Patents

Literature

45results about How to "Stable pressure relief" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

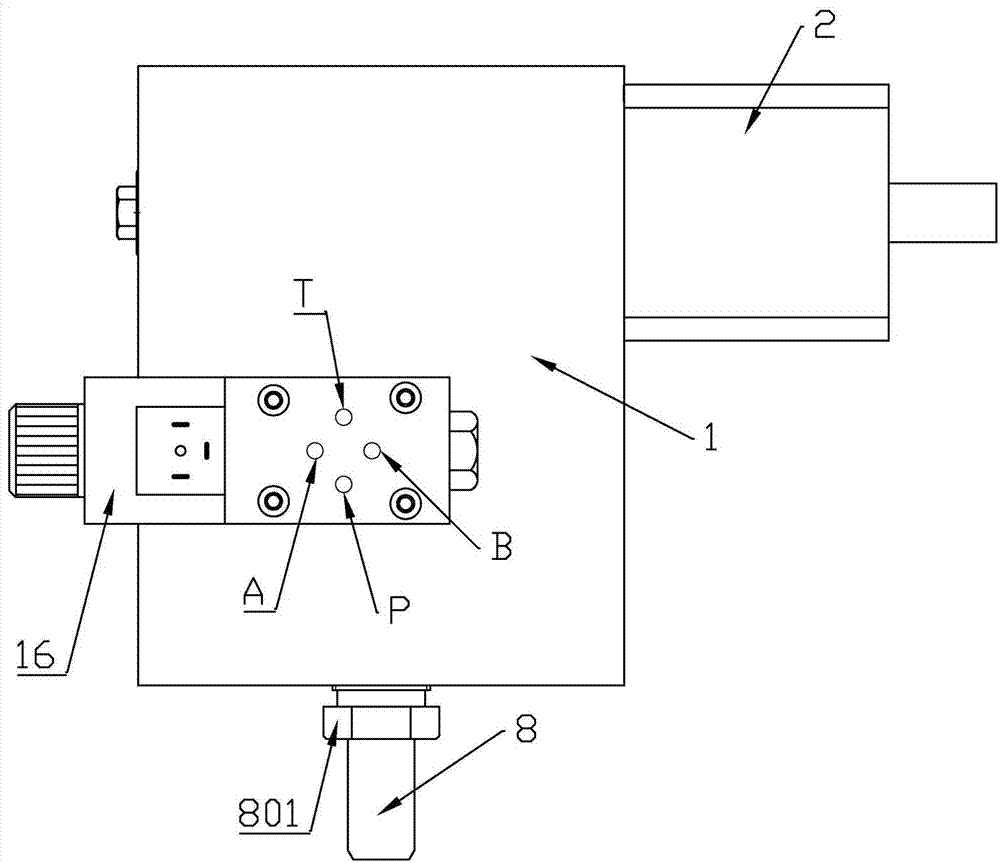

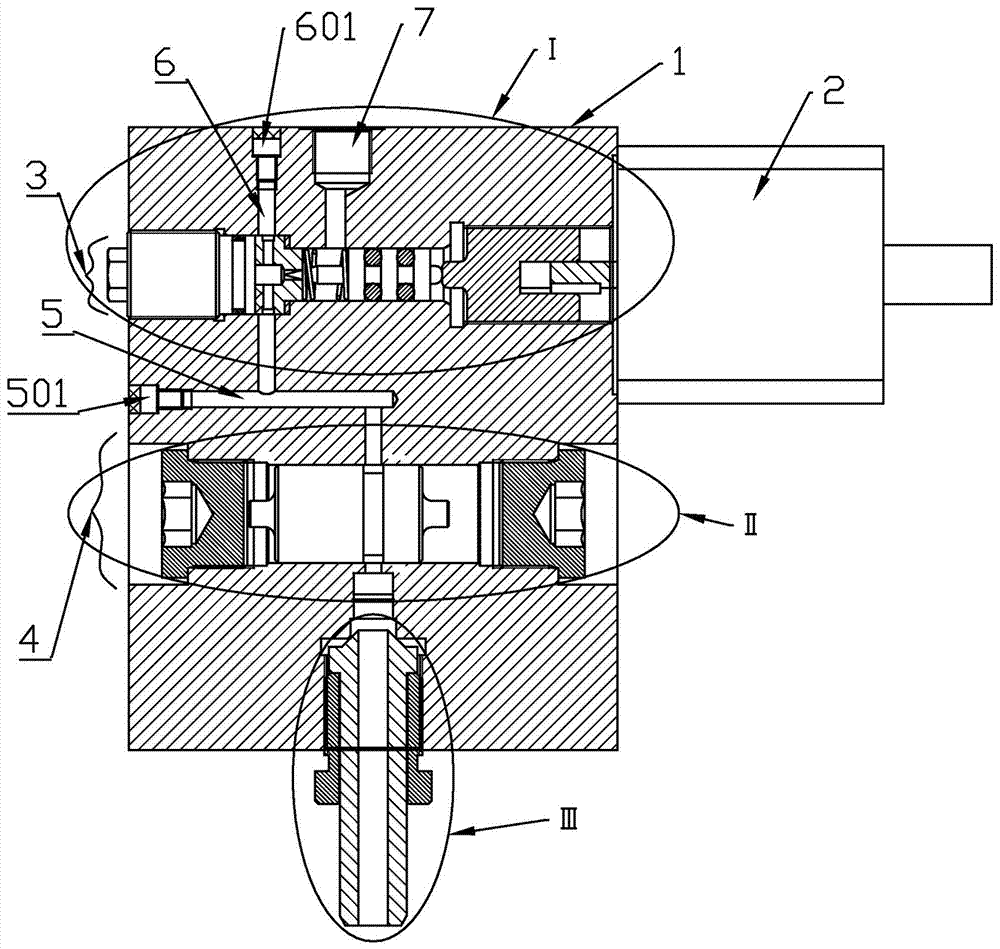

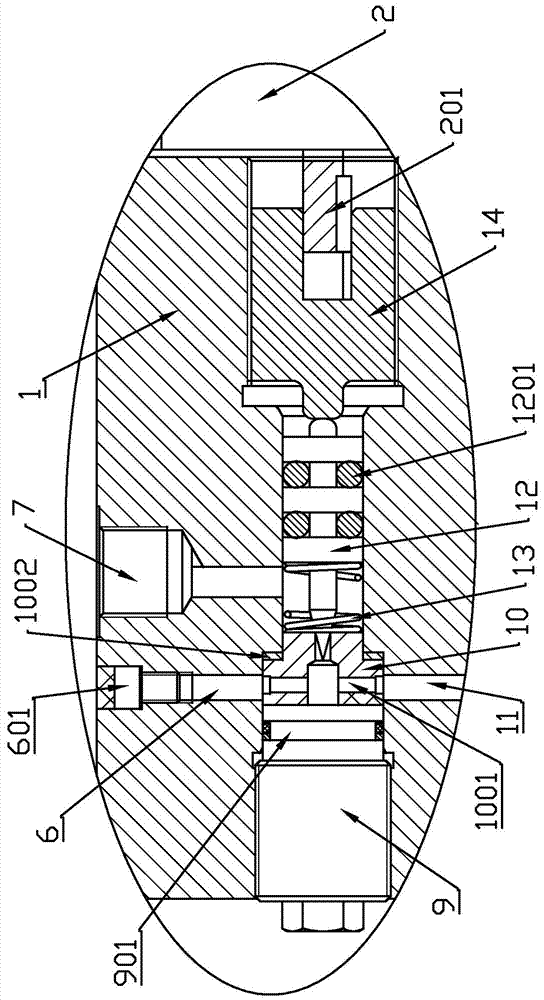

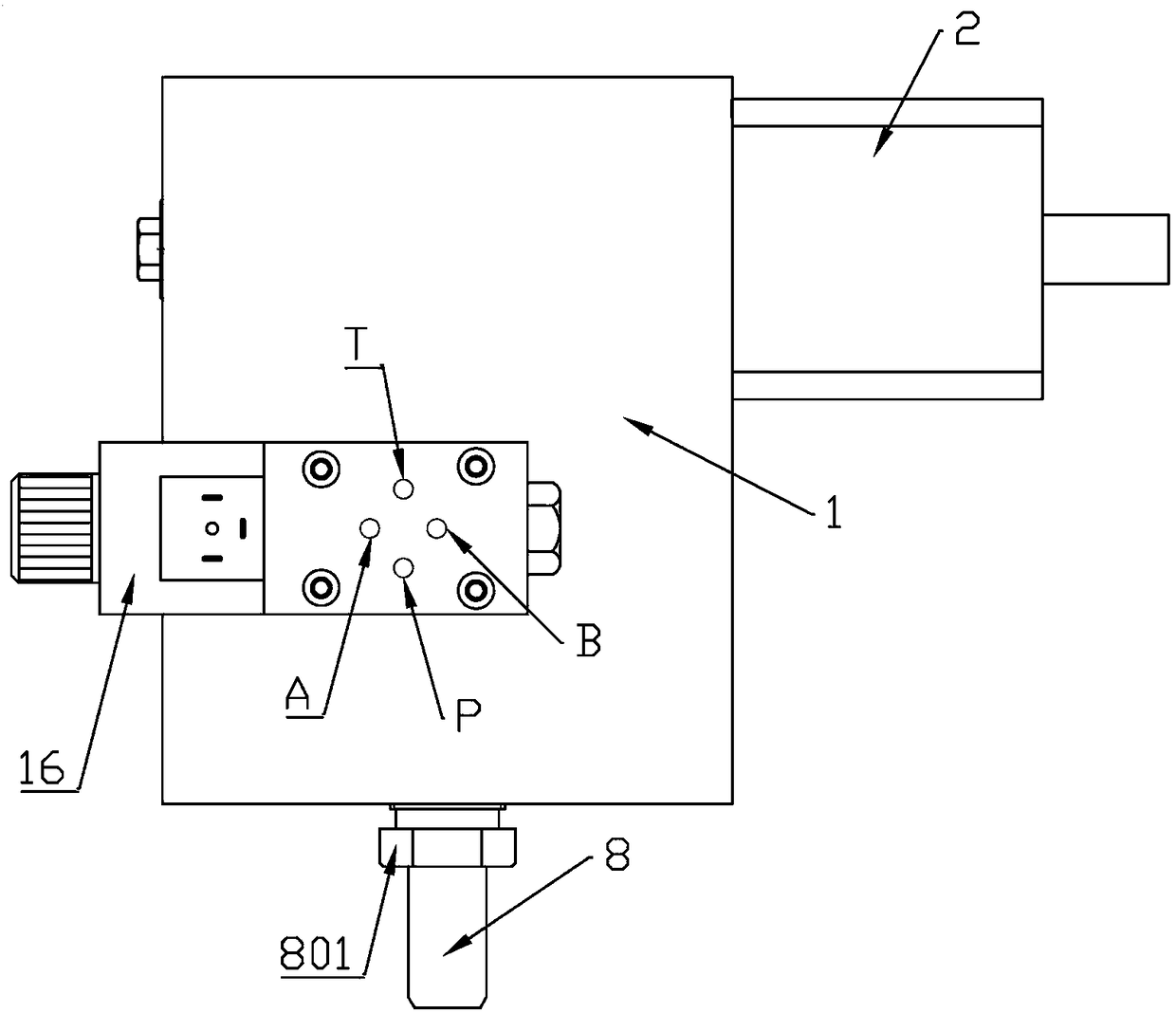

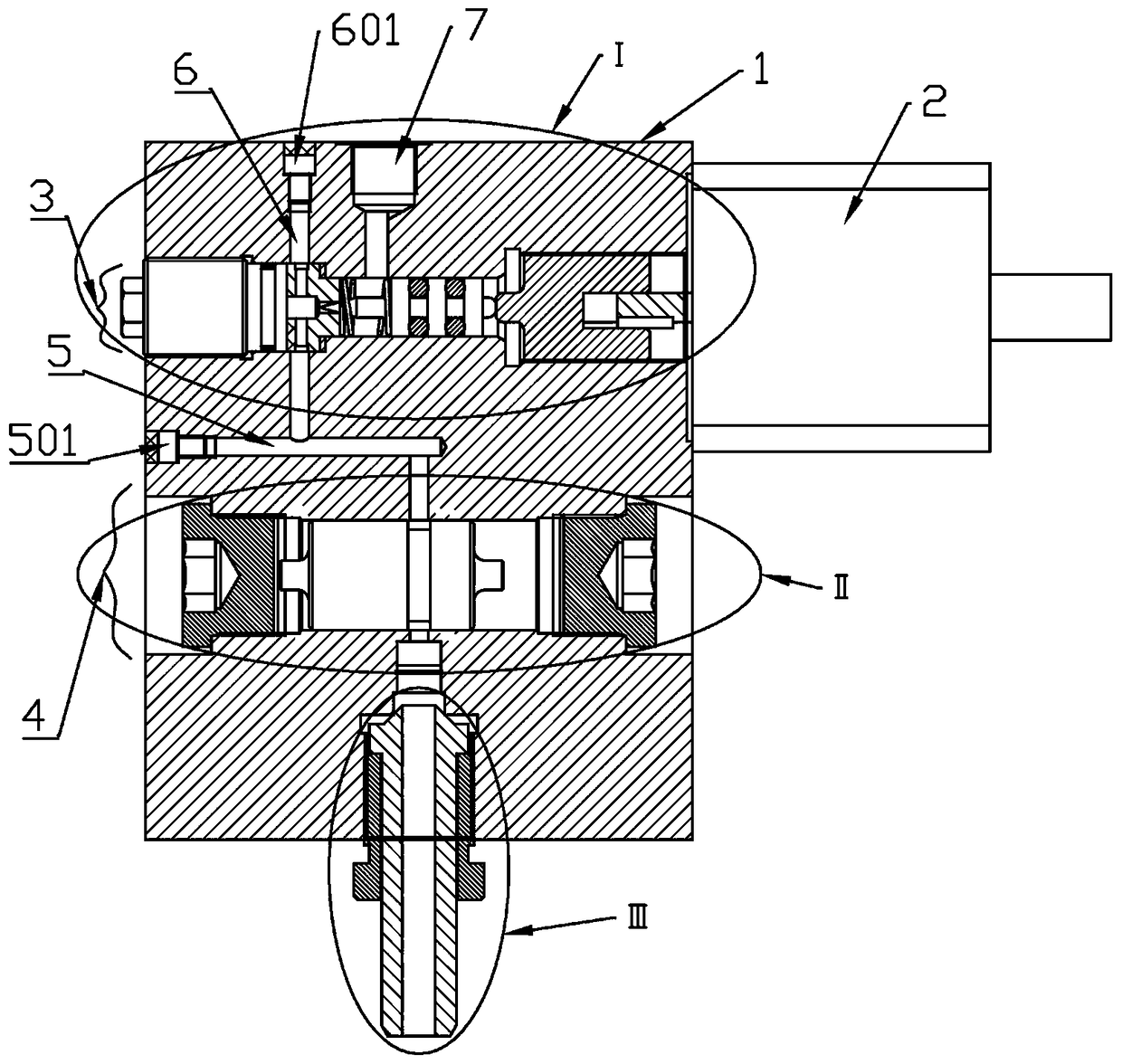

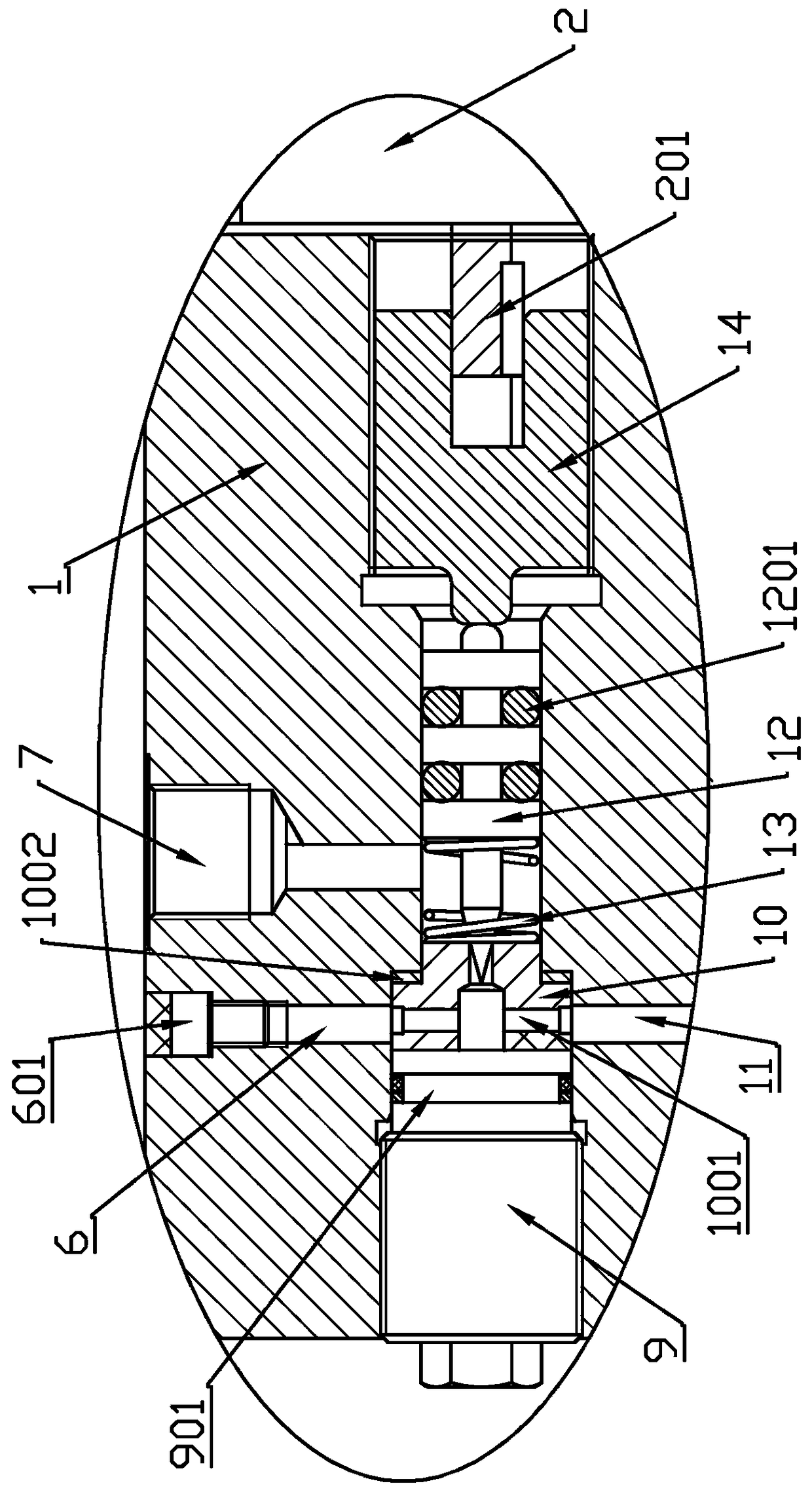

Quick hydraulic control device of hydraulic injection molding machine

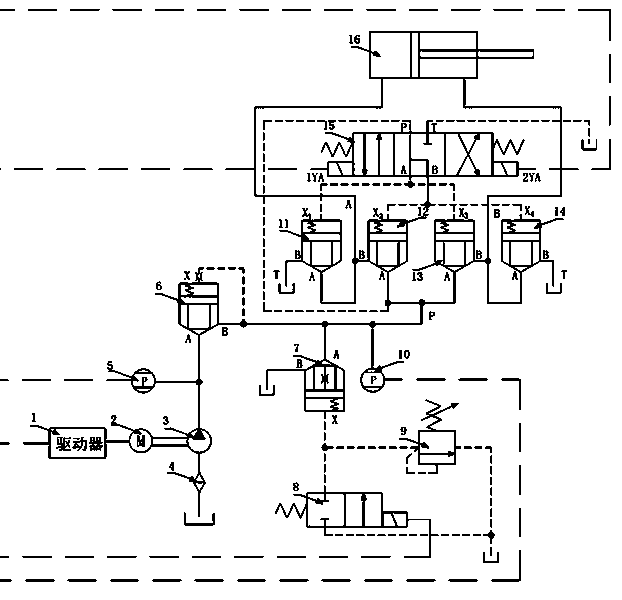

The invention discloses a quick hydraulic control device of a hydraulic injection molding machine. A control signal of a servo driver is connected with a driver; the driver is connected with a servo motor; the servo motor drives an oil pump to run; an inlet of the oil pump is connected with a filter; an oil tank is arranged below the filter; an oil pump pressure sensor is mounted at an outlet of the oil pump; a valve opening A of a unidirectional cartridge valve is connected with the outlet of the oil pump; a valve opening B of the unidirectional cartridge valve is connected with a valve opening A of a pressure valve insertion piece; a valve opening B of the pressure valve insertion piece is connected with the oil tank; a valve opening P of a direction cartridge valve is connected with the valve opening A of the pressure valve insertion piece; a valve opening T of the direction cartridge valve is connected with the oil tank; the valve openings A and B of the direction cartridge valve are connected with two cavity valve openings of an oil cylinder; and an oil cylinder pressure sensor is connected with the valve opening P of the direction cartridge valve. The quick hydraulic control device of the hydraulic injection molding machine guarantees long service lives and stable work of the motor and the oil pump and ensures that a hydraulic system works normally; a high-flow working condition is met; furthermore, the quick hydraulic control device is high in response speed and high in control precision and ensures that the injection molding speed is high and different working stages are switched; and the production efficiency and the precision of a product are improved.

Owner:ZHEJIANG UNIV

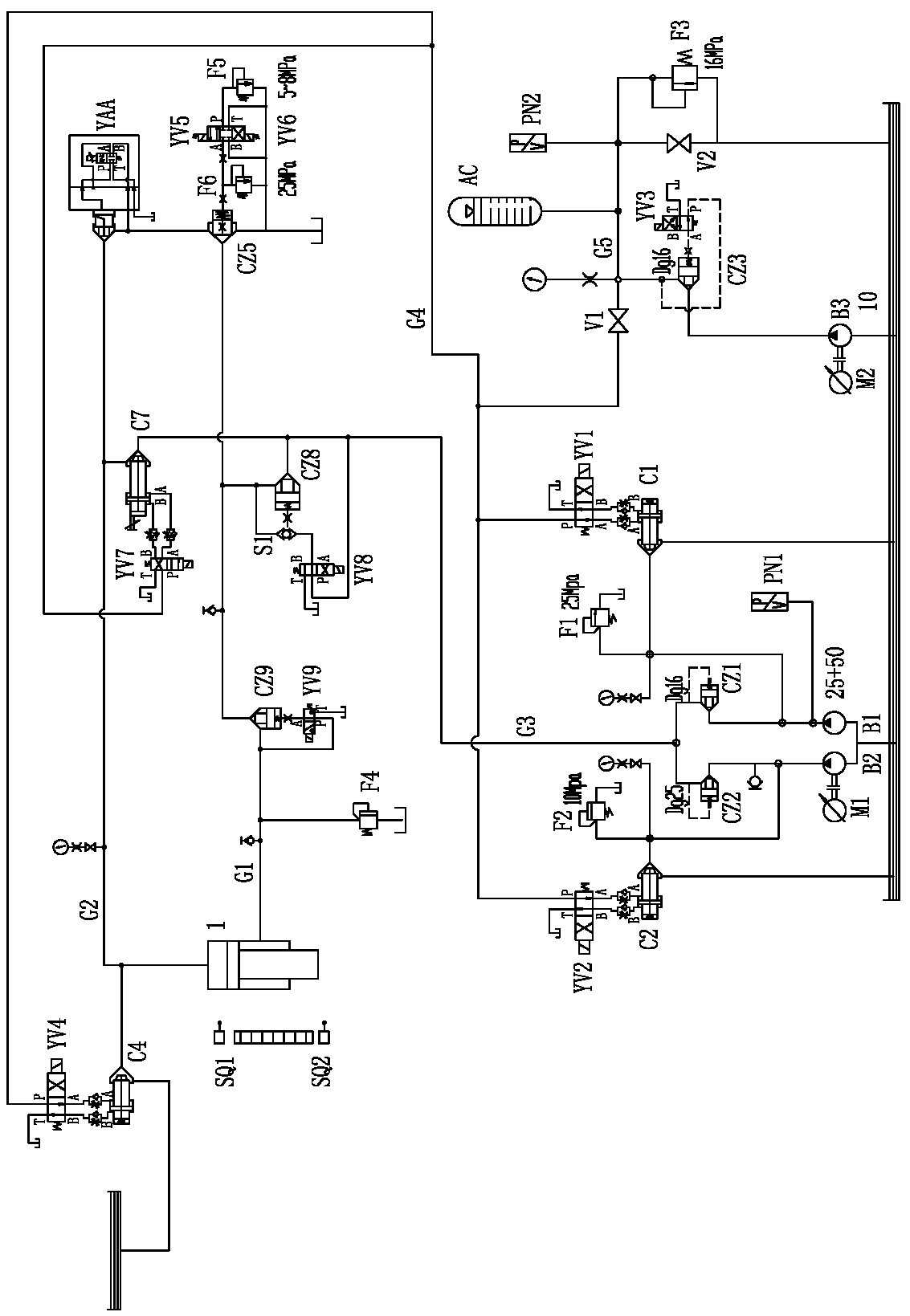

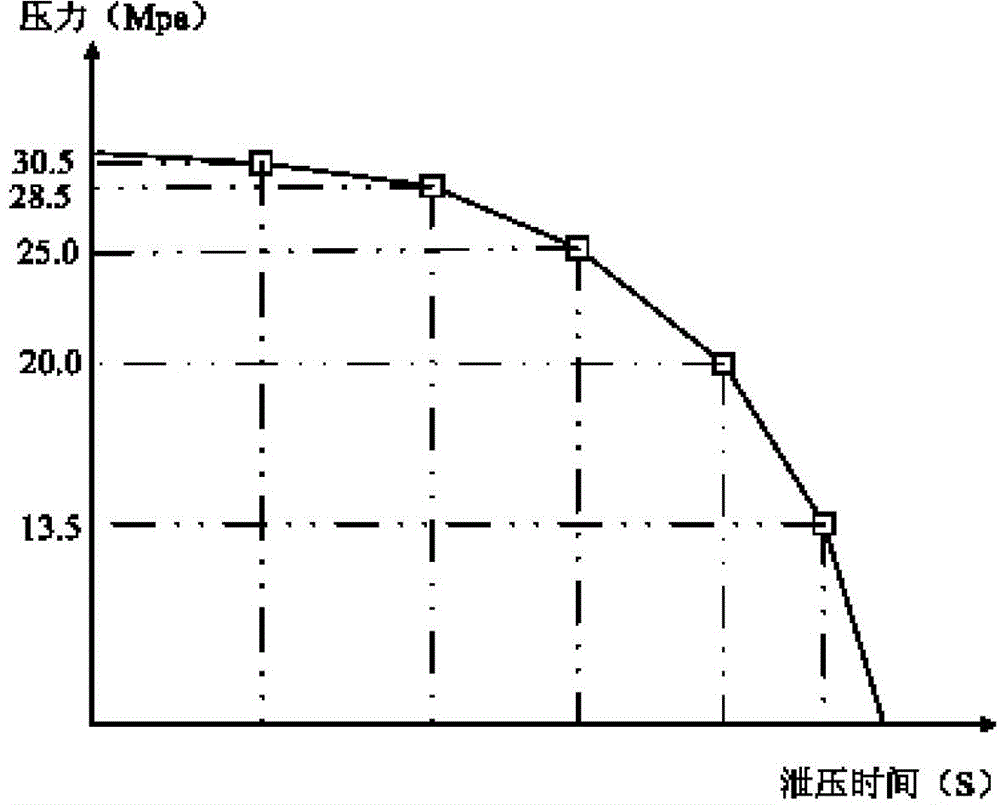

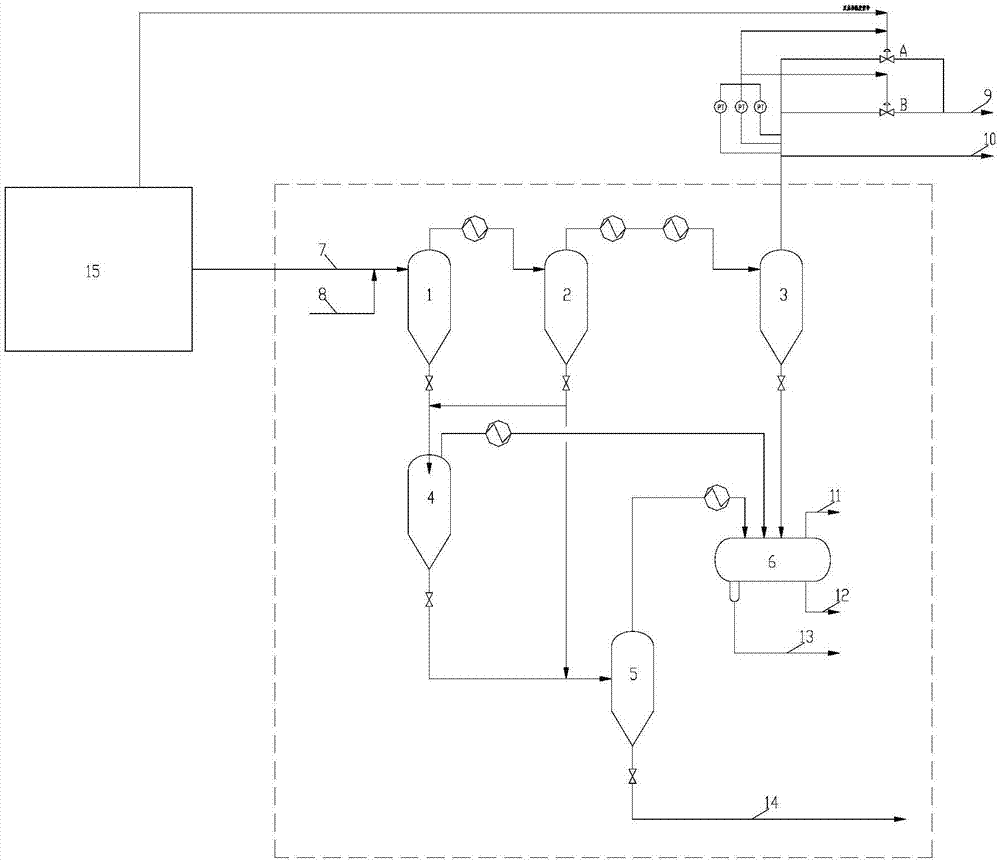

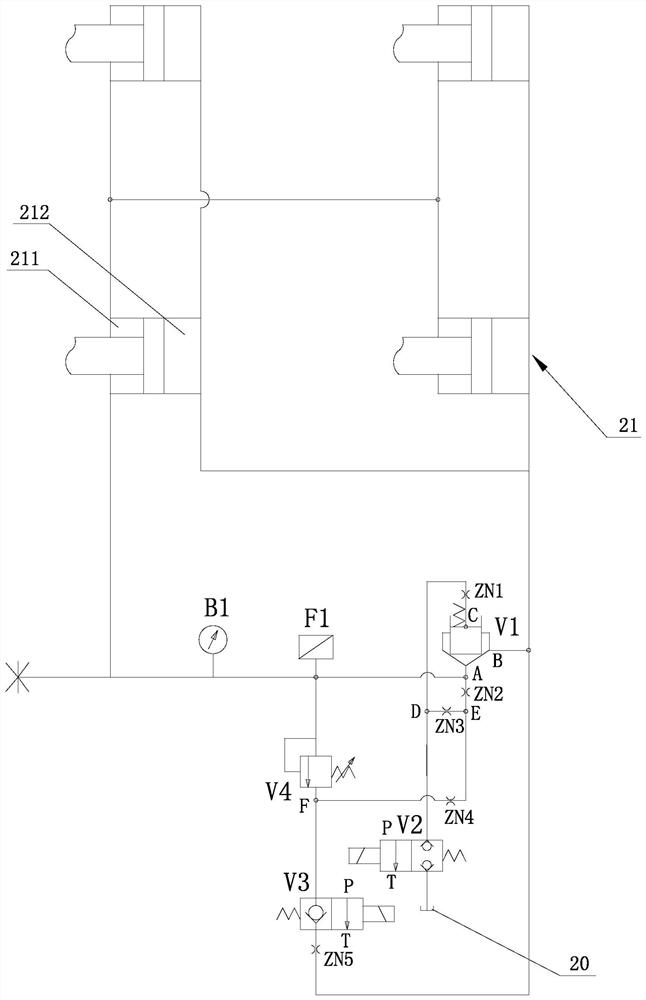

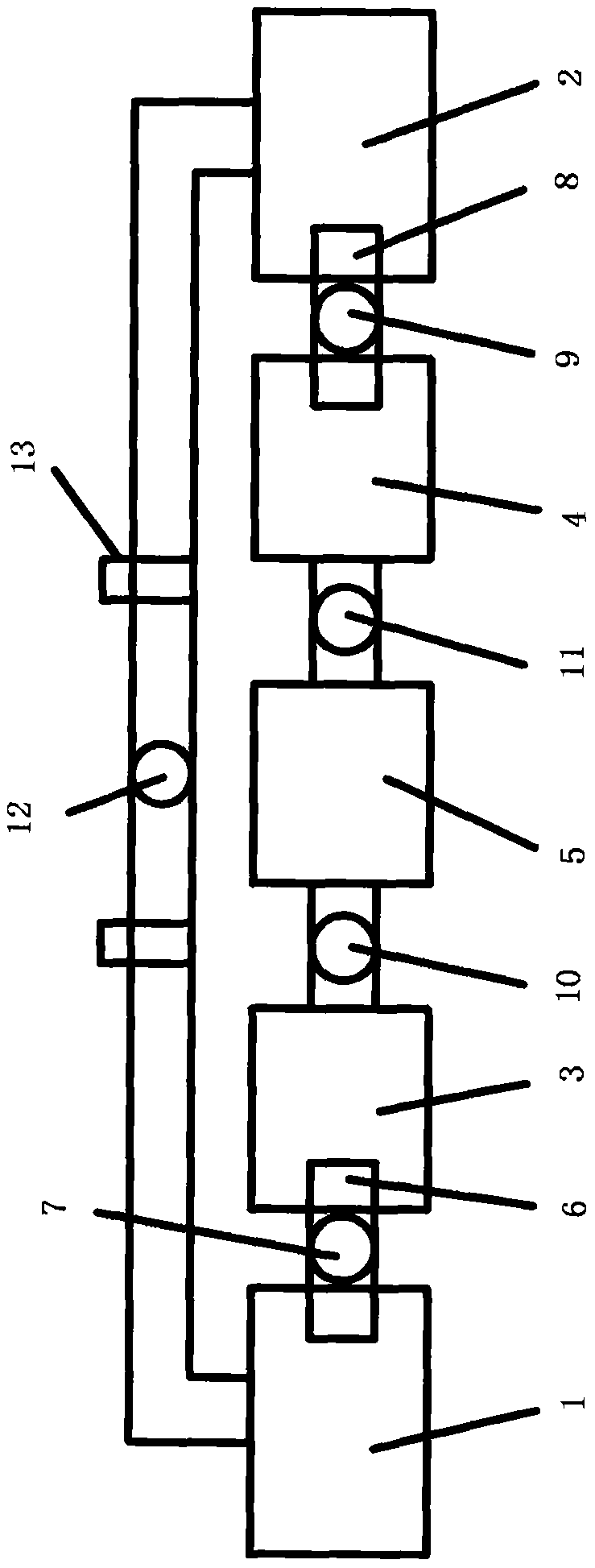

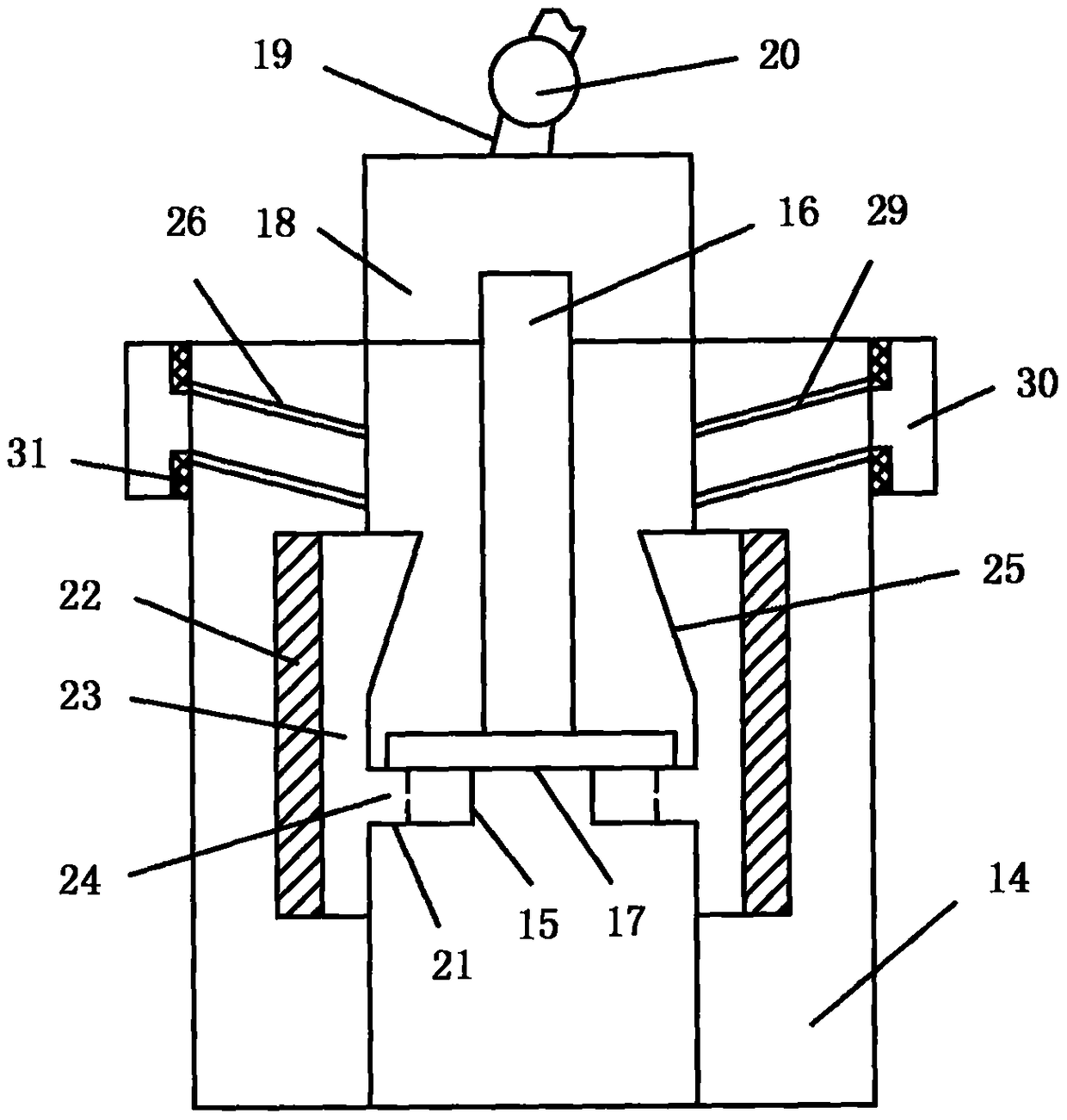

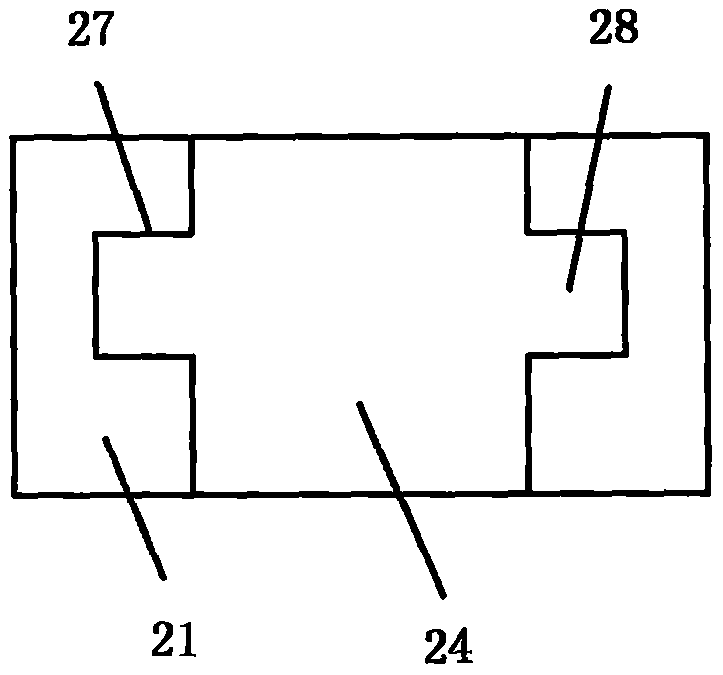

Precision pressure control system and hydraulic machining method of servo pump control hydraulic machine

ActiveCN108561346AEliminate pressure differentialsReliable return to seatServomotorsServometer circuitsControl systemWork cycle

The invention relates to a precision pressure control system and a hydraulic machining method of a servo pump control hydraulic machine. The hydraulic machine comprises a medium-flow servo pump and alarge-flow servo pump driven by a servo motor, outlet pipelines of two pumps are connected with a main cylinder upper cavity oil way through a seventh dynamic valve, and the main cylinder upper cavityoil way is further connected with an oil tank through a fourth dynamic valve and a proportional valve; a main cylinder lower cavity pipeline is connected with an outlet of a ninth cartridge valve, aninlet of the ninth cartridge valve is connected with the oil tank through a fifth cartridge valve and an eighth cartridge valve, the fifth cartridge valve supplies supporting force during deceleration and pressurization through an overflow valve, and the eighth cartridge valve is turned on during the return stroke. In hydraulic machining, each working cycle comprises the following actions of automatic pressure compensation for an energy accumulator, pressure supplementation stopping for the energy accumulator, rapid descending of a sliding block, deceleration pressurizing of the sliding block, pressure maintaining of the sliding block, pressure relief of the sliding block, and return and stopping of the sliding block. The servo driver is switched in two modes of flow control and PID regulation control, stable pressurization of the sliding block is achieved, the phenomenon that a part deforms due to pressurization overshoot is avoided, and pressure relief is stable.

Owner:江苏扬力液压装备有限公司

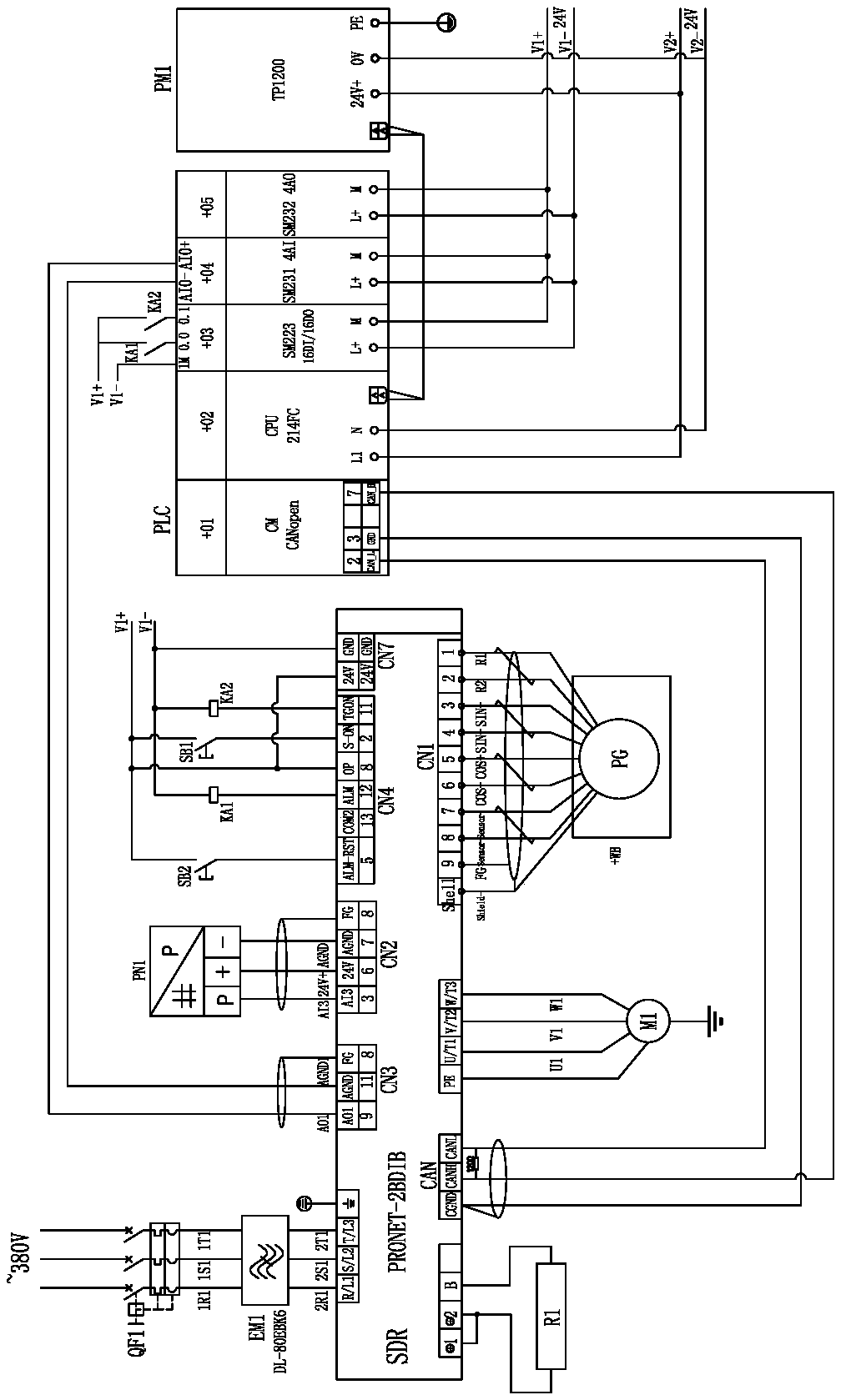

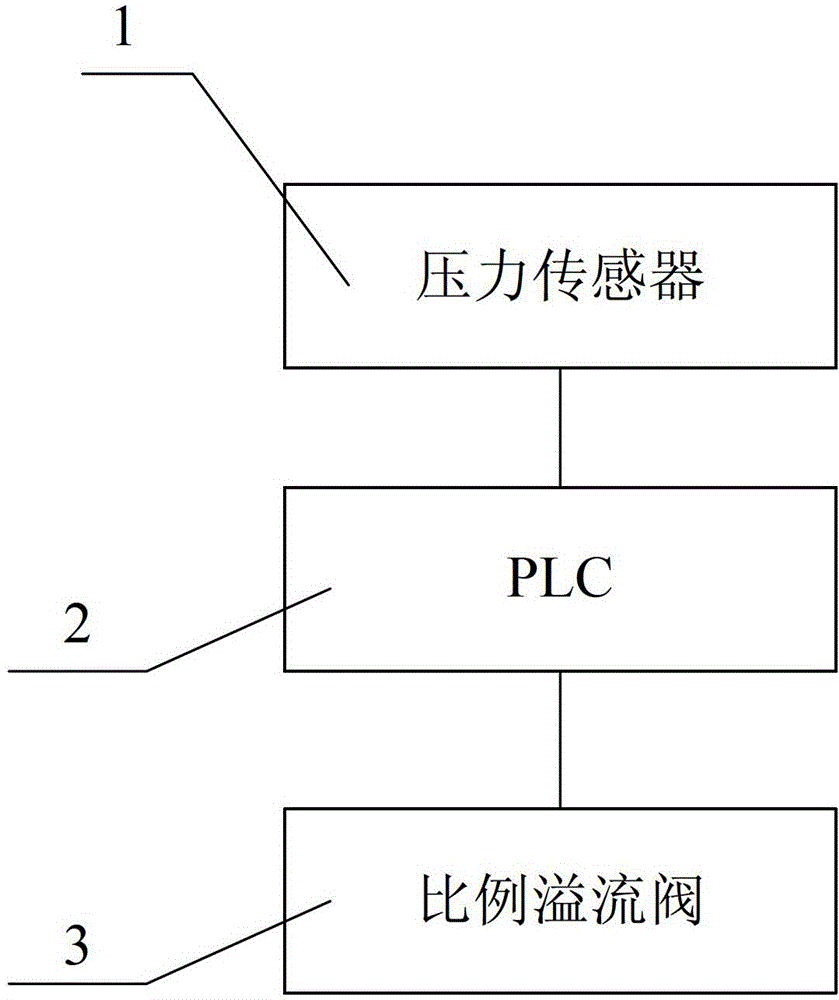

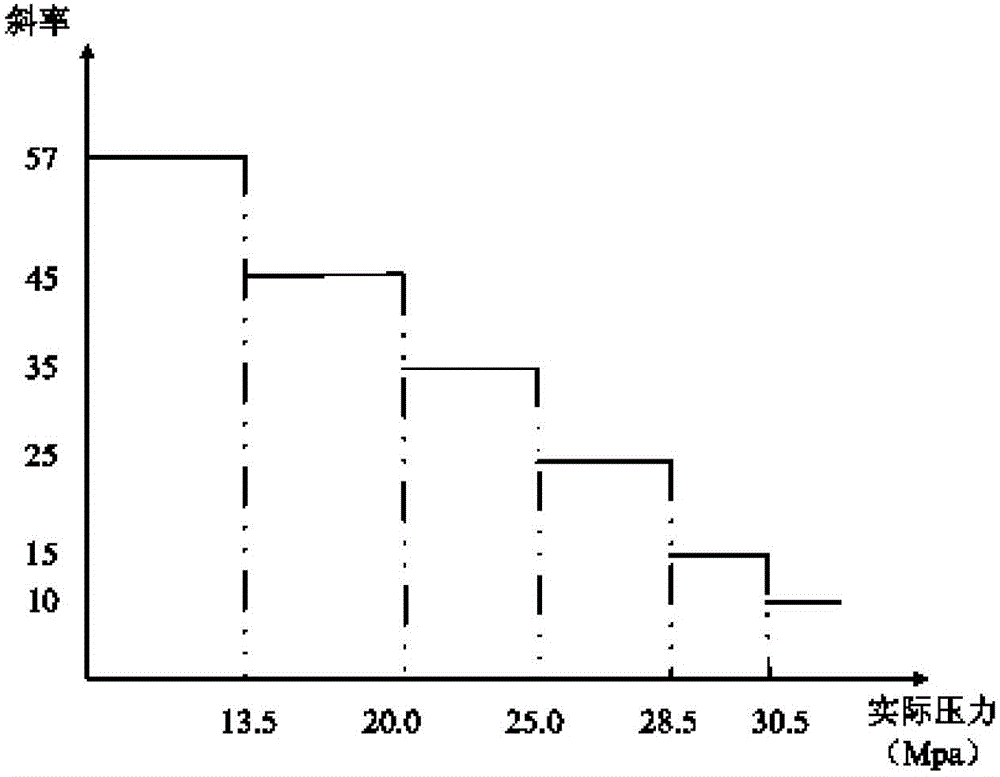

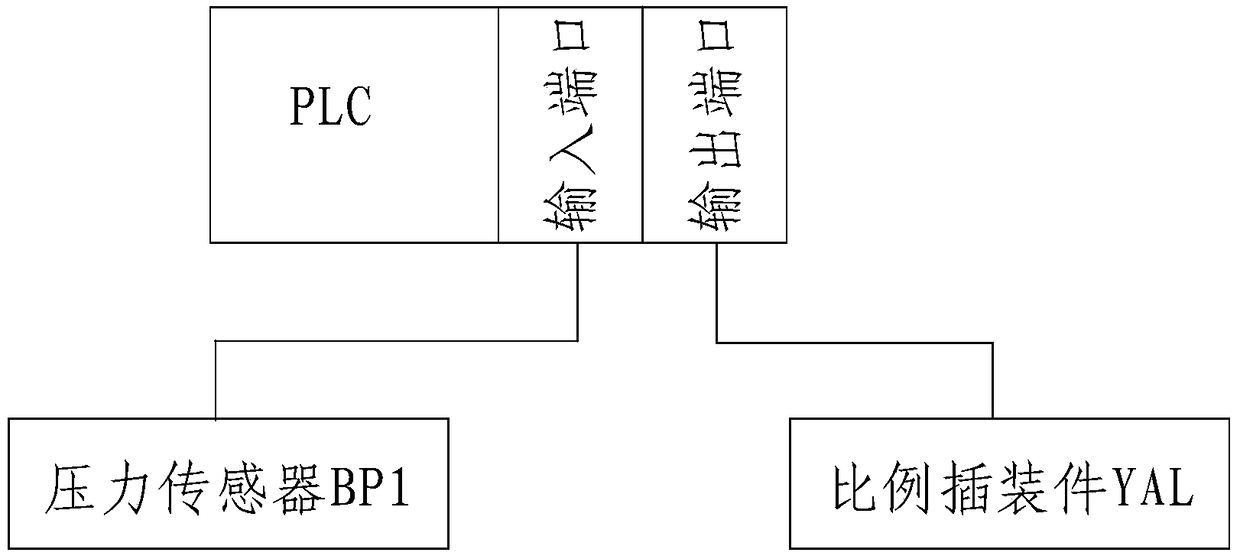

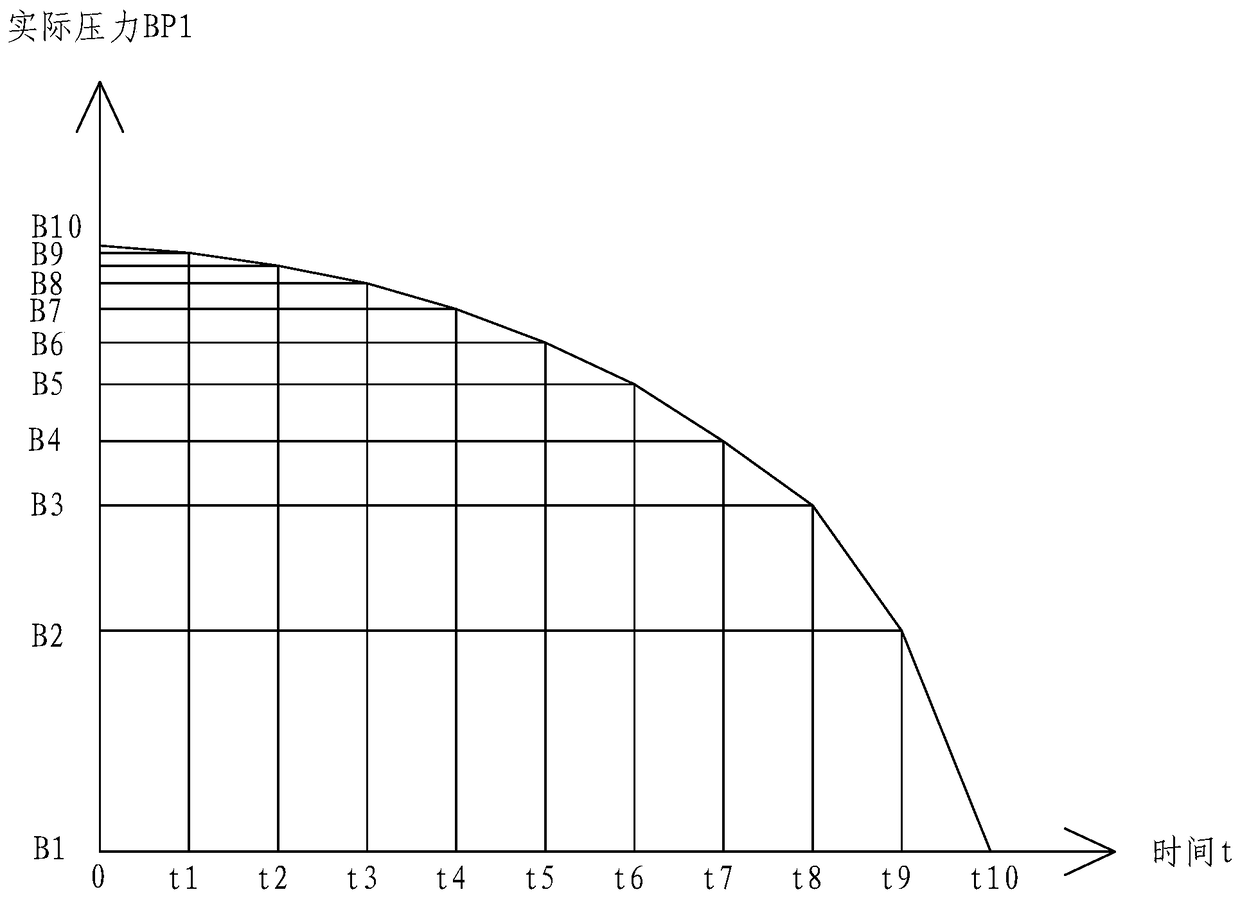

Numerical control hydraulic machine decompression system based on pressure feedback

The invention discloses a numerical control hydraulic machine decompression system based on pressure feedback, and relates to the technical field of hydraulic machines. The numerical control hydraulic machine decompression system comprises a pressure sensor, a programmable logic controller and a proportional overflow valve, wherein the pressure sensor is used for collecting oil pressure data of a slide block main cylinder, the programmable logic controller is used for receiving the oil pressure data, dividing the oil pressure data into sections according to the oil pressure data, and outputting different linear control commands in the different sections, and the proportional overflow valve is used for regulating oil pressure in the slide block main cylinder according to the linear control commands. The pressure sensor is electrically connected with an analog quantity input port of the programmable logic controller. An analog quantity output port of the programmable logic controller is electrically connected with the proportional overflow valve. The decompression of a slide block is controlled continuously in a variable-rate mode by controlling the rate of continuous progressive decrease of the proportional overflow valve according to the corresponding relationship between the oil pressure data of the slide block main cylinder and the slope of the ramp function of the proportional overflow valve. Therefore, the aims of high-pressure and small-slope stable decompression and low-pressure and large-slope rapid decompression are achieved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

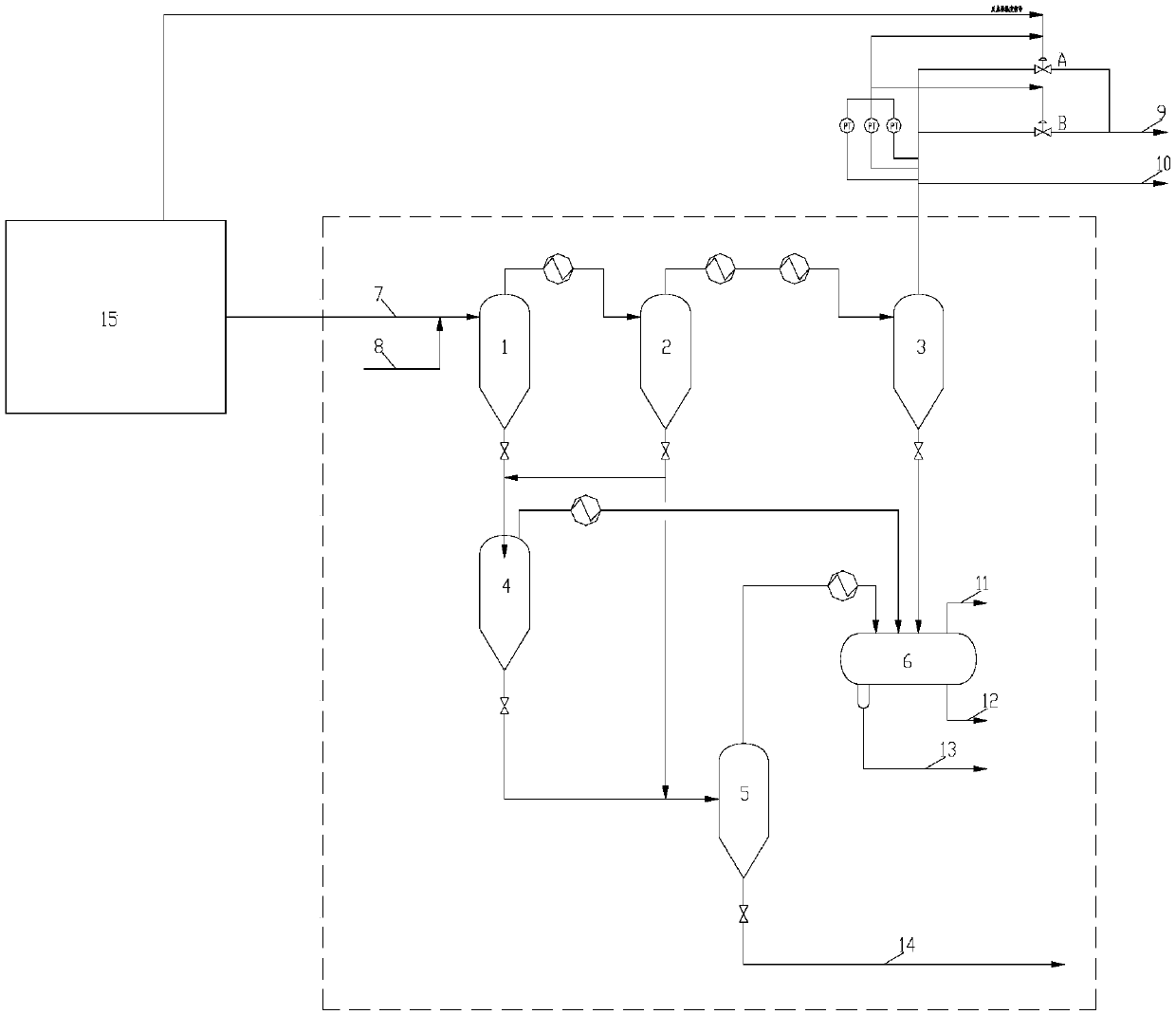

Temperature and pressure control method for hydrogenation process and design method and application of temperature and pressure control method

ActiveCN106957675AStable pressure reliefLow reaction pressureHydrocarbon oil crackingHydrocarbon oils treatmentEmergency treatmentHydrogenation reaction

The invention relates to a temperature and pressure control method for a hydrogenation process and a design method and application of the temperature and pressure control method. A pressure relief point is arranged at an outlet of a separation system behind a reactor or downstream equipment or pipeline connected with the outlet; the pressure in a reaction system is gradually released through opening the pressure relief point, wherein the temperature of the pressure relief point is 30-220 DEG C; two control points are sequentially arranged from low to high; when the temperature exceeds the control point I, the pressure reduction rate is 3-10bar / min; when the temperature exceeds the control point II, the pressure reduction rate is 10-25bar / min; the temperature of the control point I is greater than or equal to 440 DEG C and / or the pressure is greater than or equal to 19MPa; and the temperature of the control point II is greater than or equal to 460 DEG C and / or the pressure is greater than or equal to 21MPa. The invention provides emergency treatment measures such as over-temperature and overpressure of a set of hydrogenation reaction system; the pressure relief point is arranged behind a separator, especially a cold high-pressure separator; and through a new ideal of designing the pressure relief rate and the steps, high-pressure devices such as the reactor and the high-pressure separator can be more stable in the pressure relief process.

Owner:CATECH TECH

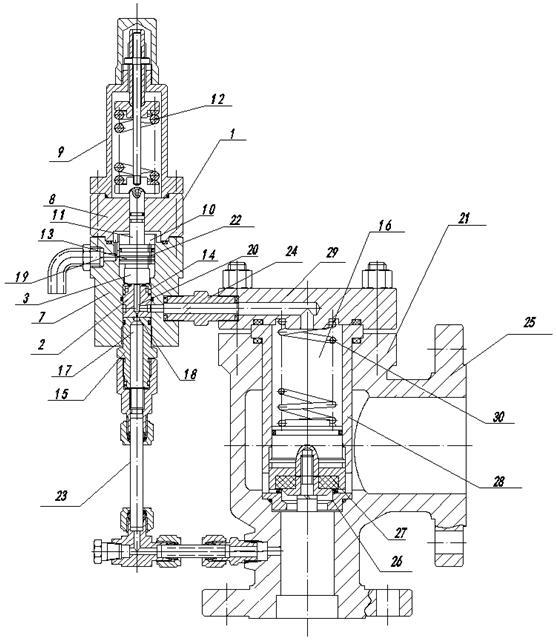

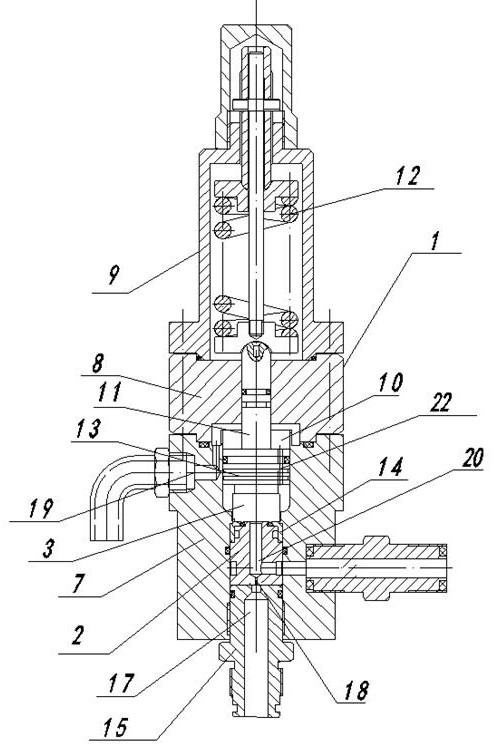

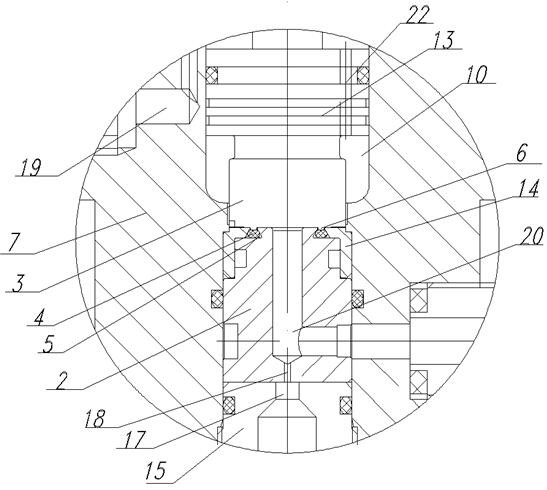

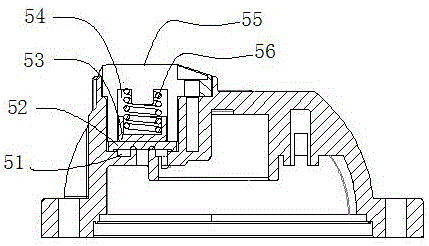

Pilot safety valve

InactiveCN111981168AAvoid impact sheddingSolve the problem of easy damage and high on-site maintenance rateEqualizing valvesSafety valvesEngineeringSafety valve

The invention discloses a pilot safety valve, and relates to the technical field of safety protection equipment for natural gas collection and transmission pipelines. The pilot safety valve disclosedby invention includes a pilot valve and a main valve; the pilot valve includes a pilot valve seat, a pilot valve clack, a pilot valve stem, a lower valve body, an upper valve body and a pilot valve cover; the main valve includes a main valve body, a main valve seat, a main valve core, a main valve sleeve and a main valve cover; a valve seat sealing O-ring is arranged on the end surface of the pilot valve seat; an annular dovetail groove is opened on the end surface of the pilot valve seat; the valve seat sealing O-ring is fixed in the annular dovetail groove; a boss is arranged on the valve clack of the pilot valve; and when closing, the boss at the bottom of the pilot valve clack enters the annular dovetail groove and axially compresses the valve seat sealing O-ring to deform, and the pilot valve closes. The pilot safety valve disclosed by the invention has good sealing performance and low failure rate, can increase the set pressure value of the pilot safety valve to 32 MPa, and has the characteristics of high-precision discharge, small return pressure, and obvious bursting effect.

Owner:四川长仪油气集输设备股份有限公司

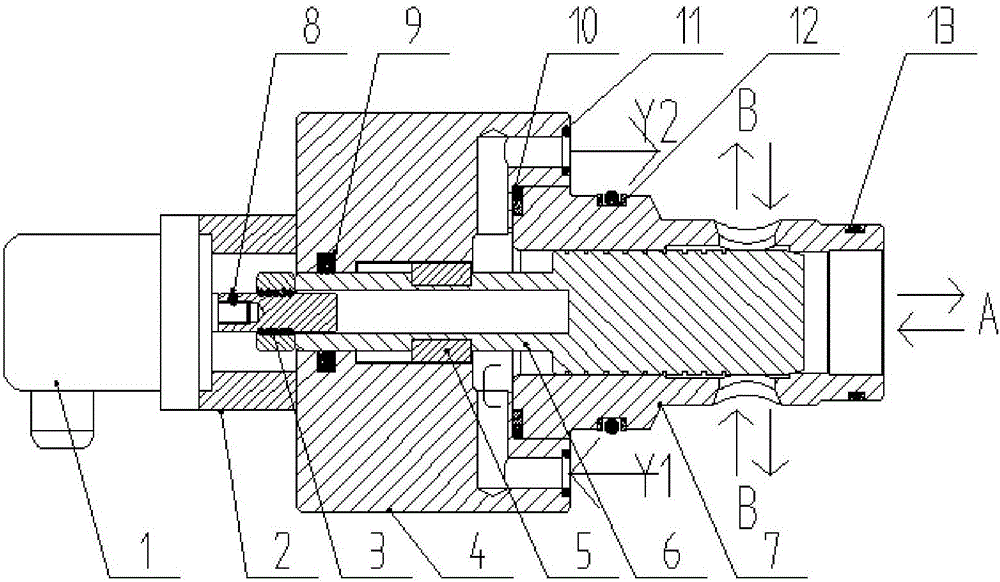

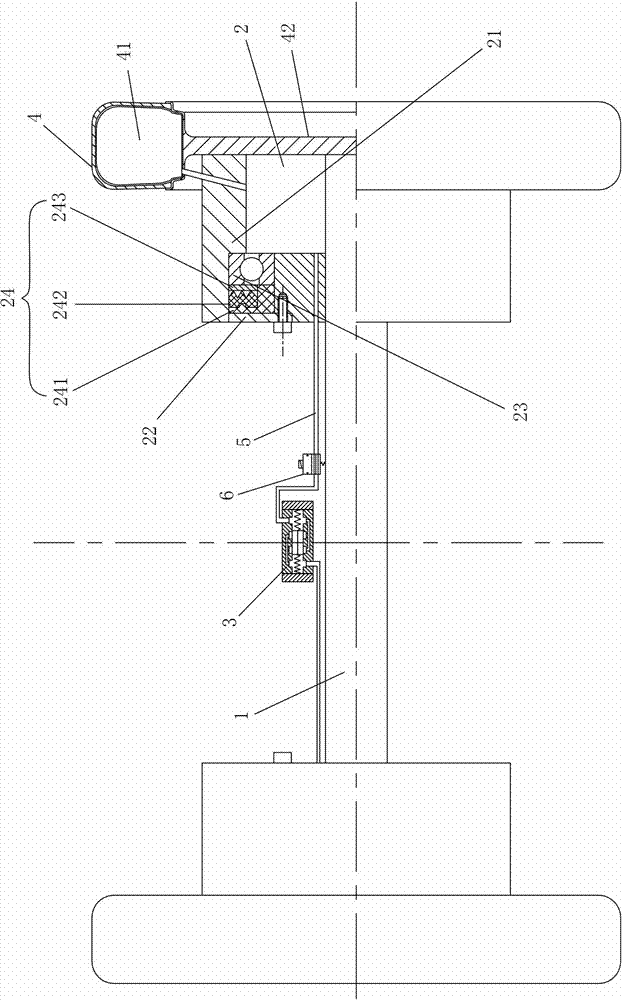

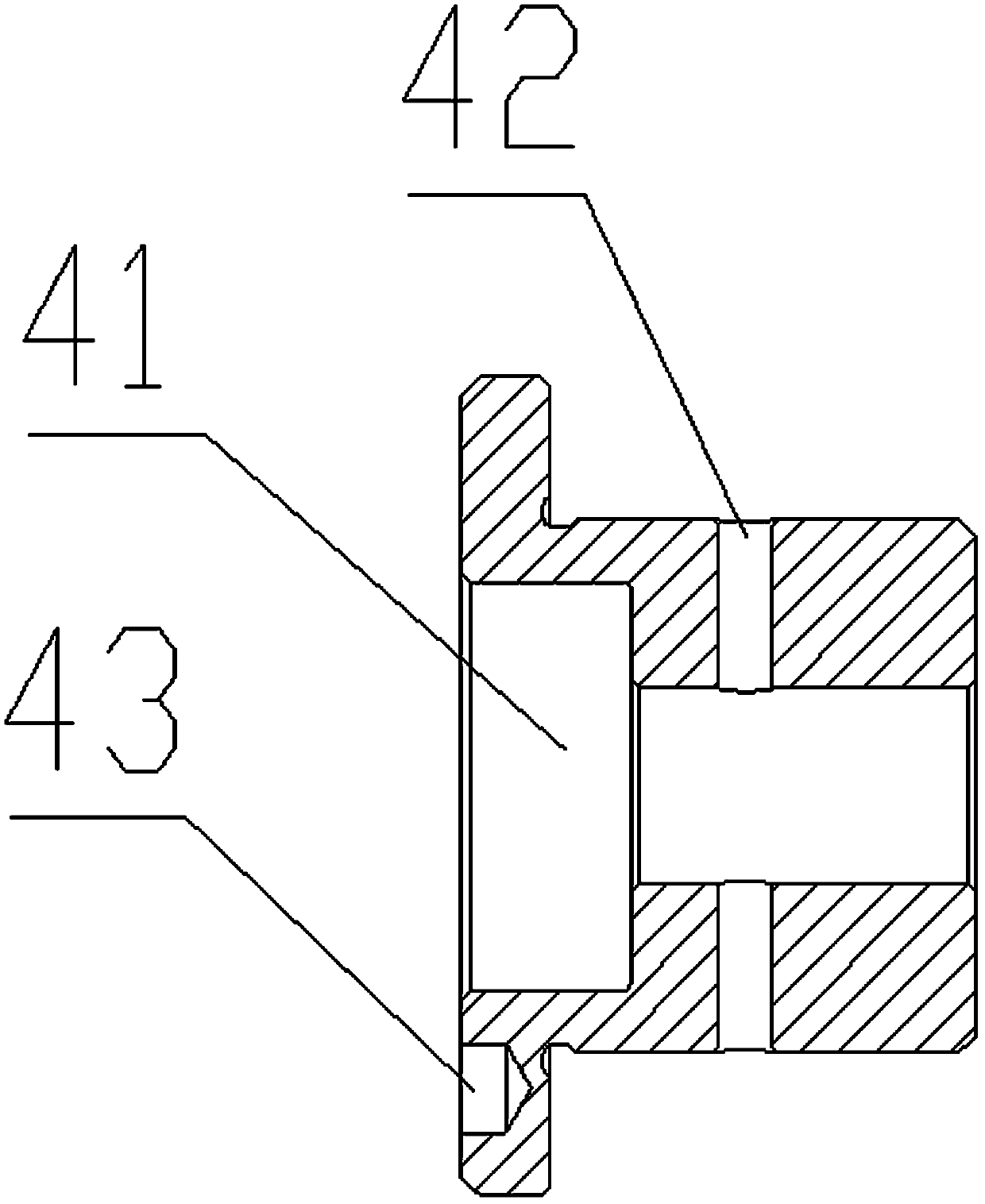

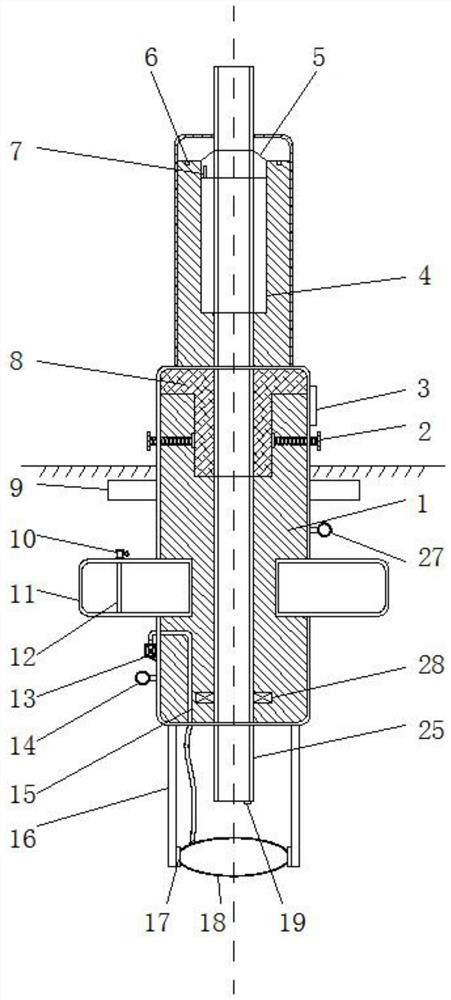

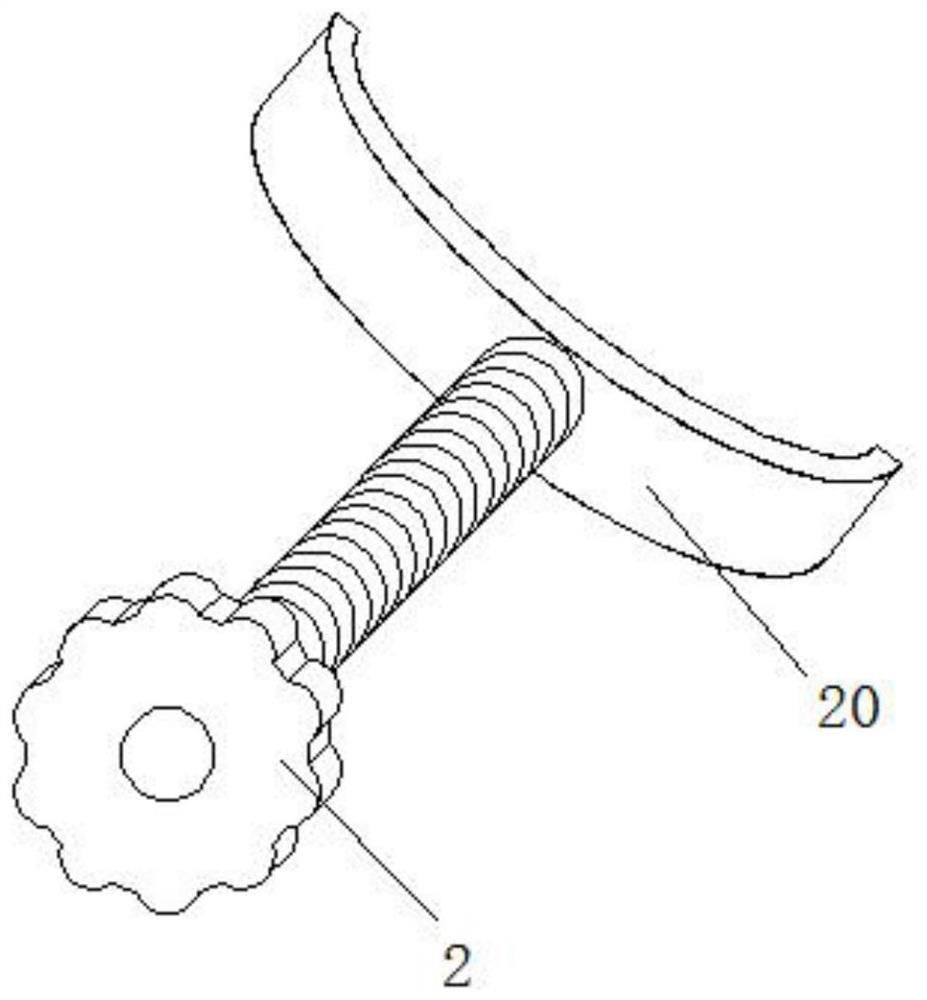

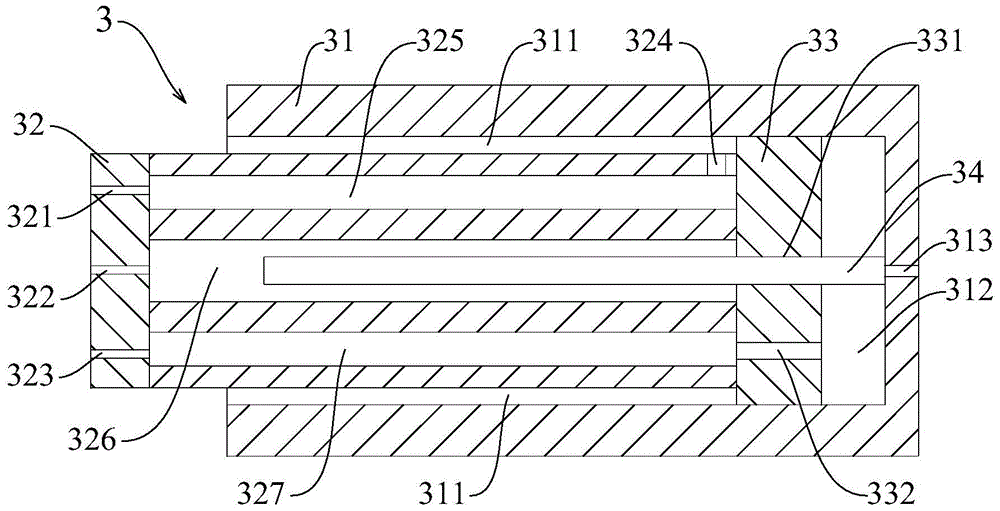

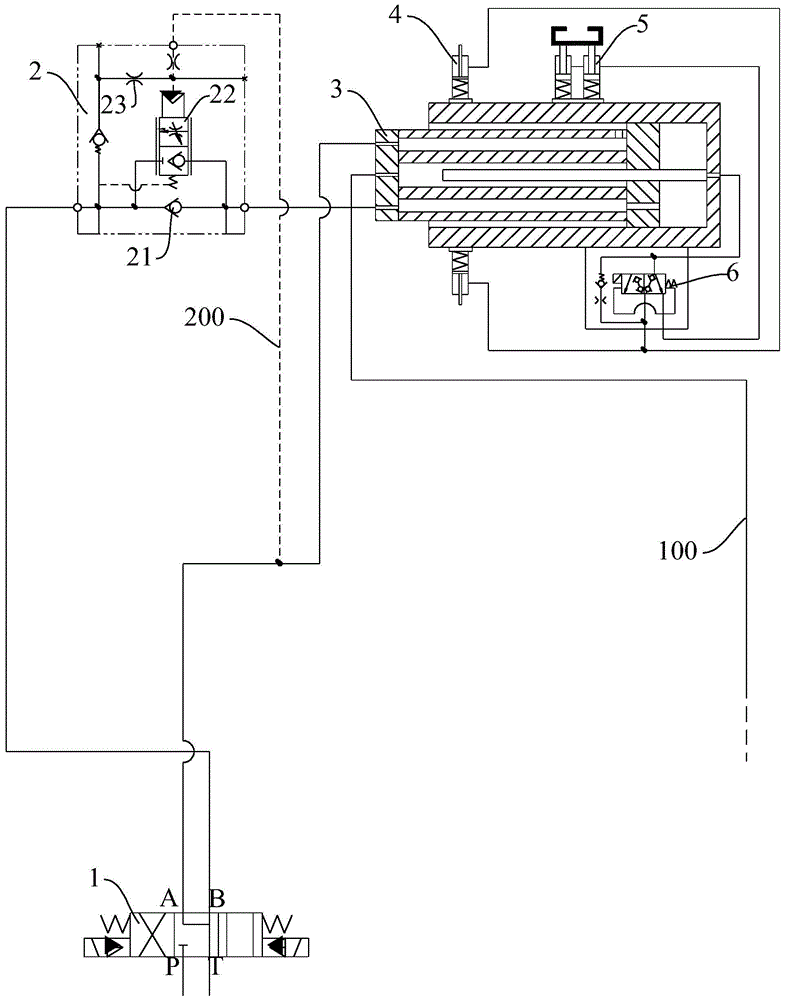

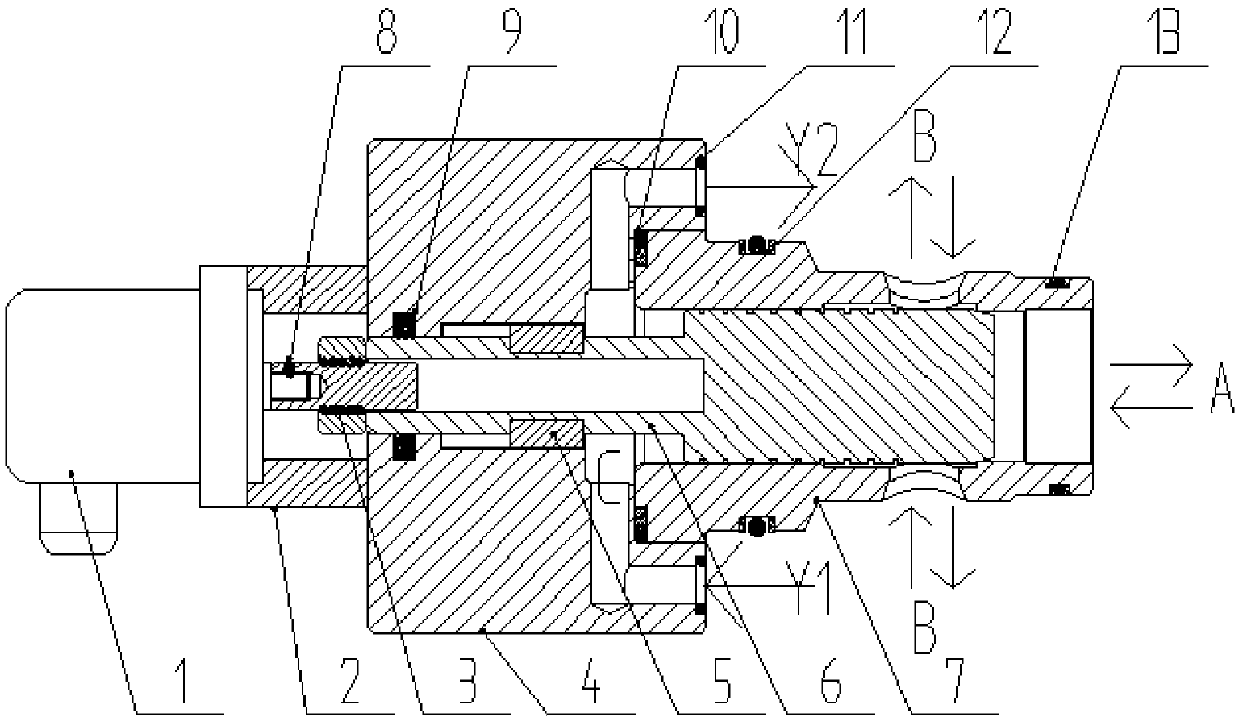

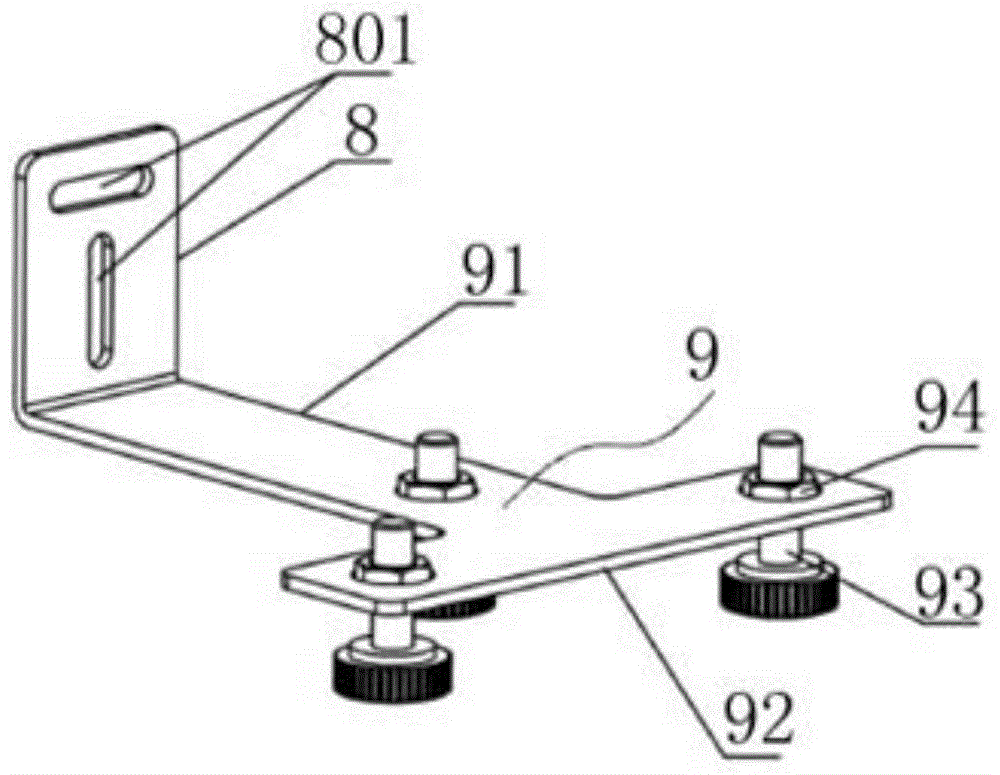

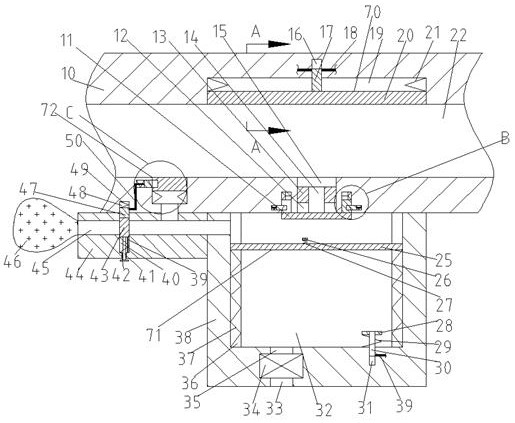

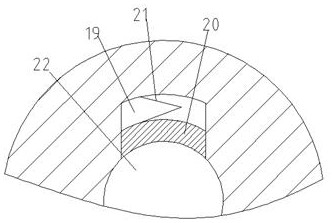

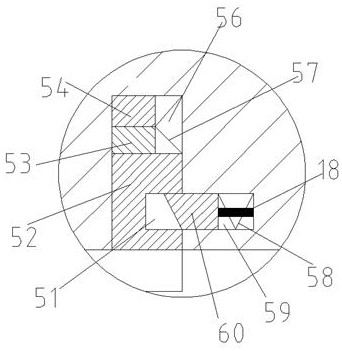

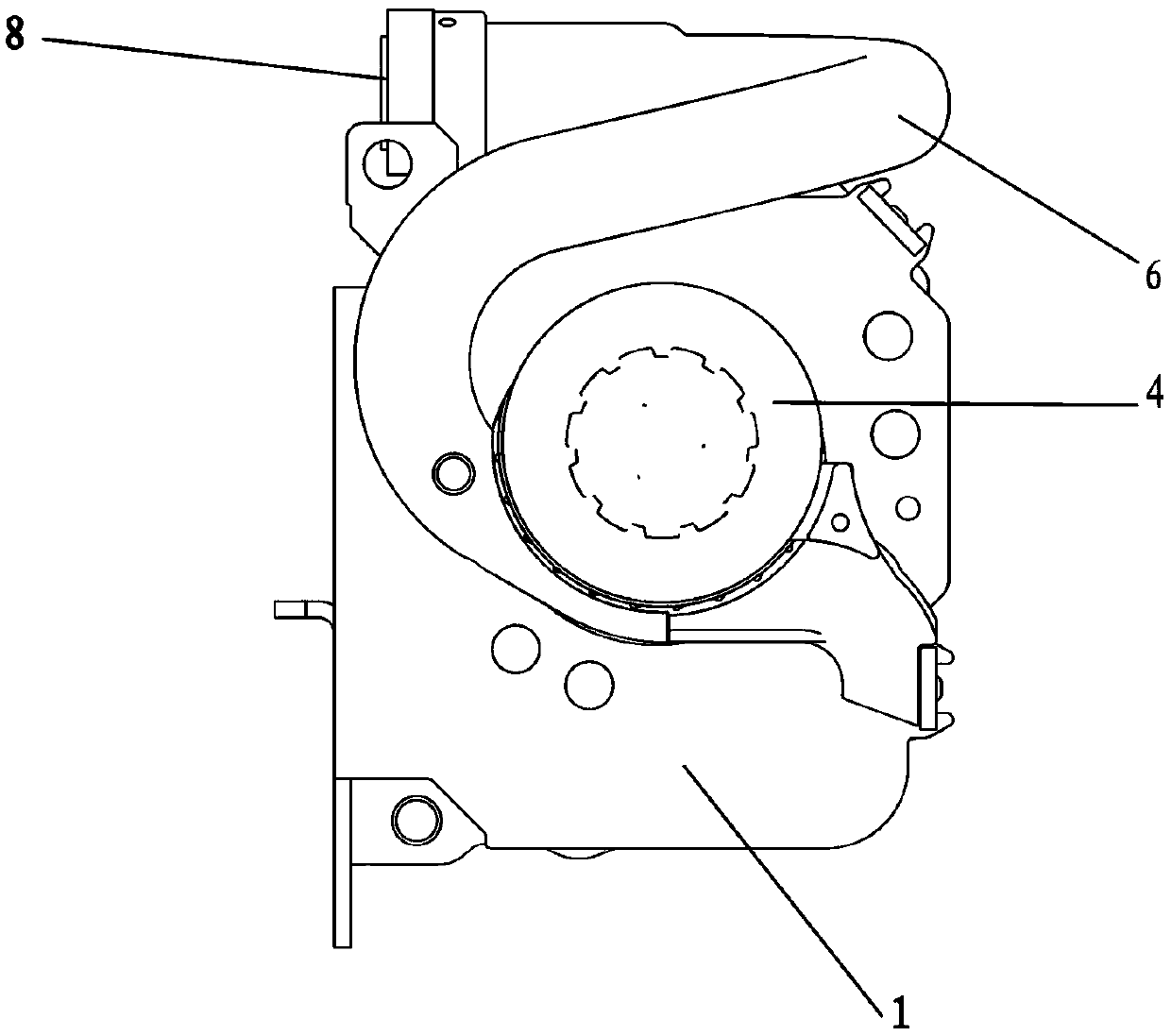

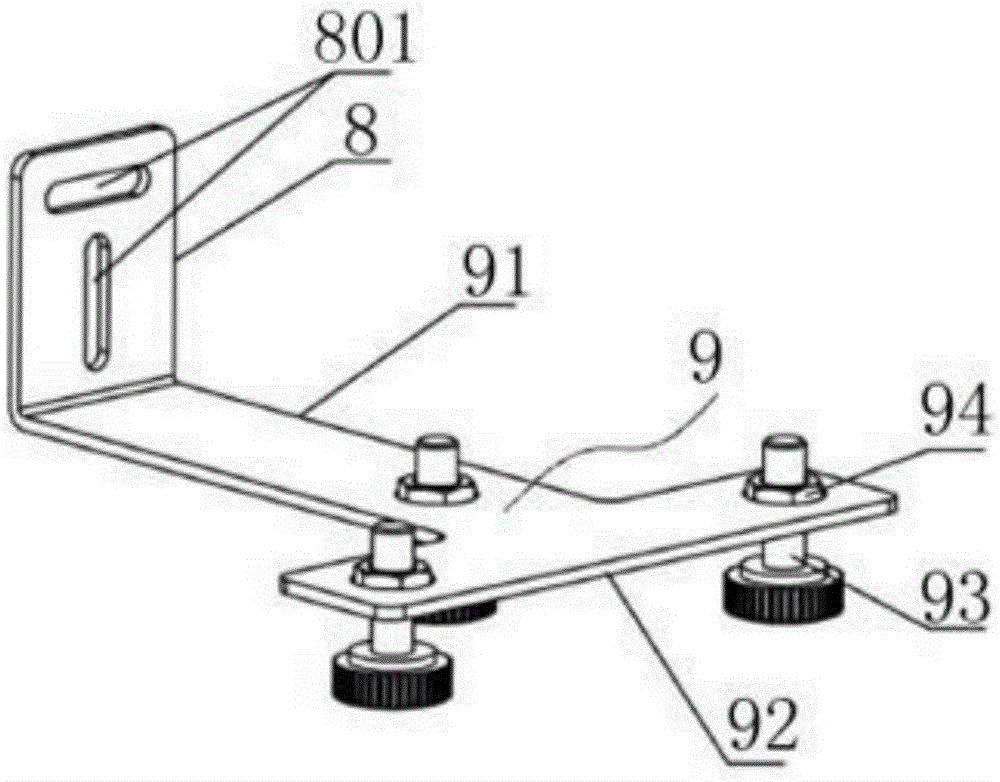

Servo quick forging valve and servo valve system

ActiveCN106762913AFast switching speedIncrease frequencyOperating means/releasing devices for valvesServomotor componentsBall screwProgrammable logic controller

The invention provides a servo quick forging valve and a servo valve system and relates to the field of quick forging hydraulic machines, in particular to the servo quick forging valve. The servo quick forging valve comprises a servo motor, a support, a guiding lubricating cover plate and a valve sleeve which are sequentially arranged from left to right, a ball screw assembly is installed in the centers of the support, the guiding lubricating cover plate and the valve sleeve in a penetrating mode, and an output shaft of the servo motor is connected with a lead screw of the ball screw assembly in a threaded mode; the guiding lubricating cover plate and the end face of the valve sleeve are tightly matched in a sealed mode and connected into an integrated structure, a servo valve core is installed in the valve sleeve, and the servo valve core and a bearing bolt of the ball screw assembly are connected to into an integrated structure; and a bearing of the ball screw assembly can be driven by the lead screw to vertically move to adjust opening and closing of a valve. The invention further relates to the servo valve system. The servo valve system comprises the servo quick forging valve and a programmable logic controller. Through the technical scheme of the servo quick forging valve and the servo valve system, the oil swapping phenomenon occurring in an existing servo quick forging valve is avoided.

Owner:青岛海德马克智能装备有限公司

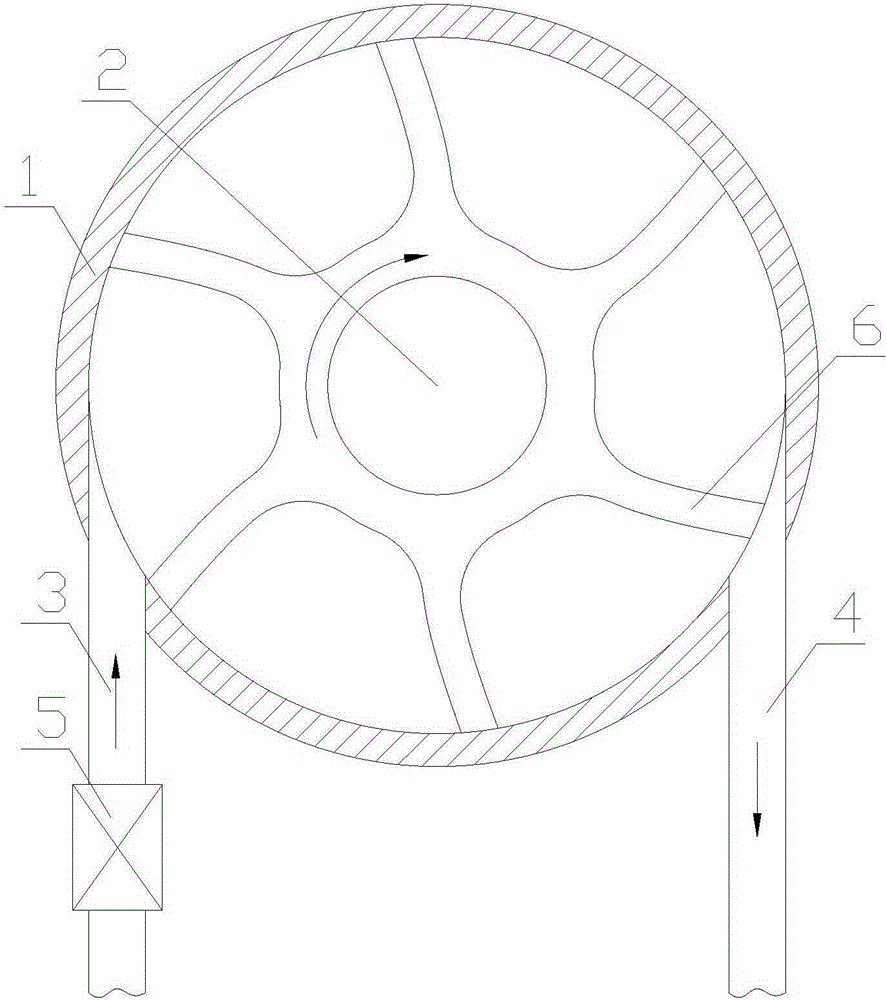

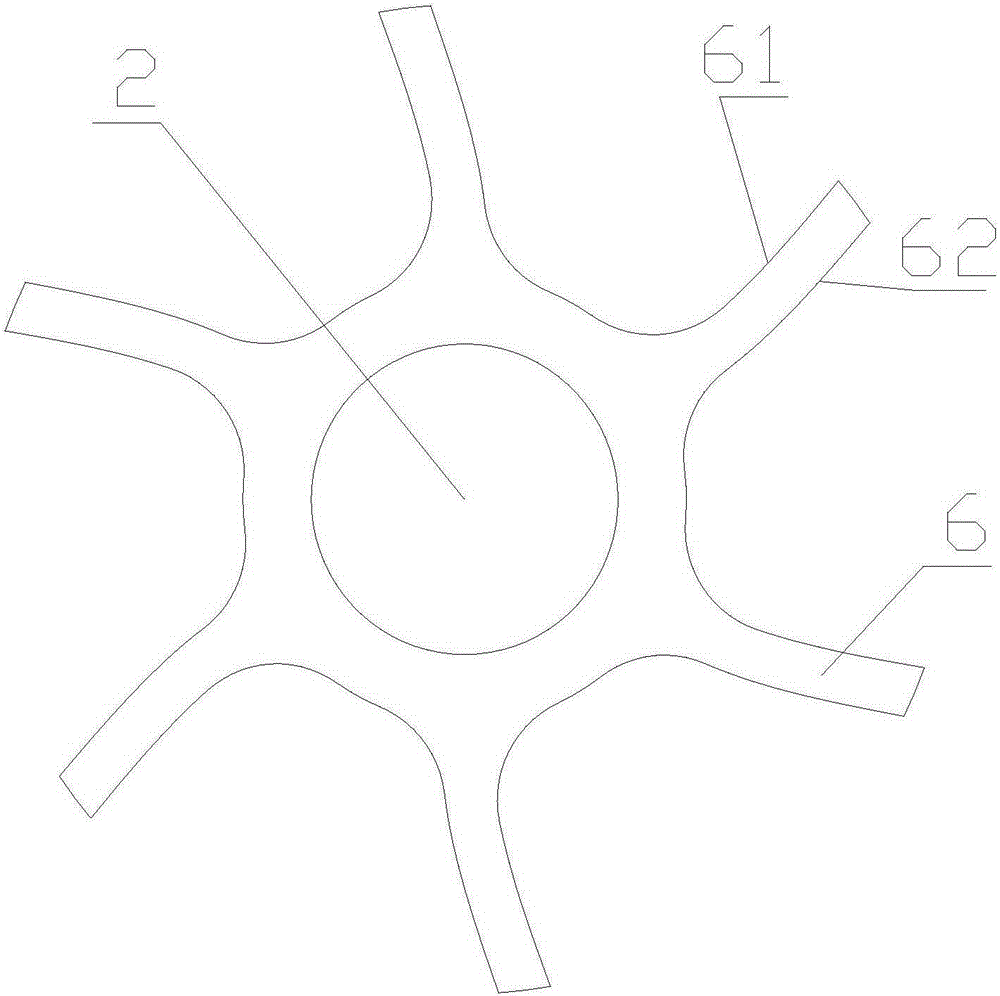

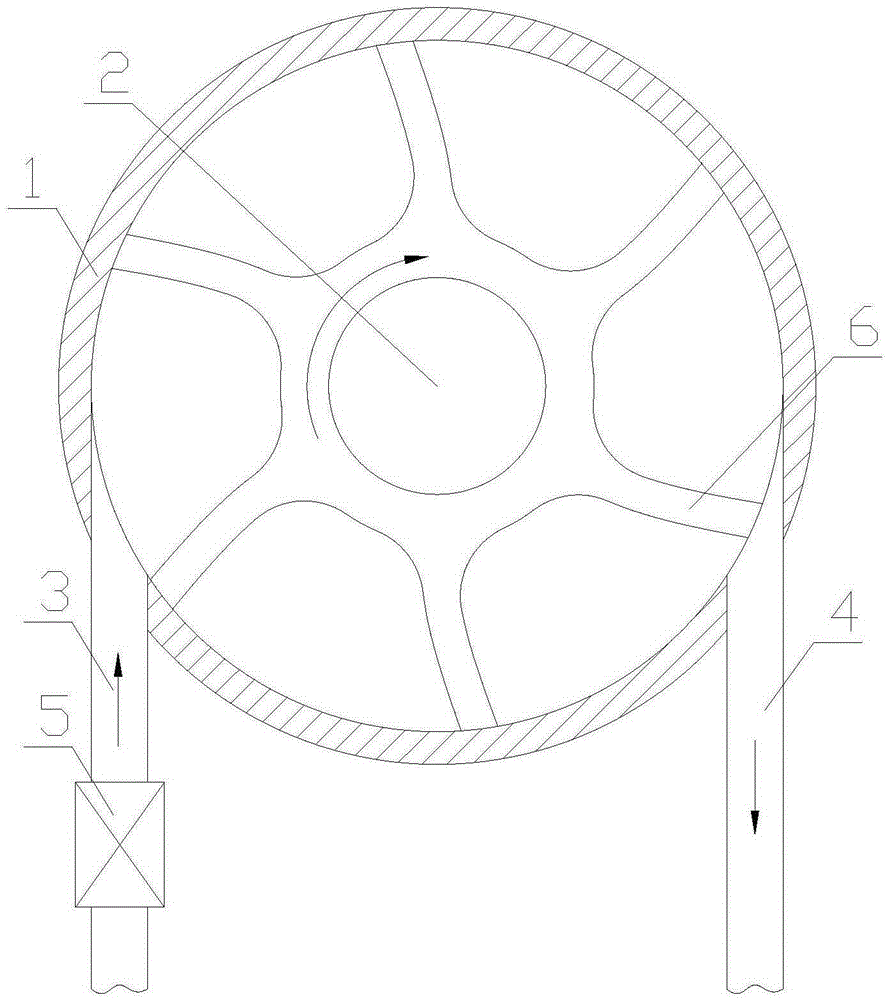

Device for automatically balancing tire pressure in running process of automobile

ActiveCN103112322AImprove securityEffects of low directional controlTyre measurementsEngineeringPressure difference

The invention discloses a device for automatically balancing tire pressure in the running process of an automobile. The device comprises two air chambers which are respectively arranged at the two ends of the axle of the automobile, can be connected through a valve for balancing the pressure difference of the two air chambers, and are respectively communicated with air cavities of adjacent tires. The device for automatically balancing the tire pressure in the running process of the automobile has the advantages of simple structure, low cost, high safety and reliability and convenience in popularization and application.

Owner:HUNAN UNIV

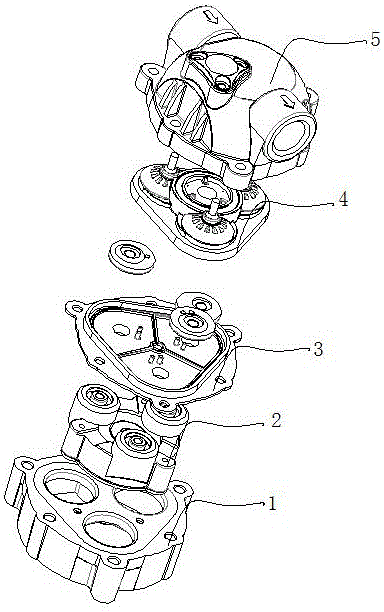

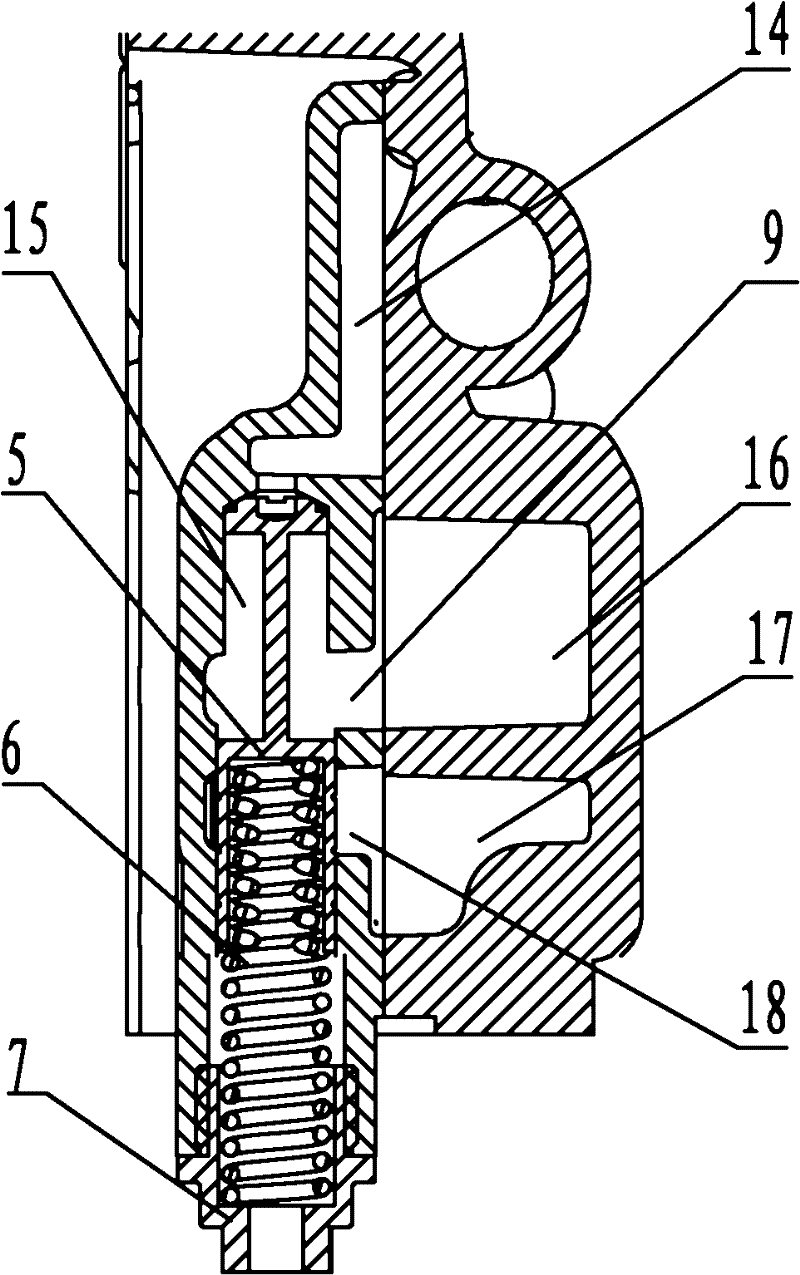

Booster pump with self pressure stabilizing performance

InactiveCN106089661AReduce vibrationEnsure safetyPositive displacement pump componentsFlexible member pumpsReverse osmosisEngineering

The invention relates to the technical field of booster pumps for a reverse osmosis system, and provides a booster pump with a self pressure stabilizing performance. The booster pump comprises a motor part and a bump head part, wherein a pump head is internally provided with a piston frame, a diaphragm and a diaphragm chamber, a plurality of check valves are arranged on the diaphragm chamber, a pressure stabilizing passage is arranged between the upper part of the diaphragm chamber and a fluid chamber, and is used for communicating a low pressure chamber with a high pressure chamber, a valve used for controlling the open and closure of the pressure stabilizing passage is arranged on the fluid chamber and is located at one side of an axis of an water inlet and a water outlet; the valve comprises an outer ring rib and an inner ring rib which are located at the middle part, the inner side of the inner ring rib is provided with a buffer relief hole, a buffer water inlet is connected with a spirally ascending relief buffer area of which the tail end is in sealing connection with the buffer relief hole in a separable manner though a spring and valve block structure at the upper part. According to the booster pump, water of which the pressure excesses a setting pressure is split to the lower pressure chamber through a valve block by virtue of the pressure stabilizing passage, the safety of the whole device is ensured, the service life is prolonged, the vibration of a pump body is reduced, the valve block is in torus contact with the buffer relief area, so the circumferential sealing performance is good, and a relief process is stable.

Owner:山东中聚电器有限公司

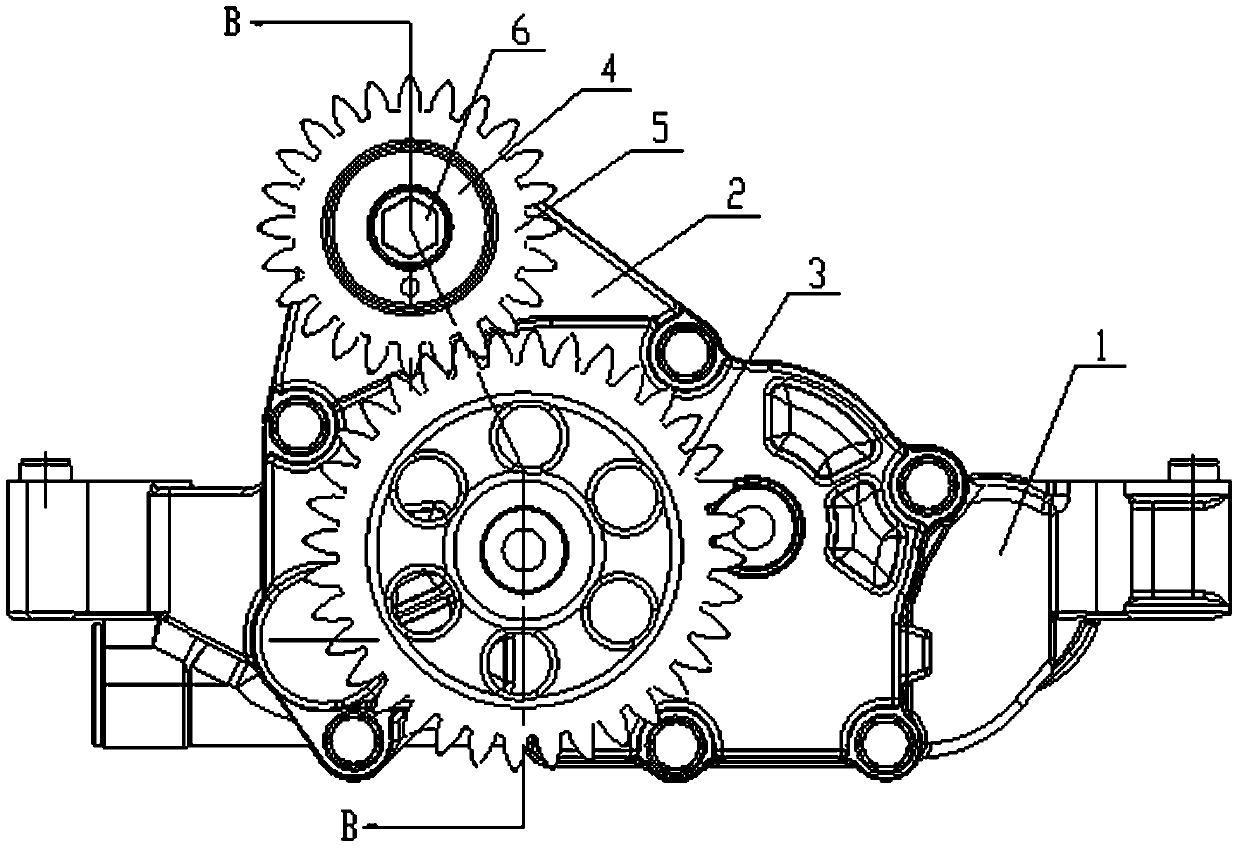

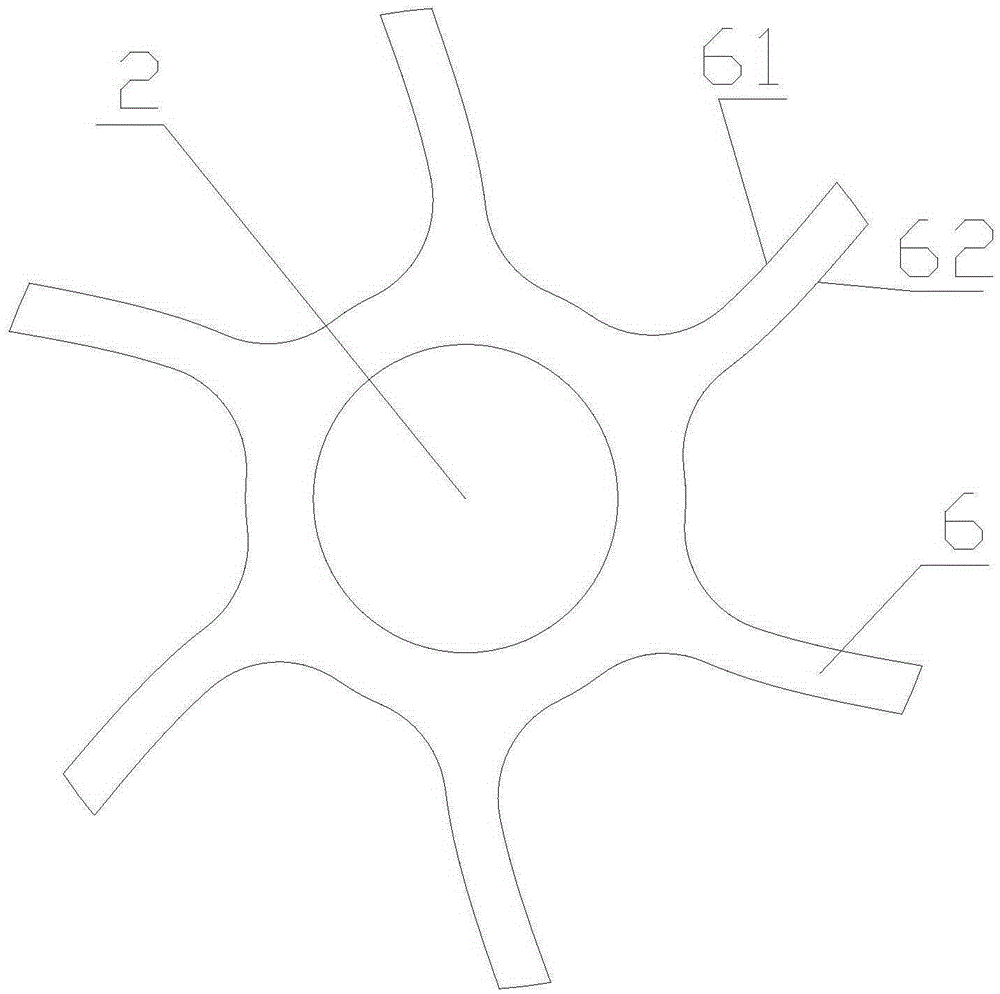

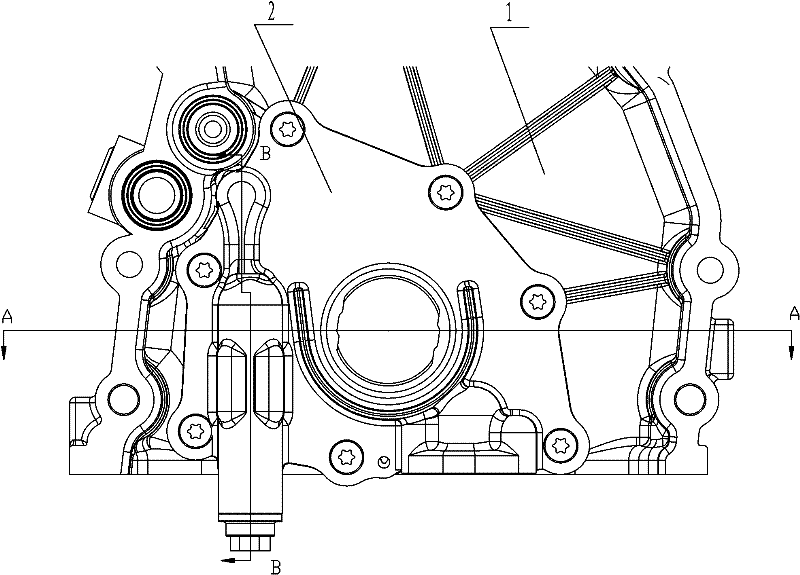

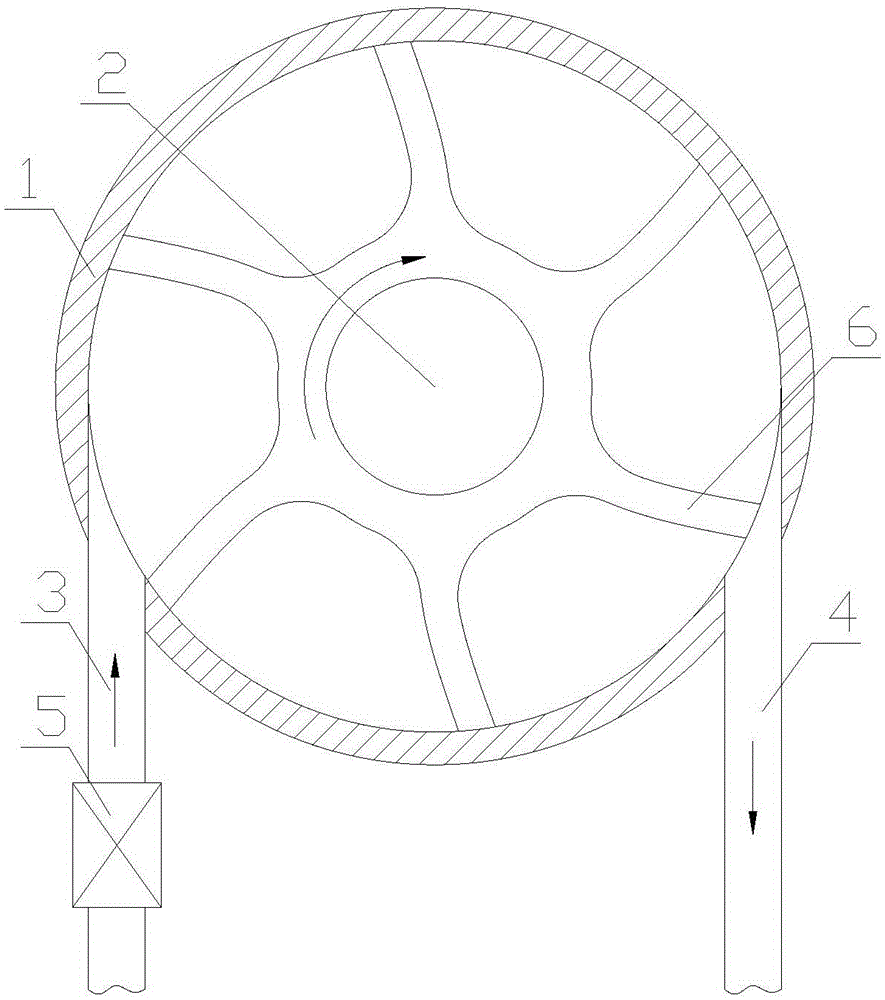

Structure-optimized machine oil pump with idle gear

PendingCN109827061AReduce weightAchieve oil circulationEqualizing valvesRotary piston pumpsEngineeringHigh pressure

The invention provides a structure-optimized machine oil pump with an idle gear. The machine oil pump comprises a pump body, a pump cover, an idle gear shaft, the idle gear and a bolt; an oil cavity is formed in the pump body; an idle gear shaft mounting hole is formed in the pump cover; the idle gear shaft is provided with an axial bolt mounting hole and a lubricating through hole intersected with the bolt mounting hole; the idle gear sleeves the idle gear shaft; a screw plug fixes the idle gear shaft on the pump cover; the diameter of the bolt is smaller than the aperture of the bolt mounting hole of the idle gear shaft; an annular gap is formed between the bolt and the inner wall of the bolt mounting hole; an oil passing groove is formed in the side, near an oil cavity, of the round hole bottom surface of the idle gear shaft mounting hole; an inclined oil hole communicating with the oil cavity is drilled in the pump cover through the oil passing groove; high-pressure oil in the oilcavity flows into a gap between an idle gear bushing and the idle gear shaft through the inclined oil hole, the oil passing groove, the annular gap and the lubricating through hole in sequence; and oil leakage grooves are formed in two end surfaces of a shaft table of the idle gear.

Owner:HUNAN OIL PUMP

Pressure relief device for ultra-high pressure sterilization apparatus

The invention relates to a pressure relief device for an ultrahigh pressure sterilization apparatus. The pressure relief device comprises an ultrahigh pressure cabin, at least an ultrahigh pressure source, at least a pressure sensor, at least a decompression valve and a control module. the invention is characterized in that ultrahigh pressure in the ultrahigh pressure cabin reaches a preset threshold value under pressurization of the ultrahigh pressure source; the control module gives instructions to the decompression valves to carry out at least one fast pressure relief on the basis of the preset threshold value of the ultrahigh pressure in the ultrahigh pressure cabin monitored by the pressure sensor such that ultrahigh pressure inside the ultrahigh pressure cabin is suddenly reduced. The decompression valves are arranged inside end caps for sealing two sides of the ultrahigh pressure cabin. The decompression valve comprises at least two decompression disks which are coaxially arranged and close fit with each other. At least two of the decompression disks make decompression areas on the decompression disks to be superposed or separated in an independent rotating mode so as to carry out pressure relief or pressure sealing. Pressure in the ultrahigh pressure cabin changes stably, and service life is prolonged.

Owner:BEIJING SUYUAN ZHONGTIAN SCI

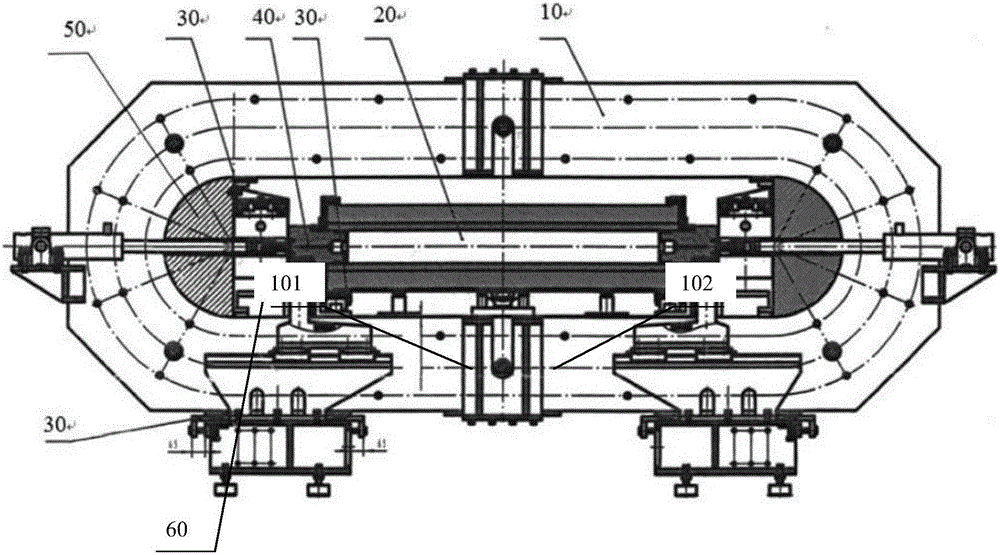

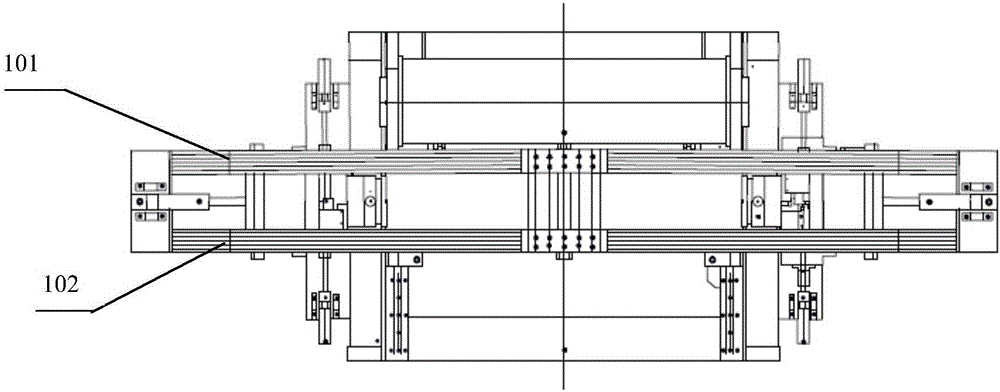

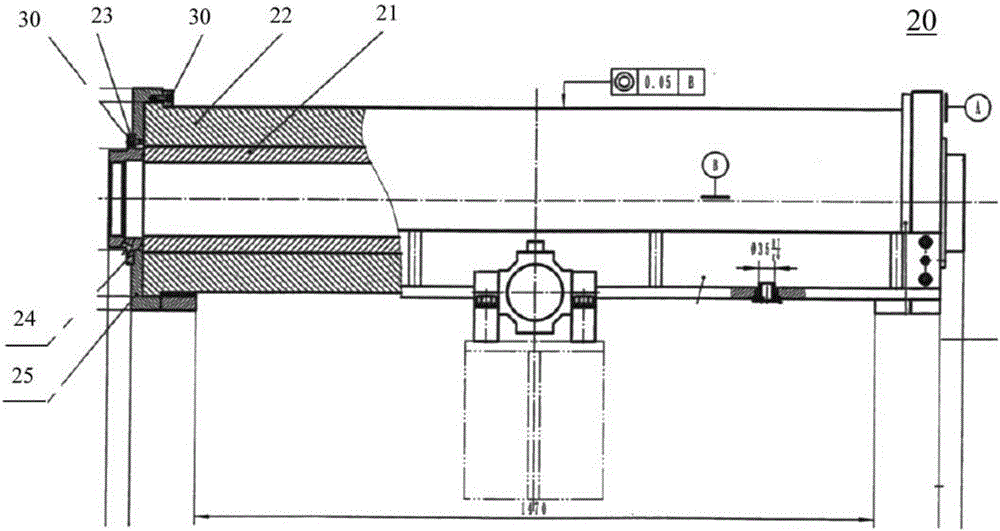

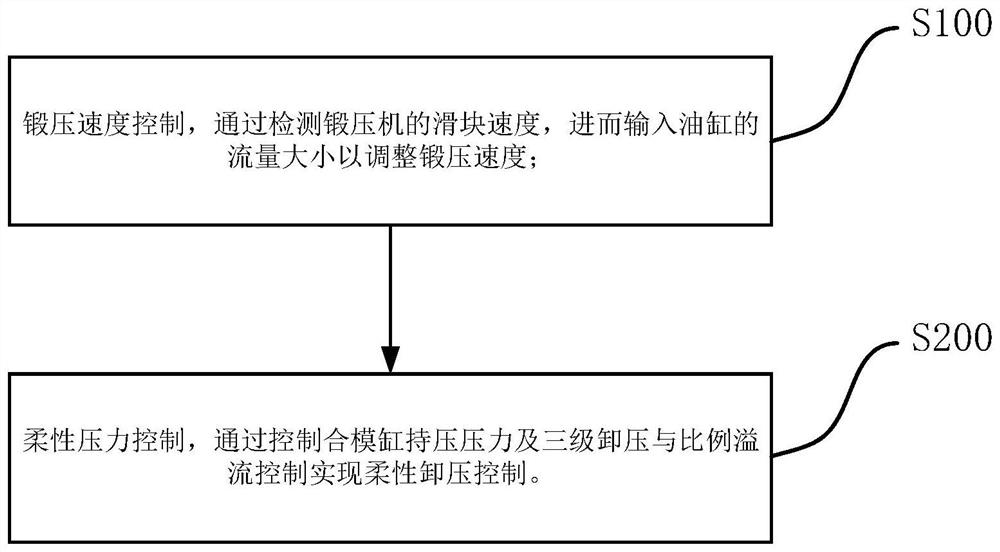

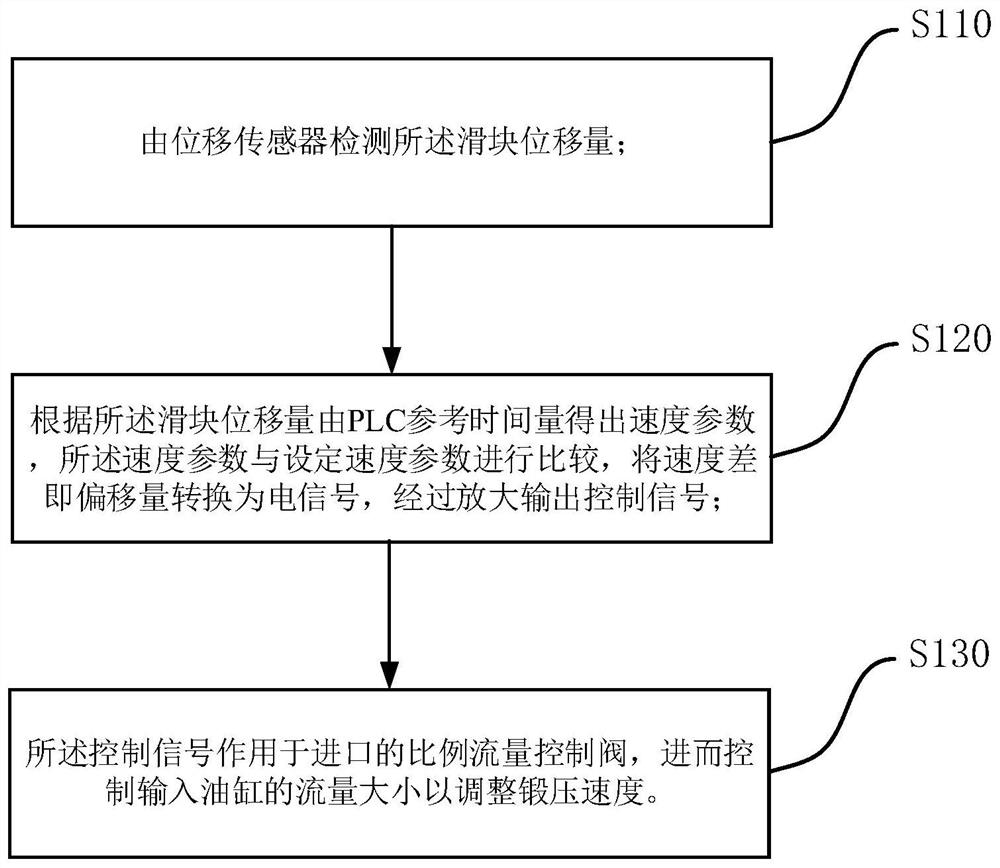

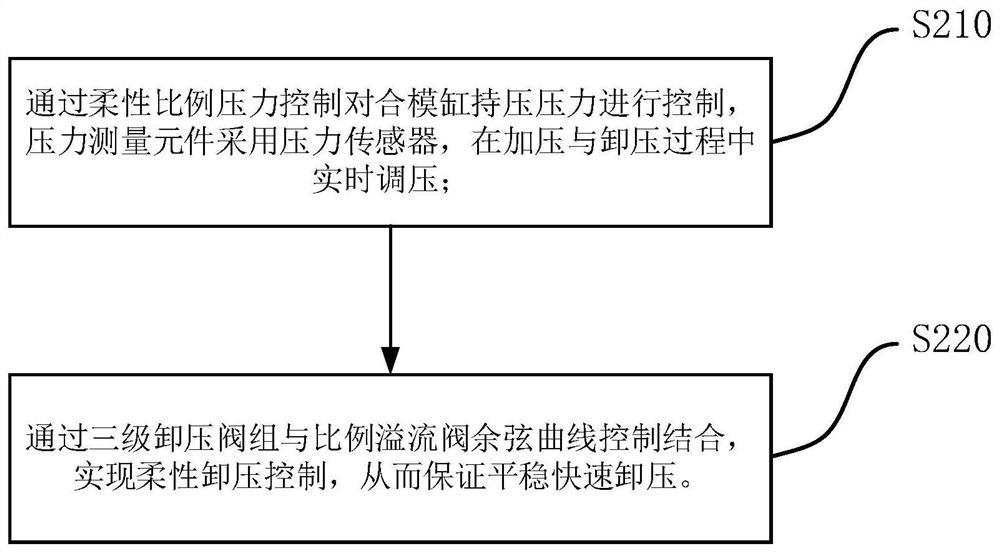

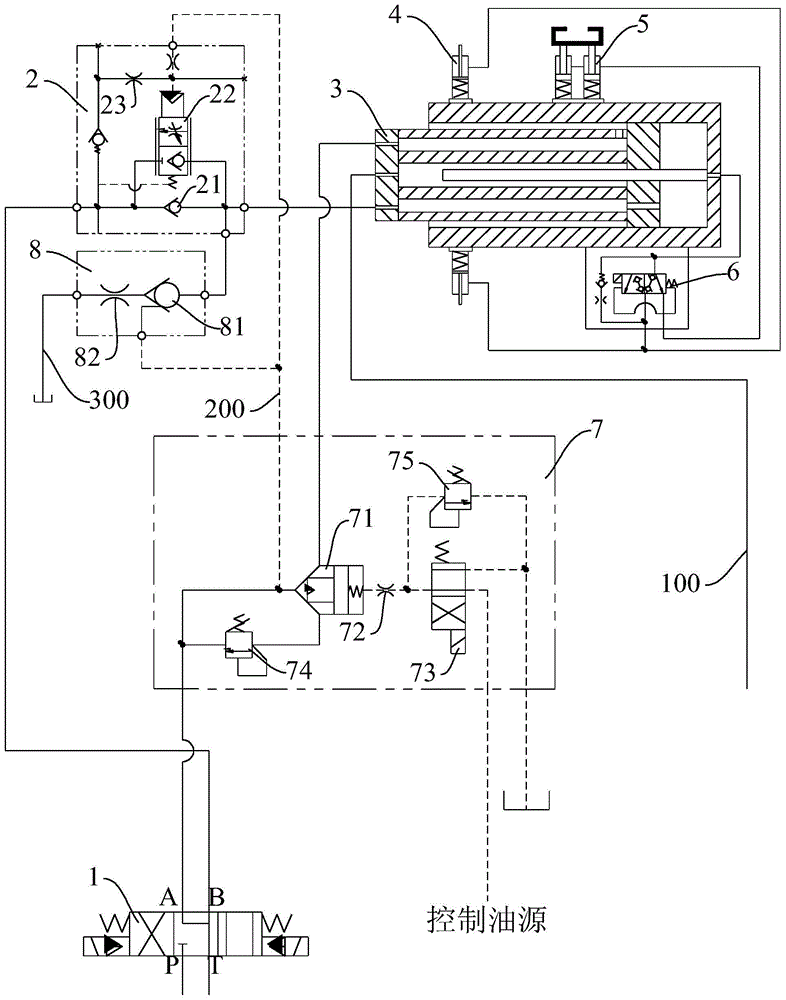

Flexible control method of forging press

PendingCN113351817ARealize flexible controlStable pressure reliefForging press drivesIndustrial engineeringPressure control

The invention discloses a flexible control method of a forging press, and belongs to the technical field of forging press control. The flexible control method of the forging press is characterized by comprising the following steps: S100, forging and pressing speed control: a forging and pressing speed is adjusted by detecting the speed of a sliding block of the forging press and further inputting the flow of an oil cylinder; and S200, flexible pressure control: flexible pressure relief control is realized by controlling the holding pressure of a die assembly cylinder of the forging press and controlling three-stage pressure relief and proportional overflow. By adopting the technical scheme, the invention provides the pressing speed control method based on an integral separation PID method; and the stroke of the sliding block is monitored in real time, and the flexible pressure relief control over the forging press is carried out by combining a three-level pressure relief valve group and a cosine curve control method of a proportional overflow valve according to the influence of an unloading process on the vehicle shape quality of wheels.

Owner:TIANJIN TIANDUAN PRESS CO LTD

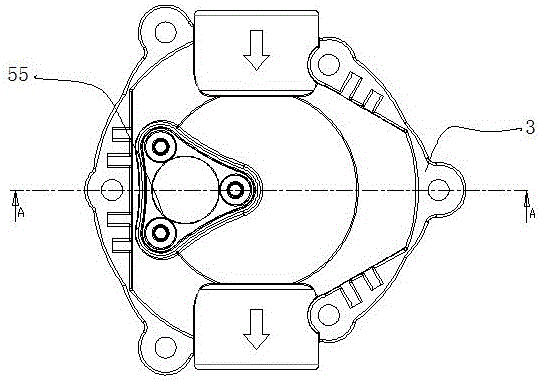

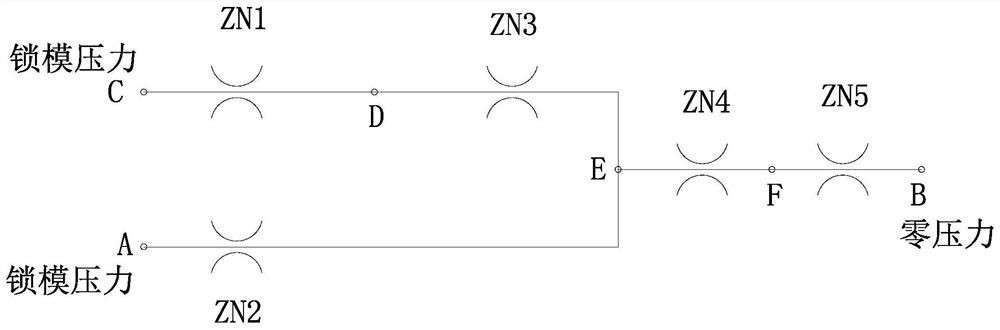

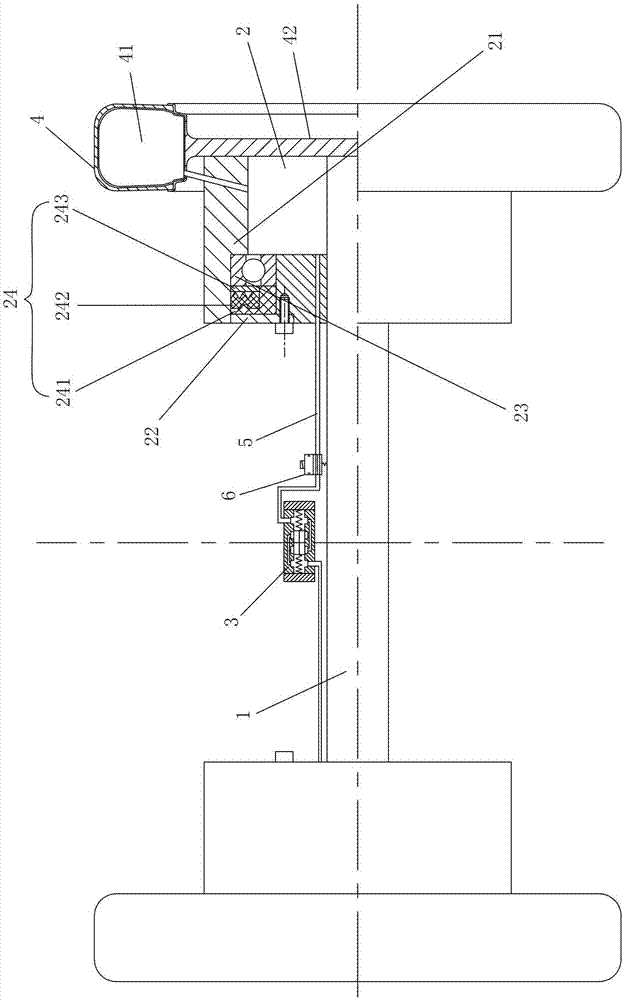

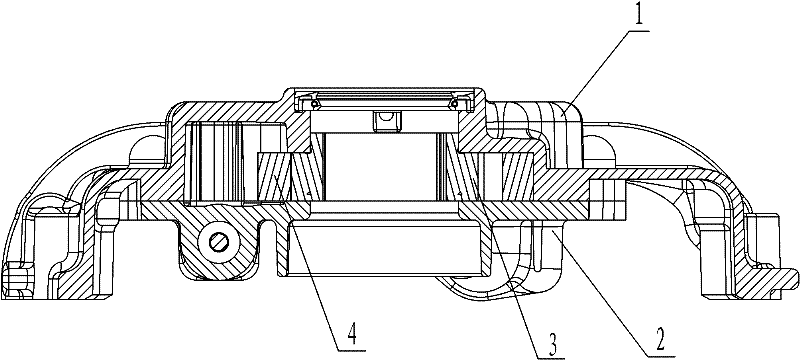

Differential type mold locking pressure relief oil way for two-plate injection molding machine

The invention discloses a differential type mold locking pressure relief oil way for a two-plate injection molding machine. The differential type mold locking pressure relief oil way comprises a cartridge valve, two two-position two-way electromagnetic directional valves and an oil tank, wherein a bottom working oil port of the cartridge valve communicates with a mold locking cavity, a side edge working oil port of the cartridge valve communicates with a mold breaking cavity to form a main channel oil way, when mold locking acts and an electromagnet of a second two-position two-way electromagnetic directional valve is electrified, a pilot port of the cartridge valve reaches a side working oil port of the cartridge valve through a first damper, a third damper, a fourth damper and a fifth damper, and a bottom working oil port of the cartridge valve reaches the side working oil port of the cartridge valve through a second damper, the fourth damper and the fifth damper, the cartridge valve is slowly opened to realize differential mold locking pressure relief, and during mold breaking action, when the electromagnet of the first two-position two-way electromagnetic directional valve is electrified, the pilot port of the cartridge valve reaches the oil tank through the first damper, so that the cartridge valve is quickly opened to realize differential mold breaking. The differential type mold locking pressure relief oil way has the advantages that the mold locking and pressure relief process is stable, the mold breaking action is considered, and the oil cleanliness is good.

Owner:NINGBO ZHAFIR PLASTICS MACHINERY

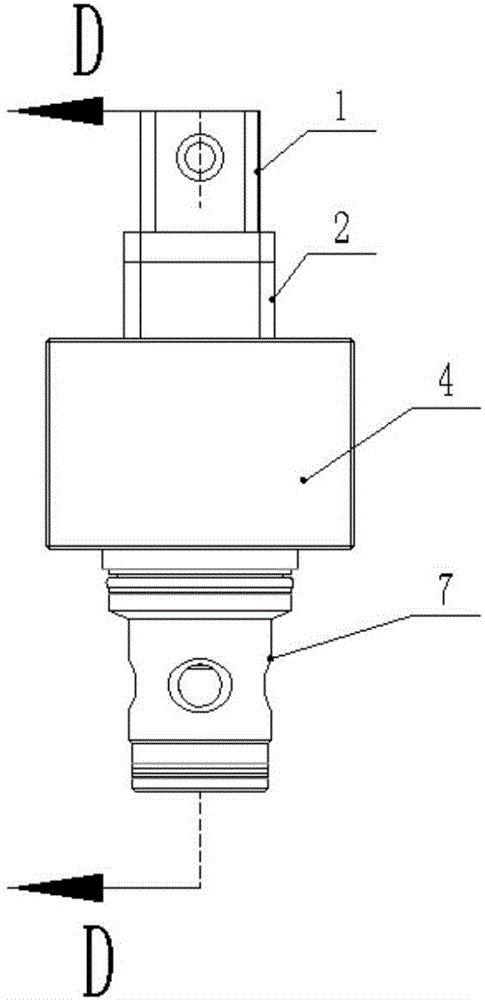

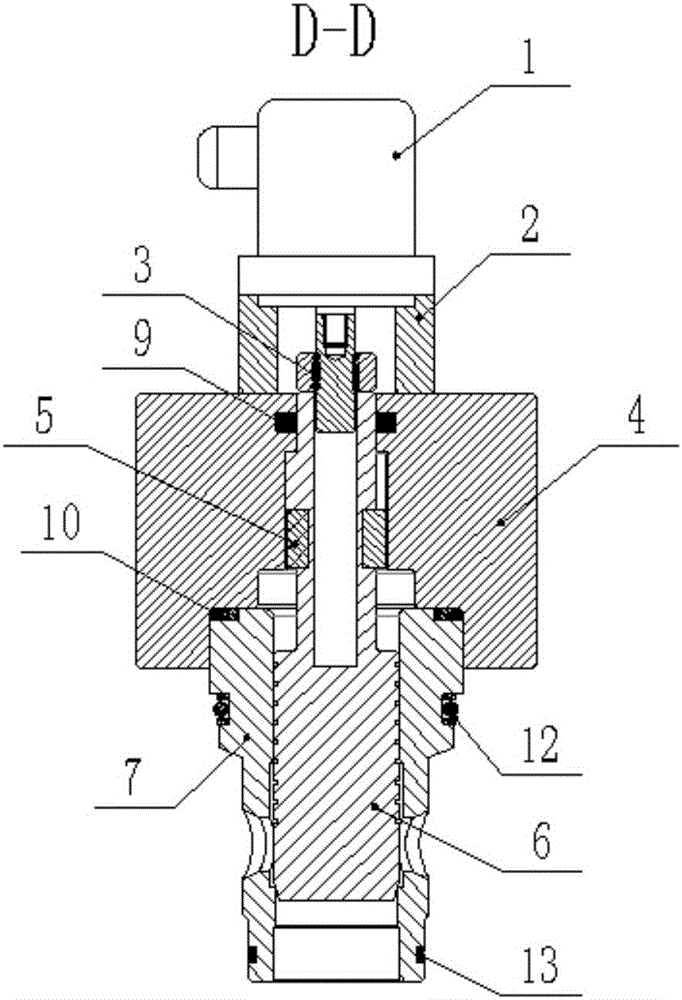

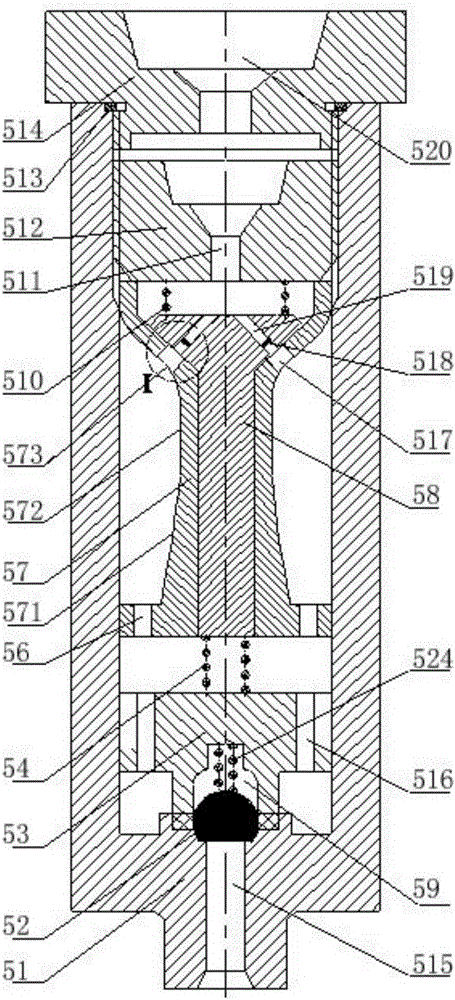

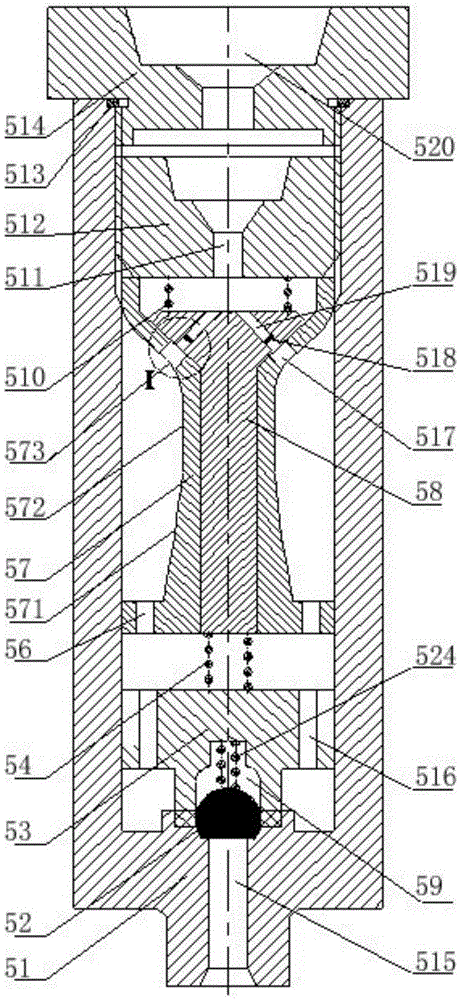

Ultrahigh-pressure fully-automatic pressure relief device

ActiveCN106907368AAvoid chronic stressExtended service lifeServomotor componentsUltra high pressureSystem pressure

The invention discloses an ultrahigh-pressure fully-automatic pressure relief device. The ultrahigh-pressure fully-automatic pressure relief device comprises a main body and a step motor positioned at the right side of the main body, wherein the main body comprises a pressure relief cavity which is through in two sides; the pressure relief cavity comprises a sealing cavity at the left side, a regulating cavity on the middle and a threaded cavity at the right side, wherein a screw plug I at the left side and a valve seat at the right side are arranged in the sealing cavity; an ejector pin which is thin in left portion and thick in right portion is arranged in the regulating cavity; the left end of the ejector pin is equipped with a tip which extends into a valve hole; the threaded cavity is internally matched with a screw; the left end of the screw is bumped, and abuts against the right end of the ejector pin; the right end of the screw is equipped with a shaft hole with a key slot; the shaft hole is in clearance fit with a motor shaft of the step motor through a flat key; the lower end of the main body is equipped with an oil inlet which is fixedly equipped with an oil inlet nozzle; and the oil inlet communicates with a first oil inlet hole path. According to the ultrahigh-pressure fully-automatic pressure relief device disclosed by the invention, the step motor is adopted to drive the screw to regulate movement of the ejector pin, so that the tip is regulated to extend into the valve opening by certain length, and therefore, linear pressure relief is realized, linear changes of system pressure are realized, and a production process curve is met.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

Smart home data collecting system based on ZigBee

InactiveCN105181030AImprove real-time performanceImprove reliabilityTransmission systemsVolume/mass flow by dynamic fluid flow effectComputer networkData information

The invention discloses a smart home data collecting system based on ZigBee, belongs to the technical field of smart homes, and aims at providing the smart home data collecting system with higher reliability and instantaneity. According to the technical scheme, the smart home data collecting system comprises a water meter, a ZigBee wireless communication module, a ZigBee routing module, a ZigBee coordinator, a GPRS module and a central processor. A water meter sensor in the water meter transmits water volume data information collected by the water meter sensor to the ZigBee coordinator through the ZigBee wireless communication module and the ZigBee routing module in sequence, and the ZigBee coordinator transmits the received water volume data information to the central processor through the GPRS module and a GPRS network. The smart home data collecting system is suitable for being used as a data collecting system in a smart home.

Owner:成都锐可科技有限公司

Oil extraction wellhead sealing device

ActiveCN113202440AVerticality real-time monitoringGuaranteed to be verticalSealing/packingData controlThermodynamics

The invention relates to an oil extraction wellhead sealing device which comprises a sealing device shell, a slag removal disc and a gradienter; a polished rod is arranged in the sealing device shell in a penetrating mode; the gradienter is fixed to the lower portion of the polished rod; connecting plates are installed on the left side and the right side of the gradienter correspondingly; sliding parts are installed on the sides, close to the gradienter, of the connecting plates; a sealing air bag is connected with the interiors of the sliding parts; a movable sliding rail is arranged at joints of the sliding parts and the connecting plates; and an inflation pipe is connected with the upper portion of the sealing air bag. According to the oil extraction wellhead sealing device, the gradienter is adopted to monitor the perpendicularity of the polish rod in real time and transmit data to a PLC, the PLC can control a centralizer to work according to received data, the position of the polish rod is adjusted, and the situation that the polish rod is in a vertical state is guaranteed, so that the situation that the polish rod is inclined, and sealing is not thorough is avoided; and in addition, through the arrangement of the slag removal disc, waste scraps and waste residues generated on the surface of the polished rod can be cleaned.

Owner:JINHU FUYUAN MACHINERY

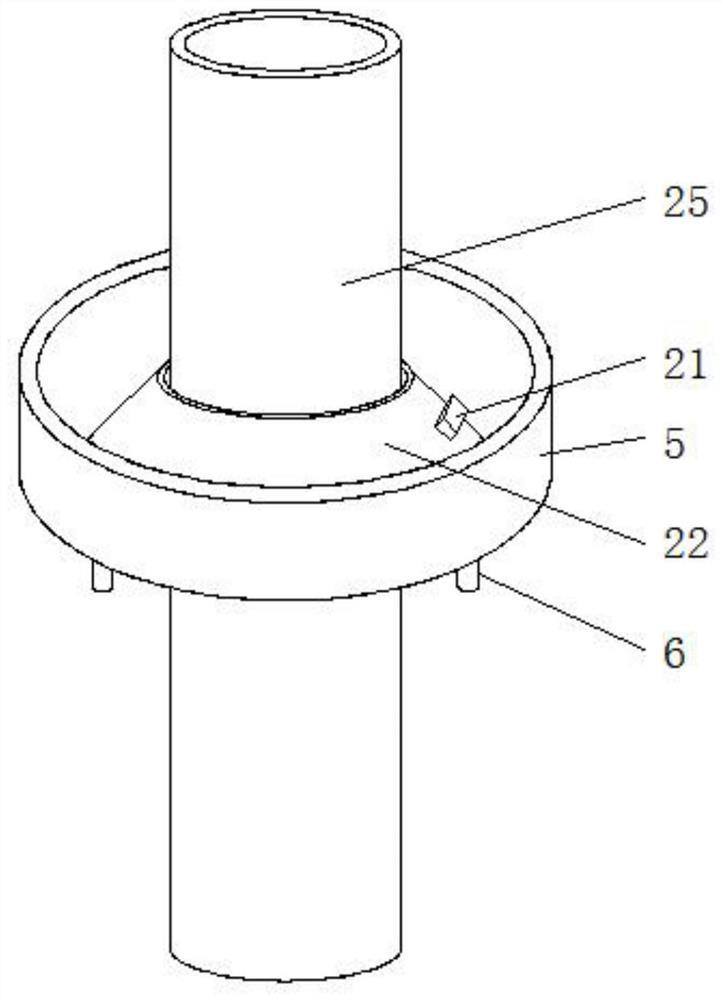

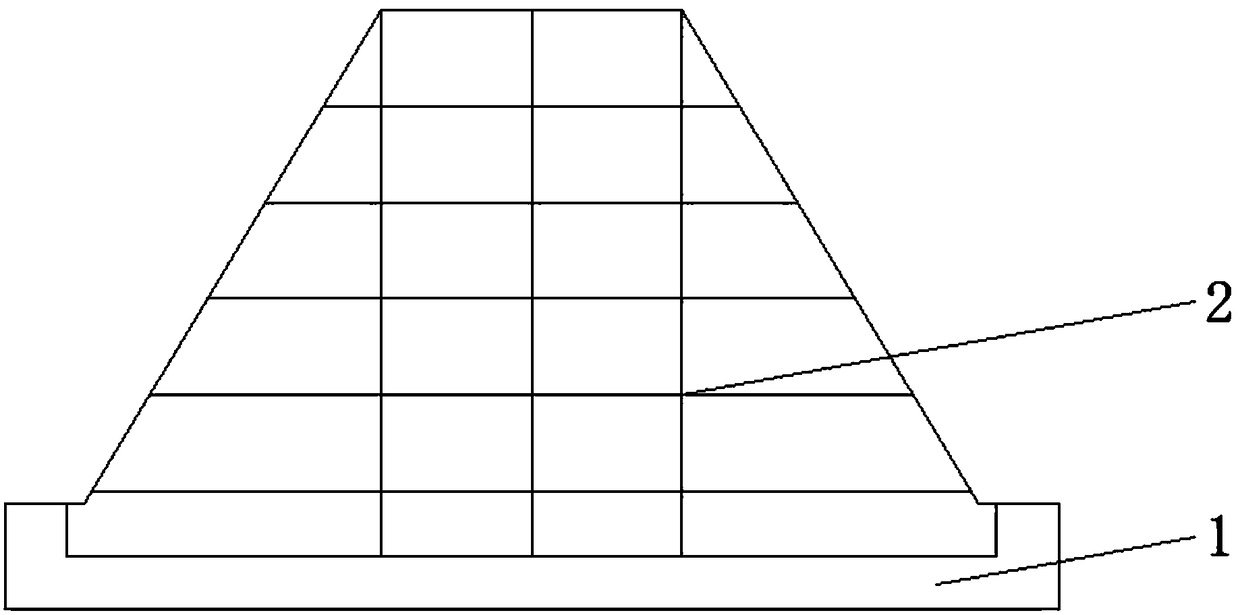

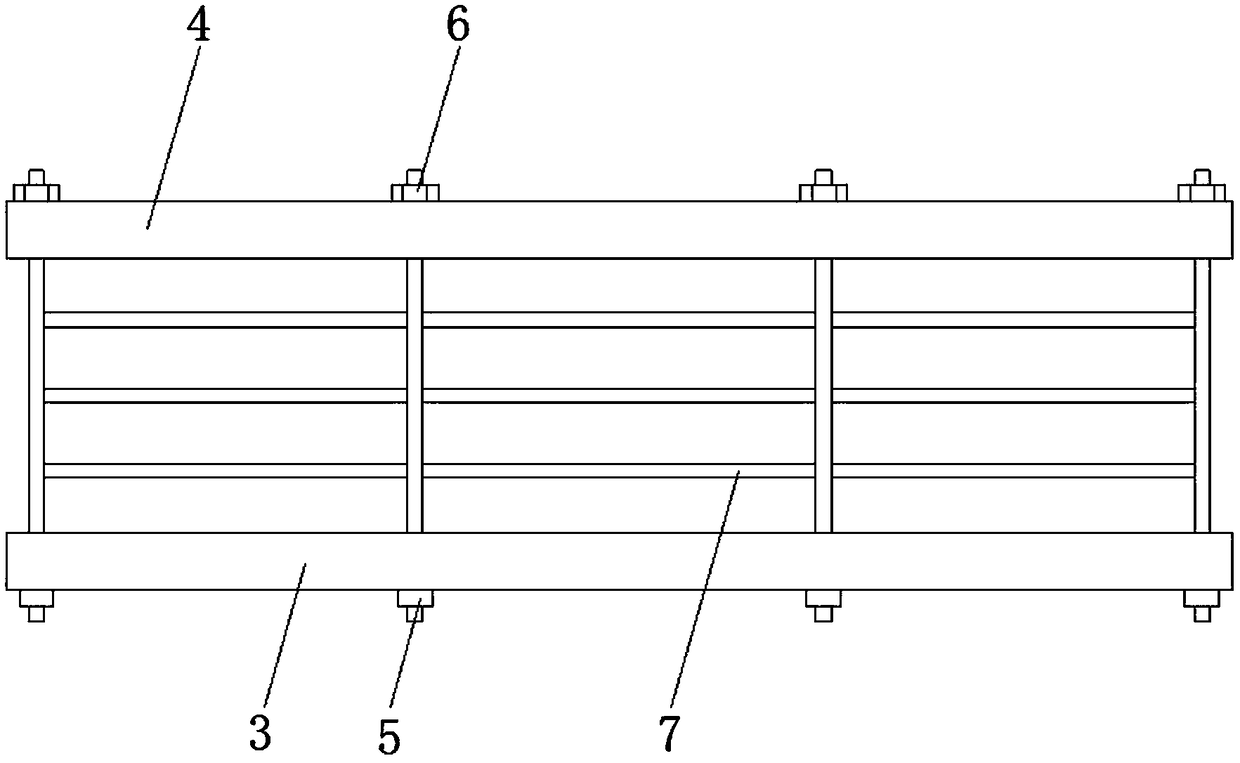

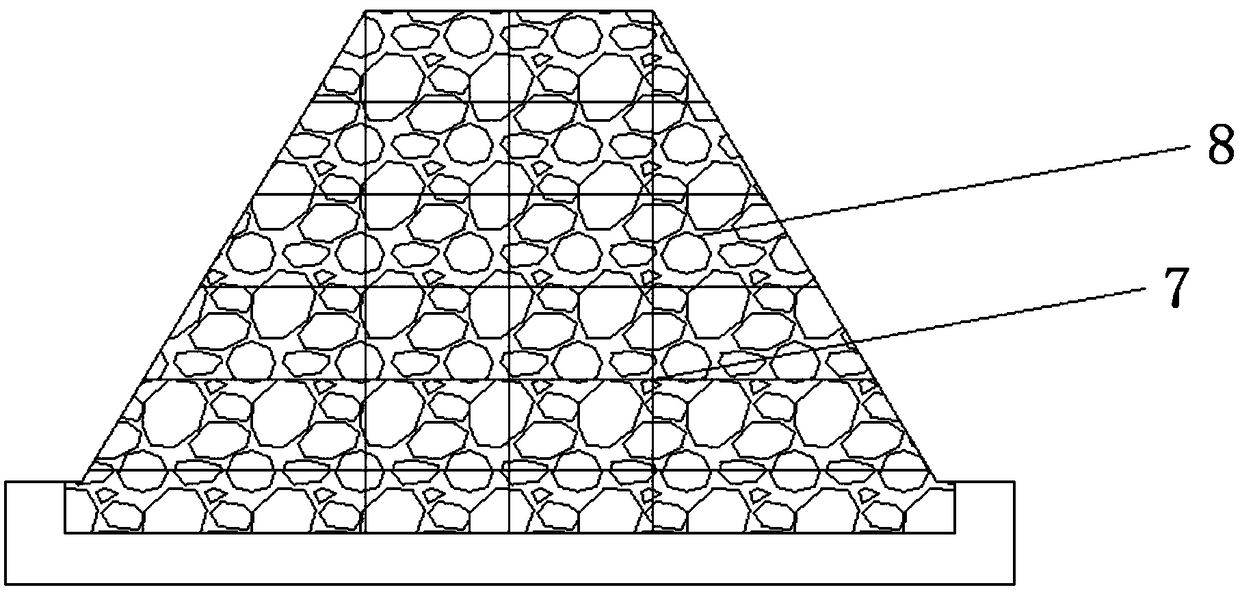

Water retaining dam fixing formwork for water conservancy project and construction method thereof

The invention discloses a water retaining dam fixing formwork for a water conservancy project and a construction method thereof, and relates to the technical field of the water conservancy projects. The fixing formwork comprises a dam base layer and a gravel block filling frame, the sides, which penetrate through and extend out of a second side form baffle plate, of split bolts are in threaded connection with fixed nuts, and a filling baffle frame is fixedly connected between a first side form baffle plate and the second side form baffle plate; and a gravel block and clay mixture fills the portions among the filling baffle frame, the gravel block and clay mixture and the filling baffle frame are mixed to form a filling gravel block layer, the filling gravel block layer and concrete anti-permeation blocks form a water retaining dam inner base layer. According to the water retaining dam fixing formwork for the water conservancy project and the construction method thereof, the partitioning construction is achieved, so that the construction difficulty is reduced, the construction time is shortened, meanwhile, the toughness of the water retaining dam is increased, and the service life of the water retaining dam is prolonged; and constant-gradient water discharging is achieved during flood releasing and water discharging, so that the purpose of stably releasing the pressure during flood control of the water retaining dam is achieved.

Owner:佛山拾念科技有限公司

Boom telescopic buffer hydraulic system and crane

ActiveCN104692266BAvoid shockReduce shockFluid-pressure actuator safetyServomotor componentsPetroleum engineeringHydraulic control

The invention discloses a hydraulic system for telescopic buffer of a crane boom and a crane. The hydraulic system for telescopic buffer of the crane boom comprises a telescopic oil cylinder, a main valve and a balance valve, wherein a first working oil port and a second working oil port of the main valve are respectively connected to a rod chamber of the telescopic oil cylinder and a free oil inlet of the balance valve in a communication way, a free oil outlet of the balance valve is connected to a rodless chamber of the telescopic oil cylinder in a communication way, and the first working oil port is also connected to a control oil port of the balance valve in a communication way through a control oil line; and the hydraulic system for telescopic buffer of the crane boom also comprises an auxiliary pressure-relief oil line, a through flow damper and a hydraulic control pressure-relief on-off valve, wherein the oil inlet end of the auxiliary pressure-relief oil line is connected to the rodless chamber of the telescopic oil cylinder in a communication way, the through flow damper and the hydraulic control pressure-relief on-off valve are arranged on the auxiliary pressure-relief oil line, and the control oil port of the hydraulic control pressure-relief on-off valve is connected to the control oil line or the first working oil port in a communication way. By implementing the hydraulic system, impact generated by the balance valve or a pressure shunting damper when the crane boom is started to be shrunk can be effectively reduced.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

Intelligent household data acquisition system based on GSM

InactiveCN105182937AImprove real-time performanceWide coverageProgramme total factory controlEmbedded systemData transmission

The invention discloses an intelligent household data acquisition system based on GSM, is the data acquisition system belonging to the intelligent household technology field and aims to realize properties of remote distance data transmission and rapid data transmission speed. The intelligent household data acquisition system based on GSM is characterized by comprising a water gauge, an acquisition device, a GSM communication module and a controller, wherein a water gauge sensor of the water gauge is electrically connected with the acquisition device, the acquisition device is electrically connected with the GSM communication module, and the GSM communication module is electrically connected with the controller. The intelligent household data acquisition system based on GSM is suitable for data acquisition.

Owner:成都锐可科技有限公司

Servo fast forging valve and servo valve system

ActiveCN106762913BFast switching speedIncrease frequencyOperating means/releasing devices for valvesServomotor componentsProgrammable logic controllerBall screw

The invention provides a servo quick forging valve and a servo valve system and relates to the field of quick forging hydraulic machines, in particular to the servo quick forging valve. The servo quick forging valve comprises a servo motor, a support, a guiding lubricating cover plate and a valve sleeve which are sequentially arranged from left to right, a ball screw assembly is installed in the centers of the support, the guiding lubricating cover plate and the valve sleeve in a penetrating mode, and an output shaft of the servo motor is connected with a lead screw of the ball screw assembly in a threaded mode; the guiding lubricating cover plate and the end face of the valve sleeve are tightly matched in a sealed mode and connected into an integrated structure, a servo valve core is installed in the valve sleeve, and the servo valve core and a bearing bolt of the ball screw assembly are connected to into an integrated structure; and a bearing of the ball screw assembly can be driven by the lead screw to vertically move to adjust opening and closing of a valve. The invention further relates to the servo valve system. The servo valve system comprises the servo quick forging valve and a programmable logic controller. Through the technical scheme of the servo quick forging valve and the servo valve system, the oil swapping phenomenon occurring in an existing servo quick forging valve is avoided.

Owner:青岛海德马克智能装备有限公司

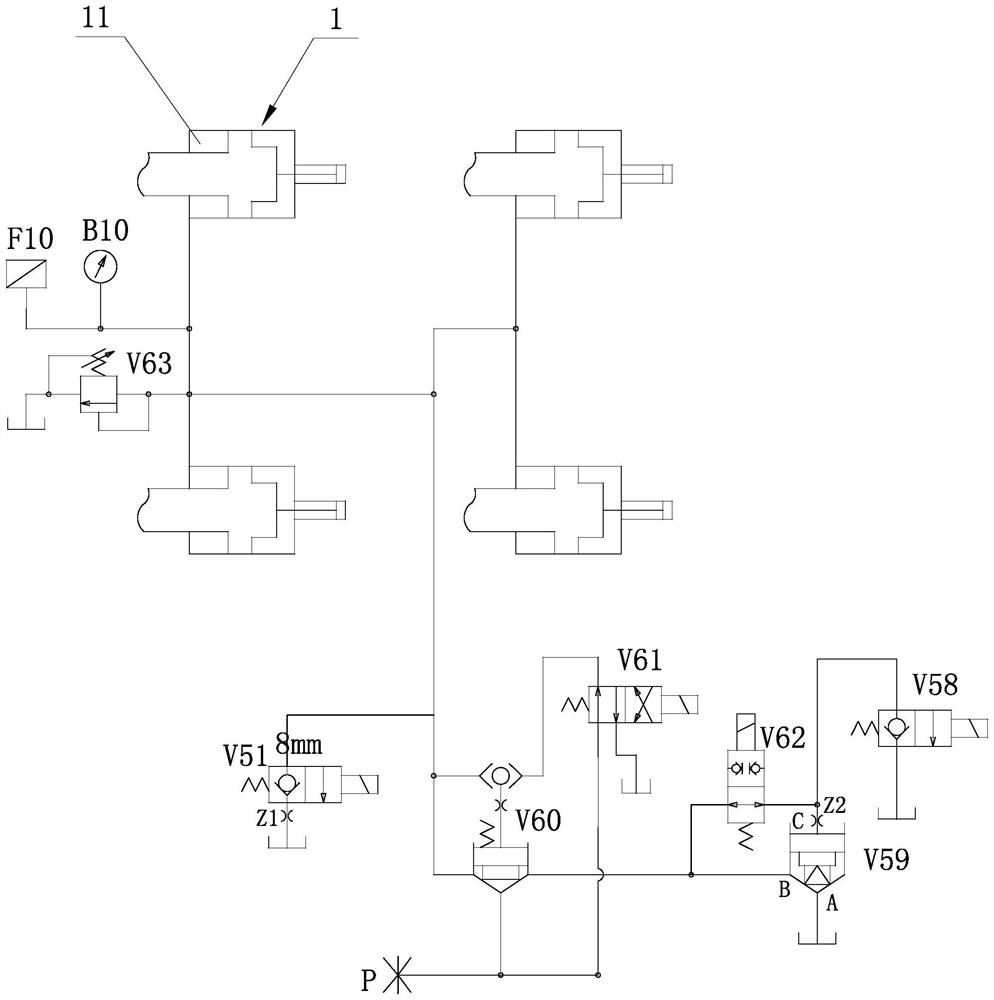

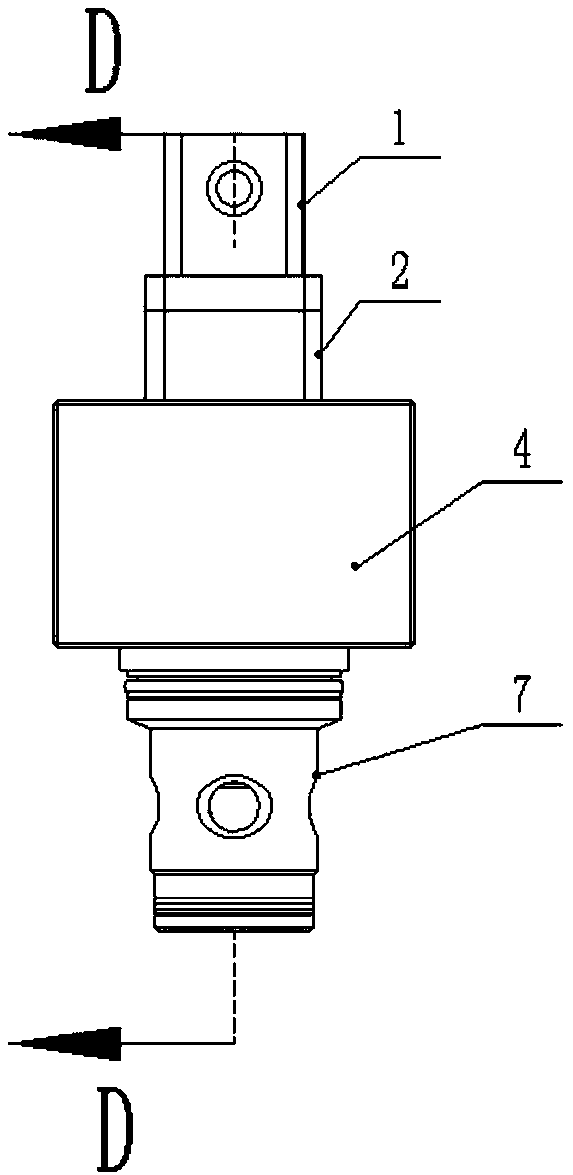

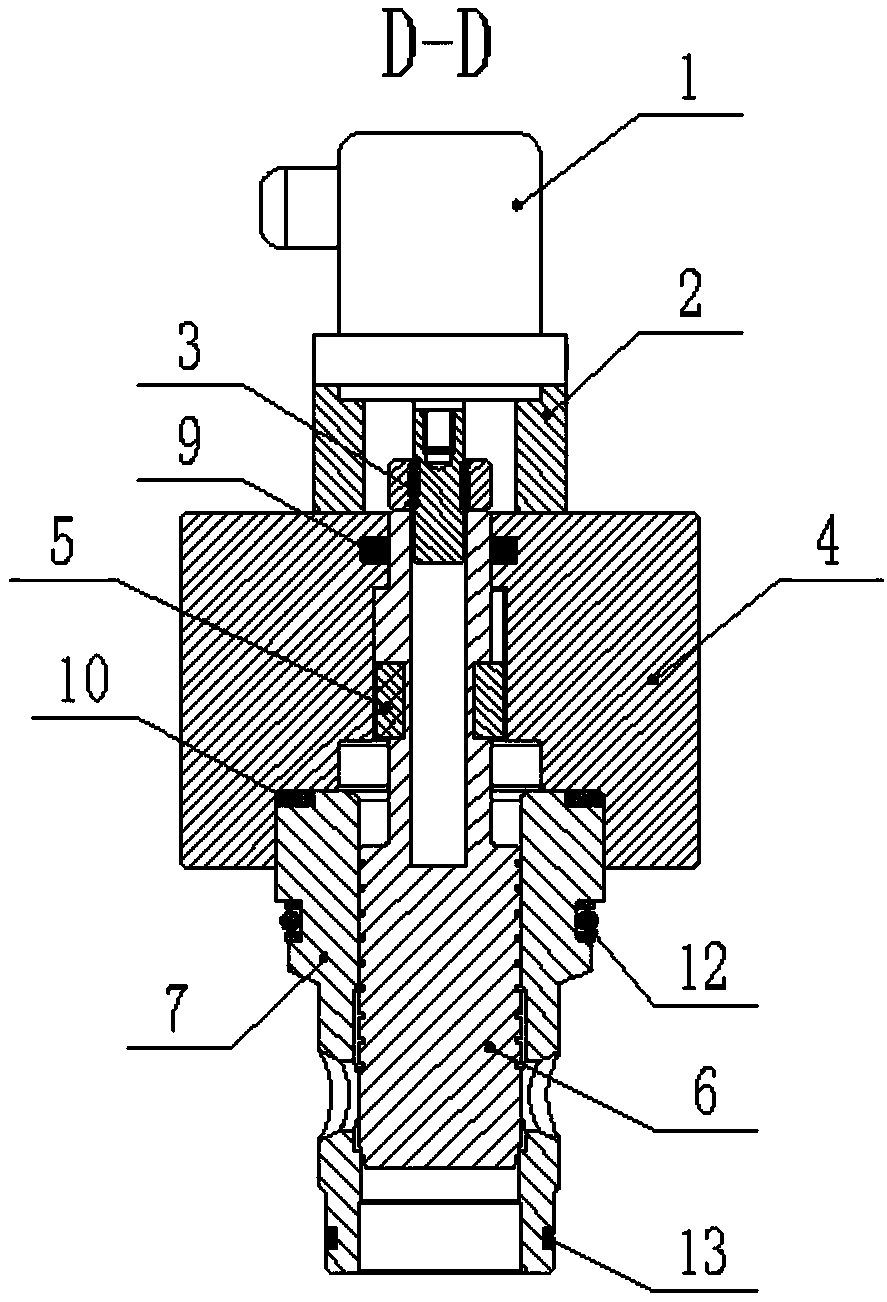

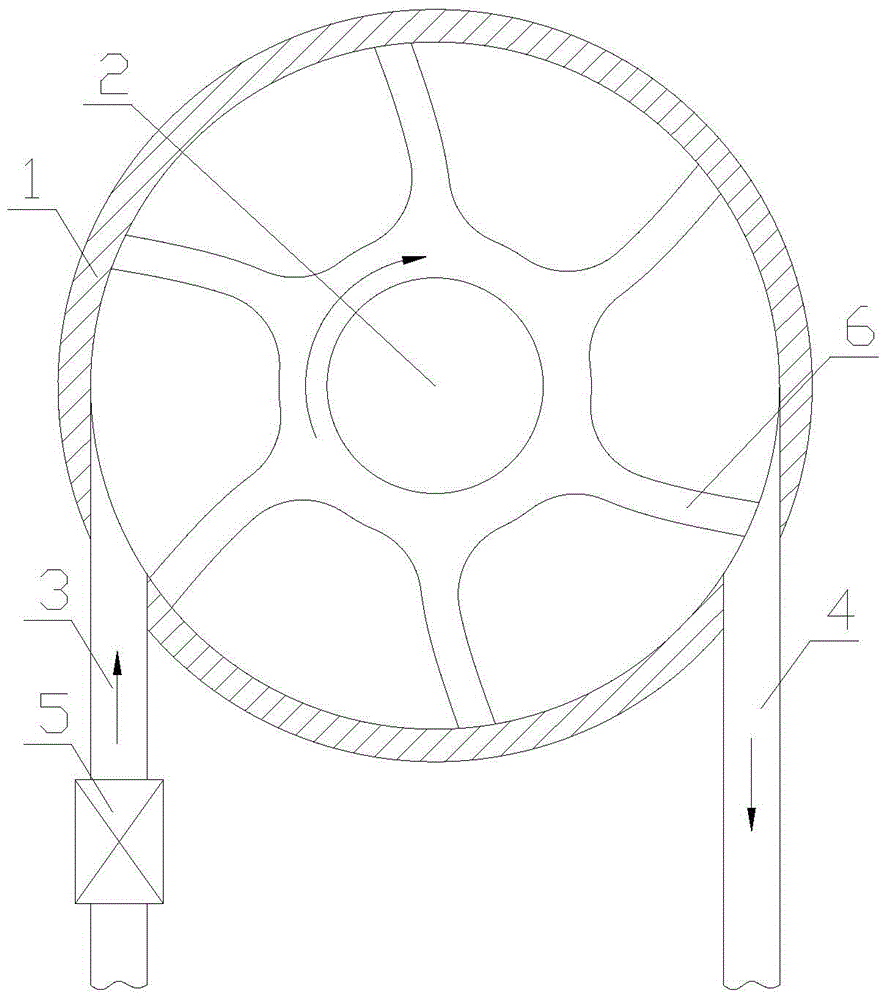

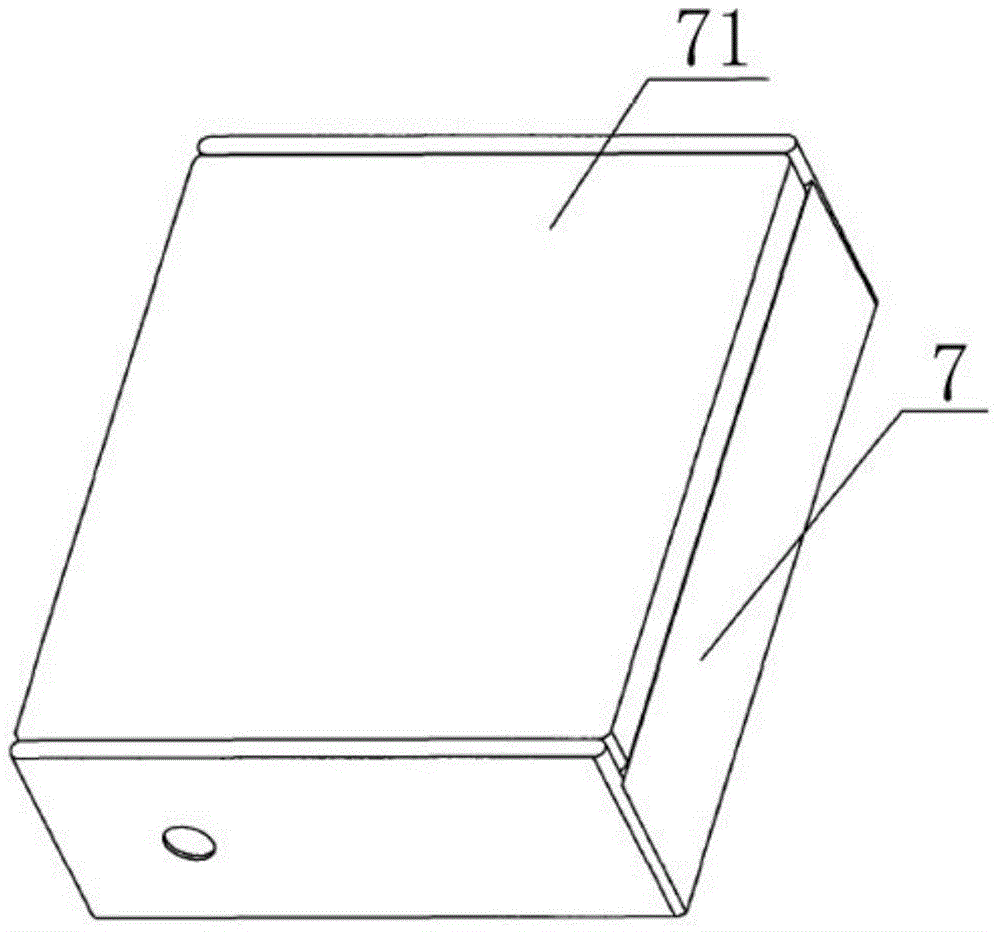

Proportional Insert Pressure Relief System of Forging Hydraulic Press and Its Pressure Relief Method

ActiveCN105268889BReduce shockStable pressure reliefForging press drivesElectricityProgrammable logic controller

The invention discloses a pressure relief system and a pressure relief method for a proportional plug-in part of a forging hydraulic press, and relates to the technical field of presses, including: a pressure sensor for collecting oil pressure data in a main cylinder of a slide block of a forging hydraulic machine; a proportional plug-in The assembly is used to receive instruction information from the programmable logic controller, and adjust the opening of the spool according to the instruction information; the programmable controller is used to receive the oil pressure data, and send instructions to the proportional insert Information; wherein: the analog output port of the programmable controller is electrically connected to the proportional cartridge valve, and the analog input port of the programmable controller is electrically connected to the pressure sensor. By adopting the above technical scheme, the present invention has the characteristics of fast pressure relief and good stability.

Owner:TIANJIN TIANDUAN PRESS CO LTD

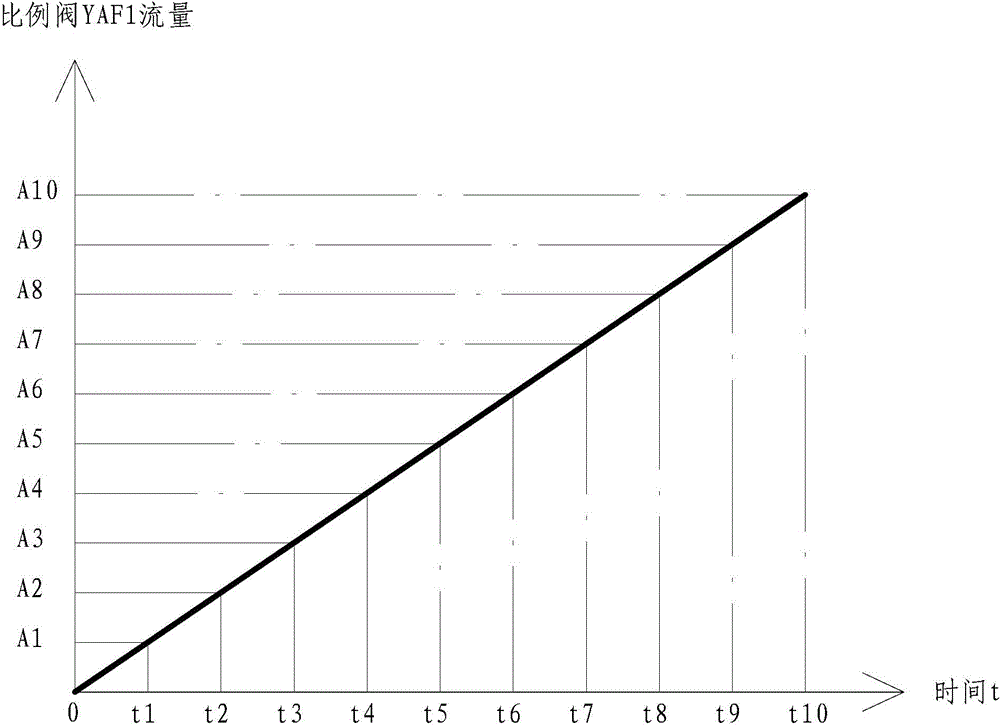

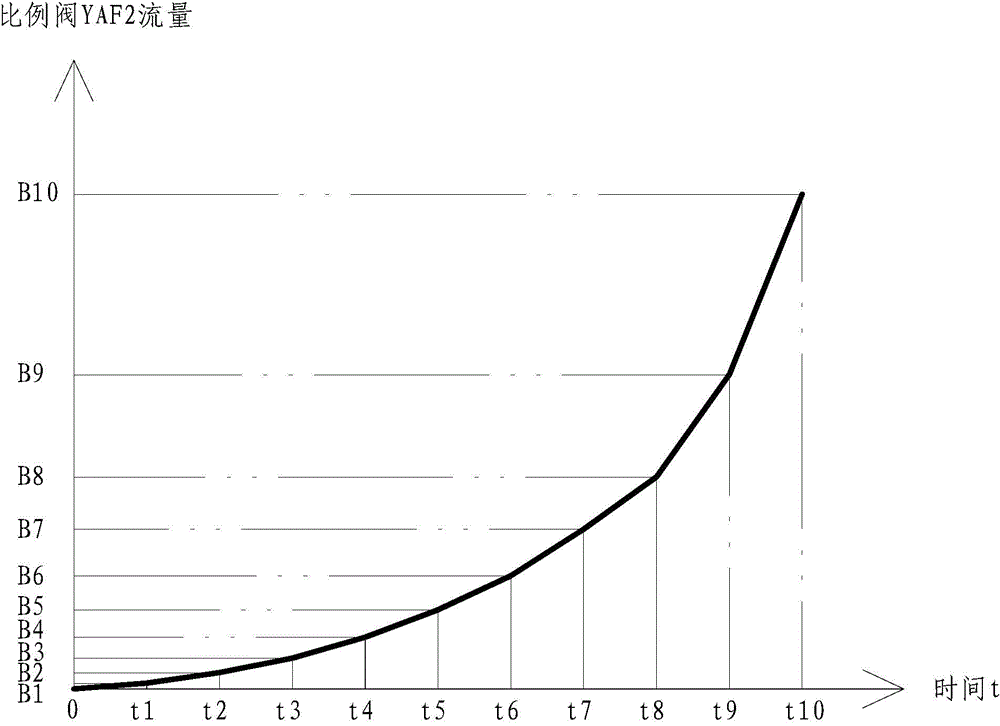

Pressure relieving system and method of forging hydraulic machine

InactiveCN105458142AImprove pressure relief efficiencyImprove stabilityForging press drivesPressesProgrammable logic controllerHigh pressure

The invention discloses a pressure relieving system and method of a forging hydraulic machine. A programmable logic controller is used for receiving oil pressure data and outputting proportional servo valve flow commands; the two parallel proportional servo valve flow commands are a coarse adjustment command given by linear flow based on time and a fine adjustment command given by segmented adjustable flow; proportional servo valves are used for adjusting the oil pressure in a slider main cylinder according to the flow commands of the programmable logic controller; a pressure sensor is used for collecting the oil pressure data in the slider main cylinder. The programmable logic controller is used for controlling the two proportional servo valves; a coarse tendency is given to one proportional servo valve so as to improve the pressure relieving efficiency, and segmented fine adjustment is given to the other proportional servo valve so as to the pressure relieving character to improve the stability, so that a good pressure reducing and relieving curve is obtained, and finally the purposes of high-pressure small-gradient stable pressure relief and low-pressure large-gradient rapid pressure relief are achieved.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Intelligent home burst transmission data acquisition system based on GSM (Global System for Mobile Communications)

InactiveCN105139618AImprove reliabilityFast reliabilityTransmission systemsVolume/mass flow by mechanical effectsComputer hardwareBurst transmission

The invention discloses an intelligent home burst transmission data acquisition system based on GSM (Global System for Mobile Communications), belongs to a water meter data acquisition system in the technical field of intelligent home, and aims to provide an intelligent home burst transmission data acquisition system which is based on GSM, remote in data transmission distance and rapid in data transmission rate. A technical scheme of the intelligent home burst transmission data acquisition system is characterized by comprising a water meter box, a water meter, an acquisitor, a GSM communication module and a controller, wherein a water meter sensor in the water meter is electrically connected with the acquisitor, the acquisitor is electrically connected with the GSM communication module, and the GSM communication module is electrically connected with the controller. The intelligent home burst transmission data acquisition system is suitable for the water meter data acquisition system in an intelligent home.

Owner:成都锐可科技有限公司

Ultra-high pressure automatic pressure relief device

ActiveCN106907368BAvoid chronic stressExtended service lifeServomotor componentsUltra high pressureSystem pressure

The invention discloses an ultrahigh-pressure fully-automatic pressure relief device. The ultrahigh-pressure fully-automatic pressure relief device comprises a main body and a step motor positioned at the right side of the main body, wherein the main body comprises a pressure relief cavity which is through in two sides; the pressure relief cavity comprises a sealing cavity at the left side, a regulating cavity on the middle and a threaded cavity at the right side, wherein a screw plug I at the left side and a valve seat at the right side are arranged in the sealing cavity; an ejector pin which is thin in left portion and thick in right portion is arranged in the regulating cavity; the left end of the ejector pin is equipped with a tip which extends into a valve hole; the threaded cavity is internally matched with a screw; the left end of the screw is bumped, and abuts against the right end of the ejector pin; the right end of the screw is equipped with a shaft hole with a key slot; the shaft hole is in clearance fit with a motor shaft of the step motor through a flat key; the lower end of the main body is equipped with an oil inlet which is fixedly equipped with an oil inlet nozzle; and the oil inlet communicates with a first oil inlet hole path. According to the ultrahigh-pressure fully-automatic pressure relief device disclosed by the invention, the step motor is adopted to drive the screw to regulate movement of the ejector pin, so that the tip is regulated to extend into the valve opening by certain length, and therefore, linear pressure relief is realized, linear changes of system pressure are realized, and a production process curve is met.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

Indoor safety pressure relief fuel gas pipeline

InactiveCN112212044AGuaranteed pressure balanceEnsure safetyOperating means/releasing devices for valvesEqualizing valvesEngineeringEnvironmental geology

The invention discloses an indoor safety pressure relief fuel gas pipeline which comprises a fuel gas pipeline body. A collecting block is fixed to the lower end face of the fuel gas pipeline body; agas pressure sensing mechanism for sensing the gas pressure in the pipeline is arranged in the fuel gas pipeline body; a gas pressure collecting device for collecting and relieving pressure is arranged in the collecting block; a fuel gas discharging mechanism for selectively discharging fuel gas is arranged at the left end of the collecting block; and when the gas pressure in the fuel gas pipelineis too large, a sensing block in the pipeline senses pressure intensity changes and automatically starts a pressure relief function, redundant fuel gas can be automatically collected in the pressurerelief process, and when the collected fuel gas is too much, a standby pressure reduction function is automatically started, so that stable pressure relief and pressure intensity balance of the fuel gas pipeline are further guaranteed, the collected fuel gas can be refilled into the fuel gas pipeline or taken out to be treated separately, and the process can be guaranteed to be carried out safelywhile pressure relief is carried out on the fuel gas pipeline.

Owner:DONGYING QIHAO DAILY NECESSITIES CO LTD

Solar ground-source heat pump system and control method thereof

PendingCN108413630AStable pressure reliefIncrease the areaSolar heating energySolar heat collector controllersRelief valveSolar thermal collector

The invention discloses a solar ground-source heat pump system which comprises a solar heat collector and a buried pipe and also comprises a first water tank, a second water tank and a mixed water tank, wherein a first heat exchanger is arranged between the solar heat collector and the first water tank; a first water pump is mounted on the first heat exchanger; a second heat exchanger is arrangedbetween the buried pipe and the second water tank; a second water pump is mounted on the second heat exchanger; the first water tank communicates to the mixed water tank through a first bidirectionalgear pump; the second water tank communicates to the mixed water tank through a second bidirectional gear pump; the solar heat collector communicates to the buried pipe through a third bidirectional gear pump; and pressure relief valves are separately arranged on two sides of the third bidirectional gear pump. The system disclosed by the invention can improve the defects in the prior art, and thepressure fluctuation of system operation is reduced effectively.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

A temperature and pressure control method for a hydrogenation process and its design method and application

ActiveCN106957675BStable pressure reliefLow reaction pressureHydrocarbon oil crackingHydrocarbon oils treatmentHydrogenation processEngineering

Disclosed are a temperature and pressure control method for a hydrogenation process, a design method therefor and the use thereof. A pressure relief point is arranged at an outlet of a separation system after a reactor, or at a downstream device or pipeline connected thereto, with the temperature at the pressure relief point being 30-220C. Two control points are arranged, wherein when control point I is exceeded, i.e., temperature 440C / pressure 19 MPa, the pressure reduction rate is 3-10 bar / min; and when control point II is exceeded, i.e., temperature 460C / pressure 21 MPa, the pressure reduction rate is 10-25 bar / min. By using this control method, a high-pressure device can be made more stable during a pressure relief process.

Owner:CATECH TECH

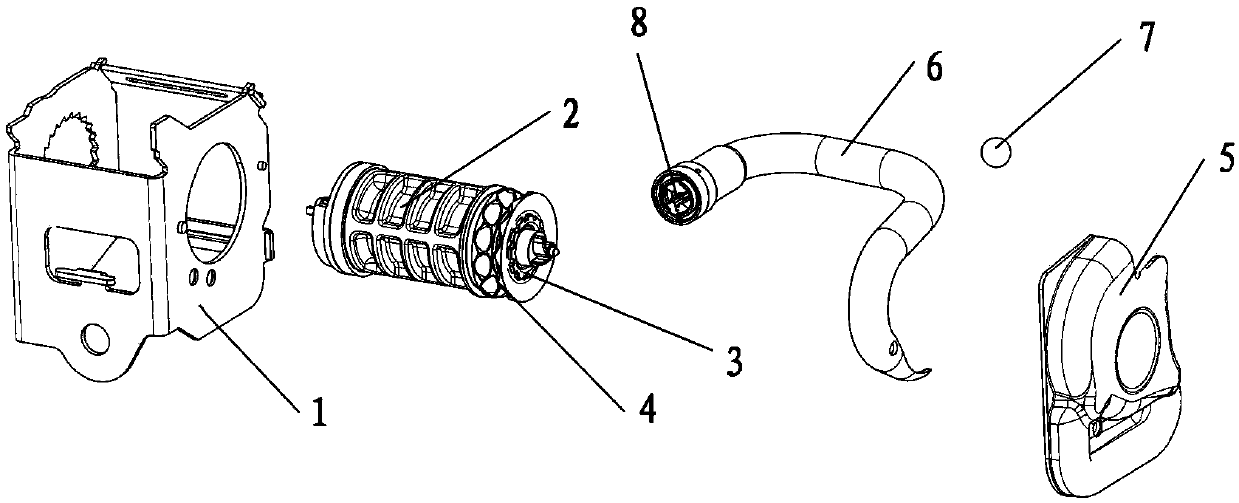

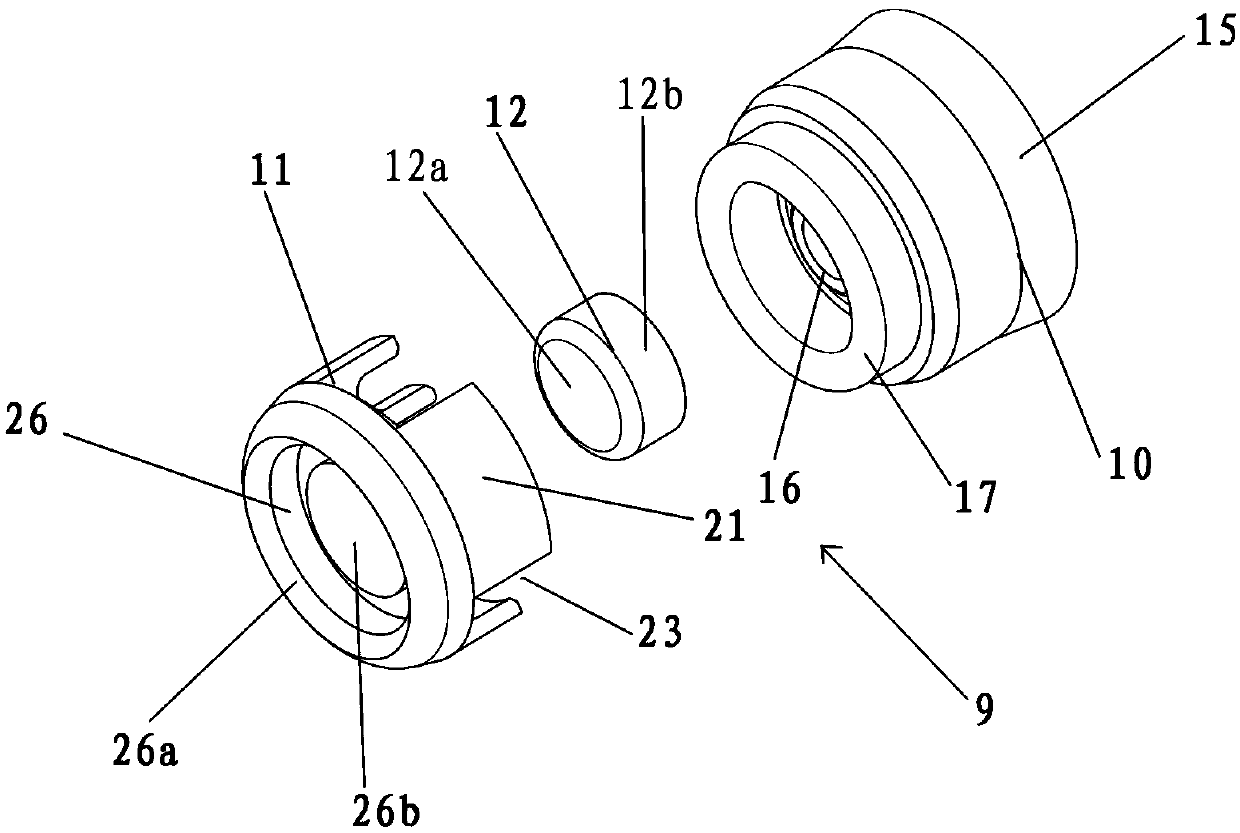

Piston, safety belt retractor and pre-tightening type safety belt

The invention relates to a piston for a safety belt pre-tightening function. The piston is provided with a front side, a circumferential side, a rear side, and a gas flowing channel which is formed inthe piston and connects the rear side to the front side or the circumferential side in a flow manner; the gas flowing channel is closed by a closing element and can be released when current pressurereaches or exceeds predetermined pressure; and the gas flowing channel is provided with a dissipation structure for dissipating energy of gas flow flowing through the gas flowing channel. The invention also relates to a safety belt retractor comprising such a piston and to a pre-tightening safety belt comprising such a safety belt retractor. In a collision accident, when the pressure of gas generated by a gas generator is too large, stable pressure relief can be achieved through the gas flowing channel, pressure drop during pressure relief is relieved while pressure relief is controlled, and meanwhile, flames possibly carried by the gas flow during pressure relief are restrained.

Owner:YANFENG AUTOMOTIVE SAFETY SYST CO LTD

A device for automatically balancing tire pressure during driving

ActiveCN103112322BImprove securityEffects of low directional controlTyre measurementsEngineeringPressure difference

The invention discloses a device for automatically balancing tire pressure in the running process of an automobile. The device comprises two air chambers which are respectively arranged at the two ends of the axle of the automobile, can be connected through a valve for balancing the pressure difference of the two air chambers, and are respectively communicated with air cavities of adjacent tires. The device for automatically balancing the tire pressure in the running process of the automobile has the advantages of simple structure, low cost, high safety and reliability and convenience in popularization and application.

Owner:HUNAN UNIV

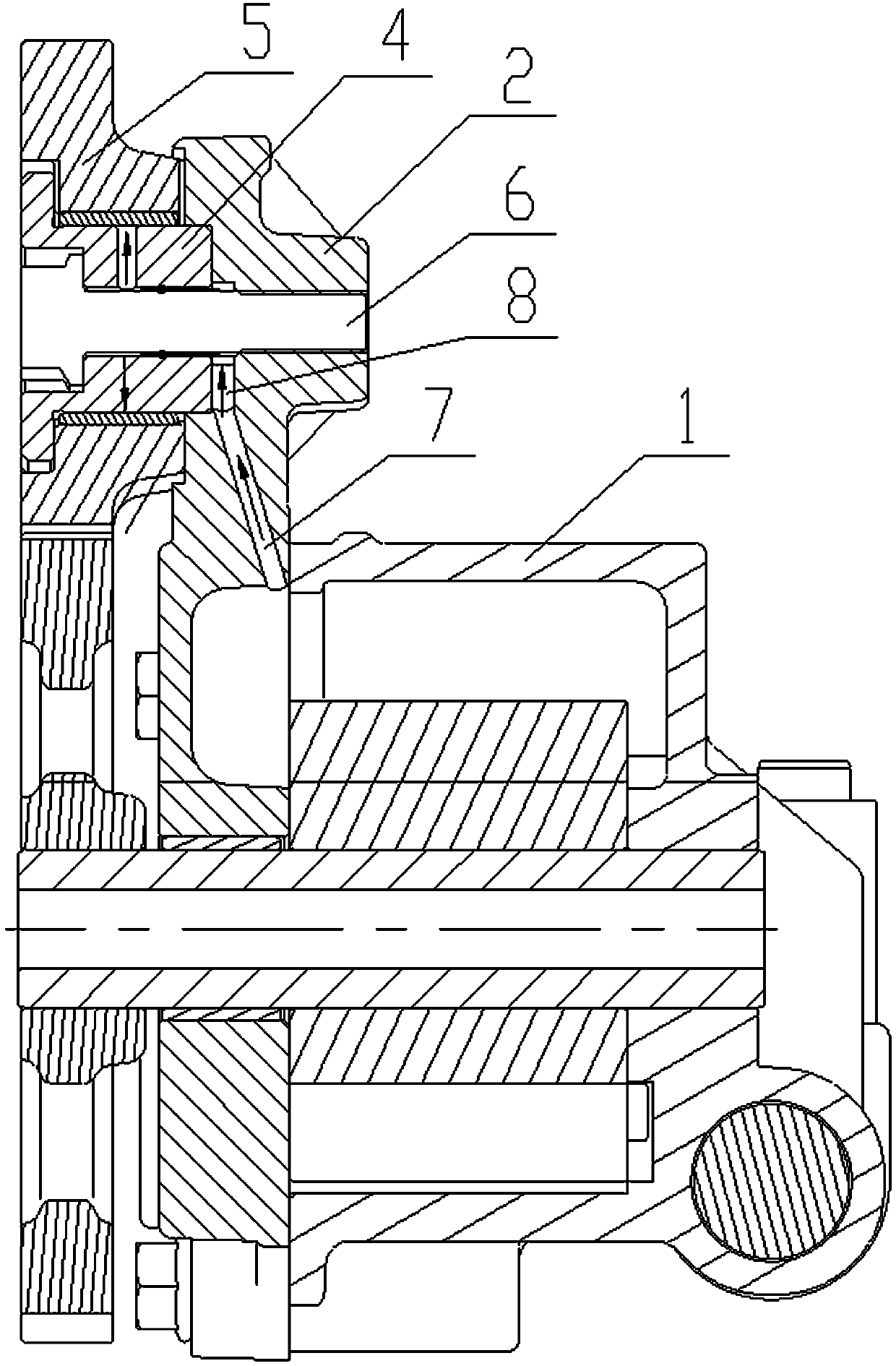

Automobile engine oil pump

ActiveCN101865003BSave layout spaceReduce quality problemsPressure lubrication with lubrication pumpEngineeringDual purpose

The invention provides an automobile engine oil pump which comprises a pump bonnet and a pump body, wherein a high-pressure oil cavity and a low-pressure oil cavity are arranged in the pump body; the pump bonnet is provided with a dual-purpose valve; the dual-purpose valve comprises a valve body; an oil return cavity, a valve cavity and a valve core are arranged in the valve body; the oil return cavity is positioned at the upper part of the valve cavity; the valve core is installed in the valve cavity and isolates the oil return cavity from the valve cavity; the valve cavity is communicated with the high-pressure oil cavity; the valve core is provided with a first end face and a second end face; the first end face is contacted with the oil return cavity and bears the downward acting forceof the oil in the oil return cavity; the second end face is contacted with the valve cavity and bears the downward acting force of the oil in the valve cavity; the area of the first end face is smaller than that of the second end face; and the position on which the dual-purpose valve is arranged on the pump bonnet is provided with a pressure relief port which is communicated with a low-pressure oil cavity. The oil pump can relieve pressure at the time of cold starting of an engine and can also steadily relieve pressure when the engine normally operates, so that the arrangement space of the oil pump is small.

Owner:华域皮尔博格泵技术有限公司

Intelligent household highly real-time data acquisition system based on Wi-Fi

InactiveCN105137801AImprove real-time performancePracticalComputer controlProgramme total factory controlData acquisitionEmbedded system

The invention discloses an intelligent household highly real-time data acquisition system based on Wi-Fi, belongs to the data acquisition system in the intelligent home technical field, and aims to provides the intelligent household highly real-time data acquisition system which is higher in reliability and real-time performance. According to the technical scheme, the intelligent household highly real-time data acquisition system comprises a water meter box body, a water meter, a WiFi communication module, a wireless interrupter, a wireless AP module and a central processor; a water meter sensor in the water meter is electrically connected with the WiFi communication module; the WiFi communication module is connected with the wireless interrupter through a wireless network; the wireless interrupter is connected with the wireless AP module through the wireless network; and the wireless AP module is connected with the central processor through a wired network.

Owner:成都锐可科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com