Coating device for coating liquid material

A coating device and coating technology, which are applied to the device, spray device, coating and other directions of coating liquid on the surface, can solve the problems of different material strengths of hot melt adhesives, avoid wasting bolts, improve compatibility, realize Effect of Nozzle Device Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

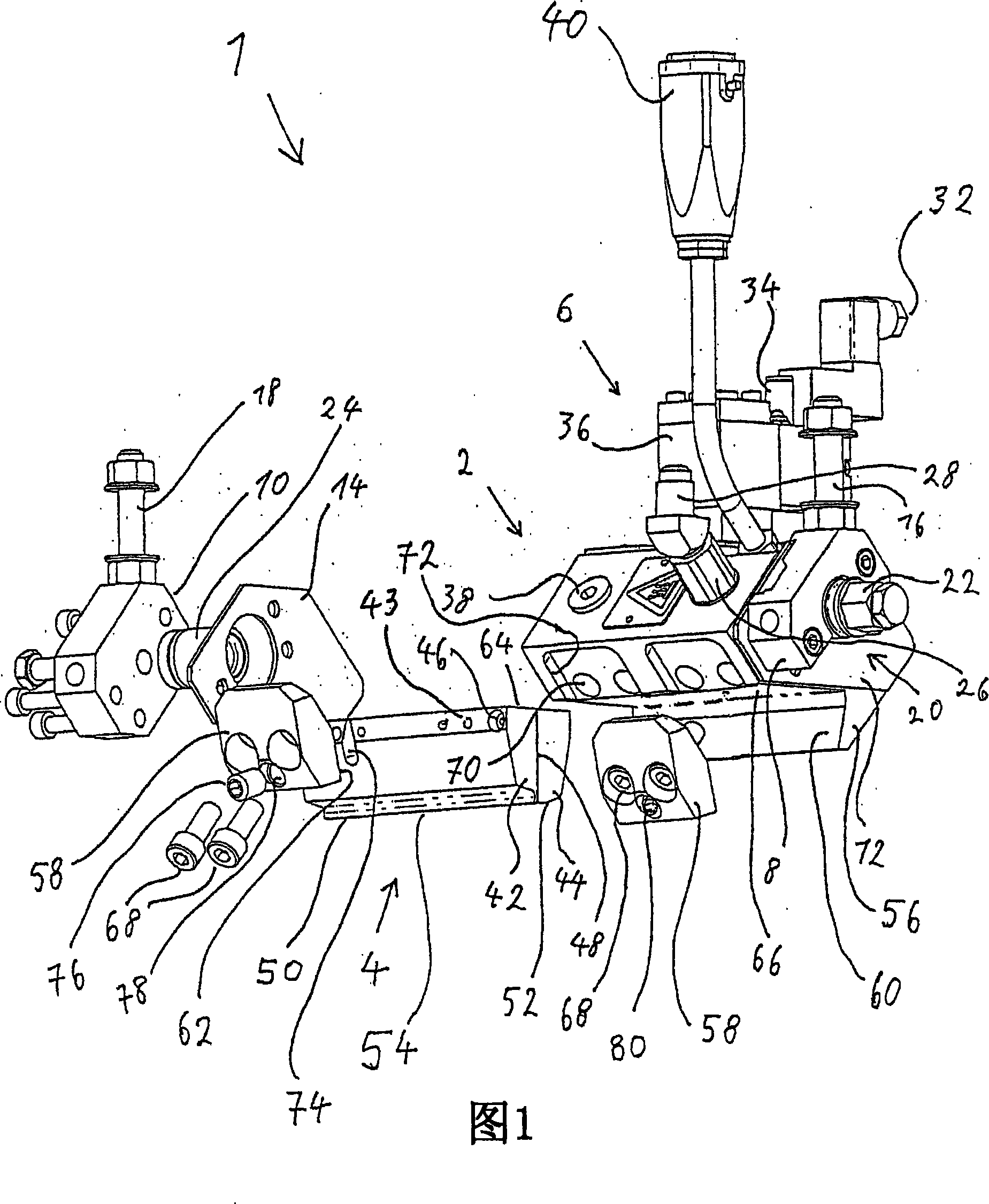

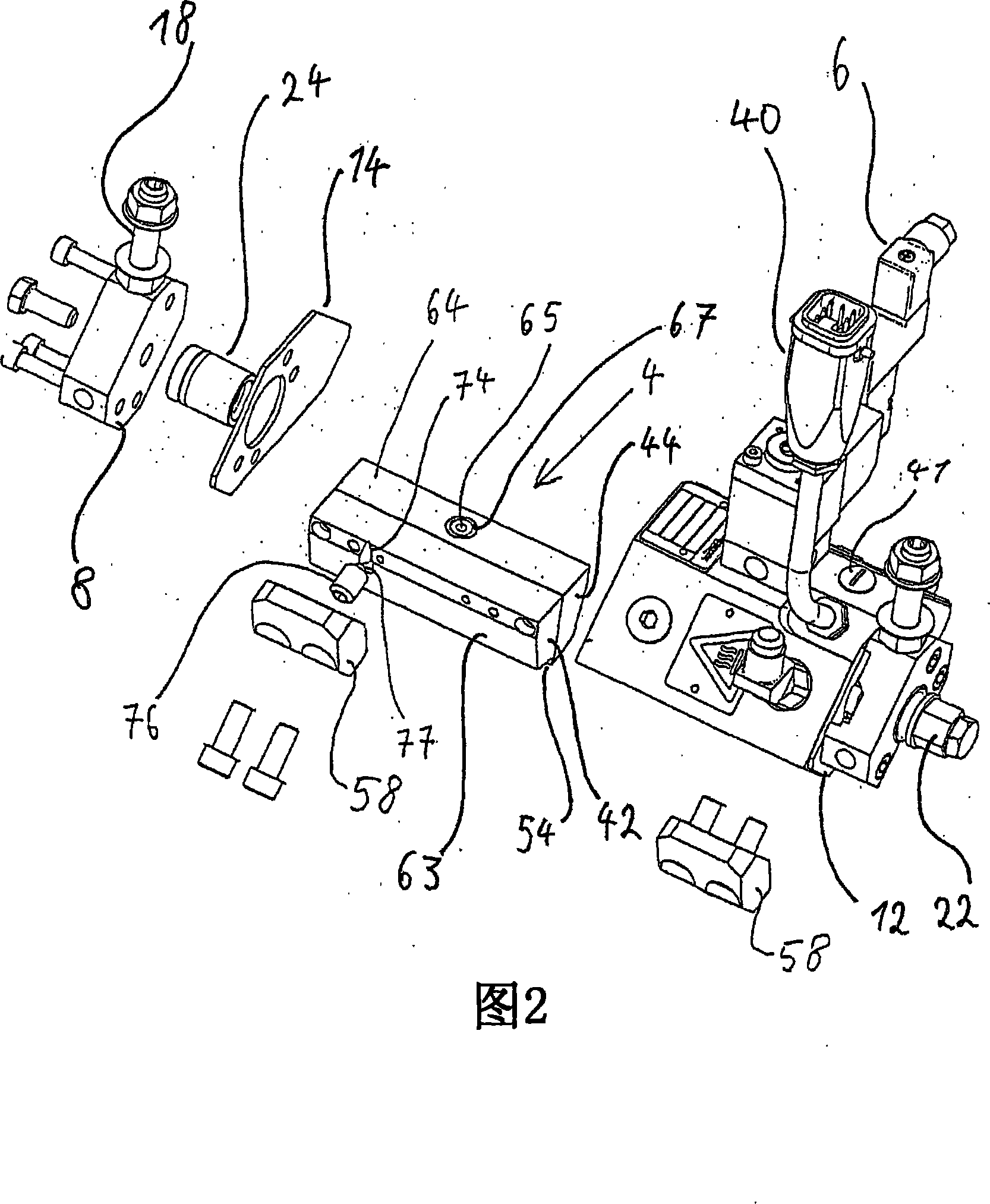

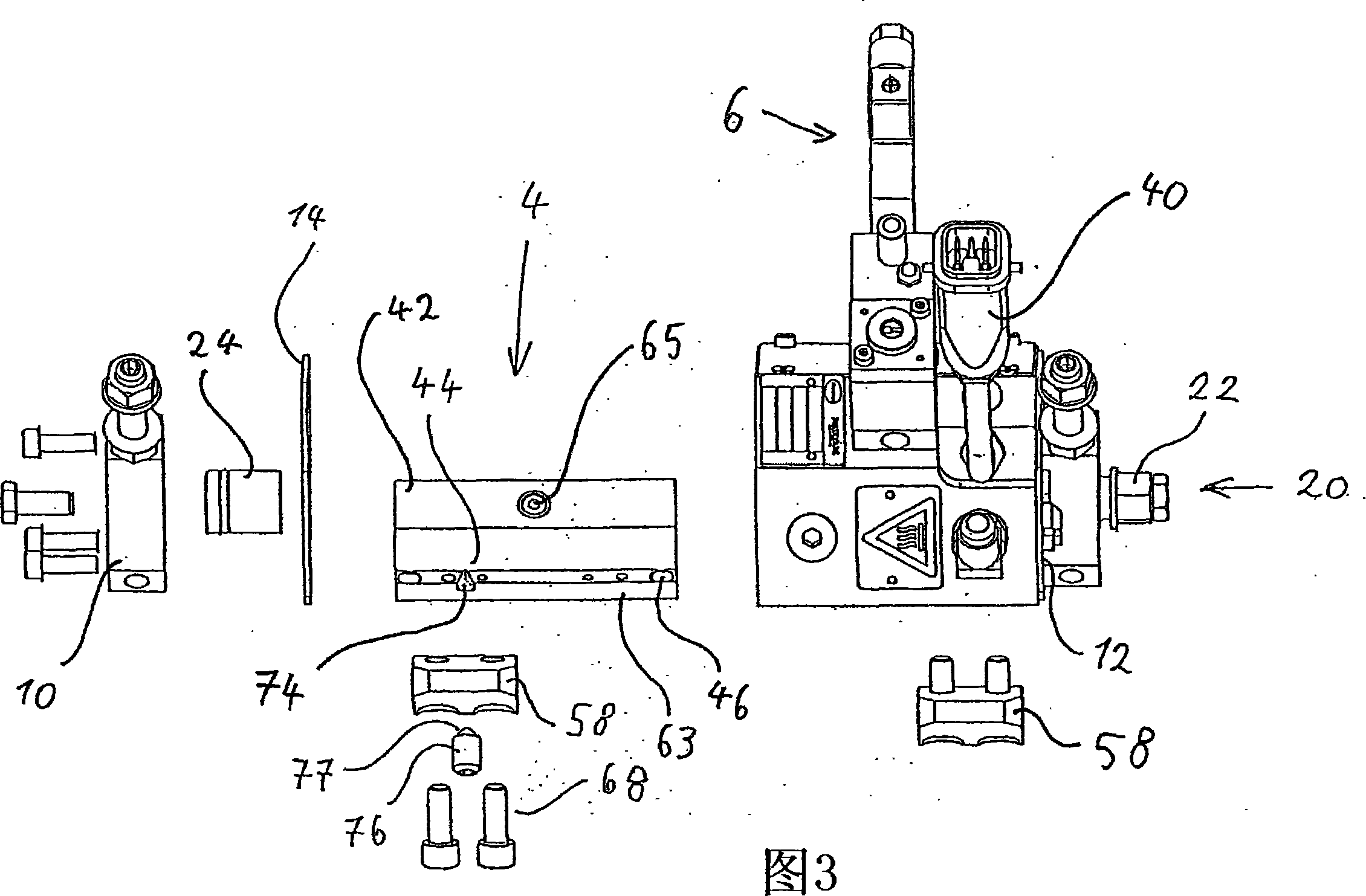

Method used

Image

Examples

no. 2 example 1

[0076] Like the second exemplary embodiment, in the third exemplary embodiment, the coating device 301 also has five fastening elements 358 , however, they are at different distances from one another. Two main electrical connections 340 are provided in the coating device 301 .

[0077] According to a fourth exemplary embodiment shown in FIG. 22 , the base body 402 has a support surface 466 and a fixed clamping section 456 with a clamping section surface 460 . The support surface 466 and the clamping section surface 460 are arranged approximately perpendicular to each other. The nozzle arrangement 404 is fixed on the base body 402 via a retaining element 490 designed as a flat rail and a resilient clip 458 designed as a spring leaf. The locking element 490 and the spring leaf 458 each engage in a groove 492 or 494 of the nozzle arrangement 4 . In this, a slot 492 into which the stop element 490 engages is provided in the mouth adapter 442 . A slot 494 into which the spring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com