Method and equipment for sequentially constructing ultra-long hanging posts

A construction method and technology of construction equipment, applied in construction, building structure, construction material processing and other directions, can solve problems such as large temporary support measures, affecting installation progress, increasing risk factor, etc., to achieve high installation efficiency and improve safety. , the effect of reducing the cost of construction measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The preferred embodiments of the present invention will be described in further detail in conjunction with the accompanying drawings.

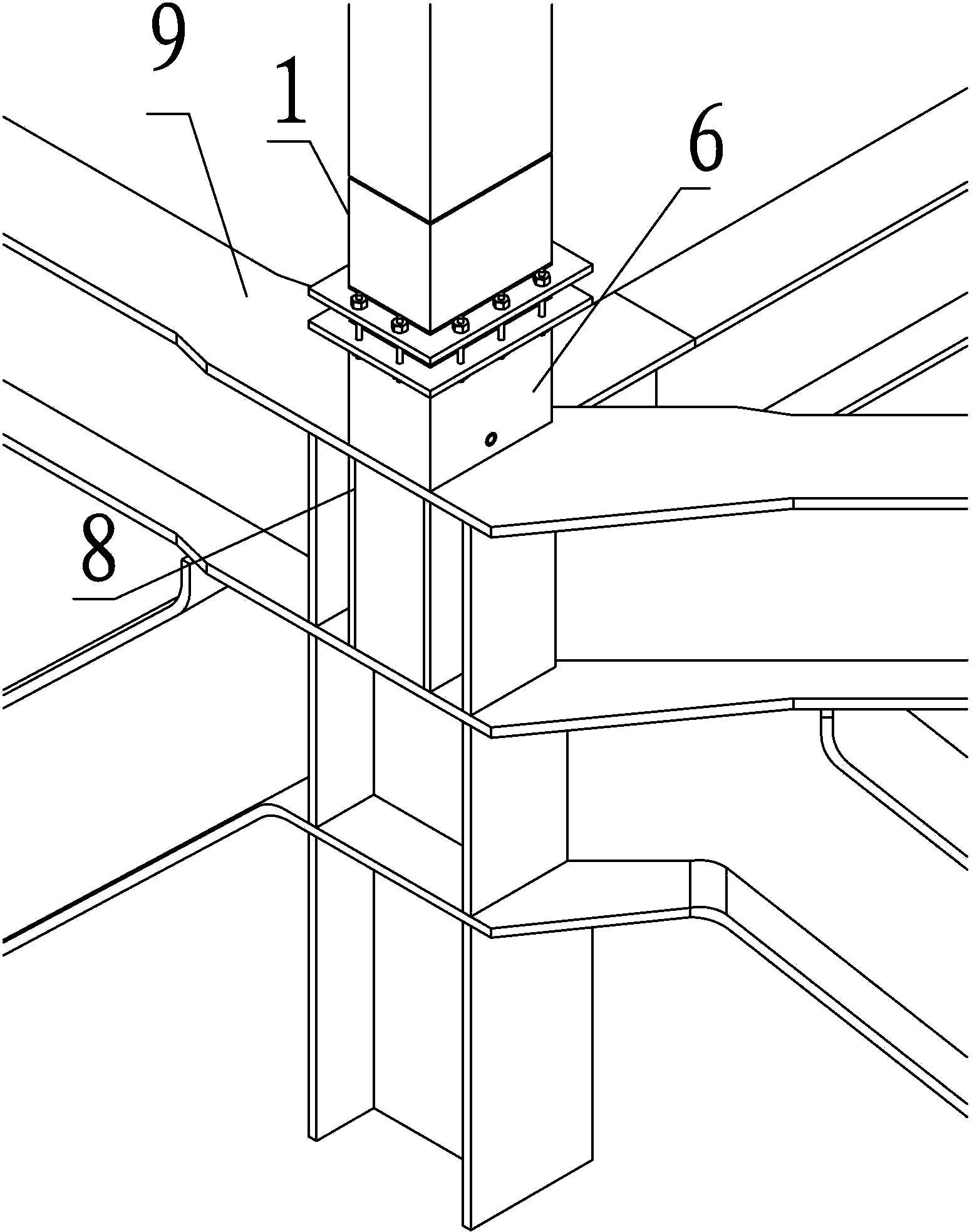

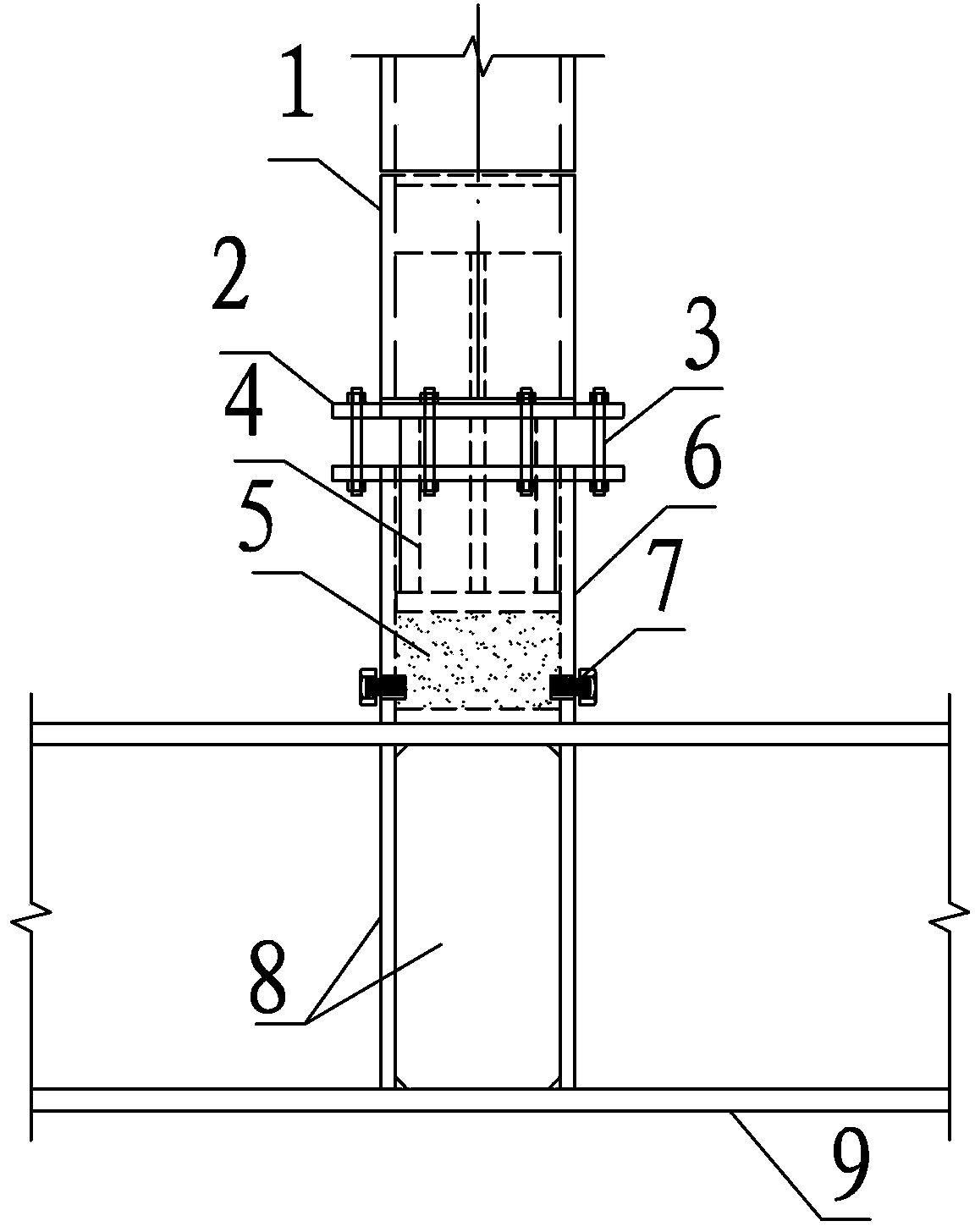

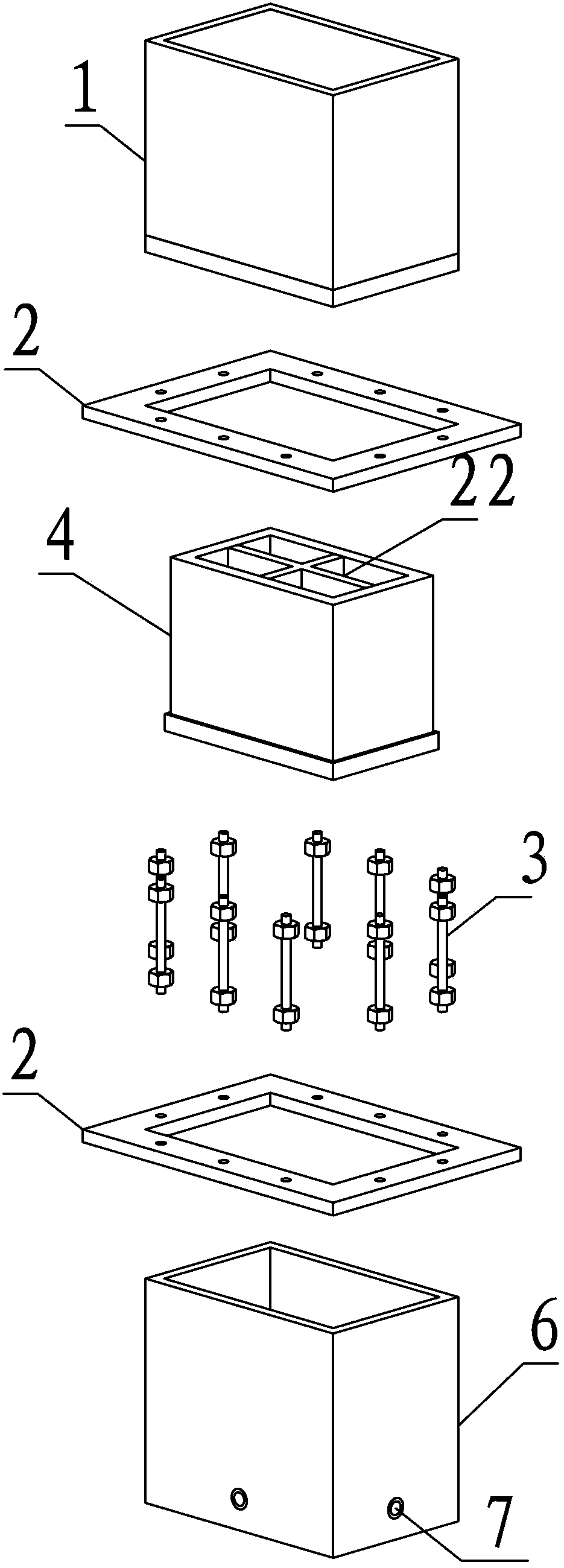

[0037] Such as Figure 1~Figure 6 , the parts mainly involved in the present invention are: hanging column 1, temporary connecting ring plate 2, temporary connecting rod 3, piston 4 at the bottom of the hanging column, high-strength steel sand 5, unloader 6, pressure relief valve 7, stiffening plate 8, Waist truss upper chord 9, cross stiffening plate at the bottom of the suspender 21, piston cross stiffening plate 22, piston bottom plate 23, flexible sealing material 31, pressure relief valve plugging steel bar 32, φ32 steel bar connector 41, threaded steel bar 42, nut 43 .

[0038] The overall building mentioned in this embodiment has a total construction area of 212,882 square meters. The tower has 62 floors above ground and 4 floors underground. The total height of the structure is 292.95 meters. The structure type of the tower i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com