Pressure relieving system and method of forging hydraulic machine

A hydraulic press and pressure relief technology, which is applied in the field of forging hydraulic presses, can solve the problems of slow pressure relief process, pressure relief impact, poor stability, etc., and achieve the effect of improving pressure relief efficiency, improving stability, and smooth pressure relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0014] see figure 1 , a forging hydraulic pressure relief system, including a programmable controller, a proportional servo valve and a pressure sensor, the analog input port of the programmable controller is electrically connected to the pressure sensor, and the analog output port of the programmable controller is connected to the proportional servo valve There are two proportional servo valves connected in parallel.

[0015] A pressure relief method using a pressure relief system, comprising the steps of:

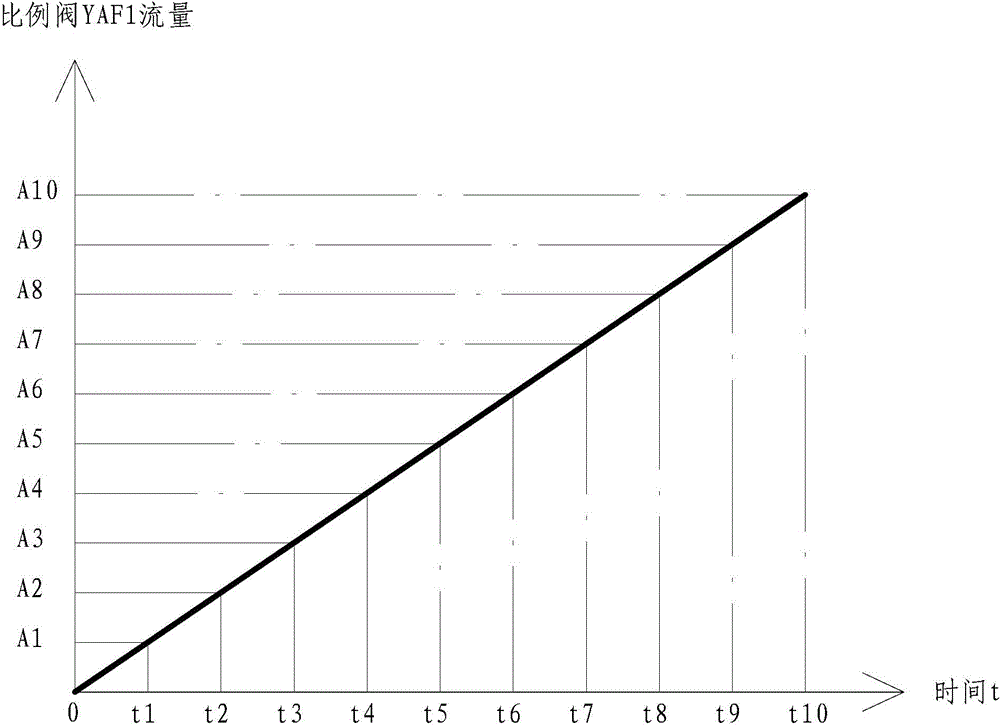

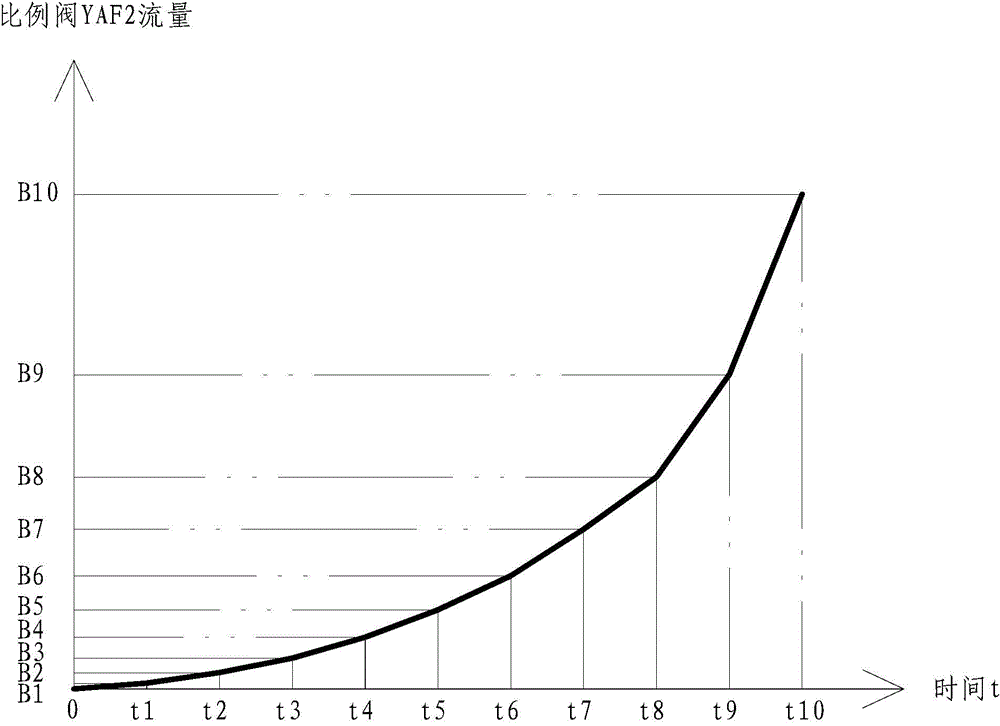

[0016] The programmable controller is used to receive the oil pressure data and output the proportional servo valve flow command. The two proportional servo valve commands in parallel are divided into: one command is a time-based linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com