Aluminum profile connecting and assembling structure

A technology for assembling structures and aluminum profiles, applied in the direction of connecting members, rod connections, pins, etc., can solve the problems of loose locks, inability to lock columns and beams, and insufficient return of lock pins to achieve the effect of convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

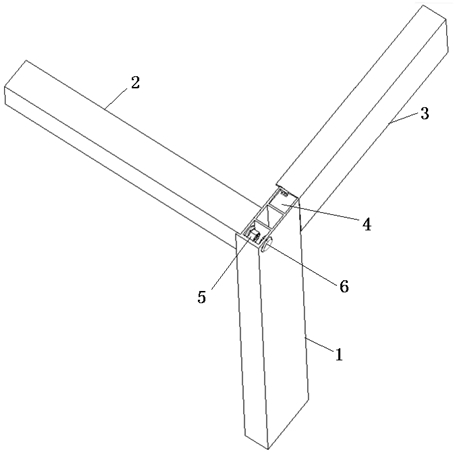

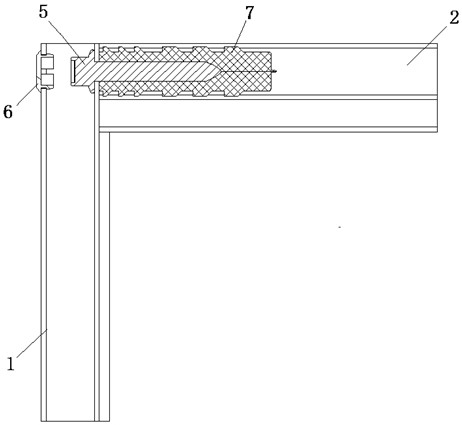

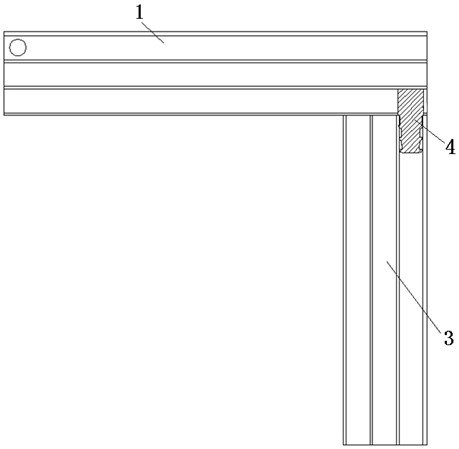

[0028]Such asFigure 1 to 8As shown, an aluminum profile connection assembly structure includes a cabinet column 1, a cabinet beam 2, a cabinet longitudinal beam 3, and also includes a plastic plug-in block 4, a hexagon socket screw 5, a decorative hole cover 6 and a separate plastic expansion Tight block 7.

[0029]The plastic plug-in block 4 is composed of a large plug-in block, a middle plug-in block and two small plug-in blocks of an integrated structure. Its cross-section is rectangular. Between the large plug-in block and the middle plug-in block, the middle plug-in block and Between the small plug-in blocks and between the two small plug-in blocks and the end surface of the first small plug-in block is a circle of raised walls 4-1, and the four raised walls 4-1 face the direction of the small plug-in block The surrounding surfaces of the four protruding walls 4-1 are curved 4-1-1, and the peripheral dimensions of the four protruding walls 4-1 gradually decrease toward the small p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com