Air passage type or water passage type soundproof wall having acoustic isolation resonance chamber formed in air passage channel or water passage channel

A resonant cavity and channel technology, which is applied in the direction of noise absorption devices, sound insulation, and sound emitting devices, can solve problems such as air permeability, different technical ideas, and different structures, and achieve the effect of reducing noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

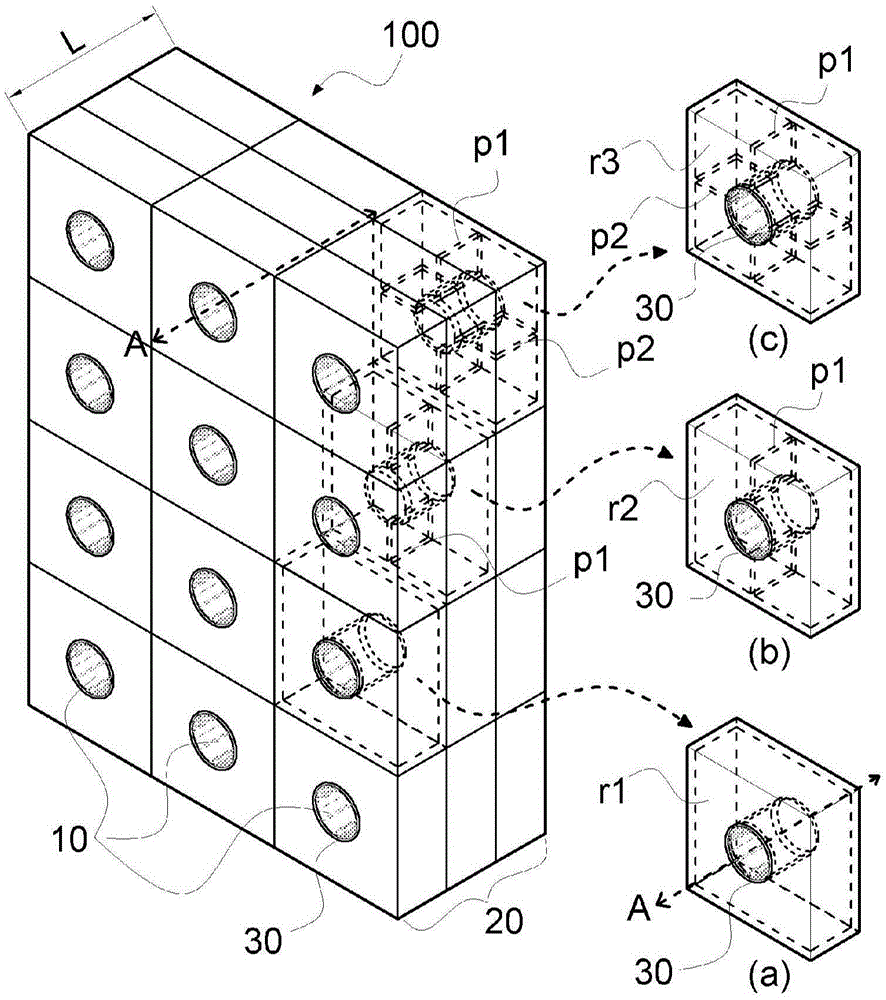

[0088] After fabricating the soundproof wall structure of the present invention according to the data described later, the sound insulation performance was tested at the Korea Machinery Research Institute, No. 171, Changdong, Yucheng District, Daejeon Metropolitan City (test acceptance number: system 350-1-12101).

[0089]The test was conducted using the simple sound insulation performance system of the Korea Machinery Research Institute, and the measurement method was carried out for the simple sound insulation performance implemented in the microcavity in compliance with the sound insulation performance test specifications (ISO140-3:1995, ASTME90-09:2009 and KSF2808:2001) Measurement, the schematic diagram of the simple sound insulation performance measurement system used in the test is as follows Figure 7 shown.

[0090] The measurement conditions are as follows.

[0091] (measurement conditions)

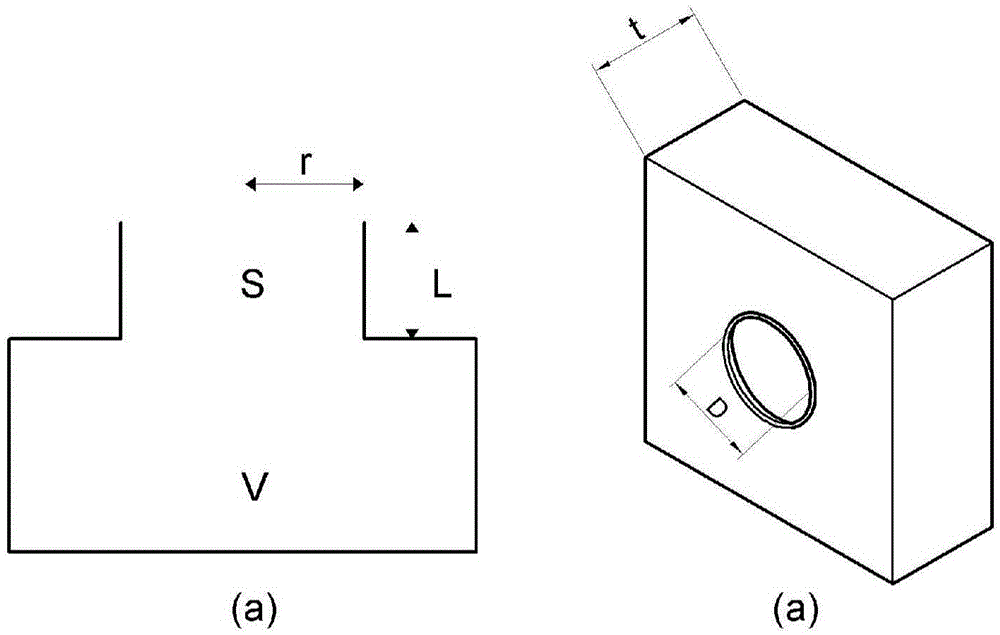

[0092] -Effective diameter of ventilation channel: 5cm

[0093] -Specime...

Embodiment 2

[0111] The diameter (D) of the ventilation passage (10) of the aforementioned embodiment 1 is 5cm, compared with it, the effective diameter (D) of the ventilation passage (10) is set to 2cm in embodiment 2, and all the other are the same as the previous embodiment 1 is the same.

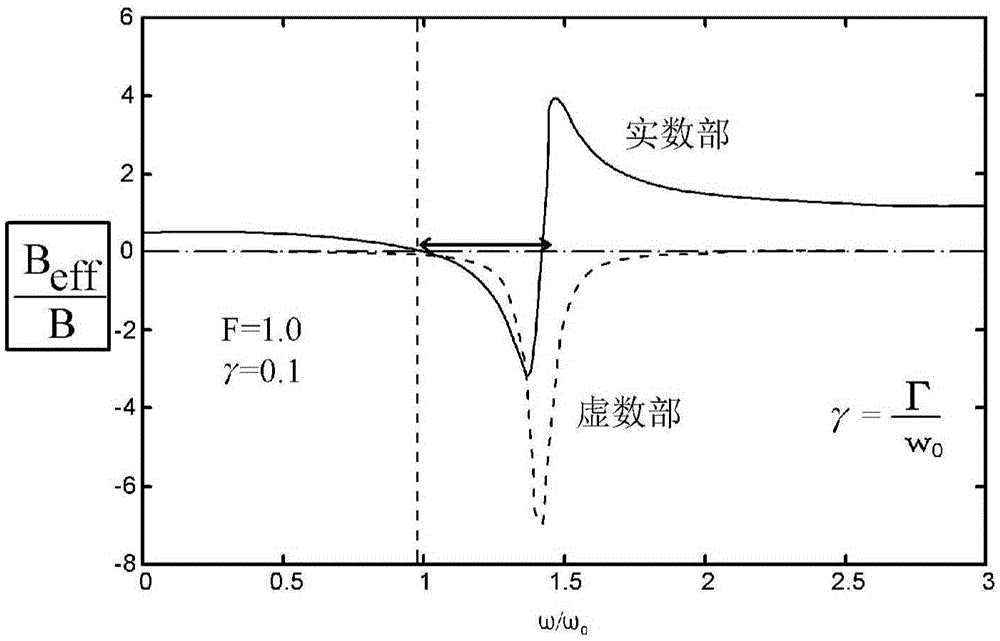

[0112] The following table 1 sorts out the test results of the foregoing embodiment 1 and embodiment 2, Figure 6 is the graph of its sound pressure transmission loss.

[0113] Table 1

[0114]

[0115] As mentioned earlier, the frequency range that humans can hear is 20Hz-20KHz, but most of the mechanical sounds are high-frequency and its value is above 500Hz. High frequencies above 5KHz are easy to scatter and cannot be transmitted to distant areas. Moreover, due to Most of the soundproof windows or soundproof walls are sufficient as long as they can block the range of 500Hz to 5000Hz. From the above Table 1, it can be seen that in the range of 400Hz to 5000Hz, both embodiments have an average...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com