Flexible control method of forging press

A control method and technology for a forging press, applied in the field of forging press control, can solve the problems of pressure relief shock, severe vibration of pipeline, rupture of hydraulic valve parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

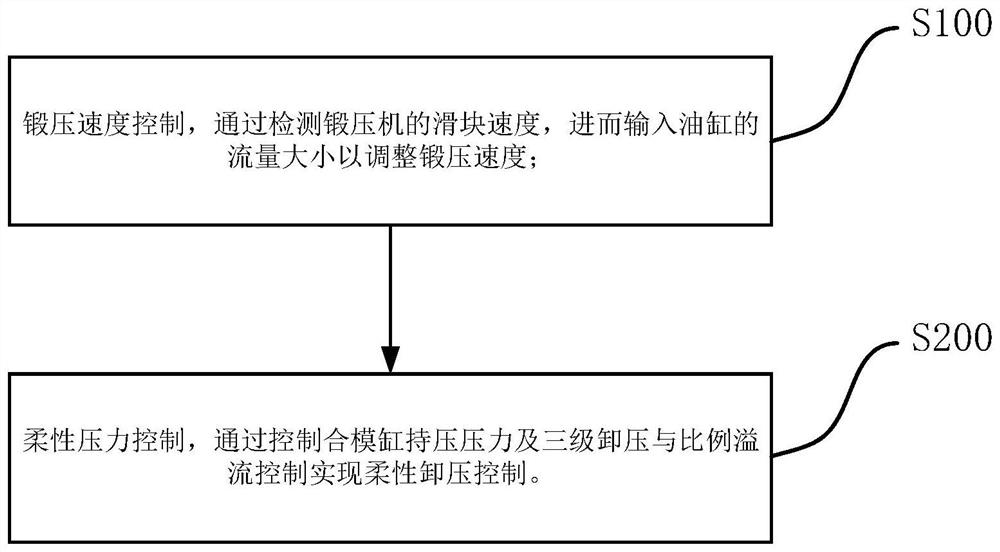

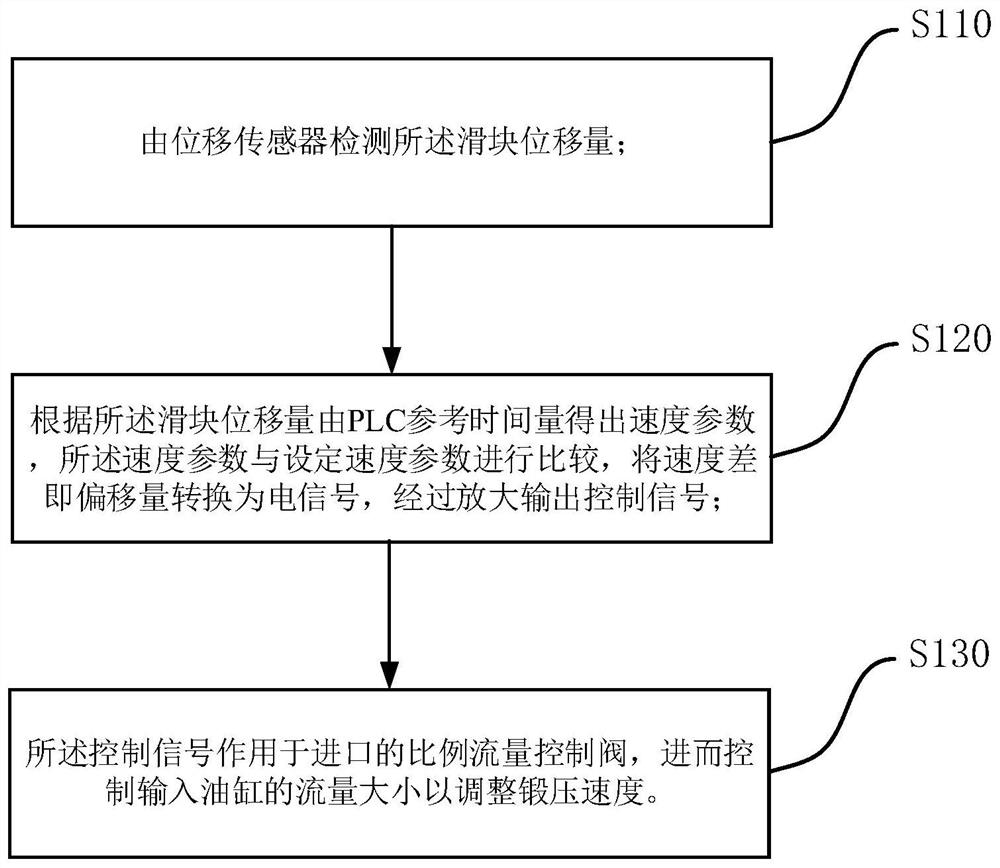

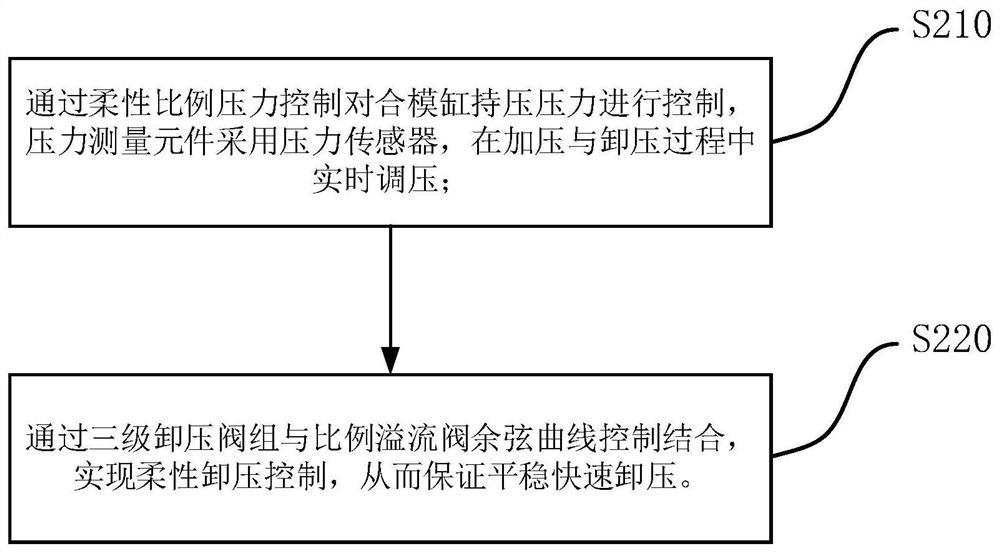

[0034] Such as Figure 1 to Figure 4 Shown, technical scheme of the present invention is:

[0035] A flexible control method for a forging press, based on a pressing speed control method based on the integral separation PID method; real-time monitoring of the slider stroke, aiming at the impact of the unloading process on the shape quality of the wheel, combined with a three-stage pressure relief valve group and a proportional relief valve cosine The curve control method is used to control the flexible pressure relief of the forging press.

[0036] Specifically include the following steps:

[0037] Operation S100: forging speed control, by detecting the speed of the slider of the forging press, and then inputting the flow rate of the oil cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com