Patents

Literature

92results about How to "Will not cause loosening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

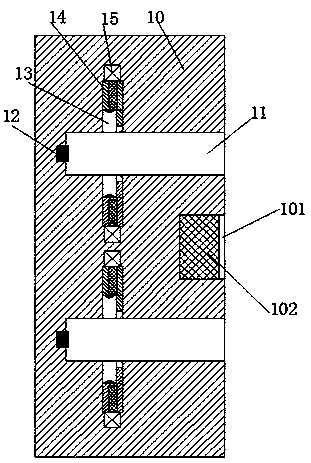

Embedded type wall power supply inserting-connecting socket assembly

ActiveCN107369990AThere will be no electric shock accidentsReduce security risksCoupling parts mountingEmbedded systemElectrical equipment

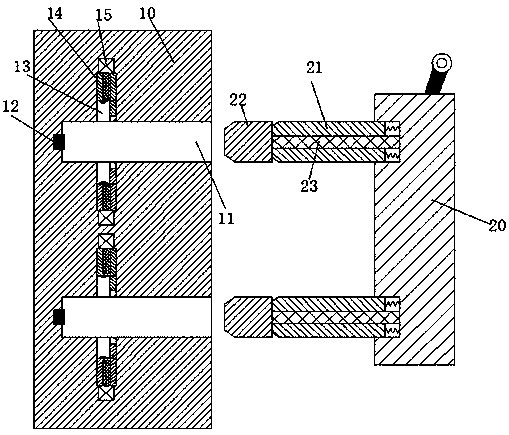

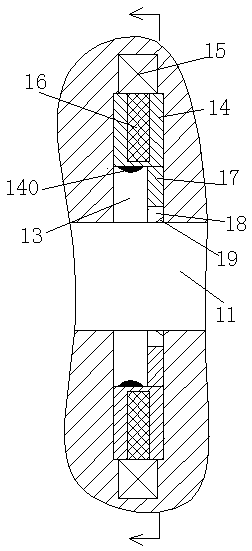

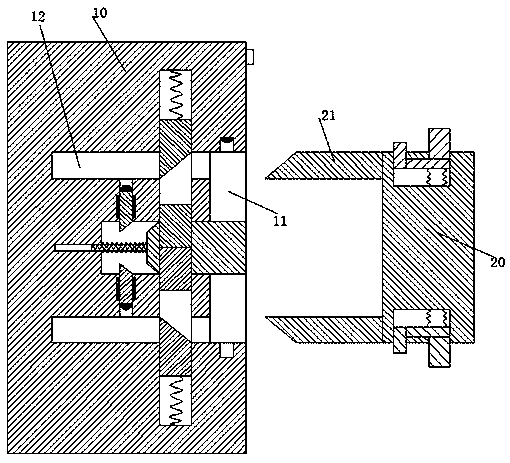

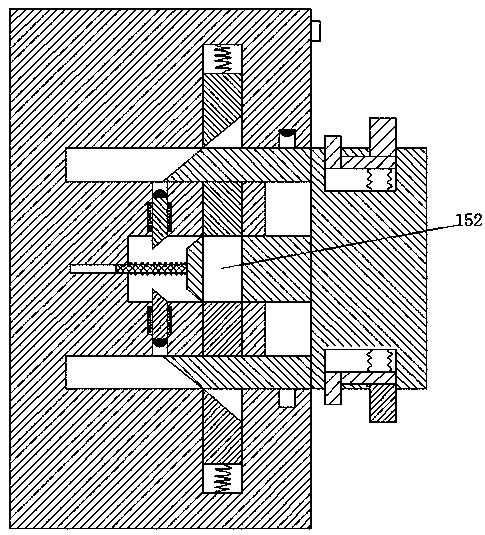

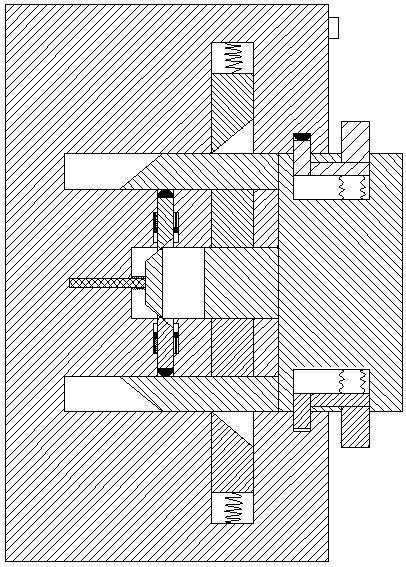

The invention discloses an embedded type wall power supply inserting-connecting socket assembly. The embedded type wall power supply inserting-connecting socket assembly comprises an inserting-connecting socket fixedly mounted in the wall and an inserting-connecting plug connected with electrical equipment; a hollow groove with a rightward opening is formed in the inserting-connecting socket; inserting-connecting grooves which extend left and right and are symmetrical up and down, and a transverse sliding groove positioned between the two inserting-connecting grooves are formed in the left end wall of the hollow groove; a longitudinal sliding groove which runs through the inserting-connecting grooves and the transverse sliding groove is formed in the inserting-connecting socket; a telescopic groove is also formed between the transverse sliding groove and the inserting-connecting grooves; a sliding block which can slide left and right is mounted in the transverse sliding groove; a through groove which runs through up and down is formed in the left end of the sliding block; a first acting inclined plane which is symmetrical up and down is on the left end plane of the sliding block; a telescopic arm is glidingly mounted in the telescopic groove; a power supply sheet connected with the mains supply is fixedly arranged on the end plane, far from the transverse sliding groove, of the telescopic arm; a first extruding-pushing inclined plane matched with the first acting inclined plane is arranged on the end plane, towards the transverse sliding groove, of the telescopic arm; and sliding arms which are symmetrical up and down are glidingly mounted in the longitudinal sliding groove.

Owner:台山市爱生电器有限公司

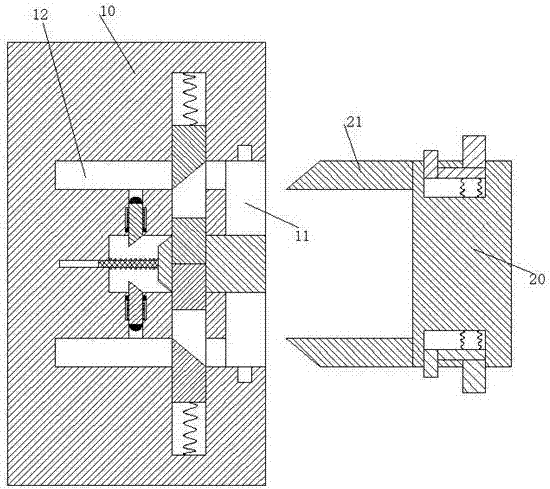

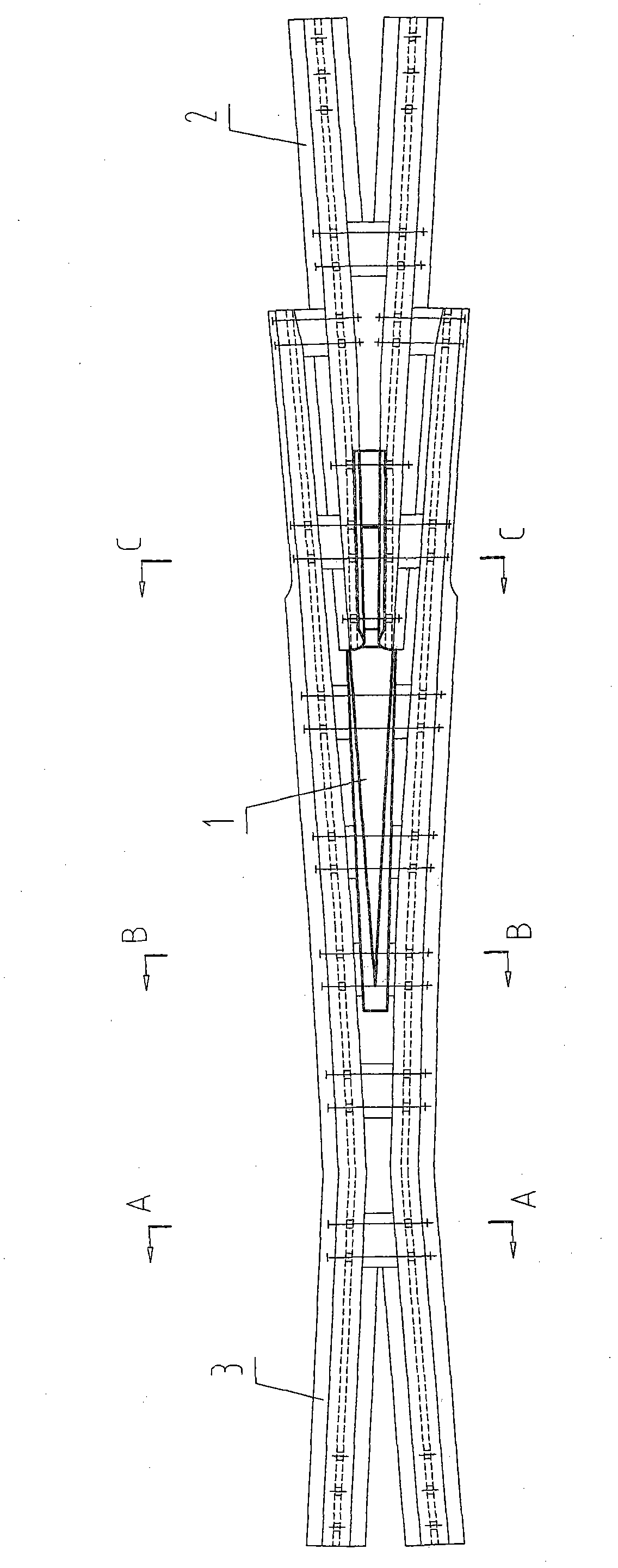

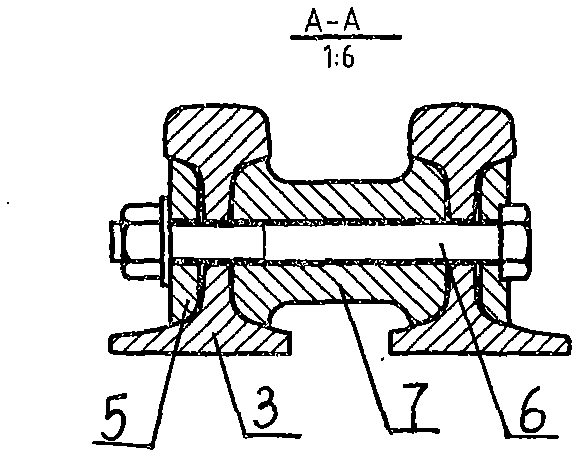

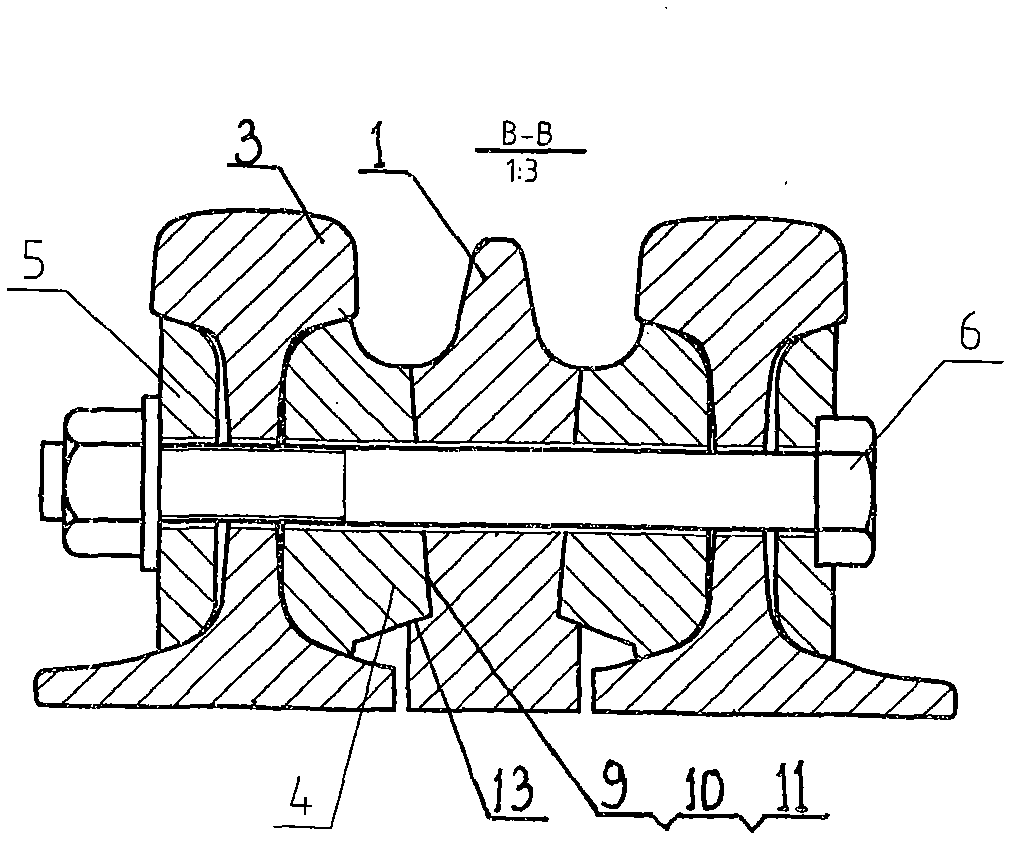

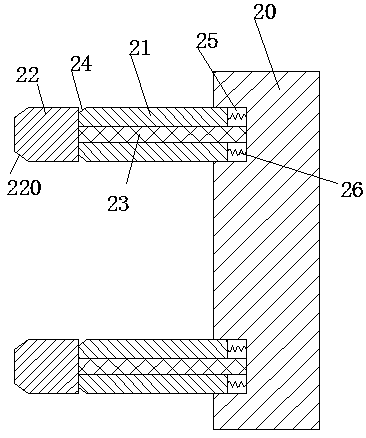

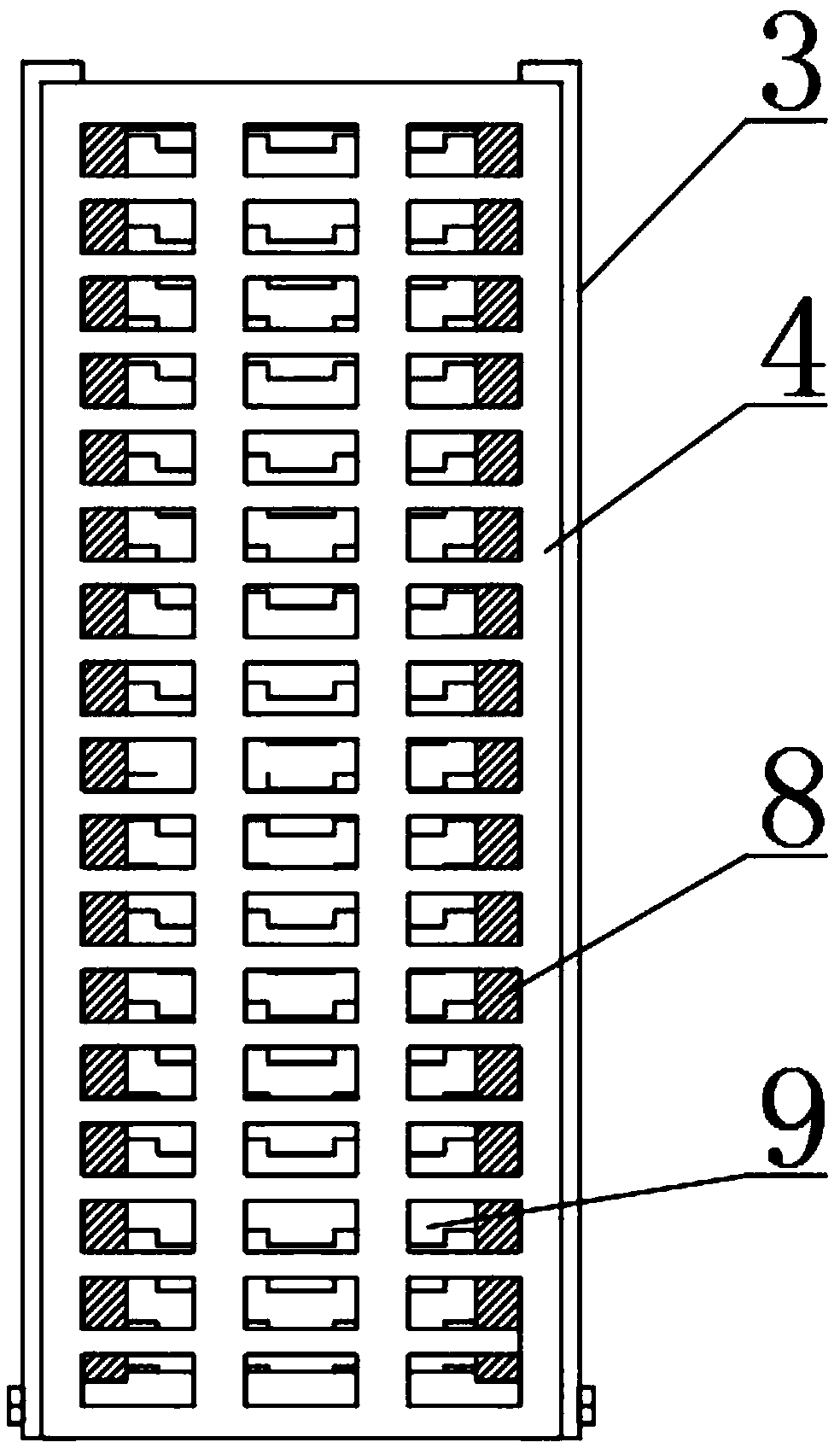

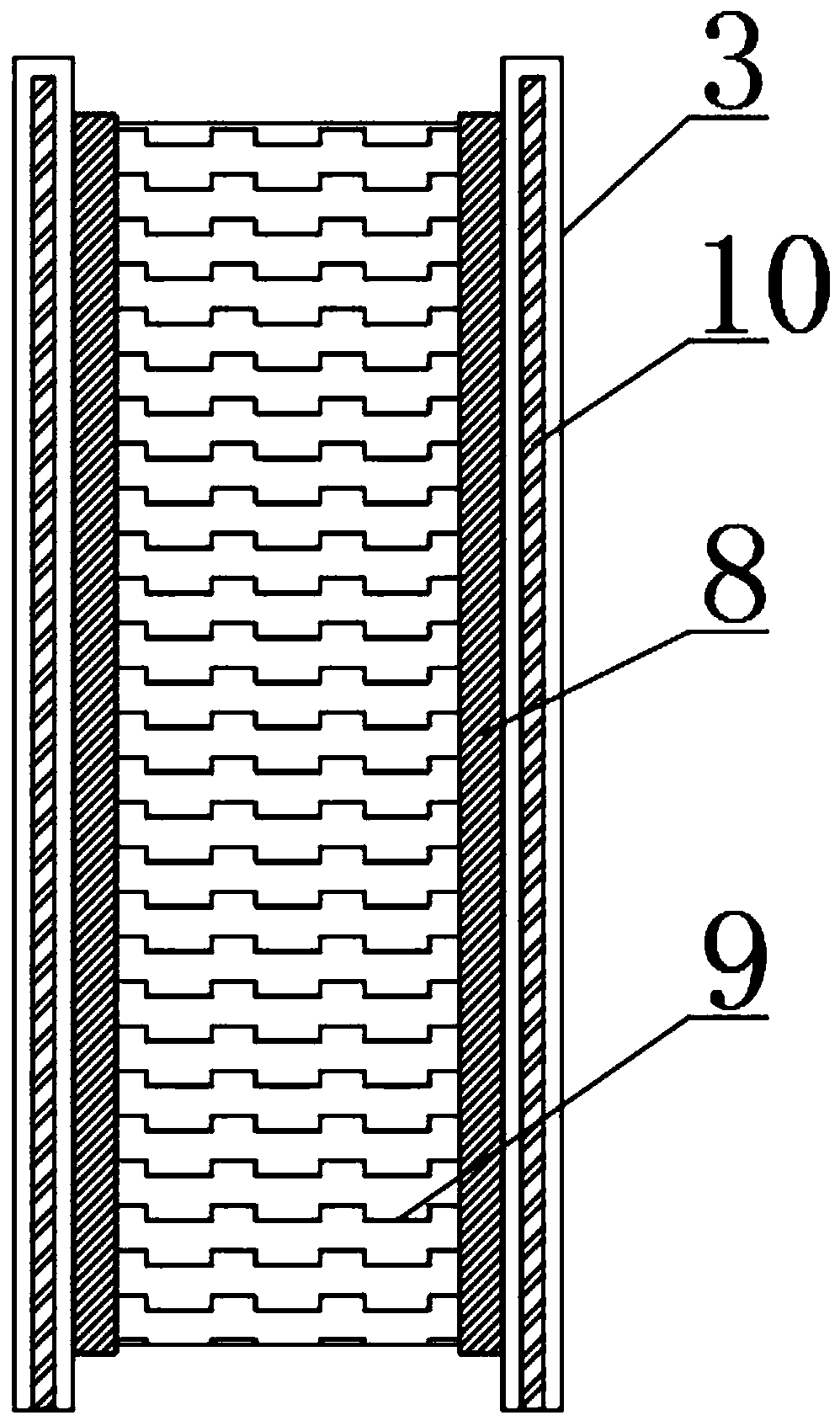

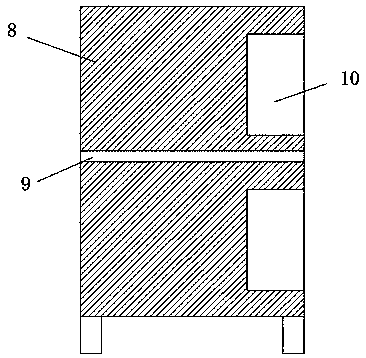

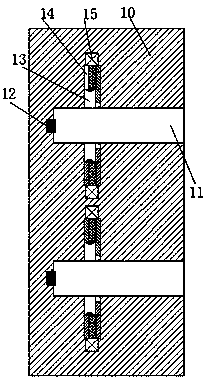

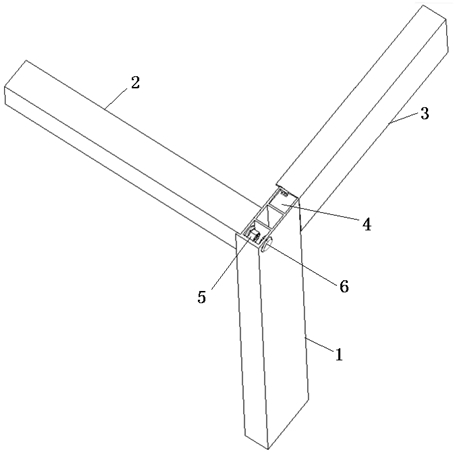

Alloy steel combined frog in wedge-shaped structure

The invention relates to an alloy steel combined frog in a wedge-shaped structure. Both side walls of a rail web of an alloy steel point rail are inclined surfaces with lower ends inclining to the inner part of the rail web so that the section of the rail web approaches to a wedge shape, and the inner end surfaces of wedge-shaped partition irons are inclined surfaces II attached to the inclined surface I; two wing rails are symmetrically positioned on both sides of the alloy steel point rail, two wedge-shaped partition irons are symmetrically positioned between the wing rail and the alloy steel point rail, the outer end surface of the wedge-shaped partition irons are matched with the side wall of the rail web of the wing rail, the inclined surfaces II of the inner end surfaces are tightlyattached to the inclined surfaces I, and the two wing rails, the two wedge-shaped partition irons and the alloy steel point rail are fixedly connected together by bolt connecting pairs and steel railgaskets; and two fork rails are symmetrically arranged on both sides of the tail part of the alloy steel point rail and positioned between the two wing rails, and the two fork rails, the alloy steel point rail and the two wing rails are fixedly connected together by the bolt connecting pairs, the steel rail gaskets and common partition irons. By the matching of the wedge-shaped alloy steel point rail and the wedge-shaped partition irons, the invention solves the problem of relative diastrophism between the alloy steel combined frog and the wing rails, enhances the integral stability of the frog and prolongs the service life of the whole set of frog.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

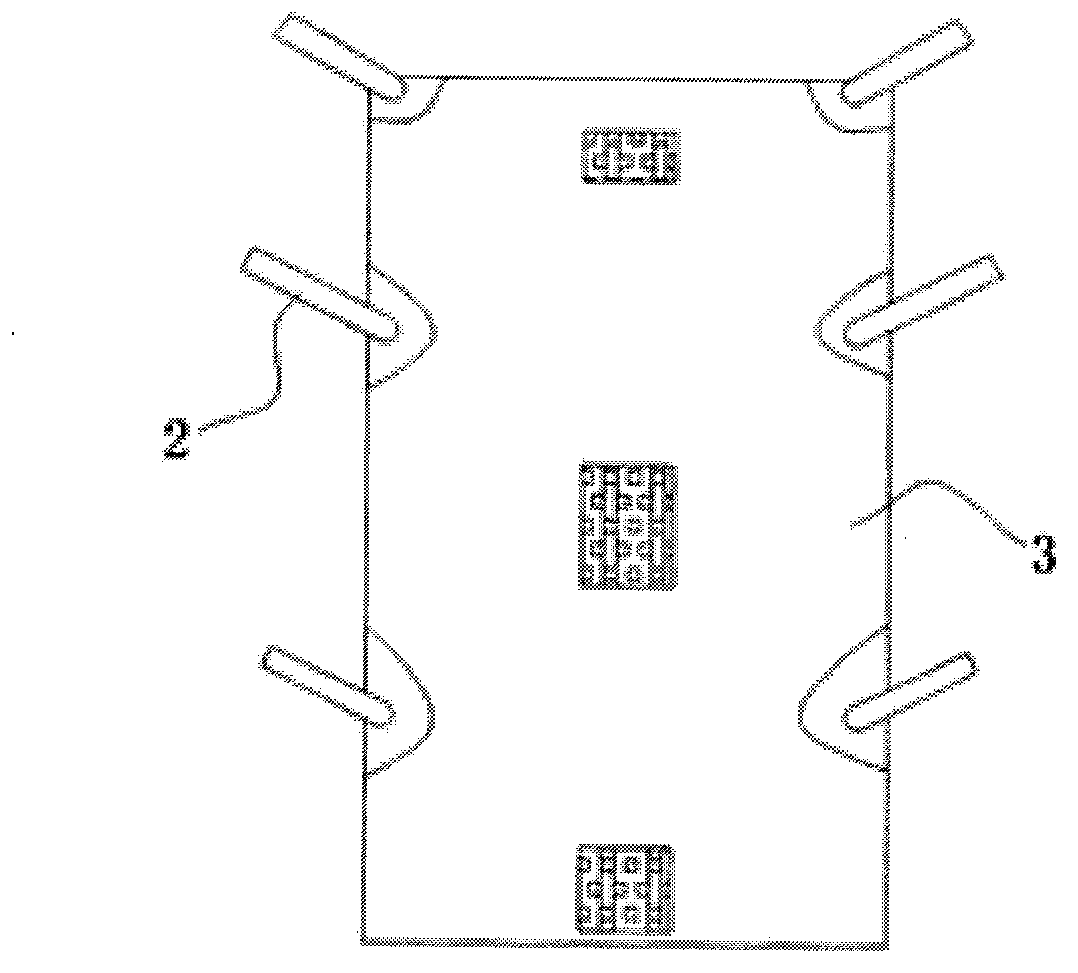

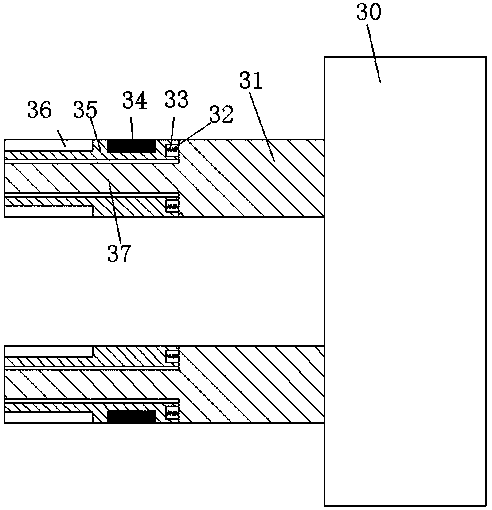

Multi-harness distribution and winding displacement device

The invention discloses a multi-harness distribution and winding displacement device, and relates to the technical field of harnesses. The multi-harness distribution and winding displacement device comprises harness bodies, a harness body winding displacement device and a protection device. The harness body winding displacement device comprises a first hollow cylinder and an annular rubber ring; arc-shaped bar grooves which are arrayed in an annular mode and are parallel to the extending direction of the first hollow cylinder are formed in the outer wall of the first hollow cylinder, and the harness bodies are distributed in the bar grooves and are sleeved with the rubber ring to be locked. The protection device comprises a second hollow cylinder arranged on the periphery of the first hollow cylinder in a sleeving mode and disk-shaped blocking covers located at the two ends of the second hollow cylinder, and rubber sleeves are bonded to the inner walls of winding displacement holes. According to the multi-harness distribution and winding displacement device, the multiple harness bodies are subjected to winding displacement and distributed, so that winding displacement of various harnesses is not disordered; when equipment is collided or bumped, the harnesses are not squeezed, no violent collision occurs between the harnesses, the service life of the harnesses is prolonged, and the production cost is lowered.

Owner:WUHU BOKANG ELECTRICAL

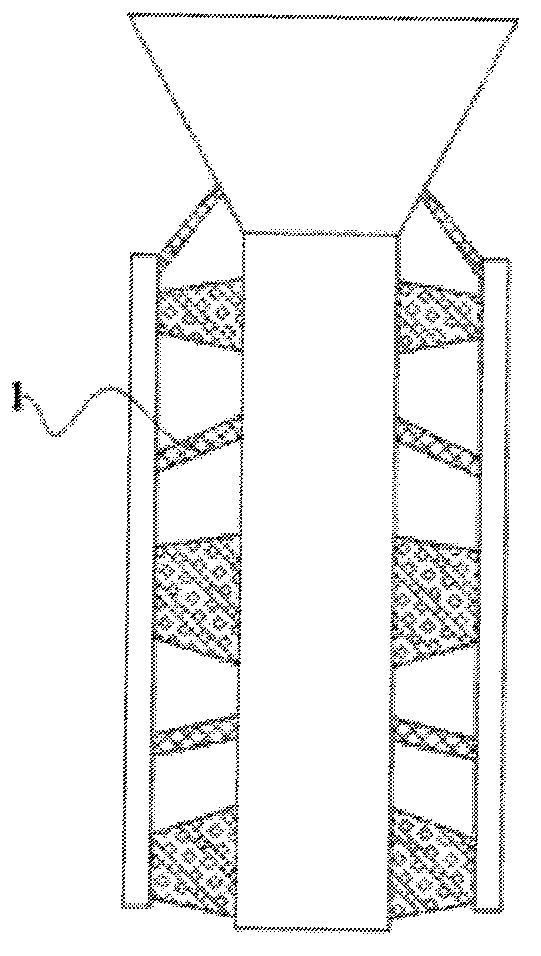

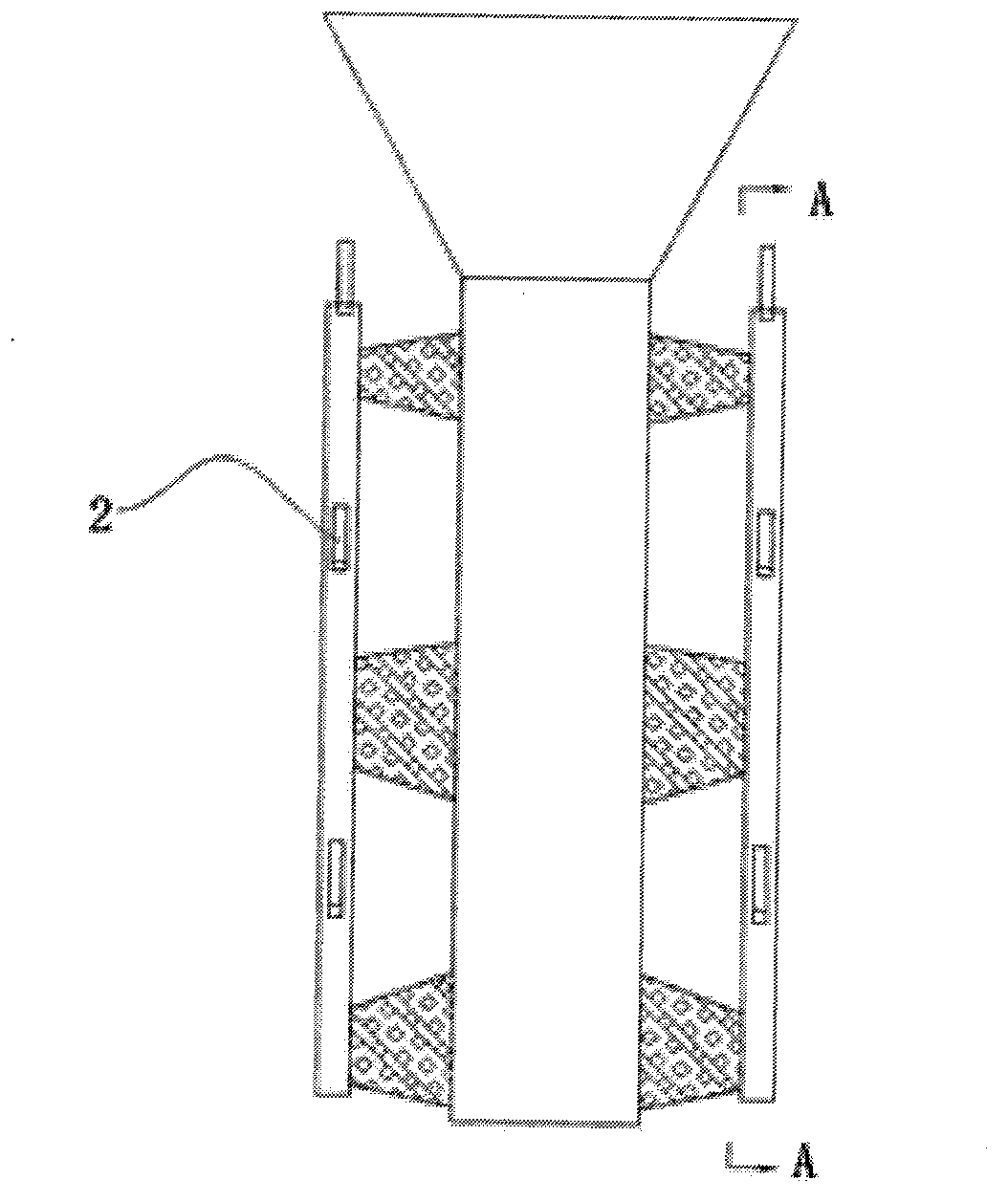

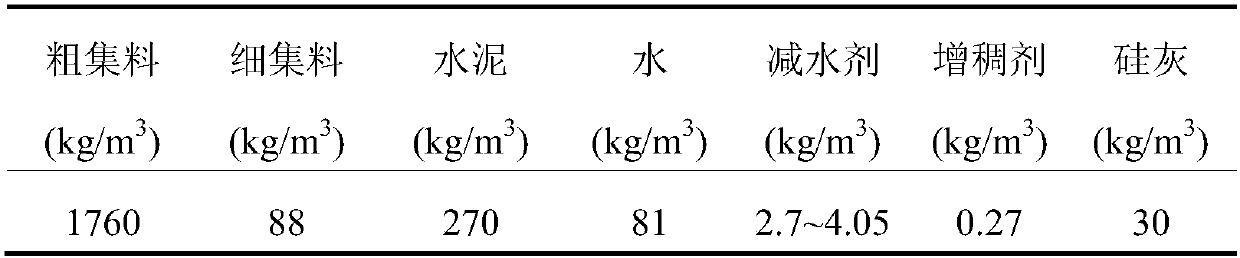

Casting method for pouring and molding thin-wall investment pattern steel casting

ActiveCN103506574ADoes not cause shrinkageWill not cause looseningFoundry mouldsFoundry coresWaxMetallurgy

The invention discloses a casting method for pouring and molding a thin-wall investment pattern steel casting, aiming to prevent the casting from cavity-shrinking, loosening or deforming. The method comprises the following steps: a. first preparing multiple wire-shaped metal materials with diameter of 0.5-1mm and length of 50-100mm and coating the outer surface of each wire-shaped metal material with a layer of wax with thickness of 0.1-0.2mm; b. inserting the wire-shaped metal materials from the last step into an assembled wax module, wherein the inserting thickness is 4-8mm; c. coating and smearing the wire-shaped metal materials with slurry and sands together with the wax module; d. after forming a module shell on the surface of the wax module, firstly destroying parts of module shell on the surface of the other end of the wire-shaped metal materials, drawing out the wire-shaped metal materials, and then performing dewaxing and roasting; e. finally pouring molten steel, wherein cavities which are formed in the module shell after the wire-shaped metal materials are drawn out can be used for drainage. By virtue of the method, the pass percent of the castings is enhanced.

Owner:JIASHAN SINHAI PRECISION CASTING

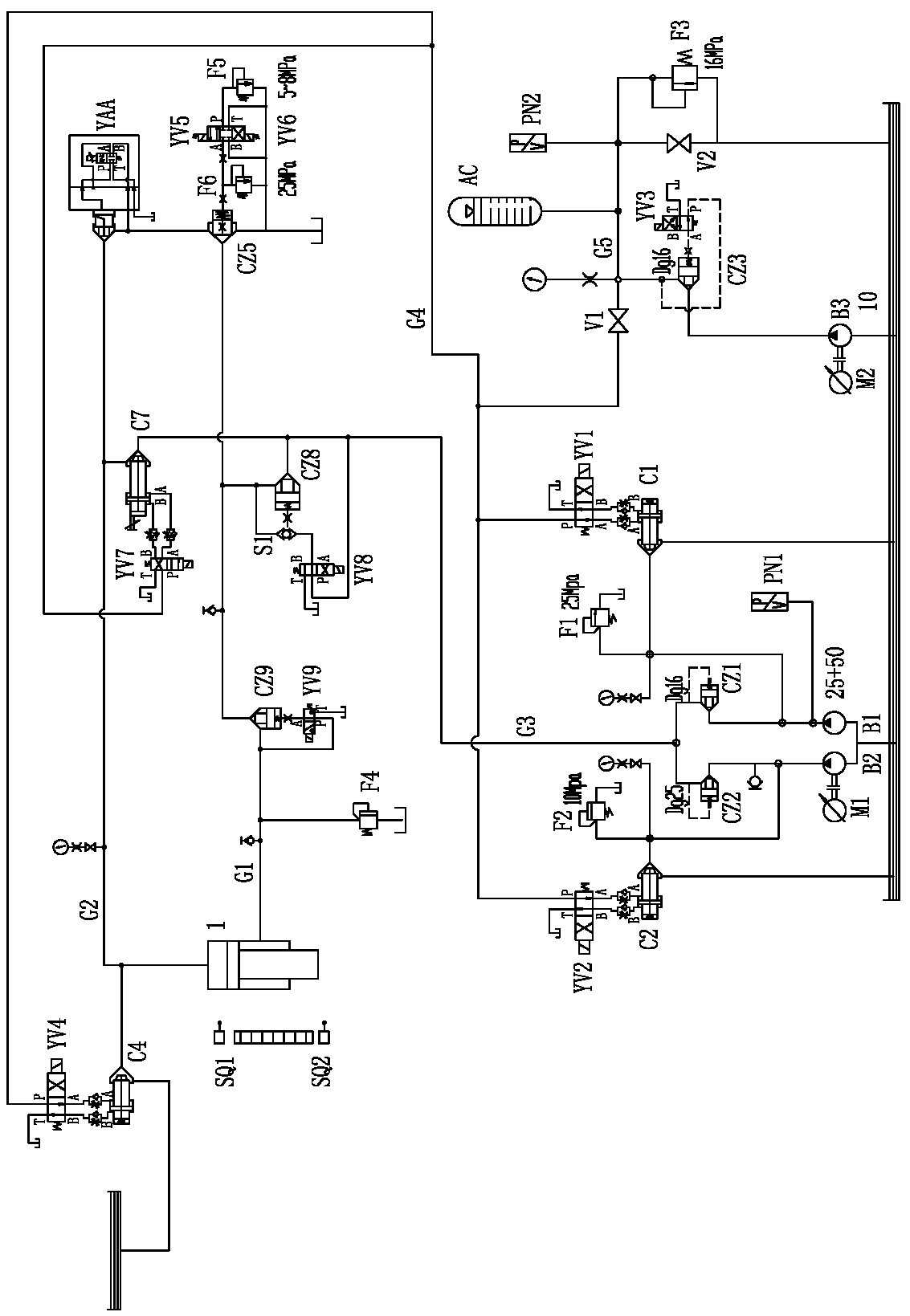

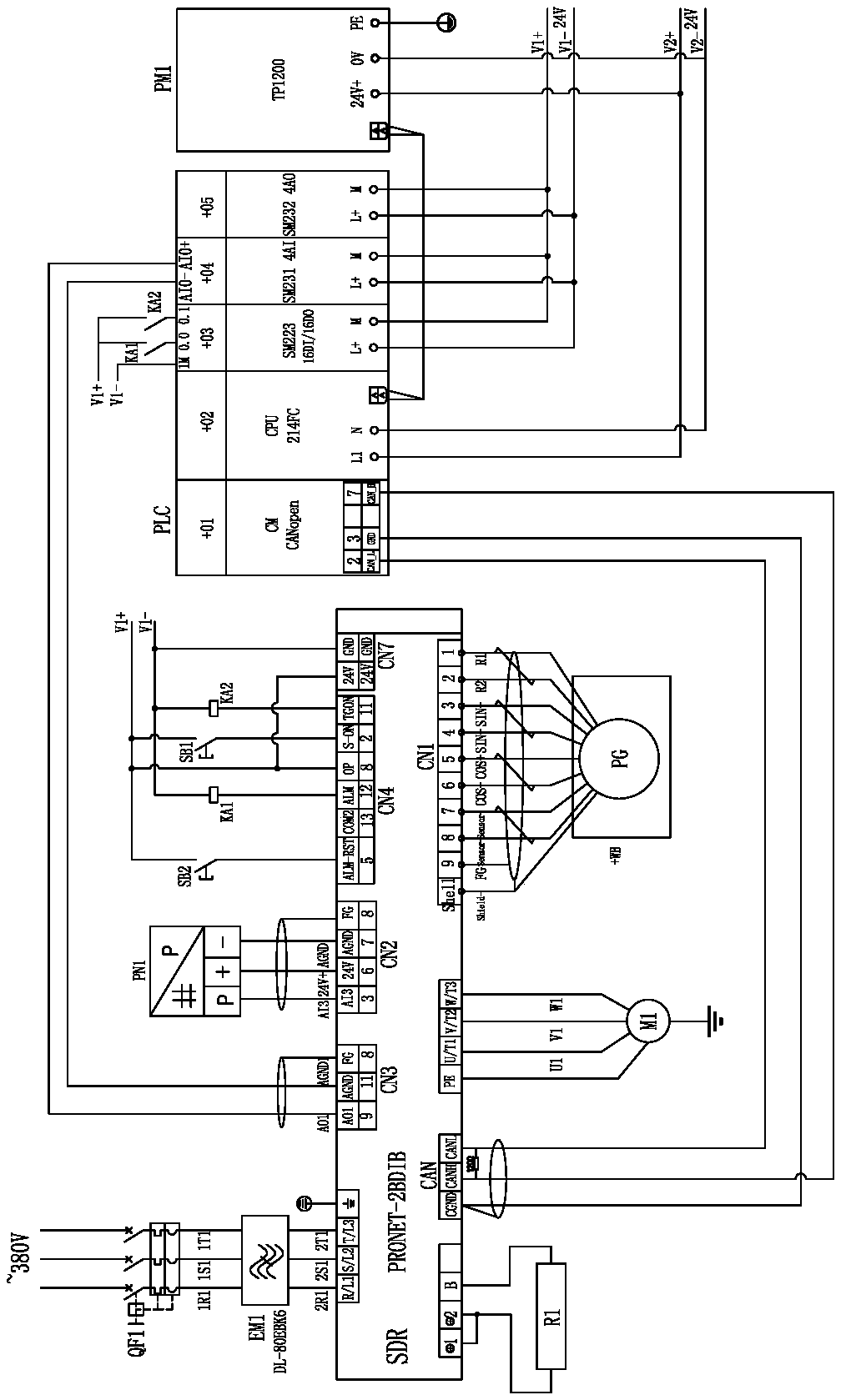

Precision pressure control system and hydraulic machining method of servo pump control hydraulic machine

ActiveCN108561346AEliminate pressure differentialsReliable return to seatServomotorsServometer circuitsControl systemWork cycle

The invention relates to a precision pressure control system and a hydraulic machining method of a servo pump control hydraulic machine. The hydraulic machine comprises a medium-flow servo pump and alarge-flow servo pump driven by a servo motor, outlet pipelines of two pumps are connected with a main cylinder upper cavity oil way through a seventh dynamic valve, and the main cylinder upper cavityoil way is further connected with an oil tank through a fourth dynamic valve and a proportional valve; a main cylinder lower cavity pipeline is connected with an outlet of a ninth cartridge valve, aninlet of the ninth cartridge valve is connected with the oil tank through a fifth cartridge valve and an eighth cartridge valve, the fifth cartridge valve supplies supporting force during deceleration and pressurization through an overflow valve, and the eighth cartridge valve is turned on during the return stroke. In hydraulic machining, each working cycle comprises the following actions of automatic pressure compensation for an energy accumulator, pressure supplementation stopping for the energy accumulator, rapid descending of a sliding block, deceleration pressurizing of the sliding block, pressure maintaining of the sliding block, pressure relief of the sliding block, and return and stopping of the sliding block. The servo driver is switched in two modes of flow control and PID regulation control, stable pressurization of the sliding block is achieved, the phenomenon that a part deforms due to pressurization overshoot is avoided, and pressure relief is stable.

Owner:江苏扬力液压装备有限公司

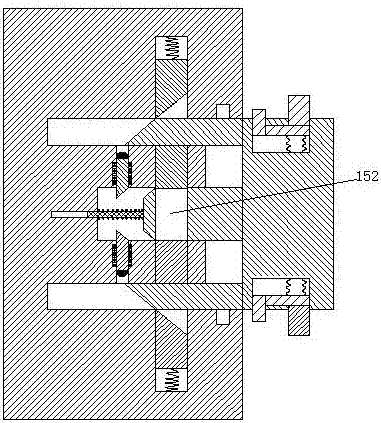

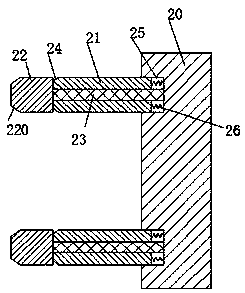

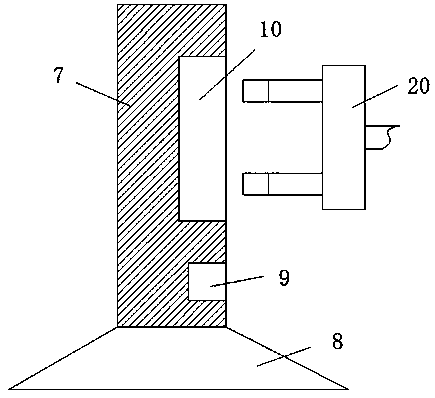

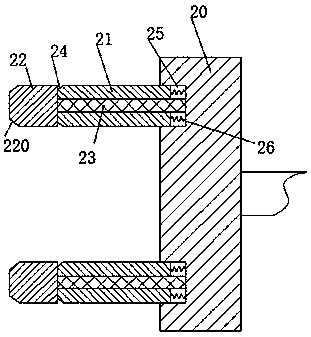

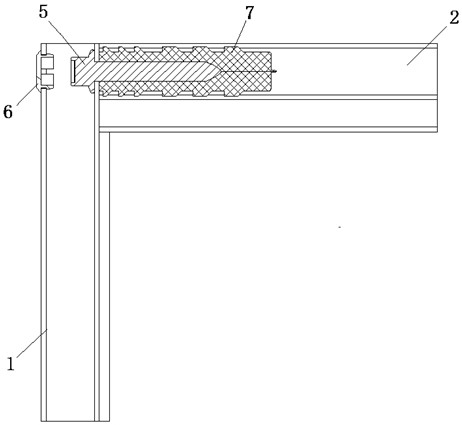

Improved type power supply bayonet socket assembly

InactiveCN107732512AThere will be no electric shock accidentsReduce security risksCoupling device detailsEngineering

The invention discloses an improved type power supply bayonet socket assembly, comprising a bayonet socket fixedly mounted in a wall and a bayonet joint connected to an electric device. The bayonet socket is provided with a hollow groove having a right opening. The left end wall of the hollow groove is provided with a plug-in groove which extends from left to right and is symmetrical up and down,and a transverse sliding groove disposed between two plug-in grooves. The bayonet socket is provided with a longitudinal sliding groove which traverses through the plug-in groove and the transverse sliding groove. A telescoping groove is disposed between the transverse sliding groove and the plug-in groove. The transverse sliding groove is provided with a sliding block in a manner of sliding fromleft to right. The left end of the sliding block is provided with a through slot which runs through up and down. The left end face of the sliding block is provided with a first acting inclined plane in an up-and-down symmetrical manner. The telescoping groove is provided with a telescoping arm in a sliding manner. The end face of the telescoping arm, away from the transverse sliding groove, is fixedly provided with a power supply sheet connected to commercial power. The end face of the telescoping arm, facing towards the transverse sliding groove is provided with a first thrusting inclined plane cooperating with the first acting inclined plane. The longitudinal sliding groove is provided with an up-and-down symmetrical sliding arm in a sliding manner.

Owner:广西景曜电子科技有限公司

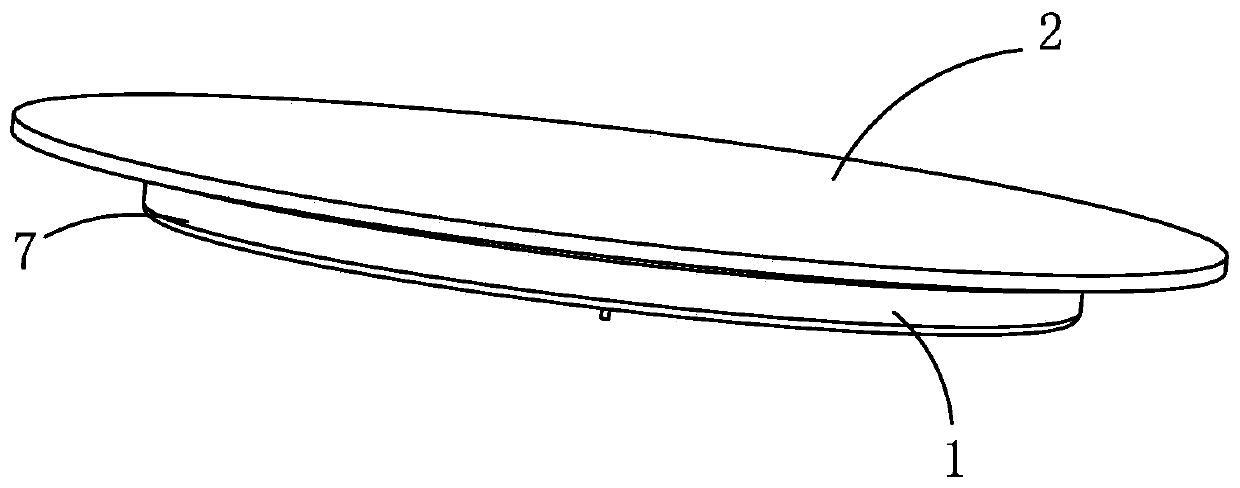

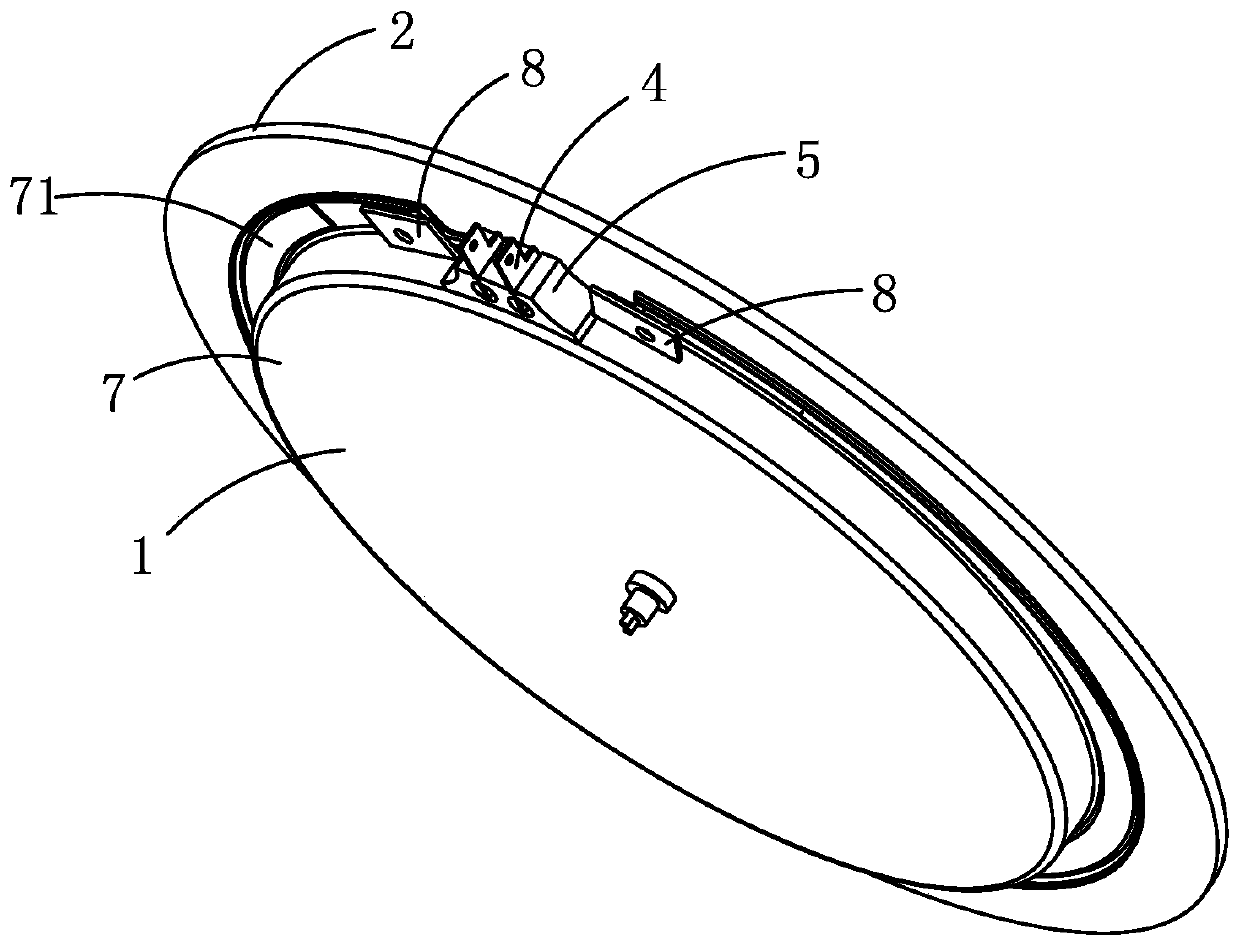

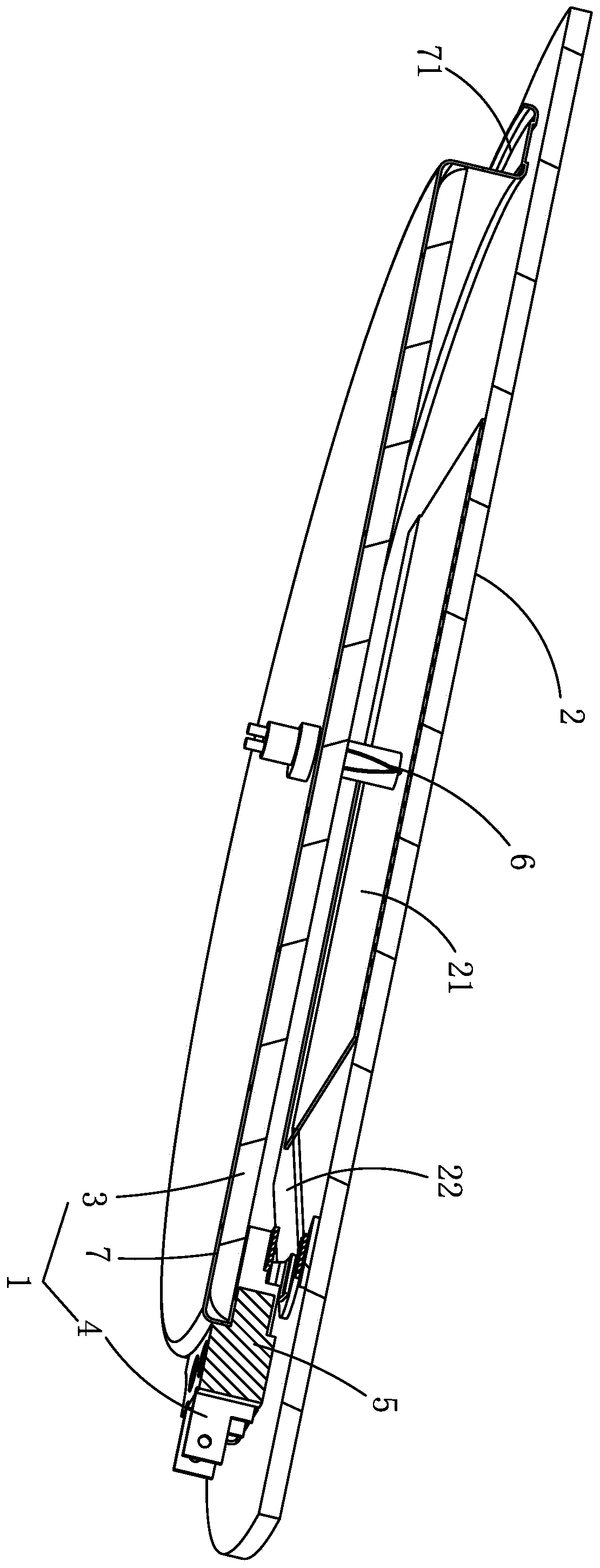

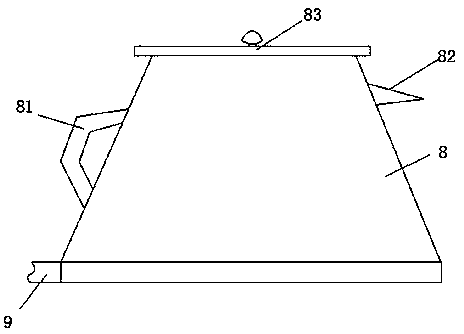

Piglet electric hot plate for observation of newborn livestock piglets

InactiveCN107873530AImprove convenienceEasy to useHeating fuelLighting and heating apparatusMicrocontrollerNose

The invention provides a piglet electric hot plate for observation of newborn livestock piglets. The piglet electric hot plate comprises an electric hot plate shell, a top plate and a water storage tank, wherein three connecting convex heads are fixedly arranged on tops of connecting plates; and an MCU (Micro Control Unit) microcontroller is fixedly arranged on the inner side of the bottom of theelectric hot plate shell. Due to the arrangement of the water storage tank and a humidifying mist outlet cover, convenience in use is facilitated, the temperature of purified water inside the water storage tank is raised when the temperature inside the electric hot plate shell is raised, and the produced water mist rises to the top via a humidifying pipeline and emits out by virtue of a mist outlet filtering net on the humidifying mist outlet cover after the water temperature is raised, so that the top of the electric hot plate can be humidified, humidification by artificial spray is not needed, use is convenient, and when the piglets are subjected to heat preservation by multiple electric hot plates, the multiple electric hot plates can be in locked connection by virtue of the connectingconvex heads and connecting holes. Therefore, when the piglets make activities on the electric hot plates, loosening of adjacent electric hot plates is avoided so as not to influence the activities ofthe piglets.

Owner:HUBEI ZANBO INFORMATION TECH CO LTD

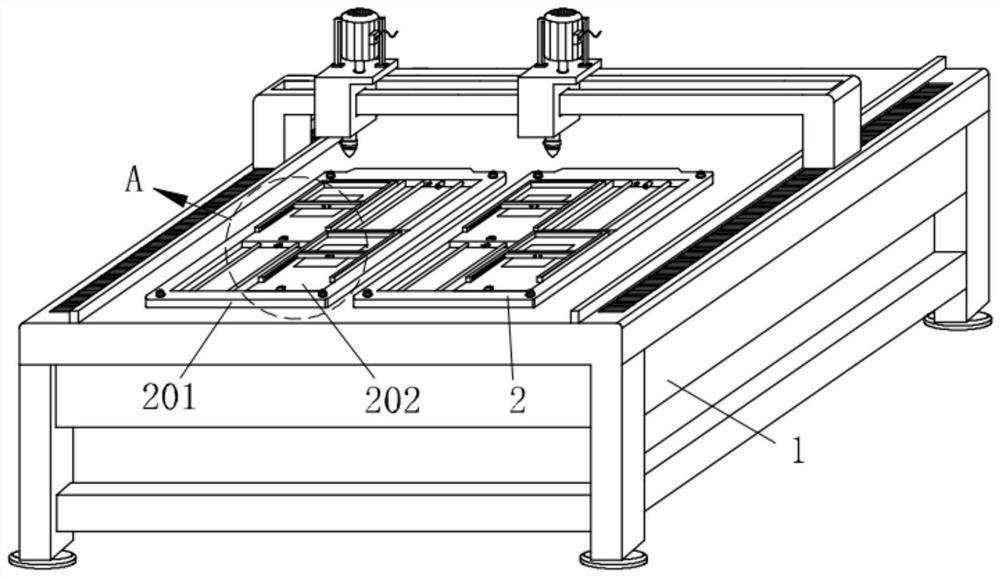

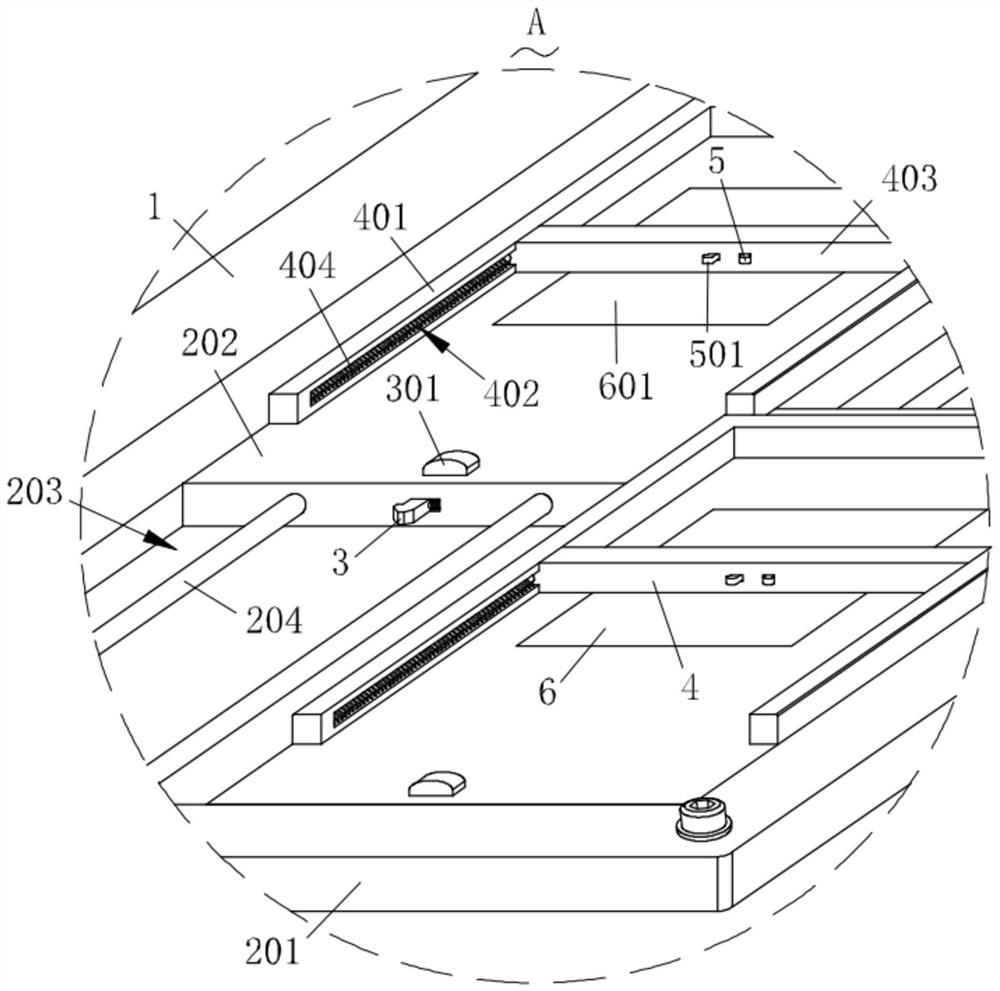

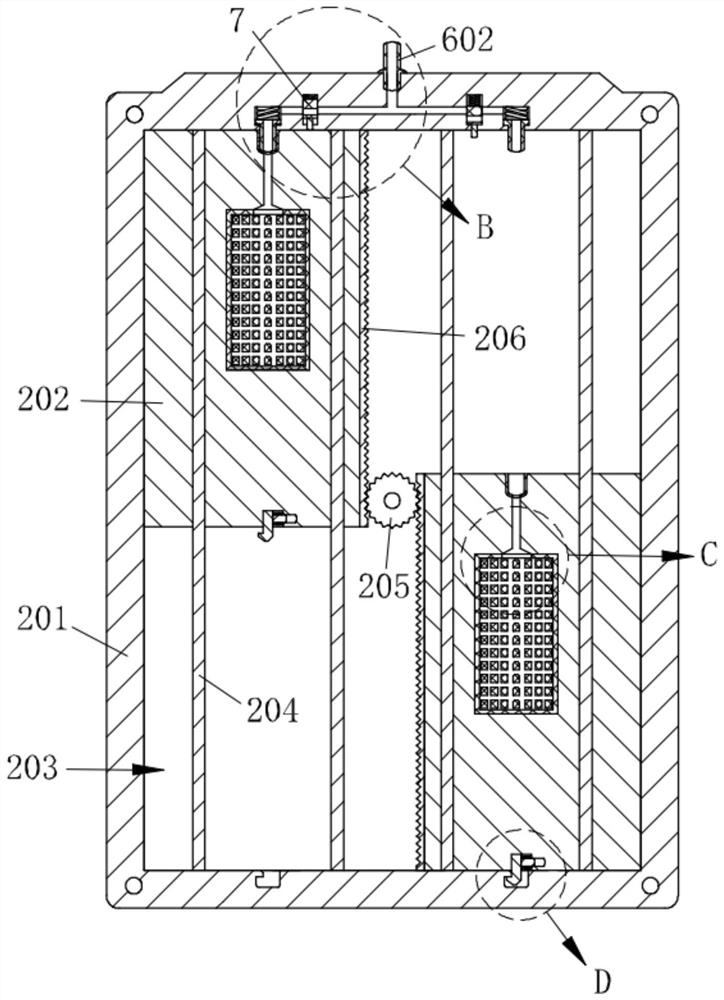

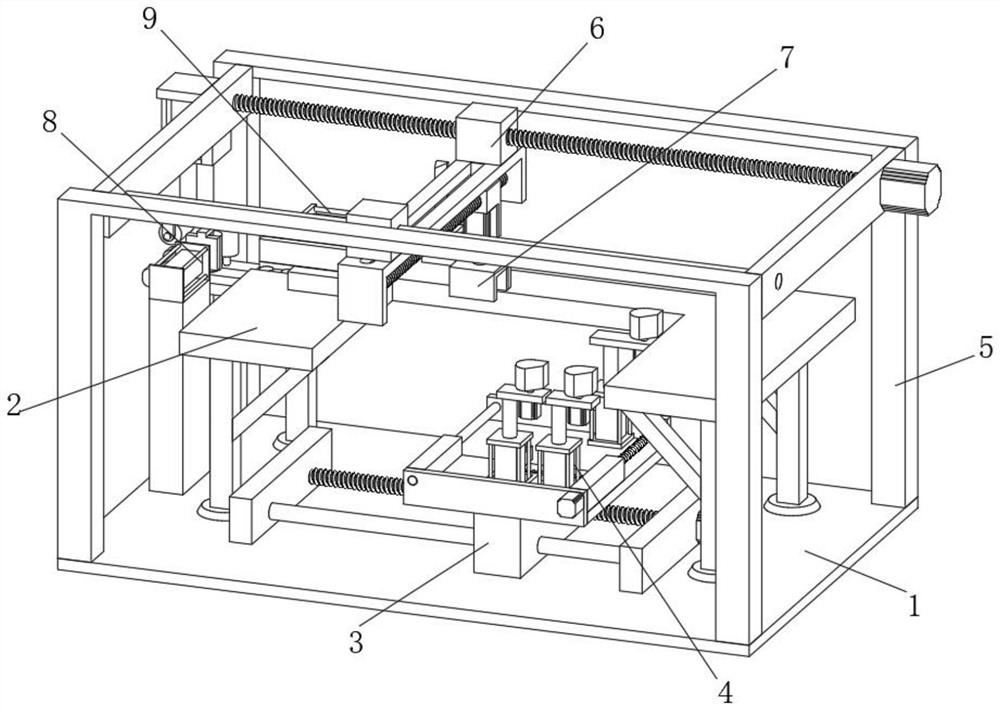

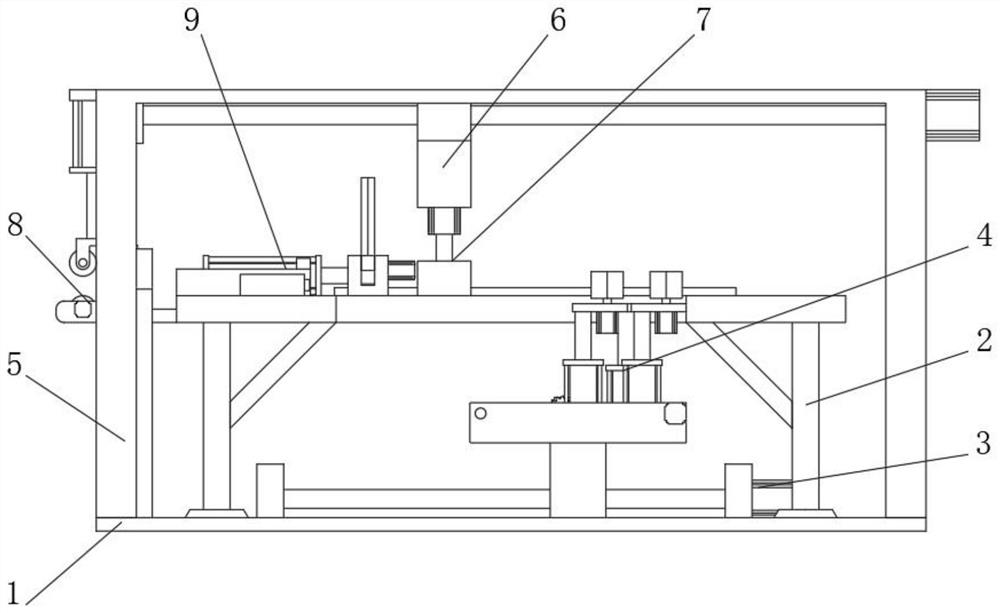

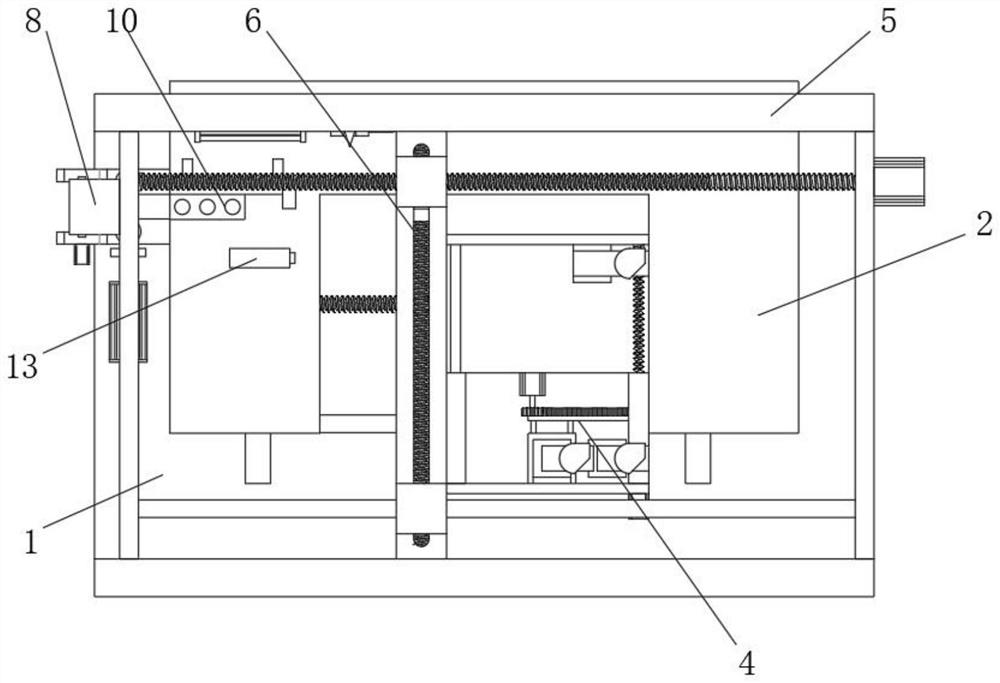

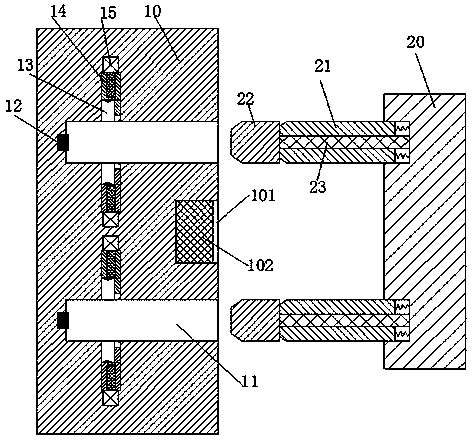

Intelligent machining equipment for machining internal mold injection molding part

PendingCN114193541AConvenient to take turns loading and processingEasy to push processingMetal working apparatusNumerical controlMachine tool

The invention relates to the technical field of injection molding part machining, in particular to intelligent machining equipment for inner mold injection molding part machining, which comprises a numerical control machine tool body, two feeding mechanisms are detachably connected to the numerical control machine tool body, locking mechanisms are mounted on the feeding mechanisms, and clamping mechanisms are connected to the feeding mechanisms. The clamping mechanism is provided with a limiting mechanism, the feeding mechanism is provided with an adsorption mechanism, and the feeding mechanism is connected with a control mechanism. The feeding mechanism and the locking mechanism are installed on the numerical control machine tool body in a matched mode, workpieces needing finish machining can be conveniently fed and machined in turn, the production efficiency is improved, the machined workpieces can be conveniently positioned, clamped and placed through cooperation of the clamping mechanism and the limiting mechanism, operation is convenient, efficiency is high, and practicability is high. Through work of the feeding mechanism, the adsorption mechanism and the control mechanism work in turn, workpieces machined on the feeding mechanism can be adsorbed firmly, and looseness of the workpieces cannot be caused.

Owner:济南超达电子有限公司

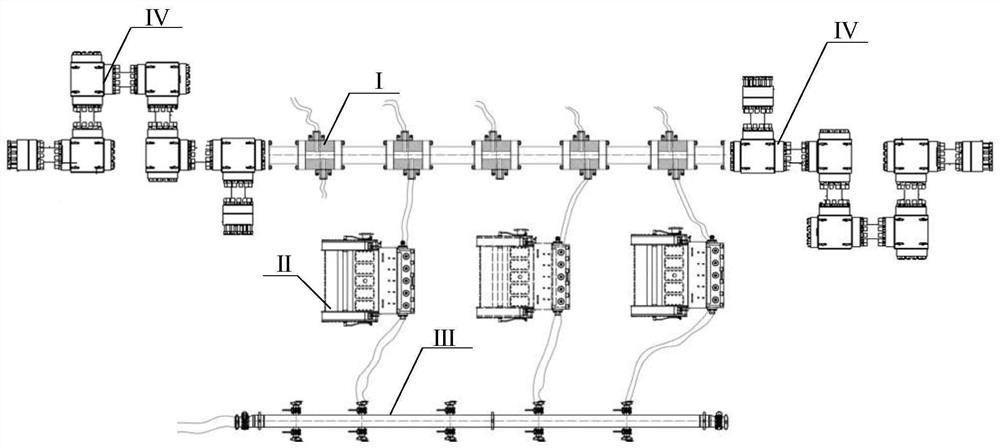

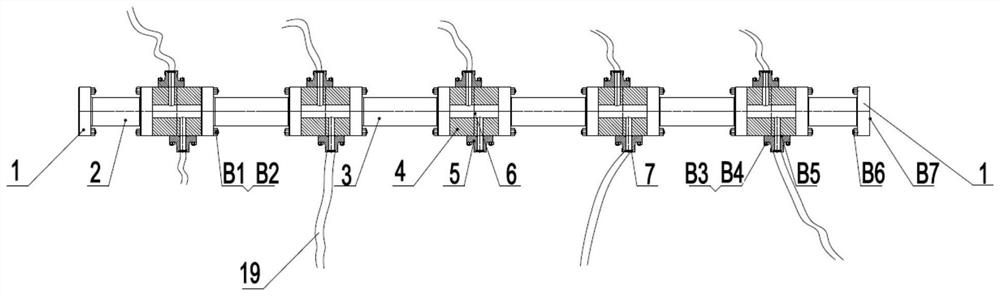

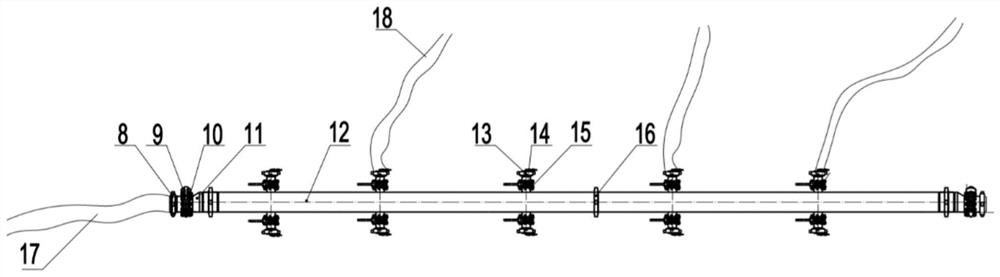

Large drift diameter high-low pressure distribution fracturing "-"-shaped manifold device

PendingCN111810059AReduce layoutReduce erosionDrilling rodsFluid removalRotational axisPressure stabilization

The invention relates to a large drift diameter high-low pressure distribution fracturing "-"-shaped manifold device which comprises a high-pressure "-"-shaped manifold, a low-pressure "-"-shaped manifold, a fracturing unit and wellhead rotary reversing mechanisms. Two ends of the high-pressure "-"-shaped manifold are separately connected to the wellhead rotary reversing mechanisms through flangepup joints; the high-pressure "-"-shaped manifold is connected to the fracturing unit through a high-pressure fracturing fluid inlet pipeline; and the fracturing unit is connected to the low-pressure"-"-shaped manifold through a low-pressure fracturing fluid inlet pipeline. The wellhead reversing structures are straight pipe structures and can move a rotating shaft according to a wellhead position, and the straight pipe and the pup joint are consistent in drift diameter without a reducing structure in the middle, so that a large displacement and pressure stabilizing conveying operation can beensured, and therefore, erosion to the inner wall of the pipeline is reduced and assembly of bended joints and multiple unions is reduced. The device is simple in structure, high in reliability, convenient to mount, long in using time and high in using efficiency.

Owner:重庆新泰机械有限责任公司

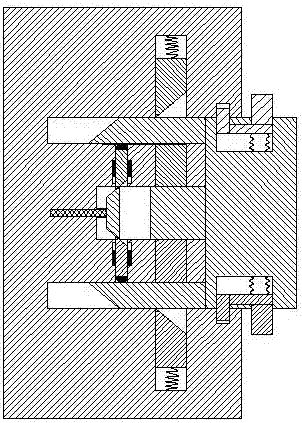

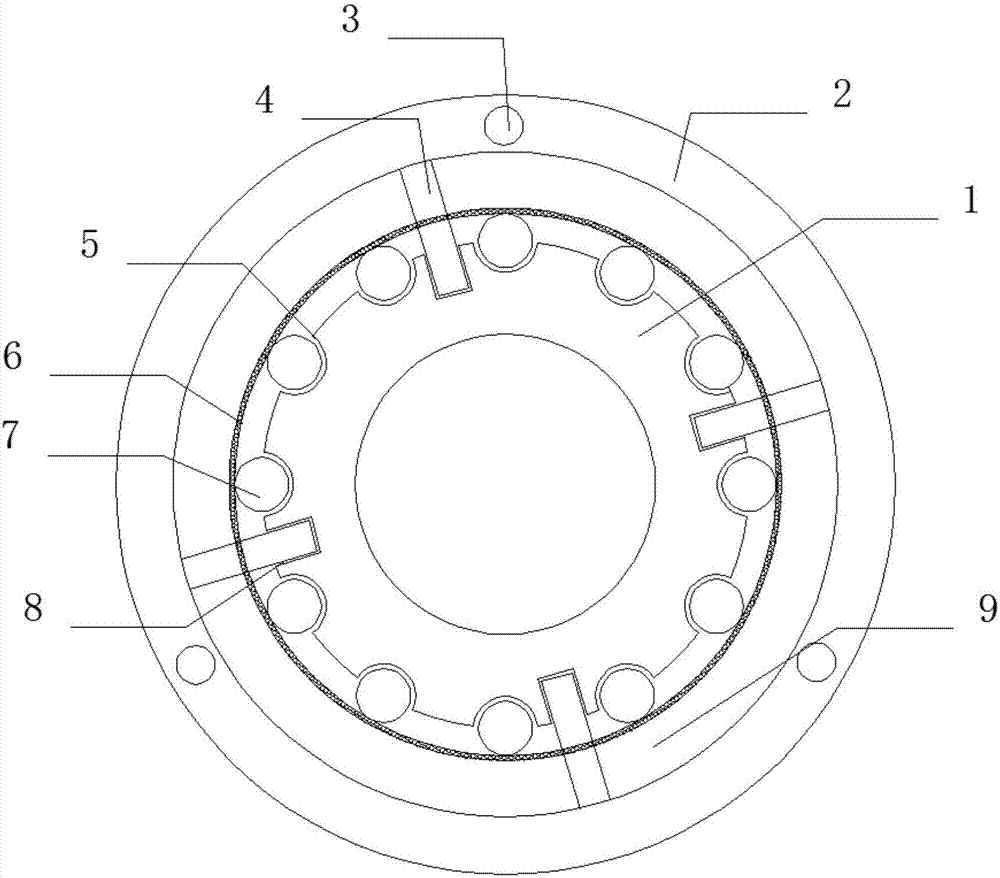

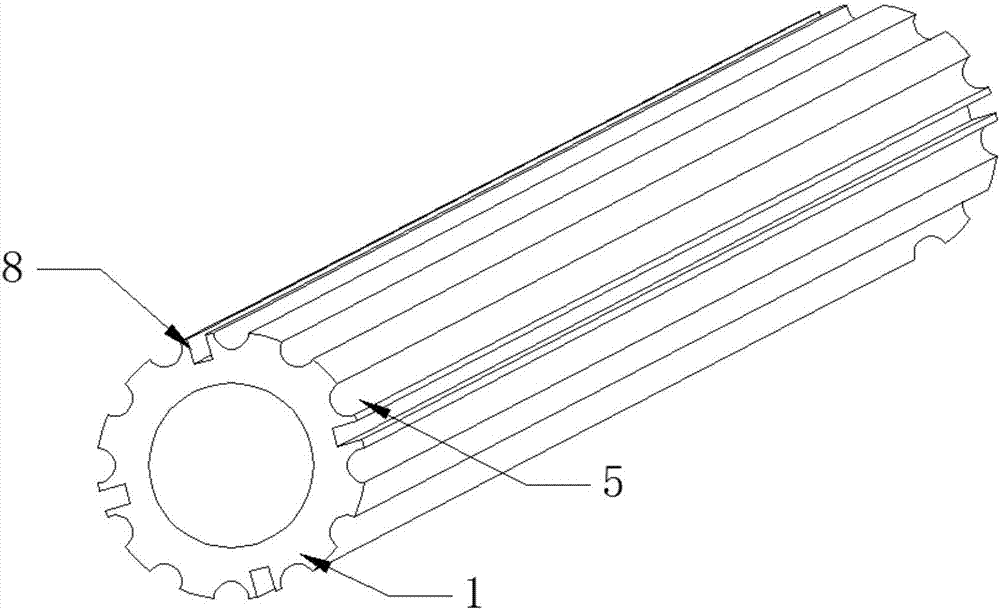

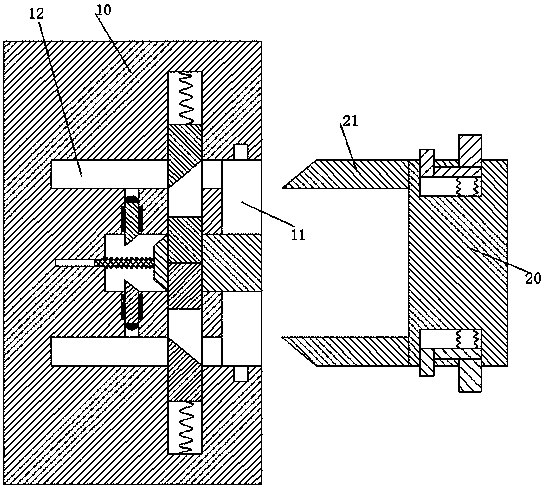

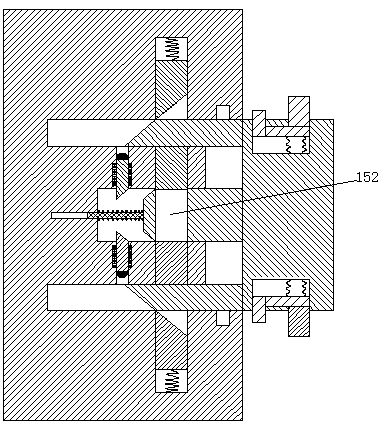

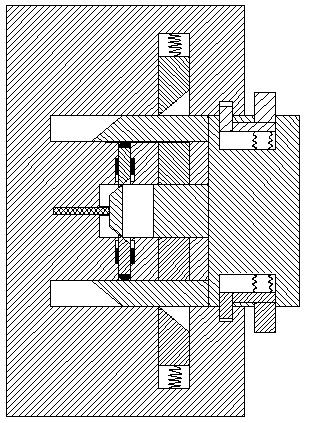

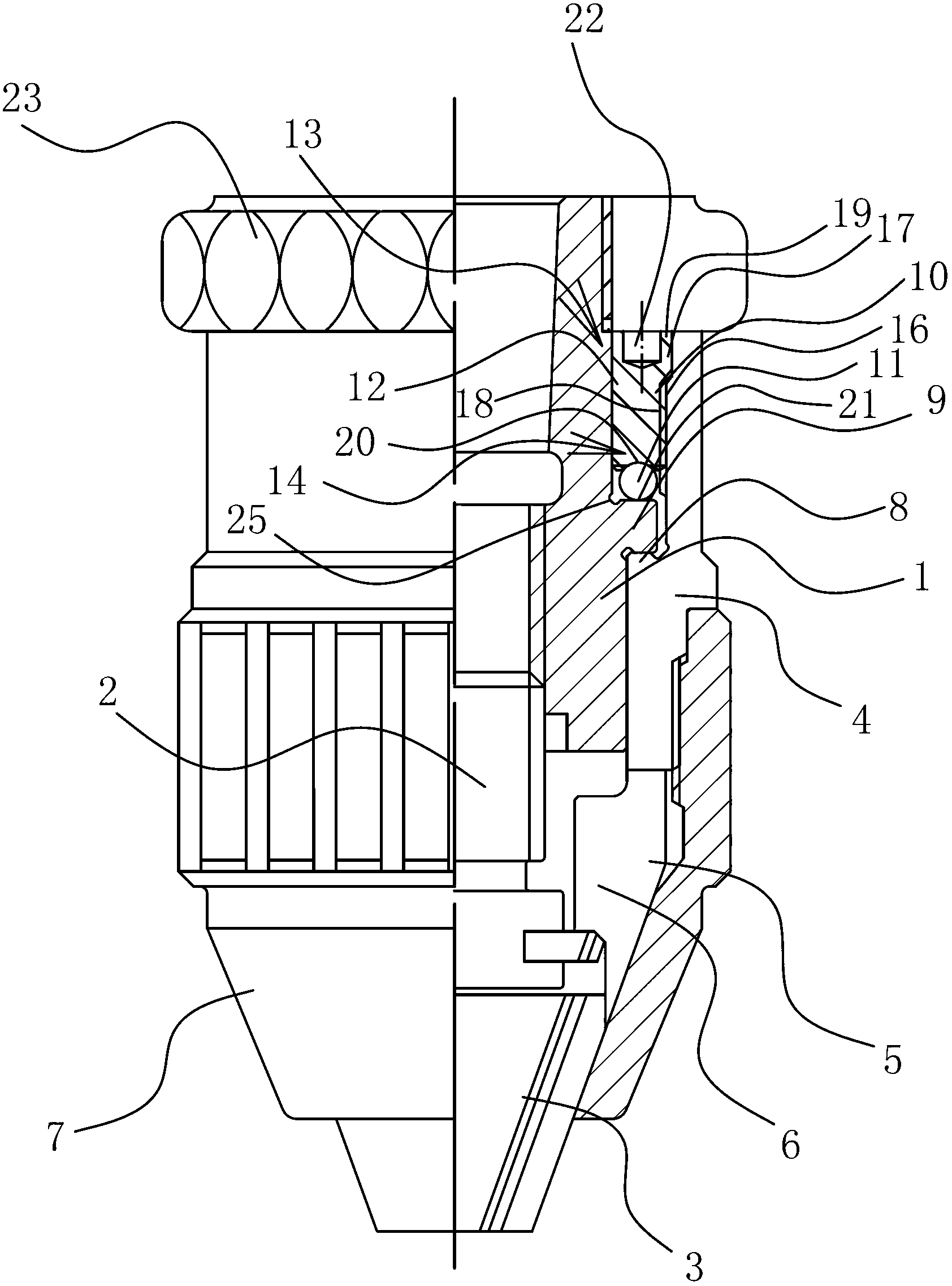

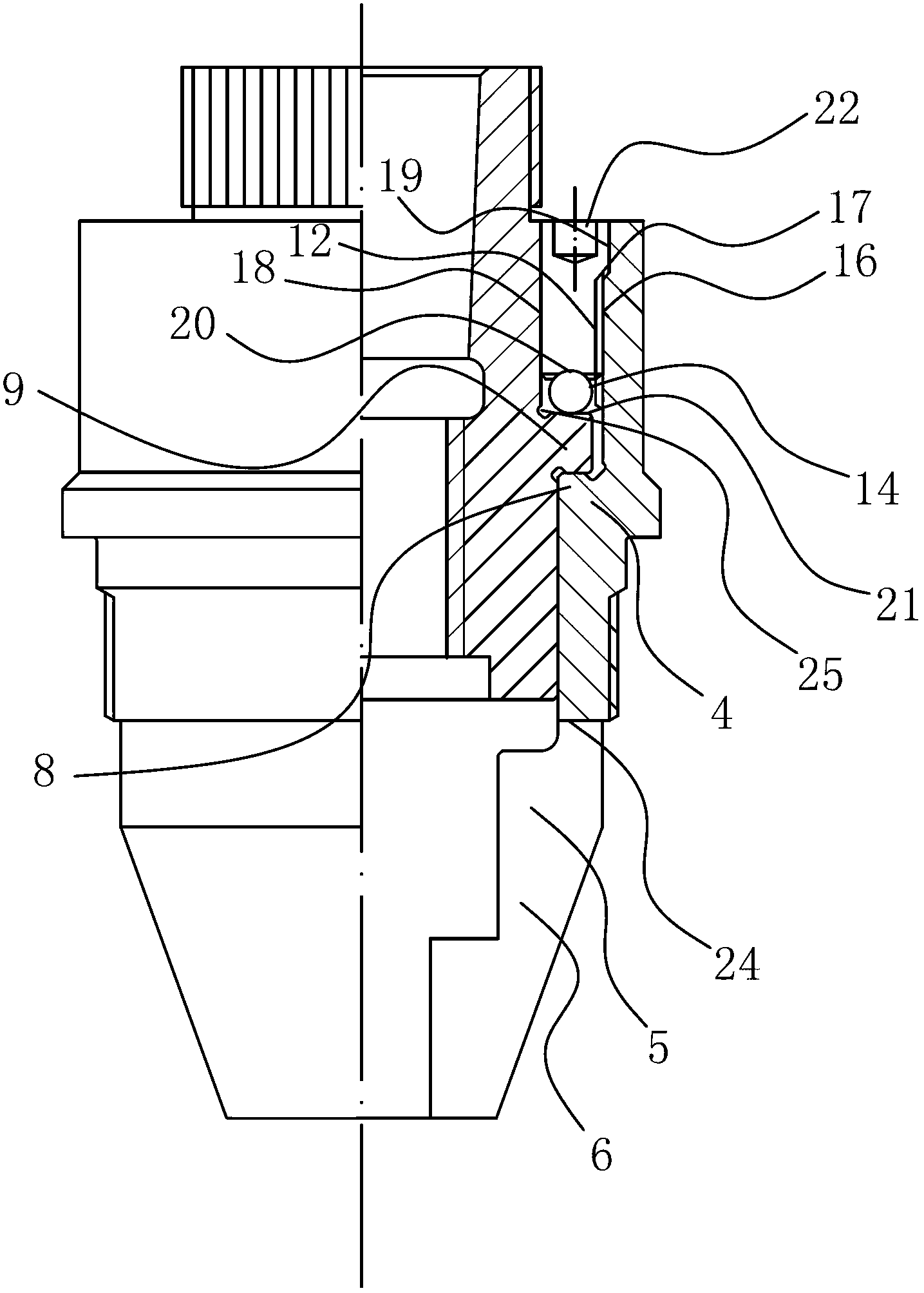

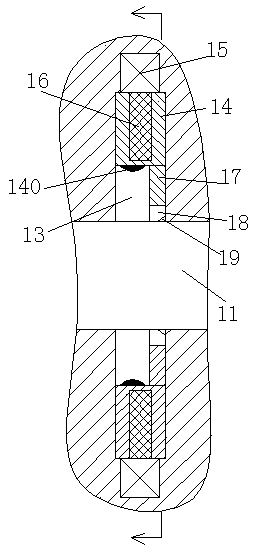

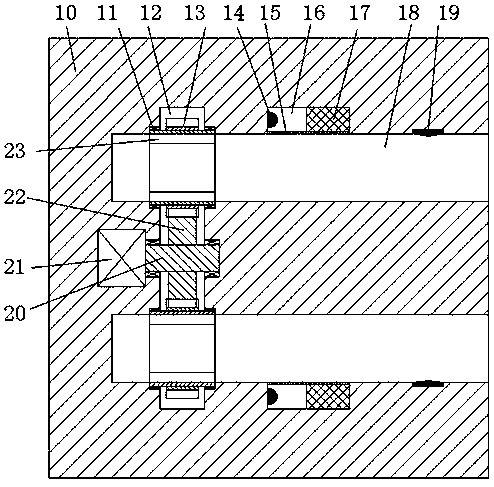

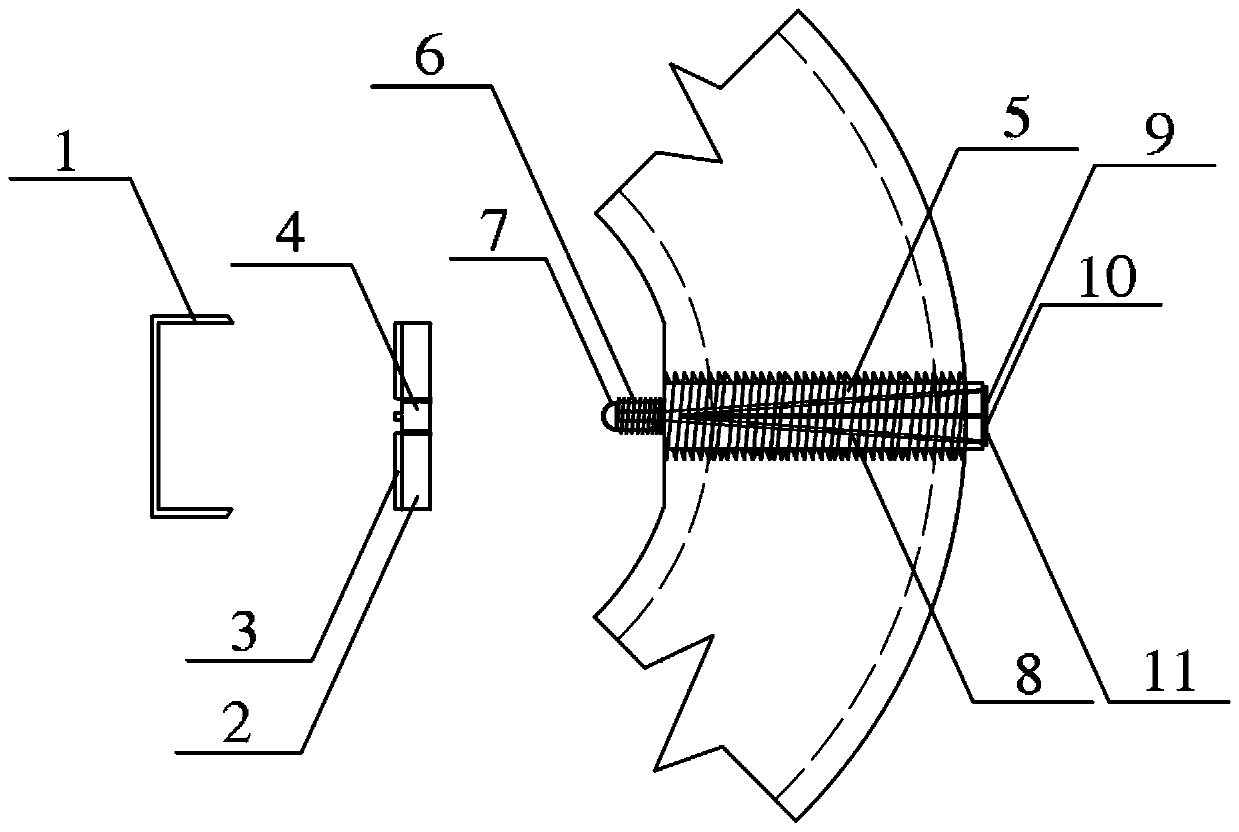

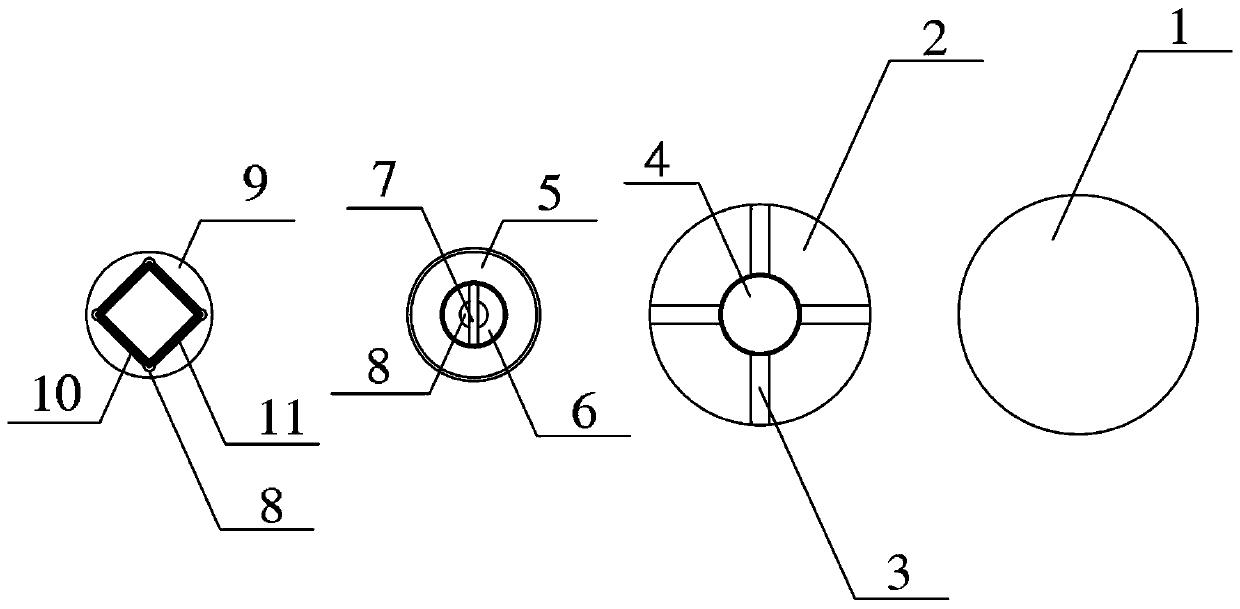

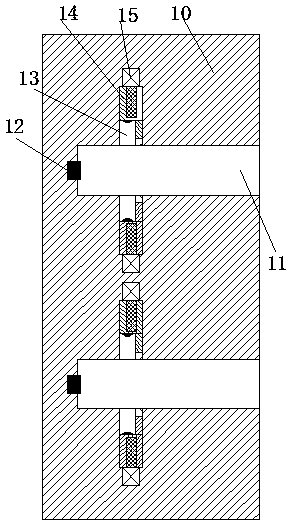

Composite bearing for self-tightening drill chuck

ActiveCN103212736AImprove integrityImprove rigidityRotary combination bearingsShaftsRolling-element bearingEngineering

The invention belongs to the technical field of machinery, relates to a self-tightening drill chuck, and particularly relates to a composite bearing for the self-tightening drill chuck. The technical problems of being unreasonable and the like in the prior art are solved. The composite bearing comprises a cylindrical axle base, and the axle base is fixedly arranged between the radial direction of a main body and an integral type bearing guide part. A radial sliding bearing is arranged on the radial inner side of the composite bearing, and a thrust rolling bearing is arranged at the lower end of the composite bearing. Compared with the prior art, the composite bearing for the self-tightening drill chuck has the advantages of being reasonable in design and simple and compact in structure, the axle base is not only a bearing bush of the radial sliding bearing but also a race of the thrust rolling bearing, the composite bearing which is good in integrality and strong in rigidity is formed through positioning and connection by matching of the axle base and the integral type bearing guide part, stable bearing to the main body can be achieved, connecting strength is high, looseness can not happen, and connecting of parts is stable and reliable.

Owner:AMICUS VERITATIS MACHINERY

Bridge facility

Owner:王晨亮

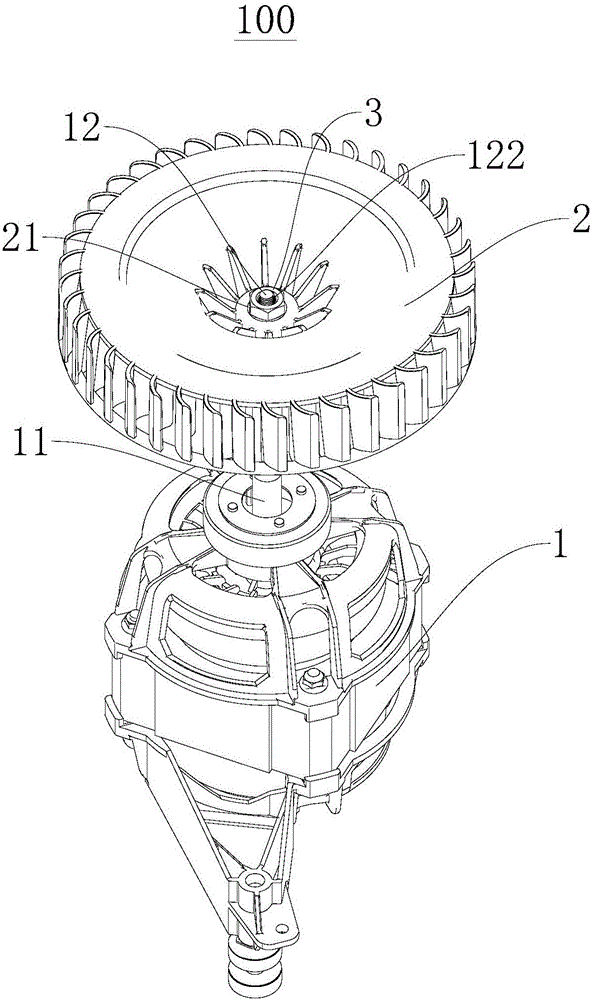

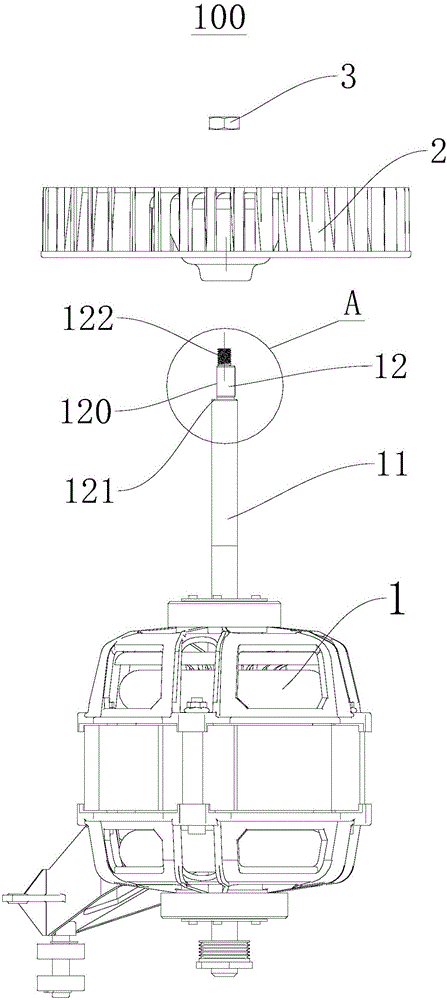

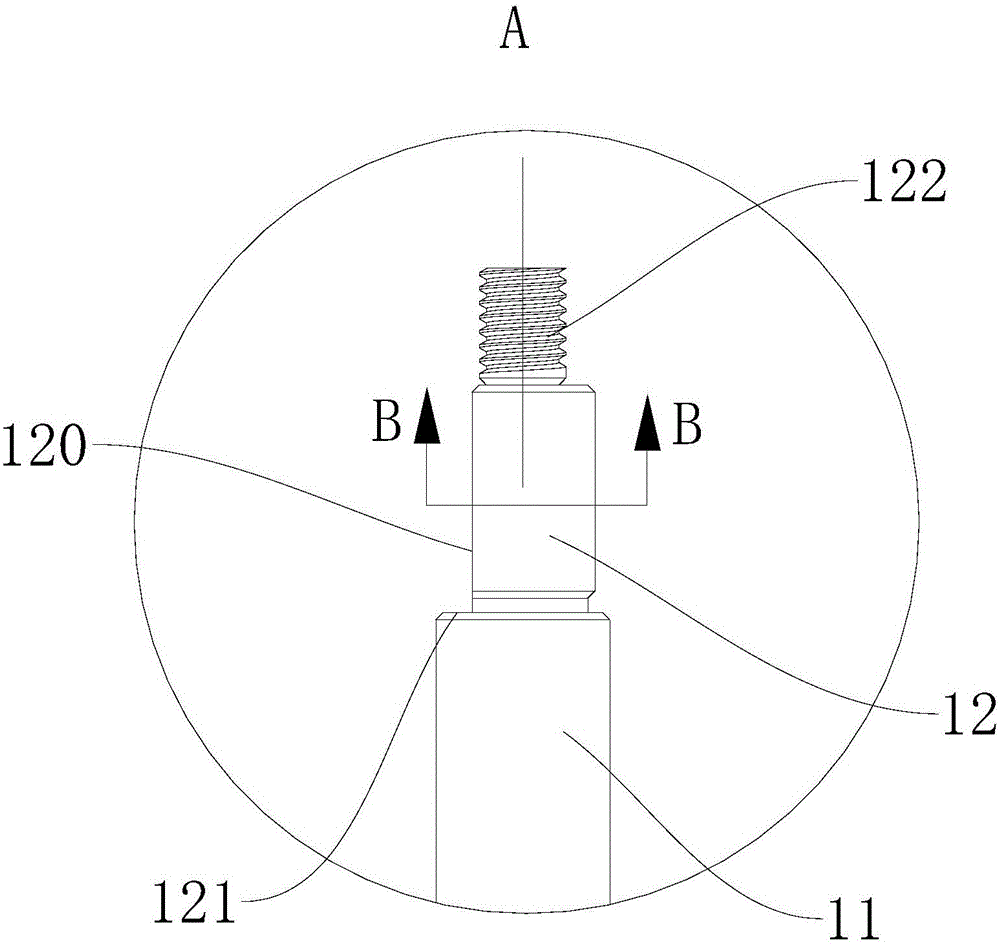

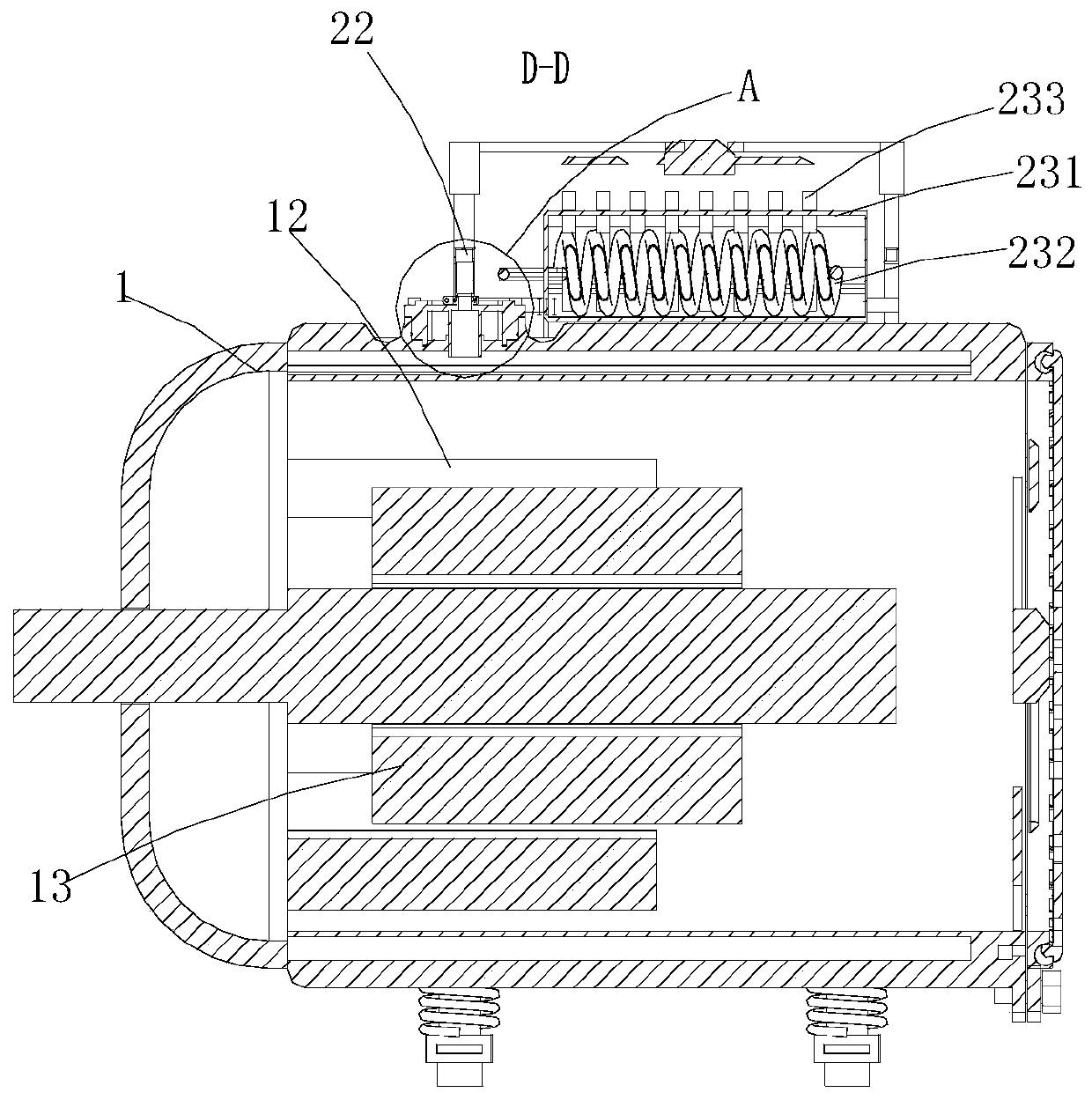

Motor assembly of clothes dryer and clothes dryer with same

InactiveCN106059191AWill not cause looseningSimple structureMechanical energy handlingImpellerEngineering

The invention discloses a motor assembly of a clothes dryer and a clothes dryer with same. The motor assembly comprises a motor, an impeller and a stopper. One end of the output shaft of the motor is provided with a fitting shaft. One end, which is next to the motor, of the fitting shaft is provided with an axial stopping part which outwards projects along the radial direction. A first plane is formed on the outer peripheral surface of the fitting shaft. The impeller is provided with a mounting hole which is through in the axial direction. The inner peripheral surface of the mounting hole is provided with a second surface which matches the first surface. The fitting shaft penetrates through the mounting hole and the free end of the fitting shaft extends out of the mounting hole. The stopper is detachably arranged at the free end. The impeller abuts against the stopper and the axial stopping part therebetween. The motor assembly according to the invention can realize clockwise rotation and counterclockwise rotation. Furthermore impeller loosening is prevented in clockwise rotation and clockwise rotation. Furthermore the motor assembly and the clothes dryer have advantages of simple structure, high safety, convenient detachment, low maintenance cost, etc.

Owner:WUXI LITTLE SWAN CO LTD

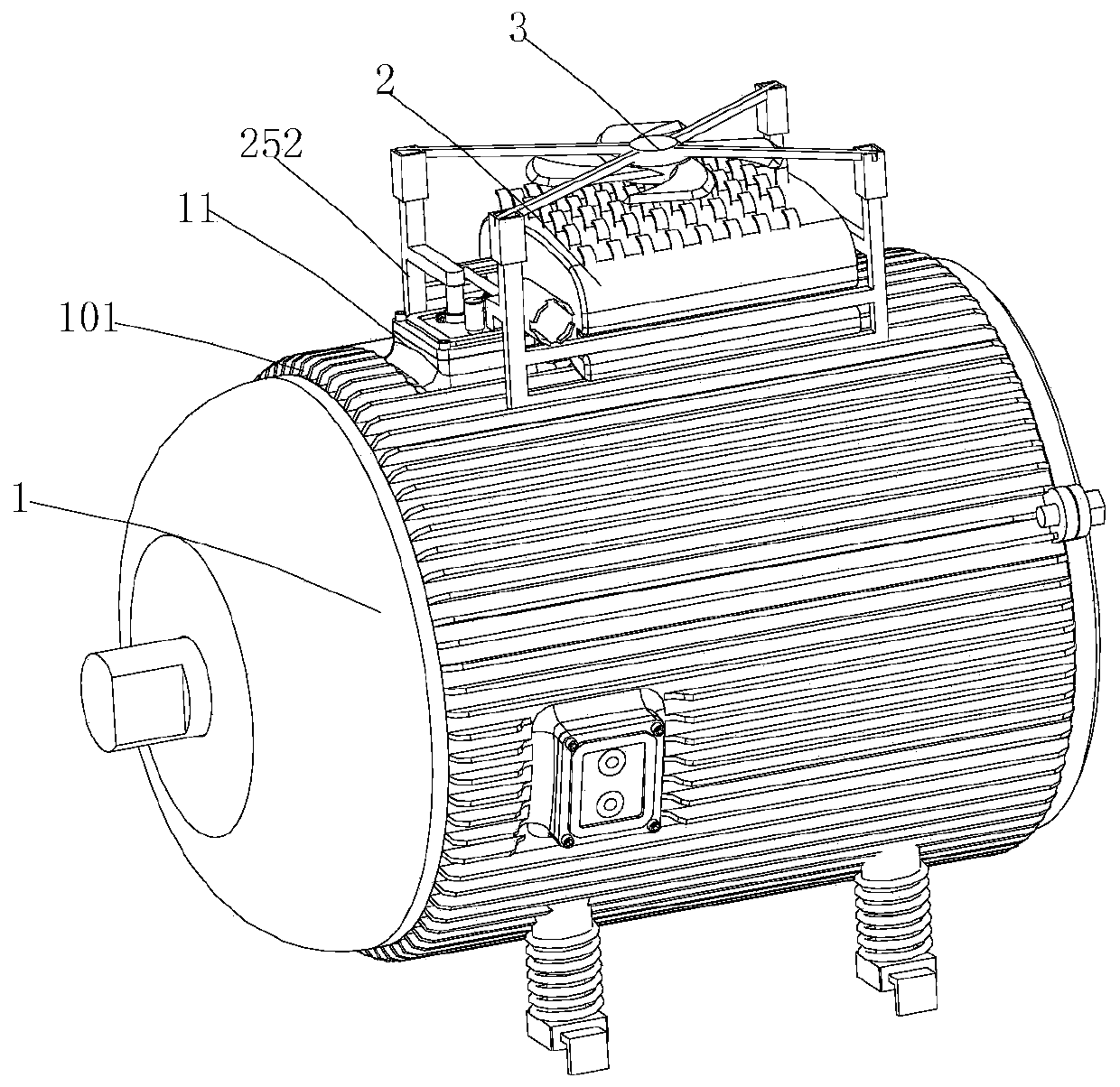

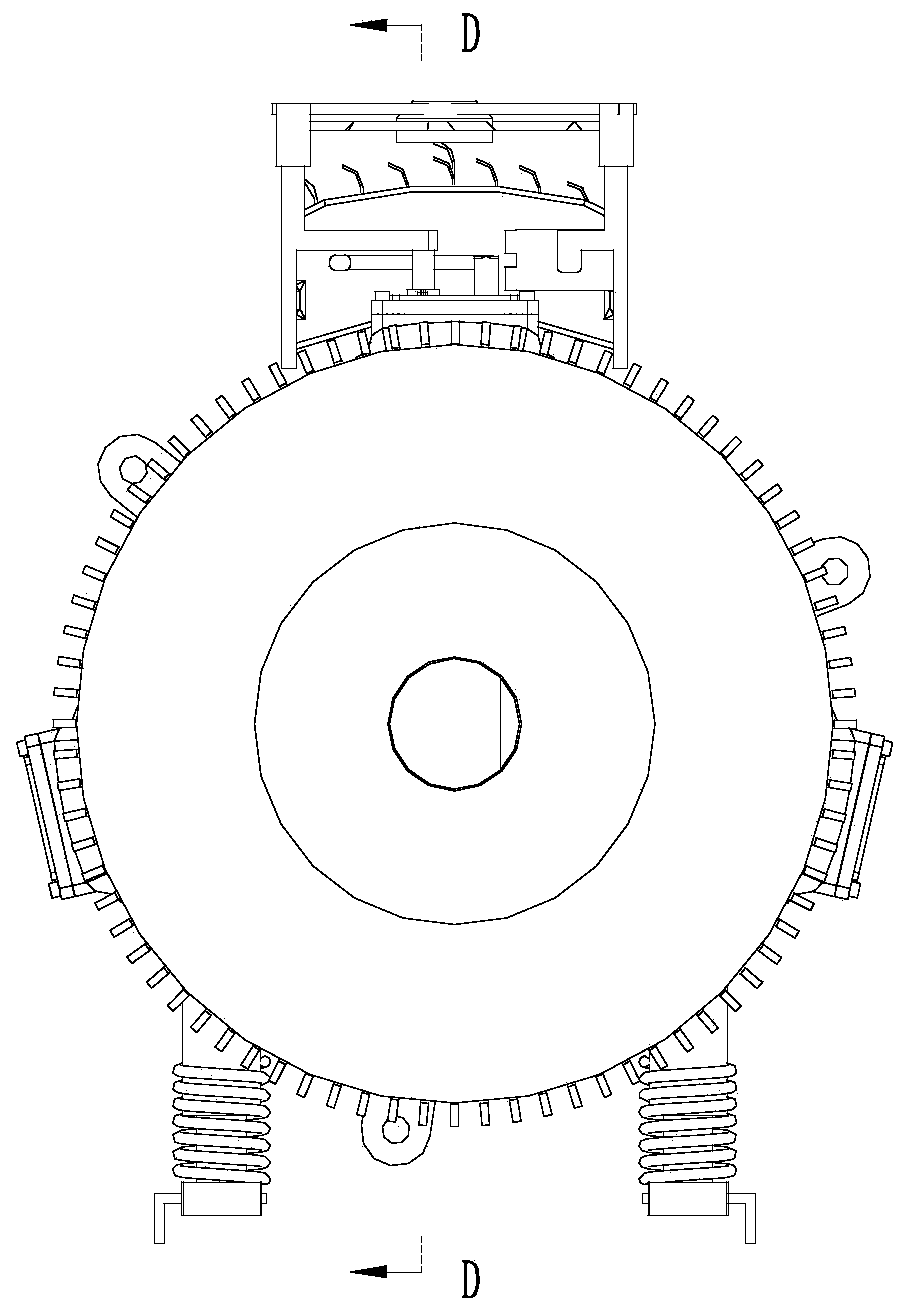

Water-cooled motor

ActiveCN110048549AWide range of assemblyEasy to assembleCooling/ventillation arrangementSupports/enclosures/casingsEngineeringRefrigerant

The invention discloses a water-cooled motor. The water-cooled motor comprises an enclosure, multiple connecting parts arranged on the enclosure, a stator arranged in the enclosure, a rotor arranged in the enclosure, a circulation device and an air-cooling component, wherein the enclosure is provided with a water-cooling cavity, and the water-cooling cavity is filled with a refrigerant; the circulation device is detachably connected with one of the connecting parts and is used for extracting the refrigerant in the water-cooling cavity to cool the refrigerant; and the air-cooling component is arranged on the circulation device and is used for air-cooling the refrigerant on the circulation device. According to the water-cooled motor, through the arrangement of the multiple connecting parts,during installation of the circulation device, one of the connecting parts can be selected according to need for installation, and therefore the circulation device can have three locations. In this way, motor installation efficiency can be effectively improved, and therefore the motor can adapt to a wider range of and a large quantity of equipment.

Owner:绍兴劲鹰机械制造有限公司

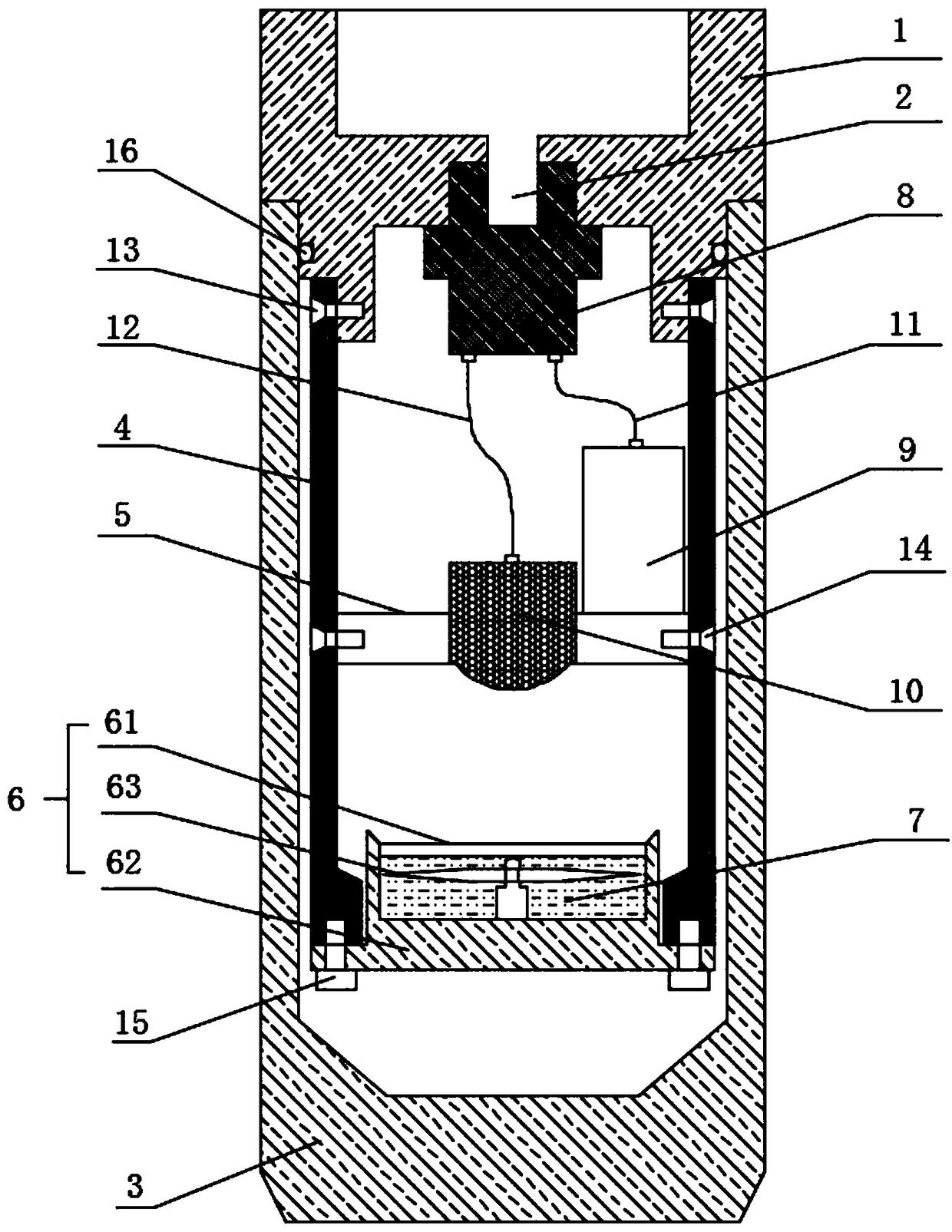

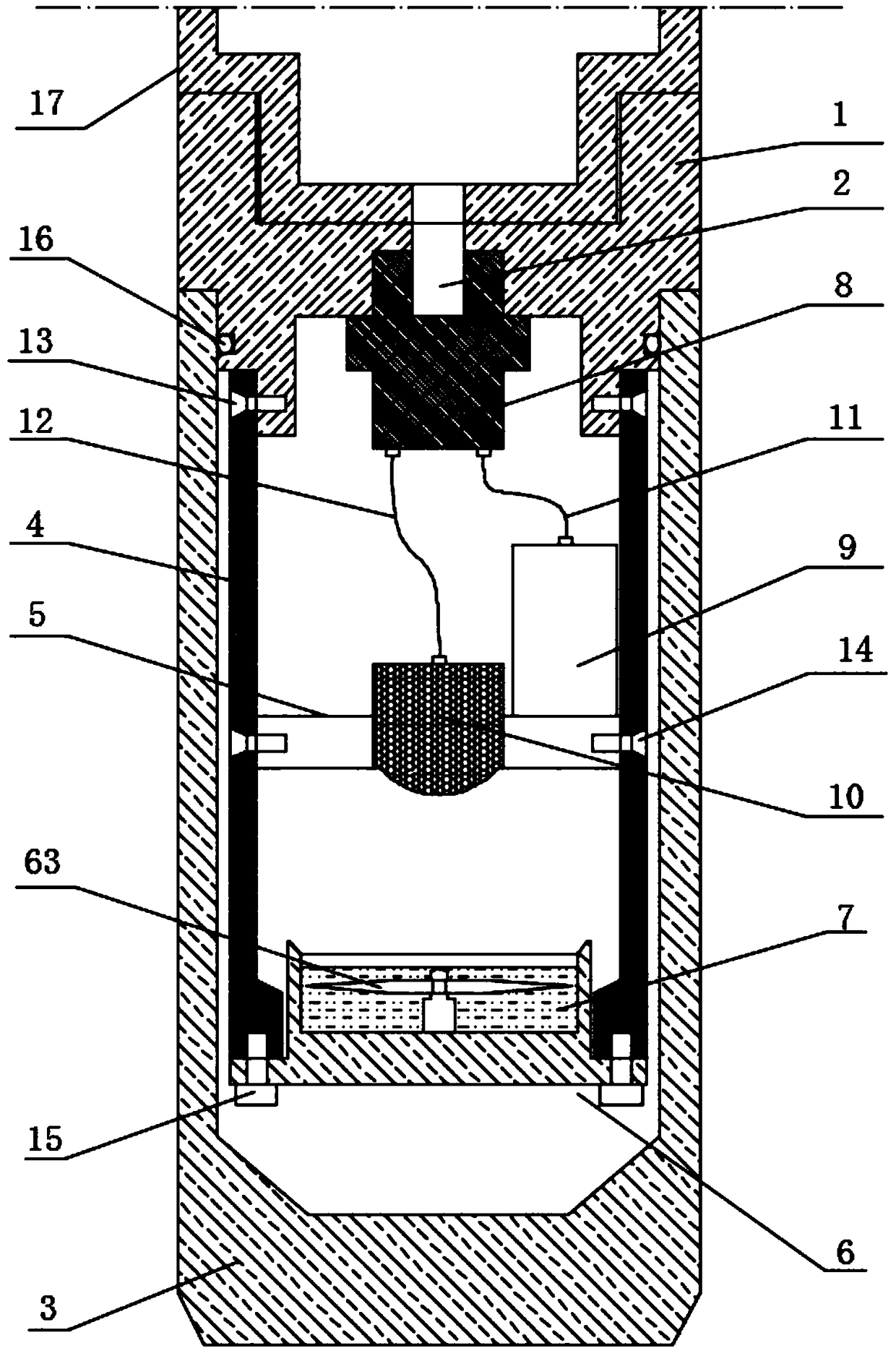

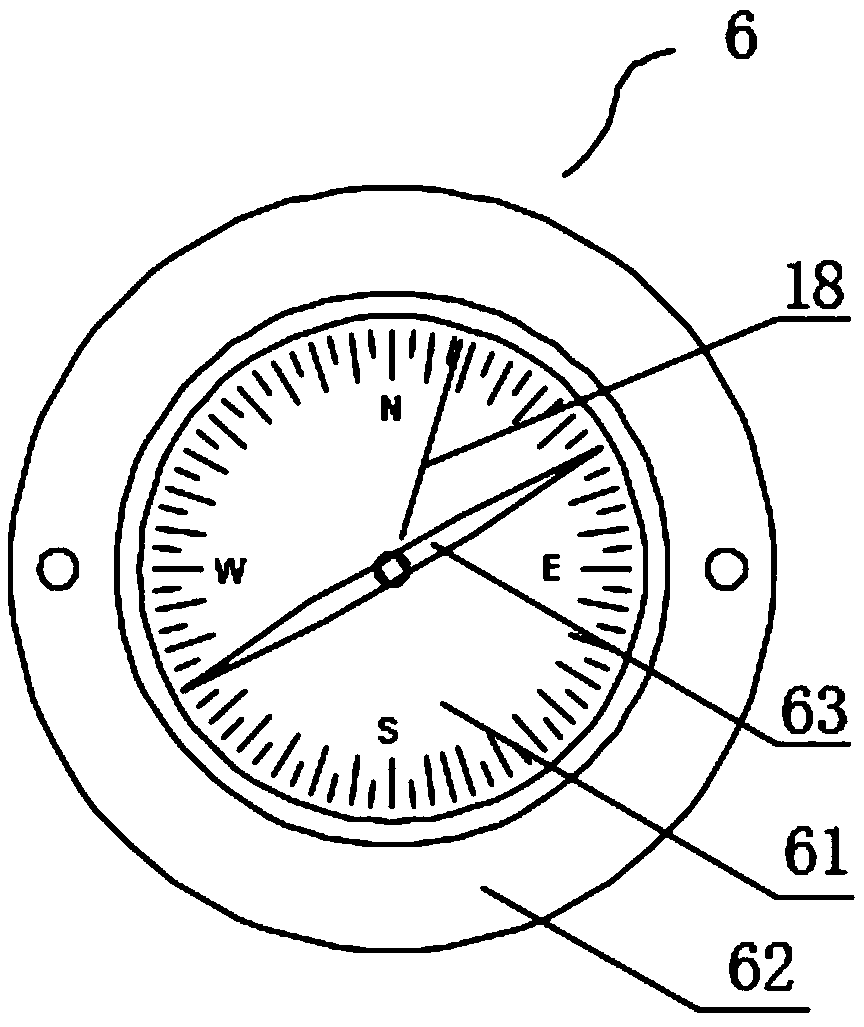

Direction determining device in drilling hole for crustal stress testing according to hydrofracturing method

The invention discloses a direction determining device in a drilling hole for crustal stress testing according to a hydrofracturing method. The device comprises a top base and an outer sleeve. The upper end of the top base is connected with the lower end of a packer through threaded connection. The lower end of the top base is connected with the upper end of the outer sleeve through threaded connection. The lower end of the top base is connected with an inner support and a pressure switch. The inner support and the pressure switch are arranged in the outer sleeve. The outer sleeve is internally provided with a battery, an ultraviolet lamp and a geological compass in which liquid UV glue is packaged. The geological compass is fixed to the lower end of the inner bracket. The battery and theultraviolet lamp are fixed to the middle part of the inner support through a middle separating board. The ultraviolet lamp right faces the dial of the geological compass. The pressure switch is communicated with a pressure hole in the top base. The pressure hole is communicated with the inner chamber of the packer. The battery is connected with the input contact of the pressure switch through a first lead harness. The ultraviolet lamp is connected with the output contact of the pressure switch through a second lead harness. The direction determining device in the drilling hole can resist a measurement error caused by loosening and deflection of a compass pointer because of any vibration interference.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Copper-aluminum cold pressure welding process for refrigerator evaporator

InactiveCN106541206AImprove connection strengthWill not cause looseningWelding/soldering/cutting articlesMetal working apparatusAlloyEngineering

The invention discloses a copper-aluminum cold pressure welding process for a refrigerator evaporator. The process is composed of four steps: treatment of a to-be-welded piece; a cold pressure welding process of an aluminum tube; thickening of a bonding surface; weldment forming; and cleaning. Threaded holes are machined at two ends of the copper-aluminum tube, and anti-loosening bolts are mounted in the threaded holes. No brittle alloy layer is available at the copper-aluminum bonding face manufactured by the process, the joint is good in compactness, and the copper-aluminum tube joint is good in quality.

Owner:SUIYANG COUNTY NAIHUAN ALUMINUM IND

Slope protecting method combining multi-hole concrete and grass vines

InactiveCN108677973AReduce window periodOptimize allocationHops/wine cultivationTurf growingSocial benefitsGreening

The invention relates to a slope protecting method combining multi-hole concrete and grass vines. According to the method, at first, the multi-hole concrete is built on a soil texture or rock textureslope, then grass seeds and vine plants are sown on the slope face and the slope bottom correspondingly, during the earlier stage, the grass seeds grow fast and provide greening, during the later stage, vines climb the multi-hole concrete and grow to cover the slope face, and the functions of fixing water and soil and adjusting local water distribution are achieved. The method fully utilizes the characteristics that the survival rate of the vines is high, the requirement for soil texture is low, the vines are cultivated easily, and the grass seeds sprout and grow fast but not lasting, vine airroots constructed and conversed well are planted in holes of the concrete, the loosening risk of coarse aggregate is reduced, and the slope protecting method has great social benefits and environment-friendly benefits and is worthy of being applied and popularized.

Owner:WUHAN UNIV OF TECH

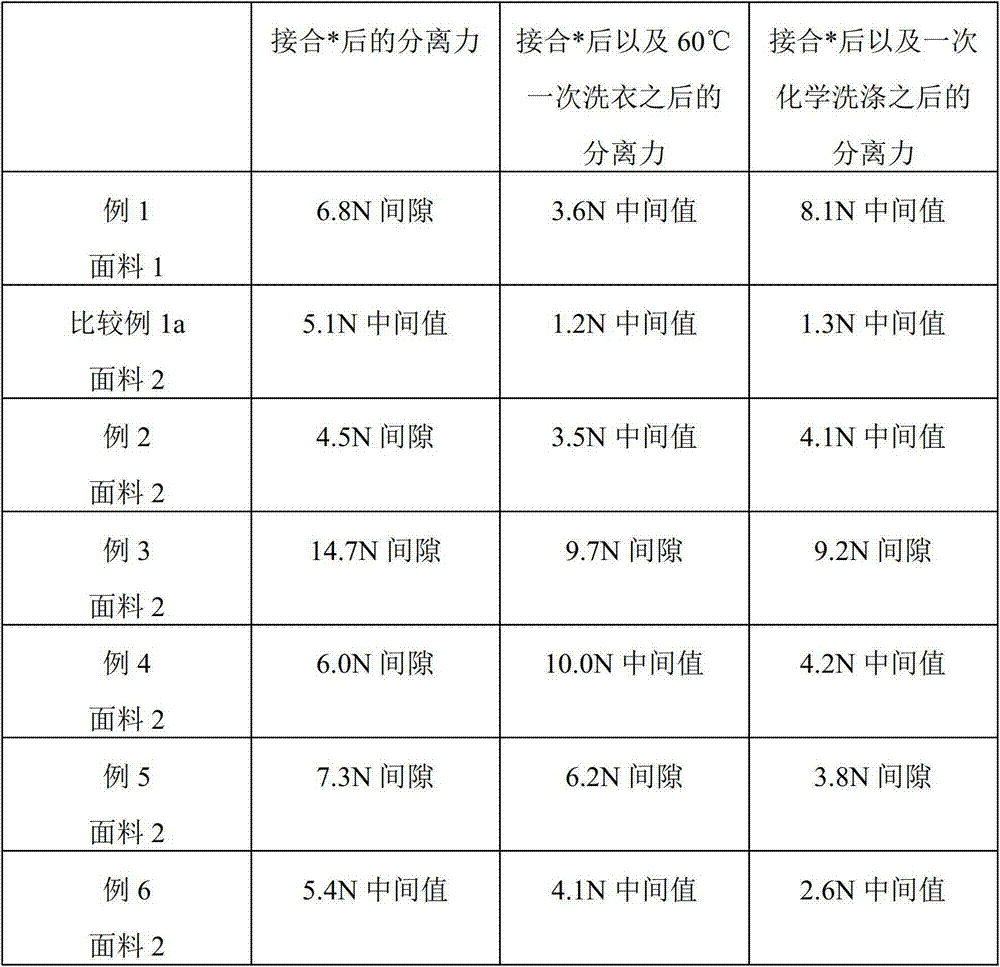

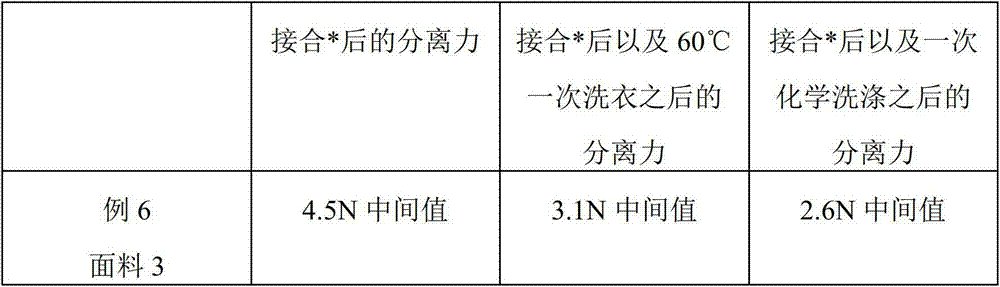

Adhesive compound for hot-sealing inserts

The invention relates to an adhesive compound for a hot-sealing insert, to an insert that is equipped with said adhesive compound, and to a method for fixing the insert. The adhesive compound consists of a thermoplastic hot-melt adhesive (A) that is not adhesive at room temperature and a pressure sensitive adhesive (B) that is adhesive at room temperature.

Owner:CARL FREUDENBERG KG

Automatic bending device for metal glasses frame machining

ActiveCN113560461AGood clamping forceWill not cause looseningMetal working apparatusElectric machineryMachine

The invention discloses an automatic bending device for metal glasses frame machining in the technical field of glasses frame machining. The automatic bending device comprises a machine base, a workbench, a supporting frame, a thickness detection mechanism, a first inductor and a second inductor. The workbench is fixedly connected to the surface of the machine base. A bending mechanism driving mechanism is fixedly connected to the position, below the workbench, of the surface of the machine base. The bending mechanism driving mechanism comprises a right mounting seat, a left mounting seat and a first motor, the right mounting seat and the left mounting seat are mounted on the surface of the machine base, and a first lead screw and a first limiting rod are mounted between the right mounting seat and the left mounting seat in an inserted manner. The device can bend glasses frames with different sizes and shapes, the bent glasses frames are diverse in modeling, meanwhile, the device can automatically carry out material conveying, bending and cutting-off work, and whether the length of tailings is enough to complete manufacturing of finished products or not can be detected.

Owner:郝建策

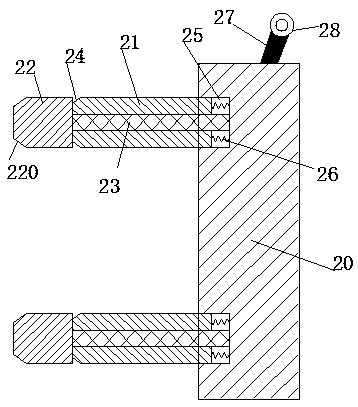

Improved safety power transmission device

The invention relates to an improved safety power transmission device. The improved safety power transmission device comprises a power supply base fixedly mounted in a wall body and a plug connector matched with the power supply base, wherein mounting cavities with openings facing the left end are vertically and symmetrically formed in the left end surface of the plug connector, each mounting cavity is slidably equipped with a rectangular sliding sleeve extending leftwards, a center hole is formed in each rectangular sliding sleeve, each center hole is slidably equipped with a conductive rod connected with a household electrical appliance, the right end of each conductive rod extends out of the corresponding rectangular sliding sleeve and is fixedly mounted in the right end wall of the corresponding mounting cavity, the left end of each conductive rod extends out of the corresponding rectangular sliding sleeve and is fixedly equipped with a rectangular conductive block, the left end ofeach rectangular sliding sleeve is vertically and symmetrically provided with pressed inclined surfaces, rectangular insertion grooves with openings facing rightwards and matched with the rectangularconductive blocks are vertically and symmetrically formed in the power supply base, sliding grooves facing the corresponding rectangular insertion groove are symmetrically formed in upper and lower end walls of each rectangular insertion groove, and a sliding block is slidably mounted in each sliding groove.

Owner:罗志杰

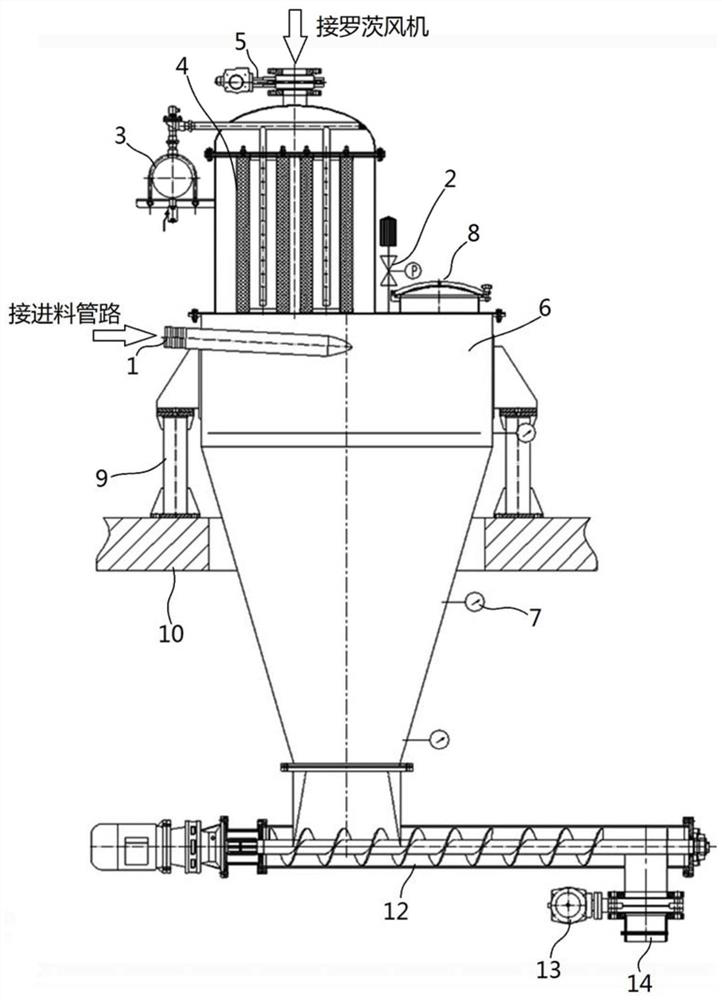

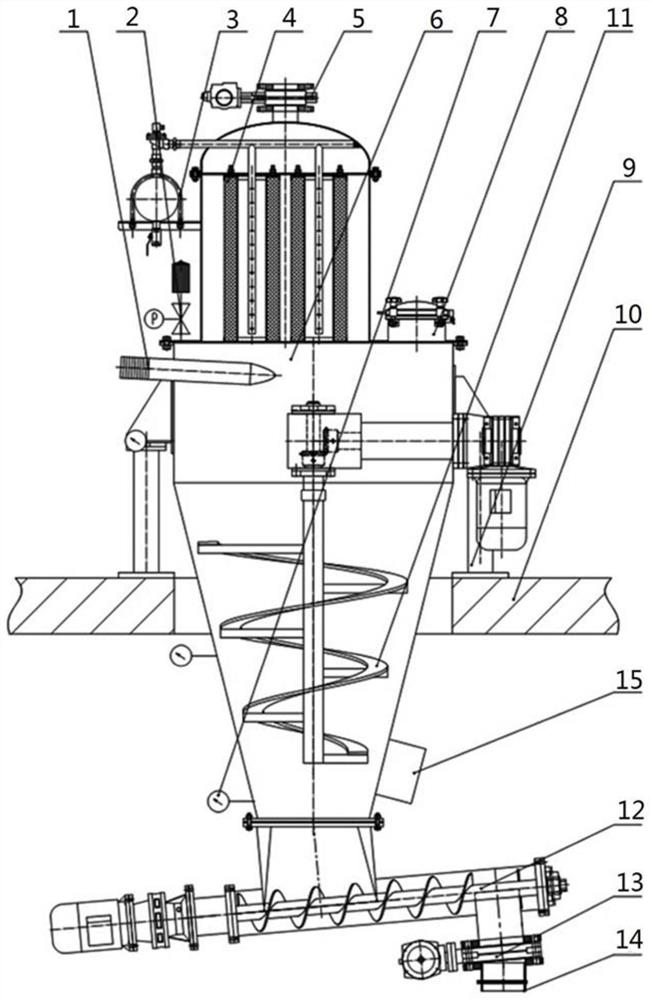

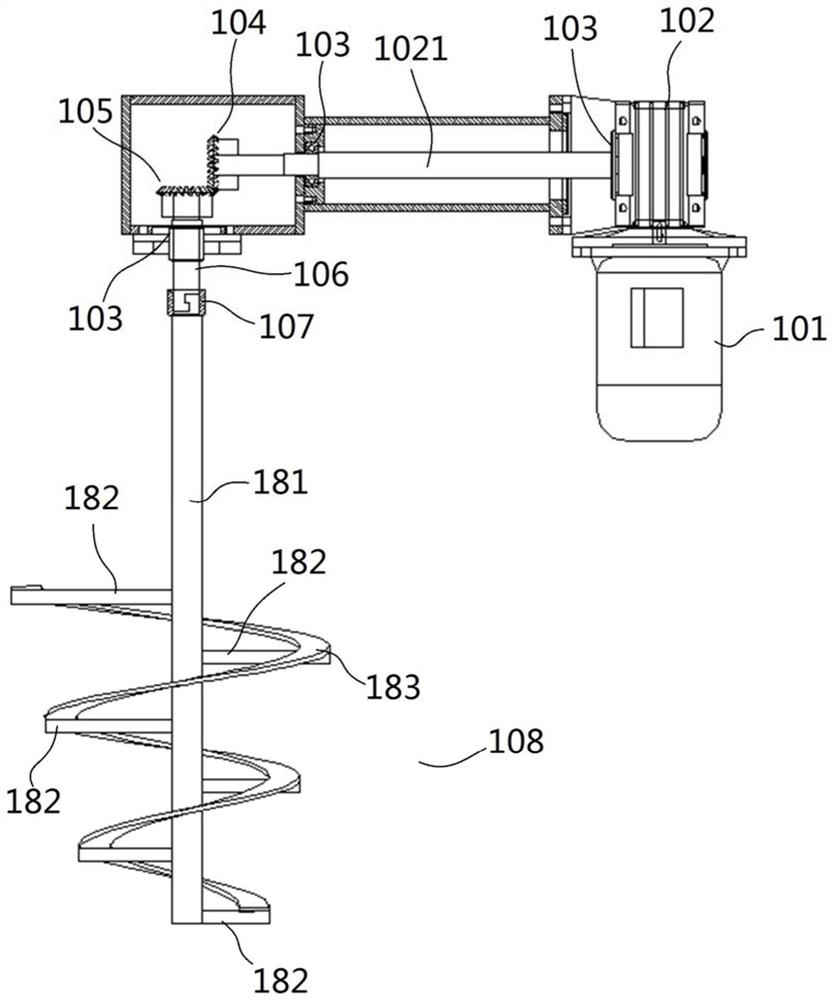

Powder storage tank

PendingCN111824610AImprove liquidityReduce liquidityLarge containersLoading/unloadingDrive shaftElectric machinery

The invention relates to a powder storage tank. The powder storage tank comprises a tank body; the lower part of the tank body is conical; a feeding pipe is arranged at the upper part of the tank body; the tank body is provided with an upper cover; a respirator, a blowback air pocket component, an air and material separator and an air suction port are arranged on the upper cover; a screw conveyeris arranged at the lower end of the tank body; an arch breaking mechanism is arranged on the tank body and comprises a drive motor, a reduction gearbox, a bevel gear set, a transmission shaft and a stirrer in drive joint sequentially; the bevel gear set comprises a driving bevel gear and a driven bevel gear; the driving bevel gear is mounted at the outer end of a horizontally arranged output shaftof the reduction gearbox; the driven bevel gear is mounted at the upper end of the transmission shaft; the drive motor and the reduction gearbox are mounted at the external part of the tank body; theoutput shaft of the reduction gearbox penetrates through the tank body and is in rotary seal fit with the tank body; the stirrer comprises a stirring paddle, and the axis of the stirring paddle is vertically arranged; the stirring paddle is positioned a conical structure at the lower part of the tank body; and the lowest end of the stirring paddle extends to the conical opening of the conical structure. The powder storage tank is small in noise, high in arch breaking capacity and is suitable for material with poor fluidity and likely to absorb moisture for caking.

Owner:上海富昶环保科技有限公司

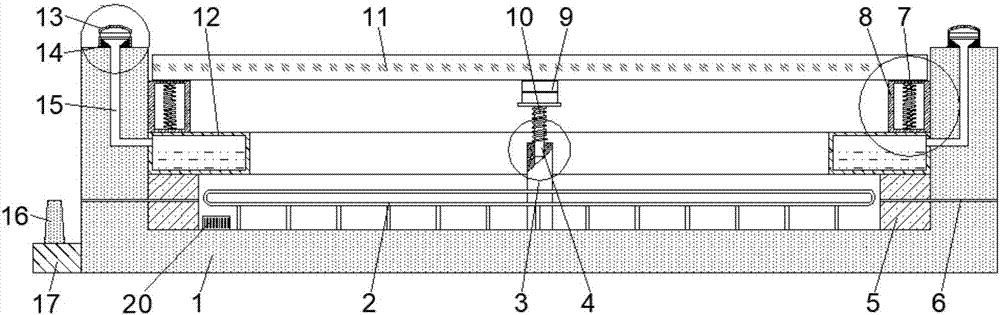

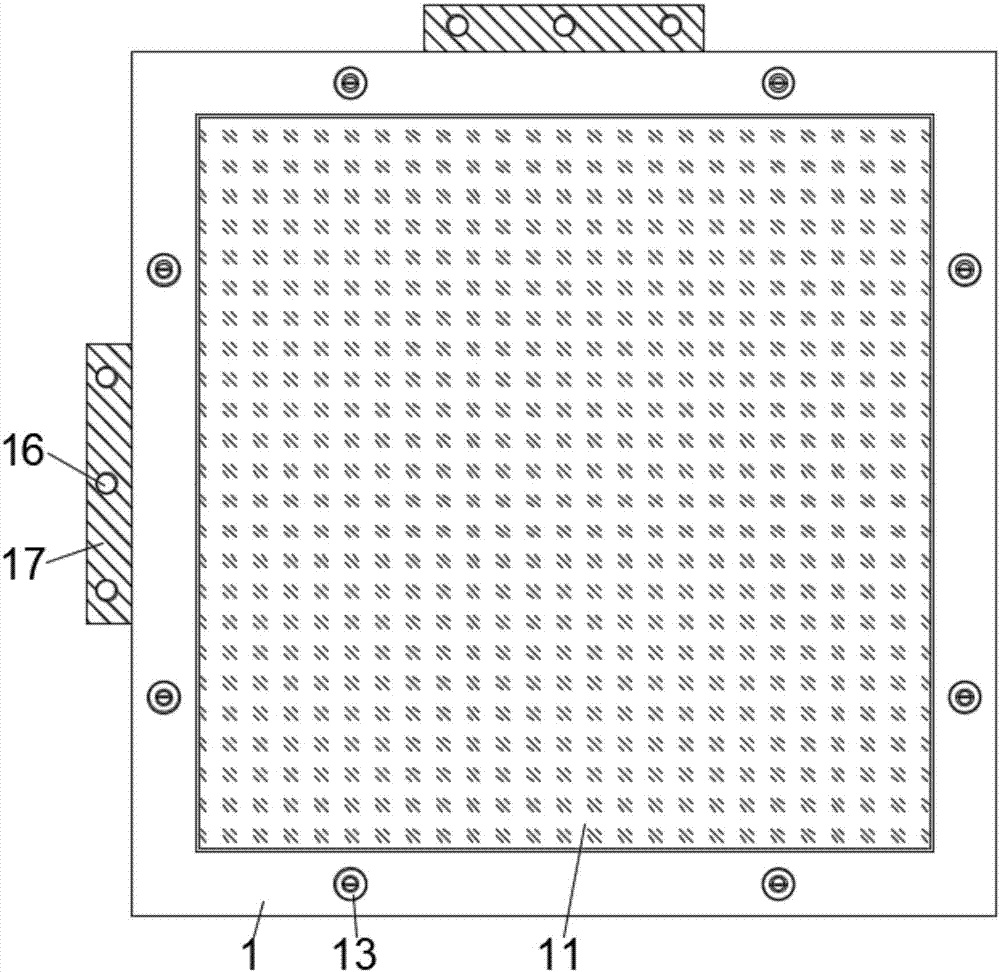

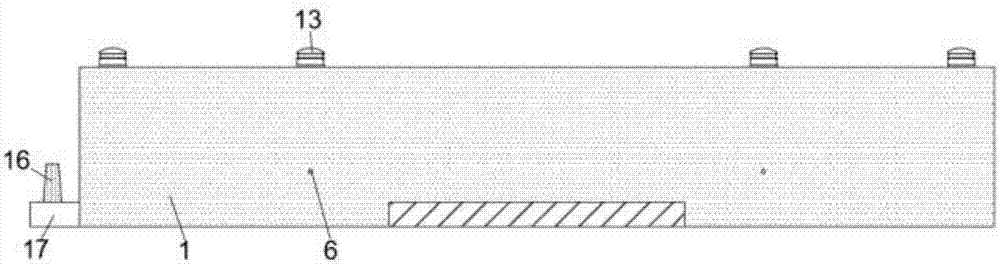

Electric heating plate

PendingCN111343737AReduce lossImprove thermal conductivityHeating element shapesInsulation layerThermal insulation

The invention relates to an electric heating plate. The electric heating plate comprises a high-temperature heat-conducting plate and a furnace body, wherein the bottom surface of the high-temperatureheat conduction plate is coated with a graphene heating coating; the bottom surface of the graphene heating coating is coated with a conductive electrode coating; the graphene heating coating is electrically connected with the conductive electrode coating; the furnace body comprises a heating disc shell, a heat insulation layer and an elastic conductive sheet, wherein the heat insulation layer isarranged in the heating disc shell, the elastic conductive sheet is arranged on the heating disc shell, and the elastic conductive sheet is in close contact with the corresponding conductive electrode coating. The graphene heating coating is directly coated on the bottom surface of the high-temperature heat conduction plate, so the heat of the graphene heating coating is directly transferred to the high-temperature heat conduction plate, the heat transfer effect is improved, the conductive electrode coating is directly coated on the graphene heating coating, the conductive electrode coating and the graphene heating coating are tightly combined, and the electric energy conduction effect is good.

Owner:中山市特美新电子商务有限公司

Household power source supply device

InactiveCN107681322ANo electric shock accidents will occurReduce security risksTwo-part coupling devicesLive contact access preventionElectricityEngineering

Owner:俞灿

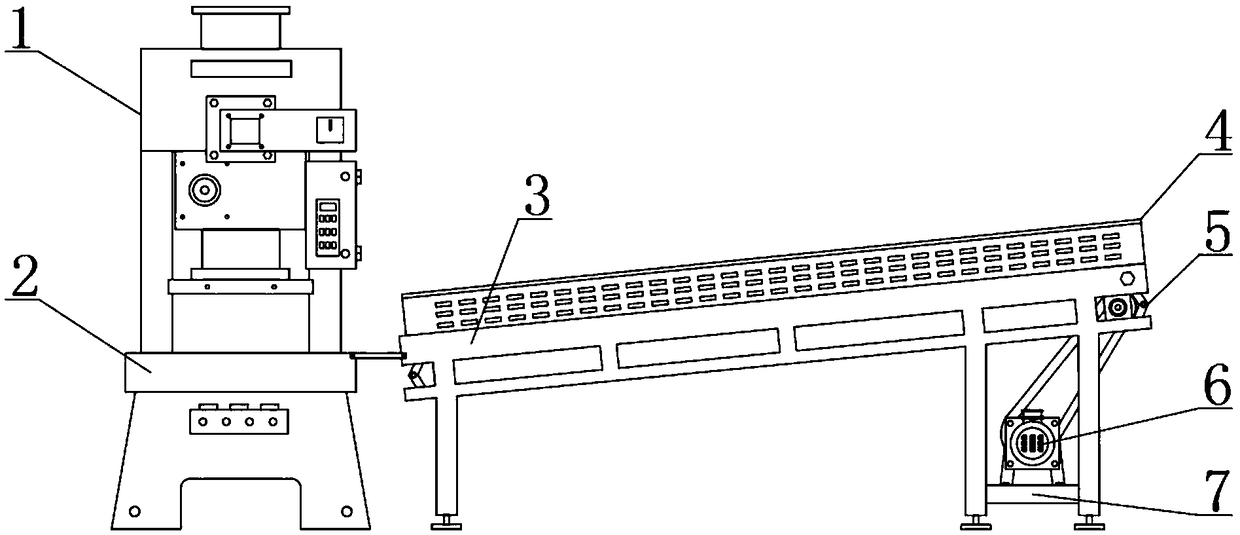

Automatic feeding device of high-precision bidirectional hammer type forging press

InactiveCN109365734ASafe working environmentAvoid excessive heatHandling devicesTemperature treatmentEngineering

The invention discloses an automatic feeding device of a high-precision bidirectional hammer type forging press. The automatic feeding device comprises the forging press and a transmission chain belt.A forging-pressing panel is arranged at the bottom of the forging press, and one side of the forging-pressing panel is connected with a conveyor. A conveying panel is arranged in the conveyor, and the two sides of the conveying panel and the conveyor are connected through the transmission chain belt. A protection plate is fixed to the top of the conveyor, and integrated sliding blocks are arranged at the bottoms of the two sides of the protection plate. Protection plate sliding grooves are formed in the tops of the two sides of the conveyor. When the conveyor is used normally, due to the factthat conveying objects on the conveying panel are subjected to high-temperature treatment and are high in temperature and the height of the conveying panel can be touched by an operator, under the action of the protection plate, the objects at the top of the conveying panel cannot be directly touched by the operator when the operator touches the conveying panel by mistake or falls over, the problem that the operator is possibly scalded is avoided, and the overall work environment is quite safe; and heat radiation holes are distributed in the surface of the protection plate.

Owner:池州市柏泰贸易有限公司

Big data device

InactiveCN107689523ASimple structureEasy to useLive contact access preventionSoftware engineeringBig data

The invention relates to a big data device. The big data device comprises a power distribution box and a data plug connected with the data device, wherein a mounting groove with a notch facing left end is vertically symmetrically arranged in a left end surface of the data plug, a sliding sleeve extending leftwards is installed in the mounting groove in a sliding manner, a middle end hole is formedin the sliding sleeve, an electric connecting rod is installed in the middle end hole in a sliding manner, the right end of the electric connecting rod penetrates through the sliding sleeve and is fixedly installed in the right end wall of the mounting groove, the left end of the electric connecting rod penetrates through the sliding sleeve and is fixedly provided with an electric connecting block, and a first bevel face is vertically symmetrically arranged on the left end of the sliding sleeve; and an insertion groove having a notch facing rightwards and matched with the electric connectingblock is vertically symmetrically arranged on a data socket, the upper end wall and the lower end wall of the insertion groove are symmetrically provided with a sliding groove facing the insertion groove, and a sliding block is installed in the sliding groove in a sliding manner.

Owner:柴玲飞

Improved intelligent robot equipment

InactiveCN107845903ASimple structureEasy to useCoupling device detailsManipulatorEngineeringMechanical engineering

The invention relates to improved intelligent robot equipment. The improved intelligent robot equipment comprises a charging pile and a charging end, wherein the charging end is connected with a robot, installation grooves are vertically and symmetrically formed in a left end surface of the charging end and are provided with ports facing leftwards, a sliding sleeve is arranged in each installationgroove in a sliding way and extends leftwards, a middle hole is formed in the sliding sleeve, a power connection rod is arranged in the middle hole in a sliding way, a right end of the power connection rod penetrates through the sliding sleeve and is fixedly arranged in a right end wall of the installation groove, a left end of the power connection rod penetrates through the sliding sleeve, a power connection block is fixedly arranged at the left end of the power connection rod, first diagonal surfaces are vertically and symmetrically arranged at a left end of the sliding sleeve, insertion grooves are vertically and symmetrically formed in a charging end part, are provided with rightward ports and are matched with the power connection block, sliding grooves are symmetrically formed in anupper end wall and a lower end wall of each insertion groove and face the insertion groove, and sliding blocks are arranged in the sliding grooves in a sliding way.

Owner:胡豪

Novel power supply bayonet socket assembly

InactiveCN107732513AThere will be no electric shock accidentsReduce security risksCoupling device detailsMechanical engineeringEngineering

The invention discloses a novel power supply bayonet socket assembly, comprising a bayonet socket fixedly disposed in a wall and a bayonet joint connected to an electrical device. The bayonet socket is provided with a hollow slot having a right opening, and the left end wall of the hollow slot is provided with a plug-in groove which extends from left to right and is symmetrical from top to bottom,and a transverse sliding groove disposed between two plug-in grooves. The bayonet socket is provided with a longitudinal sliding groove which traverses through the plug-in groove and the transverse sliding groove. A telescoping groove is disposed between the transverse sliding groove and the plug-in groove. The transverse sliding groove is provided with a sliding block in a manner of sliding fromleft to right. The left end of the sliding block is provided with a through slot penetrating from top to bottom. The left end face of the sliding block is provided with a first acting inclined planein a manner of being symmetrical from top to bottom. The telescoping groove is provided with a telescoping arm in a manner of sliding. The end face of the telescoping arm, away from the transverse sliding groove, is fixedly provided with a power supply sheet connected to commercial power. The end face of the telescoping arm, facing towards the transverse sliding groove, is provided with a first extruding and pushing inclined plane cooperating with the first acting inclined plane. The longitudinal sliding groove is provided with a sliding arm which is symmetrical from top to bottom in a slidingmanner.

Owner:广西景曜电子科技有限公司

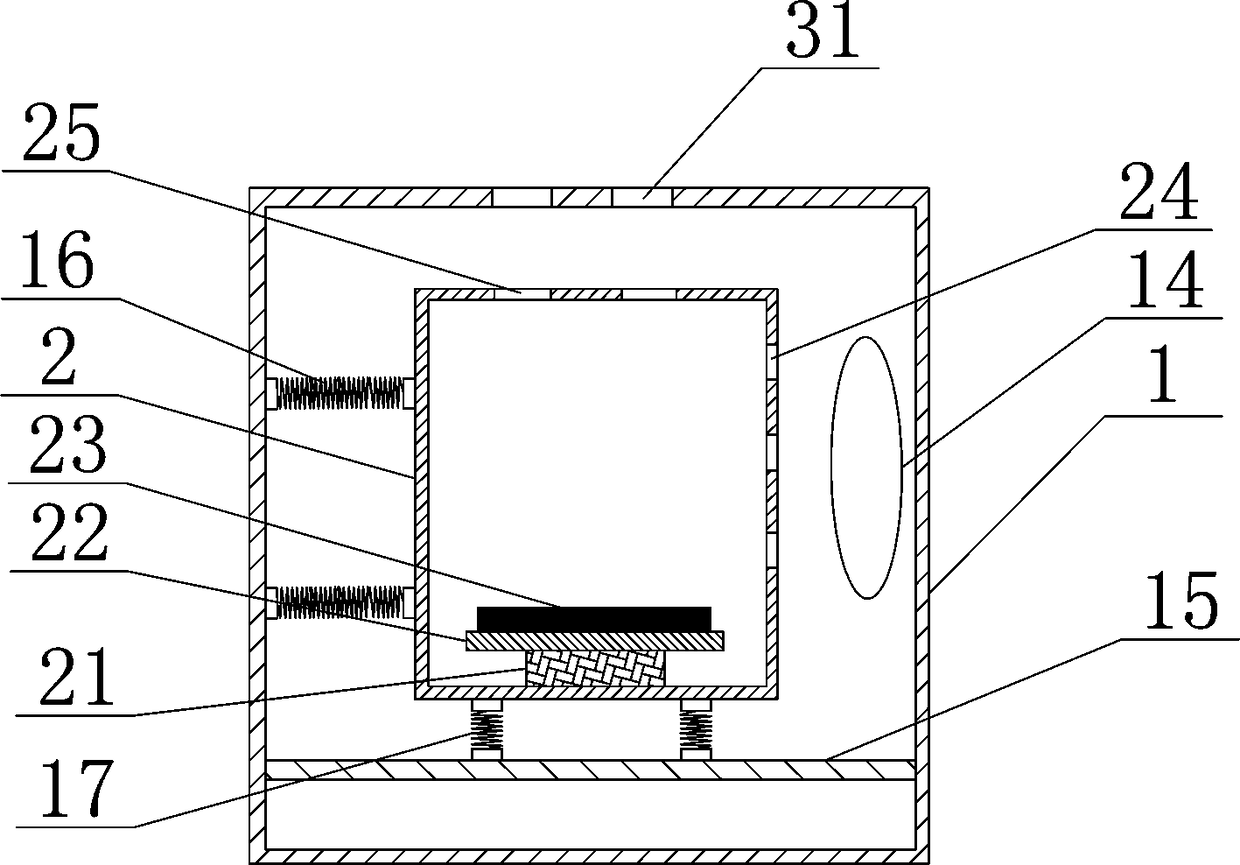

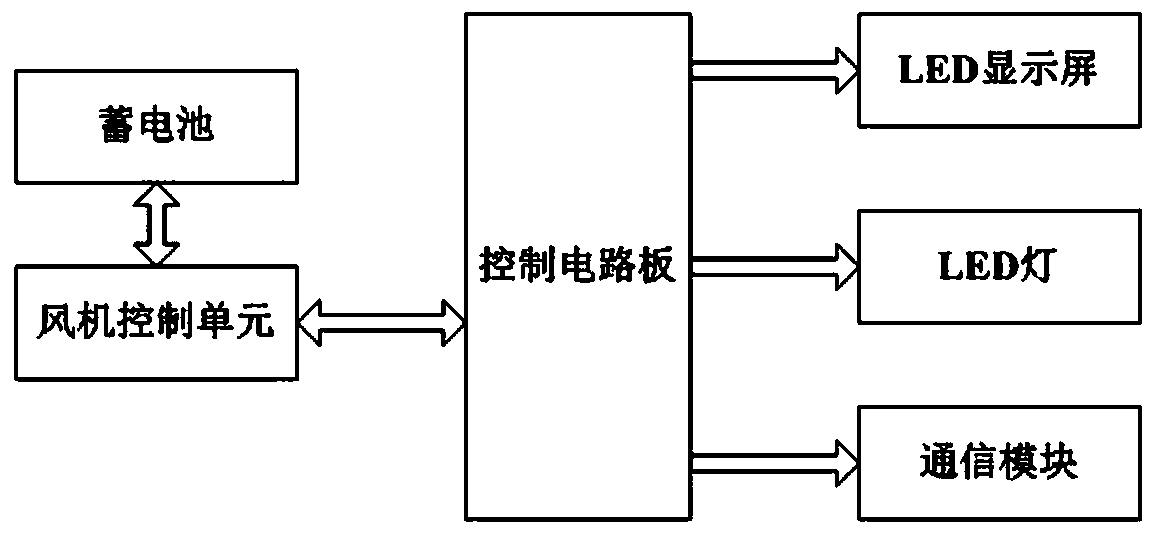

Small wind power generation street lamp control device

InactiveCN108463072AImprove stabilityLow failure rateCasings/cabinets/drawers detailsModifications by conduction heat transferFailure rateLED display

The invention provides a small wind power generation street lamp control device. The device comprises a first box body and a second box body, wherein the first box body is provided with a first threading hole, a heat dissipation window and a fixing groove, a clapboard is arranged in the first box body, the second box body is arranged in a cavity formed by the clapboard and the first box body, anda first damping part is arranged between the first box body and the second box body; a support part is arranged on the inner wall of the second box body, a mounting plate is arranged on the support part, and a control circuit board is arranged on the mounting plate; the control circuit board is respectively connected with an LED display screen, an LED lamp and a fan control unit, and the fan control unit is connected with an accumulator; and the fan control unit adopts a CQM1-AD041 controller, and the fan control unit is respectively connected with a small wind power generator and the accumulator. The device provided by the invention can avoid problems in the prior art and is higher in anti-vibration and anti-shaking capability, low in failure rate and low in maintenance cost.

Owner:ZHENGZHOU SENYUAN NEW ENERGY TECH

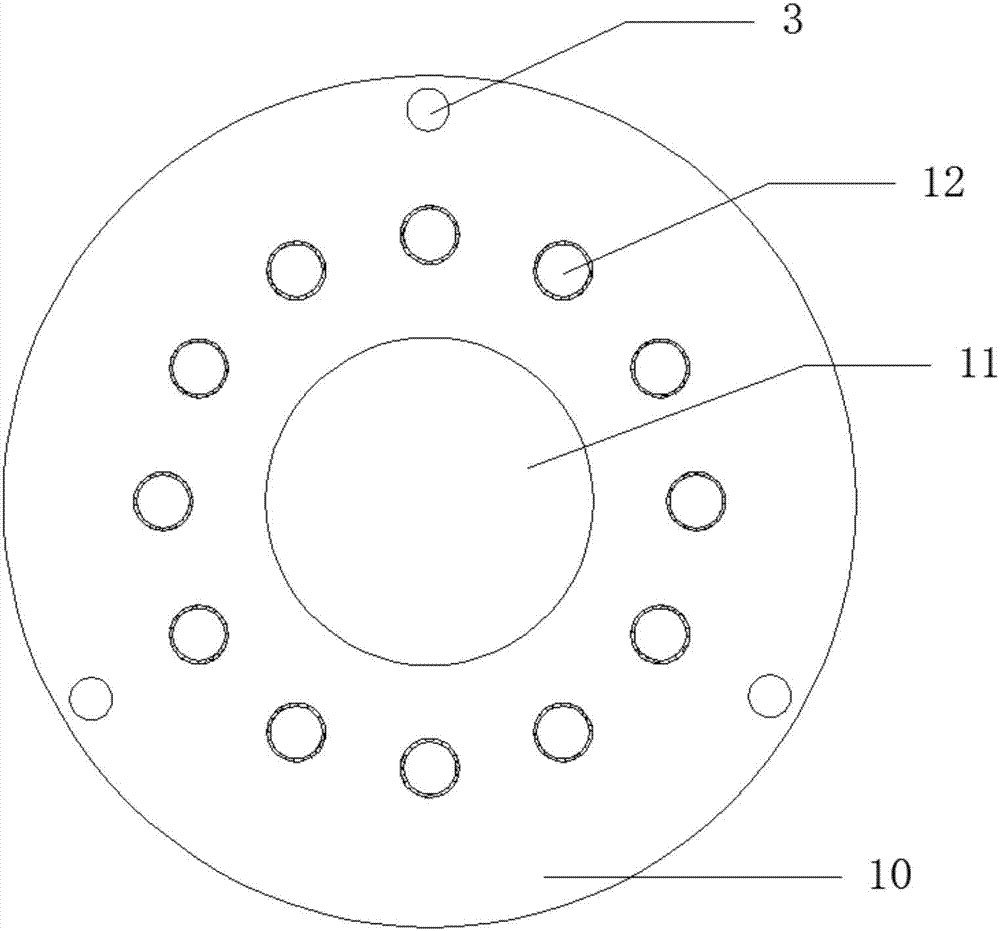

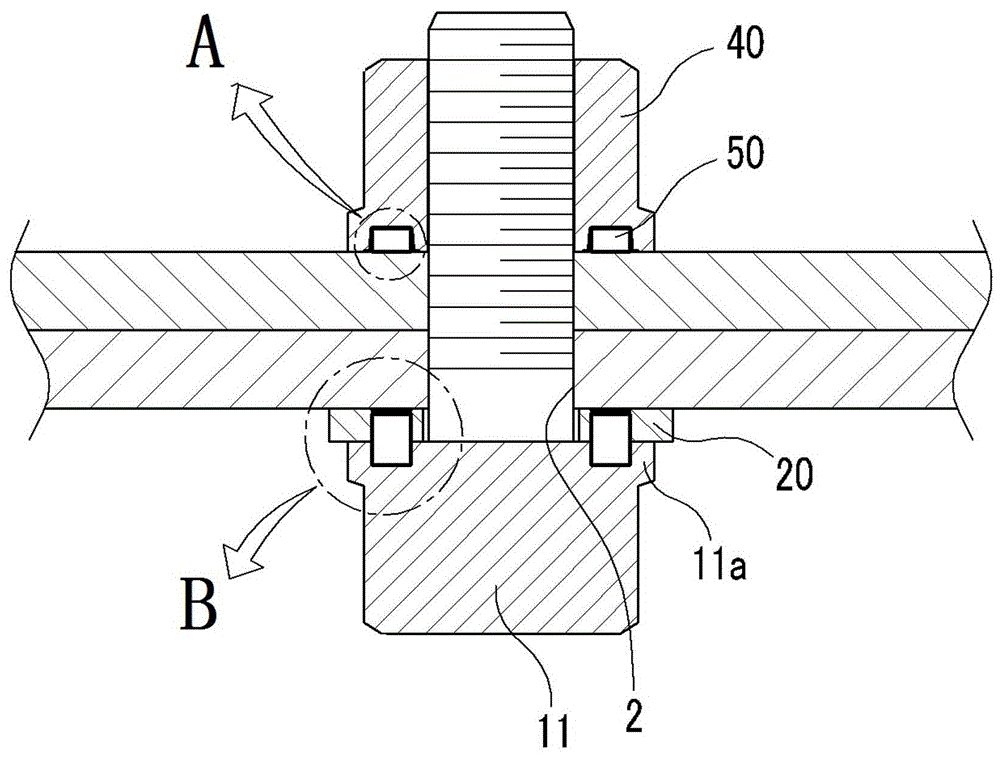

Fiber grating sensor and method for measuring pressure of shield segment

PendingCN110470418AReduce volumeEasy to assemble and disassembleUnderground chambersForce measurement by measuring optical property variationFiberGrating

The invention discloses a fiber grating sensor for measuring pressure of a shield segment. The fiber grating sensor includes a grouting hole shaft tube device, an inner ring protection device and an outer ring measurement device; and the grouting hole shaft tube device includes a grouting hole shaft tube (5), the grouting hole shaft tube (5) includes a grouting hole shaft tube segment (6) and a grouting hole shaft tube end section (7), a plurality of reserved holes (9) are disposed inside the grouting hole shaft tube (5), the inner ring protection device includes a steel protection cover (2),a threaded hole (4) is disposed in the center of the steel protection cover (2), and the outer ring measurement device includes a fiber grating (12). The invention also discloses a method for measuring the pressure of the segment. The fiber grating sensor of the invention can accurately measure the water and soil pressure outside the segment, can monitor the water and soil pressure outside the segment during an entire period, an entire interval, and an entire process, provides more comprehensive information outside a tunnel for tunnel construction and operation stages, and can be repaired andreplaced in time once the sensor is damaged,.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Water cup

InactiveCN107611708ASimple structureEasy to useWater-boiling vesselsLive contact access preventionEngineering

The invention provides a water cup, which comprises a water cup, a plug-in head connected with the water cup through a wire, and a plug-in seat matched with the plug-in head. A cup handle is arrangedon the left side surface of the water cup. A cup mouth is arranged above the right side surface, and a cup cover is covered on the top of the cup mouth. An installation groove with the opening end thereof towards the left end of the plug-in head is arranged correspondingly in the left end surface of the plug-in head in the up-and-down manner. A sleeve which extends leftwards is movably arranged inthe installation groove and a hole groove is formed in the sleeve. A conduction rod is movably arranged in the hole groove, and the right end of the conduction rod penetrates through the sleeve to befixedly arranged in the right end wall of the installation groove. The left end of the conduction rod penetrates through the sleeve and is fixedly provided with a conduction block. First inclined abutting surfaces are correspondingly arranged at the upper and lower parts of the left end of the sleeve. Insertion grooves with rightward opening ends and matched with the conduction block are correspondingly arranged on the plug-in seat up and down. The upper and lower end walls of the insertions grooves are correspondingly provided with sliding and pushing grooves arranged to face the insertion grooves. Sliding and pushing blocks are movably arranged in the sliding and pushing grooves.

Owner:詹胜超

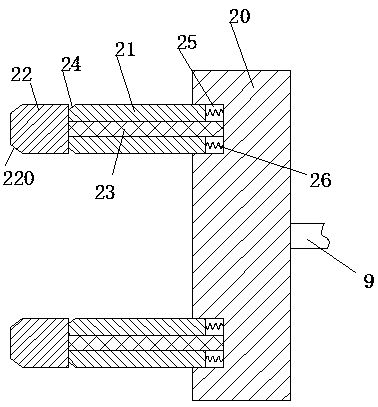

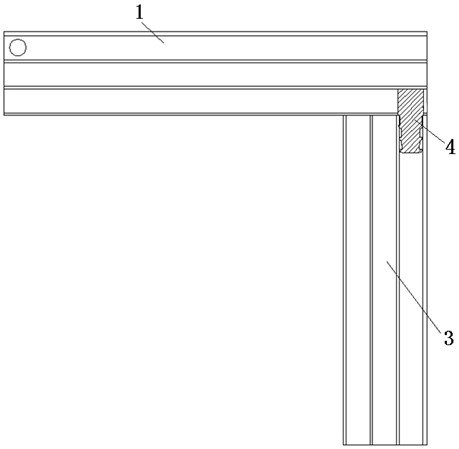

Aluminum profile connecting and assembling structure

PendingCN112392812AAchieve fasteningEasy to installRod connectionsDowelsClassical mechanicsStructural engineering

The invention relates to an aluminum profile connecting and assembling structure. A short raised strip end of a separated plastic tensioning block is inserted into a cavity II of a cross beam of a cabinet body; a screw rod of an inner hexagon screw is sequentially inserted into an outer stand column surface large hole and an inner stand column surface small hole in the upper end of a stand columnof the cabinet body and a circular hole of the separated plastic tensioning block to connect the stand column of the cabinet body and the cross beam of the cabinet body together; a decorative hole cover is buckled on the outer stand column surface large hole of the stand column of the cabinet body; four convex wall ends of a plastic inserting block are inserted into a cavity III of a longitudinalbeam of the cabinet body, and the plastic inserting block is fixed on the longitudinal beam of the cabinet body; and a large inserting block of the plastic inserting block is inserted into a cavity Ifrom the upper end of the stand column of the cabinet body, and the bent edge of the stand column of the cabinet body is arranged in a tooth-shaped notch of the plastic inserting block to connect thelongitudinal beam of the cabinet body and the stand column of the cabinet body together. The aluminum profile connecting and assembling structure has the beneficial effects that the stand column, thecross beam and the longitudinal beam of the cabinet body of an aluminum alloy storage cabinet are connected through the structure, and the structure does not come loose after being fastened.

Owner:星愿兰德(天津)企业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com