Servo fast forging valve and servo valve system

A servo valve and servo motor technology, applied in servo motor components, multi-port valves, valve devices, etc., can solve problems such as servo quick forging valve string oil, etc., and achieve the effect of smooth opening curve, fast switching speed and high frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037]The specific implementation of this embodiment is as follows:

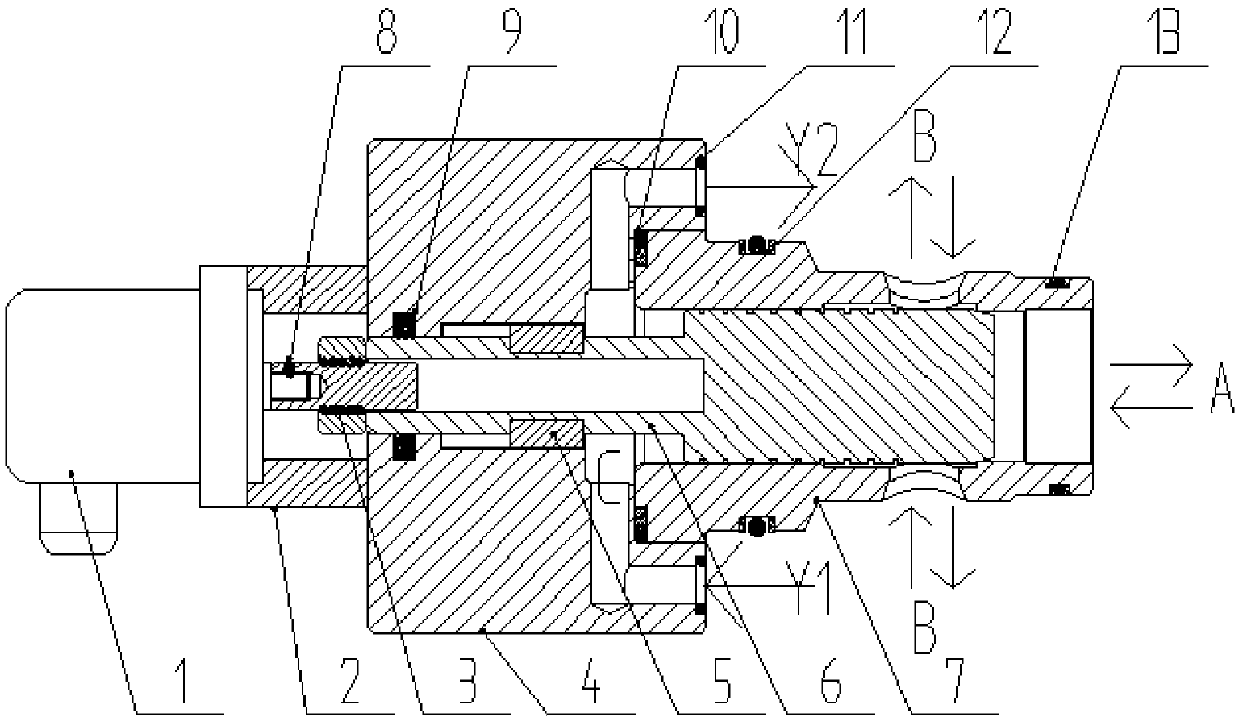

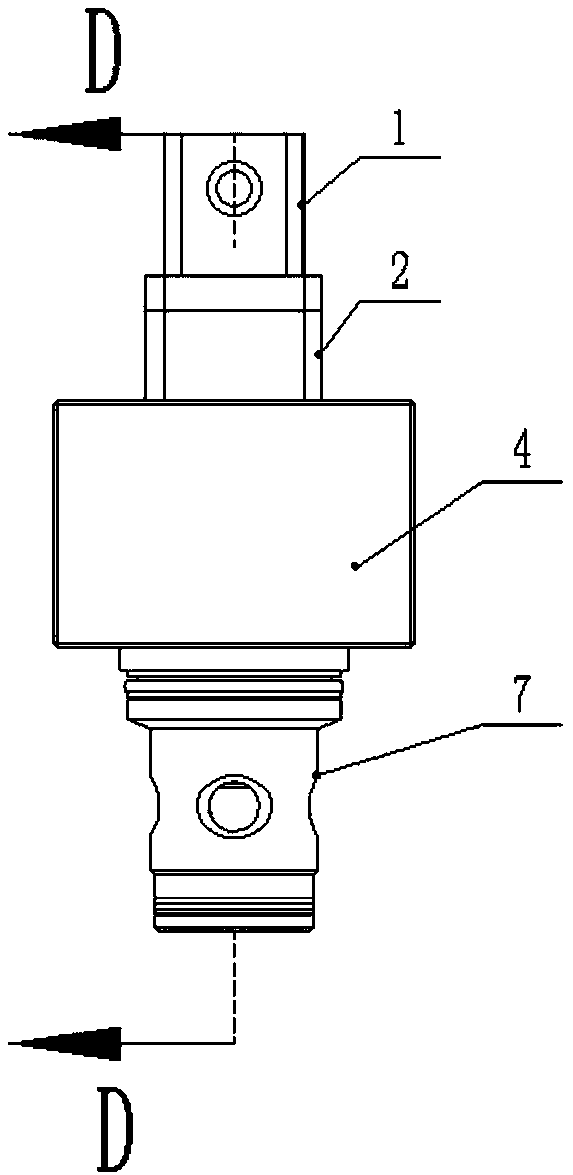

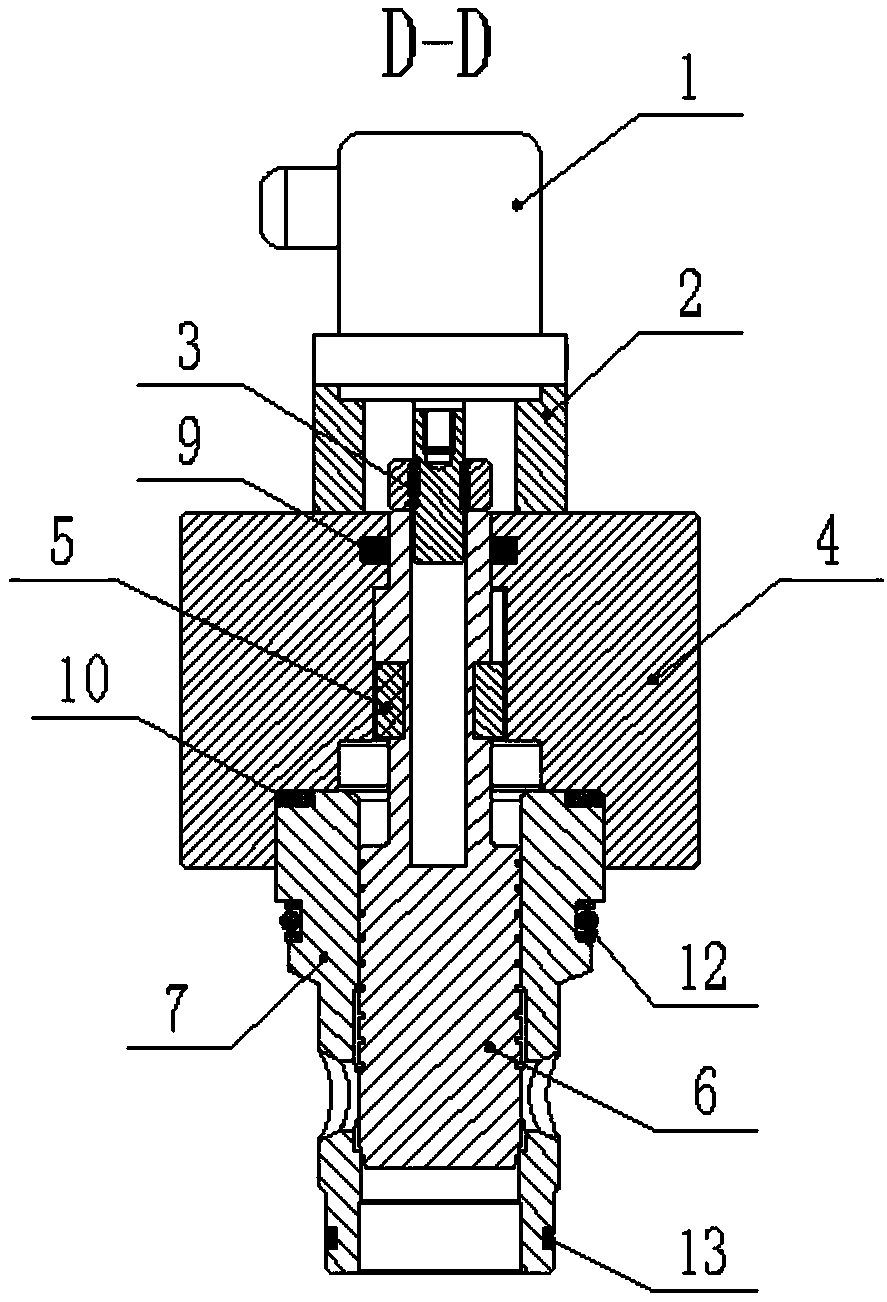

[0038] Such as figure 1 As shown in -4, a servo fast forging valve provided by this embodiment includes a servo motor 1, a bracket 2, a guide lubricating cover plate 4 and a valve sleeve 7 arranged in sequence from left to right, the bracket 2, and a guide lubricating cover plate 4 A ball screw assembly 3 is installed through the center of the valve sleeve 7, the output shaft of the servo motor 1 is threadedly connected with the lead screw of the ball screw assembly 3, and the guide lubricating cover plate 4 is tightly matched with the end face of the valve sleeve 7. connected as one structure;

[0039] The valve sleeve 7 is provided with a servo valve core 6, and the servo valve core 6 is connected with the bearing bolts of the ball screw assembly 3 as an integral structure;

[0040] The leading screw can drive the bearing of the ball screw assembly 3 to move up and down to regulate the opening and closin...

Embodiment 2

[0053] A servo valve system provided in this embodiment includes the above-mentioned servo quick forging valve, and also includes a programmable logic controller;

[0054] When there is high-pressure oil in chamber A, the programmable logic controller sends an instruction to make the servo motor 1 rotate clockwise according to the preset sinusoidal curve, so that the valve core moves upward and the chamber A communicates with chamber B, and the hydraulic oil flows from A Cavity flows to Cavity B;

[0055] When there is high-pressure oil in chamber B, the programmable logic controller sends an instruction to make servo motor 1 rotate clockwise according to the sinusoidal curve set in advance, so that the valve core moves upward, and chamber B communicates with chamber A, and the hydraulic oil flows from Chamber B flows through chamber A.

[0056] Such as figure 1 As shown in -4, the servo fast forging valve includes a servo motor 1, a bracket 2, a guide lubricating cover 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com