Proportional Insert Pressure Relief System of Forging Hydraulic Press and Its Pressure Relief Method

A proportional plug-in, hydraulic press technology, applied in the field of presses, can solve the problems of pressure relief shock, difficult adjustment of the relief valve of the hydraulic circuit, long pressure relief time, etc., to reduce the shock and ensure the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

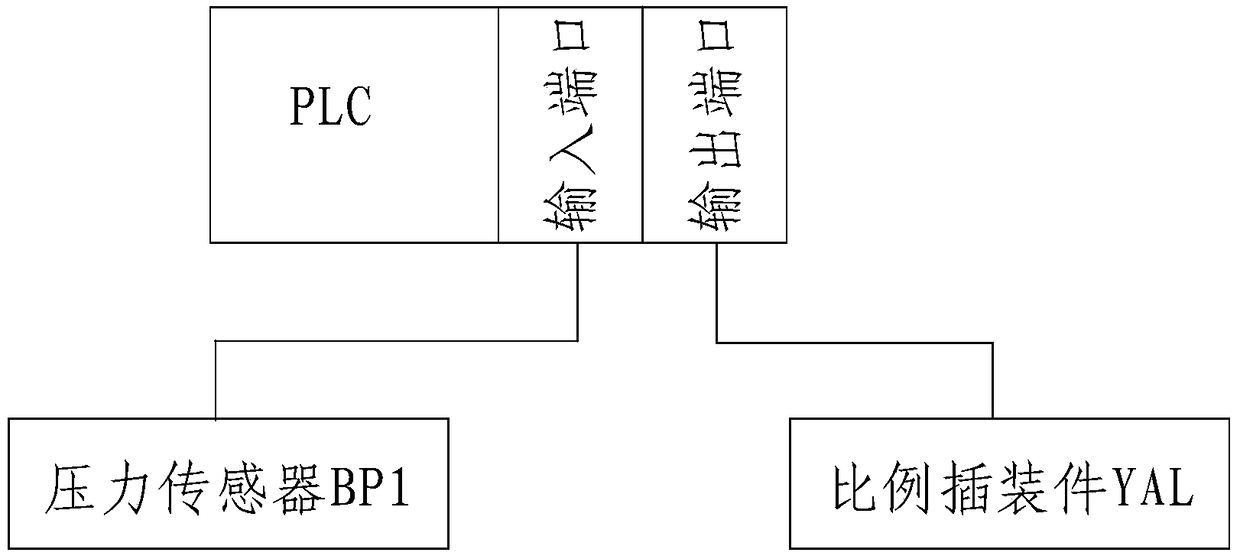

[0019] See figure 1 , A proportional cartridge pressure relief system for forging hydraulic presses, including:

[0020] Pressure sensor, used to collect oil pressure data in the main cylinder of the slider of the forging hydraulic press;

[0021] The proportional plug-in unit, as an actuator, the proportional plug-in unit is used to receive the instruction information of the programmable logic controller (that is, the opening degree of the proportional plug-in unit), and perform the opening of the proportional plug-in unit according to the instruction information Adjustment;

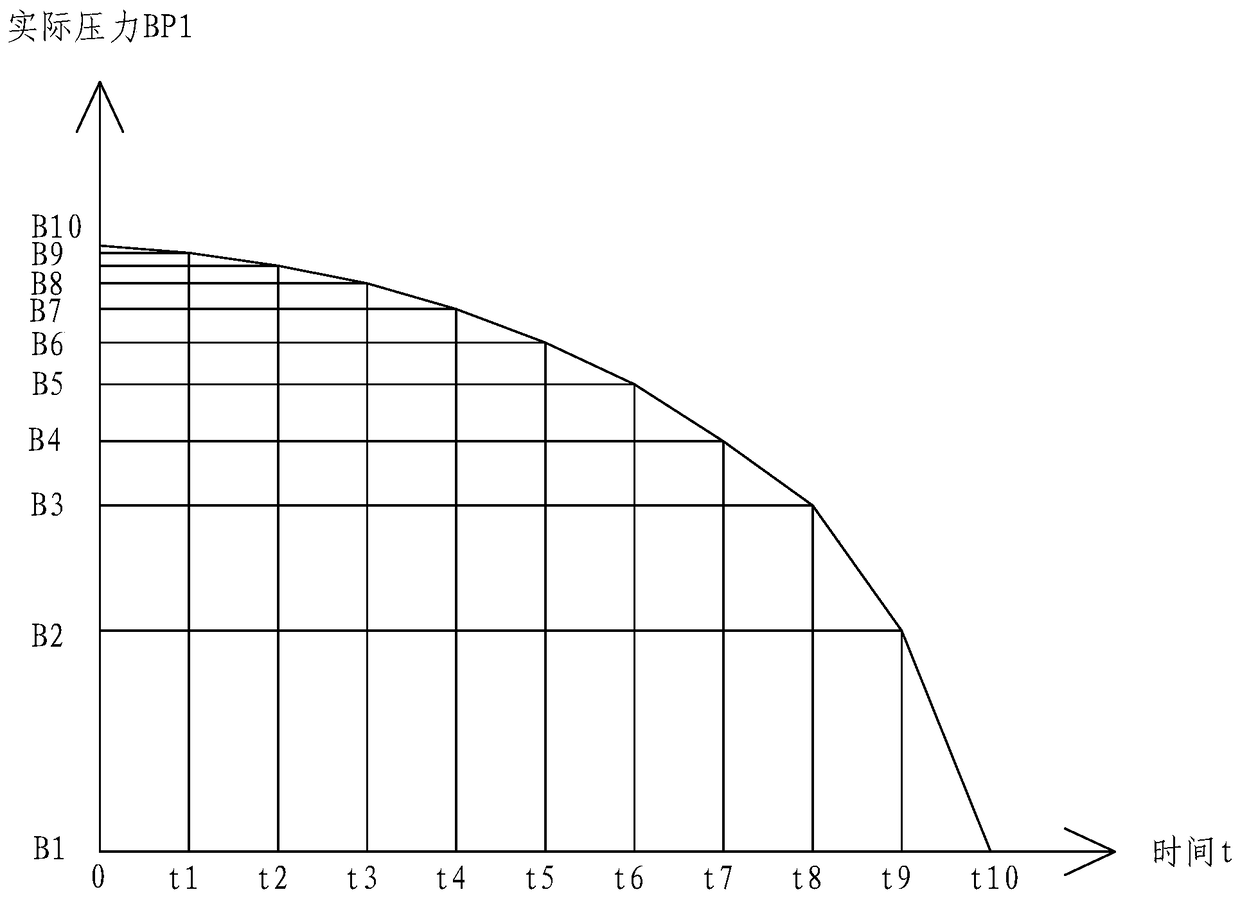

[0022] Programmable controller, the programmable controller obtains the instruction information of each sub-pressure relief process according to the following relational expression, and sends the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com