Differential type mold locking pressure relief oil way for two-plate injection molding machine

A pressure relief oil circuit, differential type technology, applied in the field of differential clamping pressure relief oil circuit, can solve the problems of obvious oil return noise, mold breaking failure, loud secondary pressure relief sound, etc., and achieve the pressure relief process. The effect of stable, good oil cleanliness and low oil return noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

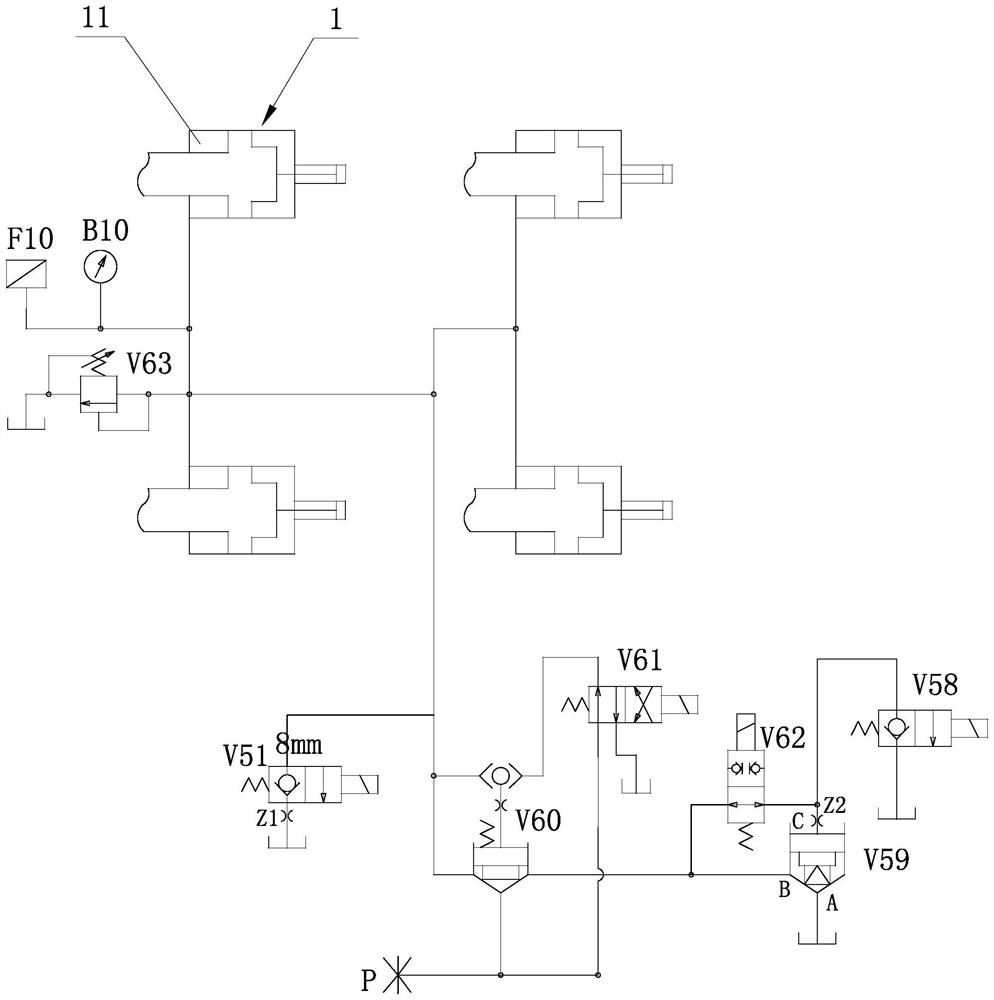

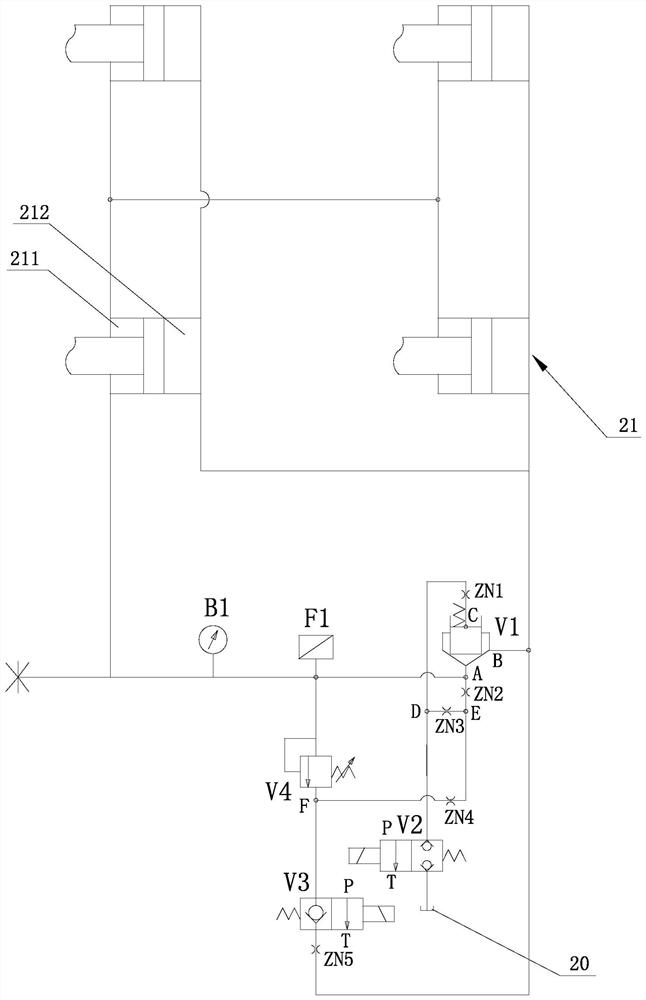

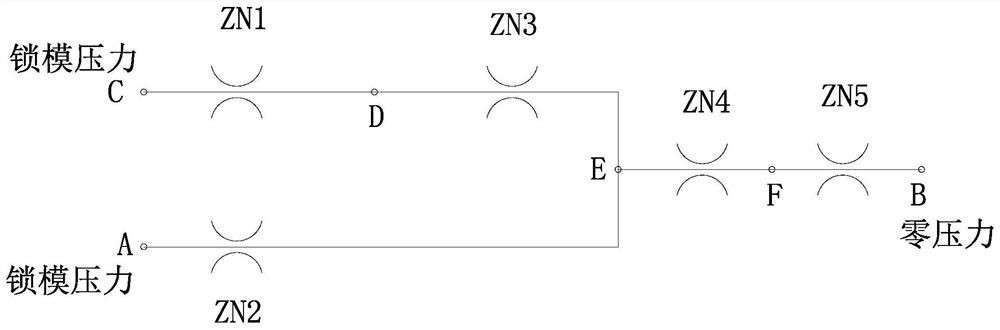

[0024] The present invention proposes a differential clamping pressure relief oil circuit for a two-platen injection molding machine, such as figure 2As shown, it includes a cartridge valve V1 with a spool of 1:1, a first two-position two-way electromagnetic reversing valve V2, a second two-position two-way electromagnetic reversing valve V3 and a fuel tank 20; the bottom of the cartridge valve V1 The working oil port, i.e. port A, communicates with the clamping cavity 211 of the clamping cylinder 21 and the side working oil port of the cartridge valve V1, i.e. port B, communicates with the mold breaking cavity 212 of the clamping cylinder 21 to form the main channel oil circuit; When the electromagnet of the two-position two-way electromagnetic reversing valve V3 is energized, the pilot port of the cartridge valve V1, that is, the C port, pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com