Flow and pressure control valve

A flow control valve, flow pressure technology, applied in the direction of fluid pressure actuators, multi-way valves, valve devices, etc., can solve the problems of inability to ensure stable oil pressure, inability to stabilize the movement speed of actuators, and damage to mechanical device components , to achieve the effect of simple structure, low vibration and noise, and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

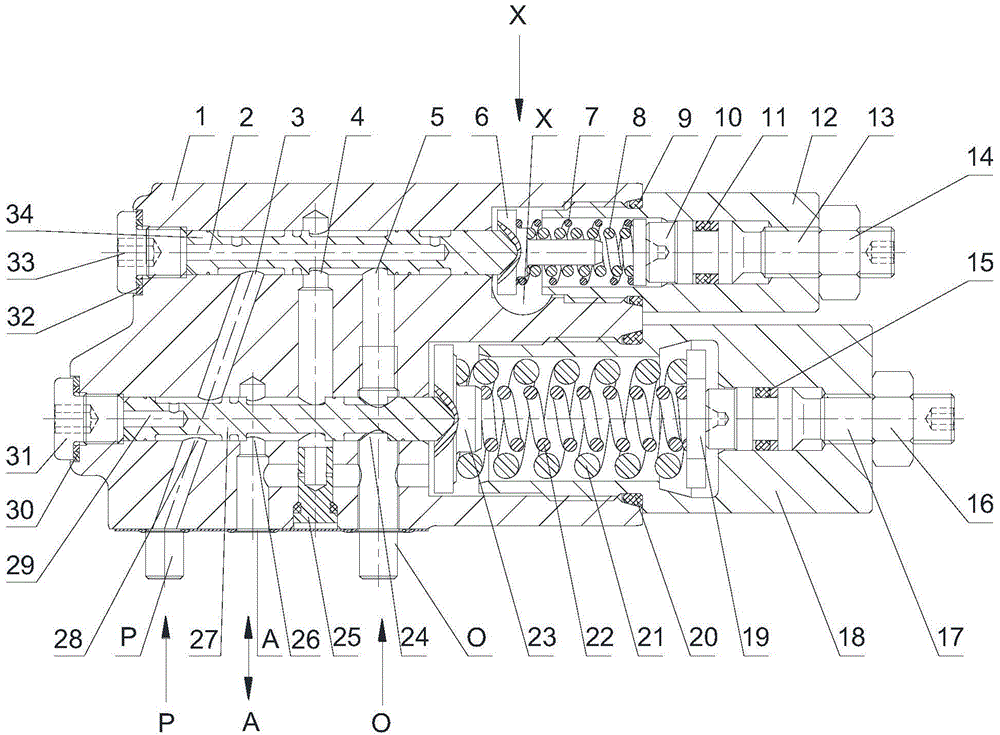

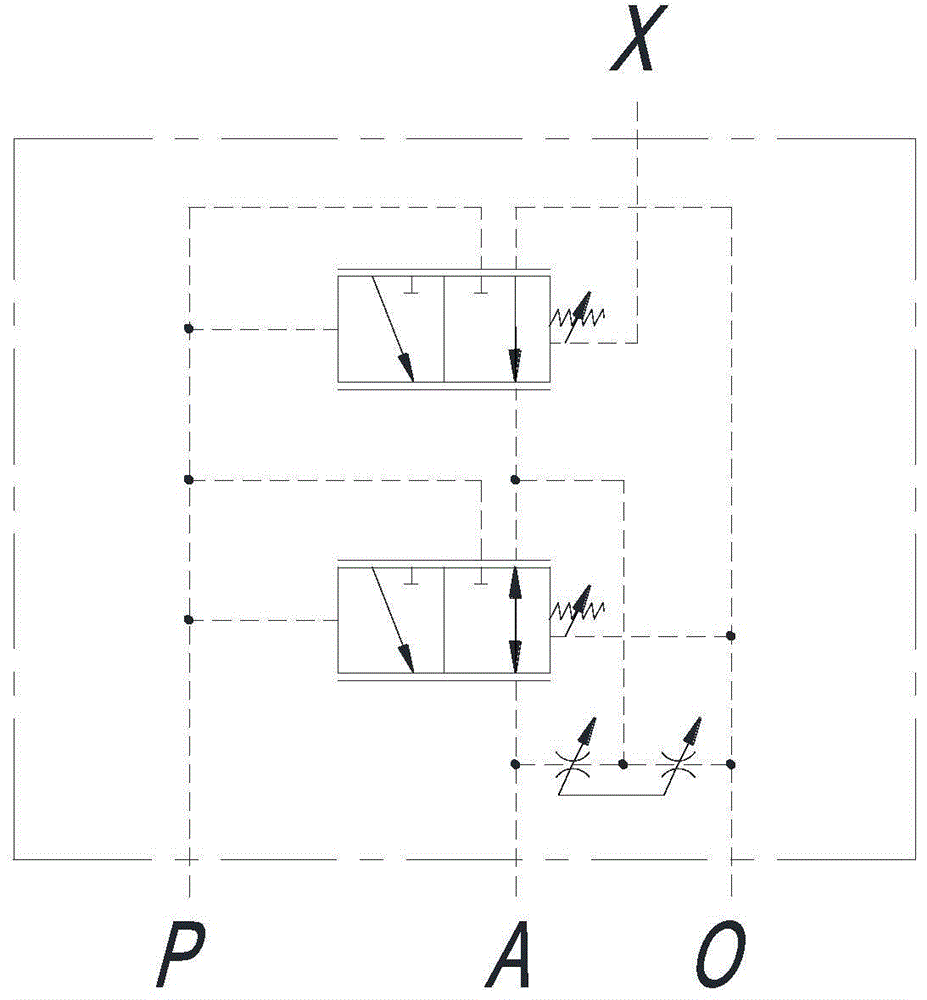

[0021] Such as figure 1 As shown, the present invention includes: valve body 1, first blind hole 2, first left working port 3, first middle working port 4, first right working port 5, first left spring seat 6, first large spring 7 , the first small spring 8, the first O-ring 9, the first right spring seat 10, the second O-ring 11, the first valve cover 12, the first pressure regulating bolt 13, the first pressure regulating nut 14, the fourth O-ring 15, second pressure regulating nut 16, second pressure regulating bolt 17, second valve cover 18, second right spring seat 19, third sealing ring 20, second large spring 21, second small spring 22, Second left spring seat 23, second right working port 24, adjustable two-way throttle valve 25, second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com