Booster-type gas compressor

A technology of compressor and compressed gas, applied in liquid variable capacity machinery, mechanical equipment, fluid parameters, etc., can solve problems such as large torque change, increased current, accelerated seal damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

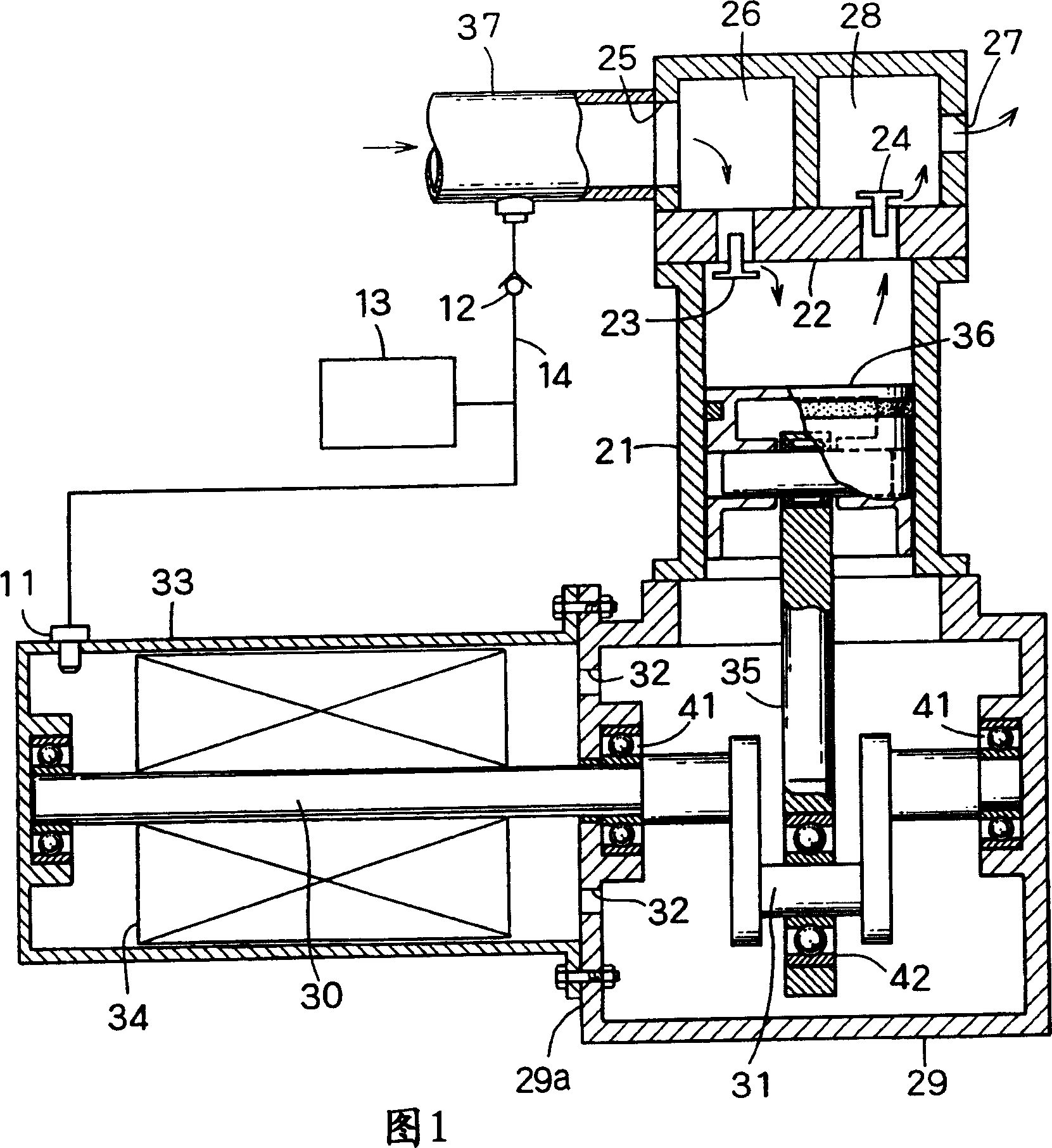

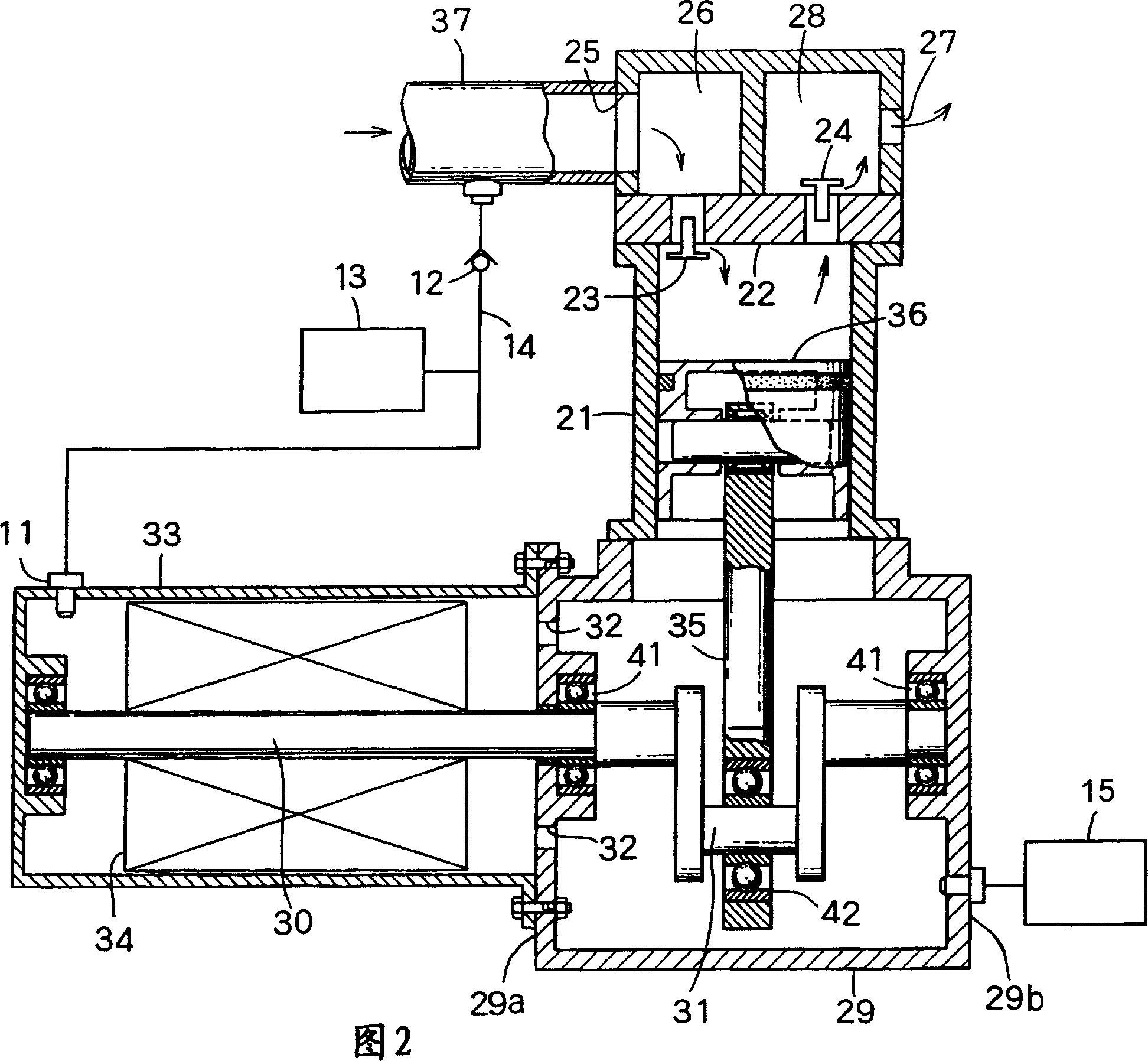

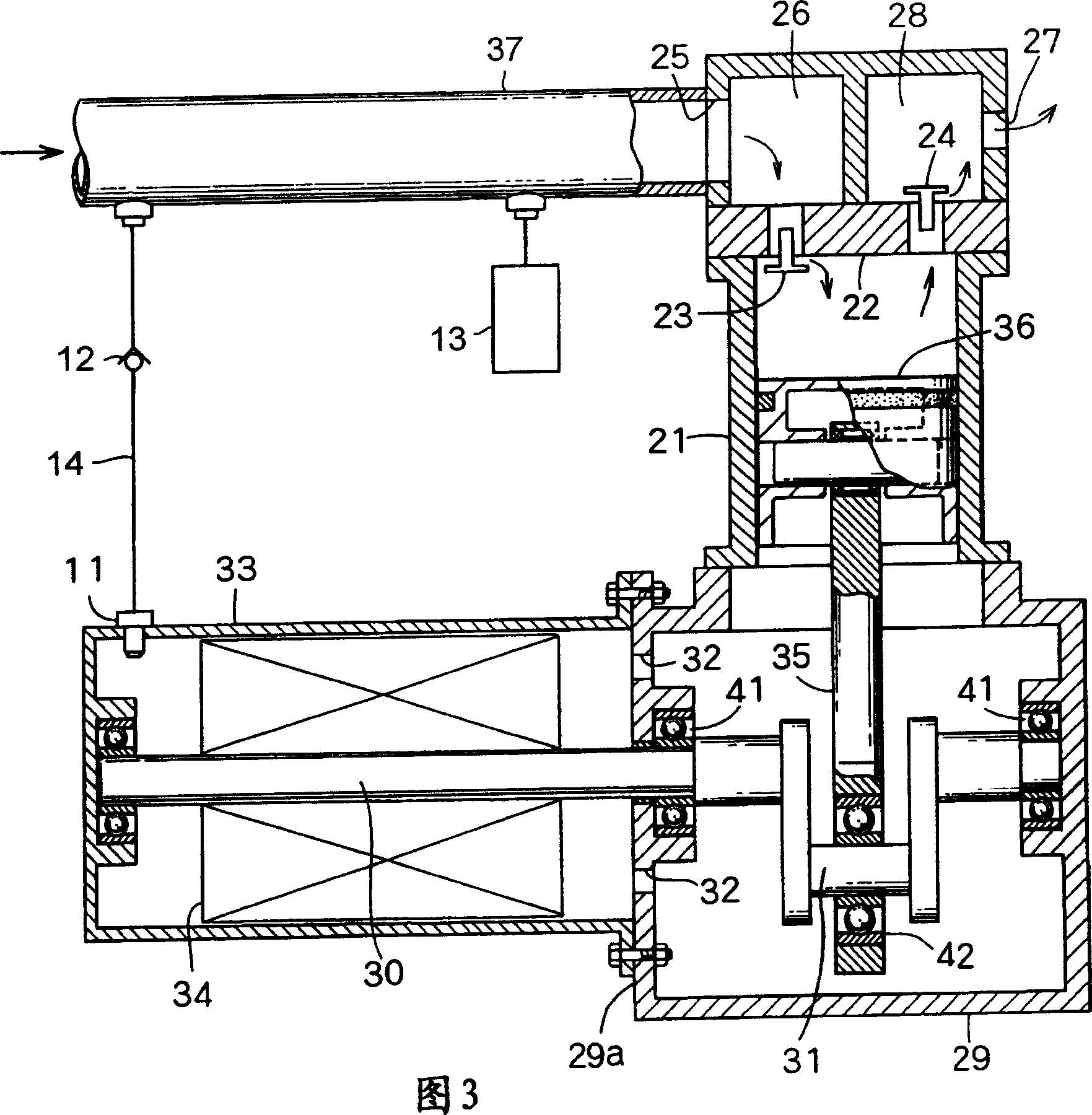

[0014] Fig. 1 shows a first embodiment of the booster type gas compressor of the present invention.

[0015] The basic structure of the supercharged gas compressor is not much different from that in FIG. 4 . The same reference numerals refer to the same components. Therefore, description thereof is omitted and only differences are described.

[0016] In FIG. 1 , there is no air hole 38 communicating with the outside air, and a compressed air introduction hole 11 is formed on the motor case 33 instead of the ventilation hole.

[0017] The compressed gas supply channel 37 is connected to the compressed gas introduction hole 11 through a bypass conduit 14 having a one-way valve 12 and a pressure regulator 13 which are closed in the direction toward the compressed gas supply channel 37 and closed in the opposite direction. open, the pressure regulator is, for example, a pressure regulating valve or a pressure reducing valve.

[0018] By opening a valve (not shown), compressed g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com