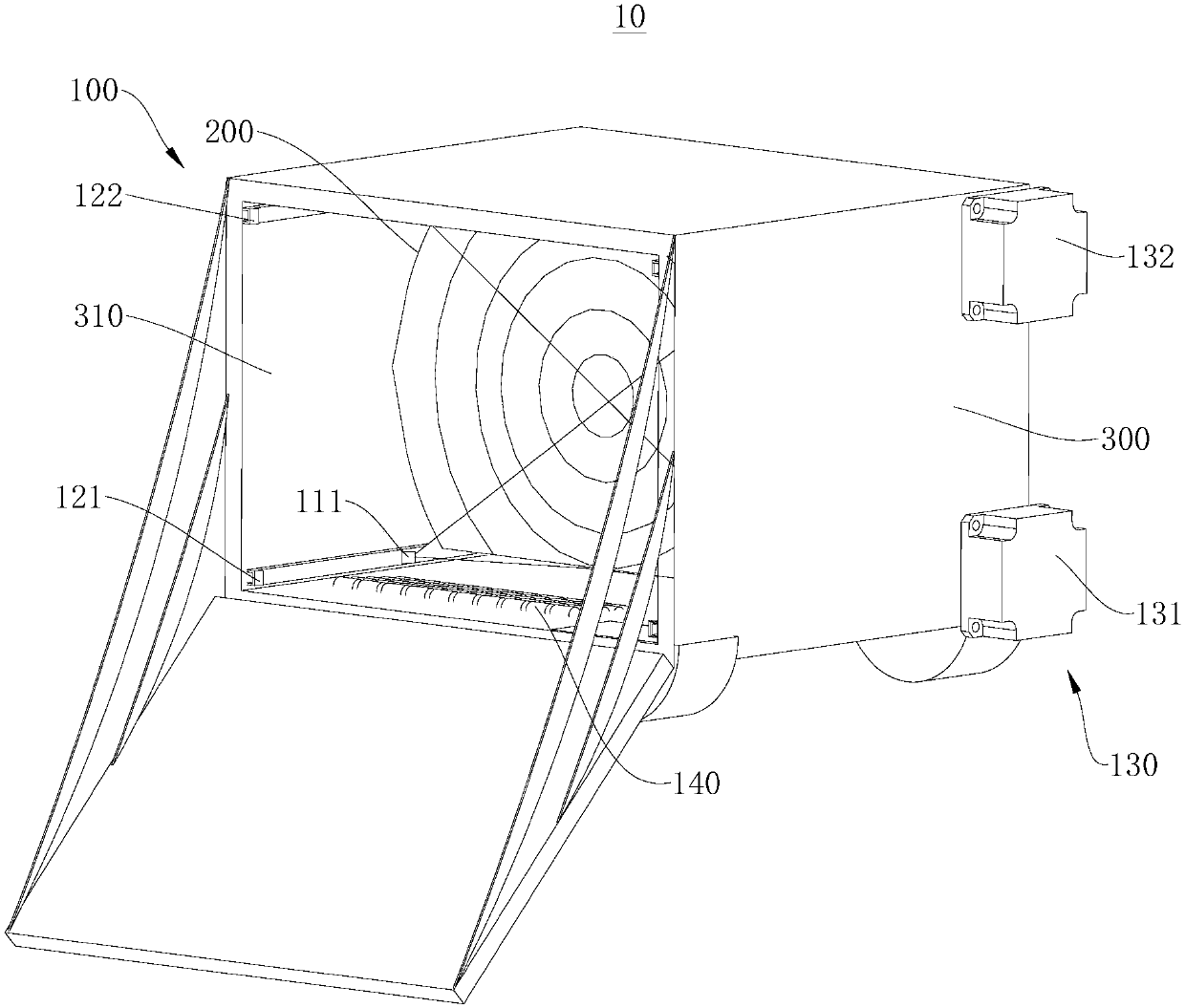

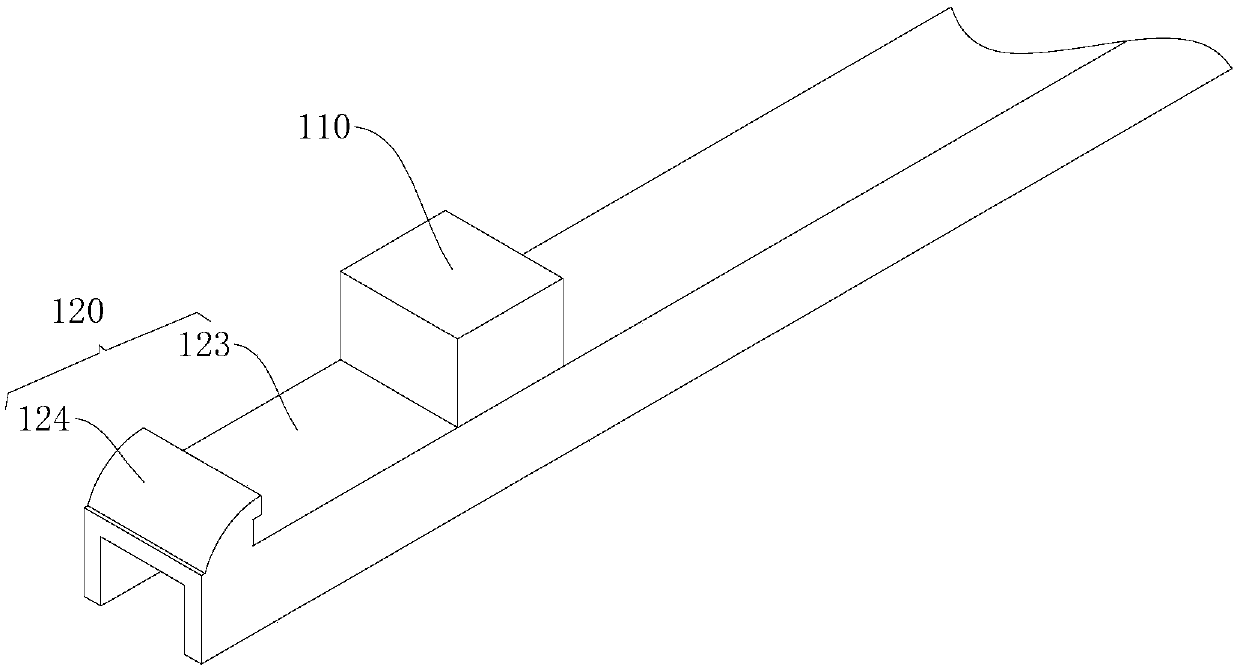

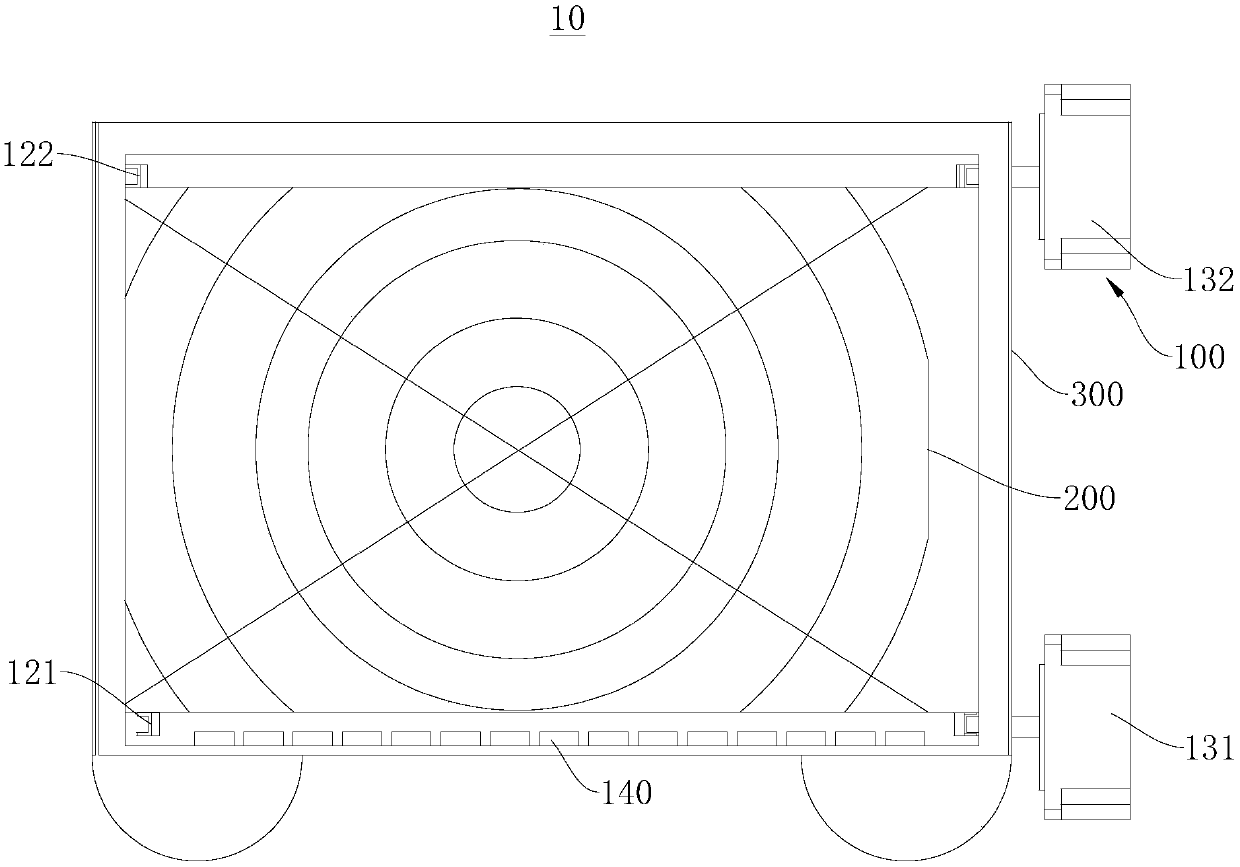

Element handler

ActiveCN107533102AEvenly loadedFast loadingElectronic circuit testingIndividual semiconductor device testingSemiconductor chipEngineering

The present invention relates to an element handler, and more specifically to an element handler for loading and unloading an element, such as a semiconductor chip, in and from a burn-in board. The element handler according to the present invention comprises: a loading unit into which a loading a tray loaded with first elements is loaded; an X-Y table for moving a burn-in board, on which a first element is to be loaded, in X-Y directions to the empty spot from which second elements have been unloaded; a buffer unit in which the second elements unloaded from the X-Y table are temporarily loaded; and an unloading unit in which second elements of acceptable quality from among the second elements loaded in the buffer unit are loaded onto a tray.

Owner:JT

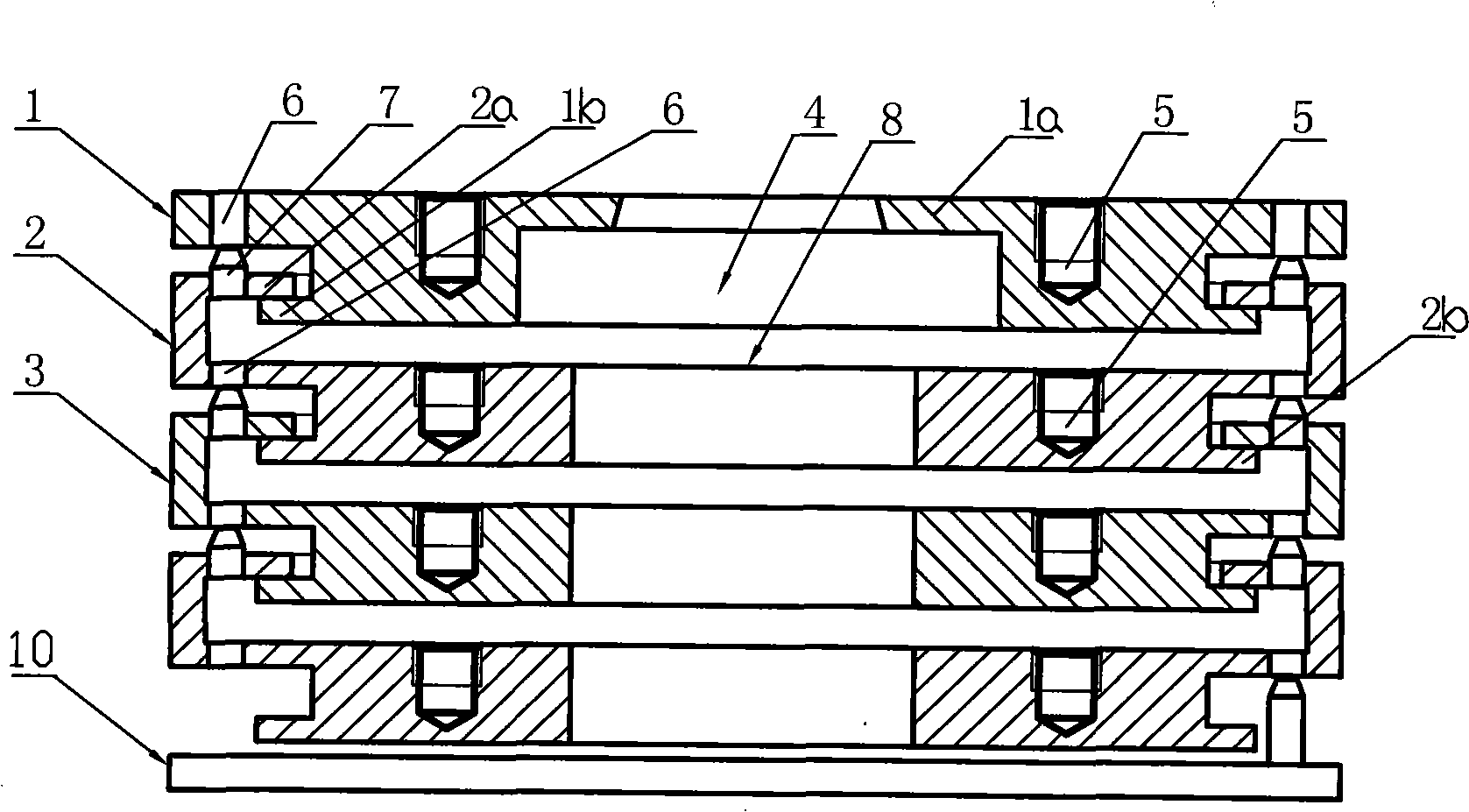

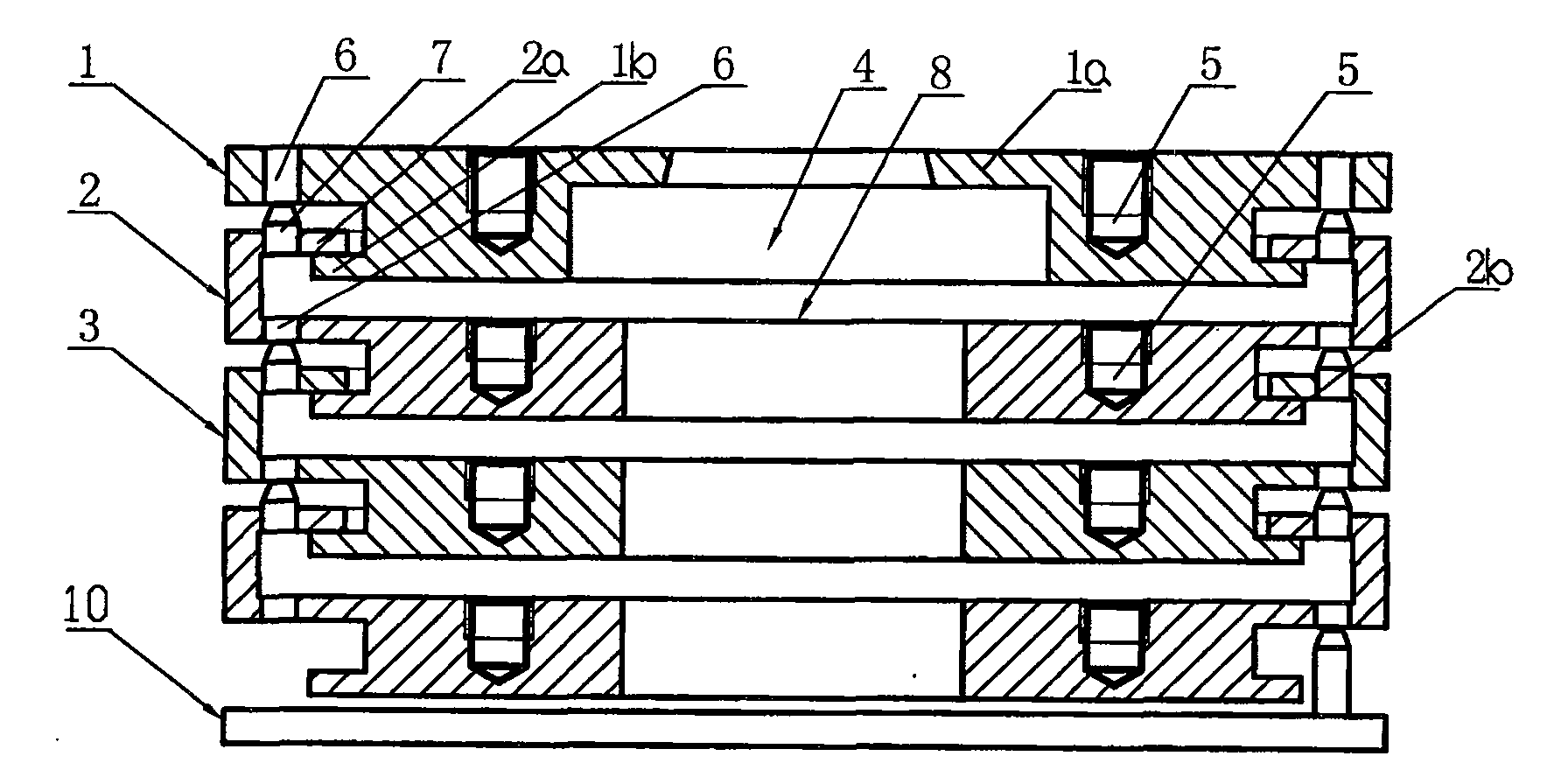

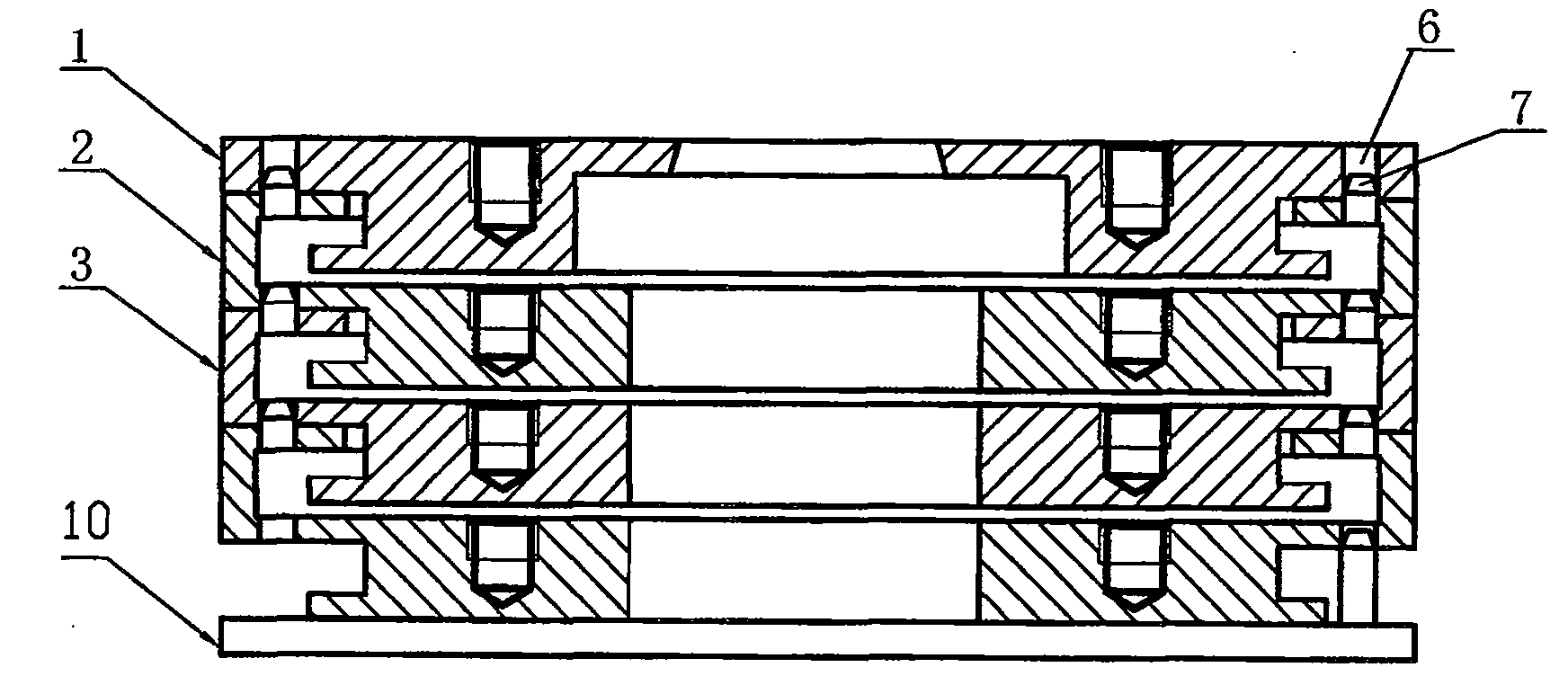

Weights of standard machine loading device

InactiveCN101281072AImplement socketAccurate massForce/torque/work measurement apparatus calibration/testingRepeatabilityDislocation

The present invention discloses a weight of standard machine loading device which comprises weight groups comprising a plurality of weights; each weight is step cylinder with circle center via; bottom circumference of small diameter section of each weight is evenly distributed with several lower spigots extending outwardly; the upper port of the first weight is evenly distributed with several upper spigots extending to the circle center; the circle center via of each weight from the second weight is step hole; the upper port at the big diameter end of the step hole is evenly distributed with several upper spigots extending to the circle center; the upper end face at the big diameter section of each weight from the second weight is evenly equipped with locating pins; the big diameter section of each weight from the first weight is further equipped with locating hole; the locating pins and locating holes of the adjacent weights are corresponding; the big diameter section of the lower weight is sleeved with the small diameter section of the upper weight in turn through the spigot. The weight is able to avoid the mutual dislocation of the upper and lower weights in the loading or unloading process, prevent the weight from swinging after loading and affect the indicating value of torque or force so as to improve the repeatability of the indicating valve.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

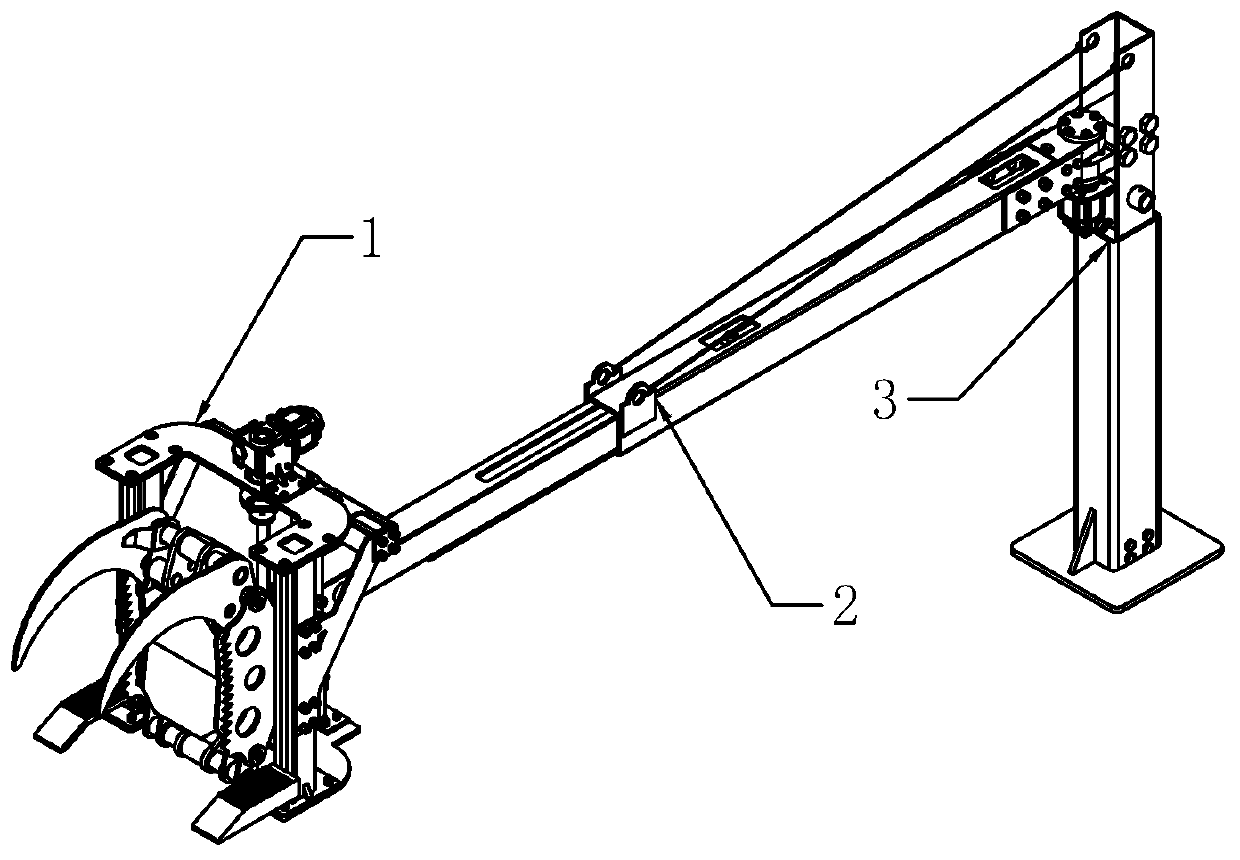

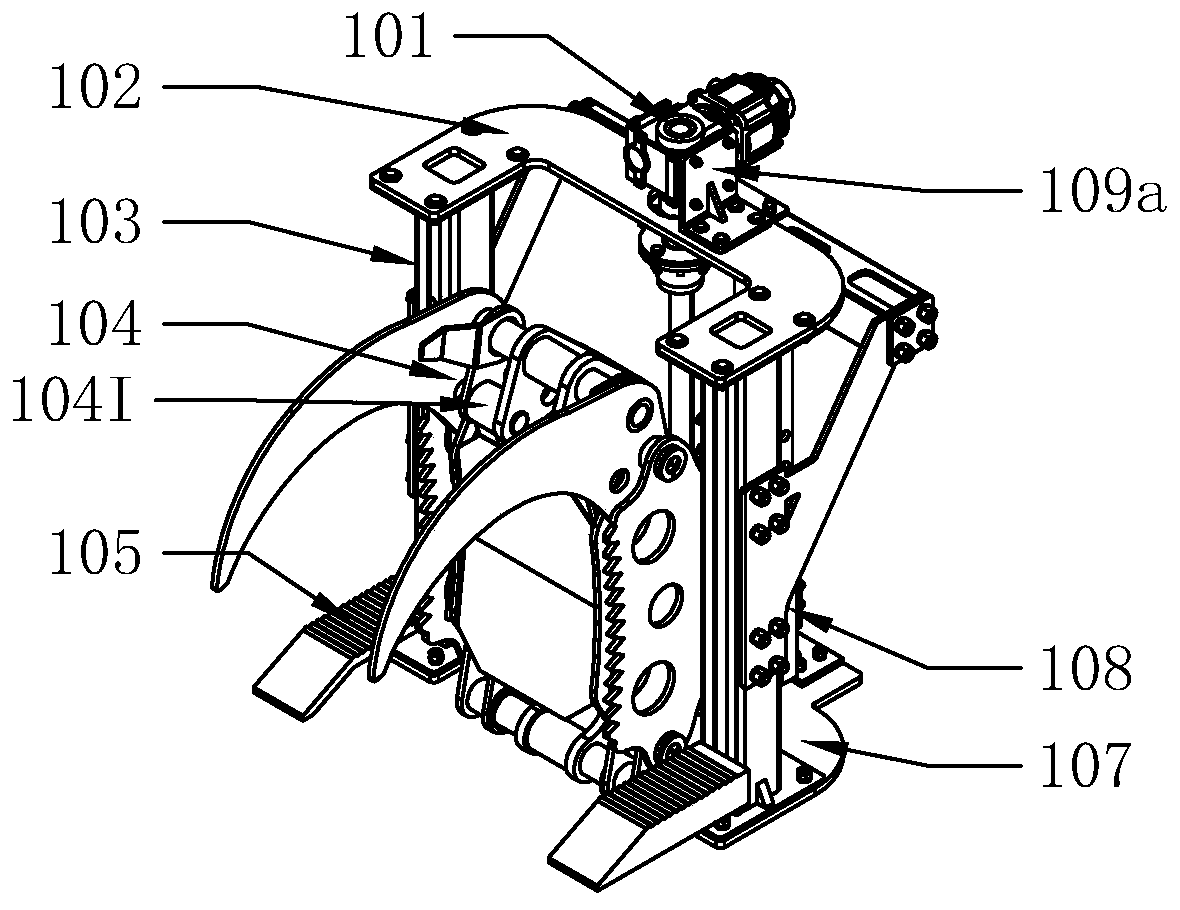

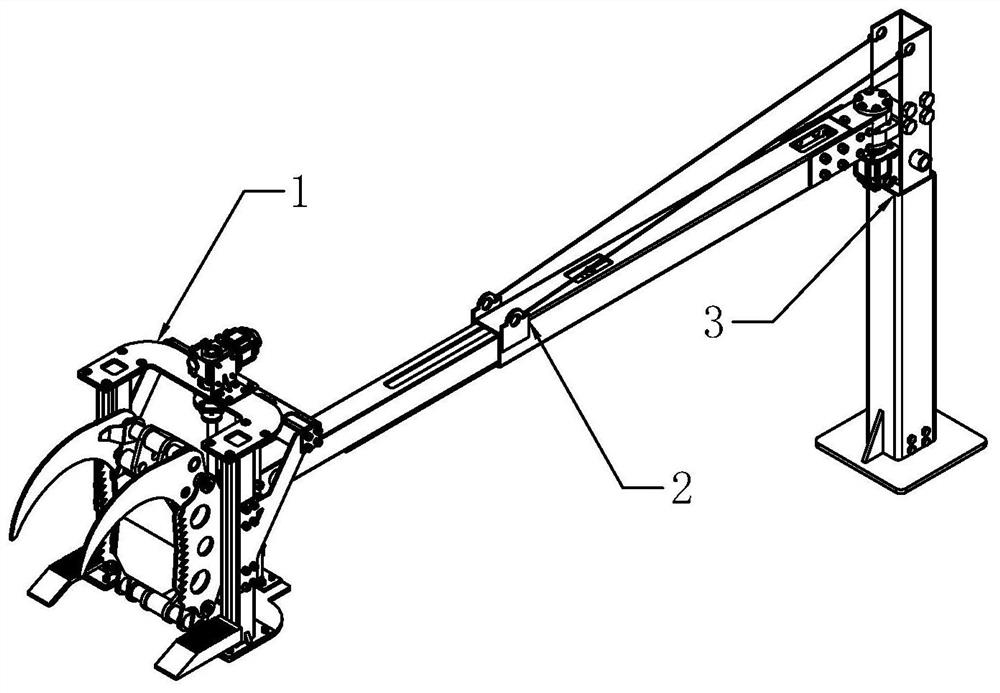

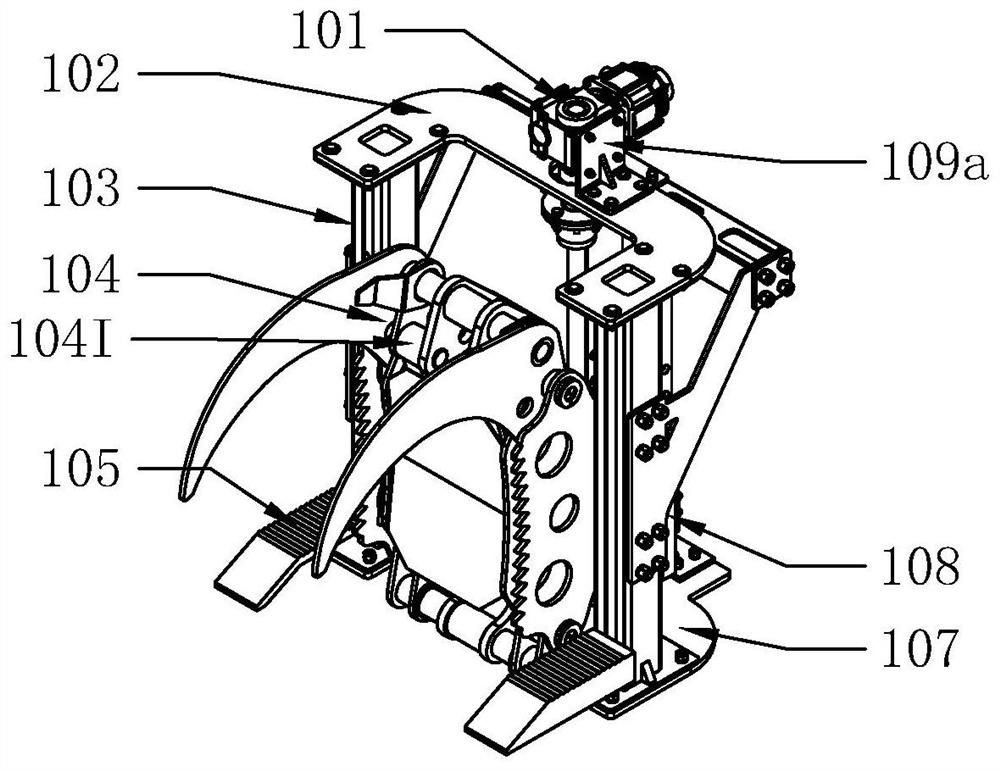

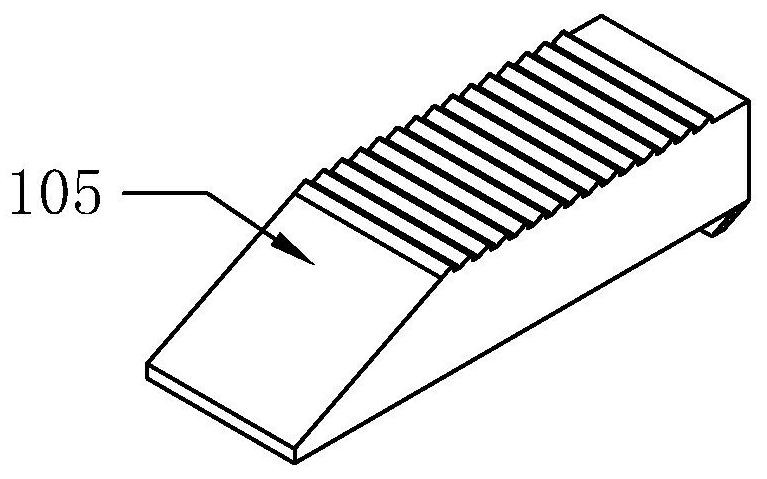

Eagle claw type unloader

ActiveCN110077842AStable uninstallEffective uninstallLoading/unloadingConveyor partsEngineeringEagle

The invention relates to an eagle claw type unloader. The eagle claw type unloader comprises a grabbing device, a transverse moving device and a longitudinal telescopic device. The grabbing device comprises a grabbing occlusion mechanism and a grabbing moving mechanism. The grabbing occlusion mechanism is mounted on the grabbing moving mechanism. The grabbing occlusion mechanism comprises an occluder, supporting teeth and supporting columns. The two supporting columns are arranged on the two sides of the supporting teeth. The supporting teeth are fixedly arranged on the supporting columns. Through the eagle claw type unloader, an operator just needs to adjust the transverse moving device and the longitudinal telescopic device to the appropriate positions in the unloading process; when touching cargos, the supporting teeth are pushed into the up-down gap between the cargos, an occlusion hydraulic element starts to operate to occlude and fix the cargos, the cargos are transferred to theother position through the transverse moving device and the longitudinal telescopic device, the grabbing occlusion device loosens, and the cargos slip off from the supporting teeth under the action ofself-weight to be stably unloaded; accordingly, the heavy cargos arranged compactly are unloaded efficiency, the problem that a forklift and the like cannot implement unloading in the unloading process is solved, the unloading efficiency is improved, and the labor cost for unloading is reduced.

Owner:HANGZHOU DIANZI UNIV

Constant-power control device and pressure variable control method thereof

The invention relates to a constant-power control device which comprises a valve body. A flow control valve and a pressure control valve are arranged in the valve body. The flow control valve comprises a first valve element, a first spring cavity and a primary spring. The pressure control valve comprises a second valve element, a second spring cavity and a secondary spring. According to the constant-power control device, the two control valves are arranged to carry out hierarchical control over oil pressure; the primary flow control valve controls the magnitude of the flow mainly through flow distribution, and the secondary pressure control valve controls the magnitude of pressure mainly through oil-return unloading; the problems that the braking torque and the oil temperature rapidly rise due to continuous rising of pressure after out of control of pressure are effectively solved, and use is reliable.

Owner:SUZHOU SABO IND DESIGN

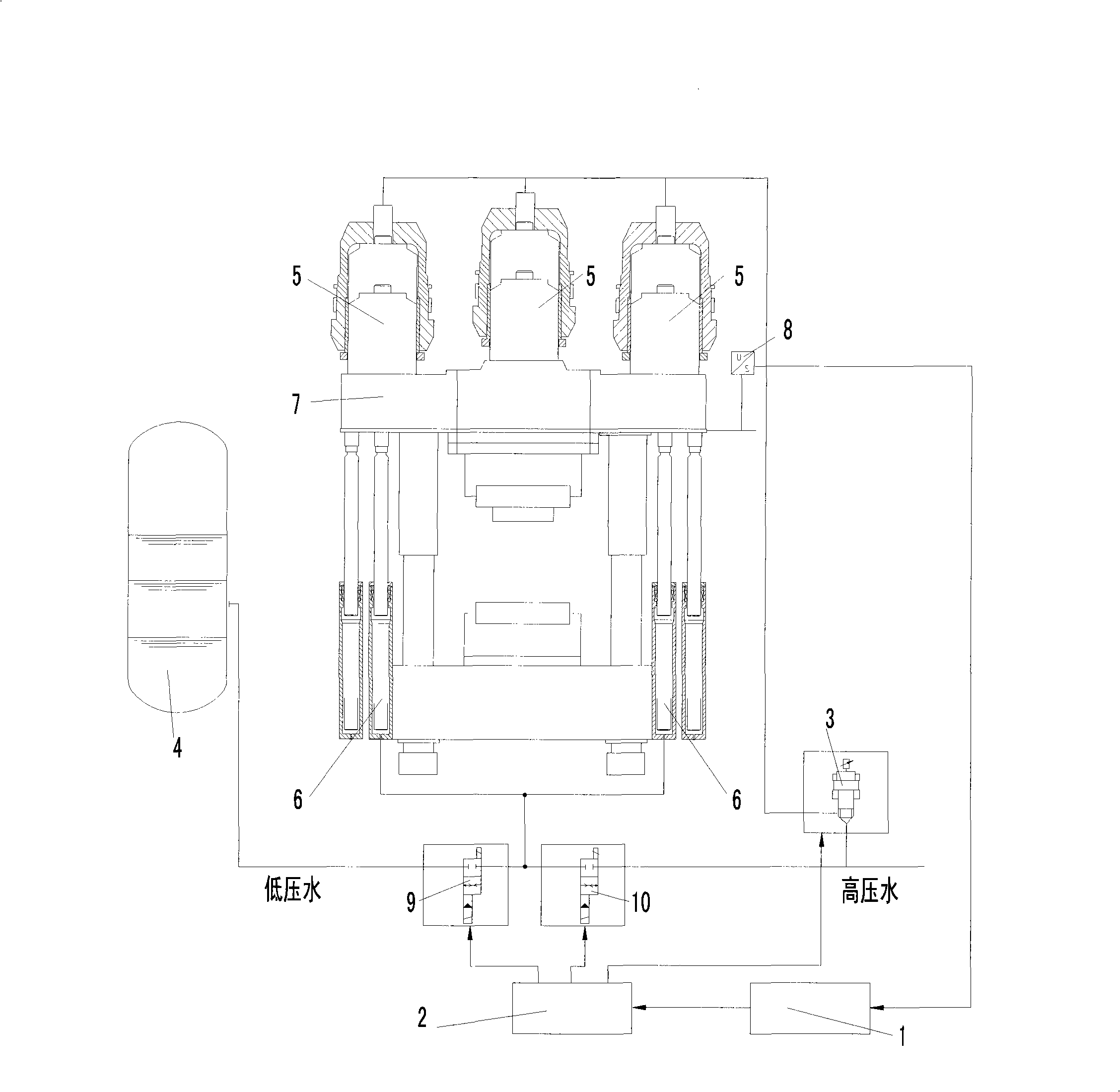

Water press large-pressure instant load-missing control method

ActiveCN101337257AStable uninstallImprove reliabilityMetal-working apparatusFluid pressure control using electric meansHigh pressure waterCompressibility

The invention discloses a method for controlling the high-pressure instantaneous loss of load of a hydraulic press, and relates to major free-forging hydraulic press equipment. The hydraulic press comprises a master cylinder, a master cylinder control valve (a proportional valve), a movable beam, a return cylinder, a return cylinder low-pressure water control valve, a return cylinder high-pressure water control valve, a programmable controller, an execution control element (an amplifier), a displacement sensor, a pipeline, etc. The method for controlling the high-pressure instantaneous loss of load of the hydraulic press is a hydraulic buffer cushion method, which is characterized in that when the hydraulic press encounters high-pressure instantaneous loss of load, the return cylinder is controlled to access high-pressure water, causing the return cylinder and the pipeline to form a hydraulic buffer cushion, so as to buffer and depressurize the movable beam, absorb residual energy and realize smooth unloading. The method effectively eliminates the intensive violation of the hydraulic press and the pipeline when punching is completed, improves the precision of punched holes in forged pieces, basically eliminates the need of oxygen blast treatment for burrs, enables direct forging of hole stretching and slash, saves energy and improves production efficiency.

Owner:CHINA FIRST HEAVY IND +1

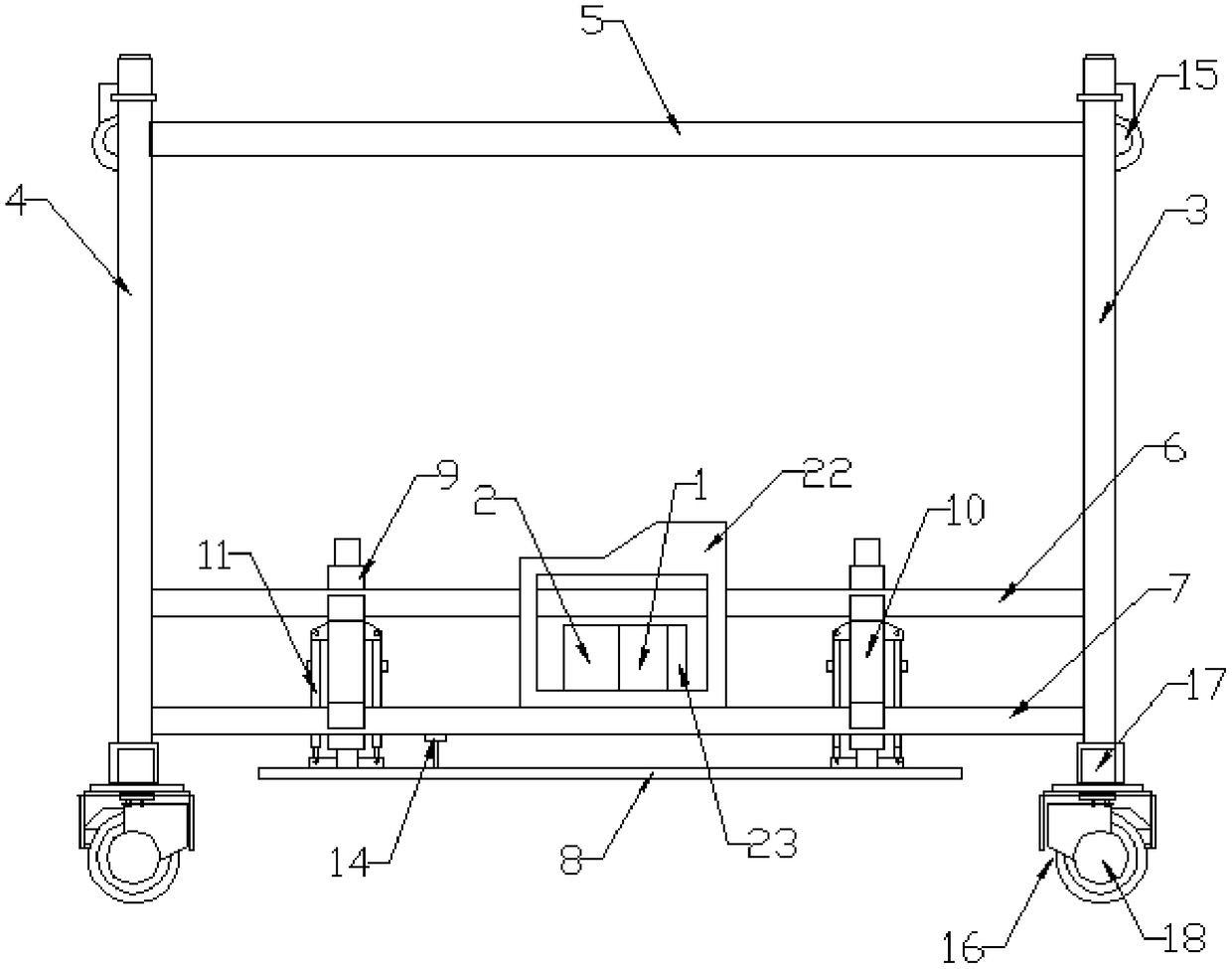

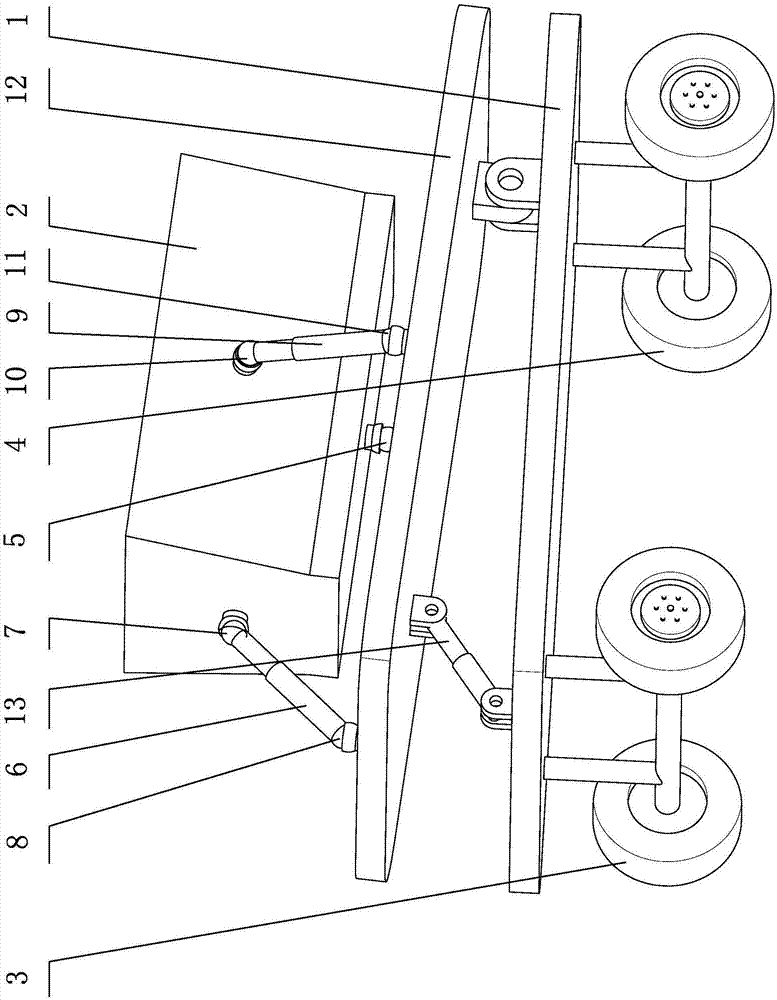

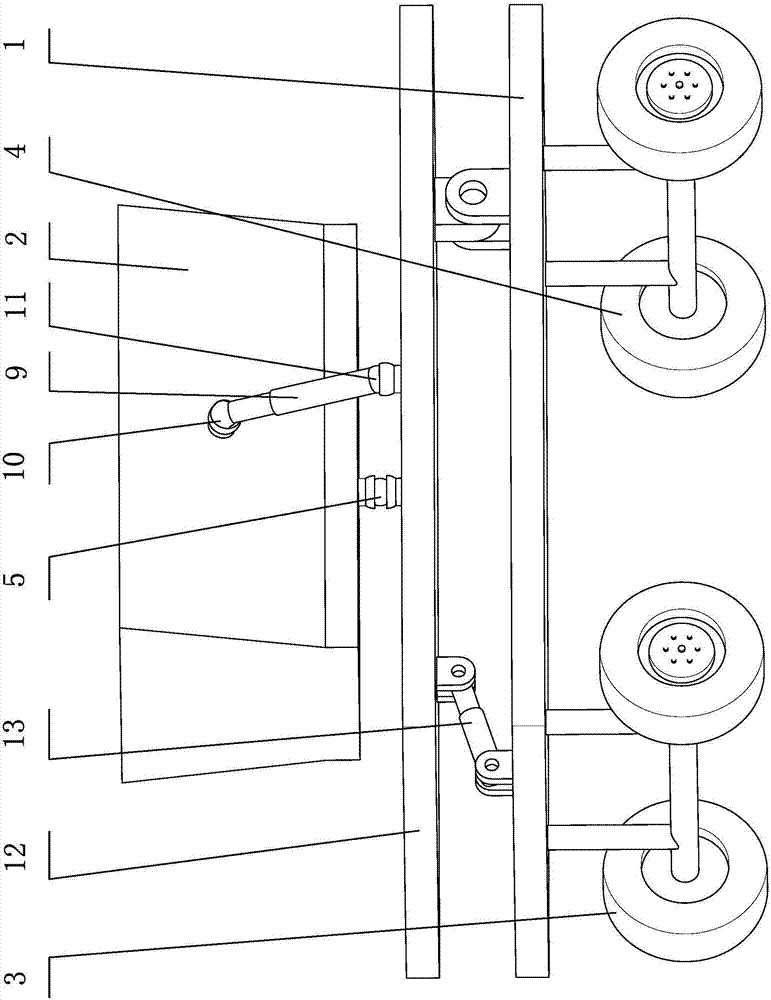

Portal frame type component transportation vehicle and component transportation method

ActiveCN109384162AWalking smoothlyPrevent rolloverPortable liftingLifting framesVehicle framePortal frame

The invention provides a portal frame type component transportation vehicle and a component transportation method. The transportation vehicle comprises a transportation vehicle frame, the transportation vehicle frame is provided with a moving steering mechanism, a supporting frame lifting and lowering mechanism, a power mechanism and a hydraulic mechanism, the power mechanism is connected with thehydraulic mechanism, the hydraulic mechanism is connected with the supporting frame lifting and lowering mechanism and the moving steering mechanism, the transportation vehicle frame comprises a first portal frame and a second portal frame, first supporting rods are arranged on the two sides of the upper end of the part between the first portal frame and the second portal frame, second supportingrods are arranged on the two sides of the lower end, and the supporting frame lifting and lowering mechanism comprises a hydraulic lifting and lowering assembly and a suspension lifting and loweringassembly. The transportation vehicle has the advantages that the structure is simple, a component temporary storage area and a special piece of hoisting equipment for a stacking field are eliminated,PC component supporting frames of different types can be adapted to, loading, unloading and the stability in the transportation process are ensured, four-wheel-driving and four-wheel-steering systemsare adopted by the moving steering mechanism, and the operation flexibility in narrow space is improved.

Owner:中原建港建筑科技有限公司

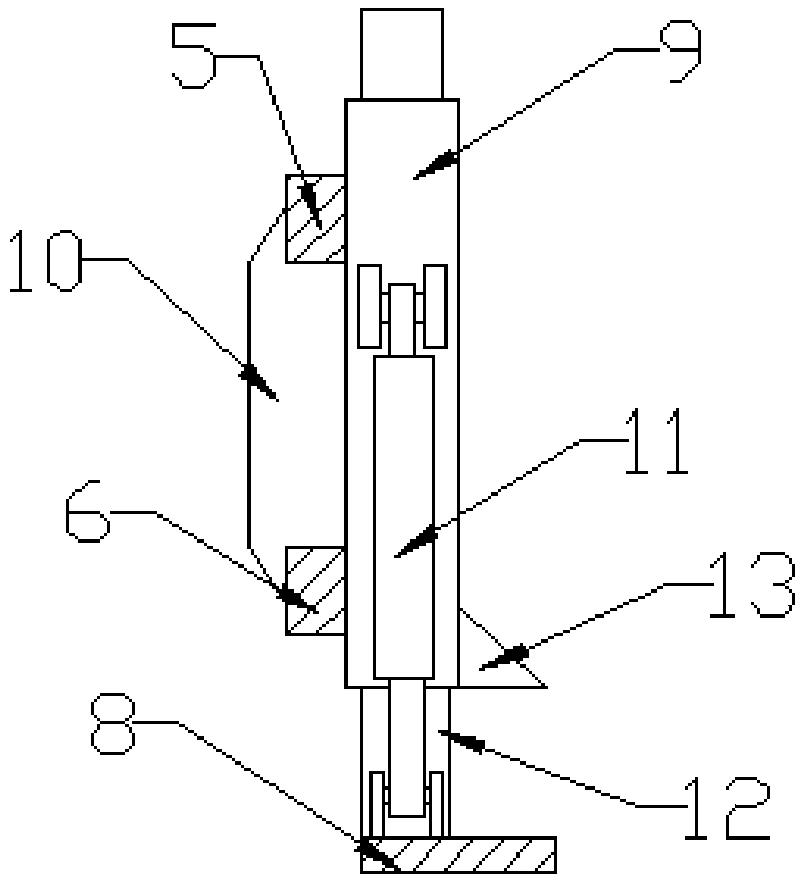

Stabilizing mechanism for hoisting shaft cage and stabilizing device

InactiveCN100532240CPrevent up and down movementReduce lifting dynamic loadMine liftsBuffer tankFuel tank

The invention discloses a tank stabilizing mechanism for lifting a shaft cage, which is composed of a support, a tank stabilizing arm, a catcher, a buffer oil cylinder or a buffer cylinder; the tank stabilizing arm is hinged to the support; the catcher is installed on the tank stabilizing arm , consisting of an oil cylinder or cylinder and a push rod, the oil cylinder or cylinder is hinged on the stabilizer arm, the oil cylinder or cylinder is hinged to the push rod, and the push rod passes through the sliding seat at the front end of the stabilizer arm; the buffer oil cylinder or buffer cylinder is supported on the stabilizer arm the lower part of the front. The tank stabilizing device is composed of two sets of tank stabilizing mechanisms, which are arranged parallel to each other, and the front parts of the two tank stabilizing arms are connected as a whole with a beam. The invention has simple structure and convenient installation and debugging. Through the use of this equipment, the cage can be locked in a horizontal position during loading and unloading, avoiding the sudden up and down movement of the cage due to elastic changes during loading and unloading, and ensuring smooth loading and unloading; And smoothly release the energy of the cage moving up and down, greatly reducing the dynamic load brought by the hoisting wire rope due to loading and unloading.

Owner:CHINA COAL SCI & TECH GRP NANJING DESIGN & RES INST CO LTD

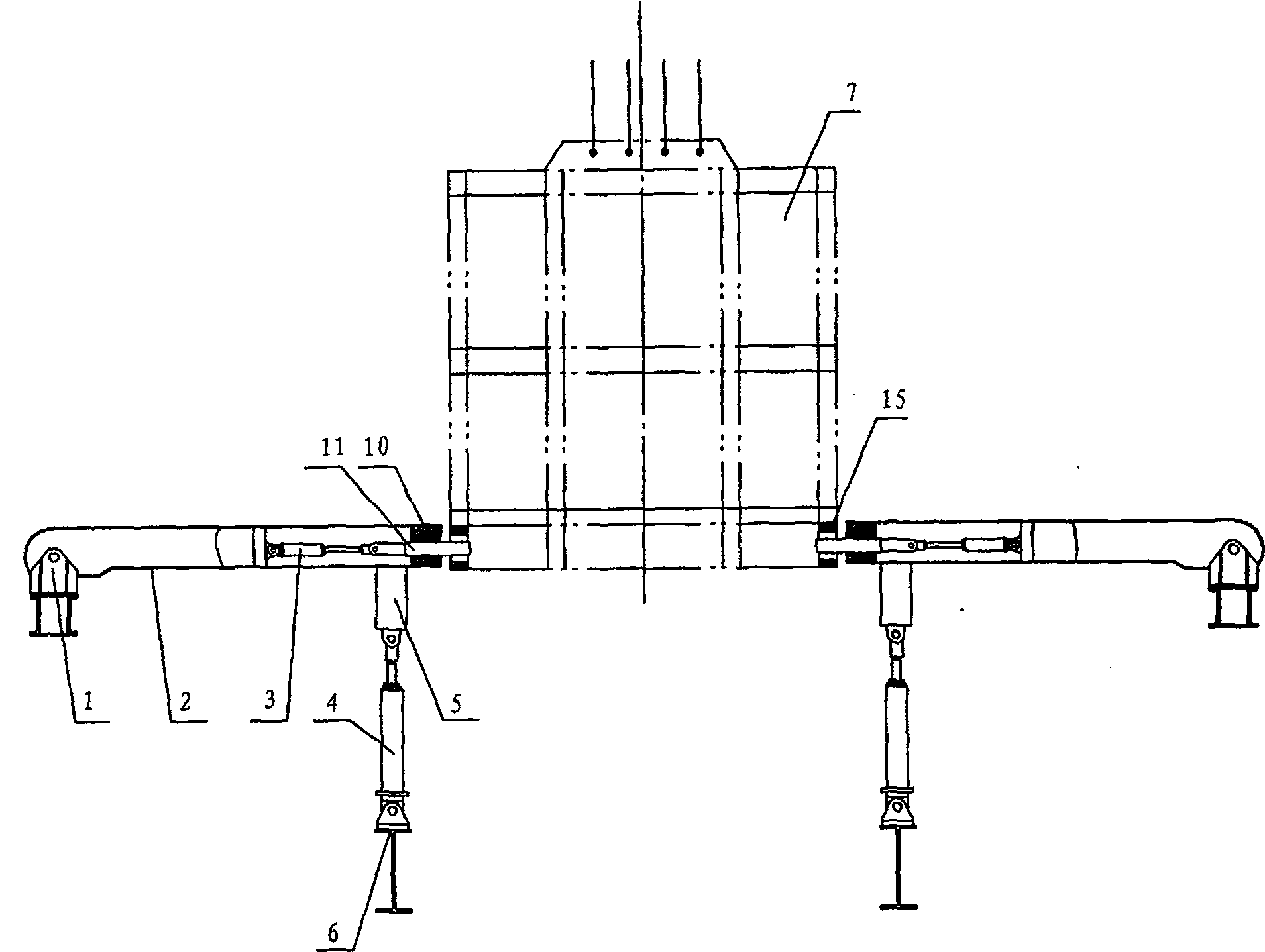

Steel truss synchronous graded unloading method with double fulcrums replaced by jacking oil cylinders

ActiveCN112392259AGuaranteed accuracyUninstall process is smoothBuilding material handlingLong spanEconomic benefits

The invention discloses a steel truss synchronous graded unloading method with double fulcrums replaced by jacking oil cylinders. The method comprises the following steps of S1, installing a supporting system; S2, installing a jacking oil cylinder; S3, jacking back to calculate a counter force; S4, support conversion; S5, synchronous graded unloading; and S6, dismounting the jacking oil cylinder and the supporting system. The invention provides an unloading method which is more stable, more accurate and safer, is particularly suitable for unloading work of a super-large-span overall stress truss with high bearing capacity, has very good popularization and practical values, and can generate good economic benefits after being widely popularized and applied.

Owner:BEIJING CONSTR ENG GRP CO LTD +1

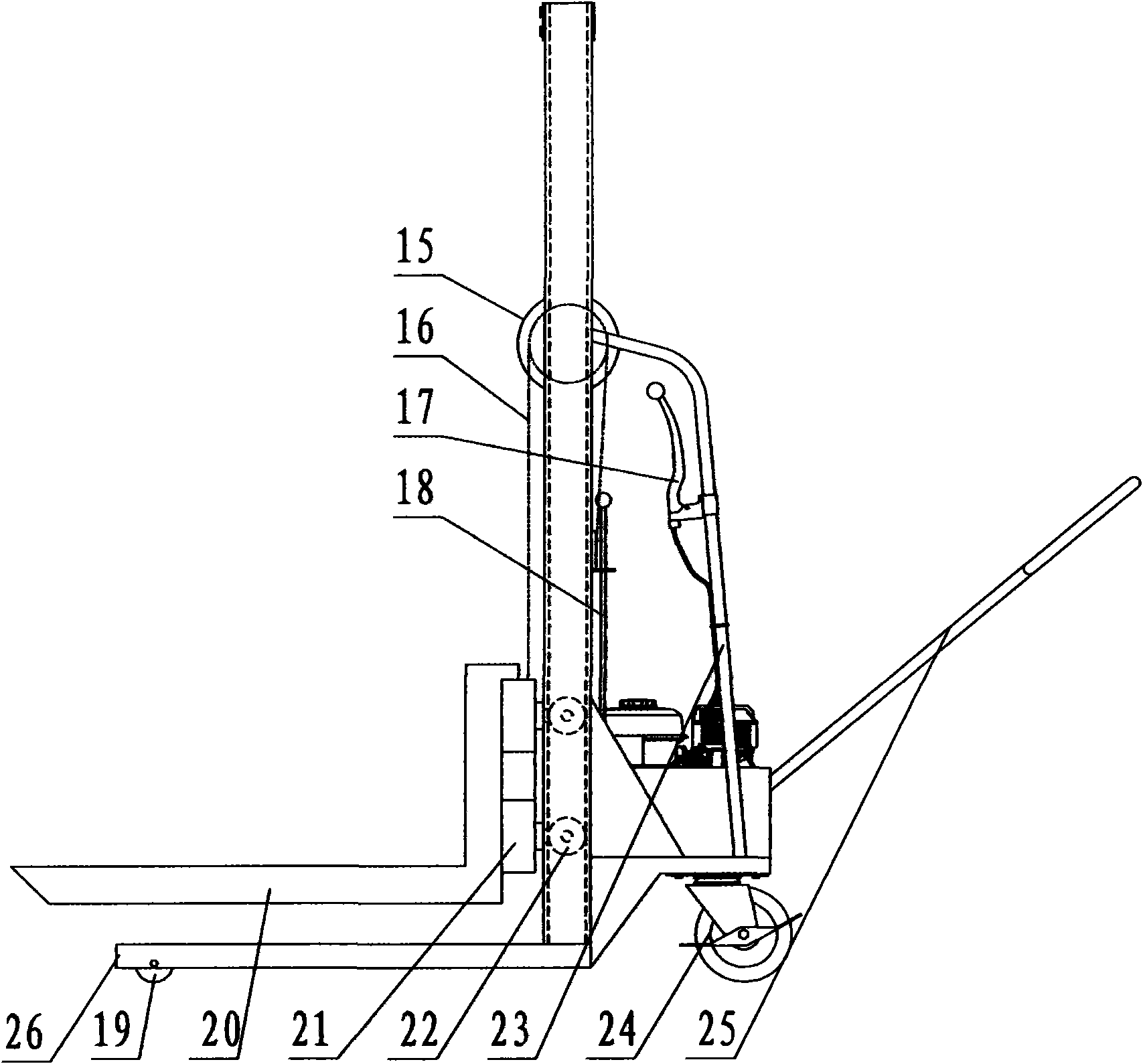

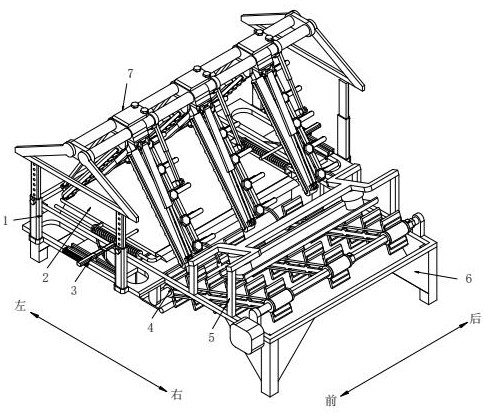

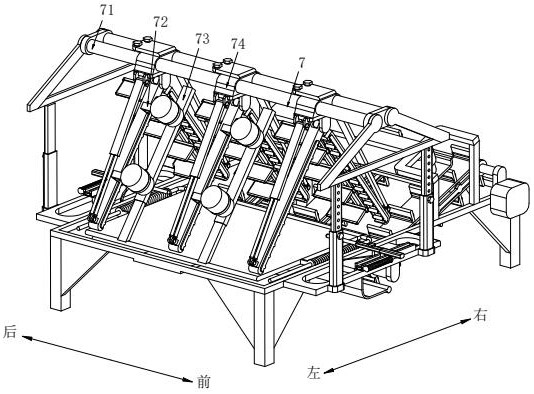

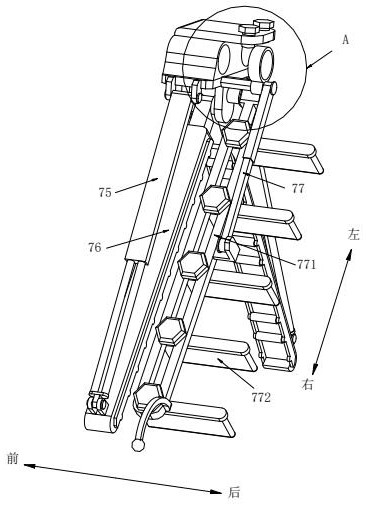

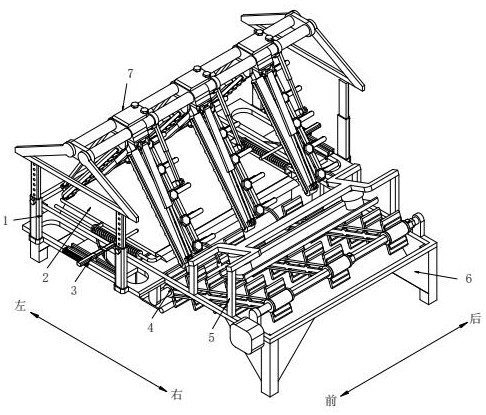

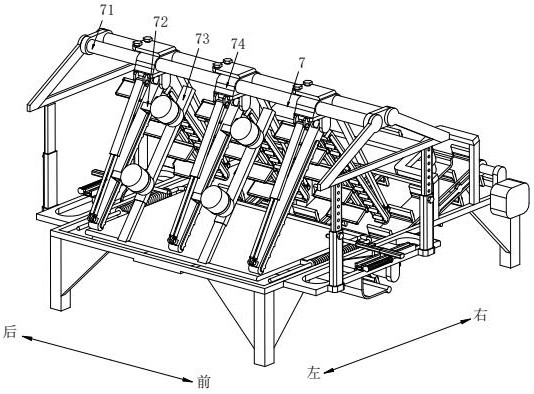

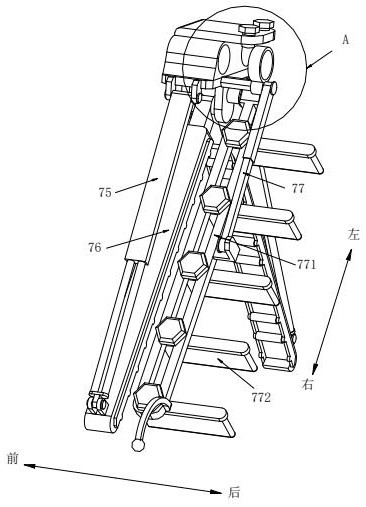

Log distributing and unloading machine for wood processing

ActiveCN114348628AStable uninstallAvoid Scattered SituationsWood working apparatusConveyor partsWood processingIndustrial engineering

Owner:徐州美邦木业有限公司

Luggage carrying vehicle and luggage unloading method

PendingCN109515503ARealize unloadingStable uninstallHand carts with multiple axesHand cart accessoriesEngineeringMechanical engineering

The invention discloses a luggage carrying vehicle and a luggage unloading method and relates to the technical field of luggage carrying. The luggage carrying vehicle comprises a drive assembly, a protecting net and a vehicle body. The vehicle body is provided with a storing space. The storing space is used for storing luggage. The protecting net is arranged in the storing space. The drive assembly is installed on the vehicle body. The drive assembly is in transmission connection with the protecting net. The protecting net is used for pushing the luggage out of the storing space. The inventionfurther provides the luggage unloading method comprising the luggage carrying vehicle. According to the luggage carrying vehicle and the luggage unloading method, the structure is simple, the occupied space is small, the manufacturing cost is low, impact on the luggage in the unloading process can be reduced effectively, and the damage rate to the luggage in the unloading process is reduced.

Owner:SICHUAN UNIV

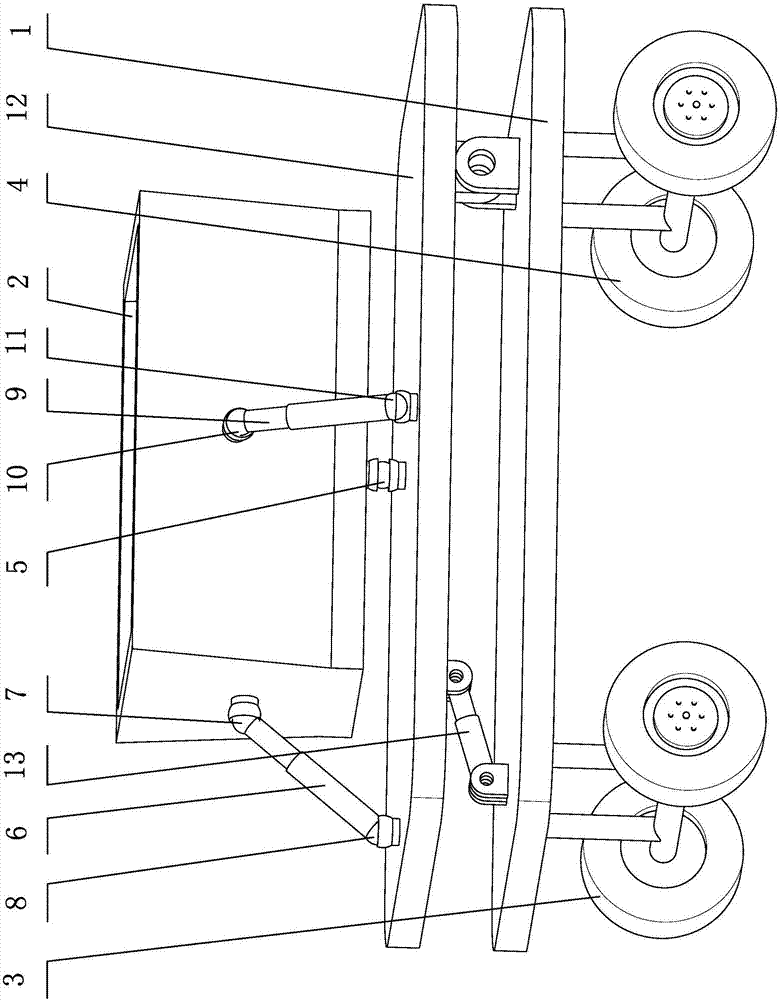

Three/four degrees of freedom bifacial hydraulic driving sugarcane collecting device

PendingCN107306593ALarge space flexibilityIncrease flexibilityLoadersHarvestersHydraulic cylinderVehicle frame

The invention discloses a three / four degrees of freedom bifacial hydraulic driving sugarcane collecting device. The device comprises a cart rack which walks through a front wheel set and a back wheel set and a sugarcane collecting box which is arranged on the cart rack, a spherical hinge on the bottom of the sugarcane collecting box is mounted on a lifting board, and no first telescopic rod or a first telescopic rod is arranged in front of the sugarcane collecting box; a spherical hinge on the front side face of the sugarcane collecting box is connected to the upper end of the first telescopic rod, a spherical hinge at the lower end of the telescopic rod is connected with the lifting board, and a second telescopic rod is arranged on the left side of the sugarcane collecting box; the upper end of the second telescopic rod is connected with a spherical hinge on the corresponding side face of the sugarcane collecting box, and a spherical hinge at the lower end of the second telescopic rod is connected with the lifting board; the back end of the lifting board is hinged to the cart vehicle, and the front end of the lifting board is mounted on a hoisting hydraulic cylinder which is arranged on the cart rack. The device can be unloaded frontwards, backwards and rightwards in large space, is high in space flexibility and flexibility degree and can be suitable for collecting and free unloading of sugarcane in hilly and mountainous areas.

Owner:QINZHOU UNIV

Servo fast forging valve and servo valve system

ActiveCN106762913BFast switching speedIncrease frequencyOperating means/releasing devices for valvesServomotor componentsProgrammable logic controllerBall screw

The invention provides a servo quick forging valve and a servo valve system and relates to the field of quick forging hydraulic machines, in particular to the servo quick forging valve. The servo quick forging valve comprises a servo motor, a support, a guiding lubricating cover plate and a valve sleeve which are sequentially arranged from left to right, a ball screw assembly is installed in the centers of the support, the guiding lubricating cover plate and the valve sleeve in a penetrating mode, and an output shaft of the servo motor is connected with a lead screw of the ball screw assembly in a threaded mode; the guiding lubricating cover plate and the end face of the valve sleeve are tightly matched in a sealed mode and connected into an integrated structure, a servo valve core is installed in the valve sleeve, and the servo valve core and a bearing bolt of the ball screw assembly are connected to into an integrated structure; and a bearing of the ball screw assembly can be driven by the lead screw to vertically move to adjust opening and closing of a valve. The invention further relates to the servo valve system. The servo valve system comprises the servo quick forging valve and a programmable logic controller. Through the technical scheme of the servo quick forging valve and the servo valve system, the oil swapping phenomenon occurring in an existing servo quick forging valve is avoided.

Owner:青岛海德马克智能装备有限公司

Device for unloading and buffering pull force

ActiveCN102121861BReduce shockPrevent leakageEngine testingFluid pressure measurementHydraulic cylinderPull force

The invention relates to a device for unloading and buffering pull force, in particular to a static calibration device of a thrust test system of a rocket engine, belonging to the field of sensing measurement and control devices. The device adopts inner and outer dual pressure springs as unloading and buffering elements and comprises a cylinder, an upper cover, a base, an inner spring, an outer spring, a hydraulic cylinder supporting flange and a connecting bolt, wherein the hydraulic cylinder supporting flange used as a support is of a stepped revolving body structure provided with a centralthrough hole; and the base is of a structure, which is provided with an outer surface tapped with screw threads and is provided with a central through hole of the base. The invention realizes the total unloading of loaded force during the in-situ calibration of a work sensor and effectively buffers the impact of the loaded force on the thrust test system and a hydraulic loading system during an unloading moment, and thus, hydraulic oil is prevented from being leaked, the unloading is also stabilized and return-trip calibration can be carried out accurately; and in addition, the device has theadvantages of higher adaptability, wider usage range and certain popularization and use value.

Owner:DALIAN UNIV OF TECH

An eagle claw unloader

ActiveCN110077842BStable uninstallEffective uninstallLoading/unloadingConveyor partsEngineeringMechanical engineering

Owner:HANGZHOU DIANZI UNIV

Pressure limiting valve with direct hydraulic damper

InactiveCN1673592BBest short pathSimple structureEqualizing valvesSafety valvesEngineeringHydraulic fluid

The invention relates to a pressure relief valve which involves direct hydraulic damping and protects hydraulic brace system from rock surges and other suddenly occurring overload. The pressure relief valve comprises a valve housing with a connection, wherein an input and an output sides of the valve housing are separated from one another by means of a closing part, which can be displaced against the force of a valve spring and comprises a seal, and are connected to one another when an overload situation occurs to drain the hydraulic fluid, wherein the closing part is formed by a piston, which is linked to the connection, and a valve spring retainer, which comprises said piston, is arranged displaceably thereon and accordingly has a cylindrical design, the seal is arranged in a groove, which is incorporated in a contact surface of the valve spring retainer at a distance from a base of the valve spring retainer, which guarantees a sufficiently large sealing surface beneath radial bores on the piston.

Owner:沃尔夫冈·福斯

Weights of standard machine loading device

InactiveCN100593701CGuaranteed accuracyImprovement of repeatability index of indication valueForce/torque/work measurement apparatus calibration/testingEngineeringRepeatability

The present invention discloses a weight of standard machine loading device which comprises weight groups comprising a plurality of weights; each weight is step cylinder with circle center via; bottomcircumference of small diameter section of each weight is evenly distributed with several lower spigots extending outwardly; the upper port of the first weight is evenly distributed with several upper spigots extending to the circle center; the circle center via of each weight from the second weight is step hole; the upper port at the big diameter end of the step hole is evenly distributed with several upper spigots extending to the circle center; the upper end face at the big diameter section of each weight from the second weight is evenly equipped with locating pins; the big diameter section of each weight from the first weight is further equipped with locating hole; the locating pins and locating holes of the adjacent weights are corresponding; the big diameter section of the lower weight is sleeved with the small diameter section of the upper weight in turn through the spigot. The weight is able to avoid the mutual dislocation of the upper and lower weights in the loading or unloading process, prevent the weight from swinging after loading and affect the indicating value of torque or force so as to improve the repeatability of the indicating valve.

Owner:CHONGQING CONSTR ELECTROMECHANICAL CO LTD

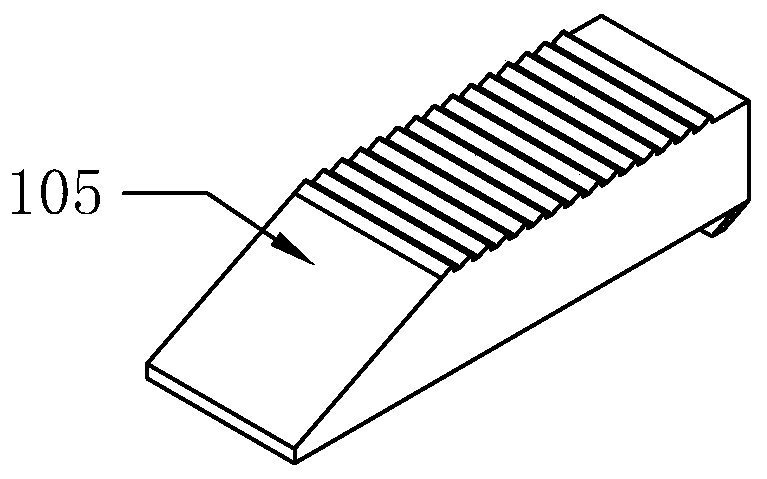

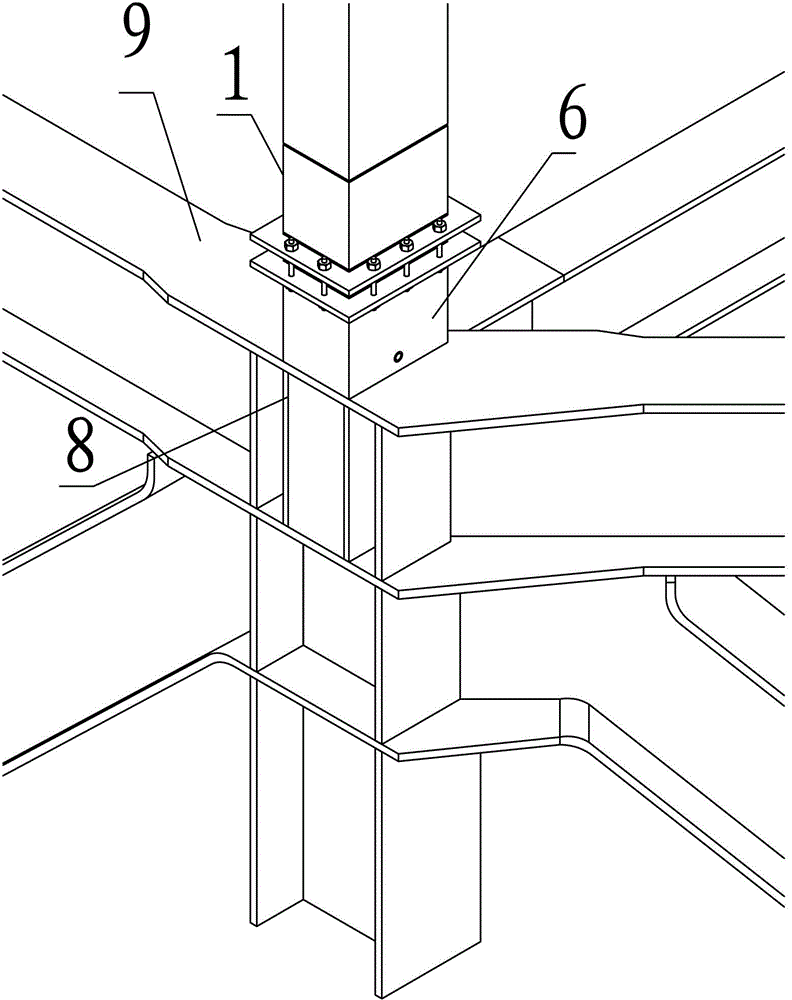

Installation method of a device capable of releasing internal forces during the installation phase of a steel support

ActiveCN105133843BEnsure safetyGuaranteed validityBuilding material handlingShoresEngineeringHigh rise

The invention relates to a device capable of releasing installation-stage internal force of a steel support and an installation method. The device comprises node connecting plates, a support connecting plate, an internal force releasing mechanism and a support axial deformation mechanism; the node connecting plates are used for being connected with node plates arranged on a main structure; the support connecting plate is connected with the end of the support; the internal releasing mechanism is used for connecting the node connecting plates with the support connecting plates into a whole and releasing loads born by the support in the installation stage through self regulation; the support axial deformation mechanism is arranged in the axial direction of the support connecting plate and used for releasing axial deformation when the support releases the internal force. By adopting the device, the problem that in high-rise steel structure installation, the support needs to bear the loads in the installation stage, so that the support is mainly used for bearing the transverse loads in installation is solved, and not only is the safety of the structure in the installation stage guaranteed, but also the earthquake-proof and wind-resistant efficiency of the support in the usage stage is guaranteed. The device and the installation method can be widely applied to high-rise steel structure installation engineering.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

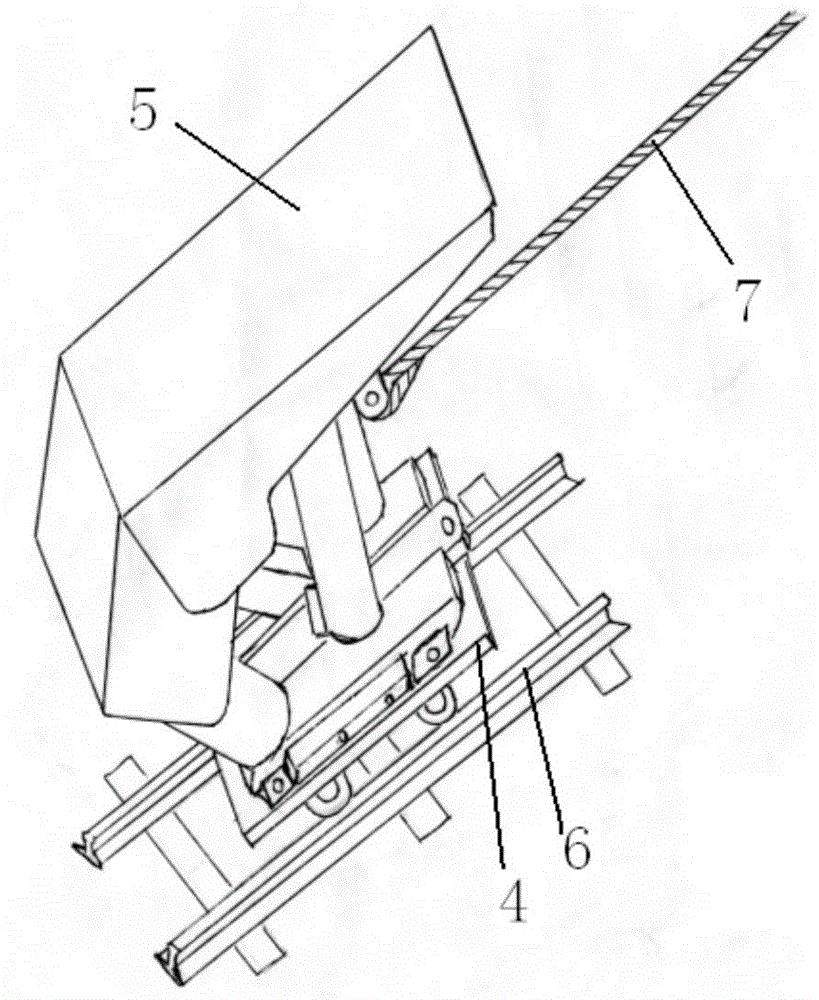

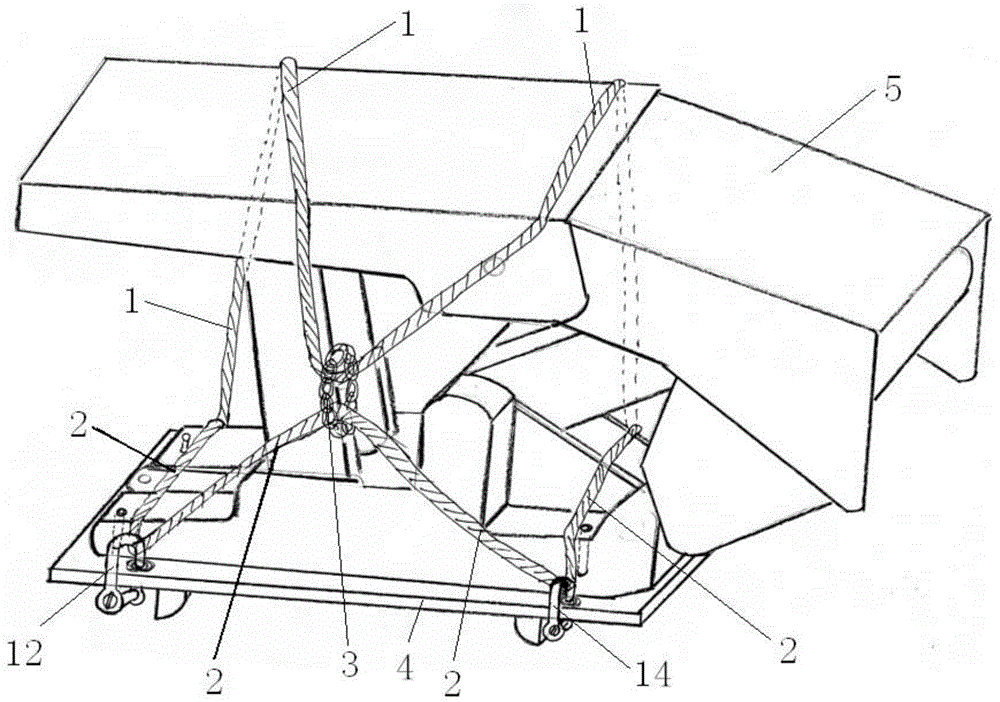

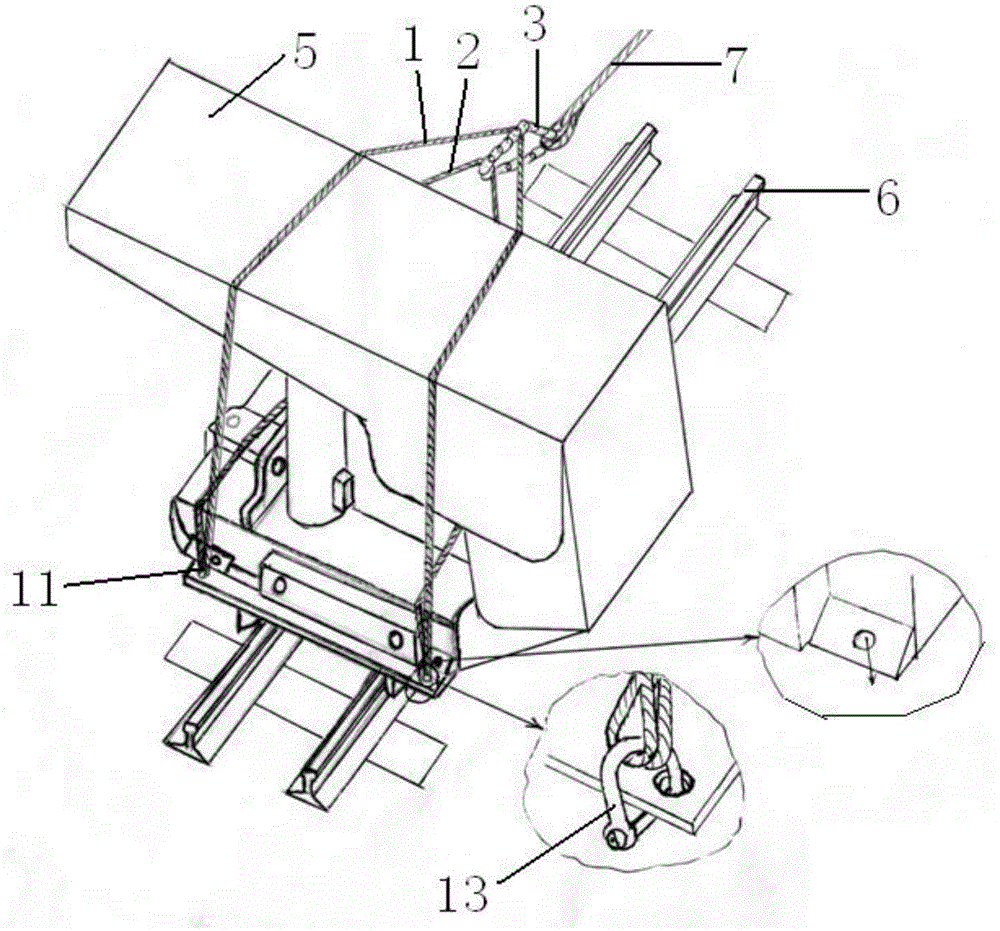

Fully-mechanized mining support lowering device and lowering method

The invention discloses a fully-mechanized coal mining support down-pass device and down-pass method, so that a fully-mechanized coal mining support is stably and safety fed downwards. According to the fully-mechanized coal mining support down-pass device, two locating ropes and a locating ring are used for fixedly binding a fully-mechanized coal mining support on a tackle horizontally, and then the fully-mechanized coal mining support is fed downwards through a winch. In the down-pass process, the fully-mechanized coal mining support is always perpendicular to slide rails and horizontally arranged. The fully-mechanized coal mining support can be in place in one time without direction adjustment, and the whole process is safe and reliable.

Owner:四川川煤华荣能源有限责任公司花山煤矿

A User-Centric Distributed Multi-User Computing Task Offloading Method

The invention provides a user-centered distributed multi-user computing task offloading method, which is characterized in that it includes the following steps: a plurality of fog computing computing nodes are uniformly abstracted into an access point with a server, and the access point has both Computing and communication capabilities, when any user generates a computing task, comprehensively consider the unloading decisions of other users, and choose one of the local computing or offloading computing tasks to other computing nodes according to the unloading decision under the current time slot to minimize the self overhead. The invention proposes a user-centered distributed multi-user calculation task offloading method. Such methods can realize stable and efficient offloading of computing tasks among multiple users in a distributed execution manner. The present invention can not only achieve satisfactory results for users, but also ensure better overall performance of the system (compared with the optimal strategy of the system).

Owner:SHANGHAI TECH UNIV

Log splitting and unloading machine for wood processing

ActiveCN114348628BStable uninstallAvoid Scattered SituationsWood working apparatusConveyor partsHydraulic cylinderStructural engineering

The invention relates to the technical field of wood processing equipment, in particular to a log splitting and unloading machine for wood processing. The left side of the front and rear surfaces of the support seat are symmetrically fixedly connected to the limit assembly, and the two limit assemblies are far away from the support seat. One side of each side is symmetrically fixedly connected with telescopic adjustment rods, and the top ends of the four telescopic adjustment rods are jointly connected with a clamping assembly, and the right side of the upper surface of the support base is fixedly connected with a conveying assembly. The pressure component is fixedly connected to the surface and above the conveying component. After the log is placed on the unloading component, multiple groups of left-right symmetrical clamping strips limit the left and right directions of the log, so that when the log is unloaded one by one, It will not be confused together. The hydraulic cylinder gradually pushes the logs through the telescopic push plate, so that the logs that are stacked as a whole are stressed at the same time when the logs are unloaded. When the telescopic push plate pushes the logs, the logs move more smoothly.

Owner:徐州美邦木业有限公司

Construction method and equipment of ultra-long suspenders in parallel

ActiveCN103452326BEasy constructionImprove installation efficiencyBuilding material handlingArchitectural engineeringSteel frame

The invention mainly discloses a method and equipment for sequentially constructing ultra-long hanging posts in a high-rise structure. The method includes steps of firstly, mounting a bottom uninstalling device of the hanging posts, filling high-strength steel sand in the uninstalling device and screwing down temporary connecting rods; secondly, mounting the hanging posts and steel frame beams adjacent to the hanging posts until a hanging post top structure is completely constructed; thirdly, synchronously unscrewing pressure release valves on the periphery of the uninstalling device to uninstalling the hanging posts; fourthly, cleaning residual steal sand in the uninstalling machine after the hanging posts are completely uninstalled, removing the temporary connecting rods, cutting off temporary connecting annular plates, sealing gaps between a bottom piston of the hanging posts and the uninstalling device and performing anti-corrosion treatment on the gaps between the bottom piston of the hanging posts and the uninstalling device so as to completely constructing the hanging posts. The equipment comprises the uninstalling device, the pressure release valves, the two temporary connecting annular plates, the multiple temporary connecting rods, the bottom piston of the hanging posts and the high-strength steel sand. The method and the equipment have the advantages that construction temporary measures can be reduced, the installation efficiency can be improved, the construction period can be shortened, the hanging posts can be conveniently and quickly uninstalled, and efficient and high-quality uninstalling work can be implemented.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

A method for synchronous staged unloading of steel trusses with double fulcrums replaced by jacking cylinders

ActiveCN112392259BGuaranteed accuracyEnsure safetyBuilding material handlingSupporting systemEconomic benefits

A method for synchronous grading and unloading of steel trusses in which double fulcrums are replaced by jacking oil cylinders, comprising the following steps: S1, installing a support system; S2, installing jacking oil cylinders; S3, returning to the jack to calculate the reaction force; S4, switching supports; S5, Synchronous unloading in stages; S6, remove the jacking cylinder and support system. The invention provides a more stable, more accurate and safer unloading method, which is especially suitable for the unloading work of super-large-span integral stressed trusses with high bearing capacity, and has good promotion and practical value. After extensive promotion and application, good economic benefits.

Owner:BEIJING CONSTR ENG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com